Page 1

SECTION 1

FLUSH INSET INSTALLATION

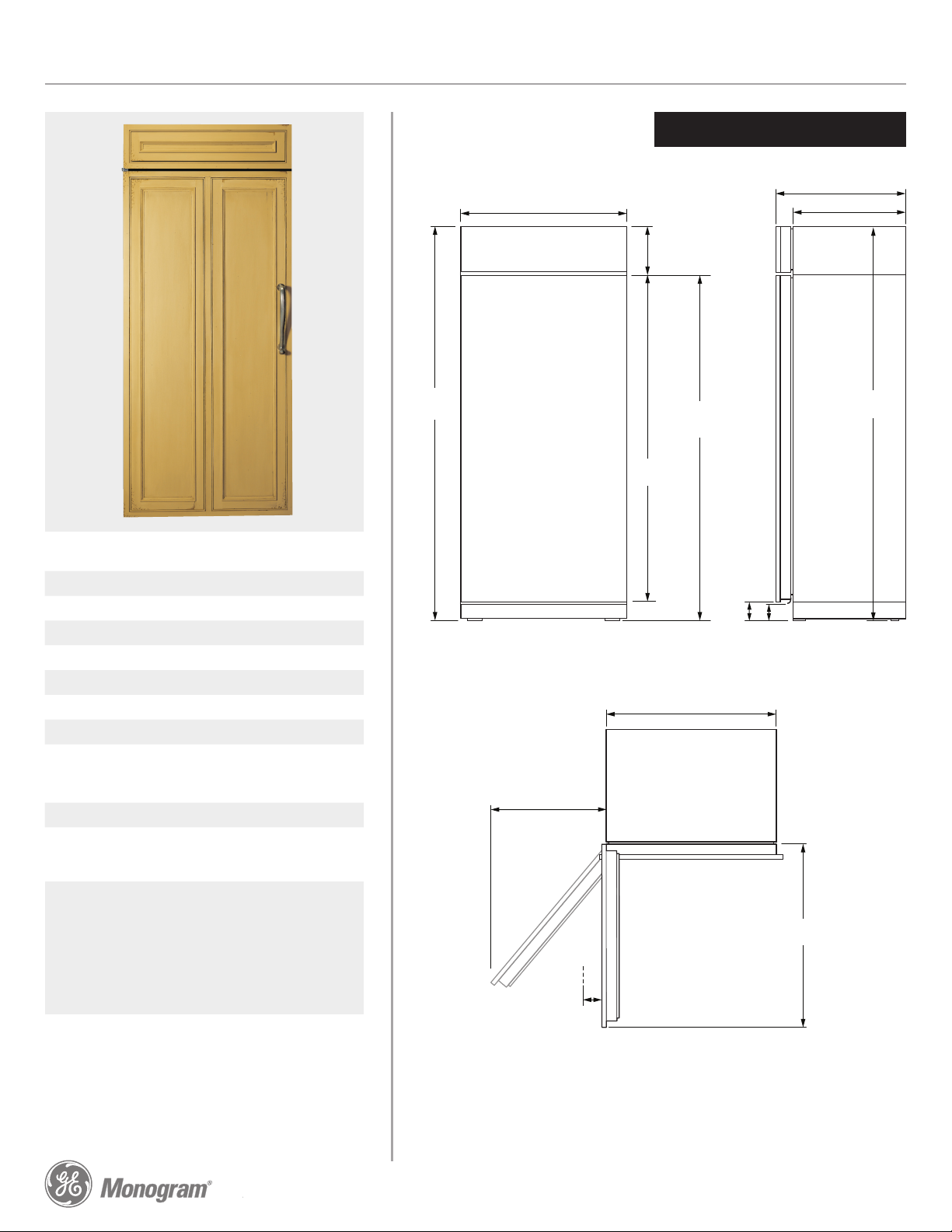

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

SECTION 2

STANDARD INSTALLATION

1/4" FRAMED PANELS 3/4" OVERLAY PANELS

Product Specification Revised 10/14

Page 2

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

SPECIFICATIONS

Overall Width 38" (96.5 cm)

Overall Height 83 1/2" (212.1 cm)

Overall Depth 25 7/8" (65.7 cm)

Door Clearance 38 3/4" (98.4 cm)

Cutout Width 39" (99.1 cm)

Cutout Height 84 1/2" (214.6 cm)

Cutout Depth 26 3/16" (66.5 cm)

Plumbing Requirements 1/4" OD copper

tubing or GE

SmartConnect kit

Shipping Weight 570 lb (258.5 kg)

†

OVERALL DIMENSIONS

FLUSH INSET INSTALLATION

25 7/8" (65.7)

*3"

(7.6)

20 5/8" (52.4)

* 83 1/2"

(212.1)

SIDE VIEW

38" (96.5)

10 5/16"

(26.2)

*83 1/2"

(212.1)

†

†

FRONT VIEW

* Shipping height . Use leveling legs and wheels for maximum 1" height

adjustment from shipping height. Nominal installation height is 84".

** Allow 17" (43.2) min

clearance for 115˚

door swing

*73 1/4"

69 13/16"

(177.3)

35" (89.0)

Case width

(186.1)

*3 3/8"

(8.6)

† Dimensions include 3/4" custom cabinet panel

ATTENTION ELECTRICIAN:

A 115 volt 60Hz., 15 or 20 amp power supply

is required. An inidividual properly grounded

branch circuit or circuit breaker is recommended.

Install a properly grounded 3-prong electrical

receptacle recessed into the back wall.

TOP VIEW

38 3/4"

(98.4)

** Allow 4" (10.2) min

clearance to a wall

for 90˚ door swing

** These freezers are equipped with a 2-position door stop. The factory-set 115° door

swing can be adjusted to 90° if clearances to adjacent cabinets or walls is restricted. Allow

a 15" minimum clearance to wall for pan removal. If the 90° door stop position is used, pan

access is maintained, but pan removal is restricted.

Dimensions in parentheses are in centimeters unless otherwise noted.

Actual product dimensions may vary due to manufacturing tolerances.

Product Specification Revised 10/14

Page 3

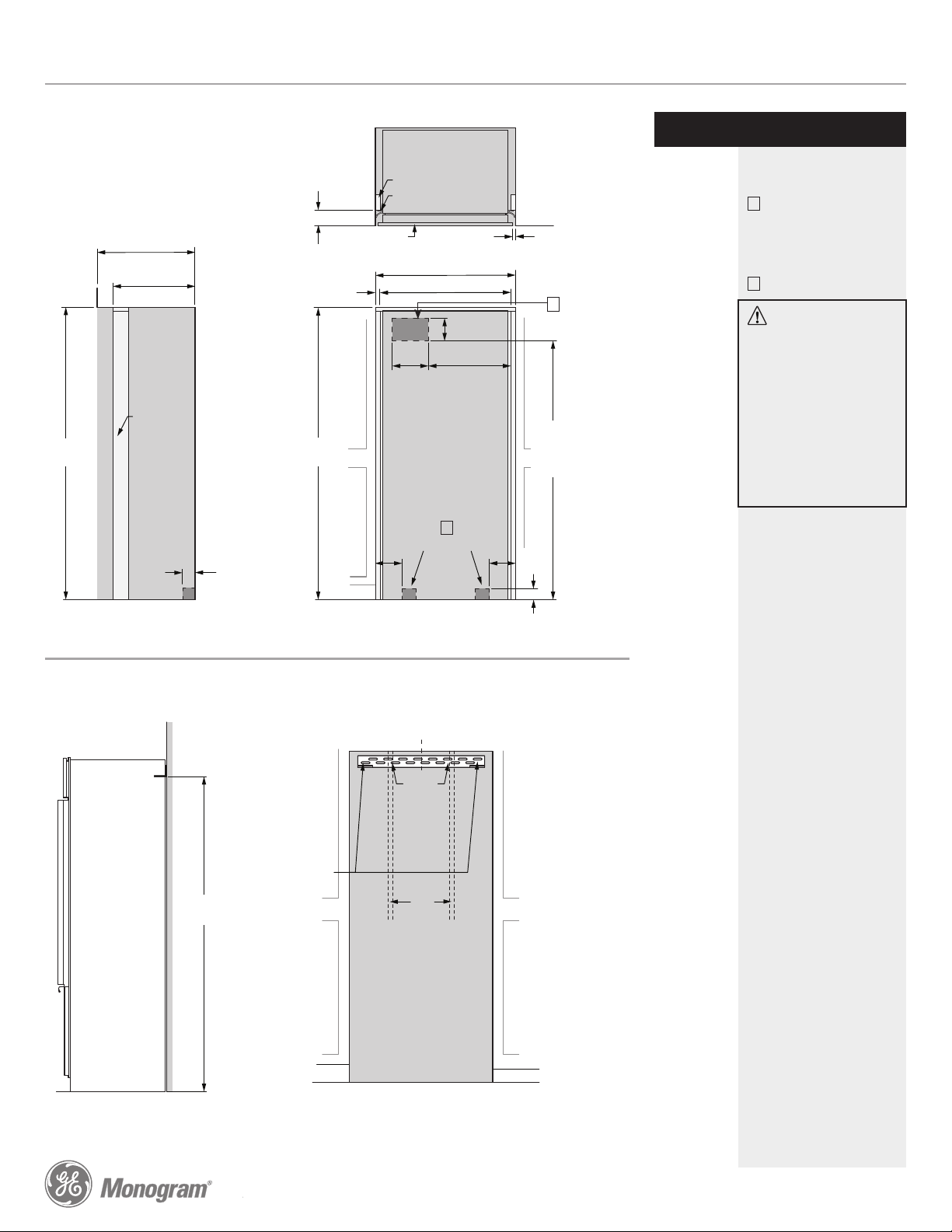

FLUSH INSET INSTALLATION 3/4" PANELS

24" (61.0)

1 1/2"

(3.8)

3"

(7.6)

7/16"

(1.1)

Trim overlap

35 1/2" (90.2)

2 5/16"

(5.9)

SIDE VIEWFRONT VIEW

3 1/2"

(8.9)

75"

(190.5 )

From floor

to bottom

of electrical

area

ELEC.

6"

(15.2)

10"

(25.4)

WATER

5"

(12.7)

5"

(12.7)

3 1/2"

(9.0)

WATER

10" (25.4)

FLUSH INSET INSTALLATION 3/4" PANELS

26 3/16" (66.5)

Flush inset depth

20 15/16" (53.2)

Depth to cleat

84 1/2"

(214.6)

Finished cleats

3 1/2"

(8.9)

W

ANTI-TIP BRACKET

81 1/2"

(207.0)

SIDE VIEW INSTALLED

WITH ANTI-TIP BRACKET

5 1/4" (13.3)

3/4" (1.9)

Width of side cleats

84 1/2"

(214.6)

Use two

additional hole

locations at end

of brackets

TOP VIEW

Case

Finished cleats

Case Trim

Door

3/4" Panel

39" (99.1) Flush inset width

37 1/2" (95.3)

Width between cleats

ELEC.

9"

(22.9)

5 1/2"

(14.0)

26 3/16"

(66.5)

B

7"

(17.8)

WATER

3 1/2"

(9.0)

7"

(17.8)

FRONT VIEWSIDE VIEW

C

L

Bracket

mounted

into vertical

wall studs

centered

within the

cutout

Ensure holes

selected are

centered on

the studs

Wall

Studs

FRONT VIEW OF CUTOUT

WITH ANTI-TIP BRACKET

1/2" (1.3)

(190.5 )

From floor

to bottom

of electrical

3 1/2"

(8.9)

A

75"

area

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

FLUSH INSET INSTALLATION

NOTES

NOTES

A

Mounting the junction

box in this location will

also allow for front

accessability through

access panel.

B

Water supply area.

WARNING:

The freezer is top heavy

and must be secured to

prevent the possibility of

tipping forward. Failure to

do so may result in death

or serious injury.

The information below is

for cabinet design only.

When installing the antitip system you must use

the product installation

instructions.

The information below

applies to all installation

constructions:

• A wall bracket, bolts and

toggles will be supplied

with the unit.

• The bolts will be used to

attach bracket to wall in

4 locations. Two of the

locations must penetrate

the center of the wall

studs.

• The toggles are used for

stability in drywall and

when metal studs are

encountered. Lag bolts

are used in wood studs.

• In installation opening,

measure 81 ½” from

floor and draw a

horizontal line.

• Locate and mark the wall

studs on horizontal line.

Verify at least two studs

have their centerlines

within the center 32.5”

of installation opening to

ensure 2 wall studs are

penetrated.

• The bracket will be

centered left to right in

opening with bottom of

bracket on the horizontal

line.

• When unit is placed in

opening, the bracket tabs

will align with openings

in back of the unit. The

unit will be secured to the

bracket using supplied

“L” bolts.

See Installation

Instructions for detailed

instructions.

Product Specification Revised 10/14

Page 4

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

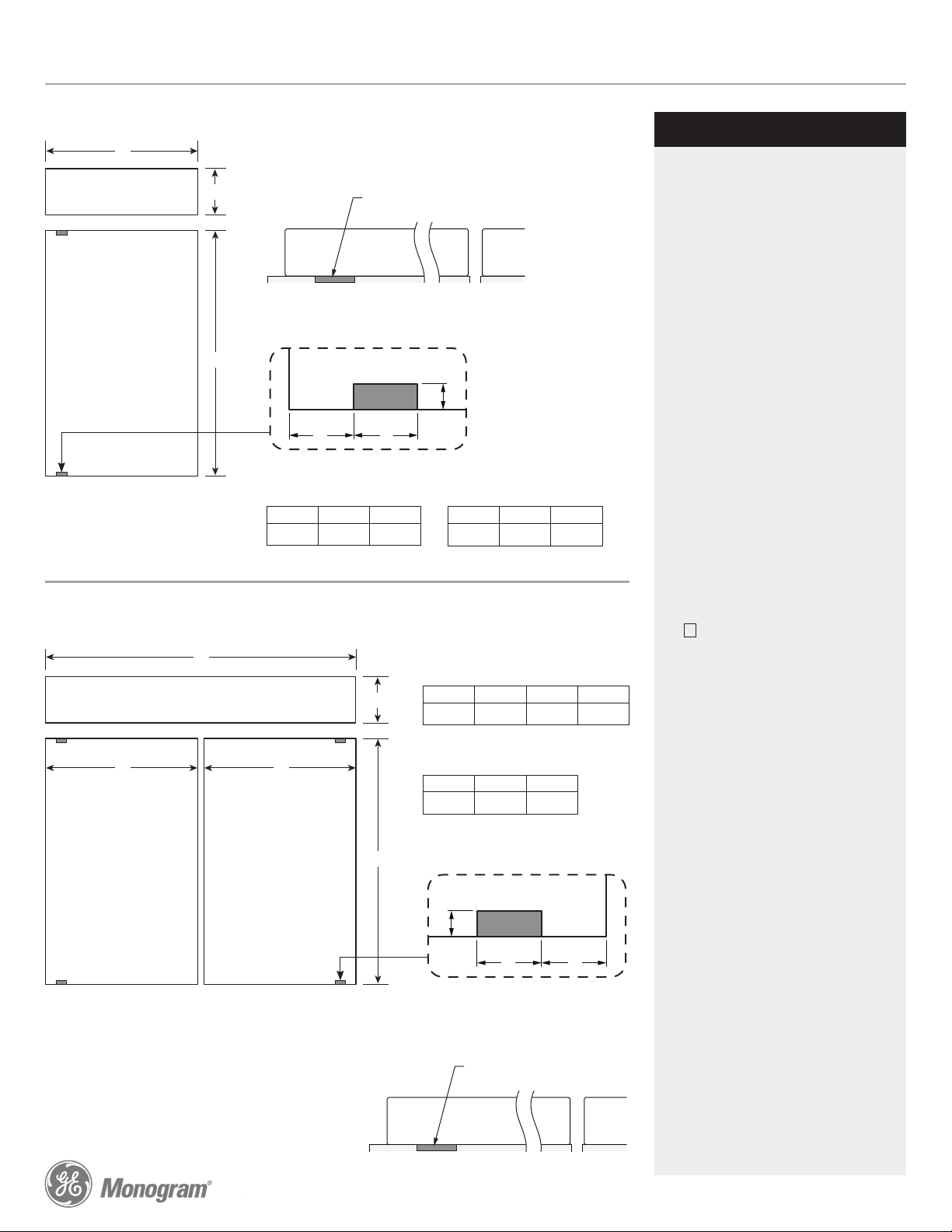

FLUSH INSET 3/4" PANEL DIMENSIONS SINGLE INSTALLATION

A

Grille Panel

B

PANEL ASSEMBLY CROSS SECTION

PANEL ASSEMBLY CROSS SECTION

1/4" Router Cut Depth

for Hinge Clearance

Door

HINGE CLEARANCES

ROUTER 1/4" DEEP

Door

Panel

FLUSH INSET 3/4" PANEL DIMENSIONS DUAL INSTALLATION

C

Z

X

PANEL DIMENSIONS

A B C

38" 9 5/8" 69 13/16"

A

Y

HINGE CLEARANCE

1 1/4" 1" 1/2"

PANEL DIMENSIONS

X Y Z

FLUSH INSET INSTALLATION

NOTES

Trimmed freezers are designed to be

customized with decorative panels. Fieldinstalled custom door and grille panels

are required.

Adjustment brackets allow 1/8” ne

adjustment of panel position in 3

dimensions.

Use templates provided to locate mounting

brackets on the door and grille panels.

Maximum total panel weight:

• Fresh food door panels – 67 lbs.

• Grille panel – 11 lbs

Door Handles

Door handles not included. Custom handle

supplied by your cabinet maker may be used.

ZKHPSS1: Professional tubular stainless steel

handle designed to fit 3/4” panels. Kit includes

one handle – 30 1/2” long.

ZKHSS2: European tubular stainless steel

handle designed to fit 3/4” panels. Kit includes

one handle – 64 1/4” long.

Order #ZUGF2H: Unified grille kit for dual

installation. Maximum total panel weight -

25 lbs.

NOTE: For side-by-side installation of a leftand-right-hand door swing product only,

see

on following page.

B

D

Door

Panel

Grille Panel

D

Door

Panel

B

A B C D

74 1/2" 9 5/8" 69 13/16" 37"

HINGE CLEARANCE

X Y Z

1 1/4" 1" 1/2"

HINGE CLEARANCES

C

PANEL ASSEMBLY CROSS SECTION

PANEL ASSEMBLY CROSS SECTION

ROUTER 1/4" DEEP

Z

Y

1/4" Router Cut Depth

for Hinge Clearance

Door

X

Product Specification Revised 10/14

Page 5

75 1/2" (191.8)

Finished Width

26 3/16" (66.5)

Min. Cutout Depth

25 3/4" (65.4)

3 7/8"

(9.8)

5 1/2"

(13.9)

9"

(22.9)

84 1/2"

(214.6)

Finished

Opening

3 1/2"

(8.9)

W

FRONT VIEW

ELEC.

5 1/2"

(13.9)

9"

(22.9)

3 1/2"

(8.9)

75 1/2"

(191.8 )

From floor

to bottom

of electrical

area

ELEC.

SIDE VIEW

7"

(17.8)

7"

(17.8)

WATER

3 1/2"

(9.0)

WATER

3 1/2"

(9.0)

5 3/4"

(14.6)

5 3/4"

(14.6)

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

DUAL INSTALLATIONS

3 7/8"

(9.8)

ELEC.

9"

(22.9)

84 1/2"

(214.6)

Finished

Opening

7"

(17.8)

WATER

3 1/2"

A

5 1/2"

(13.9)

(9.0)

FRONT VIEW

75 1/2" (191.8)

Finished Width

ELEC.

5 3/4"

5 3/4"

(14.6)

(14.6)

9"

(22.9)

WATER

3 1/2"

25 3/4" (65.4)

5 1/2"

(13.9)

(9.0)

7"

(17.8)

75 1/2"

From floor

to bottom

of electrical

3 1/2"

(8.9)

(191.8 )

area

26 3/16" (66.5)

Min. Cutout Depth

SIDE VIEW

FLUSH INSET INSTALLATION

NOTES

A

A separate 115V, 60Hz, 15- or 20-amp

power supply is recommended for each

product.

B

In a side-by-side installation of a left-and-

right-hand door swing product, 1 1/2”

clearance between the units is required.

Order ZUGF2H custom panel unified grille

kit for this installation.

C

In a side-by-side installation with same

door swing, allow 4” clearance between

the products to prevent the door swing

interference. Allow 15” minimum to a wall

to achieve full interior drawer extension

and pan removal. Additional clearances

are required when using custom panels

and handles.

NOTE: ZUG2, ZUGSS2 or ZUGPP2 grille panel

kits will not fit this installation.

3 1/2"

(8.9)

W

D

In a side-by-side installation with right

and left door hinges together, allow 5”

minimum clearance between the two

products to prevent one door from striking

the other. Additional clearances required

when using custom panels and handles.

NOTE: ZUG2, ZUGSS2 or ZUGPP2 grille panel

kits will not fit this installation.

DUAL PRODUCT CLEARANCES

25" (63.5) min

To wall

130˚

Door swing

1 1/2"

(3.8)

Door swing

B C

130˚

25" (63.5) min

To wall

5" (12.7) min

4" min

(10.2)

15" (38.1) min

To wall

D

Product Specification Revised 10/14

Page 6

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

SPECIFICATIONS

Overall Width 36" (91.4 cm)

Overall Height 84" (213.4 cm)

Overall Depth 25 3/8" (64.45 cm)

Door Clearance 36 3/4" (93.4 cm)

Cutout Width 35 1/2" (90.2 cm)

Cutout Height 83 1/2" - 84 1/2"

(212.1 - 214.6 cm)

Cutout Depth 24" (61 cm)

Plumbing Requirements 1/4" OD copper

tubing or GE

SmartConnect kit

Shipping Weight 569 lb

OVERALL DIMENSIONS

STANDARD INSTALLATION

36" (91.5)

*84"

(213.4)

*73 1/4"

69 5/8"

(176.8)

* Shipping height . Use leveling legs and wheels for maximum

1" height adjustment from shipping height.

** Allow 25" (63.5) min

clearance for 130˚

door swing

*3"

(7.6)

35" (89.0)

Case width

(186.1)

1 7/8"

(4.8)

*3 1/4"

(8.3)

25 1/8" (63.8)

23 7/8" (60.7)

*83 1/2"

(212.1)

SIDE VIEWFRONT VIEW

ATTENTION ELECTRICIAN:

A 115 volt 60Hz., 15 or 20 amp power supply

is required. An inidividual properly grounded

branch circuit or circuit breaker is recommended.

Install a properly grounded 3-prong electrical

receptacle recessed into the back wall.

36 3/4"

TOP VIEW

** Allow 4" (10.2) min

clearance to a wall

for 90˚ door swing

**These units are equipped with a 2-position door stop. The factory set 130° door swing can

be adjusted to 90° if clearance to adjacent cabinets or walls is restricted. Allow 15" minimum

clearance to wall for pan removal. If the 90˚ door stop position is used, pan access is

Dimensions in parentheses are in centimeters unless otherwise noted.

Actual product dimension may vary due to manufacturing tolerances.

Product Specification Revised 10/14

(93.4)

Page 7

35 1/2" (90.2)

2 5/16"

(5.9)

24" (61.0 )

1 1/2"

(3.8)

3 1/8"

(7.9)

7/16"

(1.1)

Trim overlap

*83 1/2" min

*84 1/2" max

(212.1-214.6)

*Trim will overlap

additional 7/16"

3 1/2"

(8.9)

75 1/2"

(191.8 )

From floor

to bottom

of electrical

area

FRONT VIEW SIDE VIEW

3 1/2"

(8.9)

ELEC.

5 1/2"

(14.0)

9"

(22.9)

W

5"

(12.7)

5"

(12.7)

WATER

3 1/2"

(9.0)

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

STANDARD INSTALLATION

2 5/16"

(5.9)

*83 1/2" min

*84 1/2" max

(212.1-214.6)

*Trim will overlap

additional 7/16"

ANTI-TIP BRACKET

SIDE VIEW INSTALLED

WITH ANTI-TIP BRACKET

ELEC.

9"

(22.9)

5"

(12.7)

35 1/2" (90.2)

A

WATER

3 1/2"

(9.0)

5 1/2"

(14.0)

B

81 1/2"

(207.0)

3 1/2"

5"

(12.7)

75 1/2"

(191.8 )

From floor

to bottom

of electrical

area

(8.9)

locations at end

Use two

additional hole

of brackets

3 1/8"

(7.9)

24" (61.0 )

1 1/2"

(3.8)

W

C

L

Bracket

mounted

into vertical

wall studs

Ensure holes

selected are

centered on

the studs

Wall

Studs

FRONT VIEW OF CUTOUT

WITH ANTI-TIP BRACKET

7/16"

Trim overlap

3 1/2"

(8.9)

STANDARD INSTALLATION

(1.1)

NOTES

A

Mounting the junction

box in this location will

also allow for front

accessability through

access panel.

B

Water supply area.

WARNING:

The freezer is top heavy

and must be secured to

prevent the possibility of

tipping forward. Failure to

do so may result in death

or serious injury.

The information below is

for cabinet design only.

When installing the antitip system you must use

the product installation

instructions.

The information below

applies to all installation

constructions:

• A wall bracket, bolts and

toggles will be supplied

with the unit.

• The bolts will be used to

attach bracket to wall in

4 locations. Two of the

locations must penetrate

the center of the wall

studs.

• The toggles are used for

stability in drywall and

when metal studs are

encountered. Lag bolts

are used in wood studs.

• In installation opening,

measure 81 ½” from

floor and draw a

horizontal line.

• Locate and mark the wall

studs on horizontal line.

Verify at least two studs

have their centerlines

within the center 32.5”

of installation opening to

ensure 2 wall studs are

penetrated.

• The bracket will be

centered left to right in

opening with bottom of

bracket on the horizontal

line.

• When unit is placed in

opening, the bracket tabs

will align with openings

in back of the unit. The

unit will be secured to the

bracket using supplied

“L” bolts.

See Installation

Instructions for detailed

instructions.

Product Specification Revised 10/14

Page 8

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

CUSTOM SIDE PANELS

F

24" (61.0)

3/16"

(.5)

1 7/8"

(4.8)

*3" - 4"

(7.6 - 10.2)

*Depending

on installation

height

*84”

*84"

(213.4)

(213.4)

*Depending

*Depending

on installation

on installation

height

STANDARD INSTALLATION

NOTES

F

Side panels must be

used whenever the

sides of the freezer will

be exposed. The 1/4”

side panels will slip

into the side case trim.

Secure the panels to the

freezer with stick-on

hook and loop fastener

strips. Order the side

panels from the cabinet

manufacturer.

2 9/16"

(6.5)

Product Specification Revised 10/14

Page 9

A

1/4" Framed Panel

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

1/4" FRAMED PANEL DIMENSIONS SINGLE INSTALLATION

PANEL ASSEMBLY CROSS SECTION

Grille Panel

Door

Panel

B

C

Trim

PANEL DIMENSIONS

A B C

1/4" Framed Panel

33 7/8" 8 7/8" 69 5/16"

Door

Supplied Handles

STANDARD INSTALLATION

NOTES

Trimmed freezers are designed to be

customized with decorative panels. Fieldinstalled custom door and grille panels are

required.

1/4” Framed Panels:

Order trim kit #ZTK36SDHLH

for 1/4" thick custom panels ordered from

your cabinet maker. The decorative panels

slide into the trim.

Maximum total panel weight:

• Door panel – 67 lbs.

• Grille panel – 11 lbs

3/4" OVERLAY PANEL DIMENSIONS SINGLE INSTALLATION

PANEL ASSEMBLY CROSS SECTION

Trim

1/4" Backer Panel

.10" Spacer Panel

PANEL DIMENSIONS

A B C

1/4" Backer Panel

.10" Spacer Panel

3/4" Overlay Panel

.25" + .10" + .75" = 1.10" Total Panel Thickness

33 7/8" 8 7/8" 69 5/16"

32 1/2" 7 5/8" 67 15/16"

34 1/8" 9" 69 9/16"

Grille Panel

Panel

A

Door

B

C

Door

3/4" Overlay Panel

Supplied Handles

3/4” Overlay Panels:

Order trim kit #ZTK36SDHLH

for 3/4" thick custom panels ordered from

your cabinet maker. The decorative panels

slide into the trim. The overlay panel must be

secured to a 1/4"-thick backer panel which

slides into the trim. A spacer panel 0.10" thick

must be placed between the overlay and

backer panels.

Center each panel over the other. Assemble

the panels with glue and screws. Screws must

be countersunk into the backer panel.

NOTE: Left-to-right offset is not always equal

to top-to-bottom offset.

Maximum total panel weight:

• Door panel – 67 lbs.

• Grille panel – 11 lbs

Door Handles:

The supplied handles can be adjusted to

accommodate both framed or overlay panels.

Custom handles of your choice, supplied by

your cabinet maker, can also be installed.

ZKHPSS1: Professional Tubular Stainless Steel

Handle designed to fit 3/4" overlay panels.

Kits include one handle - 30 1/2" long.

ZKHSS2: European tubular stainless steel

handle designed to fit 3/4" overlay panels.

Kits include one handle - 64 1/4" long.

Product Specification Revised 10/14

Page 10

1/4" Framed Panel

Supplied Handles

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

STANDARD 1/4" FRAMED PANEL DIMENSIONS DUAL INSTALLATION

D

Door

Panel

PANEL ASSEMBLY

CROSS SECTION

A

Grille Panel

Trim

D

Door

Panel

B

C

Door

PANEL DIMENSIONS

A

B

C

D

1/4"

Framed

Panel

69 7/8"

8 7/8"

69 5/16"

33 7/8"

STANDARD INSTALLATION

NOTES

Trimmed freezers are designed to be

customized with decorative panels. Fieldinstalled custom door and grille panels are

required.

1/4” Framed Panels:

Order trim kit #ZTK36SDHLH

for 1/4" thick custom panels ordered from

your cabinet maker. The decorative panels

slide into the trim.

Maximum total panel weight:

• Door panel – 67 lbs.

• Grille panel – 25 lbs

Order ZUG2: Unified grille kit for dual

installation. Maximum total panel weight -

25 lbs.

STANDARD 3/4" OVERLAY PANEL DIMENSIONS DUAL INSTALLATION

PANEL DIMENSIONS

1/4"

Backer

Panel

69 7/8" 68 1/2" 70 1/8"

A

8 7/8" 7 5/8" 9"

B

69 5/16" 67 15/16" 69 9/16"

C

33 7/8" 32 1/2" 34 1/8"

D

.25" + .10" + .75" =

1.10" Total Panel Thickness

D

Door

Panel

PANEL ASSEMBLY

CROSS SECTION

A

Grille Panel

1/4" Backer Panel

.10" Spacer Panel

Panel

Trim

D

Door

B

C

Door

3/4" Overlay Panel

Supplied Handles

.10"

Spacer

Panel

3/4"

Overlay

Panel

3/4” Overlay Panels:

Order trim kit #ZTK36SDHLH

for 3/4" thick custom panels ordered from

your cabinet maker. The decorative panels

slide into the trim. The overlay panel must be

secured to a 1/4"-thick backer panel which

slides into the trim. A spacer panel 0.10" thick

must be placed between the overlay and

backer panels.

Center each panel over the other. Assemble

the panels with glue and screws. Screws must

be countersunk into the backer panel.

NOTE: Left-to-right offset is not always equal

to top-to-bottom offset.

Maximum total panel weight:

• Door panel – 67 lbs.

• Grille panel – 25 lbs

Order ZUG2: Unified grille kit for dual

installation. Maximum total panel weight -

25 lbs.

Door Handles:

The supplied handles can be adjusted to

accommodate both framed or overlay panels.

Custom handles of your choice, supplied by

your cabinet maker, can also be installed.

ZKHPSS1: Professional Tubular Stainless Steel

Handle designed to fit 3/4" overlay panels.

Kits include one handle - 30 1/2" long.

ZKHSS2: European tubular stainless steel

handle designed to fit 3/4" overlay panels.

Kits include one handle - 64 1/4" long.

Product Specification Revised 10/14

Page 11

71 1/2" (181.6)

Finished Width

24" (61.0)

Min. Cutout Depth

24 3/16" (61.4)

2 5/16"

(5.9)

5 1/2"

(13.9)

9"

(22.9)

83 1/2" min

84 1/2" max

(212.1-214.6)

Finished Opening

3 1/2"

(8.9)

W

FRONT VIEW

ELEC.

5 1/2"

(13.9)

9"

(22.9)

3 1/2"

(8.9)

75 1/2"

(191.8 )

From floor

to bottom

of electrical

area

ELEC.

SIDE VIEW

5"

(12.7)

5"

(12.7)

5"

(12.7)

5"

(12.7)

WATER

3 1/2"

(9.0)

WATER

3 1/2"

(9.0)

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

DUAL INSTALLATIONS

2 5/16"

(5.9)

9"

5 1/2"

(13.9)

WATER

3 1/2"

(9.0)

1"

(2.5)

ELEC.

(22.9)

83 1/2" min

84 1/2" max

(212.1-214.6)

Finished Opening

5"

(12.7)

DUAL PRODUCT CLEARANCES

25" (63.5) min

To wall

A

71 1/2" (181.6)

Finished Width

ELEC.

(22.9)

5"

(12.7)5"(12.7)

FRONT VIEW

24 3/16" (61.4)

9"

WATER

3 1/2"

(9.0)

25" (63.5) min

To wall

5 1/2"

(13.9)

5"

(12.7)

of electrical

3 1/2"

(8.9)

75 1/2"

(191.8 )

From floor

to bottom

area

Min. Cutout Depth

SIDE VIEW

2" min

(5.1)

24" (61.0)

STANDARD INSTALLATION

NOTES

A

A separate 115V, 60Hz, 15- or 20-amp

power supply is recommended for each

product.

Additional cutout width may be required when

side panels are used.

B

In a side-by-side installation of a left-

and-right-hand door swing product, 1”

clearance between the units is required.

Order ZUG2: Custom panel unified grille kit for

one continuous grille panel.

C

In a side-by-side installation with same

door swing, allow 2” minimum clearance

between the products to prevent the door

swing interference. Allow 15” minimum

to a wall to achieve full drawer extension

and pan removal. Additional clearances

are required when using custom panels

3 1/2"

(8.9)

W

15"

(38.1) min

To wall

and handles.

NOTE: ZUG2, ZUGSS2 or ZUGPP2 grille panel

kits will not fit this installation.

D

In a side-by-side installation with right

and left door hinges together, allow 5”

minimum clearance between the two

products to prevent one door from striking

the other. Additional clearances required

when using custom panels and handles.

NOTE: ZUG2, ZUGSS2 or ZUGPP2 grille panel

kits will not fit this installation.

130˚

Door swing

130˚

Door swing

B C

5" (12.7) min

D

Product Specification Revised 10/14

Page 12

FEATURES AND BENEFITS

Custom Panel Model - Can be personalized with

cabinet-matching panels and handles

Enhanced Temperature Management System With precise electronic controls and thermistors,

maintains ideal storage conditions for frozen

foods

Concealed Ice Drawer - Provides quick and easy

access to filtered ice

™

GE Water

Filtration System - Provides clean,

fresh-tasting water to the freezer's icemaker

®

ENERGY STAR

Qualication - As an ENERGY

STAR® partner, GE has determined that Monogram

all-freezers meet the ENERGY STAR® guidelines for

energy efficiency

ZIF360NHLHGE Monogram® 36" Built-In All-Freezer

Adjustable, Wire Shelves, Gallon-Szie Door Bins

and Pullout Baskets - Allow customizable storage

for foods and containers of varying sizes

Concealed Halogen Lighting System Illuminates contents without compromising space

R

Product Specification Revised 10/14

Loading...

Loading...