Monogram Appliances ZIC30GNHII, ZIK30GNHII Installation Manual

INSTALLATION

INSTRUCTIONS

30” Built-In

Bottom-Freezer, 2-Drawer

Refrigerator

ENGLISH/FRANÇAIS/ESPAÑOL

Monogram.com

Safety Information

BEFORE YOU BEGIN

Read these instructions completely and carefully.

IMPORTANT – Save these instructions for

•

local inspector’s use. Observe all governing codes and

ordinances.

Note to Installer – Be sure to leave these

•

instructions with the Consumer.

• Note to Consumer – Keep these instructions with

your Owner’s Manual for future reference.

If you received a damaged unit, you should immediately

contact your dealer or builder.

Skill Level – Installation of this unit requires basic

mechanical, carpentry and plumbing skills. Proper

installation is the responsibility of the installer. Product

failure due to improper installation is not covered under

the Monogram Warranty. See the Owner’s Manual for

warranty information.

WARNING

Plug into a grounded 3-prong outlet.

Do not remove the ground prong.

Do not use an adapter.

Immediately discontinue use of a damaged supply cord.

If the supply cord is damaged it must be replaced by a

qualified service professional with an authorized service

part from the manufacturer.

WARNING

Electrical Shock Hazard.

Do not use an extension cord with this appliance.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Follow the instructions in the section Grounding the unit.

This appliance must be installed with a means in the

fixed house wiring or circuit breaker for disconnecting the

appliance from the electrical supply after installation.

Tip Over Hazard.

These appliances are top heavy, especially with any doors open, and must be secured to prevent tipping

forward which could result in death or serious injury. Read and follow the entire installation instructions for

securing the appliance with the anti-tip system.

WARNING

Explosion Hazard.

Keep flammable materials and vapors, such as gasoline, away from appliance. Failure to do so can result

in fire, explosion, or death.

WARNING

To reduce the risk associated with choking, do not allow children under 3 years of age to

have access to small parts during the installation of this product.

CAUTION

Lifting Hazard

This unit is very heavy. To reduce the risk of person injury during maneuvering and installing this appliance,

3 people are required for proper installation.

CAUTION

Keep fingers out of the “pinch point” areas; clearances between the doors and between the

doors and cabinet are necessarily small. Be careful closing doors when children are in the area.

For Monogram local service in your area, call 800.444.1845 or visit monogram.com.

For Monogram service in Canada, call 888.880.3030

For Monogram Parts and Accessories, call 800.444.1845 or visit monogram.com.

For Monogram Parts and Accessories in Canada, call 888.880.3030 or visit monogram.ca.

2

31-46542-4

Safety Information

WARNING

This appliance contains isobutane refrigerant,

R600a, a natural gas with high environmental

compatibility. However, it is also combustible.

Adhere to the warnings below to reduce the risk of

injury or property damage.

1) When handling, installing and operating the appliance,

care should be taken to avoid damage to the

refrigerant tubing.

2) Service shall only be performed by authorized service

personnel. Use only manufacturer-authorized service

parts.”

EXPLOSION HAZARD Flammable Refrigerant

Contents

Design Guide

Cabinet Enclosure Dimensions 4

Refrigerator Dimensions 5

The Installation Space 6

Grounding the Refrigerator 6

SS European or Custom Panels

115° Door Swing 7

SS European or Custom Panels

90° Door Swing 8

SS Professional Panels

115° Door Swing 9

SS Professional Panels

90° Door Swing 10

SS Panel Accessory & Dimensions 11

3/4” Custom Panel Dimensions 12

3) Dispose of refrigerator in accordance with Federal

and Local Regulations. Flammable refrigerant and

insulation material used require special disposal

procedures. Contact your local authorities for the

environmentally safe disposal of your refrigerator.

4) Keep ventilation openings in the appliance enclosures

or in the built-in structure clear of obstruction.

5) Do not use mechanical devices or other means to

accelerate the defrosting process.

6) Do not damage refrigerant circuit.

7) Do not use electrical appliances inside the food

storage compartment of the appliance.

Installation Instructions

Tools, Hardware, Materials 13

Step 1. Remove Packaging 14

Step 2. Install Anti-tip Bracket 15

Step 3. Connect Water Line 15

Step 4. Connect Power 15

Step 5. Slide Unit into Enclosure 16

Step 6. Remove Toekick and Vent 16

Step 7. Level Refrigerator 17

Step 8. Install Toekick and Vent 17

Step 9. Reverse Door Swing 18

Step 10. Adjust Door Swing 19

Step 11. Attach Hinge Guard 19

Step 12. Install Door and Drawer Panels 20

Step 13. Start Icemaker 21

31-46542-4

Badge Templates 22

3

Design Guide

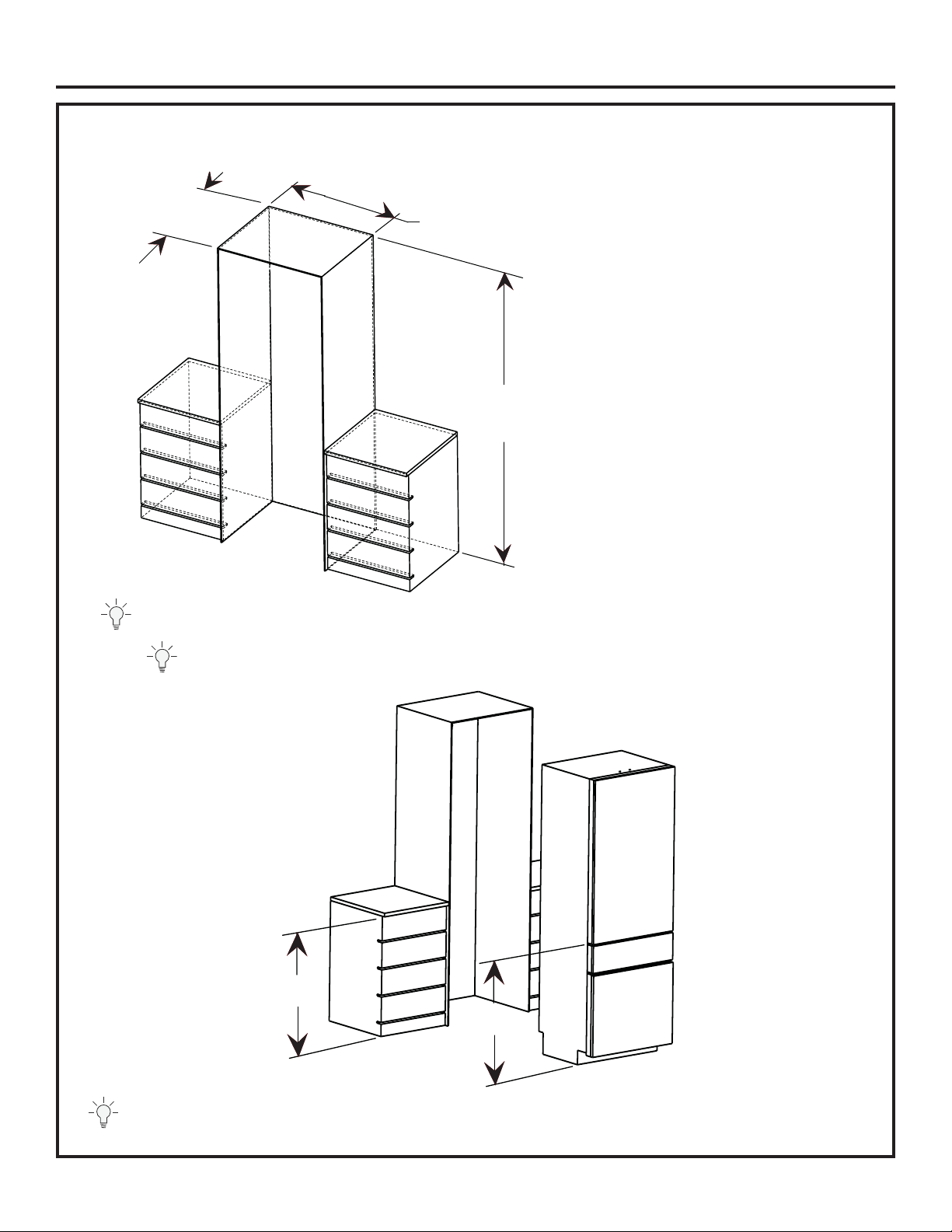

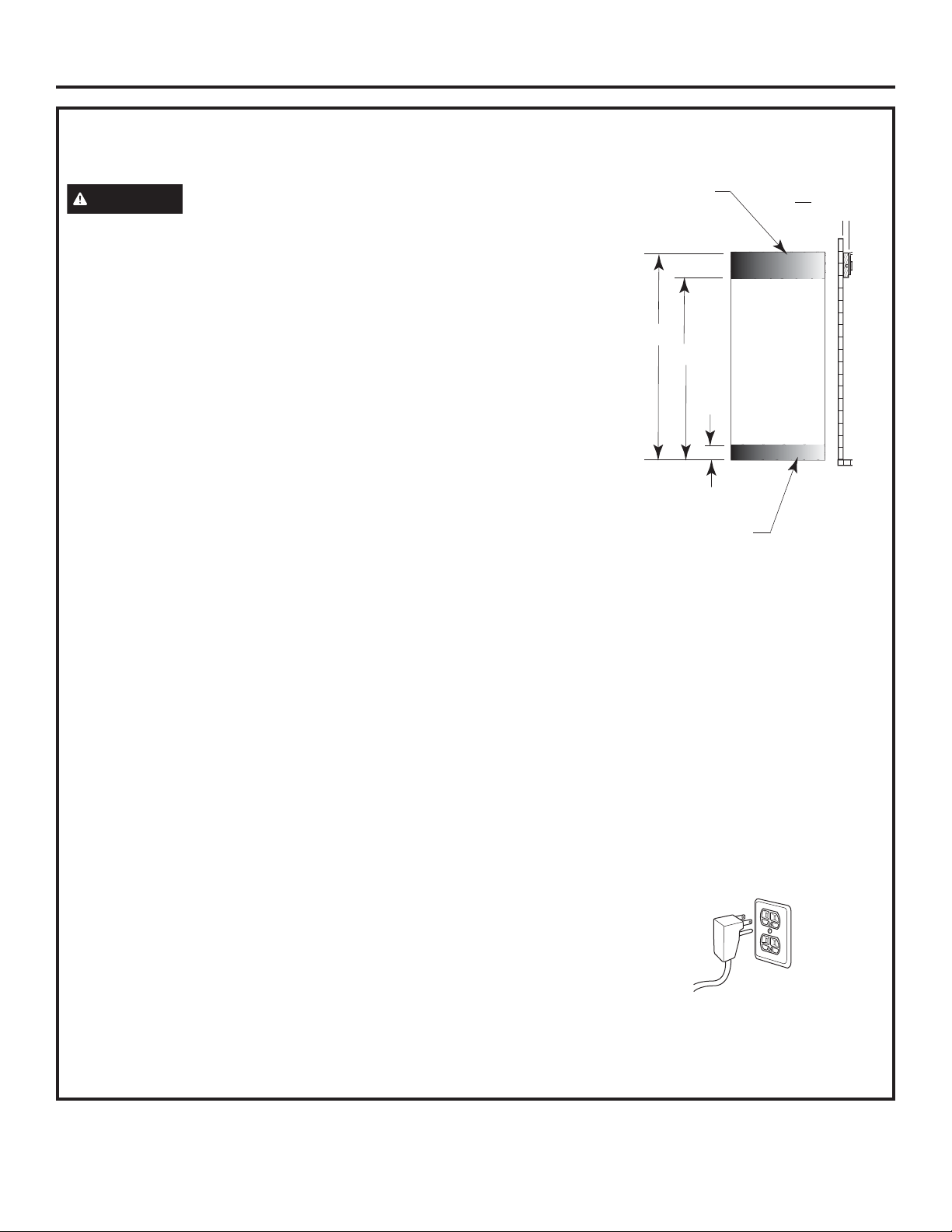

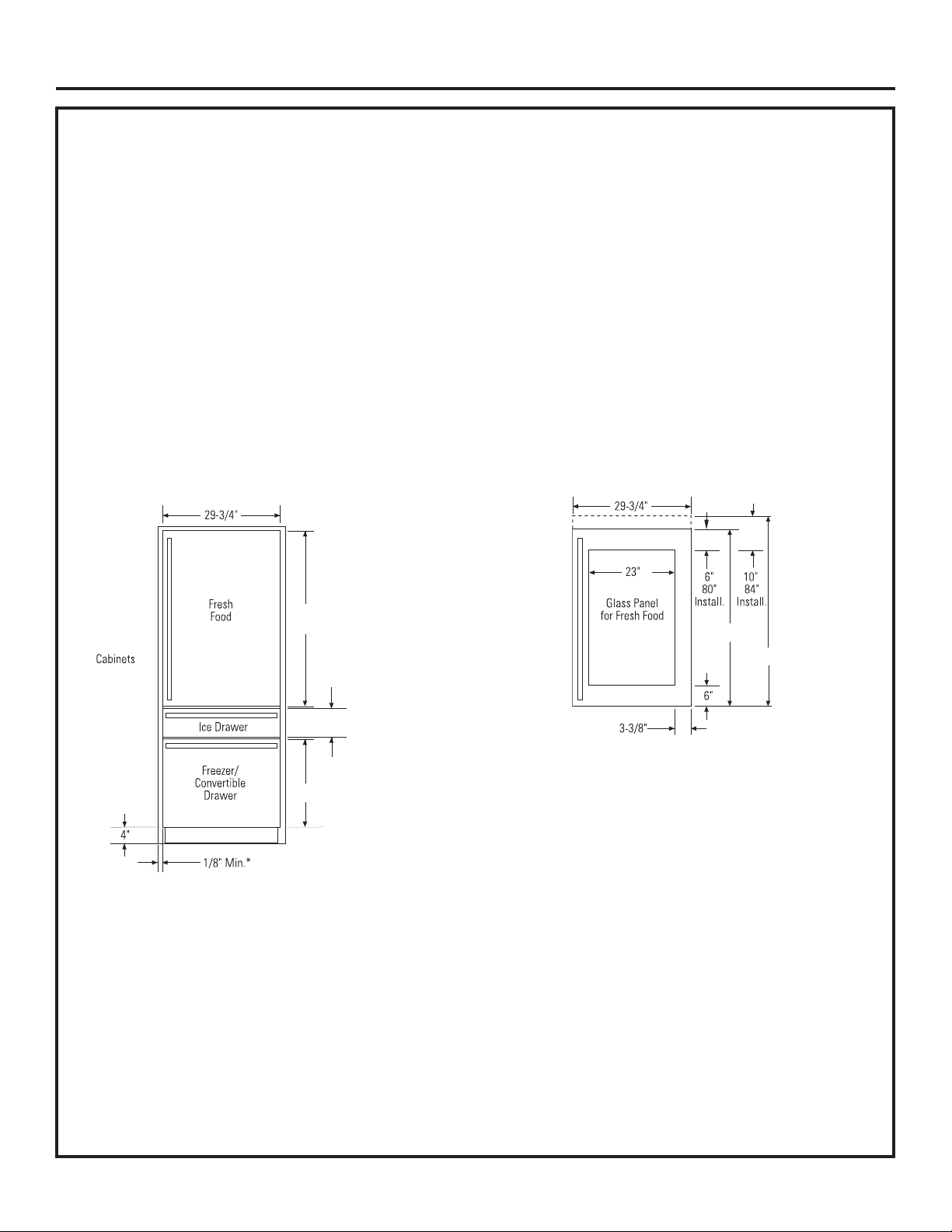

Cabinet Enclosure Dimensions For Fully Integrated Instructions

The cutout depth must be 25”for

25” min. depth

30” Finished Width

Height options

80” or * 84“

flush installations.

• The front face of the refrigerator

fits flush with 25”depth adjacent

cabinets.

• The refrigerator can fit into a

79-1/2” minimum,

84-1/2” maximum high enclosure.

Although the refrigerator itself can

only be raised to 80 3/8”,

• The fresh food door panel can be

constructed to fill additional height;

see page 11.

Design Tip: We recommend finishing the inside surface of the enclosure a min. of 4” from the front face.

Design Tip: If using 84” enclosure, consider adding a finished valence above the refrigerator case.

34 3/8”

34 3/8”

Design Tip: It is possible to align your refrigerator drawer with adjacent cabinetry for a completely

integrated look.

4

31-46542-4

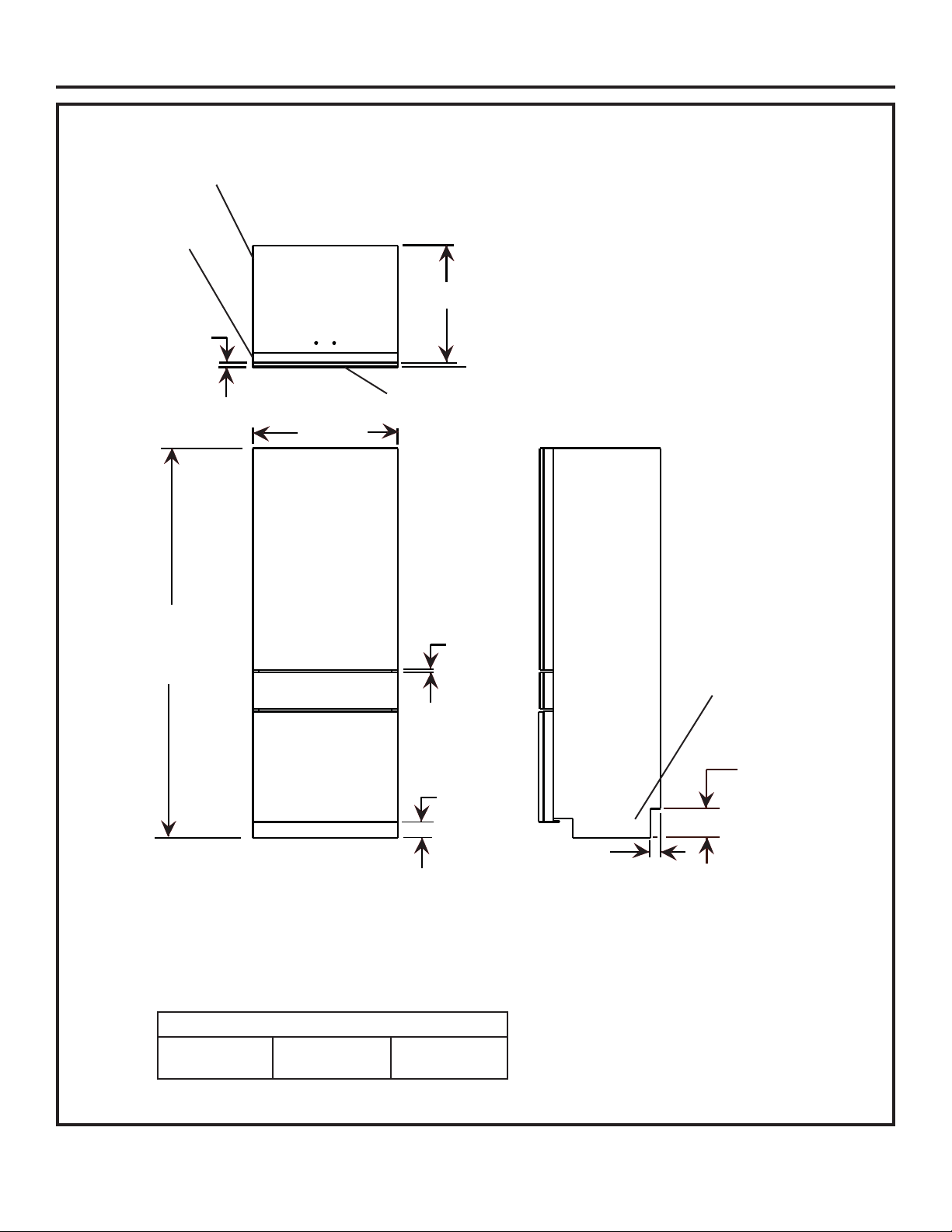

Case

Design Guide

Refrigerator Dimensions with 3/4” Panels

Door

3/4”

Height adjustable

from

79-3/8” to 80-3/8” *

Top with Panels

29 1/2”

Panel

23 3/4”

1/8”

(Case and Door only)

Clearance

31-46542-4

6”

4”

1 1/4”

Front with Panels Side with Panels

* The Refrigerator can be adjusted to fit into a cabinet space that is 83-3/8” to 84-3/8” with the

appropriate door panel kit.

Install Clearances

Top

1/8” / 3mm

Each Side

1/4” / 6mm

Rear

1/2” / 12mm

5

Design Guide

A

THE INSTALLATION SPACE

Water and Electrical Locations

Electrical and water supply should be located in shaded area only as shown.

WARNING

PREPARING INSTALL WATER LINE

• A cold water supply is required for automatic icemaker operation. The

water pressure must be between 40 and 120 p.s.i. (275-827 kPa).

• Route 1/4” OD copper or SmartConnect™ plastic tubing between the

house cold water line and the water connection location.

• Tubing should be long enough to extend to the front of the encloasure.

• Water line can enter an opening through the floor or back wall.

• Install a shut-off valve between the icemaker water valve and cold water

supply in the home.

NOTE:

• It is recommended that the water shut-off valve be placed in a location

that is easily accessible. We do not advise placing it behind the unit

because of access difficulties. If it is necessary to install the valve behind

the unit, it must be located in the shaded area.

• Saddle type shut-off valves are included in many water supply kits, but

are not recommended for this application.

• The only GEA-approved plastic tubing is supplied in the SmartConnect™

Refrigerator Tubing kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Other types of plastic may crack or rupture with age and cause water

damage to your home. SmartConnect™ Refrigerator Tubing Kits are available in the following lengths:

6’ (1.8 m) WX08X10006, 15’ (4.6 m) WX08X10015 & 25’ (7.6 m) WX08X10025

• Commonwealth of Massachusetts Plumbing Codes 248CMR shall be adhered to. Saddle valves are illegal and use

is not permitted in Massachusetts. Consult with your licensed plumber.

Electrical Specifications

• A 115-volt, 60-Hz., 15- or 20-amp power supply is required. An individual properly grounded branch circuit or circuit

breaker is recommended.

• Install a properly grounded 3-prong electrical receptacle recessed into the back wall. Electrical must be located on

rear wall as shown.

NOTE: GFI (ground fault interrupter) is not recommended.

Connect to potable water supply only.

nti-Tip location. Do

not obstruct this area.

80”

77”

Water and Electrical

Tube Outlet

Front view

Install Space

6”

GROUNDING THE REFRIGERATOR

IMPORTANT—(Please read carefully)

FOR PERSONAL SAFETY, THIS APPLIANCE MUST

BE PROPERLY GROUNDED.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

three-prong (grounding) wall receptacle to minimize the

possibility of electric shock hazard from this appliance.

Have the wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly grounded.

Where a standard 2-prong wall outlet is encountered, it

is your personal responsibility and obligation to have it

replaced with a properly grounded 3-prong wall outlet.

DO NOT, UNDER ANY

CIRCUMSTANCES, CUT

OR REMOVE THE THIRD

(GROUND) PRONG FROM

THE POWER CORD.

DO NOT USE AN ADAPTER PLUG TO CONNECT THE

REFRIGERATOR TO A 2-PRONG OUTLET.

DO NOT USE AN EXTENSION CORD WITH THIS

APPLIANCE.

6

31-46542-4

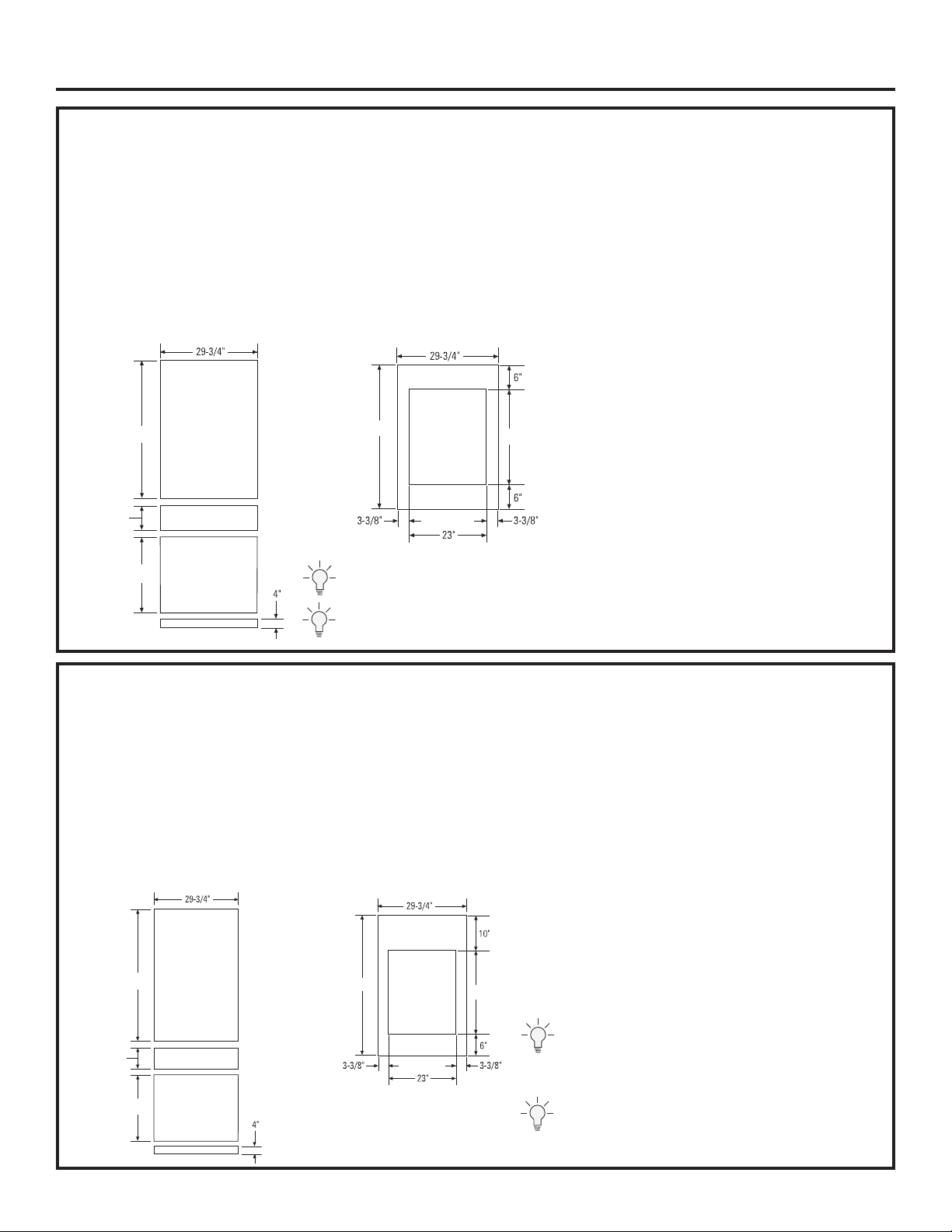

Design Guide

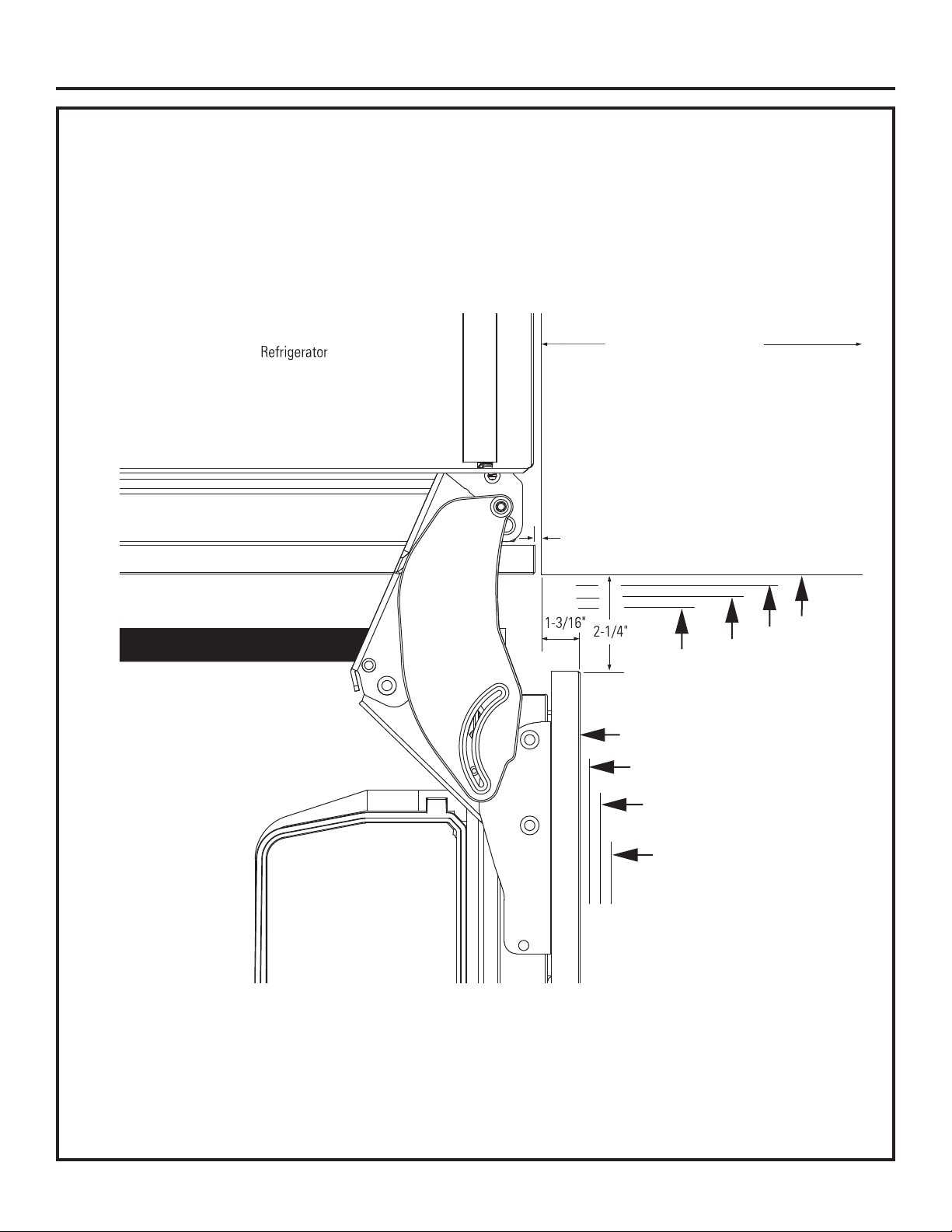

Product Clearances

These refrigerators are equipped with a 2-position door stop. The factory-set 115° door swing can

be adjusted to 90° if clearance to adjacent cabinets or walls is restricted.

For 90° Door swing see page 8.

1/8”

SS European or Custom Panels

Top View

115° DOOR SWING

(factory setting)

1-1/2”

1-1/4”

1”

3/4”

1”

1-1/4”

1-1/2”

Not to scale

3/4”

31-46542-4

7

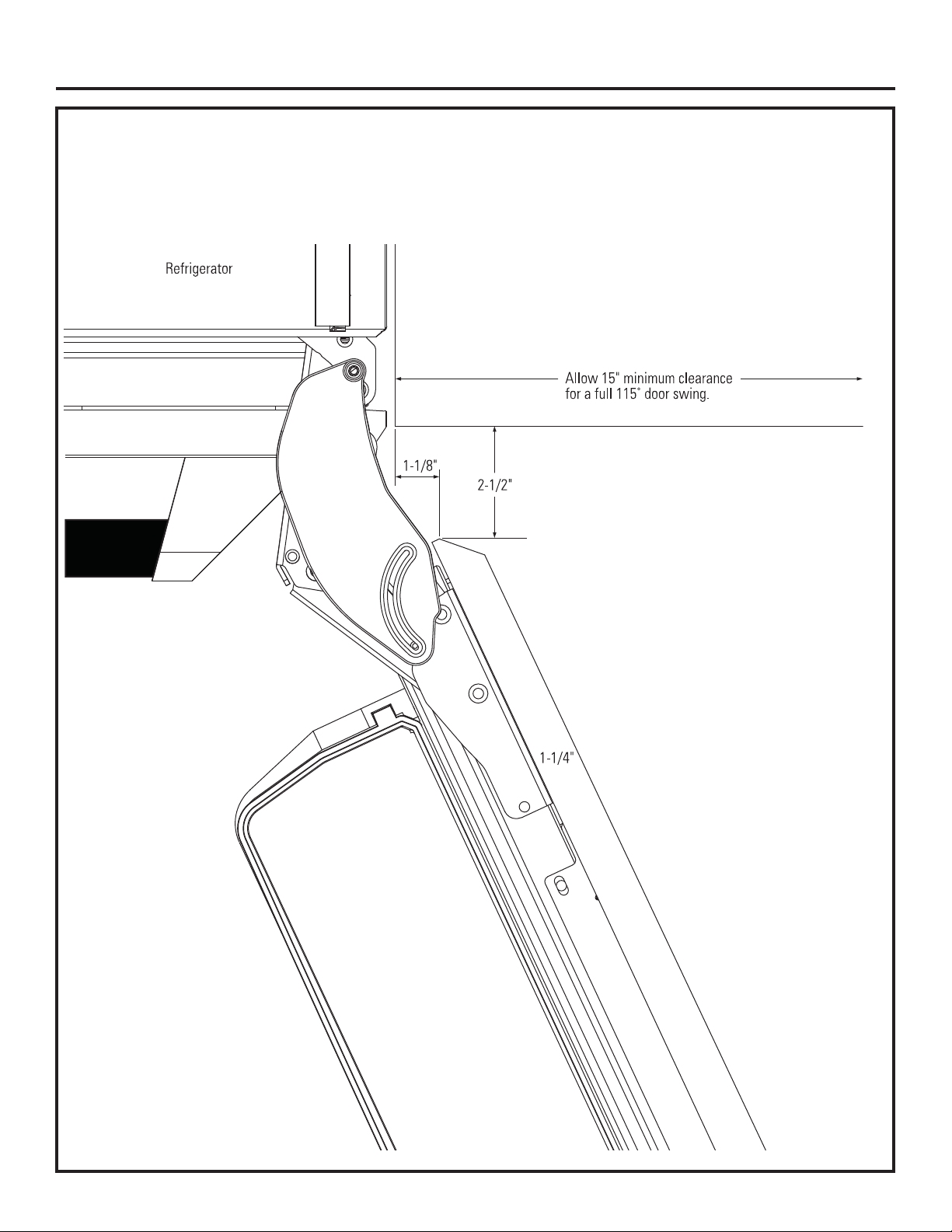

Design Guide

For a 90º door

swing allow 5” min.

clearance to a wall,

for stainless steel

models.

1/8”

3/4”

1”

1-1/2”

1-1/4”

1-1/2”

1-1/4”

1”

3/4”

SS European or Custom Panels

Top View

90° DOOR SWING

(optional setting)

Not to scale

8

31-46542-4

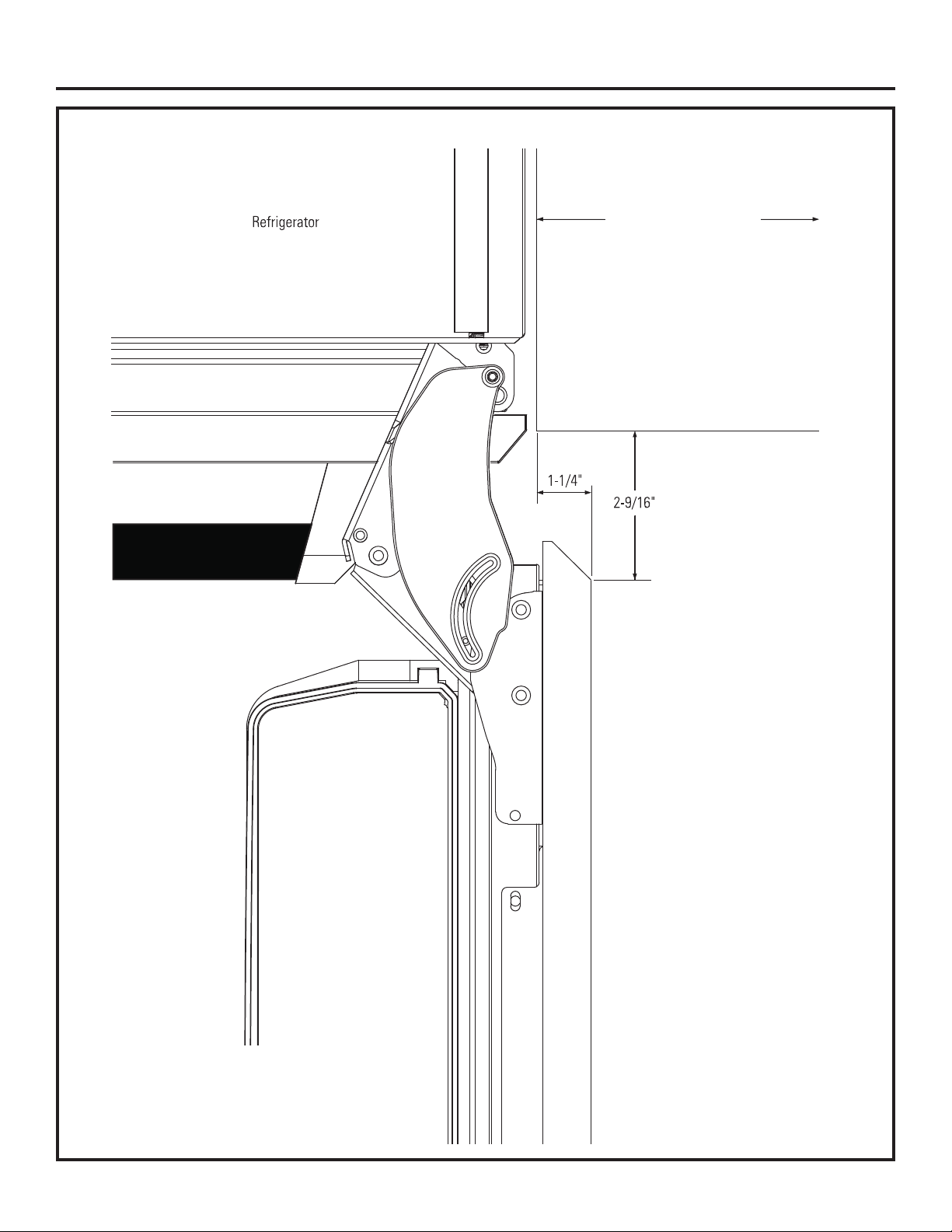

Design Guide

Product Clearances

These refrigerators are equipped with a 2-position door stop. The factory-set 115° door swing can be adjusted

to 90° if clearance to adjacent cabinets or walls is restricted.

For 90° Door swing see page 10.

SS Professional Panels

Top View

115° DOOR SWING

(factory setting)

31-46542-4

Not to scale

9

Design Guide

For a 90º door

swing allow 5” min.

clearance to a wall,

for stainless steel

models.

SS Professional Panels

Top View

90° DOOR SWING

(optional setting)

10

Not to scale

31-46542-4

Design Guide

SS PANEL ACCESSORY & DIMENSIONS

3/4”-Thick Solid Door Panel Options

For 80” High Installation

• Integrated – Panel Model ZKST300N LH & RH

capable

• Professional – Panel Model ZKSP300N LH & RH

capable

For 84” High Installation (The door panel is not

reversible for the 84” Installations. A left or right-hand

door panel accessory must be purchased.)

• LH Integrated – Model ZKST304NLH

• RH Integrated – Model ZKST304NRH

• LH Professional – Model ZKSP304NLH

• RH Professional – Model ZKSP304NRH

NOTE: Each kit also contains matching freezer and

customizable drawer panels, handles and toekick.

45-3/8” for 80” Installation

49-3/8” for 84” Installation

3/4”-Thick Frame for Glass Door Options

For 80” High Installation

• Integrated – Model ZKGT300N LH & RH capable

• Professional – Model ZKGP300N LH & RH capable

For 84” High Installation (The door panel is not

reversible for the 84” Installations. A left or right-hand

door panel accessory must be purchased.)

• LH Integrated – Model ZKGT304NLH

• RH Integrated – Model ZKGT304NRH

• LH Professional – Model ZKGP304NLH

• RH Professional – Model ZKGP304NRH

NOTE: Each option also contains matching freezer and

Convertible drawer panels, handles and toekick.

*

45-3/8”

49-3/8”

7-1/2”

22-3/4”

* There must be a minimum 1/8” gap between panels

and surrounding cabinetry.

Optional Accessory Kits #:

• Side-by-Side Installation Kit – ZUG30

• European handle kit - (3 handles) - WR12X10988

(can be purchased through GE Parts)

*Pro style window is slightly smaller..

31-46542-4

11

Design Guide

3/4” CUSTOM PANEL DIMENSIONS: 80” High Fully Integrated Installation

If you choose to install custom panels, they must be cut

to the dimensions shown. The panels will attach to the

door and drawers using a hook and bracket system.

EXTREMELY IMPORTANT: Custom wood panels

must be at least 3/4” thick where hooks and bracket

hardware are attached. Refer to Templates for hook

and bracket location.

Routing of the panels is required where the hooks and brackets attach to the panels.

PANELS FOR SOLID DOOR

AND DRAWERS

PANELS FOR

GLASS DOOR

NOTE: This product is designed to handle 3/4” panels

that are made of wood.

33-3/8” x 23” is the maximum opening for a

glass window. The opening may be smaller if

desired.

IMPORTANT NOTE: Maximum panel weight:

A Fresh Food Door Panel: 33 lbs.

B Freezer Drawer Panel: 9 lbs.

C Convertible Drawer Panel: 19 lbs.

7-1/2”

45-3/8”

22-3/4”

A

B

C

45-3/8”

33-3/8”

* Styles must be a min 3-3/8” to cover

aluminum door frame.

Design Tip: Some amount of each panel will be visible on the interior side

of the unit. It is recommended that both sides of each panel be finished.

Design Tip: If using custom panels, a custom toe kick should

be considered. The Bottom of case is white.

3/4” CUSTOM PANEL DIMENSIONS: 84” High Fully Integrated Installation

If you choose to install custom panels, they must be cut

to the dimensions shown. The panels will attach to the

door and drawers using a hook and bracket system.

EXTREMELY IMPORTANT: Custom wood panels

must be at least 3/4” thick where hooks and bracket

hardware are attached. Refer to Templates for hook

and bracket location.

Routing of the panels is required where the hooks and brackets attach to the panels.

PANELS FOR SOLID DOOR

AND DRAWERS

PANELS FOR

GLASS DOOR

NOTE: This product is designed to handle 3/4” panels

that are made of wood.

33-3/8” x 23” is the maximum opening for a

glass window. The opening may be smaller if

desired.

IMPORTANT NOTE: Maximum panel weight:

A Fresh Food Door Panel: 33 lbs.

B Freezer Drawer Panel: 9 lbs.

C Convertible Drawer Panel: 19 lbs.

7-1/2”

49-3/8”

22-3/4”

A

49-3/8”

33-3/8”

* Styles must be a min 3-3/8” to cover

aluminum door frame.

Design Tip: Some amount of each panel will

B

be visible on the interior side of the unit. It is

recommended that both sides of each panel

be finished.

C

Design Tip: If using custom panels, a custom

toe kick should be considered. The Bottom of

case is white.

12

31-46542-4

Installation Instructions

TOOLS REQUIRED

• 5/32” Allen wrench

• Utility knife

• Stepladder

• Bucket

• Level

• Appliance hand truck

• Tubing cutter

• 7/16” open-end wrench

• 1-5/16” open-end wrench

• #2 Phillips screwdriver

• Drill and bit set

• 5/16” socket

• Safety glasses

• Pliers

• 3/8” ratchet

• Torx T-20, T-30 wrench

HARDWARE SUPPLIED

• Anti-tip bracket & screws

• Panel mounting brackets

• Door panel templates- Pub # 31-46543

• Water filter - Part # GSWF

• Drywall Anchors and screws

MATERIALS REQUIRED

• 1/4” copper water line tubing or SmartConnect™

Refrigerator Tubing kits

• Water shut-off valve

• Custom panels for fresh food door, freezer drawer and

Convertible drawer

• Velcro w/adhesive if using custom toekick.

FLOORING

For proper installation, this refrigerator must be placed

on a level surface of hard material that is at the same

height as the rest of the flooring. This surface should be

strong enough to support a fully loaded refrigerator, or

approximately 1,200 lbs.

NOTE: Protect the finish of the flooring. Cut a large section of the cardboard carton and place under the refrigerator where you are working.

REFRIGERATOR/FREEZER LOCATION

Ŷ Do not install the refrigerator/freezer where the

temperature will go below 55°F (13°C). It will not run

often enough to maintain proper temperatures.

Ŷ Do not install the refrigerator/freezer where

temperatures will go above 100°F (37°C). It will not

perform properly.

Ŷ Do not install the refrigerator/freezer in a location

exposed to water (rain, etc.) or direct sunlight.

Ŷ Install it on a floor strong enough to support it fully

loaded.

31-46542-4

13

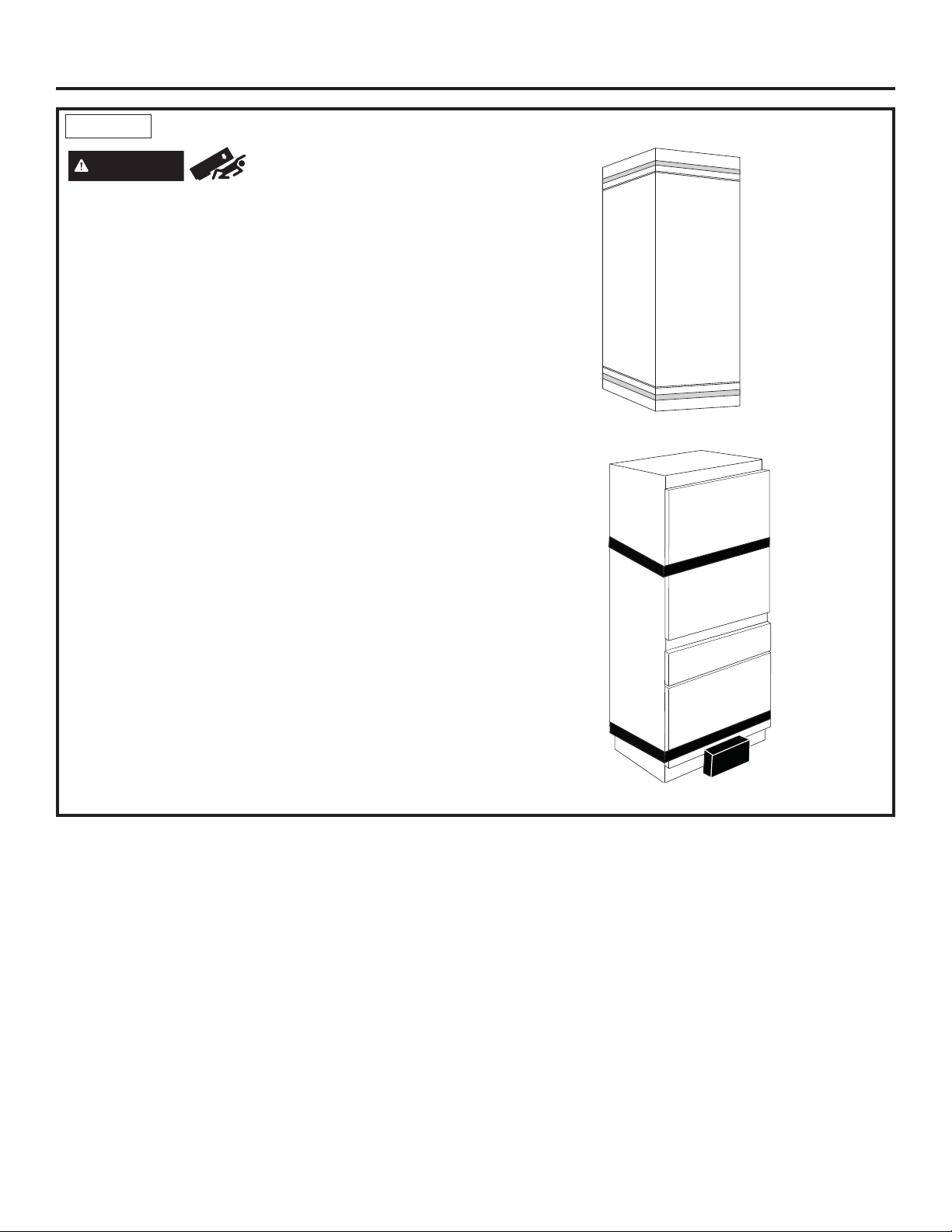

Installation Instructions

STEP 1 REMOVE PACKAGING

WARNING

This appliance is top heavy. Use extreme caution

with moving to prevent tipping over which could

result in death or serious injury.

Ŷ Cut bands and tape on the top and bottom

of packaging with a utility knife.

Ŷ Unfold the cardboard seams and remove the top

of the packaging.

Ŷ Slide the remainder of the box off of the appliance. You

can use a box cutter to cut the remaining cardboard

being VERY CAREFUL not to scratch

the appliance.

Ŷ Remove the Styrofoam supports from around the unit.

Ŷ DO NOT remove door band or lower EPS banded part

until unit is ready to go into enclosure.

Ŷ Cut EPS skid at the sides near the front from the back

of the unit.

Ŷ Push unit forward & remove rear portion of the EPS

skid.

Ŷ Carefully lower rear onto the floor.

Ŷ Lean unit back slightly & remove front portion of the

EPS skid.

Ŷ Discard all unused packaging materials appropriately.

Ŷ The unit can now be moved using an appliance hand

truck or rolled on a properly protected floor by 2

people.

Ŷ Leave any protective film on the refrigerator until

installation is complete.

Tip Over Hazard.

14

31-46542-4

Installation Instructions

WARNING

These appliances are top heavy, especially with any

doors open, and must be secured to prevent tipping

forward which could result in death or serious injury.

Read and follow the entire installation instructions for

securing the appliance with the anti-tip system.

Tip Over Hazard.

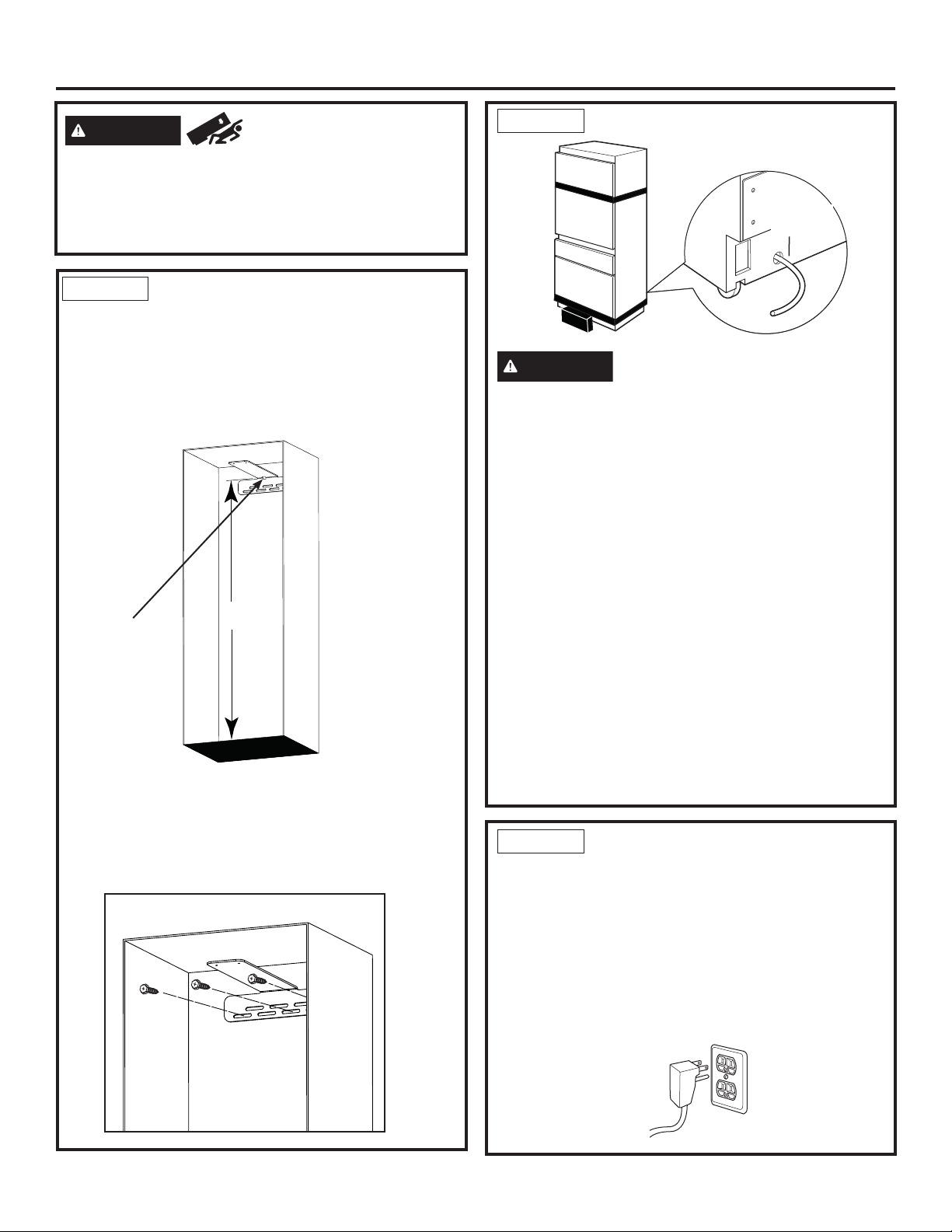

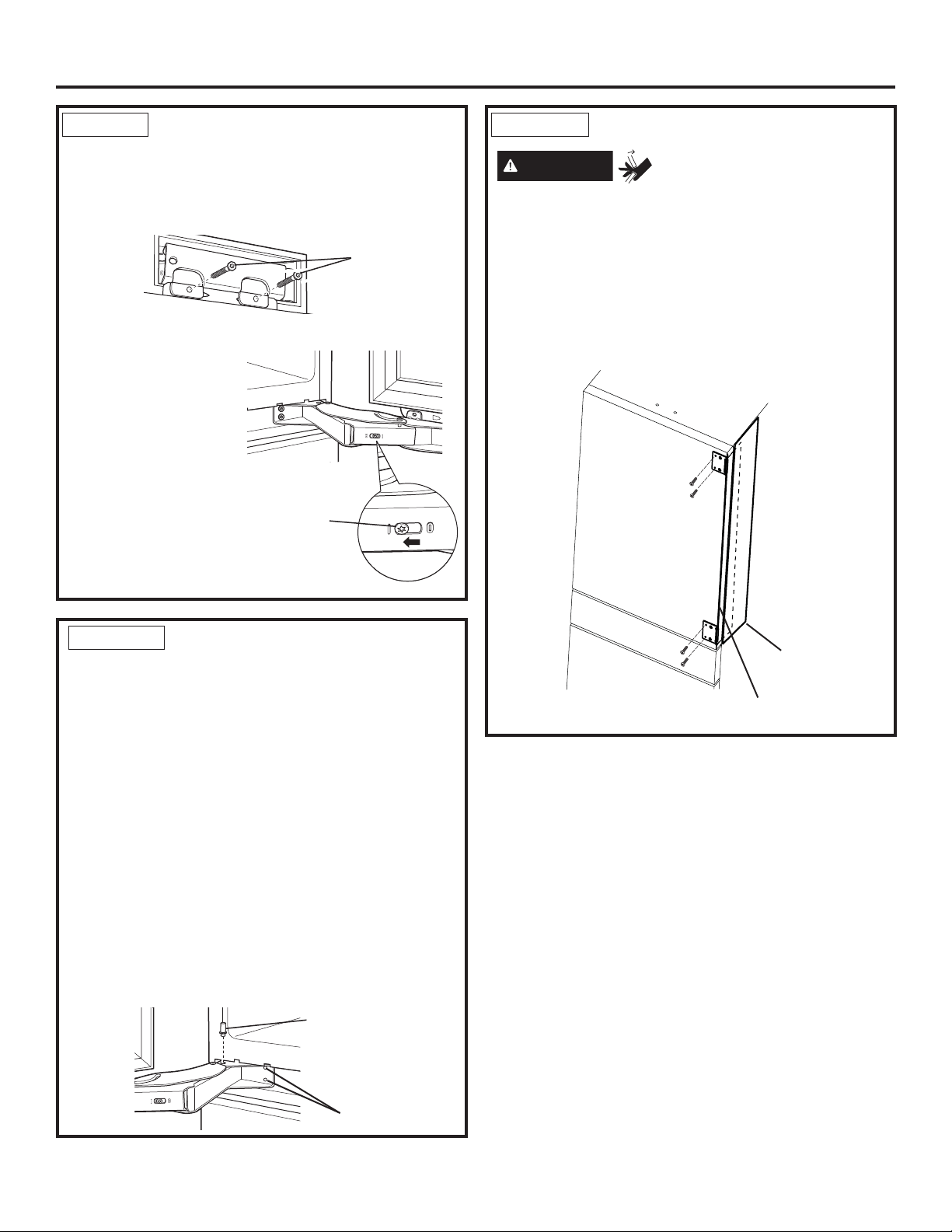

STEP 2 INSTALL ANTI-TIP

BRACKET

Ŷ Inside Top Face of bracket should be installed at

80”. “Slot” in bracket should to be placed in center of

install Space (Typically 15”).

Ŷ Mark (within slots, placement) stud and anchor

positions on brackets.

Slot

80”

STEP 3 CONNECT WATER LINE

Water

Line Hole

WARNING

Ŷ Position appliance in front of enclosure.

Ŷ Locate and bring tubing to the front of the cabinet.

Ŷ Turn the water on to flush debris from line. Run about

a quart of water through tubing into a bucket; then

shut off water.

If needed cut the tubing to the proper length so it can

be attached to the water valve.

Copper Tubing:

Ŷ Slip a 1/4” nut and ferrule over both ends of the

copper tubing. Insert tube into the union fitting on the

unit and tighten nut to union.

Ŷ Turn on the water to check for leaks.

Connect to potable water supply

only.

Ŷ Secure bracket using combination of studs &

anchors.

Ŷ At least 1 stud must be engaged. However, please

engage as many studs as possible within the

enclosure. A minimum of three fasteners should be

used for proper installation.

SmartConnect™ Tubing:

Ŷ Insert the end of the tubing into the refrigerator

connection. Tighten the compression nut until it is just

hand-tight.

Ŷ Tighten one additional turn with a wrench.

Overtightening can cause leaks!

Ŷ Turn on the water to check for leaks.

STEP 4 CONNECT POWER

Ŷ Plug the power cord into the socket.

Ŷ Check to make sure power to refrigerator is on by

opening the ice drawer (FF door will be banded shut)

to see if interior lights are on.

Ŷ The temperature controls are preset at 37°F for the

fresh food section and 0°F in both the freezer drawer

and customizable drawer.

Ŷ Allow 24 hours to stabilize before making

adjustments.

31-46542-4

15

Installation Instructions

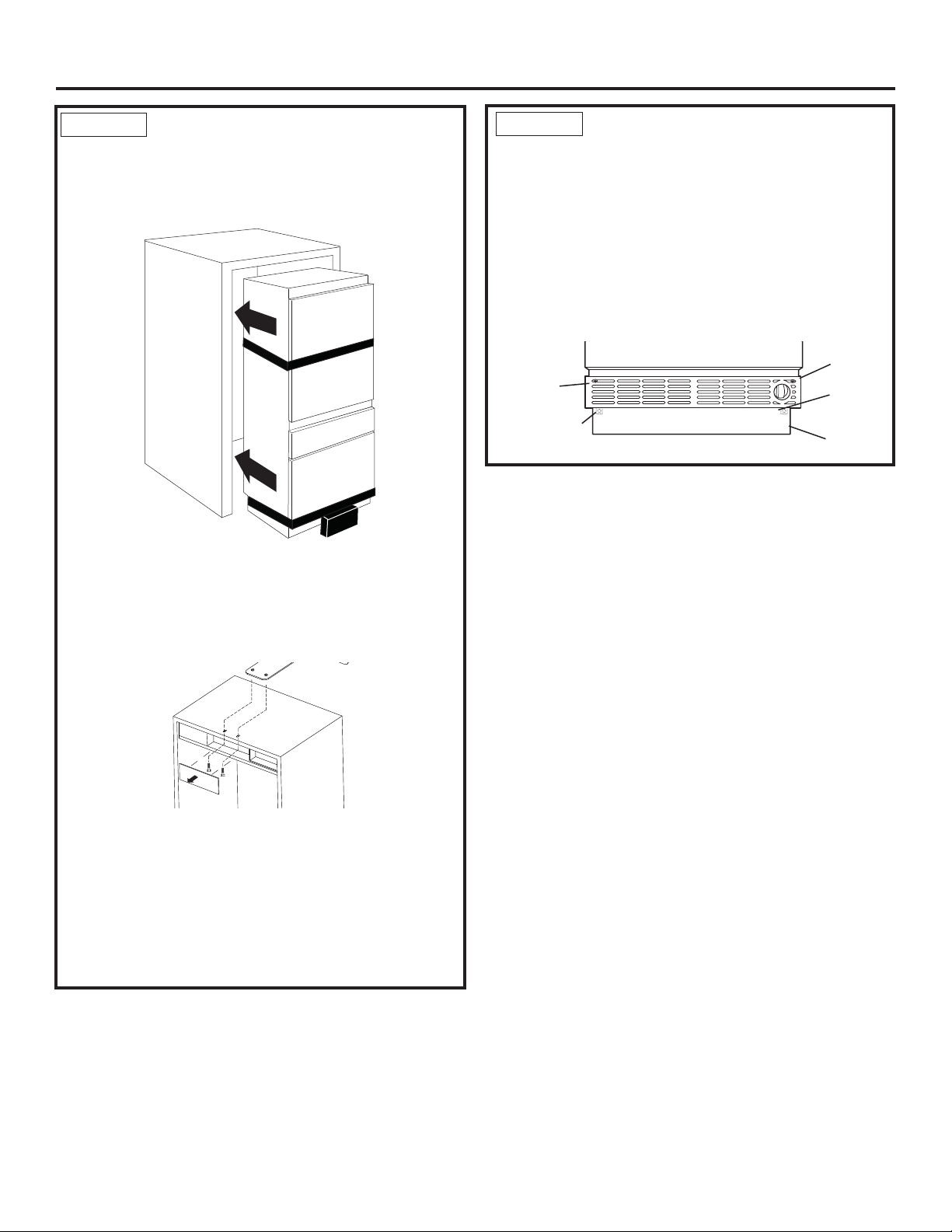

STEP 5 SLIDE UNIT INTO

ENCLOSURE

Roll the unit into the enclosure, being careful not to

pinch the water line or power cord.

Ŷ$ORQJIODWEDURU\DUGVWLFNPD\EHQHHGHGWRJXLGH

the front edge of the anti-tip bracket over the unit.

ŶIf space allows, you may also bend the front edge of

the bracket upward slightly, allowing it to clear the

back of the unit.

STEP 6 REMOVE TOEKICK AND

VENT

The toekick must be removed to access

the leveling leg system.

ŶRemove band around EPS block in front of toekick.

ŶRemove and dispose of EPS block.

ŶRemove the solid portion of the toekick by pulling

forward.

Ŷ Place the toekick, vent and screws out of the way so

you will have them for reinstallation.

Vent

Screws

(behind

toekick)

Screw

Vent

Screw

Toekick

ŶRemove Top-Center trim cover from unit.

ŶSecure the unit to the Anti-tip bracket using both

machine screws & washers to engage the threaded

inserts in the anti-tip bracket.

ŶHand start the screws until unit is in desired location

within the install space.

ŶFinalize unit install by tighening the screws fully.

ŶReinstall Trim cover.

16

31-46542-4

Installation Instructions

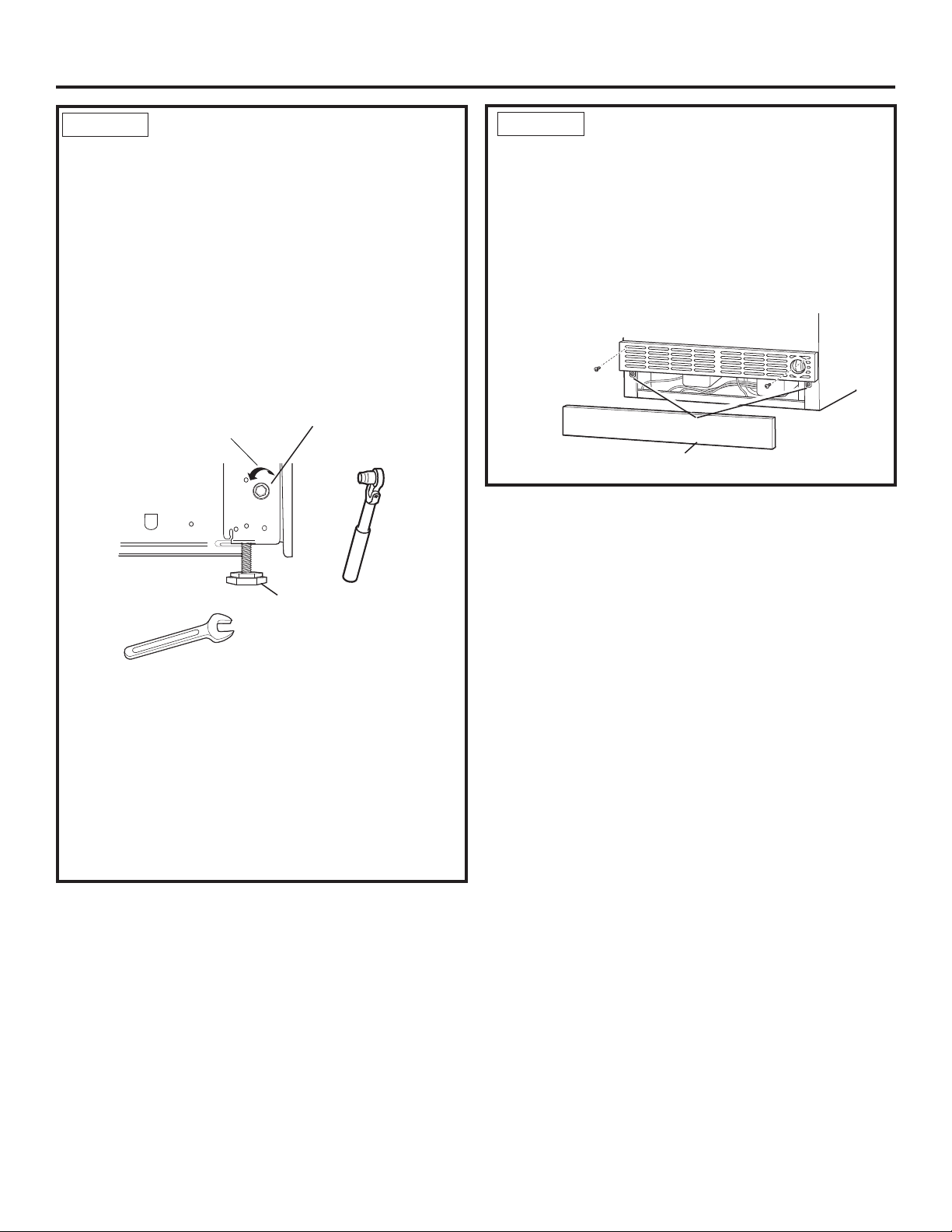

STEP 7 LEVEL REFRIGERATOR

All models have 4-point leveling. The front is supported

by leveling legs; the rear is supported by adjustable

wheels. Both are accessible from the front of the

refrigerator.

ŶTo level the back of the refrigerator, turn the 5/16”

hex nut located above the front wheels. Turn

counter clockwise to raise or clockwise to lower the

refrigerator.

ŶFor front leveling, use a 1-5/16” open-end wrench.

ŶAdjust height of refrigerator to match installation

cutout opening. The refrigerator should be level and

plumb with cabinetry.

Hex Nut

Adjusts Rear

Up

Up

Wheels

STEP 8 INSTALL TOEKICK AND

VENT

ŶLocate the toekick, vent and screws (removed

earlier).

ŶA custom toekick can be installed to match or

complement the surrounding cabinetry. Use the

supplied toekick as a template.

ŶReinstall the vent using the screws removed earlier.

ŶReinstall the toekick .

Vent Holes

Supplied Toekick

Leveling Leg

NOTICE: The rear leveling wheels and front leveling

legs are limited to a maximum height adjustment of 1”.

If the installation requires more than 84-1/2” height, the

installer should elevate the refrigerator on a sheet of

plywood or runners. Cabinetry trim could also be added

across the top of the opening to shorten the opening.

If you attempt to raise the refrigerator more than 1”, you

will damage the front leveling legs and the rear leveling

wheels.

31-46542-4

17

Installation Instructions

STEP 9 REVERSE DOOR SWING (if needed)

Skip this step if door swing is satisfactory.

WARNING

the door swing. Failure to follow these instructions,

leaving off parts, or overtightening screws, can

lead to the door falling off and result in injury and

property damage.

1. Open the fresh food door.

WARNING

Follow all steps when reversing

Door Hinge Pinch

Point Hazard

This next step is important for safe handling of an

unloaded hinge. Do not skip step 2.

2. Release the hinge springs by using a Torx T-20

wrench to loosen the Torx screw from | to 0 on both

hinges. Close the door.

Control Panel

7. Reinstall the control panel.

8. The hinges will be reinstalled in opposite corners. The

hinge from the top will be turned over and installed at

the bottom of the fresh food compartment. The hinge

from the bottom will be turned over and installed at

the top of the fresh food compartment.

Top Hinge Bottom Hinge

9. Install the screws on the fresh food compartment

cabinet in all 4 places. Screw them in about halfway.

Screws

Slots for

Tabs

3. Using a 5/32” Allen wrench, remove the 2 screws per

hinge that secure the door to the refrigerator. Have

someone hold the door while removing these screws

to keep the door from falling.

Screws

4. Open the hinges. Using a 5/32” Allen wrench, remove

the 2 screws per hinge that secure the hinge to the

refrigerator cabinet.

Screws

5. Remove the trim and hinge pocket from the top of the

refrigerator and install on the opposite sides.

6. Remove the trim and hinge pocket from the bottom

of the fresh food compartment. Remove the control

panel and gently place in the FZ drawer.

10. To install the top hinge, turn the hinge in the proper

direction—the section of the bracket that will be

attached to the door should be at the bottom of the

hinge. Slide the hinge over the screws and seat the

tabs into the hinge pocket. Tighten the screws.

Screws

11. To install the bottom hinge, turn the hinge in the

proper direction—the section of the bracket that will

attach to the door should be at the top of the hinge.

Slide the hinge over the screws and seat the tabs

into the hinge pocket. Tighten the screws. Close the

hinge.

12. Remove the hinge brackets from the door and reinstall them on the opposite end, top and bottom.

18

31-46542-4

Installation Instructions

STEP 9 REVERSE DOOR SWING

(cont).

13. With another person holding the door in place, align

the holes in the door hinge bracket with the holes in

the hinge. Install the screws to the top hinge first.

Door

Screws

14. Install screws on the bottom hinge next.

15. Using a Torx T-20

wrench, tighten the

tension on

the hinge springs by

turning the screws

from 0 to |.

Use Torx

T-20 Wrench

STEP 11 ATTACH HINGE GUARD

WARNING

Point Hazard

This appliance must be installed & operated with

the hinge guard in place !

1. Tape hinge guard cover to side of case. Align cover

with top and front edges of case.

2. Attach hinge guard by sliding flat part between case

and hinge guard cover.

3. Fasten guard to door front using 4 screws.

Door Hinge Pinch

STEP 10 ADJUST DOOR SWING

(if needed)

NOTE: This refrigerator has a 2-position door stop.

When space does not allow the door to swing to 115°,

you may limit the door swing to a 90°

Skip this step if door opening is satisfactory for your

installation situation.

Ŷ2SHQWKHIUHVKIRRGGRRUWRDFFHVVWKHWRSDQG

bottom hinges.

Ŷ/RRVHQWKHERWWRPKLQJHVFUHZVWKDWDWWDFKHGWRWKH

unit

Ŷ3XOOKLQJHIRUZDUGVOLJKWO\LQVHUWKLQJHSLQLQWRWKH

hole nearest the unit.

Ŷ<RXPD\QHHGWRXVHDVPDOOKDPPHUWRIXOO\VHDW

them in place.

Ŷ5HWLJKWHQKLQJHVFUHZV

ŶRepeat for top hinge.

Install 1 pin,

per hinge for 90°

door stop.

Cover

Hinge guard

31-46542-4

Hinge screws

19

Installation Instructions

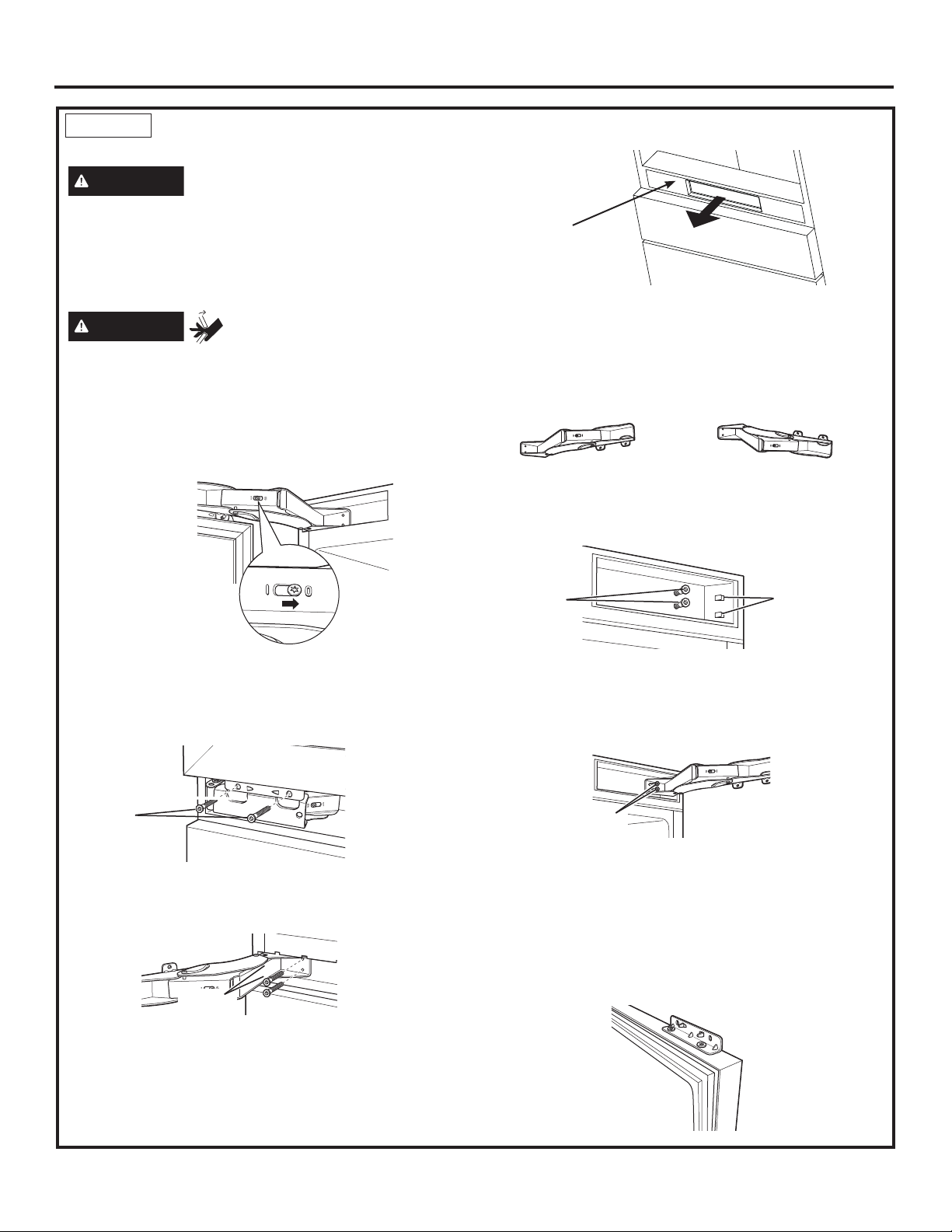

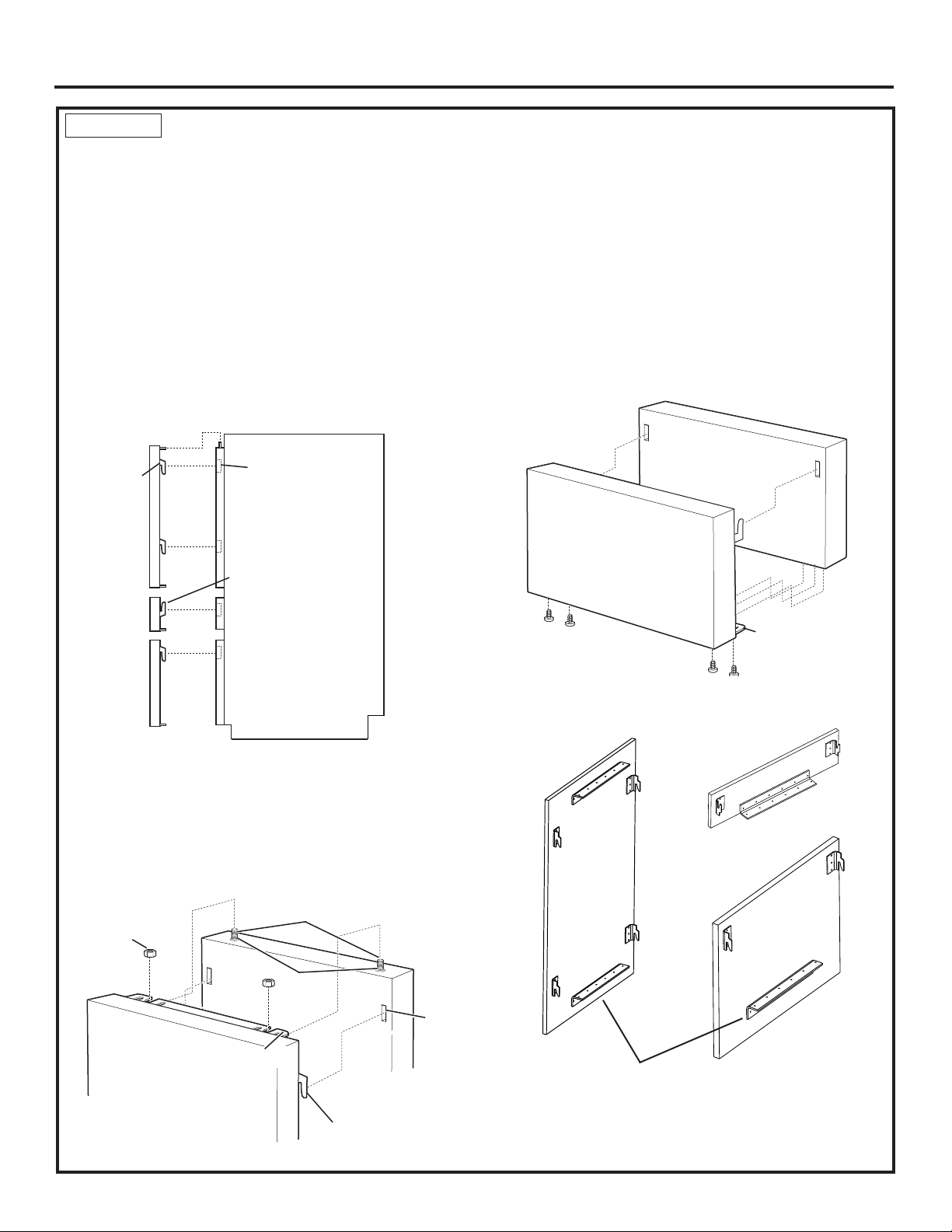

STEP 12 INSTALL DOOR AND DRAWER PANELS

1. Remove all door and drawer hooks from the unit and

screw them to the custom panels, aligning them with

the lowest set of predrilled holes for Monogram Panel

Kits on the FF door panel.

2. Attach top L-Bracket to FF panel.

3. If you had custom handles made and they are not

currently attached to your panels, do so now.

4. Open the fresh food door to attach the fresh food

panel.

5. Slide the hooks on the fresh food panel into the slots

of the door, and lower the hooks into place. Make sure

the bracket on the top of the panel slides over the

screw posts on top of the door. The brackets will rest

on top of the nuts.

Bracket

Hooks

Screw Post

Slots

8. Install the Freezer drawer panel by sliding the brackets

up into place (the opposite direction of the hooks on

the fresh food panel and Convertible drawer). .

9. Once the drawer panel is placed fasten the panel to

the drawer by screwing the bottom bracket into the

panel with the screws provided.

10. Repeat for the second drawer by sliding the hooks

down instead of up.

11. If using custom toekick attach the toekick panel by

placing Velcro on the back of the panel, and on the

front of the toekick. If using SS toekick it is magnetic.

12. Adjust drawer alignment using lower brackets as

needed to create uniform gaps.

Hooks on the Freezer

drawer panel face up.

6. Adjust the screw posts up or down under the bracket

on top of the door to level the panel.

7. Lock the panel to the door by installing the nuts

provided onto the screw posts on top of the door. Next,

screw the L-bracket provided into the bottom of the

door and the panel.

Screw Post

Nut

Nut

Freezer

Drawer

Bracket

Back View of Panel Hooks and Bracket

Freezer

Drawer

Fresh

Food

Door

Convertible

drawer

Top of

Fresh Food

Panel Door

Bracket

Hooks

Slots

The lower brackets on the Fresh Food & Convertible Drawer

should not be installed until after the panel is in place.

20

31-46542-4

Installation Instructions

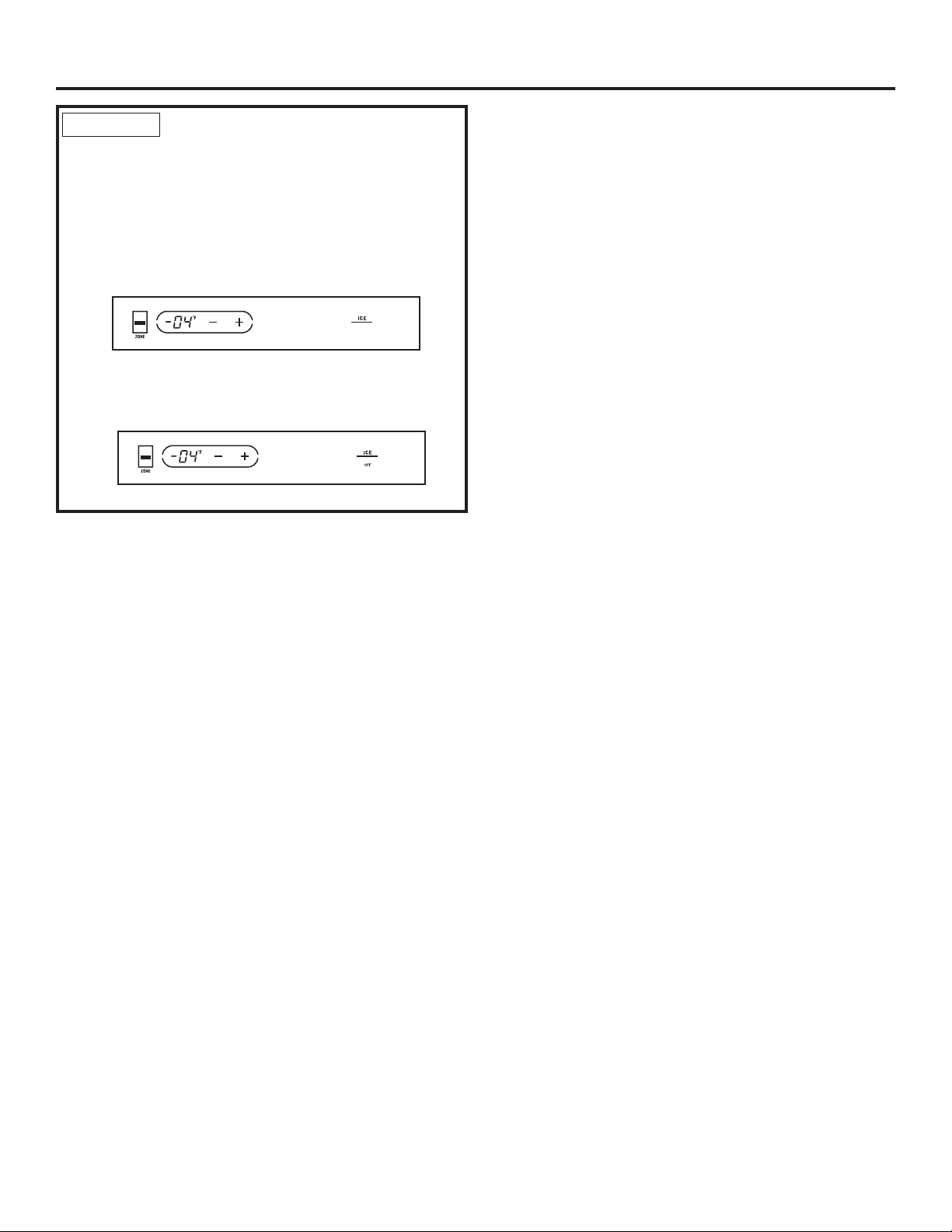

STEP 13 START ICEMAKER

Ŷ Press the zone indicator on the control pad twice

to select the freezer drawer. Press the ICE icon on

the right side of the control. A line will appear under

ICE to show that the icemaker is ON.

Ŷ Be sure nothing interferes with the sweep of the

feeler arm.

Ŷ Discard the first full bucket of ice cubes.

Ŷ To turn the icemaker off, press the ICE icon. The

word OFF appears below ICE to show that the

icemaker is OFF.

31-46542-4

21

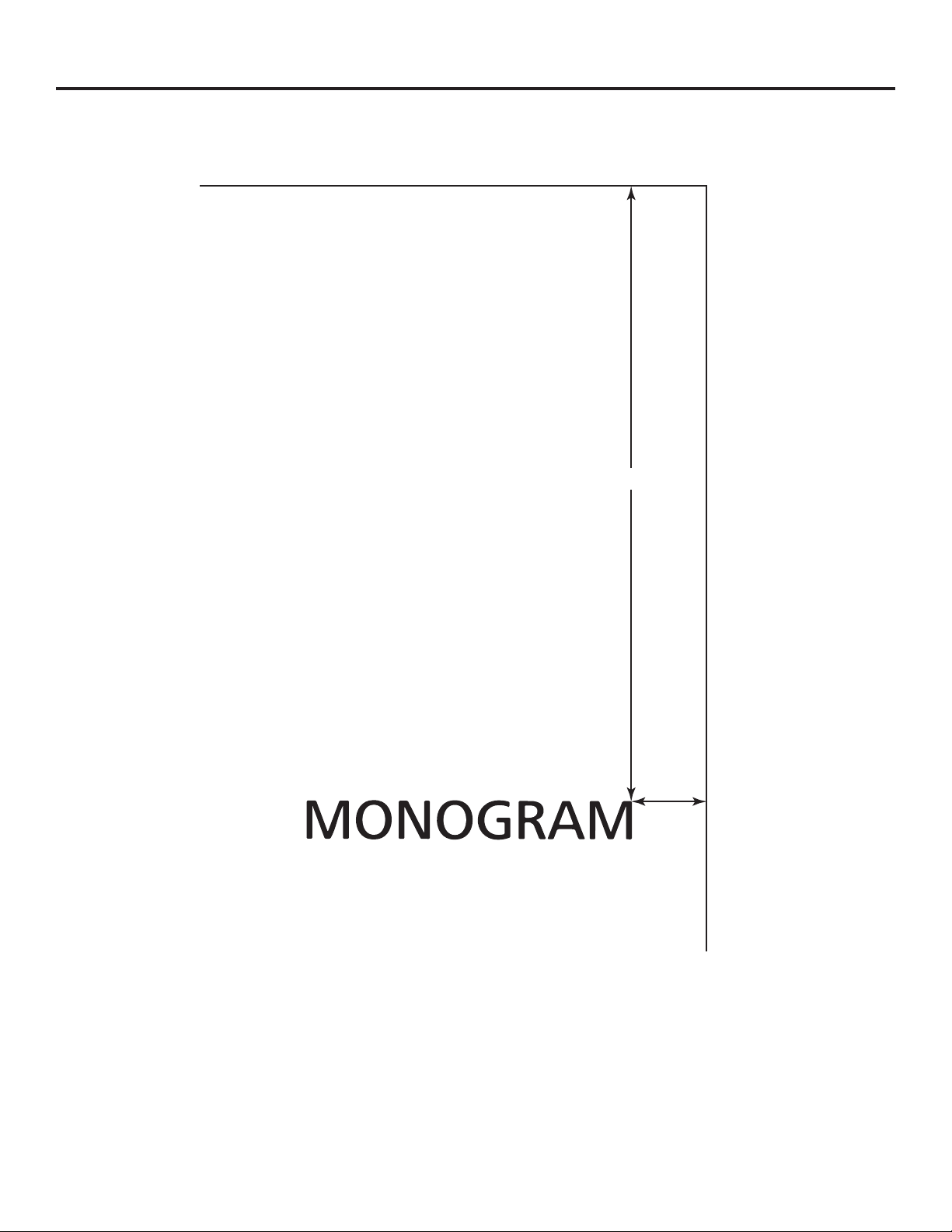

Installation Instructions

MONOGRAM BADGE PLACEMENT

TOP OF REFRIGERATOR

5.5"

0.675"

SIDE OF REFRIGERATOR

22

31-46542-4

Loading...

Loading...