Monogram ZIRS36N LH, ZIF36N LH, ZIR36N RH, ZIRS36N RH, ZIF36N RH Technical Service Manual

...

C

GE Consumer Home Services T raining

TECHNICAL SER VICE GUIDE

GE Monogram 36-inch Refrigerator

GE Monogram 36-inch Freezer

MODEL SERIES:

ZIR36N LH - All Fresh Food

ZIR36N RH - All Fresh Food

ZIRS36N LH - All Fresh Food

ZIRS36N RH - All Fresh Food

ZIF36N LH - All Freezer

ZIF36N RH - All Freezer

ZIFS36N LH - All Freezer

ZIFS36N RH - All Freezer

PUB # 31-9047 12/00

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2000

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

Table of Contents

Introduction ............................................................................................................2

Installation Highlights............................................................................................3

Specifications.........................................................................................................5

Nomenclature .........................................................................................................7

Warranty Information..............................................................................................8

Operating Characteristics .....................................................................................10

Mechanical Disassembly .......................................................................................13

Troubleshooting.....................................................................................................29

Component and Connector Locator Views .........................................................32

Schematics .............................................................................................................35

Illustrated Parts Catalog .......................................................................................40

– 1 –

Introduction

The Monogram refrigerator/freezer makes an

eloquent statement of style, convenience, and

kitchen planning flexibility . Whether chosen for it s

purity of design, practical storage arrangements,

or assiduous attention to detail - or for all of these

reasons - the Monogram refrigerator/freezer’s

superior blend of form and function will delight the

customer for years to come.

The Monogram refrigerator/freezer was designed

to provide the flexibility to harmonize with any

kitchen cabinetry. Decorative door insert panels

allow it to match kitchen cabinets or blend with

any kitchen decor. Custom handles are also

available to further personalize the refrigerator/

freezer. Through a series of product and trim kit

choices, the Monogram refrigerator/freezer can be

beautifully integrated into the kitchen.

Since this is designed to be a built-in product,

custom panels are required on the front of the

Monogram refrigerator/freezer . Customers can

consult their kitchen designer or cabinetmaker for

a customized look.

– 2 –

Installation Highlights

Installation Height Panel Height

83-1/2" 7-1/2"

84-1/2" 8-1/2"

9

8

For detailed installation instructions, refer to GE Publication # 49-60055, GE Monogram 36”

Refrigerators and 36” Freezers Custom Options Guide and Installation Instructions.

0"

3/4"

GEA0066

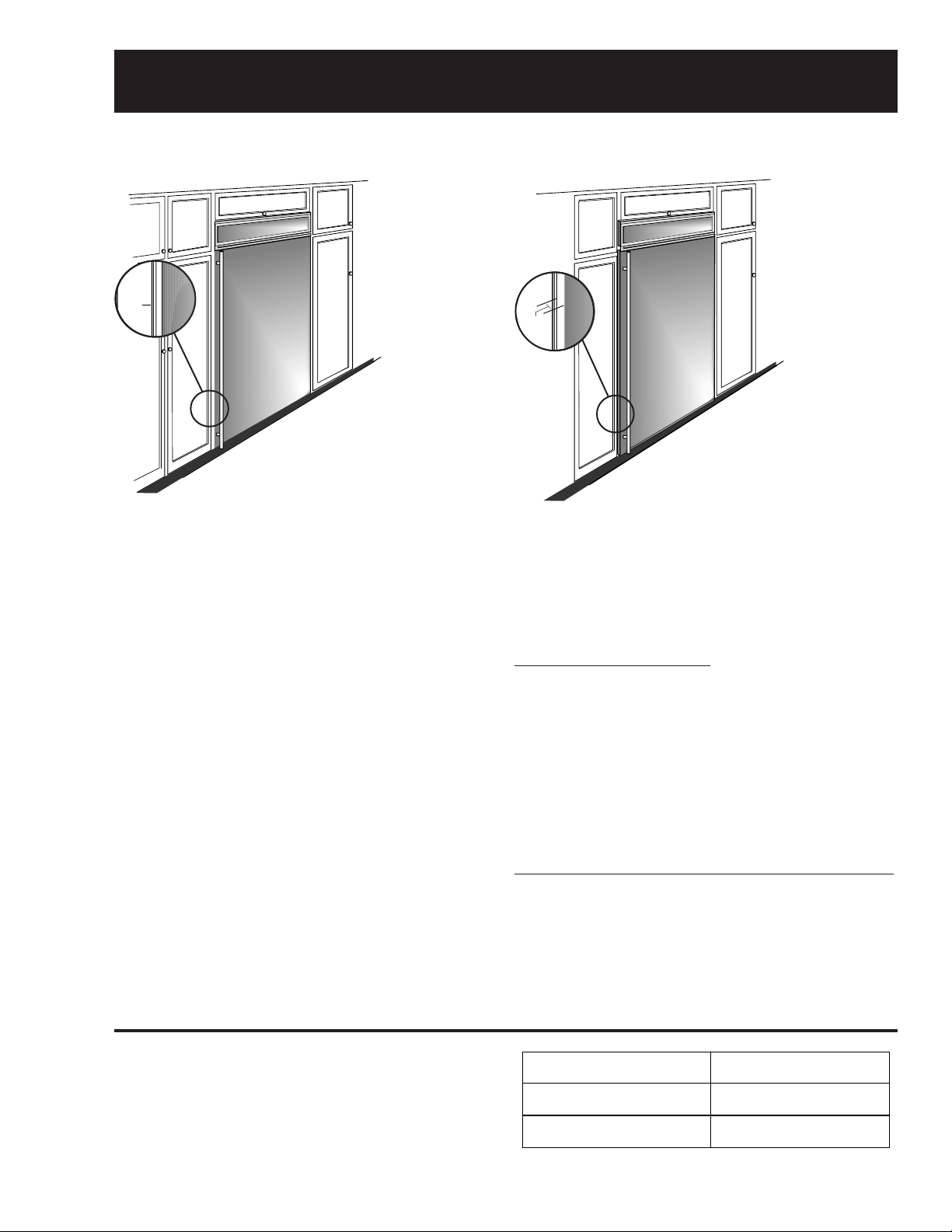

True Flush Installation

In a flush installation, the refrigerator doors

will align evenly with the front face of

adjacent cabinet doors. The refrigerator

blends into the surrounding cabinetry.

Monogram built-in refrigerators and freezers can

be installed flush with typical 24-3/4-in. deep

cabinetry.

When installed semi-flush, the case trim will

conceal slight gaps around the enclosure. The

refrigerator or freezer will project forward

approximately 3/4-in. beyond the front face of

surrounding cabinetry.

In any installation situation, a wide range of

appearance options can be accomplished through

the use of one or more trim kits. See trim kit

descriptions and appearance options in GE

Publication # 49-60055, Installation Instructions,

page 6.

GEA0066

Semi-Flush Installation

These refrigerators can also be installed

semi-flush into an enclosure using the

minimum cutout width. The case trim

creates a frame around the opening.

Side Panel Requirements:

• Side panels are not required whenever the

refrigerator is installed into an enclosure or

between pantry and oven cabinets.

• Side panels are required whenever the sides of

the refrigerator are exposed.

• Side panel sizes vary depending on the type of

installation being made.

To Accomplish an Attractive Installation, You Must:

1. Determine the need for side panels.

2. Determine side panel thickness.

3. Order matching side panels from the cabinet

manufacturer. Be sure to provide the exact

dimensions.

Caution: Maximum panel weight is 50 pounds.

When using custom panels, cut the grille panel

according to the following chart.

– 3 –

Leveling (Refrigerator and Freezer)

IMPORTANT: PLEASE READ CAREFULLY

FOR PERSONAL SAFETY, THISAPPLIANCE MUST BE PROPERLY GROUNDED.

The power cord of this appliance is equipped with a three-prong (grounding) plug that mates with a standard three-prong (grounding) wall receptacle to minimize the

risk of electric shock hazard from this appliance. The customer should have the wall receptacle and circuit checked by a qualified electrician to make sure the receptacle

is properly grounded.

Where a standard two-prong wall receptacle is encountered, it is the personal responsibility and obligation of the customer to have it replaced with a properly grounded

three-prong wall receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUTOR REMOVE THE THIRD (GROUND) PRONG FROM THE POWER CORD.

USAGE

SITUATIONS WHERE THE APPLIANCE’S POWER CORD WILL BE DISCONNECTED INFREQUENTLY

Because of potential safety hazards under certain conditions, we strongly recommend against the use of an adapter plug. However, if you still elect to use an adapter,

where local codes permit, a TEMPORARY CONNECTION may be made to a properly grounded two-prong wall receptacle by the use of a UL listed adapter which is

available at most hardware stores. The larger slot of the adapter must be aligned to provide proper polarity in the connection of the power cord.

CAUTION: Attaching the adapter ground terminal to the wall receptacle cover screw does not ground the appliance unless the cover screw is metal, and not insulated,

and the wall receptacle is grounded through the house wiring. The customer should have the circuit checked by a qualified electrician to make sure the receptacle is

properly grounded. When disconnecting the power cord from the adapter, always hold the adapter with one hand. If this is not done, the adapter ground terminal is very

likely to break with repeated use. Should this happen, DO NOT USE the appliance until a proper ground has again been established.

USAGE

SITUATIONS WHERE THE APPLIANCE’S POWER CORD WILL BE DISCONNECTED FREQUENTLY

Do not use an adapter plug in these situations because frequent disconnecting of the power cord places undue strain on the adapter and leads to eventual failure of the

adapter ground terminal. The customer should have the two-prong wall receptacle replaced with a three-prong (grounding) receptacle by a qualified electrician before

using the appliance.

MAKE SURE PROPER

GROUND EXISTS

BEFORE USE

PREFERRED

METHOD

ENSURE PROPER

GROUND AND

FIRM CONNECTION

BEFORE USE

TEMPORARY METHOD

(Adapter plugs not

permitted in Canada)

197D3266P001 31-5087 9-00 JR

The unit must be level (zero tilt) from front to back

and from side to side. Rollers at the base of the

cabinet, near all four corners, aid the installer in

positioning the unit in its final location. The rear

rollers are adjustable, but the front rollers are nonadjustable.

1. To raise the rear of the cabinet, turn the 7/16in. hex head bolt, located in the base channel

near each front corner of the cabinet.

Note: Four full turns clockwise will raise the rear

roller approximately 3/16-in.

2. To level the front of the cabinet, adjust the

leveling legs at each front corner of the base

channel.

The plug in the wall receptacle is not accessible through the freezer machine compartment

because of the V -shaped condenser. To remove power from the freezer, disconnect the power

cord connector from the machine compartment electrical housing.

– 4 –

Specifications

– 5 –

– 6 –

Nomenclature

r

Z I F S 3 6 N R H

GE Monogram

I = Built-in

Configuration

F = Freezer

R = Refrigerator

(Fresh Food)

Energy

S = Stainless Steel Model

Door Swing

RH = Right Hand

LH = Left Hand

Icemaker

N = GE Non-Icemake

Width (Inches)

– 7 –

Warranty Information

YOUR MONOGRAM WARRANTY

Staple sales slip or cancelled check here. Proof of original purchase

date is needed to obtain service under warranty.

WHAT IS

COVERED

From the Date

of the Original

Purchase

FULL TWO-YEAR WARRANTY

For two years from date of original purchase, we will provide, free of charge, parts and service labor in

your home to repair or replace any part of the refrigerator/freezer that fails because of a manufacturing

defect.

FULL FIVE-YEAR WARRANTY

For five years from date of original purchase, we will provide, free of charge, parts and service labor

in your home to repair or replace any part of the sealed refrigerating system (the compressor, condenser,

evaporator and all connecting tubing) that fails because of a manufacturing defect.

LIMITED ADDITIONAL SEVEN-YEAR WARRANTY ON THE SEALED SYSTEM

For the sixth through twelfth year from the date of the original purchase, we will provide, free of

charge, replacement parts for any part of the sealed refrigerating system (the compressor, condenser,

evaporator and all connecting tubing) that fails because of a manufacturing defect. You pay for

the service trip to your home and for service labor charges.

LIMITED LIFETIME WARRANTY ON ACCURIDE® SLIDES

From the date of the original purchase we will provide, free of charge, replacement parts for

any part of the Accuride Slides that fails because of a manufacturing defect. You pay for the service

trip to your home and for service labor charges.

This warranty is extended to the original purchaser and any succeeding owner for products

purchased for ordinary home use in the 48 mainland states, Hawaii and Washington, D.C.

In Alaska the warranty is the same except that it is LIMITED because you must pay to ship

the product to the service shop or for the service technician’s travel costs to your home.

All warranty service will be provided by our Factory Service Centers or by our authorized Customer

Care® servicers during normal working hours.

Should your appliance need service, during warranty period or beyond, in the U.S.A. call

800.444.1845.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to state. To know what your legal rights are in

your state, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. If further help is needed concerning this warranty, write:

Manager—Customer Relations, GE Appliances, Louisville, KY 40225

WHAT IS NOT

COVERED

• Service trips to your home to teach you how to

use the product.

Read your Use and Care material.

If you then have any questions about operating

the product, please contact your dealer or our

Customer Relations office at the address below,

or call, toll free:

GE Answer Center®

800.626.2000

consumer information service

• Replacement of house fuses or resetting of

circuit breakers.

• Damage to the product caused by accident, fire,

floods or acts of God.

• Failure of the product if it is used for

other than its intended purpose or used

commercially.

• Improper installation.

If you have an installation problem, contact

your dealer or installer. You are responsible for

providing adequate electrical, plumbing and

other connecting facilities.

• Loss of food due to spoilage.

WARRANTOR IS NOT RESPONSIBLE FOR

CONSEQUENTIAL DAMAGES.

– 8 –

Notes

– 9 –

Operating Characteristics

Note: Refer to Component and Connector

Locator Views.

• Refer to Schematics and Strip Circuits.

Component Description

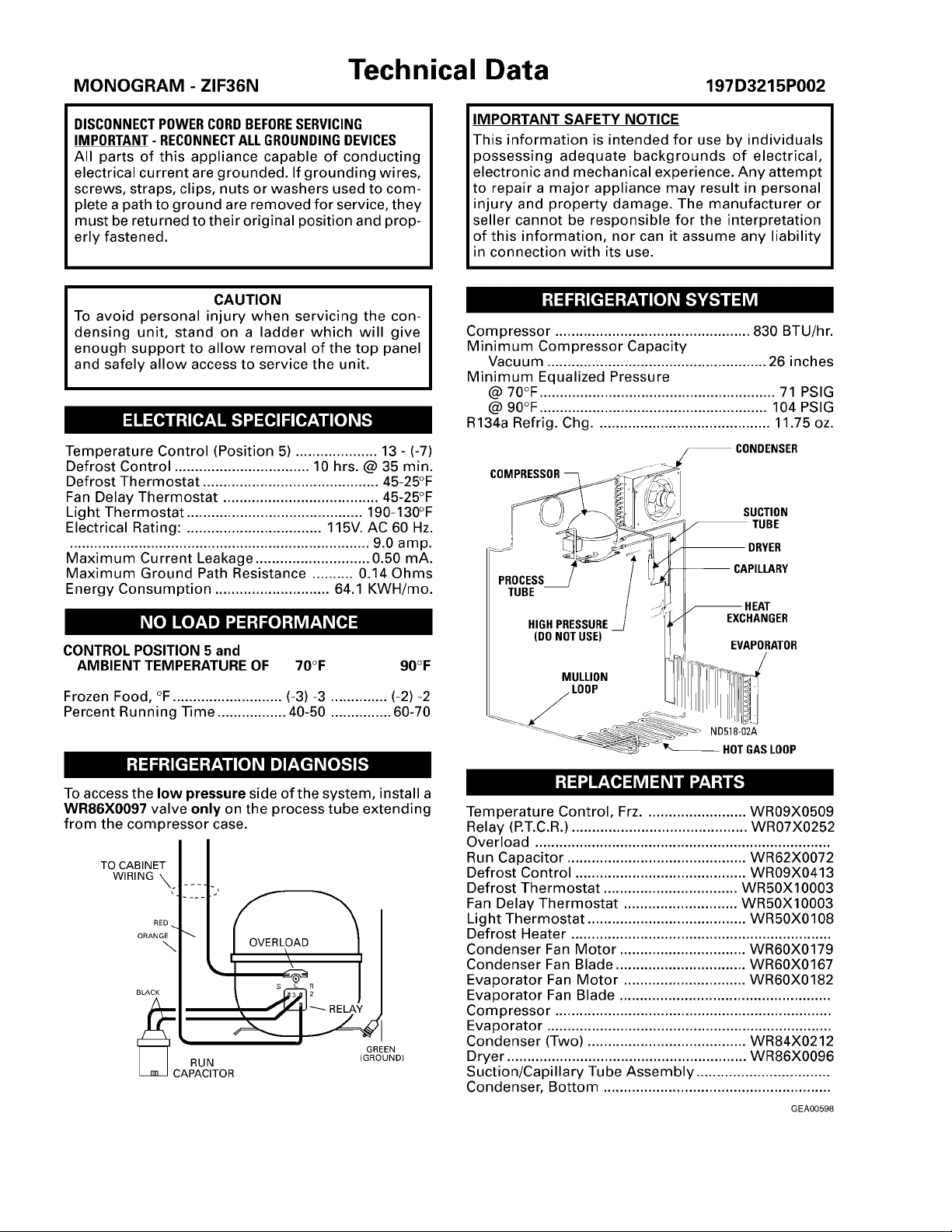

The compressor, dryer, and condenser are

located in the machine compartment on the top of

the cabinet. The evaporator is located on the

inside of the cabinet at the bottom of the back wall.

The capillary is soldered to the compressor

suction line. This arrangement serves as a heat

exchanger . The temperature control is located in

the top of the inside of the cabinet. The evaporator

fan is also located in the top of the inside of the

cabinet, behind the temperature control.

Electrical Operation (Freezer)

115V is provided from the power source to the

temperature control. The temperature control is a

thermostatic switch that closes when cabinet

temperature is higher than the control setting.

When closed, the temperature control provides

115V to the defrost control. The defrost control

contains a motor/cam mechanism that switches

the defrost control between defrost mode and

cooling mode. When in cooling mode, the defrost

control provides 115V to the compressor and to

the condenser fan. The condenser fan and

compressor always operate at the same time. In

addition to the compressor and condenser fan, the

defrost control provides 115V (in cooling mode)

through the cabinet door switch (evaporator fan

circuit) to the evaporator fan delay switch. The

door switch opens the evaporator fan switch

circuit when the cabinet door is open. The

evaporator fan delay switch opens when the

evaporator temperature has raised to 45°F and

closes when the evaporator temperature has

lowered to 25°F. When closed, the cabinet door

switch and evaporator fan delay switch provide

115V to the evaporator fan.

Electrical Operation (Refrigerator)

115V is provided from the power source to the

temperature control. The temperature control is a

thermostatic switch that closes when cabinet

temperature is higher than the control setting.

When closed, the temperature control provides

115V to the drain pan fan and defrost thermostat

switch. When closed, the defrost thermostat

switch provides 115V to the compressor and to

the condenser fan. The condenser fan and

compressor always operate at the same time.

115V is also provided from the power source to

the evaporator fan. The door switch opens the

evaporator fan switch circuit when the cabinet

door is open.

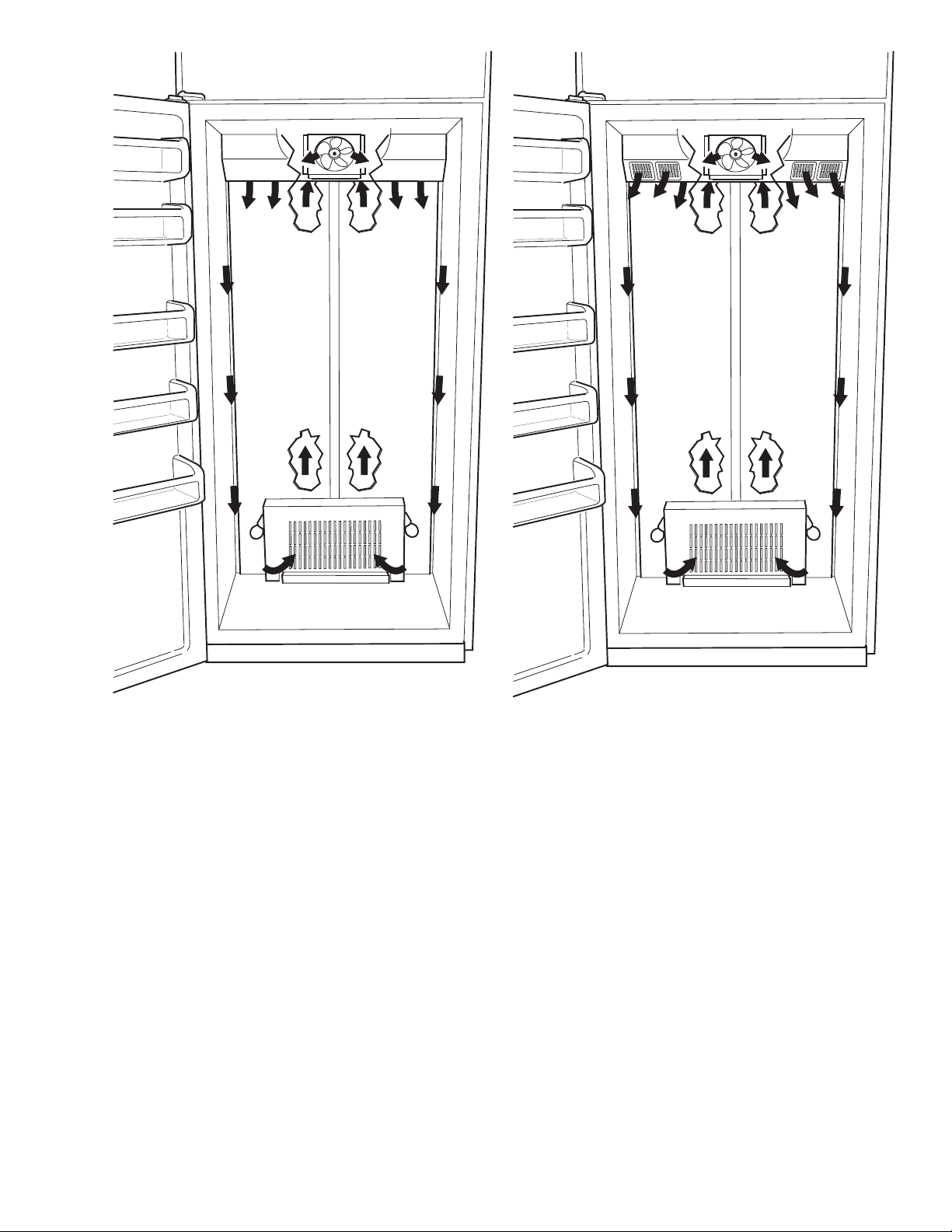

Air Movement

The cabinet is designed so that when the

evaporator fan is operating, air is drawn through

the evaporator and then up the back of the cabinet

through two ducts. At the top of the cabinet, the air

is drawn out of the ducts and through the

evaporator fan into the upper rear duct. Air moves

out of the upper rear duct and into the main part of

the cabinet. In the main part of the cabinet, the

cold air falls into the lower part of the cabinet and

is drawn into the evaporator again.

– 10 –

Refrigerator Air Flow

GEA00637

Freezer Air Flow

GEA00860

– 11 –

Notes

– 12 –

Mechanical Disassembly

Table of Contents

Door Handle (Refrigerator and Freezer) .............................................................. 15

Door Gasket (Refrigerator and Freezer)

Door Hinges (Refrigerator

Upper Door Hinge ............................................................................................. 15

Door Closure Mechanism.................................................................................15

Lower Door Hinge ............................................................................................. 16

Door Adjustment............................................................................................... 16

Door Assembly (Refrigerator

Icemaker (Freezer) .................................................................................................17

Icemaker Water V alve and W ater Line (Freezer)...................................................17

T o Replace the W ater V alve............................................................................... 17

T o Replace the Water Line from the

Water V alve to the Fill Tube Grommet......................................................... 18

and

Freezer) .............................................................. 15

and

................................................................15

Freezer) ......................................................... 16

Upper Light Shield (Refrigerator

Control Panel (Refrigerator

Upper Light Assembly (Refrigerator and Freezer)

Rear Duct (Refrigerator and Freezer)

T emperature Control (Refrigerator

Evaporator Fan (Refrigerator

and

Freezer) ...................................................19

and

Freezer) ............................................................ 19

................................................20

.....................................................................20

and

Freezer)

and

Freezer) ......................................................... 21

...................................................20

– 13 –

Storage Bin (Refrigerator

To Remove Only the Storage Bin......................................................................22

To Remove Both the Storage Bin and

the Bin Support ............................................................................................. 22

To Remove the Showcase Lid ........................................................................... 22

and

Freezer) ................................................................ 22

Storage Bin Slide Support and Center Divider (Refrigerator and Freezer) ...........

To Remove the Left or Right Slide Support .....................................................22

To Remove the Center Divider .......................................................................... 23

Evaporator Cover (Refrigerator

Defrost Heater (Freezer Only)................................................................................23

Evaporator (Refrigerator

Drain Pan Fan (Refrigerator

Grille Panel (Refrigerator

Rocker Switches (Refrigerator

and

and

Freezer)

and

Freezer) .................................................................24

Only

)......................................................................... 24

Freezer)

and

...................................................................25

Freezer) ........................................................ 25

.........................................................23

22

Defrost Control (Freezer) ....................................................................................... 26

PTCR Relay/Overload Cover (Refrigerator and Freezer)

PTCR Relay (Refrigerator

Overload (Refrigerator

Run Capacitor (Refrigerator

Slide-Out Chassis (Refrigerator

and

Freezer)................................................................ 26

and

Freezer).....................................................................27

and

Freezer)............................................................ 27

and

Freezer) ...................................................... 27

........................................26

– 14 –

8

The plug in the wall receptacle is not accessible through the freezer machine compartment

because of the V-shaped condenser. To remove power from the freezer, disconnect the power

cord connector from the machine compartment electrical housing.

Door Handle (Refrigerator and Freezer)

1. Open door to 90 degrees.

2. Remove 6 Phillips screws from the full-length

aluminum handle.

GEA0061

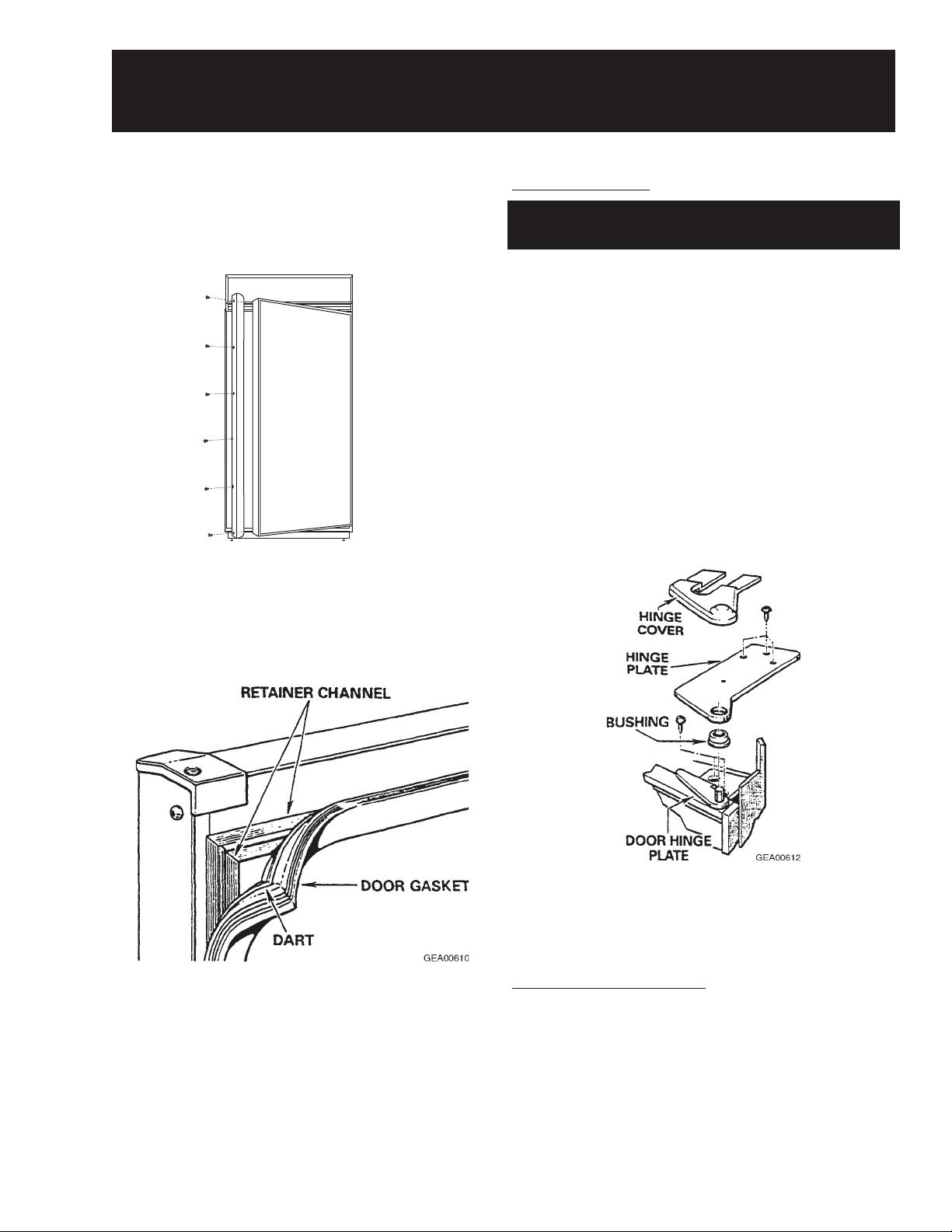

Door Gasket (Refrigerator and Freezer)

Door Hinges (Refrigerator and Freezer)

Upper Door Hinge

Note: There is no adjustment for the upper hinge

assembly.

1. Remove the grille panel (see page 25).

2. Remove 3 Phillips screws and the vent guard.

3. Carefully pry the wire guard above the hinge

upward by inserting a flat head screwdriver

between the bottom edge of the wire guard and

the hinge.

Note: The plastic hinge cover is held by doublesided adhesive tape.

4. Remove the hinge cover.

5. Remove T-20 Torx screws (3) securing the

upper hinge to the top of the cabinet.

Note: The door gasket is held in a retainer

channel.

1. Pull the old gasket out of the channel.

2. Soak the new gasket in warm water to make it

more pliable.

3. Using the back of a teaspoon, push the barbed

edge of the gasket into the retaining channel.

Note: The inner door panel is foamed in place and

is available only as a complete assembly with the

exterior door panel.

6. Remove the hinge and bushing.

7. Remove T -20 Torx screws (4) and the hinge

from the door .

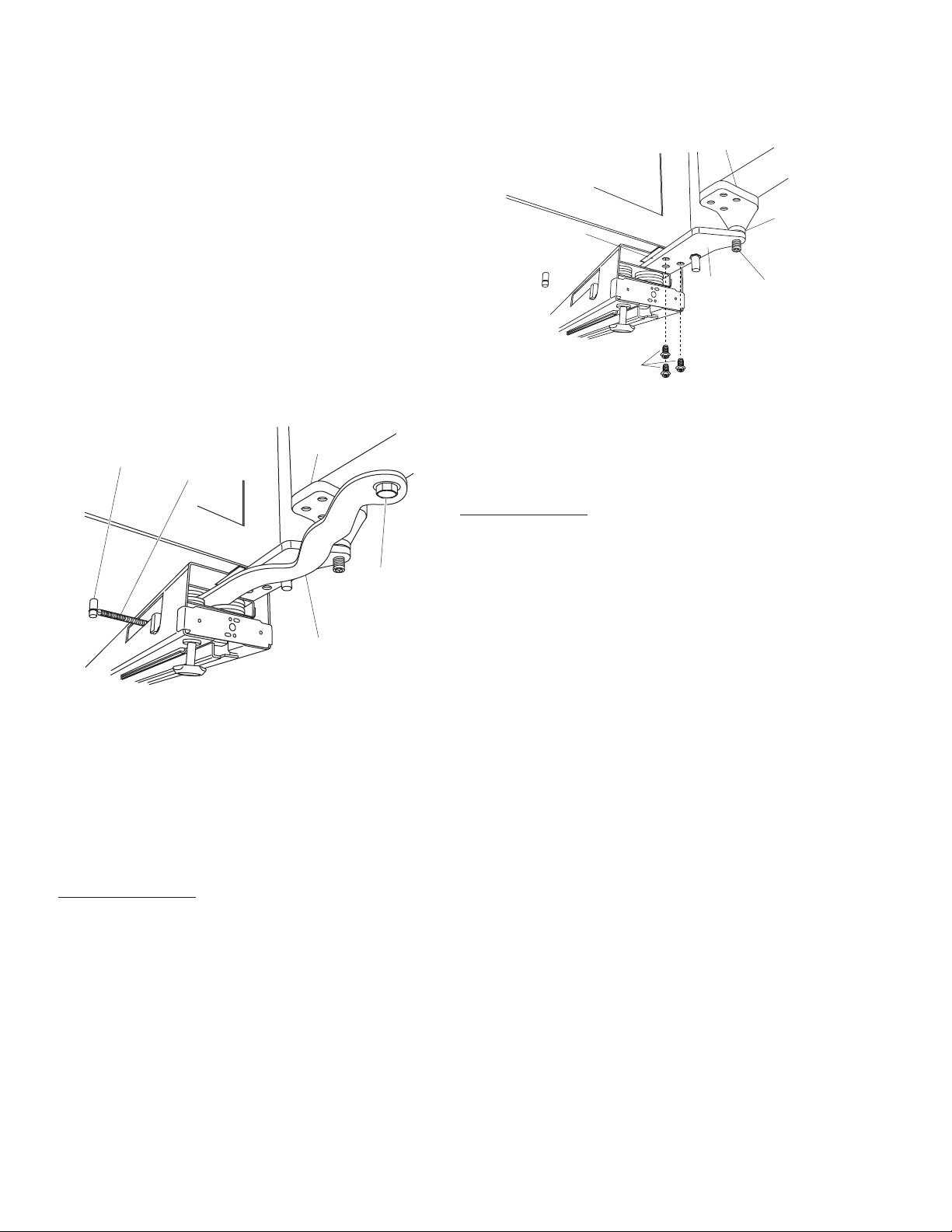

Door Closure Mechanism

The door closure mechanism uses a spring to

provide positive door closure from 30 degrees. The

door closure mechanism actuator arm has a

spring attached to the rear and is supported by

guide rollers on either side of the base channel.

The roller circumferences and the actuator arm

detents are matched for smooth operation. The

arm is attached to the door with an Allen head

shoulder bolt.

– 15 –

The closure mechanism allows easy opening to

4

3

g

B

approximately 90 degrees, where the arm has a

detent to permit the door to remain open at 90

degrees with minimal tension. Once the door is

opened beyond 90 degrees, the closure

mechanism pulls the door open until the closure

arm engages the door stop at approximately 140

degrees. The reverse action occurs when the door

is closed.

Note: Note the placement of spacers and washers

on the actuator arm for reassembly.

• The actuator arm is spring loaded with moderate

spring tension.

2. Remove T-20 Torx screws (3), base channel

spacer , and hinge from the underside of the

cabinet.

Hinge

ase Channel Spacer

Hinge

Bushin

Hinge

Pin

1. Remove the 5/16-in. bolt, washers, and spacer

from the door and actuator arm.

Door

Hinge

Pin

Spring

5/16"

Bolt

Actuator

Arm

GEA0066

2. Remove the icemaker water line from the door

closure mechanism (see page 17).

3. Remove 5 screws. The mechanism is now

loose from the cabinet.

4. Disconnect the spring from the pin on the

bottom of the cabinet.

Lower Door Hinge

1. Remove the door (see the following

procedure).

Note: Note the placement of spacers and washers

for reassembly.

Hinge

Screws

GEA0066

3. Remove T-20 Torx screws (4) fastening the

hinge to the bottom of the door .

4. Remove the hinge.

Door Adjustment

Be sure the top hinge does not hit the cabinet trim.

Adjust the door up or down by turning the threaded

hinge pin on the bottom hinge.

Door Assembly (Refrigerator and Freezer)

WARNING: The door assembly must be removed

by two people.

WARNING: Use the appropriate safety equipment

and lifting techniques.

Caution: Use wood or a heavy plastic sheet to

protect the floor where the door will be placed.

1. Remove all food and bins from the inner door

liner.

Note: Note the placement of spacers and

washers on the actuator arm for reassembly.

• The actuator arm is spring loaded with moderate

spring tension.

2. Remove the 5/16-in. bolt, washers, and spacer

from the door and actuator arm (see the

previous procedure for detailed art).

3. Remove the grille panel (see page 25).

4. Remove 3 Phillips screws from the vent guard.

5. Carefully pry the wire guard above the upper

hinge upward by inserting a flat head

screwdriver between the bottom edge of the

trim and the hinge.

– 16 –

Note: The plastic hinge cover is held by double-

6

6

sided adhesive tape.

4. Unplug the icemaker from the freezer wall and

remove.

6. Remove the hinge cover (see page 15 for

detailed art).

7. Remove T-20 Torx screws (3) securing the

upper hinge to the top of the cabinet.

8. Remove the upper hinge and bushing.

Note: Do not lose lower hinge bushing during

door removal.

9. Pull the top of the door outward until it clears

the top cabinet frame and carefully lift the door

off the lower hinge. Place door on the

protected floor area.

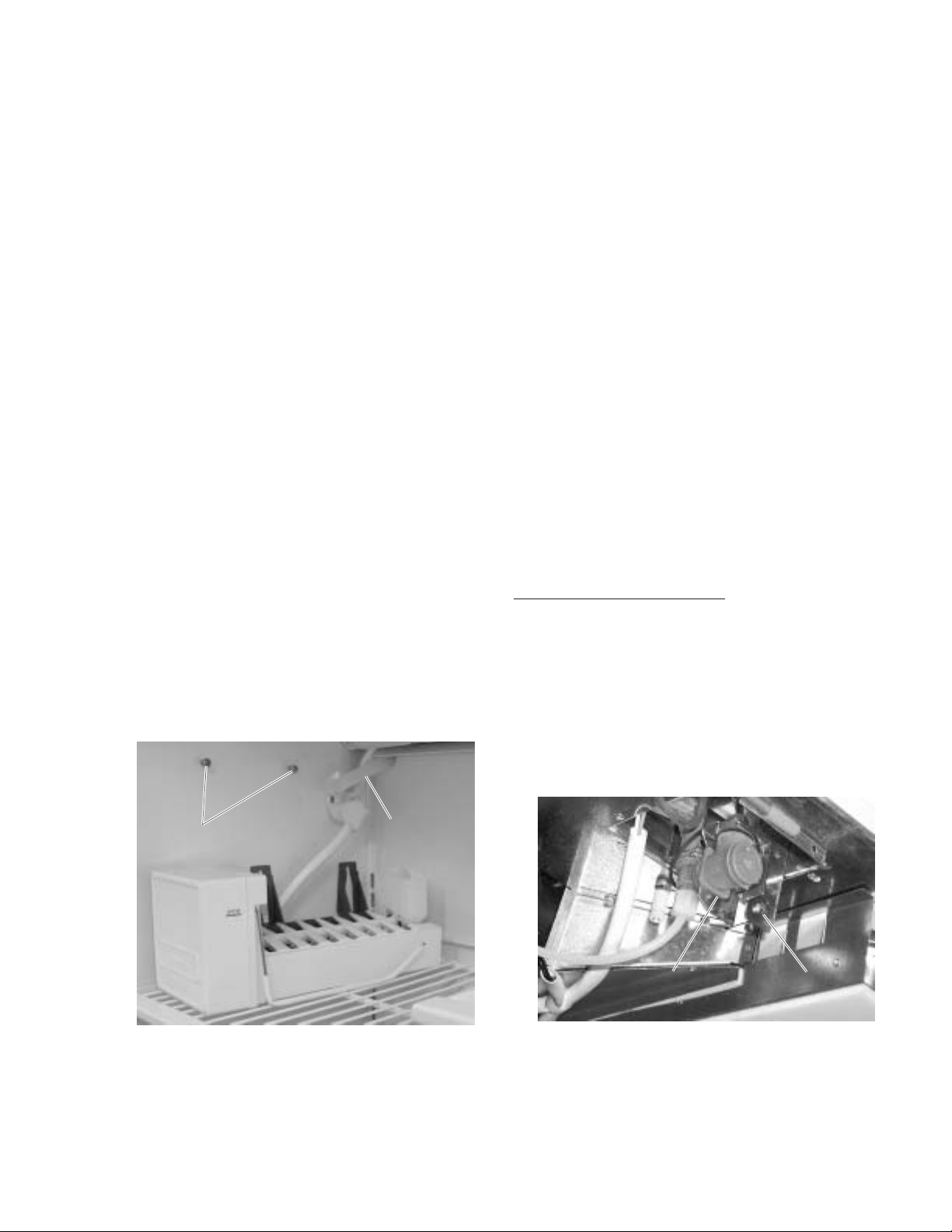

Icemaker (Freezer)

The icemaker is mounted to the upper left wall of

the freezer cabinet. Under normal operating

conditions, temperatures, door openings, and food

load, the icemaker is capable of producing

approximately 100 cubes in a 24 hour period.

1. Loosen 2 Phillips screws above the icemaker.

To service the icemaker, refer to GE Publication

31-4591, 1985 Icemakers.

Icemaker Water V alve and W ater Line

(Freezer)

The water valve is mounted under the cabinet,

beside the door closure mechanism. The valve has

a 1/4-in. stub of copper tubing to provide a

connection to the house water supply. Refer to GE

Publication # 49-60055, GE Monogram 36”

Refrigerators and 36” Freezers Custom

Options Guide and Installation Instructions for

connecting the freezer to the water supply.

A low-pressure plastic water line supplies water to

the icemaker from the water valve. The plastic

water line is routed from the water valve, under the

cabinet, through the back of the door closure

mechanism, and up the outside (back) of the

cabinet. At the top of the outside (back) of the

cabinet, the water line is connected to the fill tube

grommet. The icemaker fill tube is also plastic.

Caution: Use care to avoid damaging the water

tubing.

2. Slide the icemaker upward and pull off from the

screws.

3. Set the icemaker on the top freezer shelf.

ScrewsScrews

Water LineWater Line

GEA0062

To Replace the Water Valve:

Note: Some water may leak from the water supply

line and valve when they are disconnected.

1. Shut off the water supply to the freezer.

2. Remove the metal protective cover.

3. Remove 1 screw and lower the water valve

from the freezer .

ScrewScrewWater ValveWater Valve

GEA0066

– 17 –

Loading...

Loading...