Page 1

Installation Instructions

30” French Door Built-in Double Wall Ovens

Questions? Call GE Appliances at 1.800.GE.CARES (1.800.432.2737) or visit

www.GEAppliances.com. In Canada, call 1.800.561.3344 or visit www.GEAppliances.ca.

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

•

IMPORTANT — Save these

instructions for local inspector’s use.

•

IMPORTANT — Observe all

governing codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with Consumer.

ATTENTION INSTALLER: All electric wall ovens must be hard-wired (direct-wired)

into an approved junction box. A plug and receptacle is NOT permitted on these products.

FOR YOUR SAFETY:

WARNING

the service disconnecting means to prevent power from being switched on accidentally. When the

service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a

tag, to the service panel.

Be sure the oven is securely installed in a cabinet that is firmly attached to the house structure. Weight

on the oven door could cause the oven to tip and result in injury. Never allow anyone to climb, sit,

stand or hang on the oven door.

Make sure the wall coverings, counters and cabinets around the oven can withstand the heat (up to

200°F [93.3°C]) generated by the oven.

Before beginning the installation, switch power off at the service panel and lock

MATERIALS YOU MAY NEED

Junction Box

Wire Nuts

Strain Relief Clamp for 1/2” Conduit

• Note to Consumer – Keep these

instructions for future reference.

• Skill level – Installation of this appliance

requires a qualified installer or electrician.

• Proper installation is the responsibility

of the installer.

• Product failure due to improper installation

is not covered under Warranty.

• Product is for indoor use only.

TOOLS YOU MAY NEED

1/8” Drill Bit and Electric or Hand Drill

3/16” hex key

1/8” hex key

Phillips Screwdriver

Wire Strippers

1

REMOVE PACKAGING MATERIALS

Failure to remove packaging materials could result in damage to the appliance. Remove all

packing parts from oven, racks and heating elements. Remove protective film and labels on

the outer door and control panel. Also, remove plastic on trims and panel, all tape around the

oven and any shipping screws securing the oven to the base pad. Open oven door and remove

literature pack and oven racks. Remove the bottom trim from the top of the oven. It will be

installed at the end of the installation process. The trim is wrapped separately and taped to the top

of the unit. Remove pedestal rails from separate box and set aside.

DESIGN INFORMATION

A double oven may be installed in a cabinet alone or above a warming drawer. See the label on

top of the oven for approved models.

IMPORTANT: Always refer to individual installation instructions packed with each product for

specific requirements.

2

PREPARE THE OPENING

NOTE: If the cabinet does not have a solid

bottom, two braces or runners must be

installed to support the weight of the oven.

For double ovens, the runners and braces

must support 400 lbs. (181 kg).

NOTE: If marks, blemishes or the cutout

opening are visible above the installed oven,

it may be necessary to add wood shims

under the runners until the marks or opening

are covered.

NOTE: If the cabinet does not have a front

frame and the sides are less than ¾” (1.9 cm)

thick, shim both sides equally to establish the

cutout width.

Suitable

Bracing

to Support

Runners

2" x 4" (5 cm x 10 cm)

or Equivalent Runners Level

with Bottom of Cutout

and Flush with Sides of Cutout

C

L

2 A

NOTE: If the cabinet does not have a front frame and the sides are less than ¾” (1.9 cm) thick,

shim both sides equally to establish the cutout width.

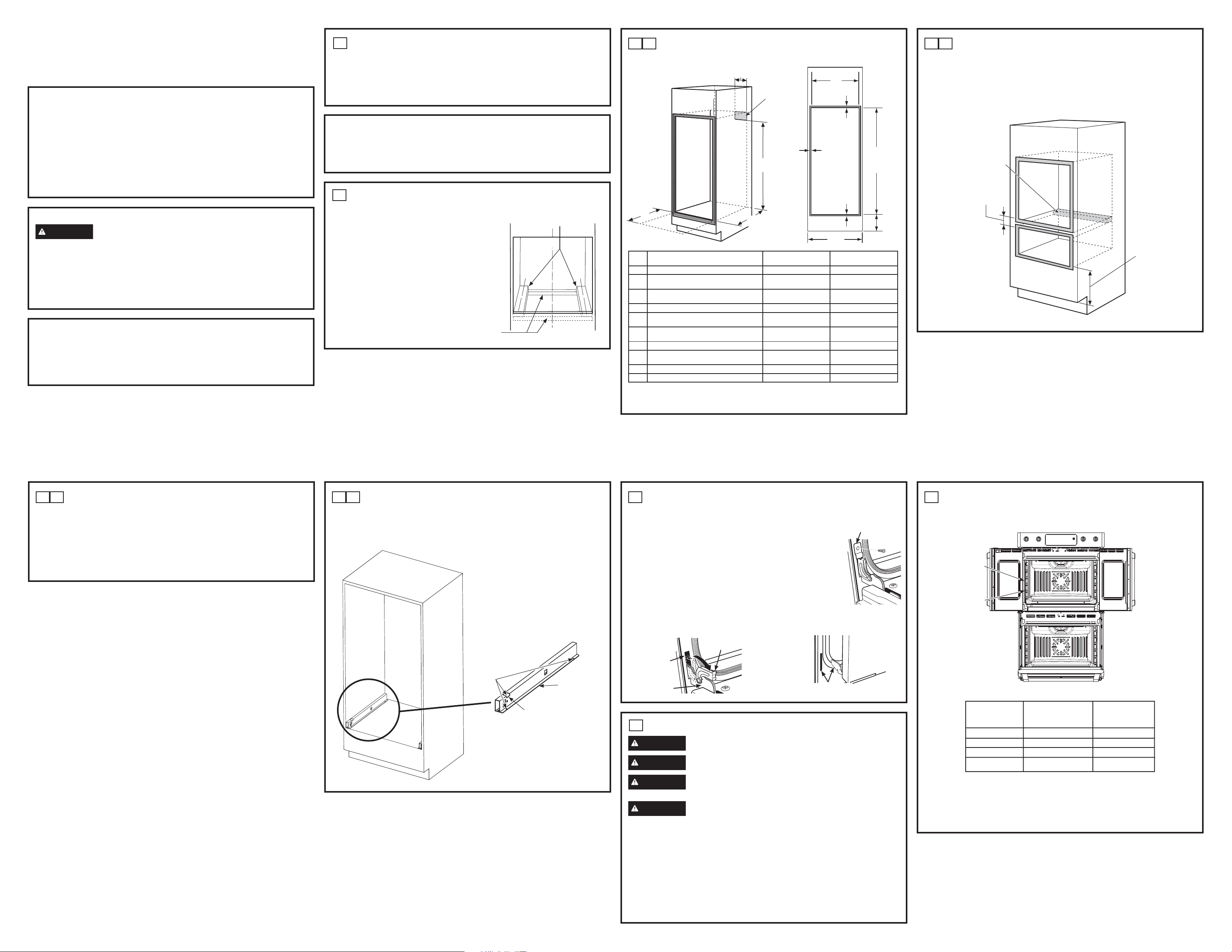

CUTOUT FOR DOUBLE OVENS (2 THERMAL OVENS)

H

Junction

Box

Location

(junction

box may

be located

in adjacent

cabinet)

B

F

D

J

C

G

E

Cutout Depth

23-1/2”

(59.7 cm) Min.

K

A

Dim. Description 30” Double Oven with

A Cabinet Width 30” (76.2 cm) 30” (76.2 cm)

B Cutout Width 28

C Cutout Height 5113»16” (131.6 cm) min.

D Clearance from cutout - side edges*

E

Clearance to Adjacent Corners, Drawers,

Walls, etc., When Door Is Open

F Clearance from cutout - top* 1” (2.5 cm) min.

G Clearance from cutout - bottom* 11»4” (3.2 cm) 11»4” (3.2 cm)

H Junction Box Location 9

J Height to Bottom of Junction Box 47” (119.4 cm) 47” (119.4 cm)

K Recommended Cutout Location from Floor 12” (30.5 cm) 12” (30.5 cm)

* Refers to minimum clearance required for wall oven installation and does not reflect actual product dimensions.

Pedestal

1

»2” (72.4 cm) min.

285»8” (72.7 cm) max.

5115»16” (131.9 cm) max.

11

»16” (1.75 cm)

23” (53.3 cm) min. 23” (53.3 cm) min.

(11»4” (3.2 cm)

1

»2” (24.1 cm) max.

right side only

30” Double Oven

without Pedestal

281»2” (72.4 cm) min.

285»8” (72.7 cm) max.

50 ¼” (127.64cm)

11

»16” (1.75 cm)

1” (2.5 cm) min.

(11»4” (3.2 cm)

91»2” (24.1 cm) max.

right side only

2 B

CUTOUT FOR INSTALLATION OVER A

WARMING DRAWER

NOTE: Install the oven only with specific models listed on the label located on top of the oven.

NOTE: Additional clearances between cutouts may be required. Check to be sure the oven

supports above the Warming Drawer location do not obstruct the required interior depth and height.

When installing a Warming Drawer below a double oven, a separate 120V, 60 HZ, properly

grounded receptacle must be installed. Refer to installation instructions packed with the Warming

Drawer for specific installation requirements.

Anti-Tip Block Against

Rear Wall Per Warming

Drawer Requirement

2" (5.1 cm)

Min.

Per Warming

Drawer

Requirement

3 A

WHEN TO USE THE PEDESTAL

When replacing an older GE Appliances 30” double wall oven with a new GE Appliances model.

Cutout height = 51-13/16” to 51-15/16”. This is our traditional cutout height.

WHEN NOT TO USE THE PEDESTAL

When replacing a 30” double wall oven from another manufacturer (ie. Whirlpool) with a new

GE Appliances 30” double wall oven. Cutout height = 50-1/4”. You will need to verify that the

existing cutout matches the 50-1/4” dimension.

If the new GE Appliances 30” double wall oven is being installed into new construction (ie. not a

replacement), then the recommended installation is to use the Pedestal.

DETERMINING WHEN TO USE THE PEDESTAL

3 B

A. Position the pedestal rails with the top cutout toward the front of the opening and the flanges

B. Drill pilot holes and attach rails to runner or bottom of cabinet with provided hardware.

PEDESTAL RAIL INSTALLATION

on the bottom, pointing toward the center. Locate each rail on the floor or cabinet runner,

slightly inward from the side of the cabinet. Make sure the front of each rail is not protruding

beyond the front of the cabinet opening.

Continue to Section 3.

LOWER DOOR REMOVAL (RECOMMENDED)

4

NOTE: Door removal is not a requirement for installation of the product but is an added convenience.

To remove the lower oven door:

A. Open the oven door as far as it will go.

B. Remove hinge bracket from front frame and set aside. The hinge bracket

must be replaced for proper door functionality when door is reinstalled.

C. Push both hinge locks down toward the door frame to the unlocked

position. This may require a flat-blade screwdriver. DO NOT LIFT THE

DOOR BY THE HANDLE!

D. Place hands on both sides of the door and close the oven door to

the removal position (approximately 1”–2” [2.5 cm–5.1 cm] from the

closed position).

E. Lift the door up and out until the hinge arms clear the slots. NOTE: The

oven door is very heavy. Be sure you have a firm grip before lifting the

oven door off the hinges. Use caution once the door is removed. Do not lay the door on its

handle. This could cause dents or scratches.

Hinge Bracket

ELECTRICAL REQUIREMENTS (CONT.)

5

This appliance must be supplied with the proper voltage and frequency and connected to an individual,

properly grounded branch circuit, protected by a circuit breaker or fuse. See the rating plate located on

the oven frame to determine the rating of the product.

Rating plate is located

on left side trim

Connected Appliance

Information is located

on left side trim

Attachment

screws

Top cutout

toward front

Flanges toward

center of cutout

Hinge Unlocked Position

Hinge Slot

Hinge Arm

5

ELECTRICAL REQUIREMENTS

WARNING

WARNING

WARNING

installation.

WARNING

electrical hazard or fire. Use only connectors designed for joining copper to aluminum and follow the

manufacturer’s recommended procedure closely.

We recommend you have the electrical wiring and hookup of your appliance connected by a qualified

electrician. After installation, have the electrician show you how to disconnect power from the appliance.

You must use a single-phase, 120/208 VAC or 120/240 VAC, 60 Hertz electrical system. If you connect

to aluminum wiring, properly installed connectors approved for use with aluminum wiring must be used.

Effective January 1, 1996, the National Electrical Code requires that new construction (not existing)

utilize a four-conductor connection to an electric oven. When installing an electric oven in new

construction, a mobile home, recreational vehicle or an area where local codes prohibit grounding

through the neutral conductor, refer to the section on four-conductor branch circuit connections.

Check with your local utilities for electrical codes which apply in your area. Failure to wire your oven

according to governing codes could result in a hazardous condition. If there are no local codes, your

oven must be wired and fused to meet the National Electrical Code, NFPA No. 70 – latest edition,

available from the National Fire Protection Association.

This appliance must be properly grounded.

To prevent fire or shock, do not use an extension cord with this appliance.

To prevent shock, remove house fuse or open circuit breaker before beginning

Improper connection of aluminum house wiring to copper leads can result in an

Hinge Clears Slot

Use the chart below to determine the minimum recommended dedicated circuit protection:

Recommended

KW Rating KW Rating Circuit Size

240V 208V (Dedicated)

.: .: $PS

4.9 KW–7.2 KW 4.2 KW–6.2 KW 30 Amp

7.3 KW–9.6 KW 6.3 KW–8.3 KW 40 Amp

9.7 KW–12.0 KW 8.4 KW–10.4 KW 50 Amp

DO NOT shorten the flexible conduit. The conduit strain relief clamp must be securely attached to the

junction box and the flexible conduit must be securely attached to the clamp. If the flexible conduit will

not fit within the clamp, do not install the oven until a clamp of the proper size is obtained.

The 3 power leads supplied with this appliance are suitable for connection to heavier gauge household

wiring. The insulation of these 3 leads is rated for temperatures much higher than the temperature

rating of the household wiring. The current-carrying capacity of the conductor is governed by the wire

gauge and the temperature rating of the insulation around the wire.

31-11065 03-17 GEA (sheet 1)

Page 2

6

MAKE ELECTRICAL CONNECTIONS

WARNING

to prevent power from being switched on accidentally. When the service disconnecting means cannot

be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

Place oven on table or platform even with the cutout opening. For a double oven, the platform must

support 400 lbs. (181 kg). Connect the flexible conduit to the electrical junction box as shown below*.

Position the conduit in such a manner that it will lie behind the unit in a natural loop when the oven is

installed. You will need to purchase an appropriate strain relief clamp to complete the connection of the

conduit to the junction box.

Switch power off at the service panel and lock the service disconnecting means

Junction Box

Ground

Conduit

Wire

THREE-CONDUCTOR BRANCH CIRCUIT CONNECTION

7

NOTE: If residence leads are aluminum conductors, see

WARNING in Section 5, Electrical Requirements.

When connecting to a three-conductor branch circuit, if local

codes permit:

A. Connect the oven ground conductor along with the

neutral (white) lead to the branch circuit neutral (white

or gray in color), using a wire nut.

B. Connect the oven red lead to the branch circuit red

lead and the oven black lead to the branch circuit black

lead in accordance with local codes, using wire nuts.

C. Install proper strain relief clamp.

D. Install junction box cover.

Range

conduit

snaps

into box

Red

Junction Box Cover

Black

Neutral wire

connection

Ground and

neutral wires (white)

Branch

circuit

Alternate

knockout

Tape or Crimp

SLIDE OVEN INTO OPENING

9

• Lift oven into cabinet cutout using

the oven opening as a grip. Carefully

push against oven front frame. Do

not push against outside edges.

MOUNT THE OVEN

10

WARNING

falling out of the cabinet, causing serious injury.

NOTE: During oven mounting step, ensure that no damage is done to oven gasket which lines

the edge of oven cavity.

NOTE: Before drilling the pilot holes, make sure the oven is pushed as far back into the opening

as it will go and is centered.

NOTE: If the cabinet is particle board, you must use #8 x ¾” particle board screws. These may

be purchased at any hardware store.

A. Drill through the mounting holes (top and bottom) of the side trim for the #8 mounting screws

provided.

B. Secure the oven cabinet with the screws provided.

Mounting screws must be used. Failure to do so could result in the oven

Ground

Strain Relief Clamp

Place Oven on a

Support to Assist in

Connecting Conduit

* Ovens come equipped with a 40” long conduit. If a longer conduit is desired, there may be one

available for your model. To check availability or order parts, call GE Appliances at 1.800.GE.CARES.

(not included) Must Be

Used at Junction Box

Red

White

Black

FOUR-CONDUCTOR BRANCH CIRCUIT CONNECTION

8

NOTE: If residence leads are aluminum conductors, see WARNING in Section 5, Electrical

Requirements.

When connecting to a four-conductor branch circuit, if local

codes permit:

A. Free the neutral (white) lead from being restrained to any

other wires. If necessary, cut the neutral (white) lead and

then re-strip it to expose the proper length of conductor.

B. Attach the appliance grounding lead (green or bare copper)

in accordance with local codes.

C. Connect the oven neutral (white) lead to the branch circuit

neutral (white or gray) in accordance with local codes, using

a wire nut.

D. Connect the oven red lead to the branch circuit red lead and

the oven black lead to the branch circuit black lead in ac cordance with local codes, using wire nuts.

E. Install proper strain relief clamp.

F. Install junction box cover.

Range

conduit

snaps

into box

Red

Junction Box Cover

Black

White

Branch

circuit

Ground

wires

Alternate

knockout

The Screws Must

Be a Minimum of

1/4” (6 mm) From the

Front of the Cutout.

Mounting

Hole

Locations

(hole locations

may vary)

Mounting

Hole

Locations

(hole locations

may vary)

11

BOTTOM TRIM INSTALLATION

With oven installed, attach the bottom trim through its mounting holes in front vertical brace using

two trim screws provided. Bottom trim lip must be placed under flange of bottom air duct.

Installations without a Pedestal

Installations with a Pedestal

IMPORTANT: If this unit is ever removed from the cabinet or the oven is ever pulled out for

service, the bottom trim must be removed first or damage to the trim will occur.

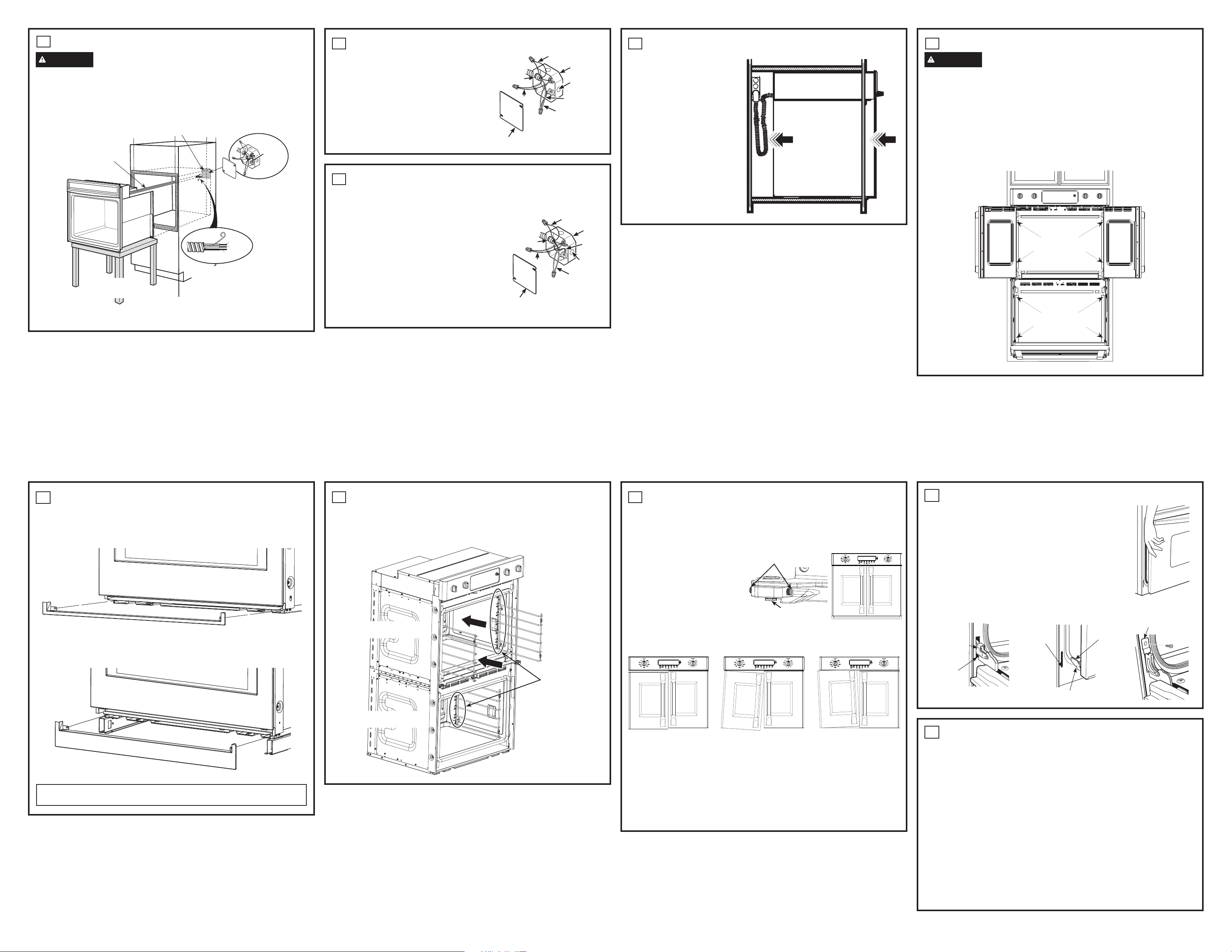

OVEN RACK GUIDE INSTALLATION

12

A. Locate included oven rack guide mounting hardware.

B. Place oven rack guides on cavity wall studs with L bracket towards back of cavity as shown.

C. Install guides using the 8 provided mounting nuts.

French doors removed for

illustration clarity only

Metal Posts to

be installed in

the rear of cavity

Oven rack

Lower oven door removed

for illustration clarity only

guide shown

in place.

DOOR ADJUSTMENT MECHANISM

13

Door Adjustment Mechanism is located on both the right and left doors at the bottom hinges. Only

the left side Adjustment Mechanism is shown in this manual.

NOTE: Adjust the doors inward only until the center gap is even. Over-adjusting can damage the

center seals and make the doors more difficult to open.

A. Using 3/16” hex key, tighten Vertical Adjustment Screw to adjust door up and loosen to adjust

door down.

B. Horizontal Adjustment Screws pivot

the door about an axis. Using a 1/8”

Hex Key, loosen both screws, then

tighten appropriate screw to pivot

door. Once door is in place, verify

both screws are tightened.

EXAGGERATED EXAMPLES FOR

LEFT DOOR ADJUSTMENT

Example 1: Left door low,

center gap even.

Steps for adjustment:

A. Tighten left Vertical

Adjustment Screw.

B. If left door is still low, loosen

right Vertical Adjustment

Screw.

Horizontal Adjustment Screws

Vertical Adjustment Screw

Example 2: Left door low,

center gap larger at bottom.

Steps for adjustment:

A. Loosen inside Horizontal

Adjustment Screw.

B. Tighten outside Horizontal

Adjustment Screw until

center gap even.

C. If left door is still low, tighten

left Vertical Adjustment

Screw.

D. Tighten inside Horizontal

Adjustment Screw.

Example 3: Left door high,

center gap larger at top.

Steps for adjustment:

A. Loosen outside Horizontal

Adjustment Screw.

B. Tighten Outside Horizontal

Adjustment Screw until

center gap even.

C. If left door is still low, tighten

Left Vertical Adjustment

Screw.

D. Tighten Inside Horizontal

Adjustment Screw.

14

REPLACING THE LOWER OVEN DOOR

NOTE: The oven door is heavy. You may need help lifting the door high

enough to slide it into the hinge slots. Do not lift the door by the handle.

A. Lift the oven door by grasping each side.

B. With the door at the same angle as the removal position (approximately

1”–2” [2.5 cm–5.1 cm] from the closed position), seat the notch of the

hinge arm into the bottom edge of the hinge slot. The notch of the

hinge arm must be fully seated into the bottom of the slot.

C. Fully open the door. If the door will not fully open, the indentation is not

seated correctly in the bottom edge of the slot.

D. Push the hinge locks up against the front frame of the oven cavity,

to the locked position.

E. Replace hinge bracket. The hinge bracket must be replaced for proper

door functionality.

F. Close the oven door.

Hinge in

Locked

Position

Notch of Hinge

Securely Fitted

Into Bottom of

Hinge Slot

15

FINAL INSTALLATION CHECKLIST

• Check to make sure the circuit breaker is closed (RESET) or the circuit fuses are replaced.

• Be sure power is in service to the building.

• Check that all packing material and tape have been removed. Failure to remove these materials

could result in damage to the appliance once the appliance has been turned on and surfaces

have heated.

• Remove all items from inside the oven.

• Check to be sure that the mounting screws are installed and flush with the side trim

(see Section 10).

• Check that the bottom trim is installed properly (see Section 11).

• Ensure that air duct opening at bottom of unit is free of obstructions.

• Check that oven rack guides are installed correctly and oven racks function smoothly.

Bottom

Edge of

Slot

Hinge Notch

Hinge

Arm

Hinge Bracket

31-11065 03-17 GEA (sheet 2)

OPERATION CHECKLIST

• Turn on the power to the oven (refer to your Owner’s Manual). Verify that the bake and broil

units and all cooking functions operate properly.

• See your Owner’s Manual for the troubleshooting list.

• Be sure all of the oven controls are OFF before leaving the oven.

Page 3

Instrucciones de instalación

Hornos de Pared Doble con Puerta Francesa de 30” Incorporada

¿Preguntas? Llame a GE Appliances al 800.GE.CARES (800.432.2737) o visita

www.GEAppliances.com. En Canadá, llame 1.800.561.3344 o visita www.GEAppliances.ca.

ANTES DE COMENZAR

Lea estas instrucciones por completo y con

detenimiento.

•

IMPORTANTE – Guarde estas

instrucciones para el uso de inspectores locales.

• IMPORTANTE – Cumpla con todos los

códigos y ordenanzas vigentes.

• Nota al instalador – Asegúrese de dejar estas

instrucciones con el Consumidor.

ATENCIÓN INSTALADOR: Todos los hornos de pared eléctricos deben contar con cableado

de conexión permanente (cableado directo) dentro de una caja de conexiones aprobada. En estos productos

NO se permite la conexión del tipo “enchufe y receptáculo”.

PARA SU SEGURIDAD:

ADVERTENCIA

y bloquee los medios de desconexión para evitar el accionamiento de la energía de manera accidental.

Cuando los medios de desconexión de servicio no pueden bloquearse, coloque sobre el panel de servicio un

dispositivo de advertencia bien visible, como una etiqueta.

El horno debe instalarse bien en un gabinete que se encuentre firmemente sujeto a la estructura de la casa. Si

se coloca peso sobre la puerta del horno, éste puede volcarse y provocar lesiones. Nunca permita que nadie

se suba, siente, pare o cuelgue de la puerta del horno.

Verifique que el revestimiento de las paredes, mostradores y gabinetes ubicados alrededor del horno puedan

soportar el calor (hasta 200°F [93,3°C]) generado por el horno.

Antes de comenzar la instalación, desconecte la energía del panel de servicio

MATERIALES QUE PUEDE

NECESITAR

Caja de conexiones

Tapones de alambre

Abrazadera de alivio de tensión para conducto

de 1/2”

• Nota al consumidor – Conserve estas

instrucciones para referencia futura.

• Nivel de destreza – La instalación de este aparato

requiere un instalador o electricista calificados.

• El instalador tiene la responsabilidad de efectuar

una instalación adecuada.

• La garantía no cubre las fallas del producto

provocadas por una instalación incorrecta.

• Este producto sólo se debe usar en áreas interiores.

HERRAMIENTAS NECESARIAS

Broca de perforadora de 1/8” y perforadora eléctrica

o de mano

Llave hexagonal de 3/16”

Llave hexagonal de 1/8”

Destornillador de estrella

Alicates pelacables

1

QUITE LOS MATERIALES DE EMPAQUE

No quitar los materiales de empaque puede provocar daños al electrodoméstico. Quite todas las partes de

empaque del horno, bandejas y elementos de calentamiento. Quite la película protectora y las etiquetas de la

puerta exterior y panel de control. También, quite los elementos plásticos de los rebordes y panel, toda la cinta

que cubre el horno y los tornillos de envío que fijan el horno a la almohadilla base. Abra la puerta del horno y

quite el material informativo y las bandejas del horno. Quite el reborde inferior de la parte superior del horno. Se

colocará al final del proceso de instalación. El reborde se encuentra envuelto en forma separada y adherido en

la parte superior de la unidad. Retire los rieles del pedestal de la caja que está aparte y déjelos a un costado.

INFORMACIÓN DE DISE

Puede instalarse un horno doble solo en un gabinete o sobre un cajón calentador. Vea la etiqueta de la parte

superior del horno para consultar los modelos aprobados.

IMPORTANTE: Siempre consulte las instrucciones de instalaciones individuales enviadas con cada producto

para requerimientos específicos.

2

PREPARE LA ABERTURA

NOTA: Si el gabinete no cuenta con un fondo

sólido, deben instalarse dos abrazaderas o guías

para soportar el peso del horno. Para hornos

dobles, las guías o abrazaderas deben soportar

400 lbs (181 kgs).

NOTA: Si marcas, imperfecciones o la abertura

resultaran visibles sobre el horno instalado, es

posible que sea necesario agregar cuñas de madera

debajo de las correderas hasta que las marcas o

aperturas estén cubiertas.

NOTA: Si el gabinete no cuenta con un armazón

frontal y los lados son menores a un grosor de

¾” (1,9 cm), coloque cuñas uniformemente sobre

ambos lados para establecer al ancho de la abertura.

2 A

NOTA: Si el gabinete no cuenta con un armazón frontal y los lados son menores a un grosor de 3/4” (1,9 cm),

coloque cuñas uniformemente sobre ambos lados para establecer al ancho de la abertura.

ABERTURA PARA HORNOS DOBLES (2 HORNOS TÉRMICOS)

H

Ubicación

de la caja de

conexiones

(la caja de

conexiones

puede hallarse

en un gabinete

adyacente

B

F

D

C

J

G

E

Profundidad de la

abertura 23-1/2”

(59,7 cm) mínimo

K

A

Dim. Descripción Horno doble de 30”

A Ancho del gabinete 30” (76,2 cm) 30” (76,2 cm)

B Ancho de la abertura 28

C Altura de la abertura 51

D Espacio desde la abertura – extremos laterales*

E Espacio respecto de esquinas adyacentes, cajones

G Espacio desde la abertura – parte inferior* 1

H Ubicación de la caja de conexiones 9

K Ubicación recomendada de la abertura

* Se refiere al espacio mínimo requerido para la instalación del horno de pared y no refleja las dimensiones reales del producto.

paredes, etc., cuando la puerta está abierta

F Espacio desde la abertura – parte superior* 1” (2,5 cm) min.

J Altura hasta la parte inferior de la caja

de conexiones

desde el piso

con pedestal

1

»2” (72,4 cm) min.

5

»8” (72,7 cm) max.

28

13

»16” (131,6 cm) min.

5115»16” (131,9 cm) max.

11

»16” (1,75 cm)

23” (53,3 cm) min. 23” (53,3 cm) min.

1

»4” (3.2 cm)

(1

1

»4” (3,2 cm) 11»4” (3,2 cm)

1

»2” (24,1 cm) max.

sólo lado derecho

47” (119,4 cm) 47” (119,4 cm)

12” (30,5 cm) 12” (30,5 cm)

Horno doble de 30”

sin pedestal

1

28

»2” (72,4 cm) min.

5

»8” (72.7 cm) max.

28

50 ¼” (127,64cm)

11

»16” (1,75 cm)

1” (2,5 cm) min.

(11»4” (3.2 cm)

91»2” (24,1 cm) max.

sólo lado derecho

2 B

ABERTURA PARA INSTALACIÓN SOBRE UN CAJÓN

CALENTADOR

NOTA: Instale el horno sólo con los modelos específicos listados en la etiqueta ubicada en la parte superior

del horno.

NOTA: Pueden necesitarse espacios adicionales entre las aberturas. Verifique que los soportes del horno

sobre la ubicación de cajón calentador no obstruyan la profundidad y altura interiores requeridas.

Al instalar un Cajón para Calentar debajo de un horno doble, debe instalarse un tomacorriente separado de

120V, 60 HZ con adecuada conexión a tierra. Consulte las instrucciones de instalación enviadas con el cajón

calentador para requisitos específicos de instalación.

3 A

Cuándo usar el Pedestal

Al reemplazar un antiguo horno de pared doble de 30” de GE Appliances por un modelo nuevo de

GE Appliances. Altura de la abertura = 51 13/16” a 51 15/16”. Ésta es la altura de la abertura tradicional.

Cuándo NO usar el Pedestal

Al reemplazar un horno de pared doble de 30” de otro fabricante (tal como Whirlpool) por un nuevo horno de

pared doble de 30” de GE Appliances. Altura de la abertura = 50 1/4”. Usted deberá verificar que la abertura

existente coincida con la dimensión de 50 ¼”.

Si el nuevo horno de pared doble de 30” de GE Appliances está siendo instalado en una edificación nueva (es

decir, no como un reemplazo), entonces se recomienda que en la instalación se use el pedestal.

DETERMINACIÓN SOBRE CUÁNDO USAR EL PEDESTAL

3 B

INSTALACIÓN DEL RIEL CON PEDESTAL

(30” HORNOS DOBLES ÚNICAMENTE)

A. Posicione los rieles del pedestal con la abertura superior hacia el frente de la abertura y las lengüetas

de la parte inferior apuntando hacia el centro. Ubique cada riel sobre el piso o la corredera del gabinete,

levemente hacia dentro desde el costado del gabinete. Asegúrese de que el frente de cada riel no

sobresalga más allá del frente de la abertura del gabinete.

B. Realice agujeros de prueba y adjunte los rieles a la rodadura o a la parte inferior del gabinete con el equipo

provisto.

Continúe en la sección 3.

4

RETIRO DE LA PUERTA INFERIOR (recomendada)

NOTA: La remoción de la puerta no es un requerimiento de la instalación del producto, pero es una

comodidad adicional.

Para retirar la puerta inferior del horno:

A. Abra la puerta del horno en su totalidad.

B. Retire el soporte de la bisagra de la estructura frontal y déjelo a un lado. El soporte

de la bisagra debe ser colocado nuevamente para un funcionamiento apropiado de

la puerta cuando está última sea reinstalada.

C. Presione ambas trabas de la bisagra hacia abajo en dirección del marco de la

puerta hasta destrabarlas. Para esto puede hacer falta un destornillador de lados

planos. ¡NO LEVANTE LA PUERTA DE LA MANIJA!

D. Coloque las manos sobre ambos lados y cierre la puerta del horno hasta la posición

de remoción (aproximadamente 1”–2” [2,5 cm–5,1 cm] de la posición de cierre).

E. Levante la puerta hasta que los brazos de la bisagra hayan salido de las ranuras.

NOTA: La puerta del horno es muy pesada. Asegúrese de tener un agarre firme

antes de levantar la puerta del horno de sus bisagras. Tenga cuidado una vez que haya quitado la puerta.

No deposite la puerta sobre la manija. Esto puede provocar abolladuras o rayones.

Posición destrabada de la bisagra

Ranura

de la bisagra

Soporte de la Bisagra

REQUISITOS ELÉCTRICOS (CONT.)

5

Este aparato debe recibir el voltaje y frecuencia adecuados, y debe conectarse a un circuito derivado individual

con adecuada conexión a tierra, protegido por un interruptor de circuitos o fusible. Ver la placa de clasificación

ubicada en el armazón del horno para determinar la clasificación del producto.

La placa de calificación

está ubicada sobre el

borde lateral izquierdo

La Información del

Electrodoméstico

Conectado está

ubicada sobre el

reborde lateral

izquierdo

Tornillos de

agarre

Lengüetas

hacia el centro

de la abertura

Abertura superior

hacia el frente

Brazo

de la bisagra

5

REQUISITOS ELÉCTRICOS

ADVERTENCIA

ADVERTENCIA

este aparato.

ADVERTENCIA

circuitos antes de comenzar la instalación.

ADVERTENCIA

puede generar un peligro eléctrico o un incendio. Sólo use conectores diseñados para unir cobre con aluminio y siga al

pie de la letra el procedimiento recomendado del fabricante.

Recomendamos que un electricista calificado conecte el cableado eléctrico de su aparato. Después de la instalación,

solicite al electricista que le indique cómo desconectar la energía del aparato.

Usted debe usar un sistema eléctrico de fase única de 120/208 VAC o 120/240 VAC de 60 hercios. Si tiene una conexión

con cableado de aluminio, deben utilizarse conectores adecuadamente instalados para utilizar con cableado de aluminio.

Vigente desde el 1 de enero de 1996, el Código Eléctrico Nacional requiere que las nuevas construcciones (no existentes)

utilicen una conexión de cuatro conductores a un horno eléctrico. Cuando instale un horno eléctrico en una construcción

nueva, una casa rodante, un vehículo recreativo o un área donde los códigos locales prohíben la conexión a tierra a través

de un conductor neutral, consulte la sección sobre conexiones en circuito derivado de cuatro conductores.

Consulte a las empresas de servicio público sobre los códigos eléctricos que se aplican en su área. No realizar el

cableado de su horno de acuerdo con los códigos vigentes puede provocar una situación peligrosa. Si no existen

códigos locales, el cableado y fusibles de su horno deben cumplir con el Código Eléctrico Nacional, NFPA Nº 70, última

edición, disponible en National Fire Protection Association (Asociación Nacional de Protección contra Incendios).

Este aparato debe contar con una adecuada conexión a tierra.

Para prevenir un incendio o descarga eléctrica, no utilice un cable de extensión con

Para prevenir una descarga eléctrica, quite el fusible o abra el interruptor de

Una conexión inadecuada de cableado doméstico de aluminio con cables de cobre

La bisagra sale de la ranura

Utilice la tabla de abajo para determinar la protección de circuito dedicado mínima recomendada:

NO acorte

Clasificación Tamaño de circuito

de KW Clasificación de KW recomendado

240V 208V (dedicado)

.: .: $PS

.:±.: .:±.: $PS

.:±.: .:±.: $PS

.:±.: .:±.: $PS

el conducto flexible. La abrazadera del alivio de tensión del conducto debe estar bien sujeta a la caja de

conexiones y el conducto flexible debe estar bien sujeto a la abrazadera. Si el conducto flexible no entra dentro

de la abrazadera, no instale el horno hasta obtener una abrazadera del tamaño adecuado.

Los 3 cables de energía suministrados con este aparato son adecuados para conexiones con cableados

domésticos de calibre mayores. La aislación de estos 3 cables está clasificada a temperaturas mucho más

elevadas que la clasificación del cableado doméstico. La capacidad

de transmitir corriente del conductor está determinada por el calibre del cable y la clasificación

de temperatura de la aislación alrededor del cable.

31-11065 03-17 GEA (sheet 1)

Page 4

6

REALICE LAS CONEXIONES ELÉCTRICAS

ADVERTENCIA

desconexión para evitar el accionamiento de la energía de manera accidental. Cuando los medios de

desconexión de servicio no pueden bloquearse, coloque sobre el panel de servicio un dispositivo de

advertencia bien visible, como una etiqueta.

Coloque el horno sobre una mesa o plataforma en forma nivelada con la abertura. Para un horno doble, la

plataforma debe soportar 400 lbs. (181 kg). Conecte el conducto flexible a la caja de conexiones eléctrica como se

indica abajo*. Posicione el conducto de modo tal que se apoye detrás de la unidad en un círculo natural cuando

el horno sea instalado. Tendrá que comprar una abrazadera para alivio de tensión apropiada para completar la

conexión del conducto a la caja de conexiones.

Coloque el horno

en un soporte para

ayudar a la conexión del

conducto

* Los hornos vienen equipados con un conducto de 40” de longitud. Si desea un conducto más largo, puede

haber uno disponible para su modelo. Para verificar la disponibilidad o solicitar piezas, llame a GE Appliances

al 800.GE.CARES.

Desconecte la energía del panel de servicio y bloquee los medios de

Caja de conexiones

Conducto

Tierra

La abrazadera del alivio

de tensión (no incluido)

debe usarse en la caja de

conexiones

Rojo

Blanco

Negro

Cable

a tierra

7

CONEXIÓN DE CIRCUITO DERIVADO DE TRES

CONDUCTORES

Cable neutral

conexión

Negro

Encinte o Prense

Cables a tierra

y neutrales (blanco)

NOTA: Si los cables del hogar poseen conductores de aluminio, ver

la ADVERTENCIA de la sección 5, Requisitos eléctricos.

Cuando conecte un circuito derivado de tres conductores, si lo

permiten los códigos locales:

A. Conecte el conductor de conexión a tierra junto con el cable

neutro (blanco) al neutro del circuito de empalmes (de color

blanco o gris), usando una tuerca para cables.

B. Conecte el cable rojo del horno al cable rojo del circuito derivado

y el cable negro del horno al cable negro del circuito derivado de

acuerdo con los códigos locales, utilizando tapones de alambre.

C. Instale una abrazadera adecuada de alivio de tensión.

D. Instale la tapa de la caja de conexiones.

8

CONEXIÓN DE CIRCUITO DERIVADO DE CUATRO

El tubo de

la estufa

se ajusta

en la caja

Tapa de la caja de conexiones

Rojo

CONDUCTORES

NOTA: Si los cables domésticos son conductores de aluminio, ver la ADVERTENCIA de la sección 5,

Requisitos eléctricos.

Cuando conecte un circuito derivado de cuatro conductores, si lo permiten los códigos locales:

A. Evite que el conductor neutro (blanco) quede enredado con

cualquier otro cable. De ser necesario, corte el conductor neutro

(blanco) y luego vuelva a pelar el mismo, a fin de exponer la

longitud adecuada del conductor.

B. Conecte el cable a tierra del aparato (verde o cobre) de acuerdo

con los códigos locales.

C. Conecte el cable neutral (blanco) del horno con el neutral de circuito

derivado (blanco o gris) de acuerdo con códigos locales, utilizando

un tapón de alambre.

D. Conecte el cable rojo del horno al cable rojo del circuito derivado

y el cable negro del horno al cable negro del circuito derivado de

acuerdo con los códigos locales, utilizando tapones de alambre.

E. Instale una abrazadera adecuada de alivio de tensión.

F. Instale la tapa de la caja de conexiones.

El tubo de

la estufa

se ajusta

en la caja

Rojo

Tapa de la caja de conexiones

Negro

Blanco

Circuito

ramificado

Agujero

ciego

alternativo

Circuito

ramificado

Cables

a tierra

Agujero ciego

alternativo

9

DESLICE EL HORNO DENTRO DE LA ABERTURA

• Levante el horno dentro de la abertura

del gabinete utilizando el horno abierto

como agarre. Con cuidado empuje contra

el armazón frontal del horno. No presione

sobre los bordes externos.

10

INSTALE EL HORNO

ADVERTENCIA

gabinete, lo que provocaría una lesión grave.

NOTA: Durante el montaje del horno, asegúrese de que no haya daños sobre la junta del horno, que aliña el

extremo de la cavidad del horno

NOTA: Antes de perforar los orificios piloto, asegúrese de que el horno se encuentre en la posición final de la

abertura y centrado.

NOTA: Si el gabinete es de placa de partículas, deben utilizarse tornillos #8 x ¾” para dicho material. Éstos

pueden adquirirse en cualquier ferretería.

A. Perfore a través de los orificios de montaje (superiores e inferiores) del reborde lateral para los tornillos de

montaje #8 provistos.

B. Asegure el gabinete del horno con los tornillos provistos.

Deben utilizarse tornillos de montaje. Si no lo hace, el horno puede caer del

Los tornillos deben

hallarse a un mínimo

de ¼” (6 mm) desde el

frente de la abertura.

Ubicaciones

de los orificios

de montaje

(las ubicaciones

pueden variar)

Ubicaciones

de los orificios

de montaje

(las ubicaciones

pueden variar)

11

INSTALACIÓN DEL REBORDE INFERIOR

Una vez instalado el horno, adjunte el borde inferior a través de sus agujeros de montaje frente al soporte

vertical, utilizando los dos tornillos con cabeza recortada provistos. El labio de la cubierta inferior deberá ser

ubicado debajo de la brida de la parte inferior del conducto de aire.

Instalaciones sin Pedestal

Instalaciones con Pedestal

IMPORTANTE: Si esta unidad alguna vez se quita del gabinete o si el horno se quita de

servicio, el reborde inferior debe quitarse antes o el reborde sufrirá daños.

GUÍA DE INSTALACIÓN DE LA ESTANTERÍA DEL HORNO

12

A. Ubique el equipo de montaje de la guía del horno incluida.

B. Posicione el conducto de modo tal que se apoye detrás de la unidad en un círculo natural

cuando el horno sea instalado.

C. Instale las guías usando las 8 tuercas de montaje provistas.

Las puertas francesas

fueron retiradas sólo para

que la ilustración sea clara

Los Pivotes

Metálicos se deben

instalar en la parte

trasera de la cavidad

La puerta inferior del

horno fue retirado sólo

con propósitos ilustrativos

La guía del

estante del horno

se muestra en su

posición.

MECANISMO DE AJUSTE DE LA PUERTA

13

El Mecanismo de Ajuste de la Puerta se encuentra ubicado tanto en la puerta derecha como en la izquierda,

en las bisagras inferiores. Sólo el lado izquierdo del Mecanismo de Ajuste es mostrado en este manual.

NOTA: Ajuste las puertas hacia adentro, sólo hasta que la brecha central esté pareja. Un ajuste excesivo

puede dañar los cierres herméticos centrales y dificultar la apertura de las puertas.

A. Utilizando una Llave Hexagonal de 3/16”, ajuste el Tornillo de Ajuste Vertical, a fin de ajustar la puerta hacia

arriba y ajustar la misma hacia abajo.

B. Los Tornillos de Ajuste Horizontal hacen

que la puerta pivote en torno a un eje.

Utilizando una Llave Hexagonal de 1/8”,

afloje ambos tornillos, y luego ajuste el

tornillo adecuado para pivotar la puerta.

Una vez que la puerta esté colocada,

verifique que ambos tornillos estén

ajustados.

Tornillos de Ajuste Horizontal

Vertical Adjustment Screw

EJEMPLOS EXAGERADOS DEL

AJUSTE DE LA PUERTA IZQUIERDA

Ejemplo 1: Puerta izquierda

baja, brecha central pareja.

Pasos para el ajuste:

A. Ajuste el Tornillo de Ajuste

Vertical.

B. Si la puerta izquierda aún

está baja, afloje el Tornillo

de Ajuste Vertical derecho.

Ejemplo 2: Puerta izquierda

baja, brecha central más

grande en la parte inferior.

Pasos para el ajuste:

A. Afloje la parte interna

del Tornillo de Ajuste

Horizontal.

B. Ajuste el Tornillo de Ajuste

Horizontal externo hasta

que la brecha central esté

pareja.

C. Si la puerta izquierda aún

está baja, ajuste el Tornillo

de Ajuste Vertical izquierdo.

D. Ajuste el Tornillo de Ajuste

Ejemplo 3: Puerta izquierda

alta, brecha central más

grande en la parte superior.

Pasos para el ajuste:

A. Afloje el Tornillo de Ajuste

Horizontal externo.

B. Ajuste el Tornillo de Ajuste

Horizontal externo hasta

que la brecha central esté

pareja.

C. Si la puerta izquierda aún

está baja, ajuste el Tornillo

de Ajuste Vertical izquierdo.

D. Ajuste el Tornillo de Ajuste

Horizontal interno.

Horizontal interno.

14

REEMPLAZO DE LA PUERTA INFERIOR DEL HORNO

NOTA: La puerta del horno es pesada. Puede necesitar ayuda para levantar la puerta lo suficiente como para

deslizarla dentro de las ranuras de la bisagra. No levante la puerta de la manija.

A. Levante la puerta del horno tomándola de ambos lados.

B. Con la puerta en el mismo ángulo de la posición de remoción (aproximadamente

1”–2” [2,5 cm–5,1 cm] desde la posición de cerrado), introduzca la muesca del

brazo de la bisagra dentro del extremo inferior de la ranura de la bisagra. La ranura

del brazo de la bisagra debe estar bien colocada en la parte inferior de la ranura.

C. Abra la puerta por completo. Si la puerta no se abre por completo, la muesca no

está bien colocada en el extremo inferior de la ranura.

D. Presione las trabas de la bisagra hacia arriba contra el armazón frontal de la

cavidad del horno, hasta alcanzar la posición de trabado.

E. Reemplace el soporte de la bisagra. El soporte de la bisagra debe ser colocado

nuevamente para un funcionamiento apropiado de la puerta.

F. Cierre la puerta del horno.

Bisagra en

la posición

de trabado

Ranura de la

bisagra bien

colocada en la

parte inferior de

la ranura de la

bisagra

15

LISTA DE CONTROL FINAL DE LA INSTALACIÓN

• Verifique que el interruptor de circuitos se encuentre cerrado (RESET) o que los fusibles del circuito se hayan

reemplazado.

• Asegúrese de que haya suministro eléctrico en el edificio.

• Controle que se haya quitado todo el material de empaque y la cinta adhesiva. No quitar estos materiales

puede provocar daños al electrodoméstico una vez que el aparato se haya encendido y las superficies se

hayan calentado.

• Quite todos los elementos ubicados dentro del horno.

• Asegúrese de que los tornillos de montaje se encuentren instalados y nivelados con el reborde lateral (ver

sección 10).

• Verifique que el reborde inferior esté bien instalado (ver sección 11).

• Asegúrese de que la abertura inferior del conducto de aire de la unidad esté libre de obstrucciones.

• Controle que las guías de los estantes del horno estén instaladas de forma correcta y que los estantes del

horno funcionen de forma fluida.

Lado

inferior de

la ranura

Ranura de la bisagra

Brazo

de la bisagra

Soporte de la Bisagra

31-11065 03-17 GEA (sheet 2)

LISTA DE CONTROL DE FUNCIONAMIENTO

• Accione la energía del horno (consulte el Manual del propietario). Verifique que las unidades de horneado y

asado y que todas las funciones de cocción operen bien.

• Ver el Manual del propietario para la lista de detección y solución de problemas.

• Asegúrese de que todos los controles del horno se encuentren en OFF (apagado) antes de dejar el horno.

Loading...

Loading...