Page 1

MONOGRAM 36" BUILT-IN FRENCH-DOOR

BOTTOM-FREEZER

ZIP360NN

FRENCH-DOOR DESIGN

Gives you wide-open access to every fresh food shelf and bin

FINELY CRAFTED GLASS-FRONT

METAL DOOR BINS

With riveted metal accents offer easy access to beverages

and quick-gra b items

LED LIGHTING

Positioned throughout the interior and under fresh food drawers

spotlights food inside the refrigerator a nd in the freezer

UPFRONT ELECTRONIC CONTROLS

WITH DIGITAL READOUT

Offer a ra nge of precise temperature settings,

all within easy reach

LARGE FULL-EXTENSION FREEZER DRAWER

Has storage bins that slide out independently of one a nother

for easy loading and unloading. An a utomatic ice maker

keeps plenty of filtered ice on hand

PRECISION GLASS-FRONT PRODUCE

AND DELI DRAWERS

Feature full-extension, soft-close slides

ALUMINUM TRIMMED GLASS SHELVES

Allow convenient access to contents in the

fresh-food compartment

For questions about your

appliance, please call 1-800-626-2000.

PAGE 1 OF 12

Product Specication Created 10/19

Page 2

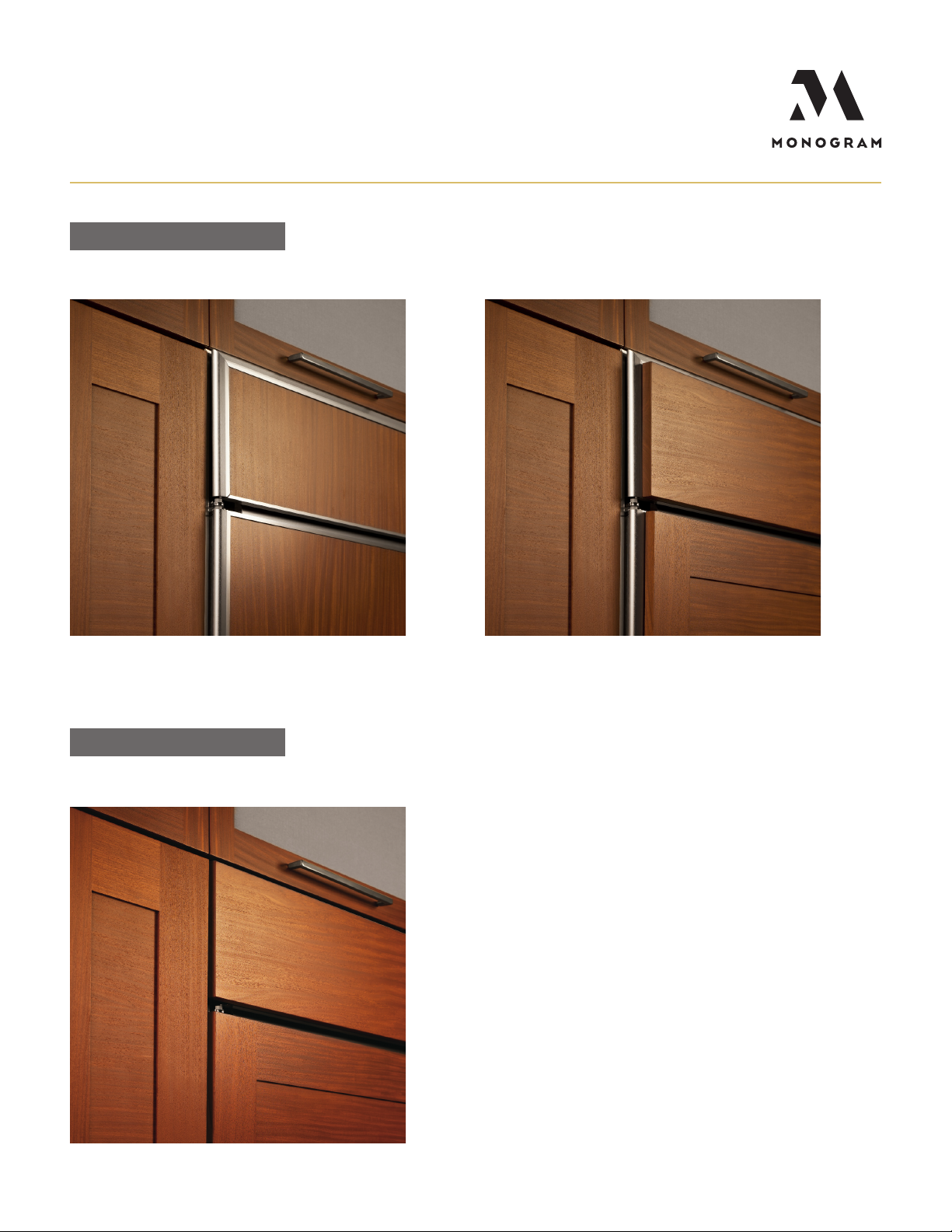

SECTION 1

STANDARD INSTALLATION

1/4" FRAMED PANELS

SECTION 2

3/4" OVERLAY PANELS

FLUSH INSET INSTALLATION

REQUIRES ADDITIONAL TRIM KIT ZKFN

For questions about your

appliance, please call 1-800-626-2000.

PAGE 2 OF 12

Product Specication Created 10/19

Page 3

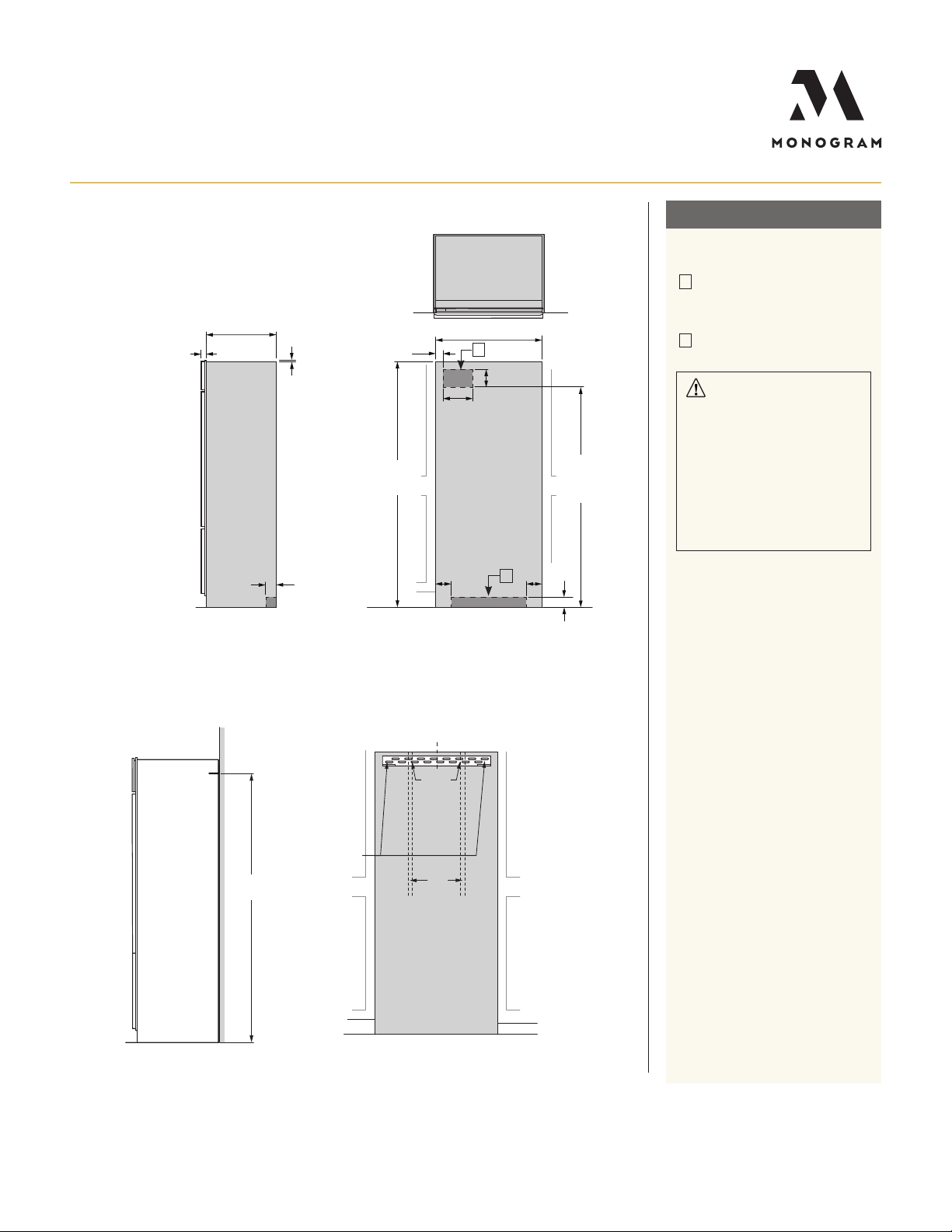

OVERALL DIMENSIONS

36" (91.4)

STANDARD INSTALLATION

25 3/8" (64.5)

23 5/8" (60.0)

10"

(25.4)

3/4"

(1.9)

SPECIFICATIONS

Overall Width 36" (91.4 cm)

Overall Height 84" (213.4 cm)

Overall Depth 25 3/8" (64.5 cm)

Door Clearance 18 1/2" (47 cm)

Cutout Width 35 1/2" (90.2 cm)

Cutout Height 84" (213.4 cm)

Cutout Depth 24" (61 cm)

Plumbing Requirements 1/4" OD copper tubing or

GE SmartConnect kit

Shipping Weight 670 lb (304 kg)

ATTENTION ELECTRICIAN:

A 115 volt 60Hz., 15 or 20 amp power supply is required. An

individual properly grounded branch circuit or circuit breaker

is recommended. Install a properly grounded 3-prong electrical

receptacle recessed into the back wall.

*84"

(213.4)

FRONT VIEW

*73 1/4"

(186.1)

*4 1/8"

(10.5)

* Shipping height. Use leveling legs and wheels for maximum 1"

height adjustment from shipping height.

35" (89.0)

Case width

**12 7/8"

(32.7)

4 9/16"

(11.6)

Allow 4" (10.2) min

clearance to wall for

90º door swing

**130° Door swing

Doors can be adjusted to

90° door swing

TOP VIEW

**12 7/8"

(32.7)

4 9/16"

(11.6)

Allow 4" (10.2) min

clearance to wall for

90º door swing

(SHOWING DOOR SWING)

** Dimensions based on custom handle height of 2 9/16" (6.5).

*83 1/2"

(212.1)

SIDE VIEW

18 3/16"

(46.2)

For questions about your

appliance, please call 1-800-626-2000.

Dimensions in parentheses a re in centimeters unless otherwise noted.

Actual product dimensions may vary due to ma nufacturing tolerances.

Product Specication Created 10/19PAGE 3 OF 12

Page 4

STANDARD INSTALLATION 3/4" PANELS

24" (61)

1 9/16"

(3.97)

7/16"

Trim overlap

(1.1)

2 5/16"

(5.874)

*84"

(213.4)

*Trim will overlap

additional 7/16"

TOP VIEW

35 1/2" (90.2)

ELEC.

10"

(25.4)

STANDARD INSTALLATION

HELPFUL TIPS

A

Mounting the junction box in this

location will also allow for front

accessibility through access panel.

B

A

6"

(15.24)

Water supply a rea.

WARNING:

e refrigerator is top heavy

and must be secured to prevent

the possibility of tipping forward.

75"

(190.5 )

From floor

to bottom

of electrical

area

Failure to do so may result in dea th

or serious injury.

e information below is for ca binet

design only. When installing the

anti-tip system you must use the

product installation instructions.

ANTI-TIP BRACKET

SIDE VIEW INSTALLED

WITH ANTI-TIP BRACKET

SIDE VIEW

81 1/2"

(207.0)

3 1/2"

(8.9)

additional hole

locations at end

Bracket

mounted

into vertical

wall studs

centered

within the

cutout

Ensure holes

selected are

Use two

of brackets

centered on

the studs

Studs

FRONT VIEW OF CUTOUT

WITH ANTI-TIP BRACKET

5"

(12.7)

WATERW

FRONT VIEW

C

L

Wall

3 1/2"

5"

(8.9)

(12.7)

B

e information below applies to all

installation constructions:

• A wall bracket, bolts and toggles will

be supplied with the unit.

• e bolts will be used to attach

bracket to wall in 4 locations. Two

of the locations must penetra te the

center of the wall studs.

• e toggles are used for sta bility in

drywall and when metal studs a re

encountered. Lag bolts are used in

wood studs.

• In installation opening, measure

81-1/2" from floor and draw a

horizontal line.

• Locate a nd mark the wall studs on

horizontal line. Verify at least two

studs have their centerlines within

the center 32-1/2" of installation

opening to ensure 2 wall studs are

penetrated.

• e bracket will be centered left

to right in opening with bottom of

bracket on the horizontal line.

• When unit is placed in opening, the

bracket tabs will align with openings

in back of the unit. e unit will be

secured to the bracket using supplied

“L” bolts.

See Installation Instructions for

detailed instructions.

For questions about your

appliance, please call 1-800-626-2000.

PAGE 4 OF 12

Product Specication Created 10/19

Page 5

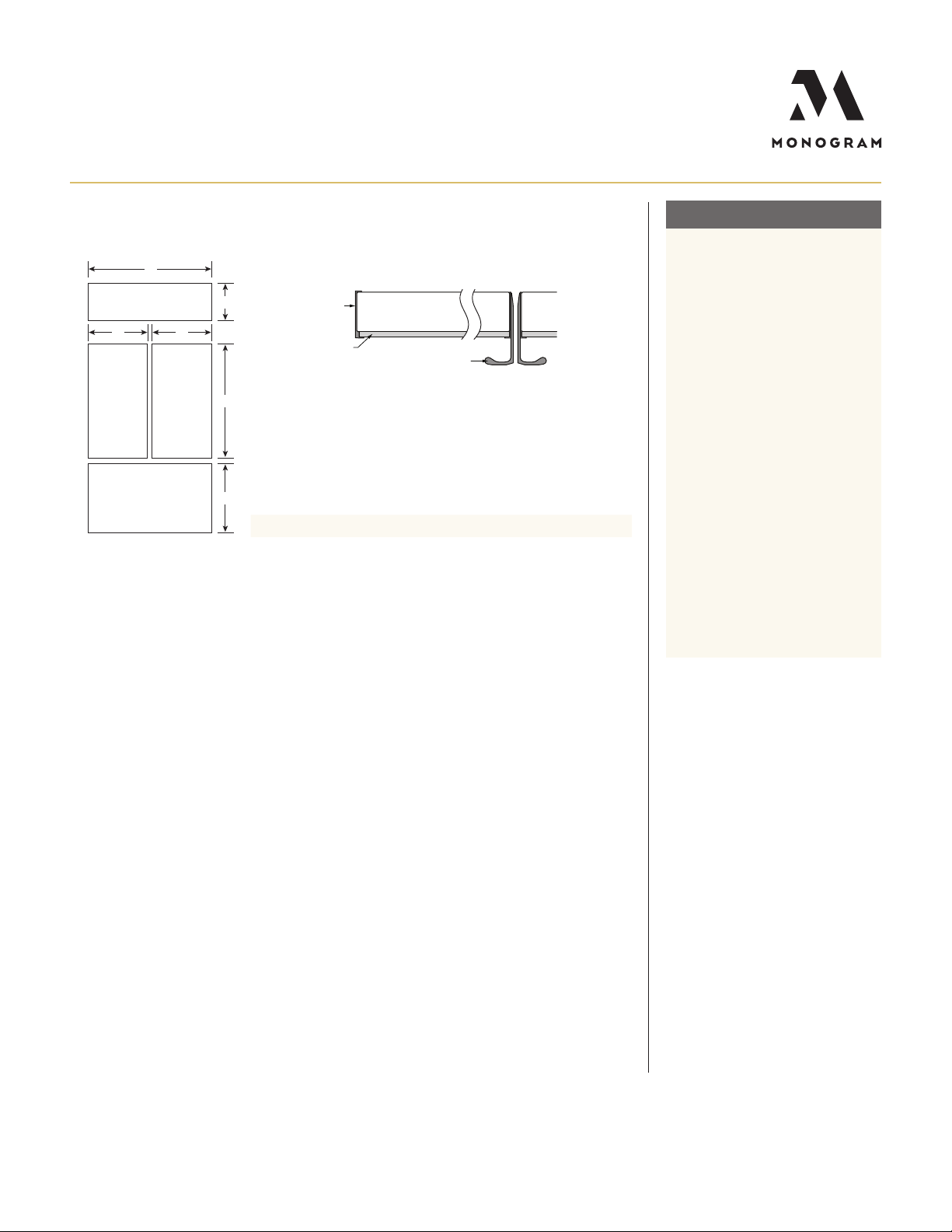

1/4" Framed Panel

STANDARD 1/4" FRAMED PANEL DIMENSIONS

A

Grille Panel

E E

PANEL ASSEMBLY CROSS SECTION

B

Trim

Door

STANDARD INSTALLATION

HELPFUL TIPS

Trimmed refrigerators a re designed

to be customized with decorative

panels Field-installed custom door

and grille pa nels are required.

Fresh

Food

Panel

Freezer Drawer Panel

Fresh

Food

Panel

Optional ZKLN kit handles

C

PANEL DIMENSIONS

D

A B C D E

1/4" Framed Panel 33 7/8" 8 7/8" 46 1/16" 21 7/8" 16 1/2"

1/4" FRAMED PANELS:

For 1/4" thick custom panels

ordered from your cabinet maker.

e decorative pa nels slide into

this trim.

MAXIMUM TOTAL PANEL

WEI GHT:

• Fresh food door panel – 30 lbs.

• Freezer drawer panel – 28 lbs.

• Grille panel – 11 lbs

DOOR HANDLES:

Door handles not included. Custom

handles supplied by your ca binet

maker may be used. Optional visor

handle kit ZKLN ava ilable.

For questions about your

appliance, please call 1-800-626-2000.

PAGE 5 OF 12

Product Specication Created 10/19

Page 6

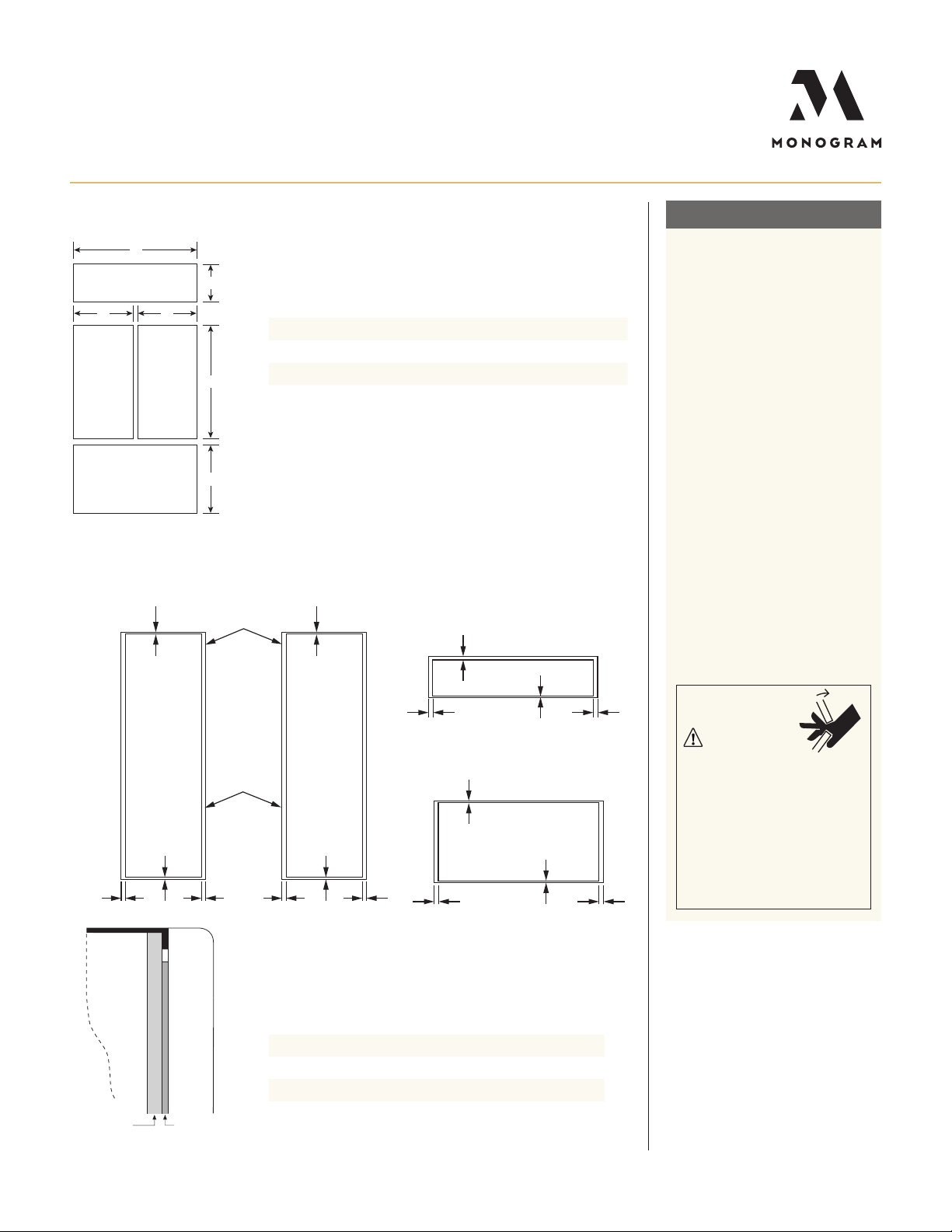

A

STANDARD 3/4" OVERLAY PANEL DIMENSIONS

STANDARD INSTALLATION

PANEL ASSEMBLY CROSS SECTION

Grille Panel

E E

Fresh

Food

Panel

Fresh

Food

Panel

B

1/4" Backer Panel

.10" Spacer Panel

C

PANEL DIMENSIONS

1/4" Framed Panel 33 7/8" 8 7/8" 46 1/16" 21 7/8" 16 1/2"

Freezer Drawer Panel

D

.10" Framed Panel 32 1/2" 7 5/8" 44 11/16" 20 1/2" 15"

3/4" Overlay Panel 34 1/8" 9" 46 5/16" 22" 16 5/8"

.25" + .10" + .75" = 1.10" Total Panel Thickness

1/4" BACKER ASSEMBLY DIMENSIONS

Hinge Side

C

C

Trim

Optional ZKLN kit handles

Door

3/4" Overlay Panel

A B C D E

Grille Back

C

A B

HELPFUL TIPS

Trimmed refrigerators a re designed to

be customized with decorative pa nels

Field-installed custom door and grille

panels a re required.

3/4" OVERLAY PANELS:

For your 3/4" thick custom panels

ordered from your cabinet maker the

overlay panel must be secured to a

1/4"-thick backer panel which slides

into the trim. A spacer panel 0.10"

thick must be placed between the

overlay and backer pa nels.

Center each panel over the other.

Assemble the panels with glue a nd

screws. Screws must be countersunk

into the backer panel.

NOTE : Left-to-right offset is not

always equal to top-to-bottom offset.

MAXIMUM TOTAL PANEL

WEI GHT:

• Fresh food door panel – 30 lbs.

• Freezer drawer panel – 28 lbs.

• Grille panel – 11 lbs

DOOR HANDLES:

Door handles not included. Custom

handles supplied by your ca binet

maker may be used. Optional visor

D

handle kit ZKLN ava ilable.

Backer with

Overlay Panel

Assembly

Fresh Food

Back

B

1/4"

A

Overlay

Panel

Spacer

1/2"

.10"

Door

Backer

Panel

For questions about your

appliance, please call 1-800-626-2000.

Fresh Food

Back

A

B

DD

C

Freezer Drawer

A

B

D

PANEL DIMENSIONS

A B C D

Fresh Food Door Panels 1/8" 0 1/8" 1/8"

Freezer Drawer Panel 1/8" 1/8" 1/16" 1/16"

Grille Panel 1/8" 1/8" 1/16" 1/16"

PAGE 6 OF 12

Product Specication Created 10/19

Page 7

OVERALL DIMENSIONS

AFTER PANEL INSTALL

FLUSH INSET

INSTALLATION

SPECIFICATIONS

Overall Width

Overall Height

Overall Depth

Door Clearance

Cutout Width

Cutout Height

Cutout Depth

Plumbing Requirements

38" (96.5 cm)

84 1/2" (214.6 cm)

25 7/8" (65.9 cm)

19 1/2" (49.5 cm)

39" (99.1 cm)

85" (215.9 cm)

26 3/16" (66.5 cm)

1/4" OD copper tubing or

GE SmartConnect kit

Shipping Weight

670 lb (304 kg)

ATTENTION ELECTRICIAN:

A 115 volt 60Hz., 15 or 20 amp power supply is required. An

individual properly grounded branch circuit or circuit breaker

is recommended. Install a properly grounded 3-prong electrical

receptacle recessed into the back wall.

38" (96.5)

10 13/16"

(27.5)

*84 1/2"

(214.6)

* Shipping height. Use leveling legs and wheels for maximum

1" height adjustment from shipping height.

35" (88.9)

Case width

**8"

(20.3)

*115° Door swing

Doors can be adjusted to

90° door swing

4 9/16" (11.6) min

Allow

clearance to a wall for

90º door swing

** Dimensions based on custom handle height of 2 9/16" (6.5).

TOP VIEW

*73 1/4"

(186.1)

7/16"

(1.1)

*26 3/8"

(70.0)

20 5/8"

(52.5)

Allow 4 9/16" (11.6) min

clearance to a wall for

90º door swing

**8"

(20.3)

*4"

(10.2)

25 7/8" (65.7)

SIDE VIEWFRONT VIEW

19 1/2"

(49.5)

20 5/8" (52.4)

*83 1/2"

(212.1)

For questions about your

appliance, please call 1-800-626-2000.

Dimensions in parentheses a re in centimeters unless otherwise noted.

Actual product dimensions may vary due to ma nufacturing tolerances.

Product Specication Created 10/19PAGE 7 OF 12

Page 8

FLUSH INSET INSTALLATION 3/4" PANELS

FLUSH INSET INSTALLATION

FLUSH INSET KIT ZKFN REQUIRED

26 3/16" (66.5)

Flush inset depth

20 15/16" (53.2)

Depth to cleat

Finished cleats

85"

(215.9)

3 1/2"

W

ANTI-TIP BRACKET

81 1/2"

(207.0)

SIDE VIEW INSTALLED

WITH ANTI-TIP BRACKET

(8.9)

5 1/4" (13.3)

3/4" (1.9)

Width of side cleats

4 1/16"

85"

(215.9)

Use two

additional hole

locations at end

of brackets

TOP VIEW

Case

Finished cleats

Case Trim

3/4" Panel

Door

39" (99.1) Flush inset width

37 1/2" (95.3)

Width between cleats

6"

(15.2)

(11.0)

ELEC.

10"

(25.4)

B

7"

(17.8)

7"

(17.8)

B

WATER

FRONT VIEWSIDE VIEW

C

L

Bracket

mounted

into vertical

wall studs

centered

within the

cutout

Ensure holes

selected are

centered on

the studs

Wall

Studs

FRONT VIEW OF CUTOUT

WITH ANTI-TIP BRACKET

1/2" (1.3)

75 1/2"

(191.8 )

From floor

to bottom

of electrical

3 1/2"

(8.9)

area

HELPFUL TIPS

A

Mounting the junction box in this

location will also allow for front

accessibility through access panel.

B

Water supply a rea

A

WARNING:

e refrigerator is top heavy a nd

must be secured to prevent the

possibility of tipping forward.

Failure to do so may result in

death or serious injury.

e information below is for ca binet

design only. When installing the antitip system you must use the product

installation instructions.

e information below applies to all

installation constructions:

• A wall bracket, bolts and toggles will

be supplied with the unit.

• e bolts will be used to attach

bracket to wall in 4 locations. Two

of the locations must penetra te the

center of the wall studs.

• e toggles are used for sta bility in

drywall and when metal studs a re

encountered. Lag bolts are used in

wood studs.

• In installation opening, measure

81-1/2" from floor and draw a

horizontal line.

• Locate a nd mark the wall studs on

horizontal line. Verify at least two

studs have their centerlines within

the center 32-1/2" of installation

opening to ensure 2 wall studs are

penetrated.

• e bracket will be centered left to

right in opening with bottom of

bracket on the horizontal line.

• When unit is placed in opening, the

bracket tabs will align with openings

in back of the unit. e unit will be

secured to the bracket using supplied

“L” bolts.

See Installation Instructions for

detailed instructions.

For questions about your

appliance, please call 1-800-626-2000.

Product Specication Created 10/19PAGE 8 OF 12

Page 9

FLUSH INSET 3/4" PANEL DIMENSIONS

FLUSH INSET INSTALLATION

A

Grille Panel

E E

B

PANEL DIMENSIONS

A B C D E

Fresh

Food

Panel

Freezer Drawer Panel

Fresh

Food

Panel

C

D

38" 10 13/16" 46 7/16" 22 3/8" 18 3/4"

3/4" RAISED FRESH FOOD DOOR PANELS ROUTING

11/32"

1/4"

DETAIL TOP

3/4"

1/4"

7/16"

NOTE: Routed areas should

be finished as they may be

visible when assembled.

Front

TOP

HELPFUL TIPS

Trimmed refrigerators a re designed

to be customized with decorative

panels. Field-installed 1/2" or 3/4"

custom door, drawer and grille

panels a re required. For 3/4" raised

panels, routing is required. e router

depth is 1/4" all the way around

the panel’s backs. Additional pa nel

width reductions are required per

the diagrams shown. is will crea te

“picture frame’ routing allowing the

panels to slide into the a ttached door,

drawer and grille trims.

MAXIMUM TOTAL PANEL

WEI GHT:

• Fresh food door panels – 30 lbs.

• Freezer drawer panel – 28 lbs.

• Grille panel – 11 lbs

NOTE : For panels constructed with

rails a nd stiles (5-panel), the rails must

be a minimum of 3” wide a nd stiles

must be a minimum of 4” wide.

DOOR HANDLES

Door handles not included. Custom

handles supplied by your ca binet

maker may be used.

Back

1/4"

CORNER VIEW SHOWING

DETAIL BOTTOM

HINGE SIDE HANDLE SIDE

ROUTER DEPTH 1/4" ROUTER DEPTH 1/4"

2 1/16"

LEFT

SIDE

3/4" PANEL BOTTOM VIEW

(AFTER ROUTING)

“PICTURE FRAME” ROUTING

Front

Back

For questions about your

appliance, please call 1-800-626-2000.

RIGHT

SIDE

3/16"

FrontBack

BOTTOM

3/4" PANEL SIDE VIEW

(AFTER ROUTING)

WARNING:

Door Trim Pinch Point Haza rd

Improper installation ca n lead to a

finger pinch point haza rd between

the side door trim and the ca binets

when operating the door, especially

with children. To minimize this risk

you must follow the installation

instructions for cabinet dimensions,

trim assembly and door stop a ngle.

Product Specication Created 10/19PAGE 9 OF 12

Page 10

3/4" RAISED FREEZER DRAWER PANEL ROUTING

TOP

DETAIL TOP

11/32"

LEFT SIDE

3/4"

1/4"

1/4"

DETAIL BOTTOM

DETAIL

ROUTER DEPTH 1/4"

2 1/16" 2 1/16"

LEFT

SIDE

1/2"

1/4"

3/4" PANEL BOTTOM VIEW

(AFTER ROUTING)

NOTE: Routed areas should

be finished as they may be

visible when assembled.

Back

CORNER VIEW SHOWING

“PICTURE FRAME” ROUTING

Front

Back

ROUTER DEPTH 1/4"

3/4" RAISED GRILLE PANEL ROUTING

Front

DETAIL RIGHT

SIDE

RIGHT

SIDE

TOP

FrontBack

BOTTOM

3/4" PANEL SIDE VIEW

(AFTER ROUTING)

FLUSH INSET INSTALLATION

HELPFUL TIPS

Trimmed refrigerators a re designed

to be customized with decorative

panels. Field-installed 1/2" or 3/4"

custom door, drawer and grille

panels a re required. For 3/4" raised

panels, routing is required. e

router depth is 1/4" all the way

around the pa nel’s backs. Additional

panel width reductions a re required

per the diagrams shown. is will

create “picture fra me’ routing

allowing the panels to slide into the

attached door, drawer a nd grille

trims.

MAXIMUM TOTAL PANEL

WEIGHT:

• Fresh food door panels – 30 lbs.

• Freezer drawer panel – 28 lbs.

• Grille panel – 11 lbs

NOTE : For panels constructed with

rails a nd stiles (5-panel), the rails

must be a minimum of 3” wide a nd

stiles must be a minimum of 4” wide.

DOOR HANDLES

Door handles not included. Custom

handles supplied by your ca binet

maker may be used.

DETAIL TOP

ROUTER DEPTH 1/4"

1 11/16"

LEFT SIDE

1/4"

DETAIL BOTTOM

LEFT

SIDE

For questions about your

appliance, please call 1-800-626-2000.

NOTE: Routed areas should

be finished as they may be

visible when assembled.

Front

Back

CORNER VIEW SHOWING

“PICTURE FRAME” ROUTING

DETAIL

ROUTER DEPTH 1/4"

2 1/16" 2 1/16"

Front

Back

3/4" PANEL BOTTOM VIEW

(AFTER ROUTING)

DETAIL RIGHT

SIDE

ROUTER DEPTH 1/4"

RIGHT

SIDE

FrontBack

BOTTOM

3/4" PANEL SIDE VIEW

(AFTER ROUTING)

Product Specication Created 10/19PAGE 10 OF 12

Page 11

FLUSH INSET INSTALLATION 1/2" PANELS

FLUSH INSET INSTALLATION

FLUSH INSET KIT ZKFN REQUIRED

26 3/16" (66.5)

Flush inset depth

20 13/16" (52.9)

Depth to cleat

Finished cleats

85"

(215.9)

W

ANTI-TIP BRACKET

81 1/2"

(207.0)

3 1/2"

(8.9)

5 3/8" (13.7)

3/4" (1.9)

Width of side cleats

4 1/16"

85"

(215.9)

Use two

additional hole

locations at end

of brackets

TOP VIEW

Finished cleats

Case Trim

1/2" Panel

39" (99.1) Flush inset width

Width between cleats

ELEC.

(11.0)

7"

(17.8)

(25.4)

FRONT VIEWSIDE VIEW

Ensure holes

Case

Door

37 1/2" (95.3)

10"

WATER

C

L

Bracket

mounted

into vertical

wall studs

centered

within the

cutout

selected are

centered on

the studs

Wall

Studs

6"

(15.2)

B

7"

(17.8)

1/2" (1.3)

75 1/2"

(191.8 )

From floor

to bottom

of electrical

3 1/2"

(8.9)

area

HELPFUL TIPS

A

Mounting the junction box in this

location will also allow for front

accessibility through access panel.

B

Water supply a rea

A

WARNING:

e refrigerator is top heavy a nd

must be secured to prevent the

possibility of tipping forward.

Failure to do so may result in

death or serious injury.

e information below is for

cabinet design only. When installing

the anti-tip system you must use the

product installation instructions.

e information below applies to

all installation constructions:

• A wall bracket, bolts and toggles will

be supplied with the unit.

• e bolts will be used to attach

bracket to wall in 4 locations. Two

of the locations must penetra te the

center of the wall studs.

• e toggles are used for sta bility in

drywall and when metal studs a re

encountered. Lag bolts are used in

wood studs.

• In installation opening, measure

81-1/2" from floor and draw a

horizontal line.

• Locate a nd mark the wall studs on

horizontal line. Verify at least two

studs have their centerlines within the

center 32-1/2" of installation opening

to ensure 2 wall studs are penetra ted.

• e bracket will be centered left to

right in opening with bottom of

bracket on the horizontal line.

• When unit is placed in opening, the

bracket tabs will align with openings

in back of the unit. e unit will be

secured to the bracket using supplied

“L” bolts.

See Installation Instructions for

detailed instructions.

SIDE VIEW INSTALLED

WITH ANTI-TIP BRACKET

For questions about your

appliance, please call 1-800-626-2000.

FRONT VIEW OF CUTOUT

WITH ANTI-TIP BRACKET

Product Specication Created 10/19PAGE 11 OF 12

Page 12

FLUSH INSET 1/2" PANEL DIMENSIONS

A

Grille Panel

E E

B

PANEL DIMENSIONS

1/4" Backer Panel

.10" Space Panel 32 1/2" 7 5/8" 44 11/16" 20 1/2" 15"

Fresh

Food

Panel

Freezer Drawer Panel

Fresh

Food

Panel

C

D

1/2" Overlay Panel 38" 10 13/16" 46 7/16" 22 3/8" 18 3/4"

1/4" BACKER ASSEMBLY DIMENSIONS

A B C D E

33 7/8" 8 7/8" 46 1/16 21 7/8" 16 1/2"

FLUSH INSET INSTALLATION

HELPFUL TIPS

e 1/2" overlay panel must be

secured to a .10" spacer pa nel and a

1/4" thick backer panel, which slides

into the trim.

ASSEMBLE THE PANELS

WITH GLUE AND SCREWS:

• Center the spacer panel on the

backer panel, left to right a nd top to

bottom. Secure the panels with glue.

• Refer to the chart for loca ting the

backer panel to the overlay pa nel.

Secure the overlay panel to the

backer panel with glue a nd screws.

Screws must be countersunk into

the backer panel.

MAXIMUM TOTAL PANEL

WEI GHT:

• Fresh food door panel – 30 lbs.

• Freezer drawer panel – 28 lbs.

• Grille panel – 11 lbs.

Hinge Side

NOTE: For pa nels constructed with

rails a nd stiles (5-panel), the rails

C

C

Grille Back

C

A B

D

must be a minimum of 3" wide a nd

stiles must be a minimum of 4" wide.

WARNING:

Backer with

Overlay Panel

Assembly

Door Trim Pinch Point Haza rd

Improper installation ca n lead to a

finger pinch point haza rd between

Fresh Food

Back

Fresh Food

Back

C

Freezer Drawer

the side door trim and the ca binets

when operating the door, especially

with children. To minimize this risk

you must follow the installation

instructions for cabinet dimensions,

B

A

A

B

DD

A

B

D

Door

1/2"

Overlay

Panel

PANEL DIMENSIONS

trim assembly and door stop a ngle.

A B C D

Fresh Food Door Panels 2 1/16" 3/16" 3/16" 3/16"

Freezer Drawer Panel 2 1/16" 2 1/16" 1/4" 1/4"

Grille Panel 2 1/16" 2 1/16" 1 11/16" 1/4"

1/4"

Backer

Panel

.10"

Spacer

For questions about your

appliance, please call 1-800-626-2000.

Product Specication Created 10/19PAGE 12 OF 12

Loading...

Loading...