MONO-MIXER 1490 Operation And Maintenance Manual

MONOMIXER

MODEL 1490

OPERATION AND

MAINTENANCE MANUAL

877 1st. AVE. NW Sioux Center, IA. 51250 Iowa 1-712-722-1488

www.siouxautomation.com MON600117

10/4/05 $15

TAKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGHOUT THIS MANUAL

IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR

PERSONAL SAFETY AND THE SAFETY OF OTHERS. FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

THIS SYMBOL MEANS

- ATTENTION!

- BECOME ALERT!

- YOUR SAFETY IS INVOLVED!

SIGNAL WORDS:

Note the use of the signal words DANGER,

WARNING and CAUTION with the safety

messages. The appropriate Signal word for

each has been selected using the following

guidelines:

DANGER: Indicates an imminently

hazardous situation that, if not avoided, will

result in death or serious injury. This signal

word is limited to the most extreme situations

typically for machine components that cannot

be guarded for functional purposes.

WARNING: Indicates a potentially

hazardous situation that, if not avoided, could

result in death or serious injury, and includes

hazards that are exposed when guards are

removed. It may also be used to alert against

unsafe practices.

CAUTION: Indicates a potentially hazardous

situation that, if not avoided, may result in

minor or moderate injury. It may also be used

to alert against unsafe practices.

If you have any questions not answered in this manual or require additional copies or the manual is

damaged, please contact your dealer or Sioux Automation Center, Inc., 877 1st Avenue N.W., Sioux

Center, IA, 51250. (Telephone) 712-722-3711, (Fax) 712-722-3706.

SAFETY ALERT SYMBOL

− THE SAFETY ALERT SYMBOL IS USED TO PINPOINT

CHARACTERISTICS WHICH IF NOT PROPERLY FOLLOWED

CAN CREATE A SAFETY HAZARD.

− WHEN YOU SEE THIS SYMBOL IN THIS MANUAL OR ON

THE UNIT ITSELF, YOU ARE REMINDED TO:

BE ALERT!

YOUR PERSONAL SAFETY IS INVOLVED!

SAFETY FIRST

FARM AND INDUSTRIAL EQUIPMENT INSTITUTE SAFETY ALERT SYMBOL.

This symbol is used preceding all CAUTION (a general safety

reminder), WARNING (denotes a potential hazard), and DANGER

(denotes a potential injury) notices!

Most farm accidents, like industrial, home, and highway accidents are caused by the failure of some

individuals to observe simple and fundamental safety rules or precautions. For this reason, farm

accidents, just as other types of accidents, can be prevented by recognising the causes of accidents

and doing something about them before an accident occurs.

Regardless of the care used in the design and construction of farm equipment, there are many points

that cannot be completely safeguarded without interfering with accessibility and efficient operation.

A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST AN ACCIDENT

The complete observance of one simple rule would prevent many thousand serious injuries each year.

That rule is "NEVER ATTEMPT TO CLEAN, OIL, OR ADJUST A MACHINE WHILE IN

MOTION".

NATIONAL SAFETY COUNCIL

BEFORE ATTEMPTING TO OPERATE YOUR NEW MACHINE, BE SURE TO READ

THIS OWNERS MANUAL AND FAMILIARIZE YOURSELF WITH THE MACHINE!!

OBSERVE THE FOLLOWING PRECAUTIONS FOR SAFE OPERATIONS OF THIS

MACHINE!!

SAFETY TIPS:

1. Keep Hands, Feet, and Clothing away from PTO Shaft!

2. DO NOT Climb on or enter Machine while in operation.

3. DO NOT Make High Speed Maneuvers with the machine.

4. Disengage PTO and remove Keys before servicing.

5. Keep ALL Shields in place.

6. DO NOT allow riders on outside of vehicle.

7. DO NOT attempt to clean, oil or adjust machine while in motion.

8. DO NOT exceed rated PTO RPM speed.

INTRODUCTION

Thank you for purchasing a MONOMIXER. The purpose of the MONOMIXER is to give

the agricultural industry the ability to incorporate long stem roughage into the total mixed ration

without additional grinders or processors. We have built the MONOMIXER to very exacting

standards and a high level of quality that will give you many years of dependable service if properly

used, maintained and serviced.

Along with the purchase of your new MONOMIXER you have also become part of a fine

family of agricultural equipment, and a fully equipped and knowledgeable service staff that can

help you with all y our needs.

In addition to reading and completely understanding this owner's manual, please take the

time to fill out the warranty registration sheet so that we may process your warranty, as well as

anticipate your future needs.

MODEL NO: ______ SERIAL NO

DATE:_____________

Please have these ready when phoning in for service.

Sioux Automation Center Inc.

877 1ST AVE NW

SIOUX CENTER IA 51250

(712) 722-1488

www.siouxautomation.com

__________________

USING YOUR MONOMIXER

READ CAREFULLY

SETUP

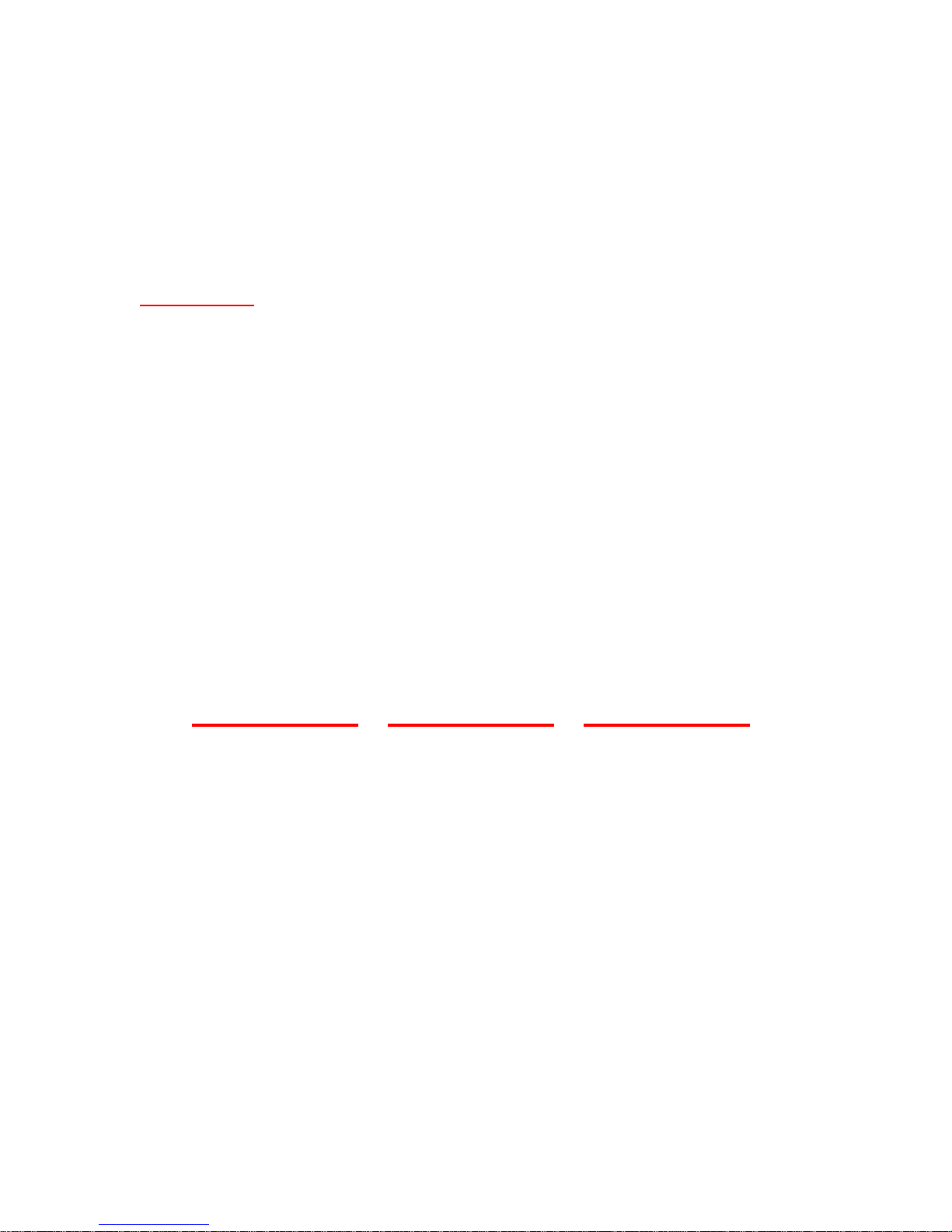

1. When you are delivered your new MONOMIXER from the factory, it is not immediately

necessary to check the machine for bearing lubrication or discharge chain tightness as these

items have been factory serviced. It is recommended to walk around the machine and

familiarize yourself with the location of all moving parts, caution decals, the general operating

dimensions and the basic working features of the MONOMIXER.

2. All lubrication has been completed at the factory prior to delivery and will not be immediately

necessary. There is however, a break in period for the planetary gear box. Oil in the planetary

will need to changed after the first 50 hours of operation. The next change interval will be 1

year or 2500 hours, which ever occurs first. See the enclosed appendix on the planetary for

correct oil specifications. Bearings should be greased with 1 pump once every 40 hours of use.

IMPORTANT! DO NOT OVER GREASE REAR BEARING, SEAL FAILURE AND

SUBSEQUENT PREMATURE BEARING FAILURE COULD RESULT.

3. When you receive your Monomixer, it will be first necessary for you to hook up the power

source for the solenoid that switches power between the discharge door and the swing arm. The

swing arm switch box is supplied with a lead that has 1 white wire and 1 black wire. The white

wire is to be hooked to positive and the black is to be hooked to ground. It is recommended to

hook these leads into a switched power source such as a keyed ignition. This will eliminate the

possibility of draining the battery if the switch is left on. The switch box has a two position

switch that either operates the swing arm for mixing or the discharge door for unloading. The

discharge door position is also marked as the off position as well. When not in use, be sure to

turn unit off.

IMPORTANT

FROM DIRT AND CORROSION! DO NOT HOOK THE LEADS FOR THE SWITCH

BOX INTO THE MIXER MOUNTED BATTER Y THA T SUP PLIES THE SCALE!

The leads for the switch box have been supplied with and inline fuse holder that holds a 10 amp

fuse.

CAUTION!

UNDERSTAND THIS OWNER'S MANUAL AND ALL CAUTION,

WARNING AND DANGER SYMBOLS LOCATED ON THE

MACHINE AND IN THIS MANUAL.

: ALWAYS KEEP POWER CONNECTIONS TIGHT, NEAT AND FREE

BEFORE OPERATING THIS MACHINE, READ AND

CAUTION!

DO NOT REPLACE A BLOWN FUSE WITH A FUSE

OF A HIGHER RATING!

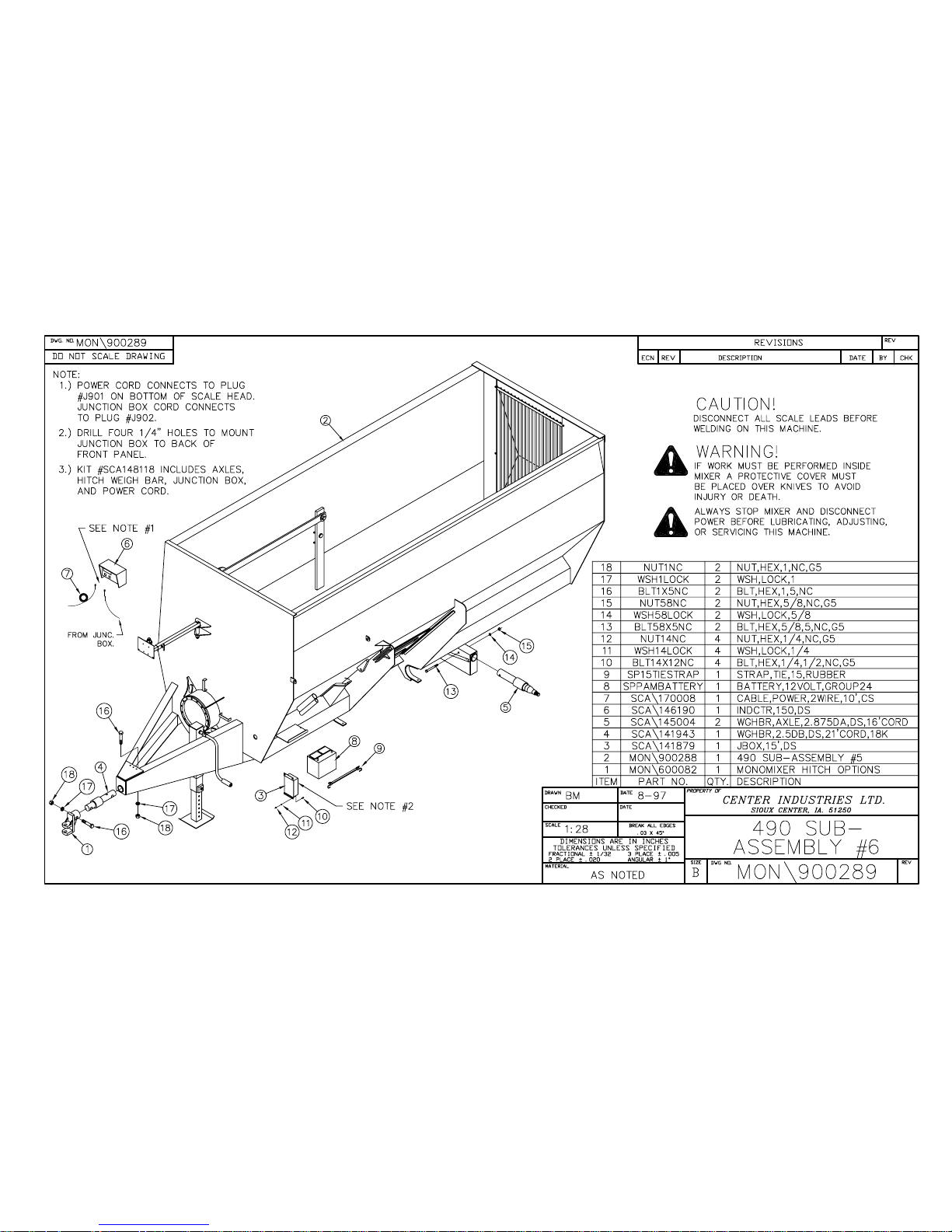

4. The MONOMIXER has also been supplied to you with a complete scale system. Read and

understand the scale manual and familiarize yourself with its different functions. The scale

indicator leads should be connected directly to the battery either on the mixer or the tractor. The

leads are supplied with 1 white wire and 1 black wire. The white wire is to be connected to the

positive and the black is to be connected to the ground. By having the scale connected to a

constant power source, it will save warm up time between feedings. It is recommended to run

the scale wires separately from other power lines to keep electrical interference to a minimum.

If the tractor, used to run the mixer, is also used for other purposes, it is recommended to put a

quality quick disconnect in the power line. The scale indicator is also protected by a 10 amp

inline fuse.

IMPORTANT! ALWAYS DISCONNECT SCALE LEADS BEFORE PERFORMING

ANY SERVICE WORK SUCH AS WELDING!

OPERATION

1. Before attempting to fill the mixer, make sure that the discharge door is completely closed, the

chute is in the up position and the mixing chamber is free of any foreign objects.

IMPORTANT! IF THE DISCHARGE DOOR IS LEFT OPEN DURING MIXING,

FEED MAY BECOME TIGHTLY PLUGGED AGAINST THE CONVEYOR AND

DAMAGE IT.

2. Refer to the Owner's Manual of the tractor before operating the mixer to ensure proper PTO

engagement.

CAUTION:

the MONOMIXER as it could cause the shear pin to shear or

damage the planetary drive.

Use 540 rpm only. Avoid high speed engagement of

3. It is very important that before using your MONOMIXER, proper PTO length be determined

and maintained. The PTO must have a minimum and maximum engagement length that falls

within the safe use of a PTO. Too short of a PTO could result in the two halves coming apart

under load or going over uneven terrain; too long of a PTO can result in serious damage to

either end of the drive train. It is recommended that a minimum of 5" of engagement be

maintained on the PTO. Your MONOMIXER has been supplied to you with a standard length

PTO that will work with all tractors provided drawbar adjustments are made to maintain the

correct PTO length.

DANGER!

OFF PTO, TURN OFF TRACTOR AND PULL THE KEY, SET PARKING

BRAKE AND WAIT FOR ALL MOTION TO STOP BEFORE ADJUSTING

PTO LENGTH AND WORKING ON THE DRAWBAR.

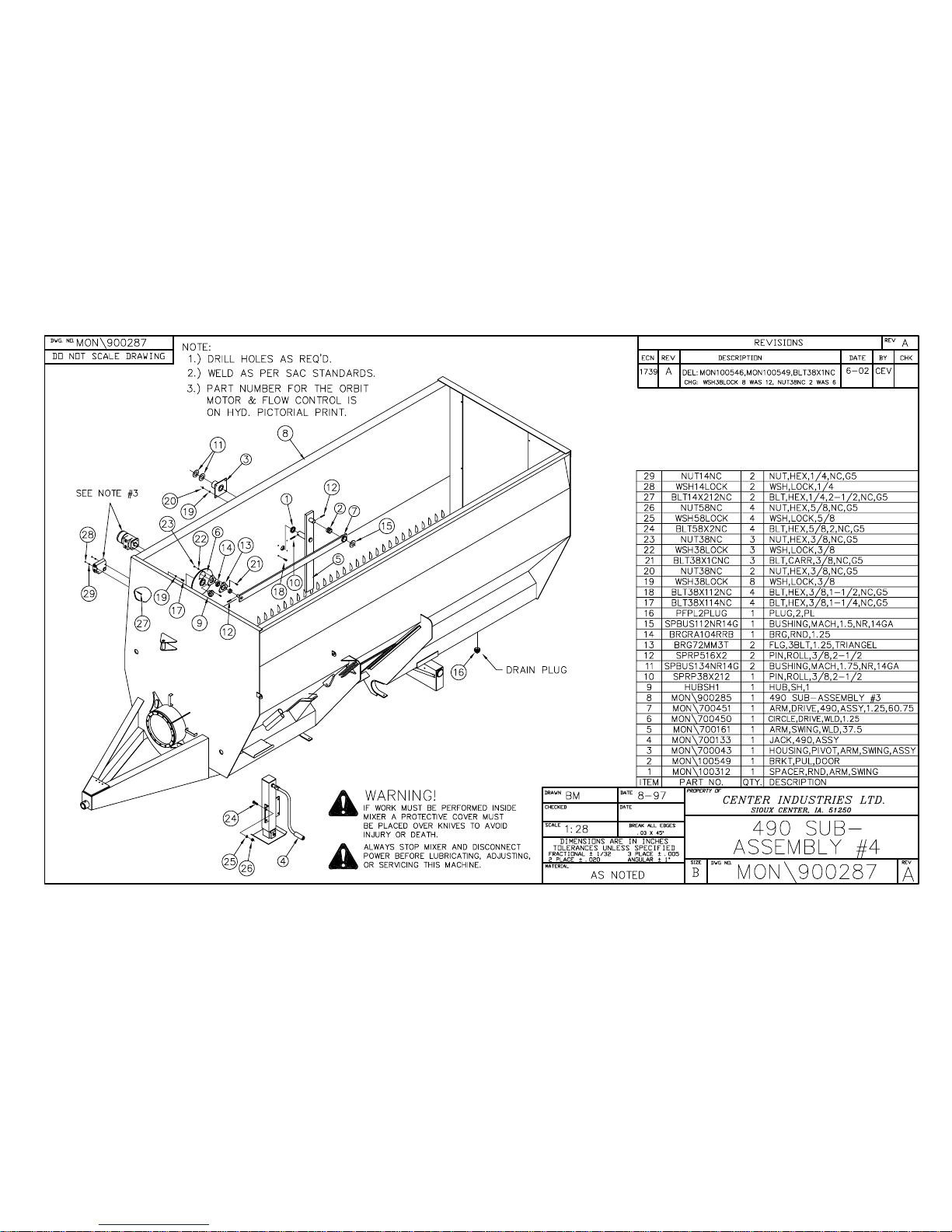

4. The swing arm is designed to move feed on the straight side of the mixer to achieve thorough

and completely mixed ration. The swing arm has an adjustable flow control, which can

increase or decrease speed. The swing arm has a factory preset of 15 RPM and it is

recommended that no more than 20 RPM maximum be exceeded. The swing arm also is

designed to stall when over loaded. If the arm does stand still, it is only because there is too

much feed in the way of the arm. When the feed has moved, the arm will automatically start

again.

CAUTION!

SWING ARM AS SERIOUS STRUCTURAL DAMAGE TO THE SIDE

OF THE MONOMIXER COULD RESULT!

5. The MONOMIXER will effectively mix all ingredients in a Total Mixed Ration including small

grains, corn, concentrates and premixes, cotton, seed, corn and hay silage etc. The

MONOMIXER is also capable of processing dry, long stem hay into your ration. It is not

recommended that wrapped and ensiled round bales be processed in the MONOMIXER.

IMPORTANT

6. Due to the nature of mixing and cutting long stem hay, pin shearing is something that can be

expected. The shear pin is designed to be the weakest link in t he drive train, and its shearing is

to prevent damage to critical components. Therefore never replace shear pins with a higher

tensile strength or grade pin. If a machine is regularly shearing pins, the operator should first

look for mechanical problems such as worn knives or a bearing failure, then evaluate loading

procedures and lastly, call for technical assistance.

! THE MIXER SHOULD ALWAYS STAND LEVEL WHEN MIXING!

TO PREVENT SERIOUS INJURY OR DEATH, TURN

DO NOT EXCEED THE MAXIMUM RPM OF THE

7. If a MONOMIXER does become plugged or jammed, to the point where normal mixing

rotation (counter clockwise from the front) will not resolve the problem, it will be necessary to

reverse the mixer. This can safely be done by first turning off all power sources, setting the

parking brake and waiting for all motion to stop before removing the PTO from the planetary

end. Then fit the supplied T handle to the drive end of the planetary and then turn the T handle

(facing the mixer) clockwise to loosen the plugged material.

DANGER! TO PREVENT SERIOUS INJURY OR DEATH, DO NOT

ENTER THE MIXING CHAMBER!

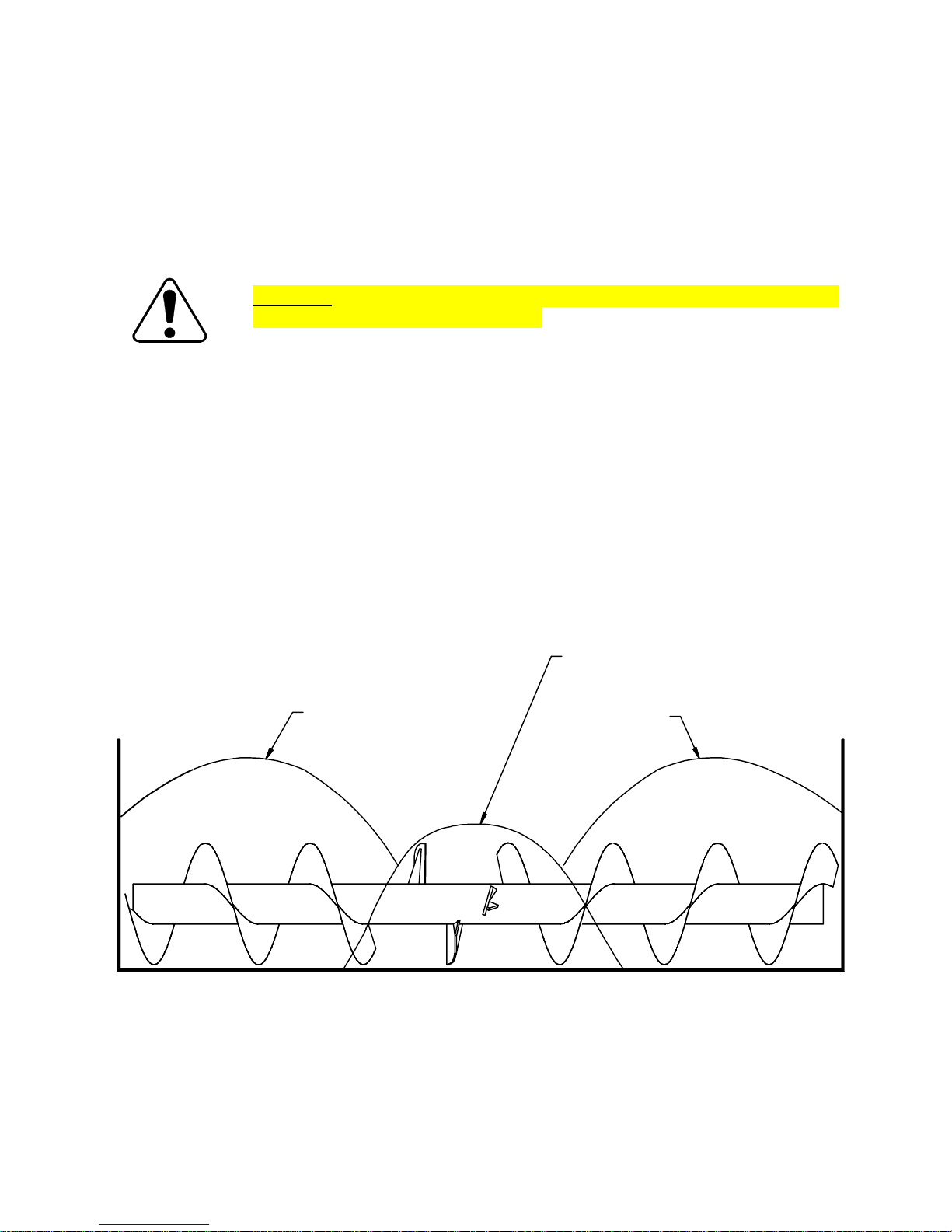

8. Proper loading procedure involves loading smaller quantity ingredients in the center of the

mixer first, to cover up the mixing paddles. This will prevent the aggressive paddles from

grabbing too much hay before it can be first adequately processed by the knives on the auger

flighting. Loading long stem hay in the center of t he mixer increases the chances of shearing

pins. If not happy with the resulting ration, some sequencing changes may need to be made. If

sequencing changes do not fix your ration problems, see the factory for further assistance. Do

not be concerned about the appearance of the ration in the mixer, the appearance and evenness

of the ration is determined only in the bunk.

SMALL INGREDIENTS

HAY HAY

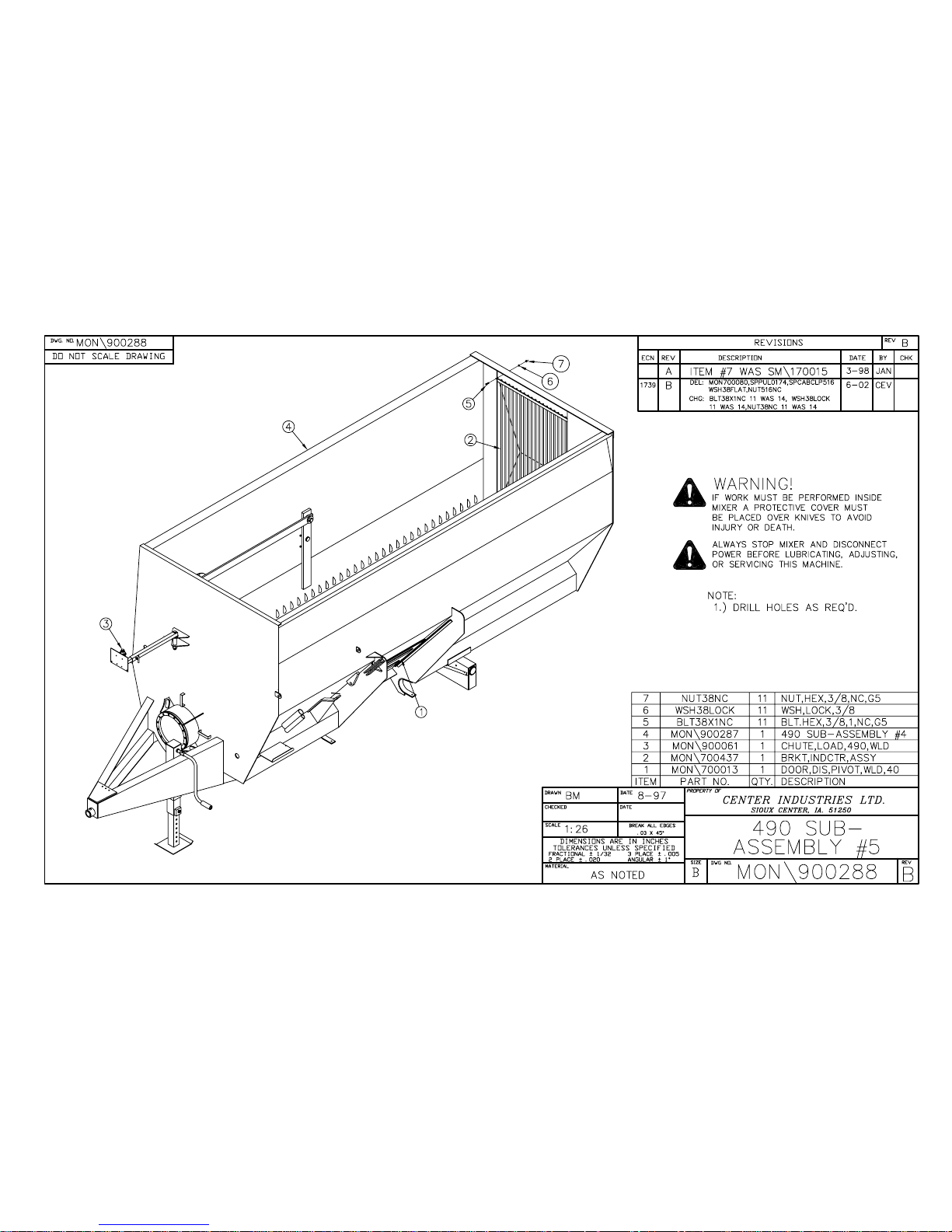

9. To discharge feed from the MONOMIXER, it is necessary to first start the conveyor (either self

contained hydraulics or tractor supplied) and then open the discharge door. The conveyor and

the door operate on two different hydraulic circuits and can be operated independently. The rate

of ration flowing from the MONOMIXER can be controlled by the door position. The higher

the door is raised, the more feed it will allow out, and vice versa.

IMPORTANT

DOOR TO PREVENT JAMMING FEED AGAINST THE CONVEYOR!

10. Normal mixing time is form 1 to 2 minutes after the last ingredient has been added. It is

necessary to run the MONOMIXER at full 540 PTO RPM during mixing of ingredients such as

long stem hay or ensilage. It is not necessary to run the machine while loading. Strive for the

shortest mixing time possible, as over-mixing will decrease the value of the ration and will

cause unnecessary wear on the machine.

11. Proper mixing patterns are achieved when two cavities are visible in the mixer, one in the front

and one in the rear. Feed must be able to tumble from the top to the bottom of the mixer to

obtain maximum mixing potential. A mixer that is struck level full will not mix properly and

will put undue stress on moving parts.

12. Do not leave partially mixed loads in the machine for long periods of time such as during the

day or overnight. Acids from the feed will react with the steel and will cause premature

deterioration of the machine. It is better to mix two small loads, than one large loa d.

! ALWAYS START THE DISCHARGE BEFORE OPENING THE

ATTENTION! ATTENTION! ATTENTION!

THE MONOMIXER WILL PROCESS LONG STEM HAY FROM

ROUND BALES ONLY IF THE ROUND BALE HAS BEEN CUT

INTO SMALLER SECTIONS, OR UNROLLED. IT WILL ALSO

PROCESS LARGE SQUARE BALES IF THEY CAN BE SHOOK

APART BY HAND.

WHOLE ROUND OR LARGE SQUARE BALES, AND BALES

THAT HAVE BEEN BALED TOO WET, HARD CAKED OR

FROZEN CANNOT BE PUT INTO THE MONOMIXER. IF ANY

TYPE OF THESE BALES ARE PUT INTO THE MONOMIXER,

THE WARRANTY WILL AUTOMATICALLY BE VOID UPON

PUTTING THE FIRST BALE IN THE MACHINE.

Loading...

Loading...