Monogram ZIRS36N LH, ZIF36N LH, ZIR36N RH, ZIRS36N RH, ZIF36N RH Technical Service Manual

...

C

GE Consumer Home Services T raining

TECHNICAL SER VICE GUIDE

GE Monogram 36-inch Refrigerator

GE Monogram 36-inch Freezer

MODEL SERIES:

ZIR36N LH - All Fresh Food

ZIR36N RH - All Fresh Food

ZIRS36N LH - All Fresh Food

ZIRS36N RH - All Fresh Food

ZIF36N LH - All Freezer

ZIF36N RH - All Freezer

ZIFS36N LH - All Freezer

ZIFS36N RH - All Freezer

PUB # 31-9047 12/00

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2000

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

Table of Contents

Introduction ............................................................................................................2

Installation Highlights............................................................................................3

Specifications.........................................................................................................5

Nomenclature .........................................................................................................7

Warranty Information..............................................................................................8

Operating Characteristics .....................................................................................10

Mechanical Disassembly .......................................................................................13

Troubleshooting.....................................................................................................29

Component and Connector Locator Views .........................................................32

Schematics .............................................................................................................35

Illustrated Parts Catalog .......................................................................................40

– 1 –

Introduction

The Monogram refrigerator/freezer makes an

eloquent statement of style, convenience, and

kitchen planning flexibility . Whether chosen for it s

purity of design, practical storage arrangements,

or assiduous attention to detail - or for all of these

reasons - the Monogram refrigerator/freezer’s

superior blend of form and function will delight the

customer for years to come.

The Monogram refrigerator/freezer was designed

to provide the flexibility to harmonize with any

kitchen cabinetry. Decorative door insert panels

allow it to match kitchen cabinets or blend with

any kitchen decor. Custom handles are also

available to further personalize the refrigerator/

freezer. Through a series of product and trim kit

choices, the Monogram refrigerator/freezer can be

beautifully integrated into the kitchen.

Since this is designed to be a built-in product,

custom panels are required on the front of the

Monogram refrigerator/freezer . Customers can

consult their kitchen designer or cabinetmaker for

a customized look.

– 2 –

Installation Highlights

Installation Height Panel Height

83-1/2" 7-1/2"

84-1/2" 8-1/2"

9

8

For detailed installation instructions, refer to GE Publication # 49-60055, GE Monogram 36”

Refrigerators and 36” Freezers Custom Options Guide and Installation Instructions.

0"

3/4"

GEA0066

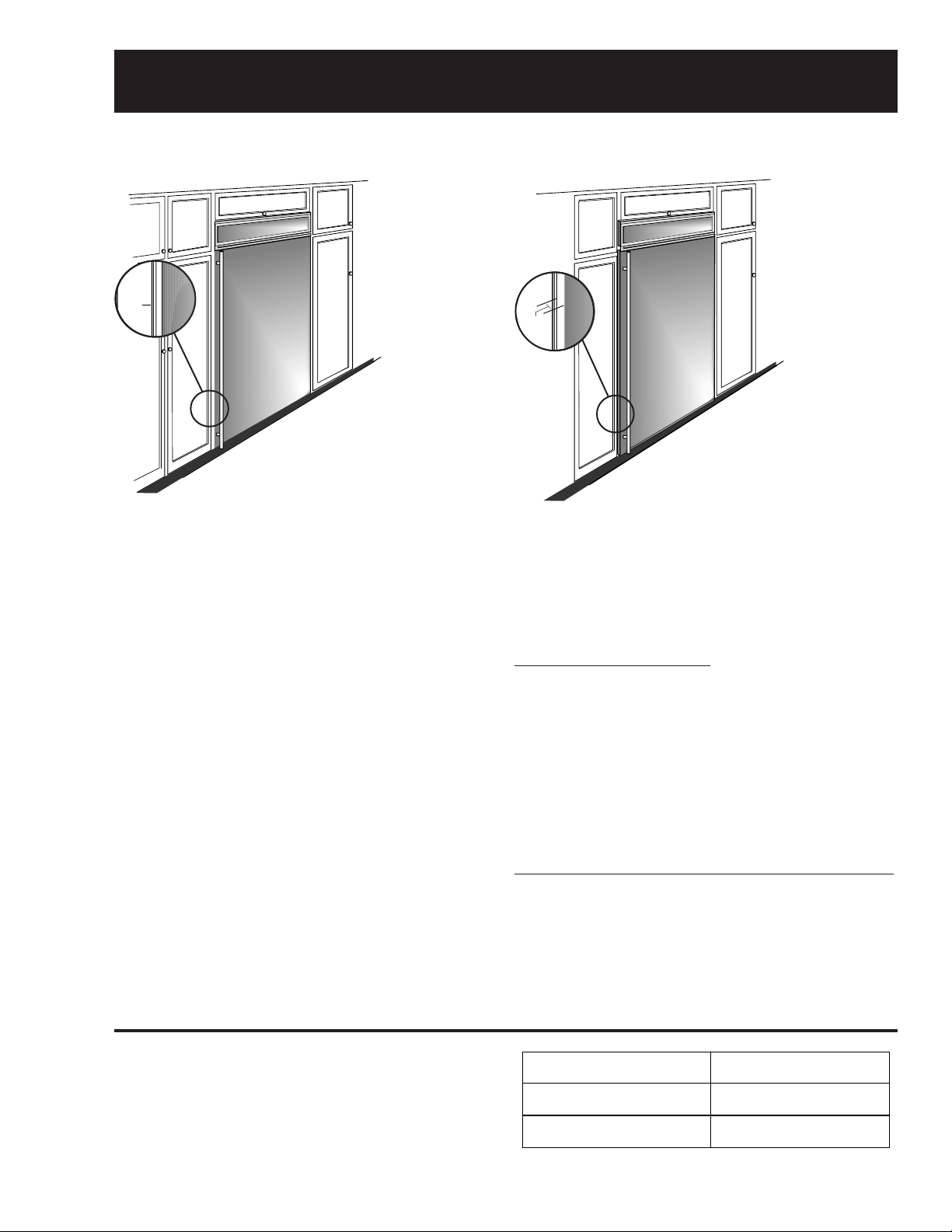

True Flush Installation

In a flush installation, the refrigerator doors

will align evenly with the front face of

adjacent cabinet doors. The refrigerator

blends into the surrounding cabinetry.

Monogram built-in refrigerators and freezers can

be installed flush with typical 24-3/4-in. deep

cabinetry.

When installed semi-flush, the case trim will

conceal slight gaps around the enclosure. The

refrigerator or freezer will project forward

approximately 3/4-in. beyond the front face of

surrounding cabinetry.

In any installation situation, a wide range of

appearance options can be accomplished through

the use of one or more trim kits. See trim kit

descriptions and appearance options in GE

Publication # 49-60055, Installation Instructions,

page 6.

GEA0066

Semi-Flush Installation

These refrigerators can also be installed

semi-flush into an enclosure using the

minimum cutout width. The case trim

creates a frame around the opening.

Side Panel Requirements:

• Side panels are not required whenever the

refrigerator is installed into an enclosure or

between pantry and oven cabinets.

• Side panels are required whenever the sides of

the refrigerator are exposed.

• Side panel sizes vary depending on the type of

installation being made.

To Accomplish an Attractive Installation, You Must:

1. Determine the need for side panels.

2. Determine side panel thickness.

3. Order matching side panels from the cabinet

manufacturer. Be sure to provide the exact

dimensions.

Caution: Maximum panel weight is 50 pounds.

When using custom panels, cut the grille panel

according to the following chart.

– 3 –

Leveling (Refrigerator and Freezer)

IMPORTANT: PLEASE READ CAREFULLY

FOR PERSONAL SAFETY, THISAPPLIANCE MUST BE PROPERLY GROUNDED.

The power cord of this appliance is equipped with a three-prong (grounding) plug that mates with a standard three-prong (grounding) wall receptacle to minimize the

risk of electric shock hazard from this appliance. The customer should have the wall receptacle and circuit checked by a qualified electrician to make sure the receptacle

is properly grounded.

Where a standard two-prong wall receptacle is encountered, it is the personal responsibility and obligation of the customer to have it replaced with a properly grounded

three-prong wall receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUTOR REMOVE THE THIRD (GROUND) PRONG FROM THE POWER CORD.

USAGE

SITUATIONS WHERE THE APPLIANCE’S POWER CORD WILL BE DISCONNECTED INFREQUENTLY

Because of potential safety hazards under certain conditions, we strongly recommend against the use of an adapter plug. However, if you still elect to use an adapter,

where local codes permit, a TEMPORARY CONNECTION may be made to a properly grounded two-prong wall receptacle by the use of a UL listed adapter which is

available at most hardware stores. The larger slot of the adapter must be aligned to provide proper polarity in the connection of the power cord.

CAUTION: Attaching the adapter ground terminal to the wall receptacle cover screw does not ground the appliance unless the cover screw is metal, and not insulated,

and the wall receptacle is grounded through the house wiring. The customer should have the circuit checked by a qualified electrician to make sure the receptacle is

properly grounded. When disconnecting the power cord from the adapter, always hold the adapter with one hand. If this is not done, the adapter ground terminal is very

likely to break with repeated use. Should this happen, DO NOT USE the appliance until a proper ground has again been established.

USAGE

SITUATIONS WHERE THE APPLIANCE’S POWER CORD WILL BE DISCONNECTED FREQUENTLY

Do not use an adapter plug in these situations because frequent disconnecting of the power cord places undue strain on the adapter and leads to eventual failure of the

adapter ground terminal. The customer should have the two-prong wall receptacle replaced with a three-prong (grounding) receptacle by a qualified electrician before

using the appliance.

MAKE SURE PROPER

GROUND EXISTS

BEFORE USE

PREFERRED

METHOD

ENSURE PROPER

GROUND AND

FIRM CONNECTION

BEFORE USE

TEMPORARY METHOD

(Adapter plugs not

permitted in Canada)

197D3266P001 31-5087 9-00 JR

The unit must be level (zero tilt) from front to back

and from side to side. Rollers at the base of the

cabinet, near all four corners, aid the installer in

positioning the unit in its final location. The rear

rollers are adjustable, but the front rollers are nonadjustable.

1. To raise the rear of the cabinet, turn the 7/16in. hex head bolt, located in the base channel

near each front corner of the cabinet.

Note: Four full turns clockwise will raise the rear

roller approximately 3/16-in.

2. To level the front of the cabinet, adjust the

leveling legs at each front corner of the base

channel.

The plug in the wall receptacle is not accessible through the freezer machine compartment

because of the V -shaped condenser. To remove power from the freezer, disconnect the power

cord connector from the machine compartment electrical housing.

– 4 –

Specifications

– 5 –

– 6 –

Nomenclature

r

Z I F S 3 6 N R H

GE Monogram

I = Built-in

Configuration

F = Freezer

R = Refrigerator

(Fresh Food)

Energy

S = Stainless Steel Model

Door Swing

RH = Right Hand

LH = Left Hand

Icemaker

N = GE Non-Icemake

Width (Inches)

– 7 –

Warranty Information

YOUR MONOGRAM WARRANTY

Staple sales slip or cancelled check here. Proof of original purchase

date is needed to obtain service under warranty.

WHAT IS

COVERED

From the Date

of the Original

Purchase

FULL TWO-YEAR WARRANTY

For two years from date of original purchase, we will provide, free of charge, parts and service labor in

your home to repair or replace any part of the refrigerator/freezer that fails because of a manufacturing

defect.

FULL FIVE-YEAR WARRANTY

For five years from date of original purchase, we will provide, free of charge, parts and service labor

in your home to repair or replace any part of the sealed refrigerating system (the compressor, condenser,

evaporator and all connecting tubing) that fails because of a manufacturing defect.

LIMITED ADDITIONAL SEVEN-YEAR WARRANTY ON THE SEALED SYSTEM

For the sixth through twelfth year from the date of the original purchase, we will provide, free of

charge, replacement parts for any part of the sealed refrigerating system (the compressor, condenser,

evaporator and all connecting tubing) that fails because of a manufacturing defect. You pay for

the service trip to your home and for service labor charges.

LIMITED LIFETIME WARRANTY ON ACCURIDE® SLIDES

From the date of the original purchase we will provide, free of charge, replacement parts for

any part of the Accuride Slides that fails because of a manufacturing defect. You pay for the service

trip to your home and for service labor charges.

This warranty is extended to the original purchaser and any succeeding owner for products

purchased for ordinary home use in the 48 mainland states, Hawaii and Washington, D.C.

In Alaska the warranty is the same except that it is LIMITED because you must pay to ship

the product to the service shop or for the service technician’s travel costs to your home.

All warranty service will be provided by our Factory Service Centers or by our authorized Customer

Care® servicers during normal working hours.

Should your appliance need service, during warranty period or beyond, in the U.S.A. call

800.444.1845.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to state. To know what your legal rights are in

your state, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. If further help is needed concerning this warranty, write:

Manager—Customer Relations, GE Appliances, Louisville, KY 40225

WHAT IS NOT

COVERED

• Service trips to your home to teach you how to

use the product.

Read your Use and Care material.

If you then have any questions about operating

the product, please contact your dealer or our

Customer Relations office at the address below,

or call, toll free:

GE Answer Center®

800.626.2000

consumer information service

• Replacement of house fuses or resetting of

circuit breakers.

• Damage to the product caused by accident, fire,

floods or acts of God.

• Failure of the product if it is used for

other than its intended purpose or used

commercially.

• Improper installation.

If you have an installation problem, contact

your dealer or installer. You are responsible for

providing adequate electrical, plumbing and

other connecting facilities.

• Loss of food due to spoilage.

WARRANTOR IS NOT RESPONSIBLE FOR

CONSEQUENTIAL DAMAGES.

– 8 –

Notes

– 9 –

Operating Characteristics

Note: Refer to Component and Connector

Locator Views.

• Refer to Schematics and Strip Circuits.

Component Description

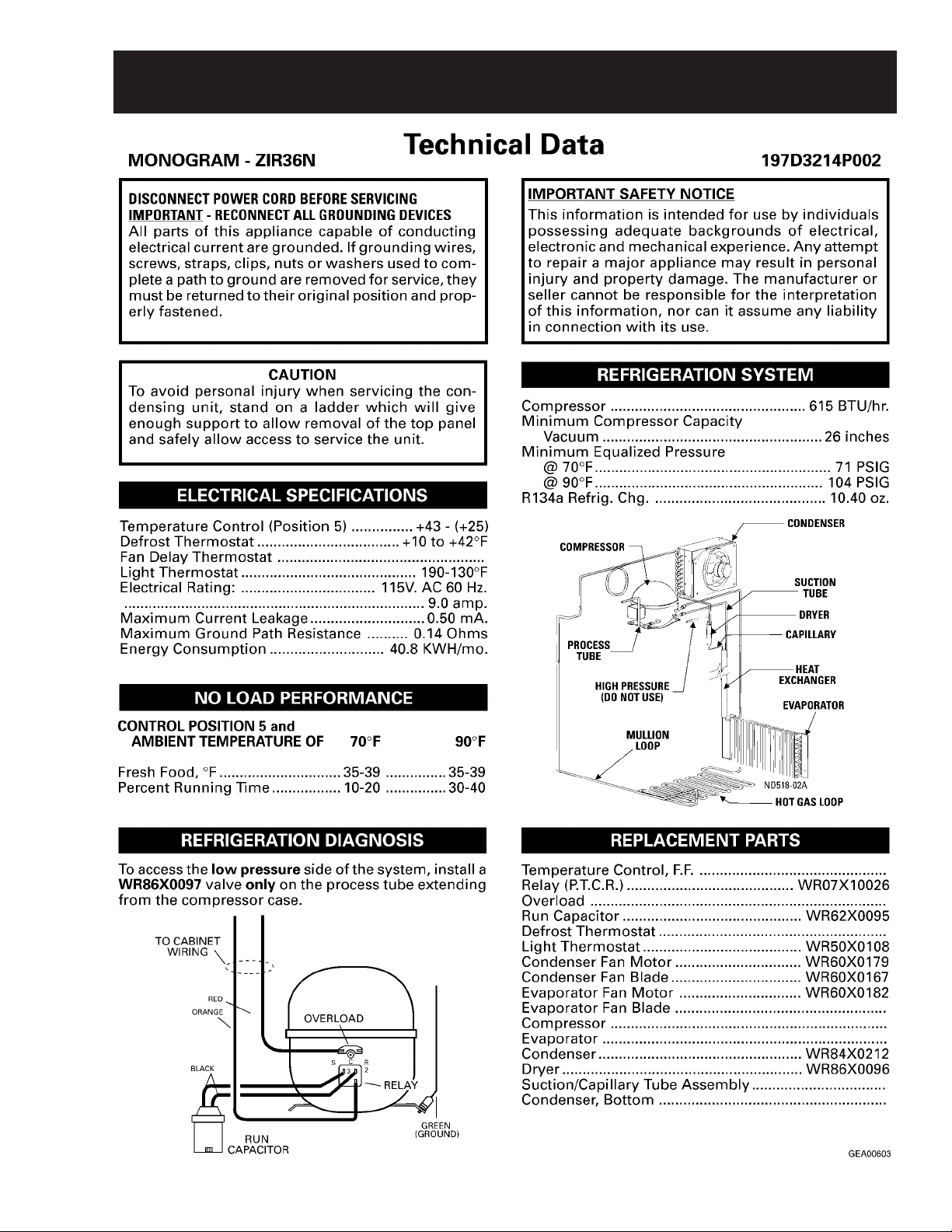

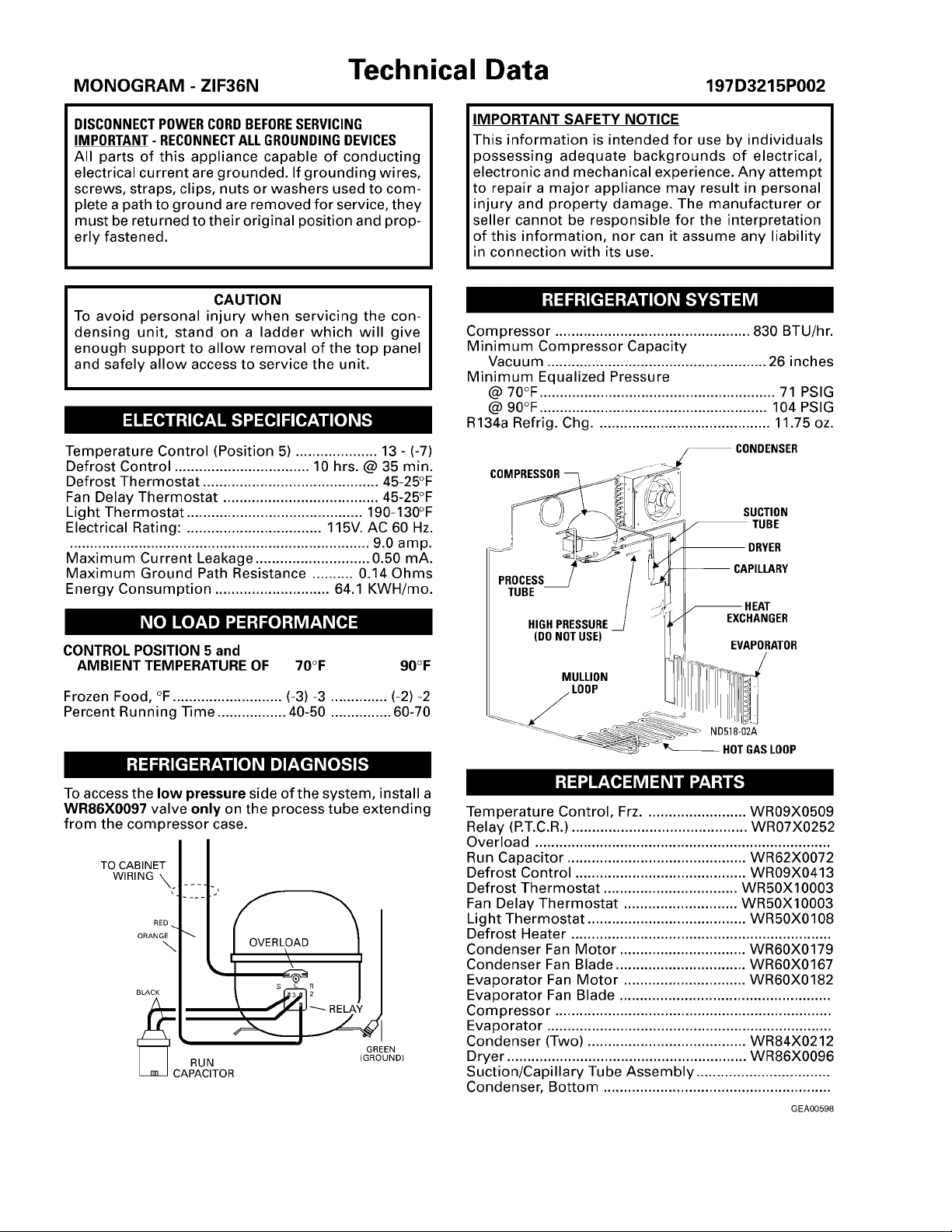

The compressor, dryer, and condenser are

located in the machine compartment on the top of

the cabinet. The evaporator is located on the

inside of the cabinet at the bottom of the back wall.

The capillary is soldered to the compressor

suction line. This arrangement serves as a heat

exchanger . The temperature control is located in

the top of the inside of the cabinet. The evaporator

fan is also located in the top of the inside of the

cabinet, behind the temperature control.

Electrical Operation (Freezer)

115V is provided from the power source to the

temperature control. The temperature control is a

thermostatic switch that closes when cabinet

temperature is higher than the control setting.

When closed, the temperature control provides

115V to the defrost control. The defrost control

contains a motor/cam mechanism that switches

the defrost control between defrost mode and

cooling mode. When in cooling mode, the defrost

control provides 115V to the compressor and to

the condenser fan. The condenser fan and

compressor always operate at the same time. In

addition to the compressor and condenser fan, the

defrost control provides 115V (in cooling mode)

through the cabinet door switch (evaporator fan

circuit) to the evaporator fan delay switch. The

door switch opens the evaporator fan switch

circuit when the cabinet door is open. The

evaporator fan delay switch opens when the

evaporator temperature has raised to 45°F and

closes when the evaporator temperature has

lowered to 25°F. When closed, the cabinet door

switch and evaporator fan delay switch provide

115V to the evaporator fan.

Electrical Operation (Refrigerator)

115V is provided from the power source to the

temperature control. The temperature control is a

thermostatic switch that closes when cabinet

temperature is higher than the control setting.

When closed, the temperature control provides

115V to the drain pan fan and defrost thermostat

switch. When closed, the defrost thermostat

switch provides 115V to the compressor and to

the condenser fan. The condenser fan and

compressor always operate at the same time.

115V is also provided from the power source to

the evaporator fan. The door switch opens the

evaporator fan switch circuit when the cabinet

door is open.

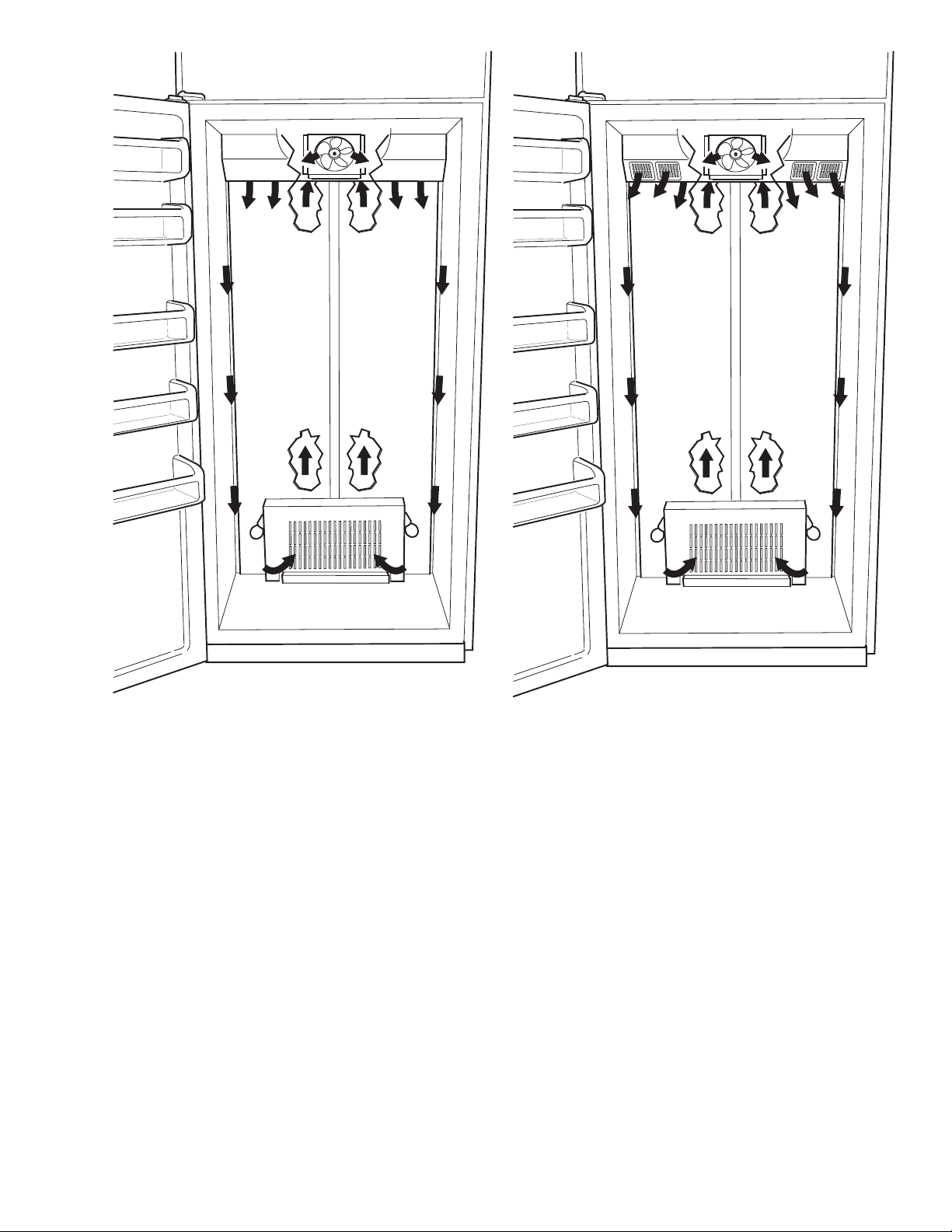

Air Movement

The cabinet is designed so that when the

evaporator fan is operating, air is drawn through

the evaporator and then up the back of the cabinet

through two ducts. At the top of the cabinet, the air

is drawn out of the ducts and through the

evaporator fan into the upper rear duct. Air moves

out of the upper rear duct and into the main part of

the cabinet. In the main part of the cabinet, the

cold air falls into the lower part of the cabinet and

is drawn into the evaporator again.

– 10 –

Refrigerator Air Flow

GEA00637

Freezer Air Flow

GEA00860

– 11 –

Notes

– 12 –

Mechanical Disassembly

Table of Contents

Door Handle (Refrigerator and Freezer) .............................................................. 15

Door Gasket (Refrigerator and Freezer)

Door Hinges (Refrigerator

Upper Door Hinge ............................................................................................. 15

Door Closure Mechanism.................................................................................15

Lower Door Hinge ............................................................................................. 16

Door Adjustment............................................................................................... 16

Door Assembly (Refrigerator

Icemaker (Freezer) .................................................................................................17

Icemaker Water V alve and W ater Line (Freezer)...................................................17

T o Replace the W ater V alve............................................................................... 17

T o Replace the Water Line from the

Water V alve to the Fill Tube Grommet......................................................... 18

and

Freezer) .............................................................. 15

and

................................................................15

Freezer) ......................................................... 16

Upper Light Shield (Refrigerator

Control Panel (Refrigerator

Upper Light Assembly (Refrigerator and Freezer)

Rear Duct (Refrigerator and Freezer)

T emperature Control (Refrigerator

Evaporator Fan (Refrigerator

and

Freezer) ...................................................19

and

Freezer) ............................................................ 19

................................................20

.....................................................................20

and

Freezer)

and

Freezer) ......................................................... 21

...................................................20

– 13 –

Storage Bin (Refrigerator

To Remove Only the Storage Bin......................................................................22

To Remove Both the Storage Bin and

the Bin Support ............................................................................................. 22

To Remove the Showcase Lid ........................................................................... 22

and

Freezer) ................................................................ 22

Storage Bin Slide Support and Center Divider (Refrigerator and Freezer) ...........

To Remove the Left or Right Slide Support .....................................................22

To Remove the Center Divider .......................................................................... 23

Evaporator Cover (Refrigerator

Defrost Heater (Freezer Only)................................................................................23

Evaporator (Refrigerator

Drain Pan Fan (Refrigerator

Grille Panel (Refrigerator

Rocker Switches (Refrigerator

and

and

Freezer)

and

Freezer) .................................................................24

Only

)......................................................................... 24

Freezer)

and

...................................................................25

Freezer) ........................................................ 25

.........................................................23

22

Defrost Control (Freezer) ....................................................................................... 26

PTCR Relay/Overload Cover (Refrigerator and Freezer)

PTCR Relay (Refrigerator

Overload (Refrigerator

Run Capacitor (Refrigerator

Slide-Out Chassis (Refrigerator

and

Freezer)................................................................ 26

and

Freezer).....................................................................27

and

Freezer)............................................................ 27

and

Freezer) ...................................................... 27

........................................26

– 14 –

8

The plug in the wall receptacle is not accessible through the freezer machine compartment

because of the V-shaped condenser. To remove power from the freezer, disconnect the power

cord connector from the machine compartment electrical housing.

Door Handle (Refrigerator and Freezer)

1. Open door to 90 degrees.

2. Remove 6 Phillips screws from the full-length

aluminum handle.

GEA0061

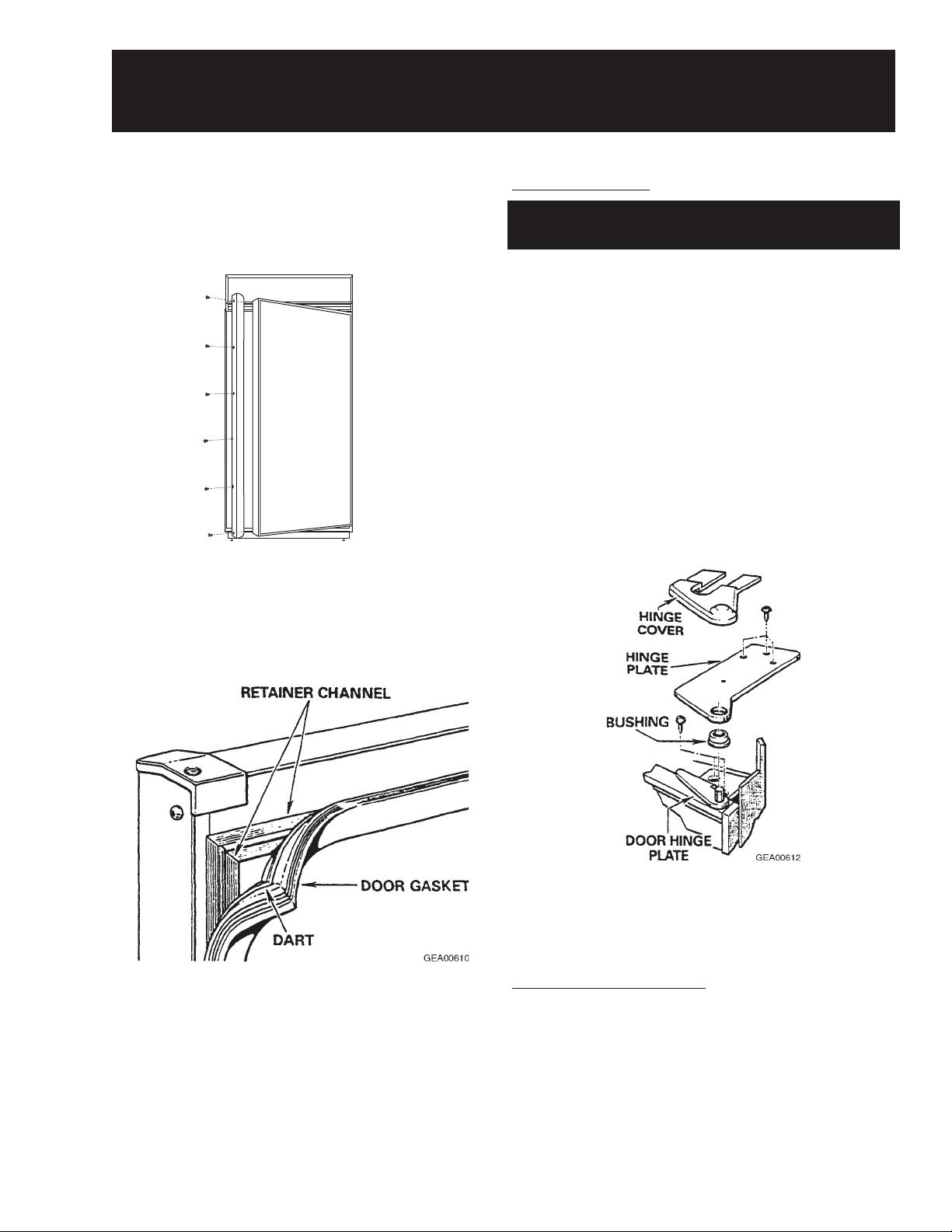

Door Gasket (Refrigerator and Freezer)

Door Hinges (Refrigerator and Freezer)

Upper Door Hinge

Note: There is no adjustment for the upper hinge

assembly.

1. Remove the grille panel (see page 25).

2. Remove 3 Phillips screws and the vent guard.

3. Carefully pry the wire guard above the hinge

upward by inserting a flat head screwdriver

between the bottom edge of the wire guard and

the hinge.

Note: The plastic hinge cover is held by doublesided adhesive tape.

4. Remove the hinge cover.

5. Remove T-20 Torx screws (3) securing the

upper hinge to the top of the cabinet.

Note: The door gasket is held in a retainer

channel.

1. Pull the old gasket out of the channel.

2. Soak the new gasket in warm water to make it

more pliable.

3. Using the back of a teaspoon, push the barbed

edge of the gasket into the retaining channel.

Note: The inner door panel is foamed in place and

is available only as a complete assembly with the

exterior door panel.

6. Remove the hinge and bushing.

7. Remove T -20 Torx screws (4) and the hinge

from the door .

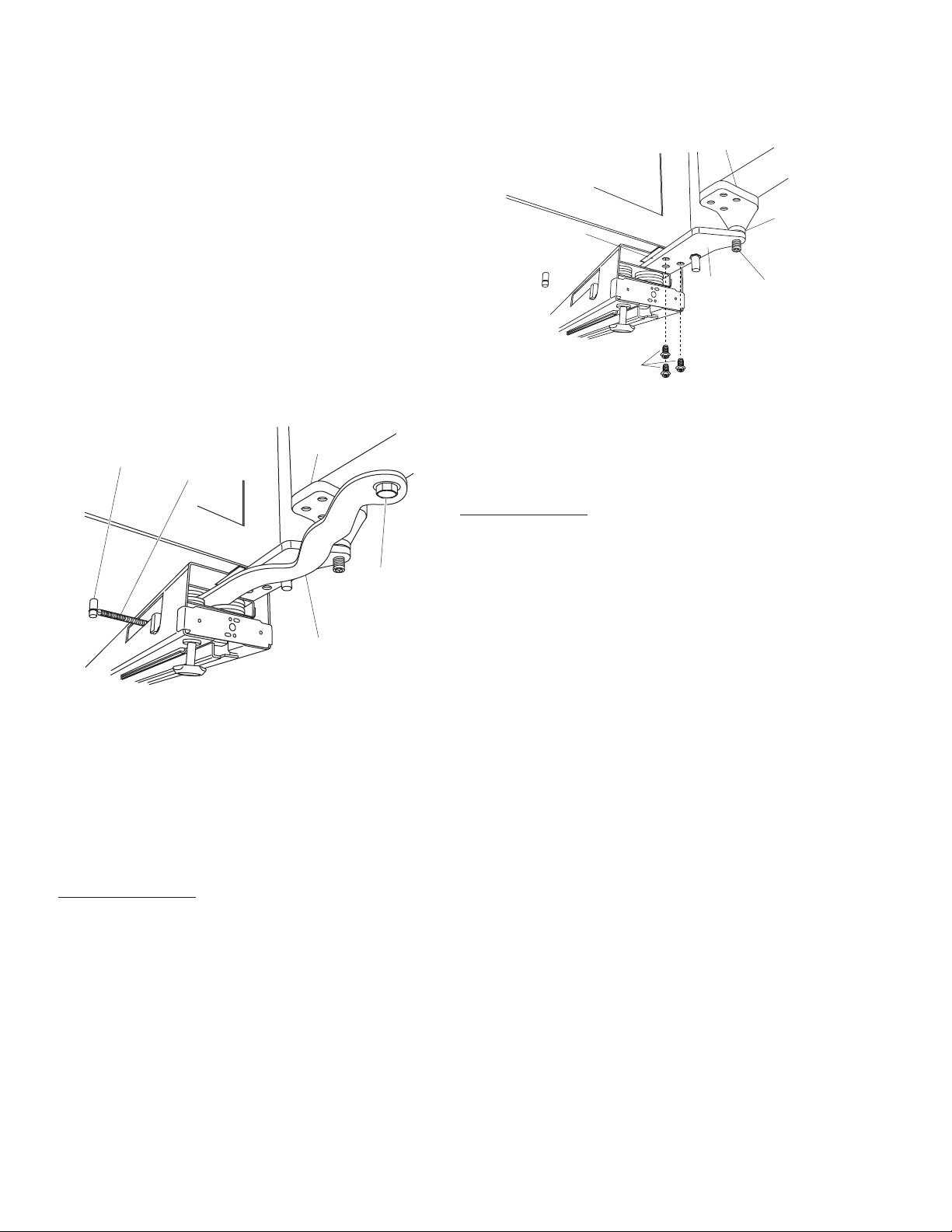

Door Closure Mechanism

The door closure mechanism uses a spring to

provide positive door closure from 30 degrees. The

door closure mechanism actuator arm has a

spring attached to the rear and is supported by

guide rollers on either side of the base channel.

The roller circumferences and the actuator arm

detents are matched for smooth operation. The

arm is attached to the door with an Allen head

shoulder bolt.

– 15 –

The closure mechanism allows easy opening to

4

3

g

B

approximately 90 degrees, where the arm has a

detent to permit the door to remain open at 90

degrees with minimal tension. Once the door is

opened beyond 90 degrees, the closure

mechanism pulls the door open until the closure

arm engages the door stop at approximately 140

degrees. The reverse action occurs when the door

is closed.

Note: Note the placement of spacers and washers

on the actuator arm for reassembly.

• The actuator arm is spring loaded with moderate

spring tension.

2. Remove T-20 Torx screws (3), base channel

spacer , and hinge from the underside of the

cabinet.

Hinge

ase Channel Spacer

Hinge

Bushin

Hinge

Pin

1. Remove the 5/16-in. bolt, washers, and spacer

from the door and actuator arm.

Door

Hinge

Pin

Spring

5/16"

Bolt

Actuator

Arm

GEA0066

2. Remove the icemaker water line from the door

closure mechanism (see page 17).

3. Remove 5 screws. The mechanism is now

loose from the cabinet.

4. Disconnect the spring from the pin on the

bottom of the cabinet.

Lower Door Hinge

1. Remove the door (see the following

procedure).

Note: Note the placement of spacers and washers

for reassembly.

Hinge

Screws

GEA0066

3. Remove T-20 Torx screws (4) fastening the

hinge to the bottom of the door .

4. Remove the hinge.

Door Adjustment

Be sure the top hinge does not hit the cabinet trim.

Adjust the door up or down by turning the threaded

hinge pin on the bottom hinge.

Door Assembly (Refrigerator and Freezer)

WARNING: The door assembly must be removed

by two people.

WARNING: Use the appropriate safety equipment

and lifting techniques.

Caution: Use wood or a heavy plastic sheet to

protect the floor where the door will be placed.

1. Remove all food and bins from the inner door

liner.

Note: Note the placement of spacers and

washers on the actuator arm for reassembly.

• The actuator arm is spring loaded with moderate

spring tension.

2. Remove the 5/16-in. bolt, washers, and spacer

from the door and actuator arm (see the

previous procedure for detailed art).

3. Remove the grille panel (see page 25).

4. Remove 3 Phillips screws from the vent guard.

5. Carefully pry the wire guard above the upper

hinge upward by inserting a flat head

screwdriver between the bottom edge of the

trim and the hinge.

– 16 –

Note: The plastic hinge cover is held by double-

6

6

sided adhesive tape.

4. Unplug the icemaker from the freezer wall and

remove.

6. Remove the hinge cover (see page 15 for

detailed art).

7. Remove T-20 Torx screws (3) securing the

upper hinge to the top of the cabinet.

8. Remove the upper hinge and bushing.

Note: Do not lose lower hinge bushing during

door removal.

9. Pull the top of the door outward until it clears

the top cabinet frame and carefully lift the door

off the lower hinge. Place door on the

protected floor area.

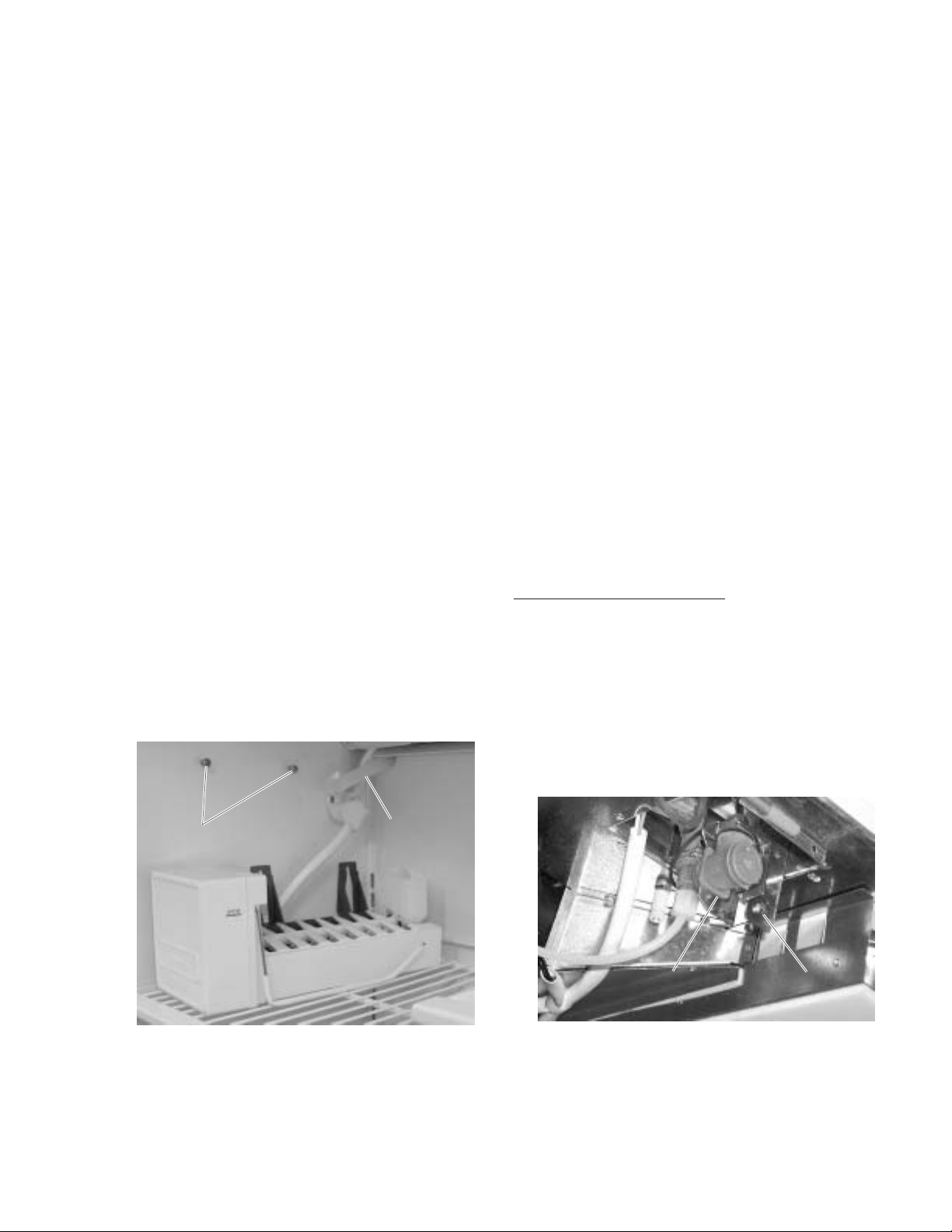

Icemaker (Freezer)

The icemaker is mounted to the upper left wall of

the freezer cabinet. Under normal operating

conditions, temperatures, door openings, and food

load, the icemaker is capable of producing

approximately 100 cubes in a 24 hour period.

1. Loosen 2 Phillips screws above the icemaker.

To service the icemaker, refer to GE Publication

31-4591, 1985 Icemakers.

Icemaker Water V alve and W ater Line

(Freezer)

The water valve is mounted under the cabinet,

beside the door closure mechanism. The valve has

a 1/4-in. stub of copper tubing to provide a

connection to the house water supply. Refer to GE

Publication # 49-60055, GE Monogram 36”

Refrigerators and 36” Freezers Custom

Options Guide and Installation Instructions for

connecting the freezer to the water supply.

A low-pressure plastic water line supplies water to

the icemaker from the water valve. The plastic

water line is routed from the water valve, under the

cabinet, through the back of the door closure

mechanism, and up the outside (back) of the

cabinet. At the top of the outside (back) of the

cabinet, the water line is connected to the fill tube

grommet. The icemaker fill tube is also plastic.

Caution: Use care to avoid damaging the water

tubing.

2. Slide the icemaker upward and pull off from the

screws.

3. Set the icemaker on the top freezer shelf.

ScrewsScrews

Water LineWater Line

GEA0062

To Replace the Water Valve:

Note: Some water may leak from the water supply

line and valve when they are disconnected.

1. Shut off the water supply to the freezer.

2. Remove the metal protective cover.

3. Remove 1 screw and lower the water valve

from the freezer .

ScrewScrewWater ValveWater Valve

GEA0066

– 17 –

4. Disconnect the wiring harness connector and

7

8

water line from the water valve.

Copper

ConnectorConnector

Water

Water

Line

Line

Copper

Tubing

Tubing

Water

Water

Valve

Valve

GEA0066

5. Disconnect the copper tubing from the water

valve.

3. Loosen 3 clamp screws.

Fill Tube GrommetFill Tube Grommet

To Replace the Water Line from the Water V alve to

the Fill Tube Grommet:

Note: Some water may leak from the water supply

line and valve when they are disconnected.

1. Shut off the water supply to the freezer.

2. Remove the unit from its installation (see GE

Publication 49-60055, GE Monogram 36”

Refrigerators and 36” Freezers Custom

Options Guide and Installation

Instructions, pages 12-17).

Clamp ScrewsClamp Screws

Water LineWater Line

GEA0063

4. Loosen the clamp at the fill tube grommet.

Caution: Do not lose the tubing sleeve when

removing the water line from the fill tube grommet.

The sleeve must be used during reassembly to

avoid leaking.

5. Remove the water line from the fill tube

grommet.

6. Remove the sleeve from the water line.

7. Slide the water line down and out of 3 clamps.

– 18 –

8. Disconnect the water line from the water valve.

1

3

9

st

GEA00643

ScrewsScrewsUpper

Light

Assembly

Upper

Light

Assembly

Water

Water

Valve

Valve

3. Pull the panel forward.

Note: On the rear of the control panel is a small

molded post which aligns the temperature control

knob. When reinstalling the control panel, make

certain to align the control knob with the post.

ClampClamp

Water

Water

Line

Line

Door Closure

Door Closure

Mechanism

Mechanism

GEA0068

9. Slide the water line out of the door closure

mechanism and clamp (on the underside of the

cabinet).

Upper Light Shield (Refrigerator and

Freezer)

1. Grasp the shield on each side.

2. Gently squeeze the front left and right sides

toward the center, then push toward the back.

Molded Po

GEA0061

Upper Light Assembly (Refrigerator and

Freezer)

1. Remove the upper light shield (see the

previous procedures).

2. Remove 4 Phillips screws and the upper light

assembly.

3. Lower the shield while disengaging it from the

control panel and then from the rear duct.

Control Panel (Refrigerator and Freezer)

1. Remove the upper light shield (see the

previous procedure).

2. Loosen (do not remove) 4 Phillips screws

behind the panel.

Control

Control

Knob

Knob

ScrewsScrews

Control

Control

Panel

Panel

GEA0065

3. Disconnect 2 wires from the temperature

control.

– 19 –

Note: The wires may be reconnected on either

5

2

6

7

side of the control.

Screws for Control PanelScrews for Control Panel

Temperature

Temperature

Control

Control

Knob Stem

Knob Stem

2. Remove 4 screws from the rear duct.

Refrigerator

ScrewsScrews

ScrewsScrews

WiresWires

Temperature

Temperature

Control

Control

Control Panel and

Control Panel and

Control Knob shown

Control Knob shown

removed for clarity

removed for clarity

GEA0064

4. Disconnect the connector.

ConnectorConnector

Rear Duct (Refrigerator and Freezer)

GEA0064

Rear DuctRear Duct

GEA0064

Freezer

ScrewsScrewsScrewsScrews

Rear DuctRear Duct

GEA0062

Caution: When removing and installing the rear

duct, insert a piece of plastic or card stock

between the cover and the unit’s side walls to

avoid scratching the walls.

3. Ease the rear duct away from the back wall.

Caution: When reinstalling the rear duct, be sure

that the wires for the upper lights and temperature

control capillary fit in the cover’s notches.

Note: When reinstalling the rear duct, put the white

screws in the holes facing the freezer door.

1. Remove the icemaker (see page 17) and

upper light shield (see page 19).

Temperature Control (Refrigerator and

Freezer)

1. Remove the upper light shield (see page 19).

2. Remove the control panel (see page 19).

3. Remove the upper light assembly (see page

17).

4. Remove the rear duct (see the previous

procedure).

– 20 –

Note: The screw does not need to be loosened

2

4

3

4

rFan Motor

r

from the clamp to complete the following step.

5. Remove the capillary from the clamp at the

evaporator fan.

Note: During reassembly, you must place the end

of the capillary through the clamp and on the foam

pad.

CapillaryCapillary

ClampClamp

Foam

Foam

Pad

Pad

GEA0068

Evaporator Fan (Refrigerator and Freezer)

1. Remove the icemaker (freezer only), upper

light shield, and rear duct (see pages 17-20).

2. Remove 2 screws from the fan motor bracket

and carefully lower the evaporator fan

assembly.

ScrewsScrews

GEA0068

3. Disconnect the wire connector from the fan

motor.

ScrewsScrews

Fan Moto

Fan Moto

Bracket

Bracket

6. Remove 2 Phillips screws and the temperature

control from the bracket.

ScrewsScrews

BracketBracket

WiresWires

Temperature

Temperature

Control

Control

GEA0065

7. Disconnect 2 wires from the temperature

control if not already done.

FanFan

Wire

Wire

Connector

Connector

Fan MotorFan Motor

GEA0068

4. Remove the fan from the motor.

5. Remove 2 screws and the fan motor bracket

from the fan motor .

– 21 –

Storage Bin (Refrigerator and Freezer)

5

1

2

3

4

4

tSupport

t

To Remove Only the Storage Bin:

1. Pull the bin out until it stops.

2. Lift the front edge of the bin upward until it

snaps out of the bin support.

BinBin

3. At the same time, use a finger to push down

on the right release lever .

GEA0062

4. While holding the levers, slide the bin out.

To Remove the Showcase Lid:

1. Remove 1 Phillips screw and plastic washer

from the hinge pin in the center support.

Bin SupportBin Support

GEA0061

3. Pull the bin forward while lifting it up and out

from the wire frame.

To Remove Both the Storage Bin and the Bin

Support:

Note: For large hands, it is much easier to remove

the storage bin first, then release the levers to

remove the bin support.

1. Pull the bin out until it stops.

Release LeverRelease Lever

GEA0062

Hinge Pin

Hinge Pin

Screw

Screw

GEA0062

2. Grasp the showcase lid with both hands and

pull off the hinge pins.

Storage Bin Slide Support and Center

Divider (Refrigerator and Freezer)

To Remove the Left or Right Slide Support:

1. Remove the appropriate storage bins (see the

previous procedure).

2. Remove 6 Phillips screws and the slide

support from inside of cabinet.

2. Grasp the bin from the sides. Use a finger to

pull up on the left release lever .

GEA0062

– 22 –

ScrewsScrews

SlideSlide

Slide

Slide

Suppor

Suppor

GEA0063

3. Remove 2 Phillips screws and the small ball

2

3

5

rEvaporator

r

1

Defrost Heater

bearing slide from slide support.

4. Remove the evaporator cover from cabinet.

4. Remove 3 Phillips screws and the large ball

bearing slide from slide support.

To Remove the Center Divider:

1. Remove all storage bins and bin supports (see

page 22).

ScrewsScrews

Evaporator CoverEvaporator Cover

Lower Light SocketsLower Light Sockets

ScrewsScrews

GEA0063

Evaporato

Evaporato

Cover

Cover

Center

Center

Divider

Divider

GEA0063

2. Remove 10 Phillips screws (5 on each side)

and center divider from inside of cabinet.

Evaporator Cover (Refrigerator and

Freezer)

The evaporator cover is attached to the lower

backside of the cabinet interior .

1. Remove the showcase lids and bins (see

page 22) and the center divider (see the

previous procedure).

2. Remove 4 Phillips screws from the evaporator

cover.

GEA0063

Defrost Heater (Freezer Only)

Note: The refrigerator does not have a defrost

system. It defrosts naturally during the OFF cycle.

1. Remove the showcase lids (see page 22), fulllength shelf, bins (see page 22), and the center

divider (see page 23).

2. Remove the evaporator cover (see the

previous procedure).

3. Disconnect 2 defrost heater connectors.

Evaporator

Clip

Defrost Heater

ConnectorConnectorConnectorConnector

3. Pull the evaporator cover forward. Disconnect

wiring from lower light sockets.

– 23 –

ClipsClips Defrost Heater

Defrost Heater

GEA0064

Caution: Use care when handling these

7

rDefrost Heater

)(Freezer Only)

r

)

sScrews

s

components to avoid damaging the evaporator and

refrigerant lines. Do not move the evaporator any

more than necessary when accessing the defrost

heater clips.

4. Remove 4 screws to access the bottom of the

evaporator . Do not disconnect the refrigerant

lines.

5. Remove 2 clips and the heater from the

evaporator.

Caution: The foam air guides on the left- and righthand sides of the evaporator must be in place

during reassembly.

Evaporator (Refrigerator and Freezer)

1. Disconnect the electrical power.

2. Recover the refrigerant.

3. Remove the evaporator cover (see the

previous procedure).

8. Remove 4 screws that hold the evaporator to

the cabinet and tilt the evaporator forward.

9. Remove the defrost heater (freezer only - see

the previous procedure).

10. Desolder the capillary tube from the

evaporator .

Caution: To prevent damage to the capillary tube,

the capillary tube must be desoldered first.

Caution: Protect cabinet wiring harness from heat

during desoldering and resoldering.

Note: It may be necessary to remove foam rubber

insulation from suction line to access solder union.

11. Desolder the suction line. Use a pair of pliers

to hold the evaporator .

12. Remove evaporator.

13. Using a file, score the capillary tube just above

the old solder and break the solder-covered

section off. This will help prevent the capillary

tube from becoming plugged when resoldering.

4. Disconnect 2 defrost heater connectors

(freezer only - see the previous procedure).

5. Remove 2 thermostat switches (1 switch only

on refrigerator) from evaporator .

6. Remove foam air guides located on each side

of the evaporator.

7. Disconnect the lower interior harness

connector from the cabinet harness connector.

Remove the lower interior harness from the

cabinet.

Caution: When removing the evaporator, use care

to avoid damaging the finish on the unit walls.

Defrost Thermostat Switch

Defrost Thermostat Switch

(Pink and Orange Wires)

(Pink and Orange Wires)

EvaporatorEvaporator

Screw

Screw

14. Position the new evaporator in the cabinet.

Insert the suction line and capillary tube into

the evaporator .

15. Braze the suction line to the evaporator using

silfos.

16. Braze the capillary tube to the evaporator

using silfos.

17. Install a replacement dryer.

18. Evacuate and recharge the system using

currently accepted procedures.

Drain Pan Fan (Refrigerator Only)

The Monogram 36-in. refrigerator has an auxiliary

evaporation fan located behind the water valve.

The purpose of this fan is to improve the

evaporation rate of drain water .

Should the fan fail or the customer complain of

excessive fan noise, follow the instructions below

for Heater Kit WR49X10016.

Fan Delay Thermostat Switch

Fan Delay Thermostat Switch

(Red and Blue Wires)

(Red and Blue Wires)

Defrost Heate

Defrost Heate

(Freezer Only

(Freezer Only

GEA0064

Note: This heater kit is also used in the Monogram

36-in. Bottom Mount Refrigerator .

• Disconnect the power to the unit before

proceeding.

1. Remove the unit’s toekick.

2. Disconnect the leads from the auxiliary

evaporation fan.

– 24 –

3. Attach 2 jumper wires with 1/8-in. spade

3

t-

4

ly

7

terminals to the fan leads.

4. Use adhesive clips to hold the wires against

the bottom of the unit. Make sure they do not

interfere with the installation or removal of the

drain pan.

Grille Panel (Refrigerator and Freezer)

WARNING: To avoid personal injury when

servicing the components in the machine

compartment, stand on a ladder which will give

enough support to allow removal of the top panel

and safely allow access to service the unit.

1. Place your thumbs under the left and right

corners of the grille panel.

2. Push up on the panel and pull it toward you.

Grille

Panel

Heater assembly is laid into place and attached by folding the front

tabs down. The rear flange of the heater assembly is over the nex

to-last tube of the auxiliary condenser. Note: Edge trim is used

wherever a wire is laying over a sharp edge and wires must be

routed so as to prevent contact with the drain pan.

GEA0061

5. Remove the drain pan. Be careful not to spill

water from the pan.

6. Install the heater assembly over the auxiliary

condenser.

Connect Heater

Adhesive Clips

Fan

Connect Jumper

to Jumper

to Fan Lead

Heater

Assemb

GEA0061

GEA0061

Rocker Switches (Refrigerator and Freezer)

Three switches are located at the top of the inside

compartment. They are, from left to right, the

evaporator fan switch (black) and 2 switches

(green) for the upper and lower light assemblies.

The switches are activated by opening the door.

1. Disconnect the electrical power.

2. Remove the grille panel (see the previous

procedure).

Note: Mark the wires for reinstallation.

3. Remove 2 connectors from the switch.

ConnectorsConnectors

7. Connect the heater leads to the jumper

harness lead.

Note: Make sure the directional arrow on the drain

pan is pointed to the rear of the unit.

8. Reinstall the drain pan and toekick.

Evaporator

Evaporator

Fan Switch

Fan Switch

Upper and Lower

Upper and Lower

Light Switches

Light Switches

4. Open the unit’s door .

5. Push in on the retainer clip on the side of the

switch, and push the switch down to remove.

– 25 –

GEA00648

9

5

0

1

The plug in the wall receptacle is not accessible through the freezer machine compartment

because of the V-shaped condenser. To remove power from the freezer, disconnect the power

cord connector from the machine compartment electrical housing.

Defrost Control (Freezer)

1. Remove the grille panel (see page 25).

2. Remove 2 Phillips screws and the defrost

control from the front baffle.

Defrost ControlDefrost Control

ScrewsScrews

GEA0063

PTCR Relay/Overload Cover (Refrigerator

and Freezer)

1. Remove the grille panel (see page 25) and

vent guard.

2. Insert a flat head screwdriver under the tab on

the cover’s top surface.

TabTab

GEA0066

3. Pry the cover up slightly while pulling it back to

remove.

3. Disconnect the connector from the defrost

control.

ConnectorConnector

Defrost

Defrost

Control

Control

GEA0065

Note: It may be necessary to manually switch

(set) the new defrost control to cooling mode or

defrost mode.

PTCR Relay (Refrigerator and Freezer)

1. Remove the grille panel (see page 25) and

vent guard.

2. Remove the PTCR relay/overload cover (see

the previous procedure).

3. Pull the relay straight out from the compressor .

PTCR

PTCR

Relay

Relay

GEA0066

4. Disconnect 3 connectors from the PTCR

relay.

– 26 –

Overload (Refrigerator and Freezer)

2

0

1. Remove the grille panel (see page 25) and the

vent guard.

2. Remove the PTCR relay/overload cover (see

page 26).

3. Remove the PTCR relay (see the previous

procedure).

4. Pull the overload straight out.

OverloadOverload

3. Discharge the run capacitor with a

screwdriver.

4. Remove 1 Phillips screw and the run capacitor

from the machine compartment.

Slide-Out Chassis (Refrigerator and

Freezer)

The machine compartment contains the

compressor and condenser on a slide-out chassis

that can be pulled out of the compartment to

facilitate servicing the refrigeration system.

1. Remove the grille panel (see page 25).

PTCR

PTCR

Relay

Relay

GEA0066

5. Disconnect 1 connector from the overload.

Run Capacitor (Refrigerator and Freezer)

1. Remove the grille panel (see page 25).

2. Disconnect the connector from the run

capacitor.

ConnectorConnector

2. Remove the vent guard and wire guard.

3. Remove 3 switches (see page 25).

4. Remove the plastic clamp for the power cord.

5. Loosen the 7/16-in. bolts (2) on the chassis

mount.

Caution: A void kinking the refrigeration tubing

while sliding the chassis out and back in.

6. Pull the chassis forward (approximately 6 in.)

until it reaches the stops provided in tracks.

Work the refrigeration tubing as you pull the

chassis out.

GEA00620

ScrewScrew

GEA0067

– 27 –

Notes

– 28 –

Troubleshooting

Note: Refer to Operating Characteristics before

choosing a troubleshooting procedure.

• Refer to Schematics and Strip Circuits.

Door Hard to Reopen Immediately After

Closing

The door has an extremely good seal and may be

hard to reopen for 10 to 15 seconds after closing.

If necessary, install vacuum break WR49X10026.

Low or No Cooling (Warm Food

Temperature)

Check for the following problems:

1. Condenser and/or grille dirty/clogged.

Unplug unit and clean condenser and grille.

2. Interior lights remain on. Check to see that

interior lights turn off when door switches are

pressed.

3. Door gasket does not seal. Check for

damaged or leaking door gasket.

4. Compressor does not operate. Go to

Compressor Does Not Operate

troubleshooting.

5. Condenser fan does not operate. Go to

Condenser Fan Does Not Operate

troubleshooting.

6. Evaporator fan does not operate. Go to

Evaporator Fan Does Not Operate

troubleshooting.

7. Evaporator is frosted (frost on evaporator

cover). Go to Defrost System Check.

8. Refrigeration system faulty. Go to

Refrigeration System Check.

Compressor Does Not Operate

Check for the following problems:

Note: The defrost control must be in cooling mode

to operate the compressor (provide 115V to the

compressor overload). It may be necessary to

manually rotate the defrost control to cooling mode

before checking for voltage at the compressor

overload.

1. 115V not present at compressor overload

(Freezer Only). If 115V is not present at the

compressor overload, check for an open

temperature control or an open defrost control

(cooling mode - terminals 3 and 4 are closed).

Note: The compressor and the condenser fan

should always operate at the same time. If the

condenser fan is operating, the temperature

control and defrost control are OK.

115V not present at compressor overload

(Refrigerator Only). If 115V is not present at

the compressor overload, check for an open

temperature control or an open defrost switch.

Note: The compressor and the condenser fan

should always operate at the same time. If the

condenser fan is operating, the temperature

control and defrost switch are OK.

2. Overload open. High heat or high current

draw will cause the overload to open. The

overload should close when the temperature

lowers to normal or when normal current draw

is present.

3. PTCR relay open. Check for continuity

between terminals 1 and 5. If there is no

continuity , replace the PTCR relay. If there is

continuity, check for continuity between

terminals 1 and 6. If there is no continuity,

replace the PTCR relay.

4. Run capacitor faulty.

5. Open wire or faulty connector. Refer to

Schematics and Strip Circuits.

6. Compressor motor faulty. Check resistance

across the compressor motor. Refer to

Schematics and Strip Circuits for resistance

values.

7. Compressor mechanically stalled.

Condenser Fan Does Not Operate

Check for the following problems:

1. Condenser fan faulty. Check for a stuck fan

motor. Check resistance across the fan motor.

Refer to Schematics and Strip Circuits for

resistance values.

2. 115V not present at condenser fan (Freezer

Only). If 115V is not present at the condenser

fan, check for an open temperature control or

an open defrost control (cooling mode terminals 3 and 4 are closed). Note: The

– 29 –

compressor and the condenser fan should

always operate at the same time. If the

compressor is operating, the temperature

control and defrost control are OK.

115V not present at condenser fan

(Refrigerator Only). If 115V is not present at

the codenser fan, check for an open

temperature control or an open defrost switch.

Note: The compressor and the condenser fan

should always operate at the same time. If the

compressor is operating, the temperature

control and defrost switch are OK.

3. Orange wire open on neutral side of

condenser fan. Refer to Schematics and Strip

Circuits.

Evaporator Fan Does Not Operate

Check for the following problems:

1. Evaporator fan faulty. Check for a stuck fan

motor. Check resistance across the fan motor.

Refer to Schematics and Strip Circuits for

resistance values.

2. 115V not present at evaporator fan.

3. Evaporator fan thermostat switch stuck

open (Freezer Only). Refer to Schematics

and Strip Circuits for switch values.

4. Orange wire open on neutral side of

evaporator fan. Refer to Schematics and Strip

Circuits.

Lights (Upper) Do Not Illuminate

Note: If only one light does not illuminate, check

for a faulty lamp or an open yellow or orange wire

in the upper light assembly.

Check for the following problems:

Check for the following problems:

1. Door switch open. Check continuity across

the door switch with the wires disconnected.

2. Open wire or faulty connector. Refer to

Schematics and Strip Circuits.

Defrost System Check (Freezer)

The automatic defrost function is controlled by the

defrost thermostat switch and the defrost control.

The defrost control contains a motor/cam

mechanism that switches the defrost control

between defrost mode and cooling mode. The

defrost control motor/cam mechanism operates

only when the temperature control (switch) is

closed. After 10 hours of motor/cam mechanism

runtime in cooling mode, the defrost control

switches to defrost mode. The defrost control will

stay in defrost mode, providing 115V to the heater

for 25 minutes of motor/cam mechanism runtime.

The defrost thermostat switch is mounted on the

evaporator , and when closed completes the

neutral side of the defrost heater circuit. The

defrost thermostat switch opens when the

evaporator temperature raises to 45°F and closes

when the evaporator temperature lowers to 25°F.

The defrost thermostat switch typically opens

during the defrost cycle, preventing the heater

from defrosting for the full 25 minutes. The purpose

for the 25-minute defrost mode at the defrost

control is to prevent the compressor from

operating and refreezing any water that may be

dripping from the evaporator.

Check for the following problems:

1. Evaporator heater open. Check resistance

across the evaporator heater. Refer to

Schematics and Strip Circuits for resistance

values.

1. Door switch open. Check continuity across

the door switch with the wires disconnected.

2. Light thermostat (switch) open. Refer to

Schematics and Strip Circuits for switch

values.

3. Open wire or faulty connector. Refer to

Schematics and Strip Circuits.

Lights (Lower) Do Not Illuminate

Note: If only one light does not illuminate, check

for a faulty lamp or an open yellow or orange wire

under the evaporator cover.

2. Defrost thermostat switch stuck open.

Refer to Schematics and Strip Circuits for

switch values.

3. Defrost control open in defrost mode.

Manually rotate the defrost control into defrost

mode. Check for continuity across the defrost

control between terminals 2 and 3. Refer to

Schematics and Strip Circuits.

4. Open wire or faulty connector. Refer to

Schematics and Strip Circuits.

– 30 –

GEA00862

CHECK SUCTION PRESSURE

SUCTION PRESSURE IN VACUUM

CHECK FOR LEAKS

AT ALL JOINTS

IN MACHINE COMPARTMENT

P ASSED TESTFAILED TEST

INSTALL DRYER

AND RECHARGE

COMPRESSOR IS OK

LOOK ELSEWHERE

REPLACE

COMPRESSOR

Add refrigerant

3 oz. - systems <6 oz.

4-1/2 oz. - systems >6 oz.

Wait 4 minutes

MAKE LEAK-RESTRICTION TEST

MAKE COMPRESSOR

CAP A CITY TEST

SUCTION PRESSURE

ABOVE ZERO

CONDENSER TEMPERA TURE

INCREASES THROUGHOUT

NO CHANGE IN CONDENSER

TEMPERATURE (LOWER 2/3)

SYSTEM HAS LEAK SYSTEM IS RESTRICTED

Check high pressure joints with

compressor running and condenser

fan stopped

FOUND LEAK NO LEAK FOUND

REPAIR LEAK, INSTALL

DRYER AND RECHARGE

CHECK EVAPORATOR

FOR LEAKS

Check low pressure joints

with compressor stopped and

defrost heaters energized

FOUND LEAK

IN EVAPORATOR

NO LEAK FOUND

IN EVAPORATOR

REPLACE LO-SIDE

AND INSTALL DRYER

RECHECK TUBING IN

MACHINE COMPARTMENT

Refrigeration System Check

– 31 –

Component and Connector Locator Views

6

9

Compressor Harness

Compressor Harness

to Cabinet Harness

to Cabinet Harness

Connector (9 pin)

Connector (9 pin)

• Freezer

• Freezer

• Refrigerator

• Refrigerator

Compressor Harness

Compressor Harness

to Cabinet Harness

to Cabinet Harness

Connector (6 pin)

Connector (6 pin)

(Freezer Only)

(Freezer Only)

Power Cord

Power Cord

Connector

Connector

(Disconnect Power

to Freezer Here)

OverloadOverload

PTCR RelayPTCR Relay

Figure 1 - Machine Compartment (Left Side)

Defrost

Defrost

Control

Control

CompressorCompressor

GEA0065

Condenser FanCondenser Fan

DryerDryer

CapillaryCapillary

Run CapacitorRun Capacitor

Evaporator

Evaporator

Fan Switch

Fan Switch

Upper and Lower

Upper and Lower

Light Switches

Light Switches

Figure 2 - Machine Compartment (Right Side)

– 32 –

Cover (Removed

Cover (Removed

from Compressor)

from Compressor)

GEA0065

7

rDefrost Heater

)(Freezer Only)

r

)

5

Cabinet Harness to Upper

)(On Outside of Assembly)

)

Cabinet Harness to Upper

Interior Harness Connector

Interior Harness Connector

Upper Interior Harness to

Upper Interior Harness to

Light Assembly Connector

Light Assembly Connector

Light Thermostat

(On Outside of Assembly)

(On Outside of Assembly)

Light Thermostat

Temperature ControlTemperature Control

Capillary

Capillary

(Temperature

(Temperature

Control)

Control)

Evaporator FanEvaporator Fan

Light Thermostat

Light Thermostat

(On Outside of Assembly

(On Outside of Assembly

Upper LightUpper Light

Figure 3 - Inside of Cabinet, Upper

Defrost Thermostat Switch

Defrost Thermostat Switch

(Pink and Orange Wires)

(Pink and Orange Wires)

Lower

Lower

Light

Light

GEA0068

EvaporatorEvaporator

Fan Delay Thermostat Switch

Fan Delay Thermostat Switch

(Red and Blue Wires)

(Red and Blue Wires)

Figure 4 - Evaporator (Inside of Cabinet, Lower)

– 33 –

Defrost Heate

Defrost Heate

(Freezer Only

(Freezer Only

GEA0065

5

Auxiliary

Auxiliary

Evaporation

Evaporation

Fan

Fan

Figure 5 - Underside of Cabinet

Icemaker

Icemaker

Water

Water

Tubing

Tubing

Water

Water

Valve

Valve

GEA0066

Note: The picture above shows the underside of the unit with the door closure mechanism removed.

– 34 –

Schematics

GEA00604

L1

BRN

BRN

BRN

BLK

BLK

RED

OVERLOAD

COMPRESSOR

RED

1

2

3

RED

RED

RED

GRAY

GRAY

BLK

BLK

3

42

+

+

BRN

BRN

BRN

BRN

BRN

NEUTRAL

176

2.9

46

5.5

10

3

1

1

2

3

2

3

5

4

4

3

130

190

+

+

4

2

1

2

5

4

8

C

R

RELAY

RUN

CAPACITOR

CONDENSER FAN

DRAIN PAN FAN

FAN

SWITCH

UPPER

LIGHT

SWITCH

LOWER

LIGHT

SWITCH

LOWER

LIGHTS

UPPER

LIGHTS

S

BLACK

BLACK

ORN

ORN

ORN

ORN

0.5

ORN

ORN

ORN

ORN

BLU

YEL

YEL

YEL

YELYELYEL

BLU

ORN

ORN

ORN

ORN

COMPRESSOR HARNESS TO CABINET HARNESS

CABINET HARNESS TO UPPER INTERIOR HARNESS

CABINET HARNESS TO LOWER INTERIOR HARNESS

SPLICE

UPPER INTERIOR HARNESS TO LIGHT ASSEMBLY

CL

OP

CL

OP

PTCR

DEFROST THERMOSTAT SWITCH

EVAPORATOR FAN

LIGHT

THERMOSTAT

SWITCH

TEMPERATURE CONTROL

Monogram 36-in. Refrigerator - ZIR36N

– 35 –

Refrigeration System - ZIR36N

B

BRN

L1

NEUTRAL

ORN

3

BRN

RN

1

BRN

1

TEMPERTURE CONTROL

BLK

2

BLK

2

BLK

3

OP

3

+

CL

42

+

BLU

BRN

DEFROST THERMOSTAT SWITCH

FAN

SWITCH

5

RED

RED

RED

2

4

GRAY

8

RED

BLK

DRAIN PAN FAN

3

BLU

EVAPORATOR FAN

RED

OVERLOAD

2

1

GRAY

0.5

46

ORN

ORN

C

3

COMPRESSOR

176

CONDENSER FAN

ORN

2.9

R

5.5

S

RELAY

ORN

ORN

PTCR

10

4

ORN

BLACK

BLACK

RUN

CAPACITOR

ORN

ORN

ORN

4

ORN

GEA00605

Refrigerator Lights - ZIR36N

+

190

+

LIGHT

THERMOSTAT

SWITCH

NEUTRAL

130

ORN

ORN

ORN

4

ORN

ORN

ORN

ORN

ORN

4

ORN

4

UPPER

LIGHTS

ORN

YELYELYEL

CL

OP

1

ORN

ORN

GEA00606

BRN

L1

3

BRN

BRN

BRN

BRN

BRN

UPPER

LIGHT

SWITCH

5

3

YEL

2

BRN

LOWER

LIGHT

SWITCH

YEL

YEL

LOWER

LIGHTS

– 36 –

Monogram 36-in. Freezer - ZIF36N

GEA00599

L1

BROWN

BRNBRNBRN

BRN

BRN

TEMPERATURE

CONTROL

NEUTRAL

ORANGE

ORANGE

ORANGE

ORANGE

ORANGE

ORANGE

YELLOW

YELLOW

YELLOW

YELLOW

FREEZER LIGHTS

(UPPER)

FREEZER LIGHTS

(LOWER)

EVAPORATOR

FAN

ORN

ORN

ORANGE

ORANGE

ORANGE

ORANGE

WATER

VALVE

WHITE

WHITE

WHITE

WHITE

ORANGE

PINK

PINK

CONDENSER FAN

DEFROST HEATER

PINK

PINK

COMPRESSOR

OVERLOAD

RUN

CAPACITOR

BLACK

BLACK

BLACK

BLACK

ORANGE

ORANGE

ORANGE

ORANGEORANGE

ORANGE

2.9

5.5

10

4

3

5

2

3

1

6

4

6

5

2

1

4

6

2

5

3

1

4

1

9

7

6

2

8

5

3

CABINET HARNESS TO UPPER INTERIOR HARNESS

CABINET HARNESS TO LOWER INTERIOR HARNESS

SPLICE

176

46

80

590

46

38

1

1

3

1

2

2

4

3

C

R

S

RED

RED

RED

RED

RED

RED

RED

RED

RED

RED

HOLD

BLACK

BLACK WHITE

BROWN

MOLD

WATER

ICEMAKER

MOTOR

BROWN

BROWN

BROWN

BROWN

FREEZER DOOR

FREEZER DOOR

BLUE

FZ FAN

SWITCH

BLUE

BLUE

BLUE

BLUE BLUE

BLUE

YELYEL

YEL

GRAY

GRAY

YELLOW

DEFROST

CONTROL

CL

25

45

OP

+

+

CL

25

45

OP

CL

OP

+

+

130

190

+

+

T.C.O.

THERMOSTAT FEELER ARM

1

2

3

ORN

UPPER INTERIOR HARNESS TO LIGHT ASSEMBLY

COMP. HARNESS TO CABINET HARNESS (6 PIN)

COMP. HARNESS TO CABINET HARNESS (9 PIN)

PTCR

RELAY

DEFROST

THERMOSTAT

SWITCH

FAN DELAY

THERMOSTAT

SWITCH

LIGHT THERMOSTAT

SWITCH

– 37 –

Refrigeration System - ZIF36N

7

BRN

BRNBRN

BRN

BRN

3

3

1

TEMPERATURE

CONTROL

2

FZ FAN

SWITCH

BROWN

RED

BLACK

BLACK

3

DEFROST

CONTROL

5

4

RED

L1

1

YELLOW

2

RED

4

RED

RED

OVERLOAD

RED

1

1

RED

2

GRAY

8

2

GRAY

ORANGE

3

NEUTRAL

C

COMPRESSOR

CONDENSER FAN

ORANGE

4

ORANGE

ORANGE

ORANGE

ORANGE

2.9

R

5.5

S

176

PTCR

RELAY

ORANGE

10

ORANGE

BLACK

BLACK

RUN

CAPACITOR

2

1

RED

1

CL

OP

FAN DELAY

THERMOSTAT

SWITCH

6

BLUE BLUE

25

+

45

+

BLUE

2

BLUE

BLUE

5

BLUE

9

46

EVAPORATOR

FAN

ORN

ORN

ORN

ORN

1

GEA00600

ORANGE

Defrost System - ZIF36N

3

BRNBRN

3

BRN

BRN

1

BRN

TEMPERATURE

CONTROL

BROWN

BLACK

3

DEFROST

CONTROL

L1

ORANGE

1

2

YELLOW

4

RED

NEUTRAL

ORANGE

ORANGE

4

ORANGE

ORANGEORANGE

4

5

4

BLACK

2

YELYEL

3

38

YEL

3

DEFROST HEATER

PINK

6

PINK

DEFROST

THERMOSTAT

PINK

25

CL

+

45

OP

+

4

5

PINK

ORANGE

1

ORANGE

GEA0060

– 38 –

Freezer Lights - ZIF36N

2

1

BRN

L1

BROWN

YELLOW

FREEZER DOOR

Icemaker System - ZIF36N

L1

3

BRNBRNBRN

3

BRN

BRN

BROWN

BROWN

T.C.O.

BROWN

6

YELLOW

130

OP

+

CL

190

3 4

BROWN

FREEZER DOOR

590

RED

MOTOR

80

MOLD

ICEMAKER

+

LIGHT THERMOSTAT

SWITCH

YELLOW

HOLD

BLACK

THERMOSTAT FEELER ARM

BLACK WHITE

WATER

5

RED

ORANGE

YELLOW

BLUE

FREEZER LIGHTS

(UPPER)

FREEZER LIGHTS

(LOWER)

ORANGE

ORANGE

ORANGE

ORN

ORANGE

ORN

ORN

ORN

ORN

ORANGE

N

N

WHITE

1

ORANGE

GEA0060

4

ORANGE

2

WATER

46

ORANGE

WHITE

1

VALVE

7

WHITE

2

WHITE

6

GEA0060

– 39 –

Illustrated Parts Catalog

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 40 –

.ON.FER.ONTRAPNOITPIRCSEDTRAP.YTQ

18705-13RELLATSNINTTA,LEBAL1

151315-13ZFDS63LAUNAM-INIM1

137006-94FERDS63TSNILLATSNI1

168006-94ERDS63.NAMERAC&ESU1

83575001X10RWHRTRC4/3X23-01#WERCS2

700524001X42RWTEKSAGROOD1

660522001X20RW060.RECAPSGNHSBEGNIH1

411558001X31RWHL.MTBROODEGNIH1

721577101X10RW.MTBROODWERCSEGNIH2

481545001X10RWMIHSEGNIH1

082514401X20RWEGNIHFFTUN/POTSROOD1

873556101X20RWSSFFO-DNATS2

193583101X17RWWODNIW/WROODFF,NIB8

604593101X17RWHRPEEDFFROOD,NIB1

704504101X17RWHLPEEDFFROOD,NIB1

300652301X87RWSS/HLMSAROODZF/FF1

605602001X79RWSS/HLPARWROOD1

935762001X10RW23-01#TESWERCS2

156786001X21RWSSRALUBUTELDNAH1

25775481X10RW009.THOTT42-21WERCS21

430828001X31RWHLDS63POTROODEGNIH1

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 41 –

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 42 –

.ON.FER.ONTRAPNOITPIRCSEDTRAP.YTQ

2029268X20RWNI-PANSVRESECIELLIRG4

5424465X10RWCYTHPLIHP8/3X23-84

0160910X06RWNAFPAVEROTOM1

5161937X20RWNAFPAVETEMMORG2

72316088X20RWEGRALNAF.PAVETEKCARB2

82315088X20RWLLAMSNAF.PAVETEKCARB1

15515465X10RWSMSHP2/1X01#54

70528913X20RWNAF.PAVE,GNIR.PMOC1

195245101X20RWM/I314#NOTTUBGULP1

34823091X10RWS/SWERCSMIRT23

615305001X06RWROTOMNAFEDALB1

300571001X58RWLIOCPAVE1

400563001X15RWDS63RETAEHTSORFED1

500584601X71RWHGUORTPAVE1

610505601X71RWLENAPLORTNOC1

940515601X71RWREPPUDLEIHSTHGIL1

580522001X05RWNAFZFTATSOMREHT1

490542501X20RWPOTSNAP2

890532001X05RWRETAEHZFTATSOMREHT1

631557601X71RW.DNOC.XUAPARTNIARD1

731567601X71RWNAPNIARDTROPPUS1

931542001X48RWYRAILLIXUARESNEDNOC1

041547601X71RW.DNOC.XUANAPNIARD1

141508101X10RWTROPPUSNAPRENETSAF2

241552501X20RWSPMALCTROPPUS2

661554001X10RWRETAEHPAVE.TERERIW2

791554101X20RWHLPAVEELFFAB2

053555601X71RWEBUTNIARD1

68550760X31RW)HL(MSAESAB1

17758649X20RWHLMSAROODZFERUSOLC1

010698601X71RW.GTM.RTMNAFROTAROPAVE1

610635601X71RWHCTACHGUORTPAVE1

715664601X71RWELFFABNIARD1

815664001X47RWTEKCARBTHGIL1

025674601X71RWZFDS63TCUDRAER1

735667401X20RWMSABONKLORTNOCZF1

775684001X47RWREVOCROTAROPAVE1

27575298X20RWFFMRATCA1

79579050X90RW24/63LORTNOCZF1

17779381X10RWMSAGNIRPSEGNIHGNIHSUB1

60878298X20RWB7043#TEKCOSTHGIL2

159715101X20RWTROPPUSTSIWT4

200842001X05RWFFTSORFED,CSIDOMREHT2

454809101X83RW"7521.1MIRTEGDE2

6938A06W06BLUBECNAILPPA4

159862501X20RW84FFERUSOLCROODGNIRS1

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 43 –

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 44 –

.ON.FER.ONTRAPNOITPIRCSEDTRAP.YTQ

11557101X10RW).JDA(MOTTOB,NIPEGNIH1

0085900X75RWMSAEVLAVRETAW1

6087012X71RWENILRETAW1

0287230X03RWTNECSERCMI1

62316373X20RWEBUTPMALC4

15515465X10RWSMSHP2/1X01#54

34823091X10RWS/SWERCSMIRT23

800594601X71RWRETNECKCARTFLEHS1

210595401X71RWHLMIRTESAC1

570557001X23RWTEKCUBECI1

680524101X20RWMB63DRAUGTNEV1

271505001X47RWMSAPOTTNEV1

932525001X47RW63LENAPELLIRGPARWSS1

743584101X20RWHLDRAUGERIW1

62655068X20RWEVLAVRETAWTEKCARB1

255674001X47RWHLDS63KCIKEOT1

375677401X20RWEVLAVRETAW,TELNI1

630704101X32RW101087#GUAHCTIWS1

172715001X10RWPATDH-PLIHP8/7*42-019

88271381X10RW.GTMELLIRGWERCS2

71376403X71RWNOLYNPMALC4/14

96577858X20RWEGNIHPOTGNIHSUB1

25775481X10RW009.THOTT42-21WERCS21

06770091X10RWTUNLERRAB61/5*23-84

36771091X10RWS/MSSURTLIHP4/1*23-86

538708001X31RWHLREVOCEGNIH1

178761001X75RW4/1TUNNOISSERPMOC1

378771001X75RWELURREFSSARB1

75979630X15RWRETAEHEBUTLLIF1

31082798X20RW.RTXETNRFTEKSAGTIFFOS3

230818001X31RWHLEGNIHESACPOT1

530816601X71RWSSDS63ESABELLIRG1

24185740X32RWTTAW-002HCTIWSREKCOR2

05380414X71RWFFKCARTFLEHS2

805867101X10RWTEMMORGTEKSAG1

015828401X20RWLLIFRETAWTEMMORG,MSA1

115838401X20RWEGNIHFF,GNIHSUB1

315899001X31RWHL/HRESAC.MTBEGNIH1

837835001X10RWKLB8/3XBAEPYT81-8#3

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 45 –

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 46 –

.ON.FER.ONTRAPNOITPIRCSEDTRAP.YTQ

35709401X20RW.MSALEEHWTNORF2

15515465X10RWSMSHP2/1X01#54

34823091X10RWS/SWERCSMIRT23

31055368X20BWHRMIRTESAC1

710532201X17RWFLEHSTNACERIWZF5

520564001X27RWERIWTEKSABGEV.PPUS4

060534001X27RWGEVTROPPUSNAP2

460534001X23RWREVOCNAPGEV2

480552201X17RWKCUBECI-ZFTNACFLEHS1

641591101X23RWNAPGEVDILESACWOHS2

502521001X27RWHREDILS,TROPPUS1

222564001X10RWTOVIPESACWOHSREHSAW2

622574001X10RWEDILGNOTTUB4

722531001X27RWHLEDILS,TROPPUS1

232584001X10RWTOVIPESACWOHS,GNIHSUB2

124505001X10RW4/3X818#,WERCS2

005504001X41RWDILESACWOHSTNORFLAES2

49551760X31RW)HR(MSAESAB1

02657738X20RWMSARAERLEEHW2

720621001X12RWREPPUMSATEKSABGEV2

820602101X23RWMSATEKSABKCANS2

835612101X23RWREWOLMSATEKSABGEV4

550787401X20RWLEEHWELXA2

19571581X10RWRCSJDA4/141X02-4/12

66779978X20RW4C220EL#LEEHWGNIRPS2

867797401X20RWGELGNILEVEL2

96770088X20RWTOVIPYEK2

558708401X20RWYTILIBOMLEEHW2

000854001X27RWAPGEV,RETNEC-REDIVID1

29289620X27RW01TXELLUFEDILS4

39280720X27RW21TXELLUFEDILS21

105842201X17RWREVOCERIWNAPKCANS1

316825001X10RWDHSLIHP2/1XBA81-8#44

605944001X27RWKCANSTROPPUSNAP2

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 47 –

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 48 –

.ON.FER.ONTRAPNOITPIRCSEDTRAP.YTQ

0936281X10RWWERCS51

6268010X32RW.MSADROCREWOP1

8463840X90RWTSORFEDLORTNOC1

0567810X06RWNAFDNOCROTOM1

1562120X06RWMSANAFDNOCEDALB1

2564171X10RWNOIHSUC,REHSAW01

3565171X10RWTUN1

5271740X78RWMSAEDISHGIH1

9279700X26RW084662-60ROTICAPACNUR1

2376227X20RWREVOCPMALC1

4374387X20RWREVOC1

53722001X80RWYYBFM214MT4DAOLREVO1

7378327X20RWGTMPMOCTEMMORG4

0476900X68RWMSARETLIFREYRD1

03316171X10RWROTOMNAF,WERCS3

15515465X10RWSMSHP2/1X01#54

25511808X20RWLIHPHPSMS8/3X019

565144001X10RWTUNXEH02-4/14

66512075X10RWREHSAW4

36324865X10RWEPYTS/SLIHP8/3X23-62

605454601X71RWNAPNOITAREGIRFER1

95555403X71RWGF/WTNORFELFFAB1

37550168X20RWGIRFERTNUOMEDILS2

146563501X20RWRENIATERNAPMETSYS1

301673501X20RW.GTM.DNOC.TKRB2

601687601X71RWDUORHS.DNOC.ZF1

801697601X71RWELFFABTNORF.ZF1

901677601X71RWREVOCKCAB.DNOCZF1

011683501X20RWGNITCENNOCDNOC.TKRB1

93477403X71RWNAFDNOCGNISUOH1

69778465X10RWRALLOCLEETS4

68084740X32RWSSENRAHROTICAPAC1

921824001X41RWMAOFELFFABEDISDNOC1

031834001X41RWMAOFELFFABPOTDNOC2

215890001X68RWZFMSAEBUTNOITCUS/PAC1

177862001X70RWRCTPYALER1

449812001X48RWDS63MSARESNEDNOC1

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 49 –

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 50 –

.ON.FER.ONTRAPNOITPIRCSEDTRAP.YTQ

0582810X92RWHWREVOC1

1582615X92RWRAEG1

35850001X92RWETALPGNITNUOM1

45820001X92RWMAEBGNIRPS1

55810001X92RWROTOM1

6588115X92RWHCTIWSGNIDLOHECAPS1

7581715X92RWMIHCTIWS1

8587615X92RWMAC1

9580915X92RWGNIRPS1

0684115X92RWHCTIWSEVLAVETALP1

1688815X92RWROTALUSNI1

3683815X92RWREVELMRA1

4683810X92RWGNISUOH1

5680610X92RWREPPIRTS1

6684715X92RWROTCEJE1

7683510X92RW)PUCLLIF(TELNIGNRB1

8684020X92RWMSARETAEH/DLOM1

9687510X92RWTATSOMREHT1

0786810X92RWSSENRAHERIW1

1788510X92RWTATSOMREHTPMALC1

2788215X92RWEVEELS1

3789215X92RWFFOTUHSMRA1

4785810X92RWFFO-TUCLAMREHT1

5781815X92RWGNIRPS1

Exploded parts view and list for Model No. ZIFS36NDALH.

Refer to microfiche for other model information.

– 51 –

Exploded parts view and list for Model No. ZIRS36NDARH.

Refer to microfiche for other model information.

– 52 –