Page 1

Installation

Instructions

Double-Door, Bottom-Drawer

Free-Standing Refrigerator

31-49050

239D4535P004

monogram.com

Français

The French section begins on page 14.

La section française commence à la page 14

Español

The Spanish section begins on page 27

La sección en español empieza en la página

27.

Page 2

Safety Information

BEFORE YOU BE GIN

Read these in struc tions completely and carefully.

• IM POR TANT – Save these instructions for

local inspector’s use. Observe all gov ern ing codes and

ordinances.

• Note to In stall er – Be sure to leave these instructions

with the Consumer.

• Note to Con sum er – Keep these instructions with your

Owner’s Manual for future reference.

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and others. All safety

messages will follow the safety alert symbol and the word “DANGER”, “WARNING”, or “CAUTION”. These words are defined as:

DANGER

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

Skill Level – Installation of this refrigerator requires

basic me chan i cal, carpentry and plumbing skills. Proper

installation is the re spon si bil i ty of the installer. Product

failure due to improper installation is not covered under

the GE Appliance Warranty. See the Owner’s Manual for

warranty information.

If you received a damaged refrigerator, you should immediately contact your dealer or builder.

WARNING

basic safety precautions, including the following:

• This appliance must be properly ground ed. See “Ground-

ing the Refrigerator,” page 5.

• Use this appliance only for its intended pur pose.

• Immediately repair or replace electric service cords that

become frayed or damaged.

• Unplug the refrigerator before cleaning or making repairs.

For Monogram local service in your area, call 1.800.444.1845.

For Monogram service in Canada, call 1.800.561.3344

For Monogram Parts and Accessories, call 1.800.626.2002.

www.monogram.com

When using this appliance, always exercise

CONTENTS

Planning Information

Product Dimensions and Clearances ...................................... 3-4

The Installation Space ..........................................................................5

Installation Instructions

Tools, Hardware, Materials ............................................................... 5

Grounding the Re frig er a tor .............................................................. 5

Step 1. Measure Cabinet Opening ................................................6

Step 2. Install Anti-Tip Bracket ................................................... 6-7

Step 3. Install the Refrigerator ........................................................8

Step 4. Remove the Freezer Drawer ............................................8

Step 5. Remove the Fresh Food Doors .................................. 8-9

• Repairs should be made by a qualified service technician.

• To reduce the risk associated with choking, do not allow

children under 3 years of age to have access to small

parts during the installation of this product.

CAUTION

Due to the weight and size of this refrigerator, and to reduce the

risk of personal injury or damage to the product – TWO PEOPLE

ARE REQUIRED FOR PROPER INSTALLATION.

Step 6. Move the Refrigerator .........................................................9

Step 7. Replace the Freezer Drawer ......................................... 10

Step 8. Leven the Freezer Drawer ...............................................10

Step 9. Replace Fresh Food Doors ............................................. 11

Step 10. Install Water Line ............................................................. 11

Step 11. Connect Water Supply .................................................. 12

Step 12. Connect Power ................................................................. 12

Step 13. Level Refrigerator ............................................................ 12

Step 14. Level Doors ......................................................................... 13

Step 15. Remove Packaging, Start Icemaker ....................... 13

Step 16. Temperature Controls ..................................................... 13

2

Page 3

Planning Information

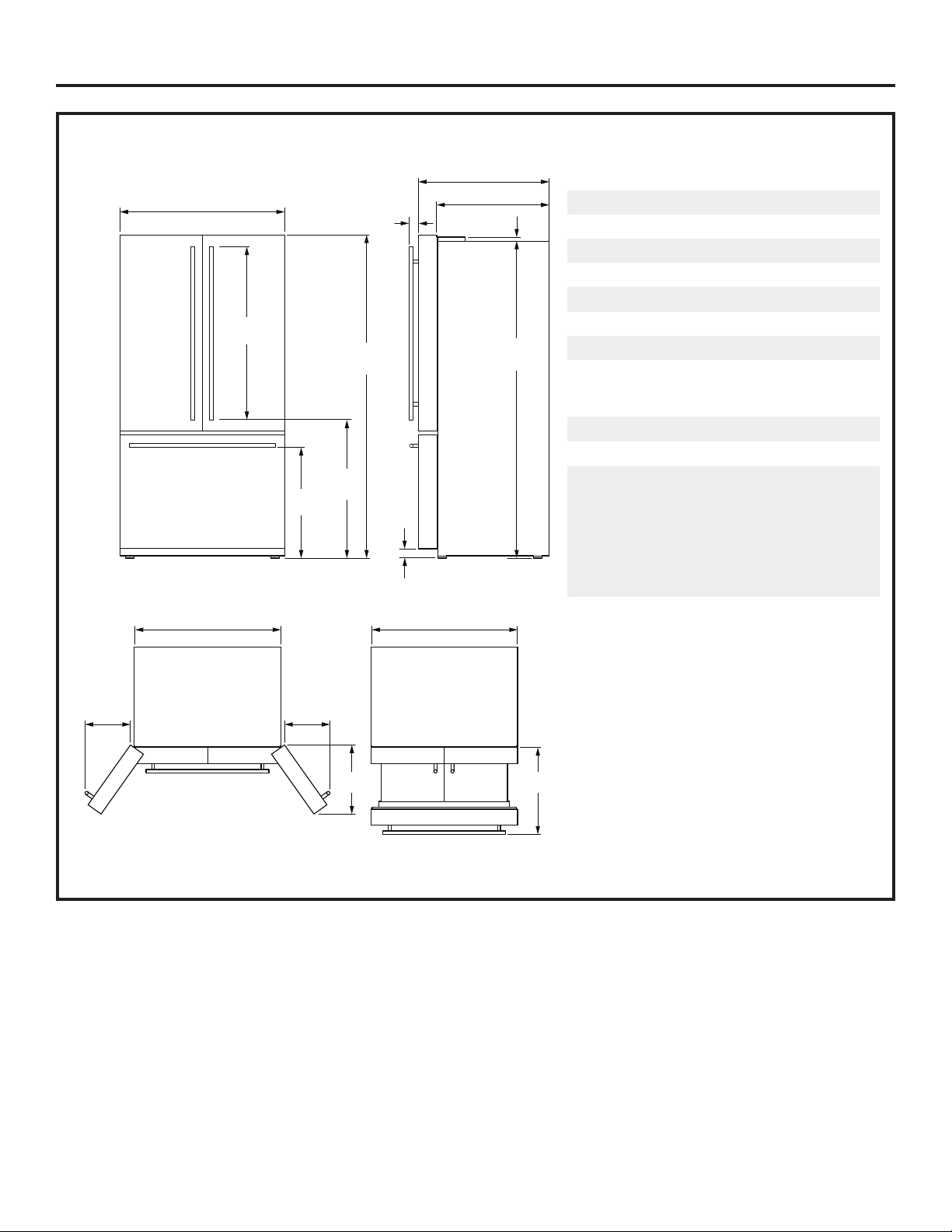

PRODUCT DIMENSIONS AND CLEARANCES ZWE23E Models

28 11/16" (72.9)

36" (91.4)

Case width

24 3/8" (61.9)

13/16"

(2.1)

69 1/8"

(175.6)

36" (91.4)

37 1/2"

(95.25)

30 7/16"

(77.3)

24 3/8"

(61.9)

FRONT VIEW SIDE VIEW

36" (91.4)

Case width

70 1/2"

(179.1)

2"

(5.1)

2"

(5.1)

SPECIFICATIONS

Overall Width 36" (91.4 cm)

Overall Height 70 1/2" (179.1 cm)

Overall Depth 30 11/16" (76.2 cm)

Door Clearance 21 1/4" (54 cm)

Cutout Width 36 1/4" (92.1 cm)

Cutout Height 71" (180.3 cm)

Cutout Depth 26 3/8" (67 cm)

Plumbing Requirements 1/4" OD copper

tubing or GE

SmartConnect kit

Shipping Weight 400 lb (181.4 kg)

ATTENTION ELECTRICIAN:

A 115 volt 60Hz., 15 or 20 amp power supply

is required. An individual properly grounded

branch circuit or circuit breaker is recommended.

Install a properly grounded 3-prong electrical

receptacle recessed into the back wall.

Air Circulation Clearances:

• 1/8” on each side

• 2” at the back side

• 1” at top (cabinet/hinge cover)

*11 11/16"

(29.7)

*124° Door swing

TOP VIEW

(SHOWING DOOR SWING)

*11 11/16"

(29.7)

18"

(45.7)

TOP VIEW

(FREEZER DOOR OPEN)

21 1/4"

(53.9)

3

Page 4

Planning Information

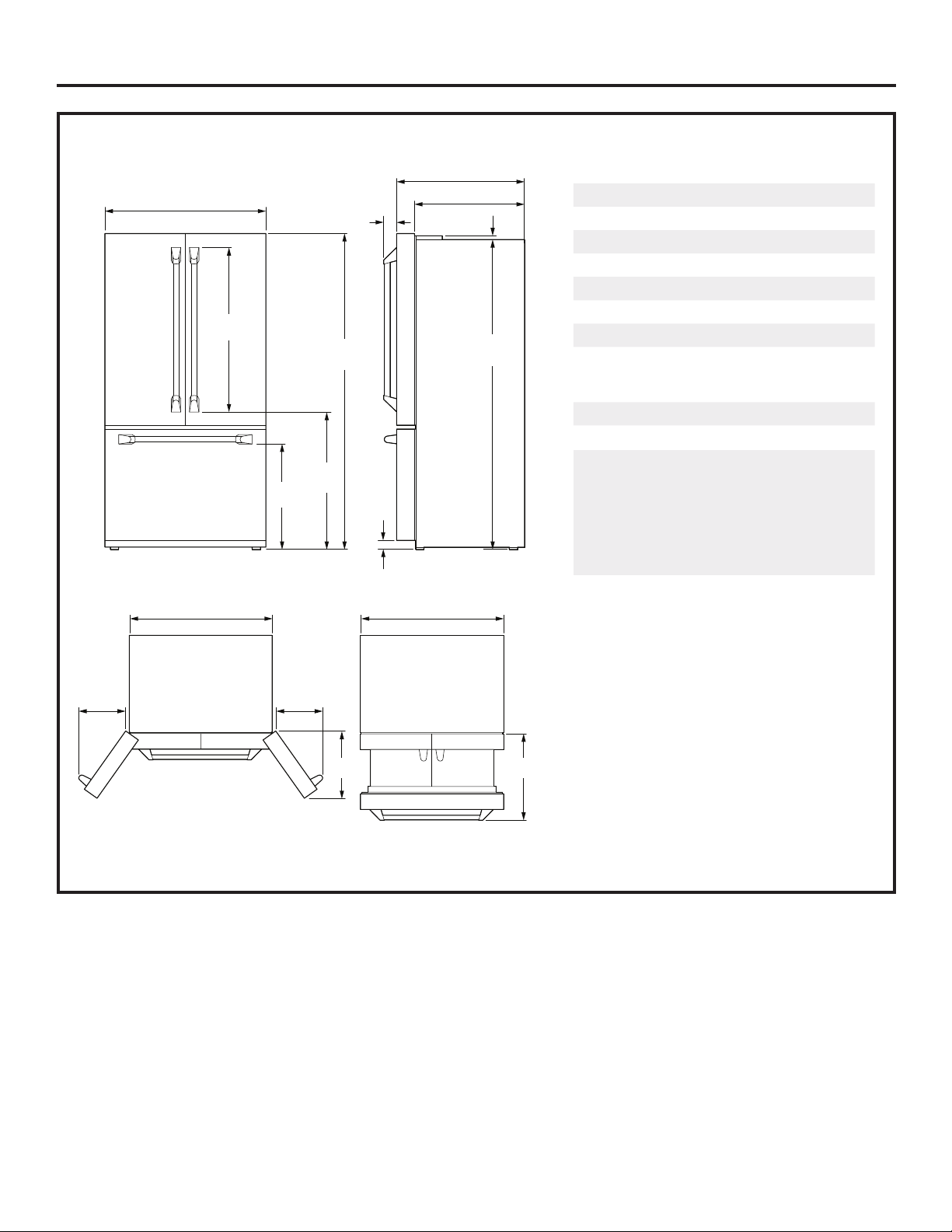

PRODUCT DIMENSIONS AND CLEARANCES ZWE23P Models

28 11/16" (72.9)

36" (91.4)

37 1/4"

(94.6)

23 3/4"

(60.3)

FRONT VIEW SIDE VIEW

36" (91.4)

Case width

70 1/2"

30 1/2"

(77.5)

2 13/16"

(7.1)

(179.1)

2"

(5.1)

24 3/8" (61.9)

36" (91.4)

Case width

13/16"

(2.1)

69 1/8"

(175.6)

SPECIFICATIONS

Overall Width 36" (91.4 cm)

Overall Height 70 1/2" (179.1 cm)

Overall Depth 31 1/2" (78.7 cm)

Door Clearance 22 1/8" (56.2 cm)

Cutout Width 36 1/4" (92.1 cm)

Cutout Height 71" (180.3 cm)

Cutout Depth 26 3/8" (67 cm)

Plumbing Requirements 1/4" OD copper

tubing or GE

SmartConnect kit

Shipping Weight 400 lb (181.4 kg)

ATTENTION ELECTRICIAN:

A 115 volt 60Hz., 15 or 20 amp power supply

is required. An individual properly grounded

branch circuit or circuit breaker is recommended.

Install a properly grounded 3-prong electrical

receptacle recessed into the back wall.

*12 7/16"

(31.6)

*124° Door swing

TOP VIEW

(SHOWING DOOR SWING)

*12 7/16"

(31.6)

18"

(45.7)

TOP VIEW

(FREEZER DOOR OPEN)

22 1/8"

(56.2)

4

Page 5

Installation Instructions

TOOLS REQUIRED

• Adjustable wrench

• 3/8” socket ratchet/driver

• Phillips head screwdriver

• Flat-Head ScrewdriveR

• 5/32”, 3/32”, 1/8”, 1/4” Allen wrenches

• 1/8” Drill bit and electric or hand drill

• Tape measure

• Pencil

• Wire cutters

• 1/4” Nut driver

• Level

• Torx T20, T25

MATERIALS REQUIRED

• 1/4” O.D. compression nut and 2 ferrules (sleeves)

OR GE SmartConnect™ Refrigerator Tubing Kits

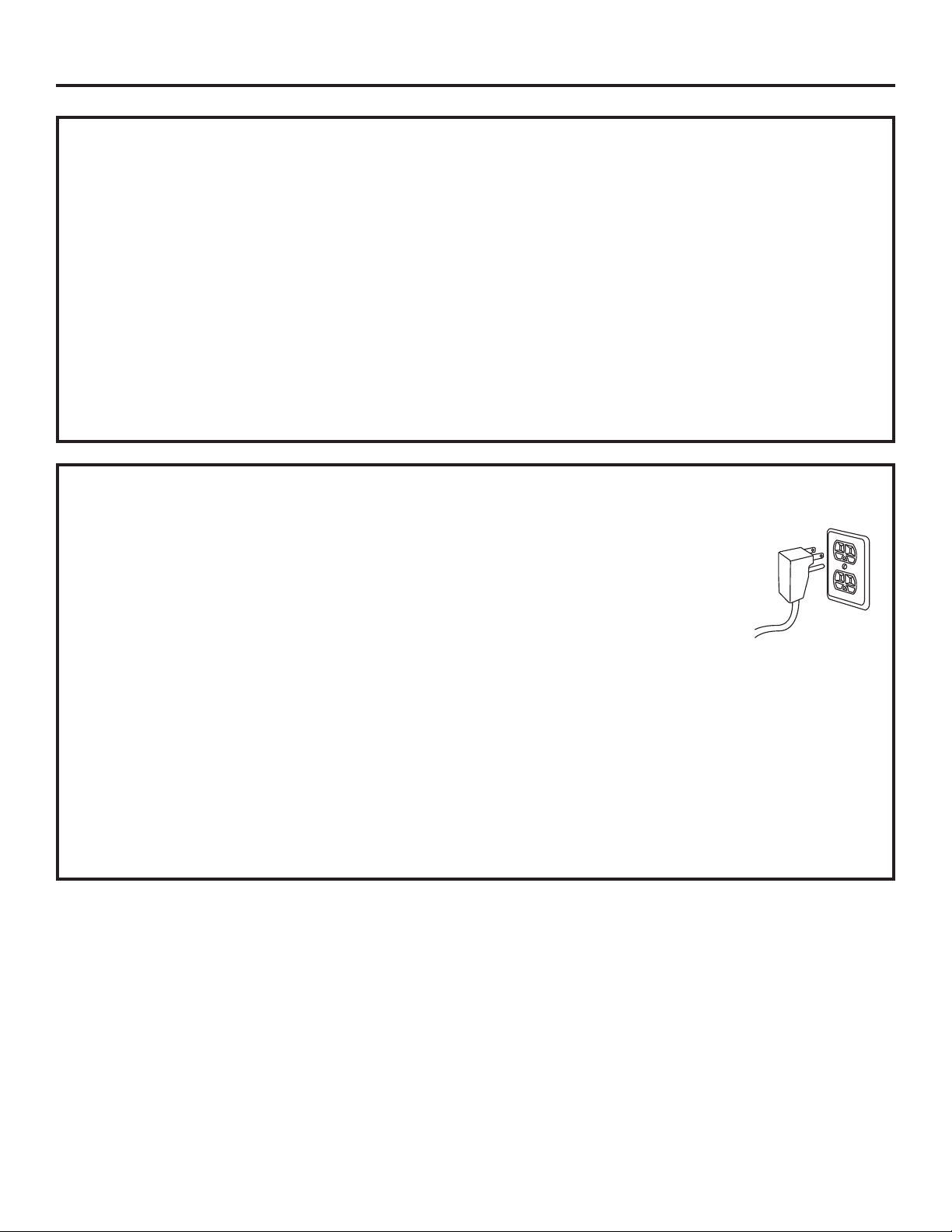

GROUNDING THE REFRIGERATOR

IMPORTANT – (Please read carefully)

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED.

The power cord of this appliance is equipped with

a 3-prong (grounding) plug which mates with a

standard 3-prong (grounding) wall receptacle to

minimize the possibility of electric shock hazard

from this appliance.

FLOORING

For proper installation, this refrigerator must be placed on

a level surface of hard material that is at the same height

as the rest of the flooring. This surface should be strong

enough to support a fully loaded refrigerator.

IMPORTANT NOTE: Protect the finish of the flooring.

Cut a large section of the cardboard carton and place

under the refrigerator where you are working.

DO NOT, UNDER ANY

CIRCUMSTANCES, CUT

OR REMOVE THE THIRD

(GROUND) PRONG

FROM THE POWER CORD.

DO NOT USE AN ADAPTER PLUG TO CONNECT

THE REFRIGERATOR TO A 2-PRONG OUTLET.

Have the wall outlet and circuit checked by a

qualified elec tri cian to make sure the outlet is

properly grounded.

Where a standard 2-prong wall outlet is en coun tered,

it is your personal responsibility and obligation to

have it replaced with a properly grounded 3-prong

wall outlet.

DO NOT USE AN EXTENSION CORD WITH

THIS APPLIANCE.

5

Page 6

Installation Instructions

WARNING

Under certain

circumstances, this

refrigerator can tip forward.

Injury to persons can result.

Install Anti-Tip Bracket packed with this refrigerator.

STEP 1 MEASURE CABINET OPENING

AVAILABLE VS. REFRIGERATOR

WIDTH

Measure width of cabinet opening where refrigerator

will be placed, W.

Be sure to account for any countertop overhang,

baseboard thickness and any clearance desired.

Width, W, should not be less than 36 inches. The

refrigerator will be placed approximately in the

middle of this opening.

Rear Wall

W

REFRIGERATOR

Front

Baseboard

Thickness

or Countertop

Overhang

(Whichever

is Greater) Plus

Any Desired

Clearance

RH Side

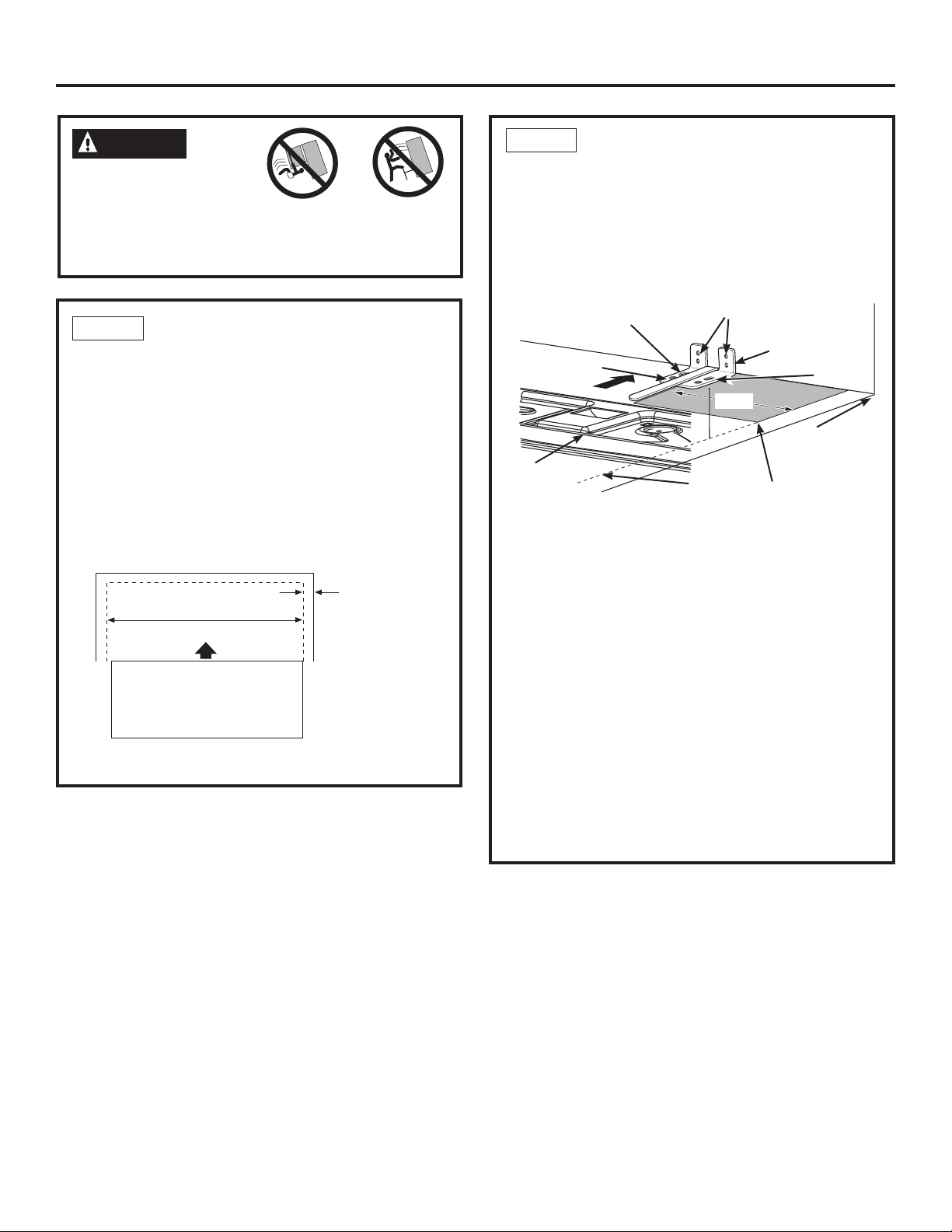

STEP 2 LOCATE ANTI-TIP BRACKET

A. Place the anti-tip floor bracket locator template

(included inside the anti-tip kit) onto the floor up

against the rear wall, within W, and in line with the

desired location of the RH side of the refrigerator

(see Figure 1).

Figure 1 – Installation Overview

Floor – Concrete

(2 Holes)

Floor – Wood

(2 Holes)

Base Bracket

on the

Refrigerator

B. Place the anti-tip floor bracket onto the locator

template with its RH floor holes lined up with

the floor holes indicated on the template sheet,

approximately 15-1/4” from the edge of the sheet or

the RH side of the refrigerator.

C. Hold down in position and use the anti-tip floor

bracket as a template for marking the holes based

upon your configuration and type of construction

as shown in Step 3. Mark the hole locations with a

pencil, nail or awl.

NOTE: It is REQUIRED to use at least 2 screws to

mount the floor bracket (one on each side of the

anti-tip floor bracket). Both must be into either the

wall or the floor. Figure 2 indicates all the acceptable

mounting configurations for screws. Identify the

screw holes on the anti-tip floor bracket for your

configuration.

2 Wall Holes

15 ¼”

RH Side of

Refrigerator

Floor Bracket

to Install

RH Holes

Rear RH

Corner of

Cabinet Wall

Locator Template

Sheet

6

Page 7

Installation Instructions

STEP 2A LOCATE ANTI-TIP FLOOR

BRACKET (CONT.)

Figure 2 – Acceptable Screw

Placement Locations

Preferred Installation –

Wood

Minimum Acceptable #1 –

Wall Plate Stud

Minimum Acceptable #3 –

Concrete Floor

Preferred Installation –

Concrete

Minimum Acceptable #2 –

Wood Floor

STEP 2B INSTALL ANTI-TIP BRACKET

(CONT.)

CONCRETE Wall and Floor Construction:

A. Anchors required (not provided):

4 each 1/4” x 1 1/2” lag bolts

4 each 1/2” O.D. sleeve anchors

B. Drill the recommended size holes for the anchors

into the concrete at the center of the holes marked

in Step 2.

C. Install the sleeve anchors into the drilled holes.

Place the anti-tip floor bracket as indicated in Step 2.

Remove the locator template from the floor.

D. Install the lag bolts through the anti-tip floor bracket

and tighten appropriately.

WOOD Wall and TILE Floor Construction:

A. For this special case, locate the 2 wall holes

identified in Fig. 1. Drill an angled 1/8” pilot hole

(approx. as shown in Fig. 3) in the center of each

hole.

B. Mount the anti-tip floor bracket using the Minimum

Acceptable Installation #1, as illustrated in Fig. 2.

STEP 2B INSTALL ANTI-TIP BRACKET

WOOD Wall and Floor Construction:

A. Drill the appropriate number of 1/8” pilot holes in the

center of each floor bracket hole being used (a nail

or awl may be used if a drill is not available) AND

remove the locator template from the floor.

B. Mount the anti-tip floor bracket by fastening the 2,

or preferably 4, #10-16 hex-head screws tightly into

place as illustrated in Figure 3.

Figure 3 – Attachment to

Wall and Floor

Rear RH Corner

of the Refrigerator

Floor Bracket

2 Screws Must

Enter Wood

or Metal Stud

Floor

Wall

Wall

Plate

Stud

STEP 2C POSITION THE

REFRIGERATOR TO ENGAGE

THE ANTI-TIP FLOOR

AND BASE BRACKETS

A. Before pushing the refrigerator into the opening,

plug the power cord into the receptacle and connect

waterline (if equipped). Check for leaks.

B. Locate the refrigerator’s RH side and move back

approximately in line with the RH side of the cabinet

opening, W. This should position the anti-tip floor

bracket to engage the anti-tip base bracket on the

refrigerator.

C. Gently roll the refrigerator back into the cabinet

opening until it comes to a complete stop. Check to

see if the refrigerator front lines up with the cabinet

front face. If not, carefully rock the refrigerator

forward and backward until engagement occurs

and you notice thatthe refrigerator is fully pushed up

against the rear wall.

D. OPTIONAL: Adjust the rear (and front) wheel height

settings to fully engage the rear anti-tip brackets,

while also aligning the refrigerator front with the

cabinet front face.

NOTE: If you pull the refrigerator out and away from

the wall for any reason, make sure the anti-tip floor

bracket is engaged when the refrigerator is pushed

back against the wall rear wall.

7

Page 8

Installation Instructions

STEP 3 INSTALL THE REFRIGERATOR

BEFORE MOVING REFRIGERATOR

INDOORS

IMPORTANT:

the installation location require a 31-1/4” min. opening.

If the opening is less than 31-1/4”, the top cap, doors

and drawers must be removed. (See steps 4–6.)

NOTE: Skip steps 4–5 if door removal is not required.

Go to page 9, Move The Refrigerator.

NOTE: To prevent damage, leave inside

packaging, door spacer and outside

protective wrap in place until the unit

is moved to the installation location.

Doors and passageways into

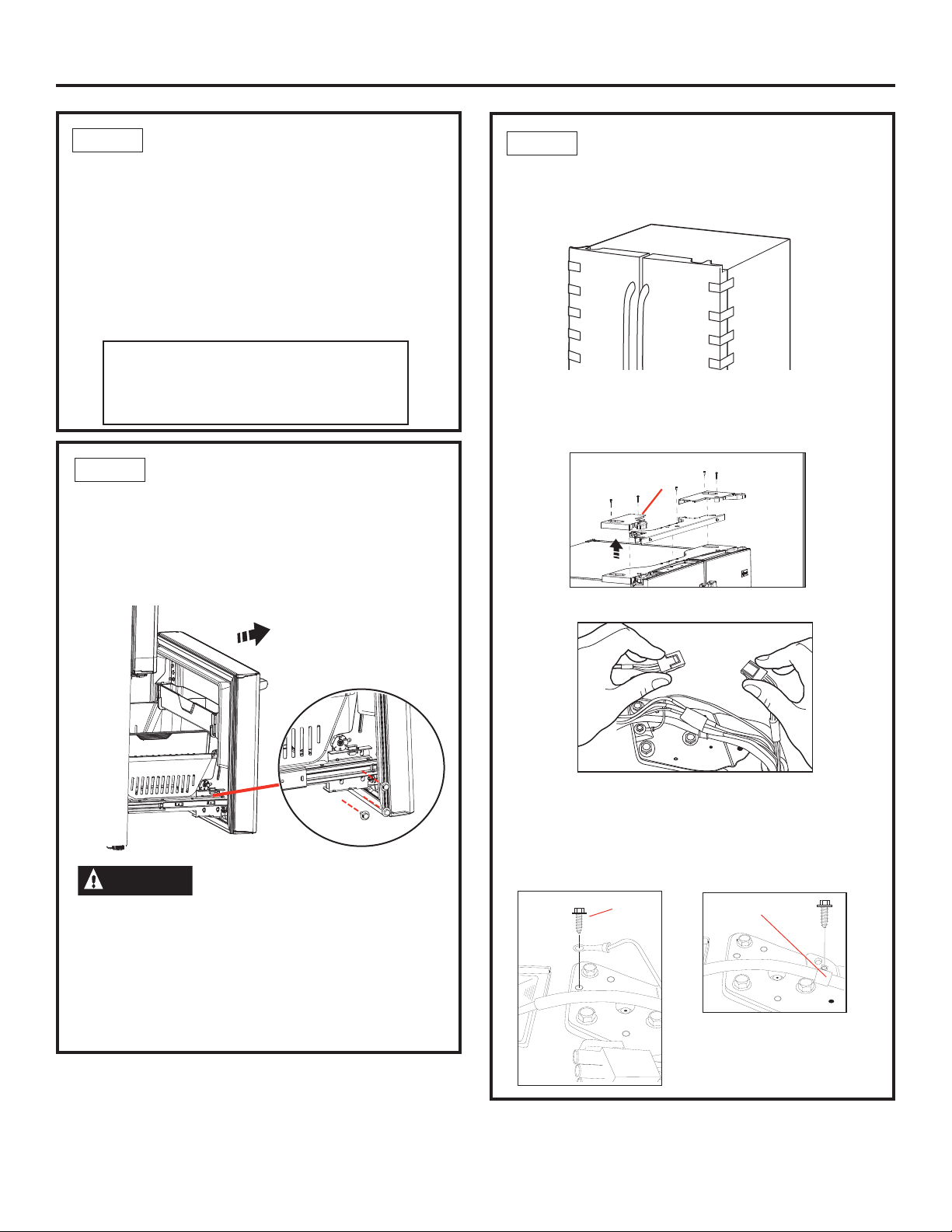

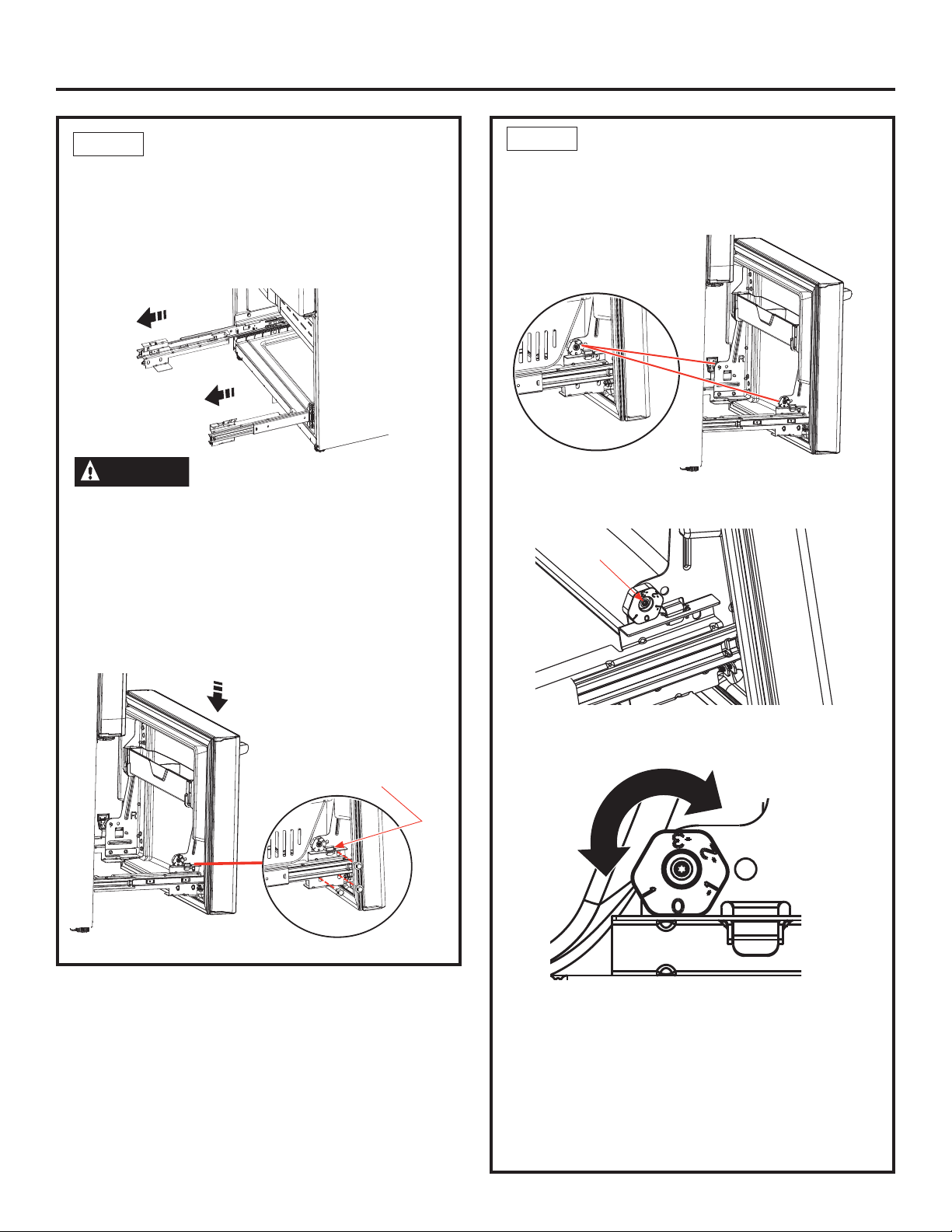

STEP 4 REMOVE THE FREEZER DRAWER

The freezer drawer can be removed, if needed, to fit

through tight areas.

Read these instructions completely and carefully.

A.

Pull the freezer door open to full extension.

B.

Remove 3 attachment screws, located at the bottom on each

side of the freezer door using 3/8” hex socket driver.

STEP 5 REMOVE THE FRESH

FOOD DOORS

A. Securely tape the door shut with masking tape or

have a second person support the door.

B. Start with left-hand door first: Remove the hinge

cover on top of the left refrigerator door by removing

all hex screws and pulling it up. Do the same for the

right-hand door and the middle cover.

Hinge

Cover

Disconnect both electrical connectors at the top cover.

C.

CAUTION

Lifting Hazard

Freezer door is heavy Use both hands to secure the door

before lifting.

C.

Lift the freezer door to disengage it from the slide

mechanism. The door can safely rest on the bottom.

Do not rest the door on any other surfaces to avoid

scratches. Push the slide mechanism back completely

until it self retracts.

Remove the 1/4” hex head screw to disconnect the

ground wire from the hinge.

Remove the 1/4” hex head screw to remove the

strain relief from the water line.

Ground

screw

Strain

Relief

8

Page 9

Installation Instructions

STEP 5 REMOVE THE FRESH

FOOD DOORS (CONT)

D. Disconnect the water line from the back of the unit

by pressing down on the dark grey collar while

pulling up on the water line.

Pull waterline through case conduit from the top to

free the line for door removal. The water line is more

than 4’ long and may need to be taped to Door for

accessibility when reinstalling.

E. Using a 3/8” socket ratchet/

driver, remove the screws

securing the top hinge to the

cabinet, then lift the hinge

straight up to free the hinge

pin from the location in the top

of the door.

CAUTION

Single person lift could cause injury. Use assistance

when handling, moving or lifting the refrigerator

doors.

Lifting Hazard.

STEP 5 REMOVE THE FRESH

FOOD DOORS (CONT)

Note: for proper installation later, please follow the next

step carefully.

F. Fresh Food doors to be REMOVED and INSTALLED

opened at 90° with case front.

REMOVE OPPOSITE DOOR

Follow the same procedure on the opposite door.

There are no wires or water lines on the opposite

side.

G. REMOVE CENTER HINGE (if necessary)

Remove the 3/8ļscrews securing the center hinge to the

cabinet. Use T20 driver to remove outboard screw.

Remove

center screw

Loosen Outer screws

STEP 6 MOVE THE REFRIGERATOR

• Place a piece of the carton or soft cloth against

the side panel of the refrigerator to pad and protect

the stainless steel finish.

• Place the refrigerator on the handtruck with a side

against the truck only.

• Move the refrigerator indoors. Place refrigerator close

to the installation location.

9

Page 10

Installation Instructions

STEP 7 REPLACE THE FREEZER

DRAWER

ATTACH AND SECURE THE DRAWER FRONT

TO THE SLIDES

A. Pull the slide Mechanism to full extension using both

hands simultaneously.

B. Remove the basket resting on the slides.

CAUTION

Freezer door is heavy Use both hands to secure the door

before lifting.

C.

Lift the freezer door and place it on the slide

mechanism

D.

Replace the attachment screws and torque the

screws to 65 in-lb

E.

Adjust freezer door gap if necessary.

Lifting Hazard

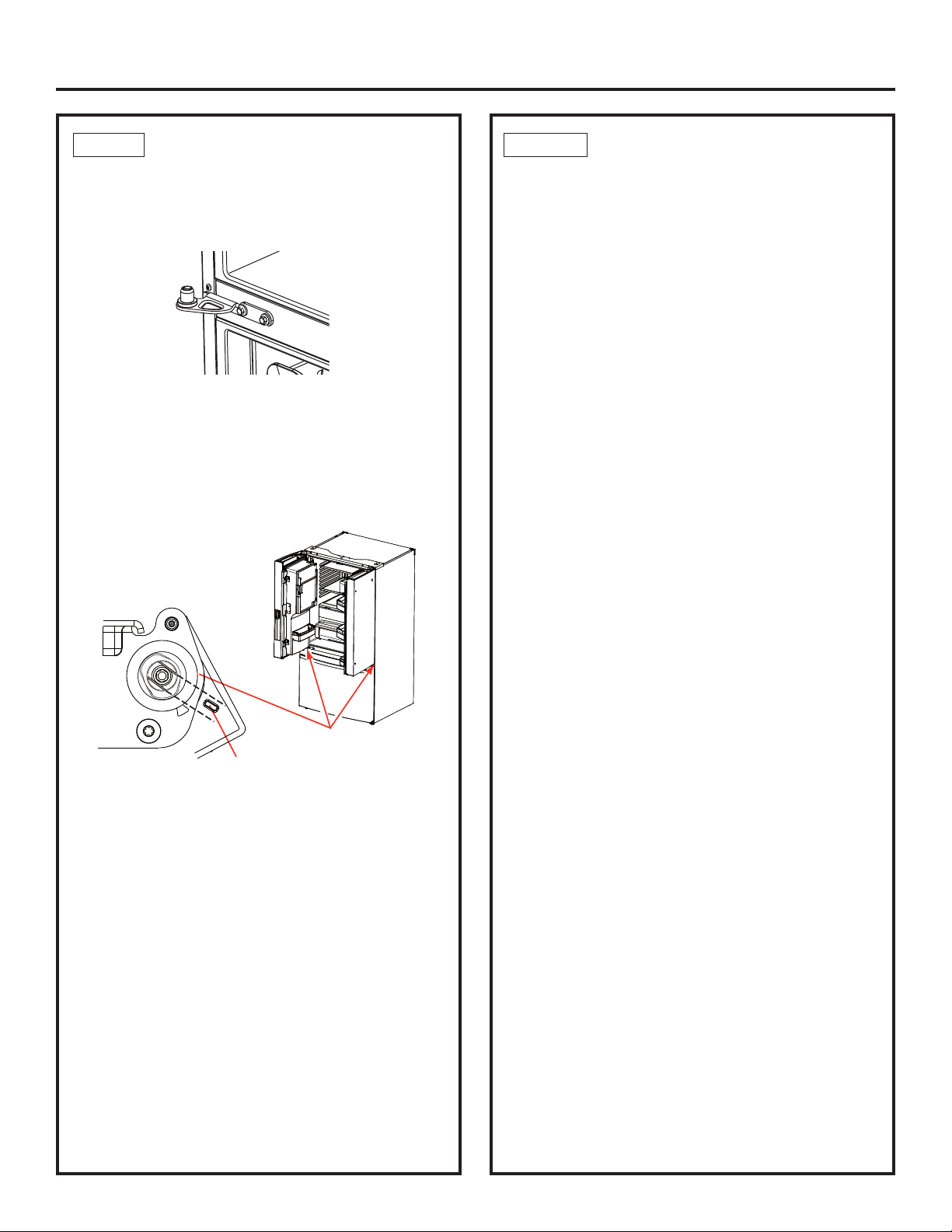

STEP 8 LEVEL THE FREEZER DRAWER

A. Locate the height adjuster cam in the freezer

door. Slightly loosen the three door attachment

screws on both sides using a 3/8” hex socket

driver.

B. Locate and loosen the cam screw using the

T-27 screw driver.

Cam

Screw

Align and insert tab on

freezer door bracket into slot

on freezer slide bracket.

C. Lift the door on the side requiring adjustment,

rotate the cam to required position.

0 - Initial position

1 - Lift by 0.050”

-1 - Lower by 0.050”

-2 - Lower by 0.100

-3 - Lower by 0.150”

D. After adjustment tighten the 3 attachment

screws using to 65 in-lb.

10

Page 11

Installation Instructions

STEP 9 REPLACE FRESH FOOD DOORS

A. Reinstall center hinge first and torque the screws

to 65 in-lbs. With the LH door at 90º to the front ofthe

case, lower the refrigerator door onto the center

hinge. Ensure that the door and hinge align correctly.

B. Rotate door closed and make sure moveable center

sealing portion of the door aligns with the striker. If

the door will not self-close after reinstalling, remove

door, turn door upside down, check alignment mark

and arrow; (there is an alignment mark on the door

closure mechanism It corresponds to an alignment

mark on the bottom end cap. Rotate door closure

mechanism to align mark and arrow, reinstall door).

Underside OF

Fresh Food Door

align marks

If door cannot be installed at 90° follow steps below:

1. If space or model limits opening door to less than 180°, then:

a) Remove door, carefully turn door upside down.

b) Check alignment of door closure mechanism shaft on

underside of door. The flats on the shaft should

correspond to alignment tab on plastic ring or mark

on bottom end cap.

c) If shaft is not aligned to tab/mark, using 5/32” Allen

wrench, rotate door closure mechanism shaft

counterclockwise for right door and clockwise for left

door. Then align flat with tab/mark.

d) Install the door at 90°.

Securely tape the door shut with masking tape or have a

second person support the door. Reinstall the top hinge

and torque the screws to 65 in-lbs.

C. Be sure to reinstall the ground wire and strain relief

to the top hinge.

D. Reinstall the hinge cover. Note: Ensure wires are not

pinched or under screw bosses before tightening

.

screws

E. Follow the same procedure on the opposite door.

STEP 10 INSTALL WATER LINE

Recommended copper water supply kits are WX8X2, WX8X3

or WX8X4, depending on the amount of tubing you need.

Approved plastic water supply lines are GE SmartConnect™

Refrigerator Tubing (WX08X10006, WX08X10015 and

WX08X10025).

When connecting your refrigerator to a GE Reverse Osmosis

Water System, the only approved installation is with a GE

RVKit. For other reverse osmosis water systems, follow the

manufacturer’s recommendations.

If the water supply to the refrigerator is from a Reverse

Osmosis Water Filtration System (RO)AND the refrigerator

also has a water filter, use the refrigerator’s filter bypass

plug. Using the refrigerator’s water filtration cartridge in

conjunction with an RO water filter can result in hollow ice

cubes.

This water line installation is not warranted by the

refrigerator or ice maker manufacturer. Follow these

instructions carefully to minimize the risk of expensive

water damage.

Water hammer (water banging in the pipes) in house

plumbing can cause damage to refrigerator parts and

lead to water leakage or flooding. Call a qualified plumber

to correct water hammer before installing the water

supply line to the refrigerator.

To prevent burns and product damage, do not hook up

the water line to the hot water line.

Do not install the ice maker tubing in areas where

temperatures fall below freezing.

When using any electrical device (such as a power drill)

during installation, be sure the device is double insulated

or grounded in a manner to prevent the hazard of electric

shock, or is battery powered.

All installations must be in accordance with local

plumbing code requirements.

• Copper or GE SmartConnect™ Refrigerator Tubing kit,

1/4” outer diameter to connect the refrigerator to the

water supply. If using copper, be sure both ends of the

tubing are cut square.

To determine how much tubing you need:

measure the distance from the water valve on the back of

the refrigerator to the water supply pipe. Be sure there is

sufficient extra tubing to allow the refrigerator to move out

from the wall after installation.

GE SmartConnect™ Refrigerator Tubing Kits are available

in the following lengths:

6’ (1.8 m) – WX08X10006

15’ (4.6 m) – WX08X10015

25’ (7.6 m) – WX08X10025

11

Page 12

Installation Instructions

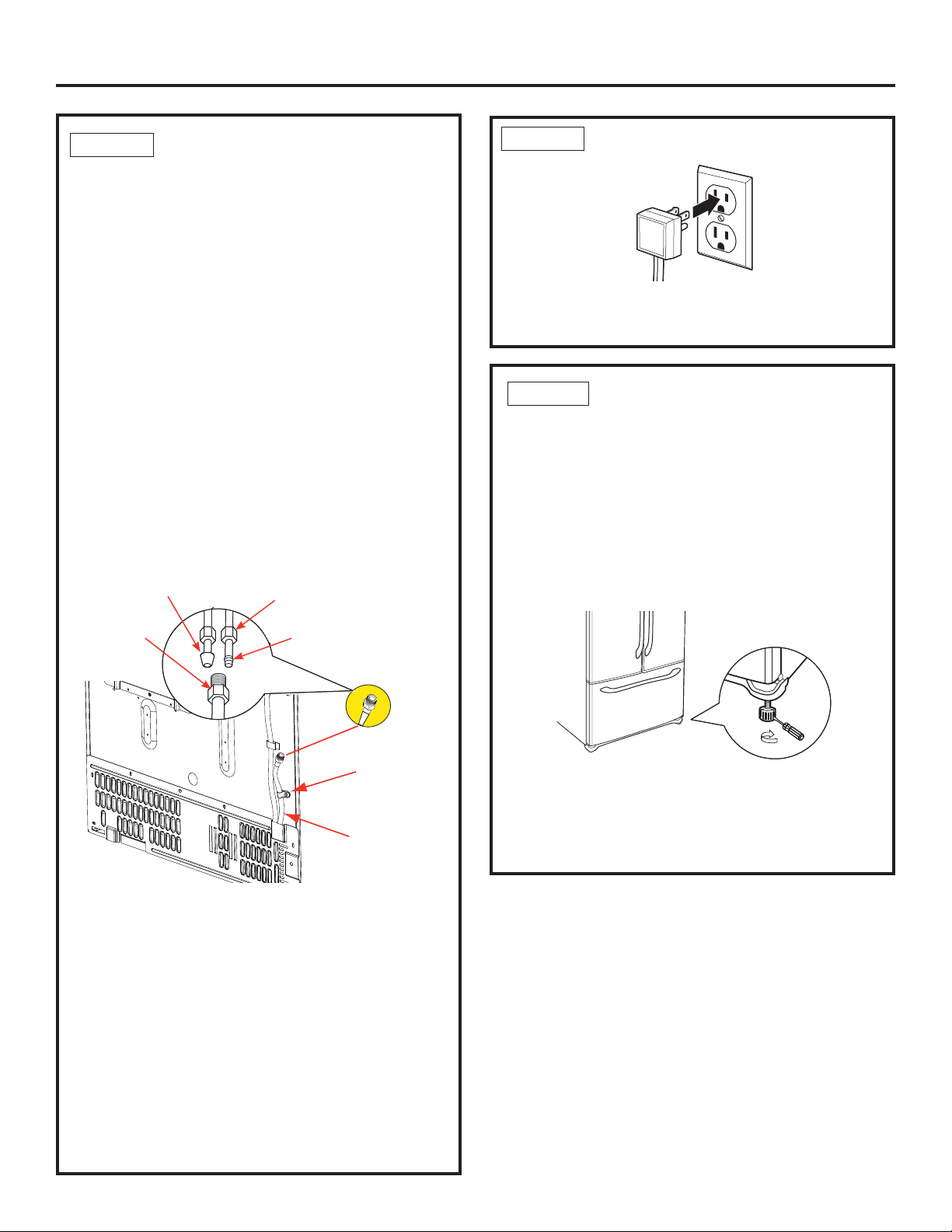

STEP 11 CONNECT WATER SUPPLY

A cold water supply is required for automatic ice maker

operation. If there is not a cold water supply, you will need

to provide one. See Installing the Water Line section.

NOTES:

• Before making the connection to the refrigerator, be sure

the refrigerator power cord is not plugged into the wall

outlet.

• If your refrigerator does not have a water filter, we

recommend installing one if your water supply has

sand or particles that could clog the screen of the

refrigerator’s water valve. Install it in the water line

near the refrigerator. If using GE SmartConnect™

Refrigerator Tubing Kit, you will need an additional tube

(WX08X10002) to connect the filter. Do not cut plastic

tube to install filter.

• Before connecting the water line to the house, purge the

house line for at least 2 minutes.

A. If you are using copper tubing, place a compression nut

and ferrule (sleeve) onto the end of the tubing coming

from the house cold water supply.

If you are using the GE SmartConnect™ tubing, the nuts

are already assembled to the tubing.

SmartConnect™

Tubing

Refrigerator

Connection

1/4” Compression Nut

Ferrule

(sleeve)

STEP 12 PLUG IN THE REFRIGERATOR

See the grounding information attached to the power

cord.

STEP 13 LEVEL THE RE FRIG ER A TOR

The leveling legs have two purposes:

• Leveling legs adjust so the refrigerator is firmly positioned on the floor and does not wobble.

Leveling legs serve as a stabilizing brake

•

to hold the refrigerator securely in position during

operation and cleaning. The leveling legs also prevent

the refrigerator from tipping.

Turn the leveling legs clockwise to raise the refrigerator,

counterclockwise to lower it.

Tubing Clamp

Bride

Abrazadera del tubo

1/4“ Tubing

Tuyau de 1/4 po

Tubería de 1/4“

B. If you are using copper tubing, insert the end of the

tubing into the refrigerator connection, at the back of the

refrigerator, as far as possible. While holding the tubing,

tighten the fitting.

If you are using GE SmartConnect™ tubing, insert

the molded end of the tubing into the refrigerator

connection, at the back of the refrigerator, and tighten

the compression nut until it is hand tight. Then tighten

one additional turn with a wrench. Over tightening may

cause leaks.

C. Fasten the tubing into the clamp provided to hold it in

position. You may need to pry open the clamp.

D. Turn on the water at the shut-off valve to check

for leaks.

Raise

Flat-Head Screwdriver

NOTICE: To avoid possible property

damage, the leveling legs must be firmly

touching the floor.

12

Page 13

Installation Instructions

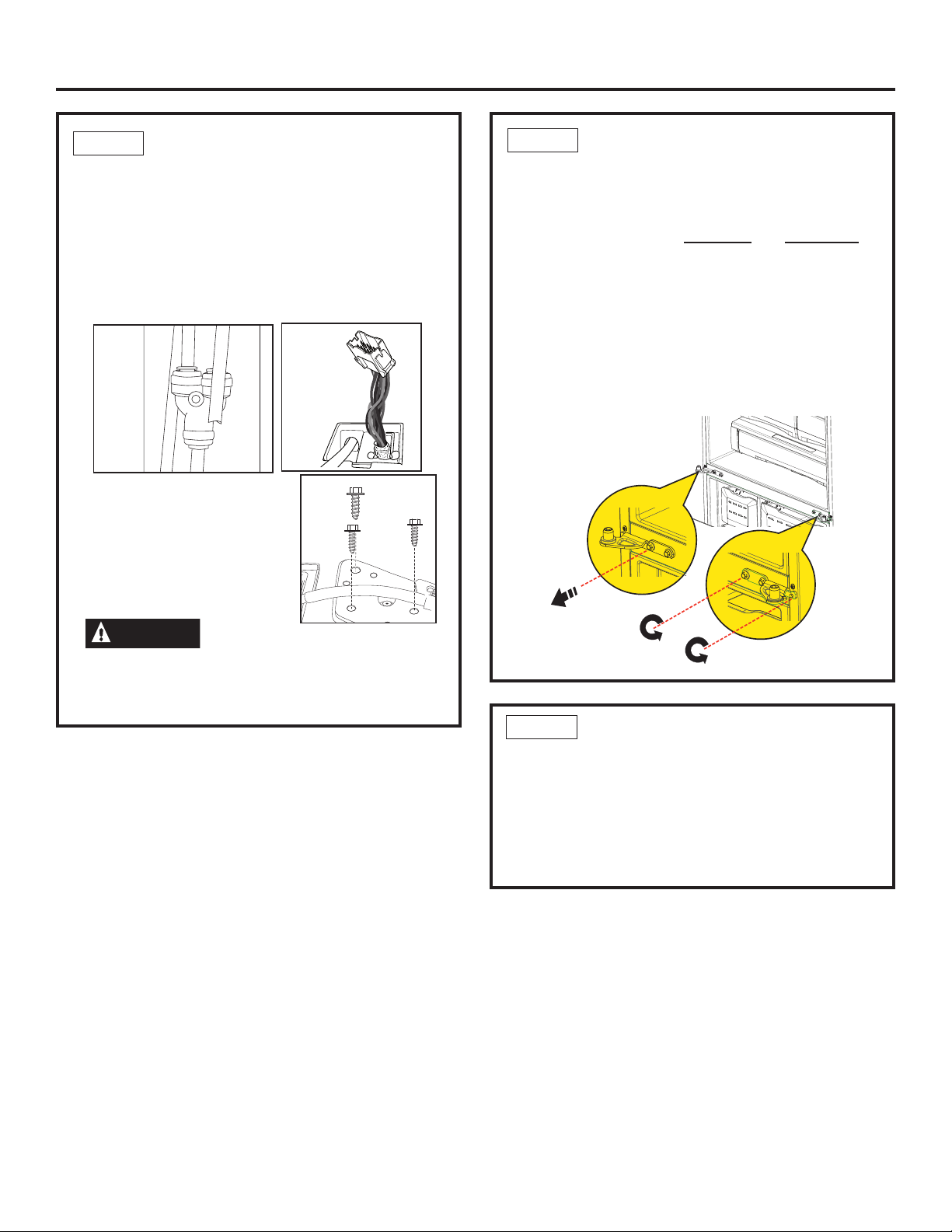

STEP 14 LEVEL THE DOORS

Remember a level refrigerator is necessary for

getting the doors perfectly even. If you need

help, review the previous section on leveling the

refrigerator.

When

the left

door is

lower than

the right

door.

A. If you open the freezer door, you can see the

center hinge.

B. Insert 1/4” Allen wrench into the shaft of the

center hinge.

C. Adjust the height by turning clockwise

or counterclockwise. When you turn

counterclockwise, the door will move up.

When

the left

door is

higher

than

the right

door.

Adjustment

point

STEP 15 REMOVE PACKAGING

START ICEMAKER

Power Switch

Feeler Arm

A. Remove all tape, foam and protective packing from

shelves and drawers.

B. Remove the tie downs from the freezer baskets.

Set the icemaker power switch to the I (on) position.

The icemaker will not begin to operate until it reaches

its operating temperature of 15°F (–9°C) or below. It will

then begin operation automatically. It will take 2–3 days

to fill the ice bin.

NOTE: In lower water pressure conditions, the water

valve may turn on up to 3 times to deliver enough water

to the icemaker.

STEP 16 TEMPERATURE CONTROLS

• The temperature controls are preset at 37°F

for the refrigerator and 0°F for the freezer.

• Allow 24 hours to stabilize before making adjustments.

RAISE

13

Page 14

SOMMAIRE

Planification

Dimensions et dégagements ....................................16-17

Espace d’installation ..............................................................18

Instructions d’installation

Outils, quincaillerie, matériaux ........................................18

Mise à la terre du réfrigérateur ........................................ 18

Etape 1, Mesure de l’ouverture dans le meuble .....19

Etape 2, Installation du support

anti-basculement ......................................................19-20

Etape 3, Installation du réfrigérateur ............................21

Etape 4, Retrait du tiroir de congélation ......................21

Etape 5, Retrait des portes du réfrigérateur .......21-22

Etape 6, Déplacement du réfrigérateur .......................22

Etape 7, Remontage du tiroir de congélation ...........23

Etape 8, Mise à niveau du tiroir de congélation ....... 23

Etape 9, Remontage des portes du réfrigérateur ..24

Etape 10, Installation du tuyau

d’alimentation en eau ....................................................... 24

Etape 11, Branchement de l’alimentation

en eau ....................................................................................25

Etape 12, Branchement de l’alimentation

électrique ..............................................................................25

Etape 13, Mise à niveau du réfrigérateur ....................25

Etape 14, Mise à niveau des portes ...............................26

Etape 15, Retrait de l’emballage, mise en marche

de la machine à glaçons ...............................................26

Etape 16, Commandes de température ......................26

14

Page 15

Consignes de Sécurité

AVANT DE COMMENCER

Lisez ces instructions entièrement et attentivement.

• IM POR TANT – Conservez ces instructions

pour l’inspecteur local. Conservez ces instructions pour

l’inspecteur local.

Remarque à l’intention de l’installateur –

•

Assurez-vous de remettre ces instructions à l’utilisateur.

• Remarque à l’intention de l’utilisateur –

Conservez ces instructions avec votre notice d’utilisation

pour toute référence future.

Ce symbole représente une alerte de sécurité. Ce symbole vous avise de dangers possibles pouvant causer la mort, des

blessures ou autres. Tous les messages de sécurité seront précédés du symbole d’alerte de sécurité ainsi que des mots «

DANGER », « AVERTISSEMENT » ou « MISE EN GARDE ». Ces messages sont les suivants :

DANGER

AVERTISSEMENT

ATTENTION

Signale une situation qui présente un danger imminent et qui, si elle n’est pas évitée, entraînera des bles

sures graves, voire la mort.

Signale une situation qui présente un danger imminent et qui, si elle n’est pas évitée, peut entraîner des

blessures graves, voire la mort. .

Signale une situation qui présente un danger imminent et qui, si elle n’est pas évitée, peut entraîner des

blessures mineures ou graves.

Niveau de compétence - L’installation de ce

réfrigérateur demande des connaissances de base en

mécanique, en menuiserie et en plomberie. L'installateur est

responsable de l'installation correcte de l'appareil. La panne

de l’appareil due à une mauvaise installation n’est pas

couverte par la garantie GE Électroménagers. Consultez le

manuel d’utilisation pour toute information sur la garantie.

Si le réfrigérateur reçu est endommagé, contactez immédiatement votre vendeur ou votre installateur.

AVERTISSEMENT

observez toujours certaines précautions de base, notamment :

•

Este electrodoméstico deberá estar conectado a tierra

de forma adecuada. Consulte “Cómo Conectar a Tierra el

Refrigerador”, página 18.

• Il ne faut utiliser cet appareil que pour l’utilisation appropriée.

• Réparer ou remplacer immédiatement tout cordon électrique

effiloché ou endommagé.

• Il faut débrancher le réfrigérateur avant le nettoyage ou toute

intervention.

Pour les services locaux Monogram dans votre secteur, appelez le 1.800.444.1845.

Pour les services Monogram au Canada, appelez le 1.800.561.3344.

Pour les Pièces et Accessoires Monogram, appelez 1.800.626.2002.

www.monogram.com

Lorsque vous utilisez le réfrigérateur,

• Les réparations doivent être faites par un technicien qualifié.

• Pour réduire le risque d’étouffement pendant l’installation de ce

produit, ne pas laisser les petites pièces à la portée des enfants

âgés de moins de 3 ans.

ATTENTION

À cause du poids et de la taille de ce réfrigérateur et pour réduire

le risque de blessure et de dommages, IL FAUT DEUX PERSONNES

POUR FAIRE L’INSTALLATION CORRECTEMENT.

15

Page 16

Planification

DIMENSIONS ET DÉGAGEMENTS POUR LES MODÈLES ZWE23E

*11 11/16"

(29.7)

28 11/16" (72.9)

36" (91.4)

Case width

24 3/8" (61.9)

13/16"

(2.1)

69 1/8"

(175.6)

36" (91.4)

37 1/2"

(95.25)

30 7/16"

(77.3)

24 3/8"

(61.9)

VUE FRONTALE VUE LATERALE

36" (91.4)

Case width

*11 11/16"

(29.7)

70 1/2"

(179.1)

2"

(5.1)

2"

(5.1)

CARACTÉRISTIQUES TECHNIQUES

Largeur hors tout 36" (91.4 cm)

Hauteur hors tout 70 1/2" (179.1 cm)

Profondeur hors tout 30 11/16" (76.2 cm)

Dégagement pour les portes 21 1/4" (54 cm)

Largeur de l’ouverture découpée

Hauteur de l’ouverture découpée

Profondeur de l’ouverture découpée

Conditions à remplir pour

la plomberie

36 1/4" (92.1 cm)

71" (180.3 cm)

26 3/8" (67 cm)

tuyau de cuivre

d’1/4 po de diamètre

extérieur ou kit

GE SmartConnect

Poids à l’expédition 400 lb (181.4 kg)

A L’ATTENTION DE L’ÉLECTRICIEN :

Une alimentation électrique de 115 volts, 60 Hz

et de 15 à 20 ampères est demandée. L’utilisation

d’un circuit de dérivation individuel correctement

mis à la terre ou d’un disjoncteur est recommandée.

Installez un boîtier électrique à 3 fiches correctement

branché à la terre et encastré dans le mur du fond.

Dégagement pour l’aération :

• 1/8 po de chaque côté

• 2 po à l'arrière

• 1 po sur le dessus (armoire/cache

de la charnière)

*124° Door swing

VUE DU DESSUS

(MONTRANT L’OUVERTURE

18"

(45.7)

21 1/4"

(53.9)

VUE DU DESSUS

(PORTE DU CONGELATEUR OUVERTE)

16

Page 17

Planification

DIMENSIONS ET DÉGAGEMENTS POUR LES MODÈLES ZWE23P

28 11/16" (72.9)

36" (91.4)

37 1/4"

(94.6)

23 3/4"

(60.3)

VUE FRONTALE VUE LATERALE

36" (91.4)

Case width

70 1/2"

30 1/2"

(77.5)

2 13/16"

(7.1)

(179.1)

2"

(5.1)

24 3/8" (61.9)

36" (91.4)

Case width

13/16"

(2.1)

69 1/8"

(175.6)

CARACTÉRISTIQUES TECHNIQUES

Largeur hors tout 36" (91.4 cm)

Hauteur hors tout 70 1/2" (179.1 cm)

Profondeur hors tout 31 1/2" (78.7 cm)

Dégagement pour les portes 22 1/8" (56.2 cm)

Largeur de l’ouverture découpée

Hauteur de l’ouverture découpée

Profondeur de l’ouverture découpée

Conditions à remplir pour

la plomberie

36 1/4" (92.1 cm)

71" (180.3 cm)

26 3/8" (67 cm)

tuyau de cuivre d’1/4 po

de diamètre extérieur

ou kit GE SmartConnect

Poids à l’expédition 400 lb (181.4 kg)

A L’ATTENTION DE L’ÉLECTRICIEN :

Une alimentation électrique de 115 volts, 60 Hz

et de 15 à 20 ampères est demandée. L’utilisation

d’un circuit de dérivation individuel correctement

mis à la terre ou d’un disjoncteur est recommandée.

Installez un boîtier électrique à 3 fiches correctement

branché à la terre et encastré dans le mur du fond.

*12 7/16"

(31.6)

*12 7/16"

*124° Door swing

VUE DU DESSUS

(MONTRANT L’OUVERTURE

DES PORTES)

(31.6)

18"

(45.7)

VUE DU DESSUS

(PORTE DU CONGELATEUR

OUVERTE)

22 1/8"

(56.2)

17

Page 18

Instructions d’installation

OUTILS REQUIS

• Clé à molette

• Tournevis à cliquet de 3/8 po

• Tournevis cruciforme Phillips

• Tournevis à tête plate

• Clés hexagonales de type Allen de 5/32 po,

3/32 po, 1/8 po et de 1/4 po

• Mèche de 1/8 po et perceuse manuelle ou électrique

• Mètre

• Crayon

• Coupe-fils

• Tournevis à douille ¼ po

• Niveau

• Tournevis Torx T20, T25

MISE À LA TERRE DU RÉFRIGÉRATEUR

IMPORTANT– (À lire attentivement)

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED.

Le cordon d’alimentation de cet appareil est équipé d’une

fiche à trois broches (pour une mise à la terre) qui s’adapte

à la prise de courant standard à 3 broches (pour une mise

à la terre) pour minimiser les risques de chocs électriques

par cet appareil.

Faites vérifier la prise murale et le circuit électrique par un

électricien qualifié pour s’assurer que le système est correctement mis à la terre.

Dans le cas d’une prise biphasée, l’installateur a la responsabilité et l’obligation de la remplacer par une prise triphasée correctement mise à la terre.

ÉQUIPEMENT REQUIS

• Un écrou à compression d’un diamètre extérieur d’1/4 po

et 2 bagues (manchons) ou trousse pour réfrigérateur GE

SmartConnect™

SOL

Pour une installation correcte, le réfrigérateur doit être

placé sur une surface horizontale en matériau dur qui est

au même niveau que le reste du sol. Cette surface doit être

suffisamment solide pour supporter le poids d’un réfrigérateur rempli.

REMARQUE IMPORTANTE : Protégez la finition du sol.

Découpez un grand morceau de carton et placez-le sous le

réfrigérateur sur l’aire de travail.

NE COUPEZ PAS OU N’ENLEVEZ PAS,

SOUS AUCUN PRÉTEXTE, LA TROISIÈME

BROCHE DE MISE À LA TERRE DU

CORDON D’ALIMENTATION.

N’UTILISEZ PAS D’ADAPTATEUR POUR

BRANCHER LE RÉFRIGÉRATEUR À UNE

PRISE BIPHASÉE.

N’UTILISEZ PAS DE RALLONGE AVEC CET APPAREIL.

18

Page 19

Instructions d’installation

É

AVERTISSEMENT

Dans certaines circonstances,

ce réfrigérateur peut basculer

vers l'avant.

Cela présente un risque de blessure aux personnes.

Veuillez poser la ferrure anti-basculement emballée

avec le réfrigérateur.

ETAPE 1 MESURE DE L'OUVERTURE

DISPONIBLE COMPARÉE A LA

LARGEUR DU RÉFRIGÉRATEUR

Mesurez W, la largeur de l’ouverture dans laquelle vous

voulez mettre votre réfrigérateur.

Mesurez W, la largeur de l’ouverture dans laquelle vous

voulez mettre votre réfrigérateur.

Assurez-vous de tenir compte de tout surplomb du

comptoir, de l’épaisseur de la plinthe et de tout espace

libre désiré. La largeur W doit être supérieure à 36

pouces. Le réfrigérateur doit être approximativement

placé au milieu de cette ouverture.

Mur arrière

W

RÉFRIGÉRATEUR

paisseur de la

plinthe ou surplomb

du comptoir

(la mesure la plus

grande) plus tout

espace libre désiré

Côté droit

ETAPE 2 INSTALLATION DU SUPPORT

ANTI-BASCULEMENT

A. Placez le gabarit de positionnement du support

anti-basculement par fixation au sol (fourni dans

la trousse anti-basculement) sur le sol contre le

mur arrière, à l’intérieur de W, et en ligne avec

l'emplacement souhaité pour le côté droit du

réfrigérateur (voir figure 1).

Figure 1 – Vue d’ensemble de l'installation

Sol - Béton

(2 trous)

Sol – Bois

(2 trous)

Support de

base sur le

réfrigérateur

2 trous dans

le mur

15 ¼”

Côté droit du

réfrigérateur

B. Placez le support anti-basculement par fixation au

sol sur le gabarit de positionnement avec ses trous

au sol de droite alignés aux trous au sol indiqués sur

le gabarit, à approximativement 15¼ po du bord du

gabarit ou du côté droit du réfrigérateur.

C. Maintenez en position et utilisez le support anti-

basculement par fixation au sol comme gabarit

pour marquer les trous en vous basant sur votre

configuration et la catégorie de construction

indiquée dans l’étape 3. Marquez l’emplacement des

trous avec un crayon, un clou ou un poinçon.

Système de fixation au sol à

installer

Trous à

droite

Coin arrière

gauche du mur

de l’armoire

Gabarit

de positionnement

Avant

REMARQUE : Il est OBLIGATOIRE d'utiliser au

moins 2 vis pour fixer le support de fixation au sol

(un de chaque côté du support anti-basculement

par fixation au sol). Les deux doivent entrer dans

le mur ou dans le sol. La figure 2 indique toutes

les configurations acceptables de montage pour

ces vis. Identifiez les trous de vis sur le support

anti-basculement par fixation au sol pour votre

configuration.

19

Page 20

Instructions d’installation

ETAPE 2A INSTALLATION DU SUPPORT

ANTI-BASCULEMENT (SUITE)

Figure 2 - Emplacements

acceptables pour les vis

Installation conseillée

Preferred Installation –

Wood

- Bois

Minimum Acceptable

Minimum Acceptable #1 –

Wall Plate Stud

1 – Montant du mur

Minimum Acceptable

Minimum Acceptable #3 –

3 - Sol en béton

Concrete Floor

Installation conseillée

Preferred Installation –

- Béton

Concrete

Minimum Acceptable 2

Minimum Acceptable #2 –

Wood Floor

– Plancher en bois

ETAPE 2B INSTALLATION DU

SUPPORT ANTI-BASCULEMENT (SUITE)

Mur et plancher en BETON :

A. Ancrages nécessaires (non fourni) :

4 tire-fonds d’ ¼ po (6 mm) x 1- ½ po (38 mm)

4 manchons d’ancrage d’½ po (12 mm)

de diamètre externe

B. Percez les trous de taille recommandée pour les

ancrages dans le béton au centre des trous marqués

dans l’étape 2.

C. Placez les manchons d’ancrage dans les trous percés.

Placez le support anti-basculement par fixation au

sol comme indiquée à l'étape 2. Retirez le gabarit de

positionnement du sol.

D. Installez les tire-fonds à travers le support anti-

basculement par fixation au sol et serrez correctement.

Mur en BOIS et sol CARRELE :

A. Pour ce cas particulier, localisez les 2 trous sur le mur

identifié dans la figure 1. Percez diagonalement un trou

de guidage de 1/8 po au centre de chaque trou (comme

indiqué à la Fig. 3).

B. Installez la fixation de sol anti-basculement en utilisant le

Minimum Acceptable 1, comme illustré dans la Fig. 2.

ETAPE 2B INSTALLATION DU SUPPORT

ANTI-BASCULEMENT

Mur et plancher en BOIS :

A. Percez le nombre approprié de trous de guidage

de 1/8 po au centre de chaque trou pour la fixation

de sol utilisée (vous pouvez utiliser un clou ou un

poinçon si vous n’avez pas de perceuse) ET retirez le

gabarit de positionnement au sol.

B. Montez le support anti-basculement par fixation de

sol en vissant fermement les 2 ou 4 (recommandé)

vis à tête hexagonale, n° 10-16 comme illustré à la

figure 3.

Figure 3 - Fixation au mur et au sol

Coin arrière droit

du réfrigérateur

Support de fixation au sol

2 Vis doivent

pénétrer dans

le montant en bois

ou en métal du mur

Sol

Mur

Montant

du mur

ETAPE 2C

POSITIONNEMENT DU

RÉFRIGÉRATEUR POUR L’ENGAGER

DANS LE SUPPORT ANTI-BASCULEMENT

A. Avant de mettre le réfrigérateur dans son emplacement

final, branchez le cordon d'alimentation dans la prise de

courant et raccorder l’eau (si nécessaire). Vérifiez qu’il n’y

a pas de fuite.

B. Trouvez le côté droit du réfrigérateur et faites le reculer

jusqu’à ce qu’il soit approximativement aligné avec le

côté droit de l’ouverture W. Cette manœuvre devrait

positionner le support anti-basculement pour que

celui-ci s’accroche à la base anti-basculement du

réfrigérateur.

C. Faites doucement rouler le réfrigérateur dans

l’ouverture jusqu'à ce qu’il s’arrête. Vérifiez que l’avant

du réfrigérateur s'aligne avec la façade des placards.

Dans le cas contraire, faites délicatement basculer le

réfrigérateur vers l'avant et vers l'arrière jusqu'à ce

que le système anti-basculement soit engagé et que

vous remarquez que le réfrigérateur est complètement

poussé contre le mur du fond.

D. EN OPTION : Réglez la hauteur des roulettes arrière

(et avant) de manière à engager complètement le

support anti-basculement, tout en alignant l’avant du

réfrigérateur à l’avant des armoires.

REMARQUE :

tirant et l’écartez du mur pour une raison quelconque,

assurez-vous de bien engager le support anti-basculement quand vous repoussez le réfrigérateur contre le

mur du fond.

Si vous faites sortir le réfrigérateur en le

20

Page 21

Instructions d’installation

ETAPE 3 INSTALLATION DU RÉFRIGÉRATEUR

PREPARATION DU RÉFRIGÉRATEUR

AVANT DE L’AMENER A L’INTERIEUR

IMPORTANT :

qui mènent à l'emplacement d'installation doivent avoir une

largeur d’au moins 31 ¼ po. Si l'ouverture est inférieure à 31

¼ po, il est nécessaire de retirer le couvercle supérieur, les

portes et les tiroirs. (Voir étapes 4 à 6)

REMARQUE : Sautez les étapes 4 et 5 s’il n’est pas

nécessaire de retirer la porte. Passez à la page 22 «

Déplacement du réfrigérateur ».

REMARQUE : Pour éviter tout dommage, laissez les

emballages intérieurs, la cale de porte et le film de

protection extérieur sur le réfrigérateur jusqu'à ce

que l'appareil soit amené à son emplacement final.

Les portes et les passages

ETAPE 4 RETRAIT DU TIROIR

DE CONGÉLATION

Si nécessaire, il est possible de retirer le tiroir de congélation pour passer dans espaces étroits.

Lisez ces instructions entièrement et attentivement.

A. Ouvrez complètement la porte du congélateur.

B.

Retirez les 3 vis de fixation, situées au bas de chaque côté de

la porte du congélateur en utilisant le tournevis à cliquet hexagonal de 3/8 po.

ETAPE 5 RETRAIT DES PORTES

DU RÉFRIGÉRATEUR

A. Maintenez la porte bien fermée à l’aide de ruban-

cache ou demandez à une deuxième personne de

maintenir la porte.

B. Commencez par la porte de gauche : Retirez le

cache de la charnière supérieure de la porte gauche

du réfrigérateur en retirant les vis cruciformes et en

le tirant vers le haut. Faites de même pour la porte

de droite et le cache central.

Cache de

charnière

Débranchez les deux connecteurs électriques au

C.

niveau du cache supérieur.

ATTENTION

La porte du compartiment congélateur est lourde. Utilisez

les deux mains pour stabiliser la porte avant de la soulever.

C.

Soulevez la porte du congélateur pour la dégager des

glissières. La porte peut reposer en toute sécurité sur

sa base. Ne posez pas la porte sur toute autre surface

pour éviter les rayures. Repoussez complètement le

mécanisme à glissières jusqu'à ce qu'il se rétracte

automatiquement.

Avertissement de porte lourde.

21

Retirez la vis à tête hexagonale de ¼ po pour

débrancher le fil de masse de la charnière.

Retirez la vis à tête hexagonale de ¼ po pour

débrancher le réducteur de tension du tuyau d’alimentation en eau.

Vis de

terre

Réducteur

de tension

Page 22

Instructions d’installation

ETAPE 5 RETRAIT DES PORTES DU

RÉFRIGÉRATEUR (SUITE)

D.

Débranchez l’alimentation en eau à l'arrière de l'appareil

en appuyant sur le collier gris foncé tout en tirant le tuyau

d’alimentation en eau vers le haut. Faites passer le tuyau

d’alimentation en eau à travers le passage prévu à cet effet

pour libérer le tuyau avant de retirer la porte. La longueur

du tuyau d’alimentation en eau est supérieure à 4 pi. Celuici doit être fixé à l’aide de ruban adhésif à la porte pour y

accéder facilement lors de la réinstallation de la porte.

E. A l'aide d’un tournevis à

cliquet de 3/8 po, retirez les

vis de fixation de la charnière

supérieure au corps du

réfrigérateur, puis soulevez la

charnière vers le haut pour

dégager l'axe de la charnière

de son emplacement dans le

haut de la porte.

ATTENTION

lourde.

Le soulèvement de la porte par une seule

personne peut présenter un risque de blessure.

Obtenir de l'assistance lors de la manipulation,

du déplacement ou du soulèvement des portes du

réfrigérateur.

REMARQUE : lorsque vous retirez la porte, pour éviter

d'endommager celle-ci ainsi que les composants électroniques qu’elle contient, placez-la soigneusement

dans un endroit approprié.

REMARQUE : La charnière inférieure et son axe sont

numérotés. Ils doivent donc être associés pour que la

porte se ferme correctement de façon automatique.

Veuillez suivre les instructions scrupuleusement.

Avertissement de porte

ETAPE 5 RETRAIT DES PORTES DU

RÉFRIGÉRATEUR (SUITE)

REMARQUE : pour que l’installation se fasse correctement

plus tard, veuillez suivre attentivement la prochaine étape.

F. Les portes du compartiment de réfrigération doivent

RETIRÉES et INSTALLÉES en position ouverte à 90°

par rapport à la façade du réfrigérateur.

RETRAIT DE LA PORTE OPPOSÉE

Effectuez la même procédure sur la porte du côté

opposé. Il n’y a pas de câbles ou de tuyau d’alimentation en eau sur la porte du côté opposé.

G. RETRAIT DE LA CHARNIÈRE CENTRALE (si

nécessaire)

Retirez les vis de 3/8 po maintenant la charnière centrale

au corps du réfrigérateur. Utilisez le tournevis T20 pour

retirer la vis extérieure.

Retirez la vis

centrale

ETAPE 6

Desserrez les vis

extérieures

DEPLACEMENT DU

RÉFRIGÉRATEUR

• Placez un morceau de carton ou un chiffon doux sur

la paroi latérale du réfrigérateur pour protéger la

finition en acier inoxydable.

• Placez le réfrigérateur sur le diable en appuyant un

seul des côtés contre le diable.

• Déplacez le réfrigérateur à l'intérieur. Posez le

réfrigérateur à proximité de l’endroit où vous

souhaitez l’installer.

22

Page 23

Instructions d’installation

ETAPE 7 REMONTAGE DU TIROIR DE

CONGÉLATION

FIXEZ ET SECURISEZ L’AVANT DU TIROIR AUX

GLISSIERES

A. Tirez simultanément avec les deux mains sur le

mécanisme à glissières jusqu’à extension complète.

B. Retirez le panier reposant sur les glissières.

ATTENTION

La porte du compartiment congélateur est lourde. Utilisez

les deux mains pour stabiliser la porte avant de la sou-

lever.

C.

Soulevez la porte du congélateur et placez-la sur le

mécanisme à glissières.

D.

Remettez les vis de fixation en place et serrez-les au

couple de 65 po-lb.

E.

Si nécessaire, réglez l’écart de la porte du congélateur.

Avertissement de porte lourde.

ETAPE 8 MISE À NIVEAU DU TIROIR

DE CONGÉLATION

A.

Localisez la came de réglage de la hauteur dans

la porte du congélateur. Desserrez les trois vis de

fixation de la porte sur les deux glissières à l’aide

B. Localisez et desserrez la vis à came en

utilisant le tournevis T-27.

Vis à

came

Alignez et insérez la

languette sur le support

de la porte du congélateur

dans la fente du support du

mécanisme à glissières du

congélateur.

C. Soulevez la porte sur le côté nécessitant un

réglage, faites tourner la came jusqu’à la

position requise.

0 - Position initiale

1 - Lever de 0,050 po

-1 - Abaisser de 0,050 po

-2 - Abaisser de 0,100 po

-3 - Abaisser de 0,150 po

D. Une fois le réglage terminé, resserrez les 3 vis

de fixation jusqu’à un couple de 65 po-lb.

23

Page 24

Instructions d’installation

ETAPE 9 REMONTAGE DES PORTES DU

RÉFRIGÉRATEUR

A. Réinstallez la charnière centrale d'abord, puis

serrez les vis à un couple de 65 po-lb. Avec la

porte gauche à 90° par rapport à la façade du

réfrigérateur, abaissez

la porte du réfrigérateur

sur la charnière centrale.

Assurez-vous que la porte

et la charnière s’alignent

correctement.

B. Fermez les portes et assurez-vous que la partie

mobile d'étanchéité de la porte soit alignée avec la

gâche. Si la porte ne se ferme pas automatiquement

après la réinstallation, retirez la porte, retournez-la,

vérifiez le repère d'alignement et la flèche (il y a un

repère d'alignement sur le mécanisme de fermeture de

la porte. Celui-ci correspond à un repère d'alignement

sur le cache inférieur. Faites pivoter le mécanisme de

fermeture de la porte pour aligner le repère et la flèche.

Réinstallez ensuite la porte).

Dessous de la porte du compartiment de réfrigération.

Alignez les repères

align marks

Si la porte ne peut pas être installée à 90°, suivez les étapes ci-dessous :

1. Si l’espace disponible ou le modèle limite l’ouverture de la porte à

moins de 180°, alors :

a) Enlevez la porte, retournez-la doucement.

b) Vérifier l'alignement de l'axe du mécanisme de fermeture de la

porte sur le dessous de la porte. Les parties planes sur l’axe correspondent au repère d’alignement sur l'anneau en plastique ou au

repère sur le cache inférieur.

c) Si l'axe n'est pas aligné sur le repère, à l’aide d’une clé Allen de

5/32 po, faites pivoter l’axe du mécanisme de fermeture de la

porte dans le sens inverse des aiguilles d’une montre pour la porte

droite, et dans le sens des aiguilles d’une montre pour la porte

gauche. Ensuite, alignez les parties planes avec le repère.

d) Installez la porte à 90°.

Maintenez la porte bien fermée à l’aide de ruban-cache

ou demandez à une deuxième personne de maintenir la

porte. Réinstallez la charnière supérieure d'abord, puis

serrez les vis à un couple de 65 po-lb.

C. Assurez-vous d’avoir remis le fil de terre et le réduc-

teur de tension au niveau de la charnière supérieure.

D. Réinstallez le cache de la charnière.

REMARQUE : Assurez-vous que les fils ne sont pas

pincés ou sous des emplacements de vis avant de

serrer ces dernières.

E. Effectuez la même procédure sur la porte opposée.

ETAPE 10 INSTALLATION DU TUYAU

D’ALIMENTATION EN EAU

Nous recommandons les trousses d’alimentation d’eau en

cuivre WX8X2, WX8X3, WX8X4, selon la longueur de tuyau dont

vous avez besoin.

Nous approuvons les conduites d’eau en matière plastique

GE SmartConnect™ Refrigerator Tubing (WX08X10006,

WX08X10015 et WX08X10025).

Si vous installez un système d’eau à osmose inverse GE dans

votre réfrigérateur, la trousse GE RVKIT est la seule installation

approuvée. Pour les autres systèmes à osmose inverse, suivez

les recommandations du fabricant.

Si l’alimentation d’eau du réfrigérateur provient d’un système

de filtration de l’eau par osmose inverse (OI) ET si votre

réfrigérateur est équipé d’un filtre à eau, utilisez le bouchon de

dérivation du filtre du réfrigérateur. En cas d’utilisation de la

cartouche de filtration d'eau du réfrigérateur associée à un filtre

à OI peut produire des glaçons creux.

L’installation de cette conduite d'eau n'est pas garantie par le

fabricant du réfrigérateur ou de la machine à glaçons. Suivez

attentivement ces instructions afin de minimiser le risque de

fuite d'eau et de dommages onéreux.

Les coups de bélier (coups dans les tuyaux) dans la tuyauterie

de la maison peuvent endommager les pièces de votre

réfrigérateur et provoquer des fuites d'eau ou des inondations.

Appelez un plombier certifié pour corriger les coups de bélier

avant de brancher l'alimentation en eau au réfrigérateur.

Pour prévenir les brûlures et éviter d’endommager votre produit,

ne branchez pas le tuyau d’eau à une conduite d'eau chaude.

N’installez pas la tuyauterie de la machine à glaçons dans un

endroit où la température descend en dessous de zéro.

Lorsque vous utilisez un appareil électrique (tel qu’une perceuse)

lors de l'installation, assurez-vous que celui-ci est à double

isolation ou relié à la terre pour prévenir tout risque de choc

électrique. L’outil peut également être alimenté par batterie.

Toutes les installations doivent être conformes aux

exigences du code de plomberie local.

• Tuyaux en cuivre ou trousse GE SmartConnect™

Refrigerator Tubing, diamètre extérieur d’¼ po pour

brancher le réfrigérateur à l’alimentation d’eau. Si vous

utilisez un tuyau en cuivre, les deux extrémités du tuyau

doivent être coupées bien droit.

Pour déterminer la longueur de tuyau dont vous avez

besoin :

mesurez la distance entre le robinet d'eau à l'arrière

du réfrigérateur et le tuyau d'alimentation en eau.

Assurez-vous d’avoir une longueur de tuyau suffisante

pour permettre d’éloigner le réfrigérateur du mur après

l'installation.

Les trousses de tuyauterie pour réfrigérateur GE

SmartConnect™ sont disponibles dans les longueurs

suivantes :

6 pi (1,8 m) – WX08X10006

15 pi (4,6 m) – WX08X10015

25 pi (7,6 m) – WX08X10025

24

Page 25

Instructions d’installation

ETAPE 11 BRANCHEMENT DE

L’ALIMENTATION EN EAU

Une alimentation d'eau froide est requise pour faire

fonctionner la machine à glaçons automatique. Vous devrez

en installer une si elle n’existe pas. Consultez la section «

Installation de l’alimentation en eau ».

REMARQUE :

• Avant de raccorder la conduite d’eau au réfrigérateur,

assurez-vous que le cordon d’alimentation électrique du

réfrigérateur n’est pas branché à la prise murale.

• Si votre réfrigérateur n’est pas équipé de filtre à eau, nous

recommandons d’en monter un si votre alimentation d’eau

contient du sable ou des particules qui peuvent boucher la

grille du robinet d’eau du réfrigérateur. Installez-le dans la

conduite d'alimentation d'eau froide près du réfrigérateur.

Si vous utilisez une trousse GE SmartConnect™ Refrigerator

Tubing, vous aurez besoin d’un tuyau supplémentaire

(WX08X10002) pour brancher le filtre. Ne coupez pas le

tuyau en plastique pour installer le filtre.

•

Before connecting the water line to the house, purge the

house line for at least 2 minutes. Avant de raccorder la

conduite d'eau au système de distribution d’eau de la maison,

purgez la ligne de la maison pendant au moins 2 minutes.

Tuyau

SmartConnect™

Raccord du

réfrigérateur

Ecrou de compression d’1/4 po

Virole

(manchón)

ETAPE 12 BRANCHEMENT DU RÉFRIGÉRATEUR

Veuillez lire les informations de mise à la terre fixées au

cordon d'alimentation.

ETAPE

13 MISE À NIVEAU DU

RÉFRIGÉRATEUR

Les pieds de mise à niveau servent :

• à ajuster le réfrigérateur pour que celui-ci soit correctement positionné sur le sol et ne vacille pas

• de frein pour stabiliser le réfrigérateur pendant son

utilisation et son nettoyage. Les pieds de mise à

niveau permettent aussi d’empêcher le réfrigérateur

de basculer.

Tournez les pieds de mise à niveau dans le sens des

aiguilles d’une montre pour relever le réfrigérateur et

dans le sens inverse des aiguilles d’une montre pour

l'abaisser.

Tubing Clamp

Bride

Abrazadera del tubo

1/4“ Tubing

Tuyau de 1/4 po

Tubería de 1/4“

A. Si vous utilisez un tuyau de cuivre, placez un écrou de

compression et une bague (manchon) à l’extrémité du tuyau

qui vient de l’alimentation d’eau froide de la maison.

Si vous utilisez le tuyau GESmartConnect™, les écrous sont

déjà assemblés au tuyau.

B. Si vous utilisez un tuyau de cuivre, insérez aussi loin que

possible l’extrémité du tuyau dans le raccord à l’arrière du

réfrigérateur. Tout en tenant le tuyau, serrez le raccord.

Si vous utilisez un tuyau GE SmartConnect™, insérez

l’extrémité moulée du tuyau dans le raccord à l’arrière du

réfrigérateur, puis serrez l’écrou à compression à la main.

Serrez ensuite d’un autre tour à l’aide d’une clé. Serrez un

tour supplémentaire avec la clé. Des fuites peuvent survenir si

l'écrou est trop serré.

C. Fixez le tuyau dans le collier de serrage fourni pour le maintenir

en position. Vous aurez peut être besoin d’écarter la bride.

D. Ouvrez le robinet d'eau pour vérifier l'absence de fuites.

Lever

Tournevis à tête plate

REMARQUE : Pour éviter tout

dommage matériel, les pieds de mise à

niveau doivent bien reposer sur le sol.

25

Page 26

Installation Instructions

ETAPE 14 MISE À NIVEAU DES PORTES

Rappelez-vous qu’il est nécessaire que le

réfrigérateur soit de niveau pour que les portes

soient parfaitement de niveau. Si vous avez besoin

d'aide, consultez la section précédente sur la mise à

niveau du réfrigérateur.

Lorsque la

porte de

gauche

est plus

haute que

la porte de

droite.

A. Si vous ouvrez la porte du congélateur, vous

verrez la charnière centrale.

B. Insérez une clé Allen d’¼ po dans l'axe de la

charnière centrale.

C. Ajustez la hauteur en tournant dans le sens

des aiguilles d’une montre ou dans le sens

inverse des aiguilles d’une montre. Lorsque

vous tournez dans le sens inverse des

aiguilles d’une montre, la porte se déplace

vers le haut.

Lorsque la

porte de

gauche

est plus

basse que

la porte de

droite.

Point de réglage

ETAPE 15 RETRAIT DE L’EMBALLAGE, MISE

EN MARCHE DE LA MACHINE À GLAÇONS

Interrupteur

Power Switch

Feeler Arm

A. Retirez les bandes adhésives, les emballages en

mousse et les protections des clayettes et des tiroirs.

B. Retirez les arrimages des bacs de congélateur.

Placez l’interrupteur de la machine à glaçons est sur la

position I (marche). La machine à glaçons ne commence à

fonctionner qu'à partir du moment où sa température de

fonctionnement est égale ou inférieure à 15°F (-9°C). Elle

commencera alors à fonctionner automatiquement. 2 à 3

jours seront nécessaires pour remplir le bac à glaçons.

REMARQUE : Lorsque la pression de l’eau d’alimentation

est faible, le robinet d'eau peut s’ouvrir jusqu’à 3 fois

pour fournir le volume d'eau nécessaire à la machine à

glaçons.

ETAPE 16 COMMANDES DE TEMPÉRATURE

• Les commandes de température sont réglées à 37°C

pour le réfrigérateur et 0°C pour le congélateur.

• Attendez 24 heures que la température se stabilise

avant de faire les réglages.

RAISE

26

Page 27

CONTENIDOS

Información de Planificación

Dimensiones y Espacios del Producto ....................29-30

El Espacio de Instalación .....................................................31

Instrucciones de Instalación

Herramientas, Hardware, Materiales .............................31

Conexión a Tierra del Refrigerador ..................................31

Paso 1, Mida la Abertura del Gabinete ......................... 32

Paso 2, Instale el Soporte Antivolcaduras ............32-33

Paso 3, Instale el Refrigerador ..........................................34

Paso 4, Retire el Cajón del Freezer ................................... 34

Paso 5, Retire las Puertas de Comidas Frescas

Paso 6, Mueva el Refrigerador .......................................... 35

Paso 7, Reemplace el Cajón del Freezer .......................36

Paso 8, Nivele el Cajón del Freezer .................................. 36

Paso 9, Reemplace las Puertas

de Comidas Frescas ........................................................ 37

Paso 10, Instale la Tubería de Agua .............................37

Paso 11, Conecte el Suministro de Agua .....................38

Paso 12, Conecte la Corriente .......................................... 38

Paso 13, Nivele el Refrigerador ........................................38

Paso 14, Nivele las Puertas ................................................39

Paso 15, Retire el Embalaje, Inicie

la Máquina de Hielos ......................................................39

Paso 16, Controles de Temperatura ...............................39

....34-35

27

Page 28

Información sobre Seguridad

ANTES DE COMENZAR

Lea estas instrucciones en su totalidad y atentamente.

• IM POR TANTE – Conserve estas instrucciones

para uso del inspector local. Cumpla con todos los

códigos y ordenanzas gubernamentales.

• Nota para el Instalador – Asegúrese de que el

Comprador conserve estas instrucciones.

•

Nota para el Consumidor – Guarde estas instruc-

ciones con su Manual del Usuario para referencia futura.

Éste es el símbolo de alerta de seguridad. El mismo alerta sobre potenciales riesgos de muerte o lesiones tanto para usted con

para otras personas. Todos los mensajes de seguridad estarán a continuación del símbolo de alerta de seguridad y con la palabra

“PELIGRO”, “ADVERTENCIA” o “PRECAUCIÓN”. Estas palabras se definen como:

PELIGRO

ADVERTENCIA

blessures graves, voire la mort. .

PRECAUCIÓN

blessures mineures ou graves.

ADVERTENCIA

las precauciones básicas de seguridad, incluyendo lo siguiente:

• Este electrodoméstico deberá estar conectado a tierra

de forma adecuada. Consulte “Cómo Conectar a Tierra el

Refrigerador”, página 31.

• Use este electrodoméstico sólo para su propósito original.

• De forma inmediata, repare o reemplace los cables del servicio

eléctrico que sufran daños o peladuras.

• Desenchufe el refrigerador antes de realizar su limpieza o

reparaciones.

Signale une situation qui présente un danger imminent et qui, si elle n’est pas évitée, entraînera des blessures

graves, voire la mort.

Signale une situation qui présente un danger imminent et qui, si elle n’est pas évitée, peut entraîner des

Signale une situation qui présente un danger imminent et qui, si elle n’est pas évitée, peut entraîner des

Al usar este electrodoméstico, siempre siga

Nivel de habilidad – La instalación de este dispositivo

requiere un nivel básico de habilidades mecánicas, de

carpintería y plomería. La correcta instalación del producto

es responsabilidad del instalador. Si se producen fallas en el

producto debido a una instalación inadecuada, la Garantía

del Producto de GE no cubrirá las mismas. Para obtener

información sobre la garantía, consulte el Manual del

Propietario.

Si el refrigerador que recibió está dañado, se debería comunicar de inmediato con su vendedor o contratista.

• Cualquier reparación deberá ser realizada por un técnico calificado

del servicio técnico.

• A fin de reducir el riesgo asociado con asfixia, no permita que los

niños menores de 3 años tengan acceso a las partes pequeñas

durante la instalación de este producto

PRECAUCIÓN

Debido al peso y tamaño de este refrigerador, y a fin de reducir

el riesgo de lesiones personales o daños sobre el producto - SE

DEBERÁ CONTAR CON DOS PERSONAS PARA UNA INSTALACIÓN

ADECUADA.

Para acceder al servicio local de Monogram en su área, llame al 1.800.444.1845.

Para acceder al servicio de Monogram en Canadá, comuníquese al 1.800.561.3344.

Para acceder a piezas y accesorios de Monogram, llame al 1.800.626.2002.

www.monogram.com

28

Page 29

Información de Planificación

DIMENSIONES Y ESPACIOS DE DESPEJE DEL PRODUCTO EN MODELOS ZWE23E

*11 11/16"

(29.7)

28 11/16" (72.9)

36" (91.4)

Case width

24 3/8" (61.9)

13/16"

(2.1)

69 1/8"

(175.6)

36" (91.4)

37 1/2"

(95.25)

30 7/16"

(77.3)

24 3/8"

(61.9)

VISTA FRONTAL VISTA LATERAL

36" (91.4)

Case width

*11 11/16"

(29.7)

70 1/2"

(179.1)

2"

(5.1)

2"

(5.1)

ESPECIFICACIONES

Ancho Total 36" (91.4 cm)

Altura Total 70 1/2" (179.1 cm)

Profundidad Total 30 11/16" (76.2 cm)

Espacio de Despeje de la Puerta 21 1/4" (54 cm)

Ancho del Recorte 36 1/4" (92.1 cm)

Altura del Recorte 71" (180.3 cm)

Profundidad del Recorte 26 3/8" (67 cm)

Requisitos de Plomería Tubería de cobre

OD de ¼’ o kit GE

SmartConnect kit

Peso del Envío 400 lbs. (181.4 Kg.)

ATENCIÓN ELECTRICISTA:

Se requiere un suministro de corriente de 115 voltios,

60Hz., y 15 o 20 amperes. Se recomienda el uso

de un circuito de empalmes individual o un disyuntor

correctamente conectado a tierra. Instale un

receptáculo eléctrico de 3 patas correctamente

conectado a tierra, y empotrado en la pared trasera.

Espacios de Despeje para la Circulación de

Aire:

• 1/8' a cada lado

• 2' en la parte trasera

• 1' en la parte superior

(tapa del gabinete/ bisagra)

*124° Door swing

VISTA SUPERIOR

(MOSTRANDO EL GIRO

DE LA PUERTA)

18"

(45.7)

21 1/4"

VISTA SUPERIOR

(PUERTA DEL FREEZER ABIERTA)

29

(53.9)

Page 30

Información de Planificación

DIMENSIONES Y ESPACIOS DE DESPEJE DEL PRODUCTO EN MODELOS ZWE23P

28 11/16" (72.9)

36" (91.4)

37 1/4"

(94.6)

23 3/4"

(60.3)

VISTA FRONTAL VISTA LATERAL

36" (91.4)

Case width

70 1/2"

30 1/2"

(77.5)

2 13/16"

(7.1)

(179.1)

2"

(5.1)

24 3/8" (61.9)

36" (91.4)

Case width

13/16"

(2.1)

69 1/8"

(175.6)

ESPECIFICACIONES

Ancho Total 36" (91.4 cm)

Altura Total 70 1/2" (179.1 cm)

Profundidad Total 31 1/2" (78.7 cm)

Despeje de la Puerta 22 1/8" (56.2 cm)

Ancho del Recorte 36 1/4" (92.1 cm)

Altura del Recorte 71" (180.3 cm)

Profundidad del Recorte 26 3/8" (67 cm)

Requisitos de Plomería Tubería de cobre OD

de ¼’ o kit GE

SmartConnect

Peso del Envío 400 lbs. (181.4 kg.)

ATENCIÓN ELECTRICISTA:

Se requiere un suministro de corriente de 115 voltios,

60Hz., y 15 o 20 amperes. Se recomienda el uso

de un circuito de empalmes individual o un disyuntor

correctamente conectado a tierra. Instale un

receptáculo eléctrico de 3 patas correctamente

conectado a tierra, y empotrado en la pared trasera.

*12 7/16"

(31.6)

*124° Door swing

VISTA SUPERIOR

(MOSTRANDO EL GIRO

DE LA PUERTA)

*12 7/16"

(31.6)

18"

(45.7)

22 1/8"

(56.2)

VISTA SUPERIOR

(PUERTA DEL FREEZER ABIERTA)

30

Page 31

Instrucciones de Instalación

HERRAMIENTAS REQUERIDAS

• Llave ajustable

• Trinquete/ destornillador de 3/8’

• Destornillador Phillips

• Destornillador con cabeza plana

• Llaves Allen de 5/32', 3/32’, 1/8’,1/4'

• Broca y taladro eléctrico o manual de 1/8’

• Cinta de medición

• Lápiz

• Cortacables

• Llave de tuercas de ¼’

• Nivel

• Llave Torx T20, T25

MATERIALES REQUERIDOS

• Tuerca de compresión O.D. de ¼’ y 2 abrazaderas de

refuerzo (mangas) O Kits de Tuberías para Refrigerador

GE SmartConnect™

CONEXIÓN A TIERRA DEL

REFRIGERADOR

IMPORTANTE – (Lea detenidamente)

PARA SU SEGURIDAD PERSONAL, ESTE

ELECTRODOMÉSTICO DEBERÁ ESTAR ADECUADAMENTE

CONECTADO A TIERRA.

El cable de corriente de este electrodoméstico cuenta con

un enchufe de 3 cables (conexión a tierra) que se conecta

a un tomacorriente de pared estándar de 3 cables (conexión a tierra) para minimizar el riesgo de posibles descargas eléctricas por parte del mismo.

Contrate a un electricista calificado para que controle el

tomacorriente y el circuito eléctrico, a fin de asegurar que

el enchufe esté correctamente conectado a tierra.

Donde se encuentre un tomacorriente de pared de 2

cables, es su responsabilidad y obligación reemplazarlo

por un tomacorriente de pared de 3 cables correctamente

conectado a tierra.

PISO

Para una instalación correcta, el refrigerador se deberá

ubicar en una superficie nivelada de material duro que

posea la misma altura en el resto del piso. Esta superficie

debe ser lo suficientemente fuerte para soportar un refrigerador con carga completa.

NOTA IMPORTANTE: Proteja el acabado del piso. Corte

una sección amplia de cartón y coloque la misma debajo

del refrigerador donde se encuentra trabajando.

NUNCA, BAJO NINGUNA

CIRCUNSTANCIA, CORTE

NI ELIMINE EL TERCER CABLE

(TIERRA) DEL CABLE DE

CORRIENTE.

NO USE UN ENCHUFE

ADAPTADOR PARA CONECTAR

EL REFRIGERADOR A UN TOMACORRIENTE

DE 2 PATAS.

NO USE UN PROLONGADOR CON ESTE

ELECTRODOMÉSTICO.

31

Page 32

Instrucciones de Instalación

ADVERTENCIA

Bajo ciertas circunstancias,

este refrigerador se puede

caer hacia adelante.

Puede haber personas lesionadas como resultado de esto.

Instale el soporte antivolcaduras, incluido con este

refrigerador.

Paso 1 MIDA LA ABERTURA DEL

GABINETE DISPONIBLE VS. EL ANCHO

DEL REFRIGERADOR

Mida el ancho de la abertura del gabinete donde

será ubicado el refrigerador, W.

Asegúrese de contar con espacio por encima de la

mesada, grosor en el rodapié y cualquier espacio de

despeje deseado. El ancho, W, no debería ser inferior

a 36’. El refrigerador será ubicado aproximadamente

en el medio de esta abertura.

Pared Trasera

W

REFRIGERADOR

El Grosor del Rodapié

o el Espacio Encima

de la Mesada

(Cualquiera Sea Más

Grande) Además

de Cualquier Espacio

de Despeje Deseado

Pared Trasera

PASO 2 INSTALE EL SOPORTE

ANTIVOLCADURAS

A. Coloque la plantilla de ubicación del soporte de piso

antivolcaduras (incluida dentro del kit antivolcaduras)

sobre el piso contra la pared trasera, dentro de W, y

alineada con la ubicación deseada del lado derecho

del refrigerador (vea la Figura 1).

Figura 1 – Visión General de Instalación

Piso – Concreto

(2 Agujeros)

Piso – Madera

(2 Agujeros)

Soporte de

Base en el

Refrigerador

B. Coloque el soporte para piso antivolcaduras en la

plantilla de ubicación con sus agujeros para piso

del lado derecho alineado con los agujeros del piso

indicados en la hoja de la plantilla, aproximadamente