Page 1

Installation

Instructions

WB28K10553 High Altitude Kit

For Monogram Professional Range and Rangetop Installations

at Elevations of 6,000 Feet or More Above Sea Level

WARNING: This conversion must be

performed by a qualified installer or gas supplier in

accordance with the manufacturer’s instructions and

all codes and requirements of the authority having

jurisdiction. Failure to follow instructions could result

in serious injury or property damage. The qualified

agency performing this work assumes responsibility

for the conversion.

This kit is designed for both LP and Natural Gas range

and rangetop models. Use only the orifices specified.

Additional orifices may be present.

Keep all orifices and parts that are removed for

possible future use.

TOOLS YOU NEEDED FOR CONVERSION

Small Flat-Head Screwdriver

Safety Glasses

1/2” Deepwell

Socket Wrench

1/4” and 7mm Nutdrivers

(2 to 2.4 mm or 3/32” tip size,

60 mm long)

Small Pliers

Philips

Screwdriver

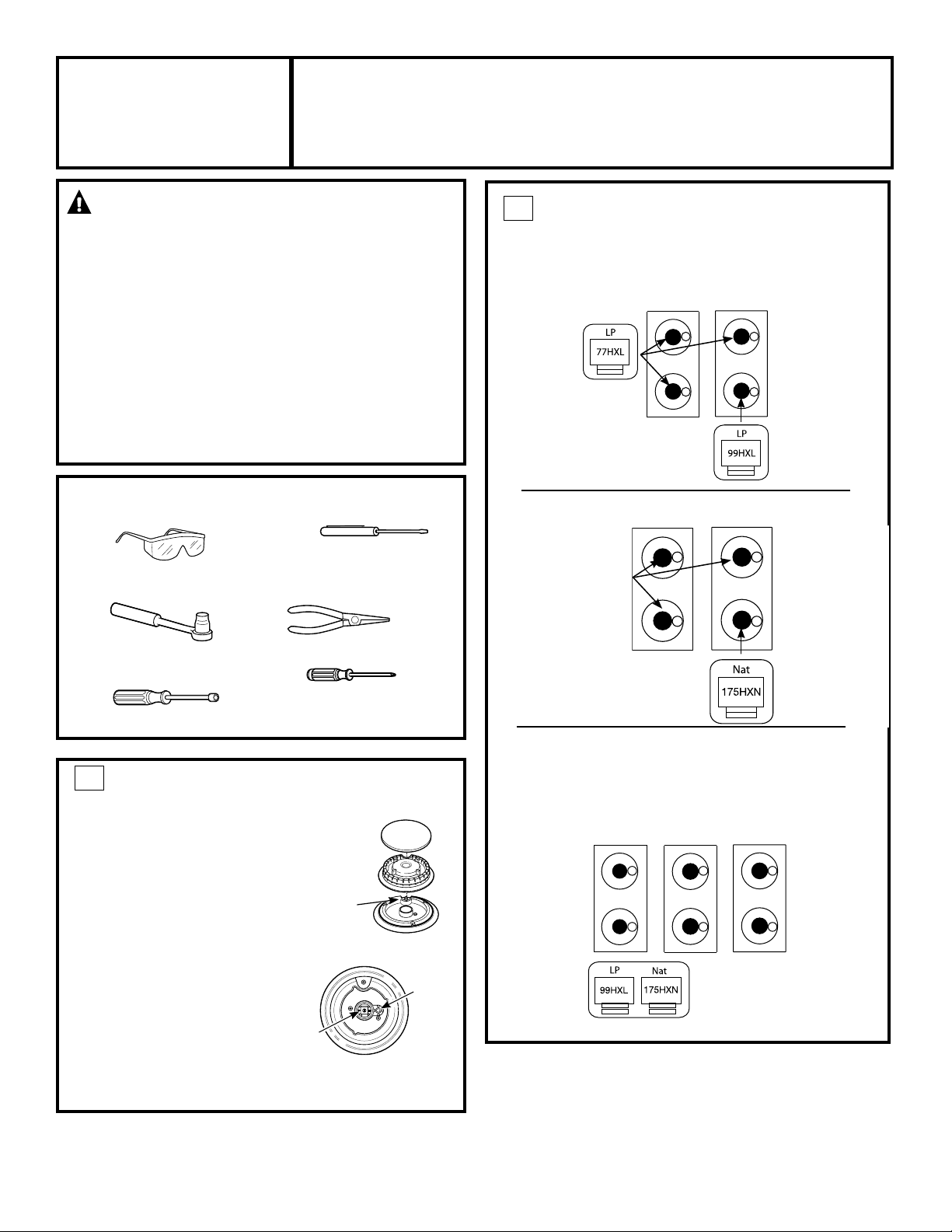

2

CHANGE BURNER ORIFICES

IMPORTANT: Find your model number below. Read

each orifice label to identify and install them in the

exact locations shown.

A.

Replace the main burner orifice on all burners

30” LP Range Model ZDP304L and ZGP304L

as indicated.

B.

Replace the burner heads, caps and top grates

Use 77HXL orifice

on three burners

for LP model

ZDP304L and

ZGP304L.

30” Natural Gas Range Model ZDP304N and ZGP304N

DO NOT

CHANGE THESE

NATURAL GAS

ORIFICES.

Use a 99HXL

orifice for the

right-front

burner.

Use a 175HXN

orifice for the

right-front

burner.

.

1

CHANGE BURNER ORIFICES

INSTALLATION TIP: The orifices for

ranges and rangetops operating on

either gas type—Natural or LP—are

included in this kit. Select and use only

the orifices specified for the type of

gas being used.

A. Remove the burner grates, burner

caps and burner heads.

B. Change only the main burner

orifices. The main orifice is located in

the center of the burner. The simmer

orifice is located higher beside the

center of the burner. Do not change

the simmer orifice.

NOTE: Models equipped with a grill do not require a grill

orifice change.

Spark

Igniter

Main

Orifice

Burner Cap

Burner

Head

Burner Base

Simmer

Orifice

ALL 36” AND 48” RANGE OR RANGETOP MODELS:

ZDP364, ZDP366, ZDP484, ZDP486, ZGP364,

ZGP366, ZGP484, ZGP486, ZGU364, ZGU366,

ZGU484, ZGU486

MAIN

ORIFICES

Use 99HXL or

175HXN orifices

for all burners.

31-10698-3 11-10 GE

Page 2

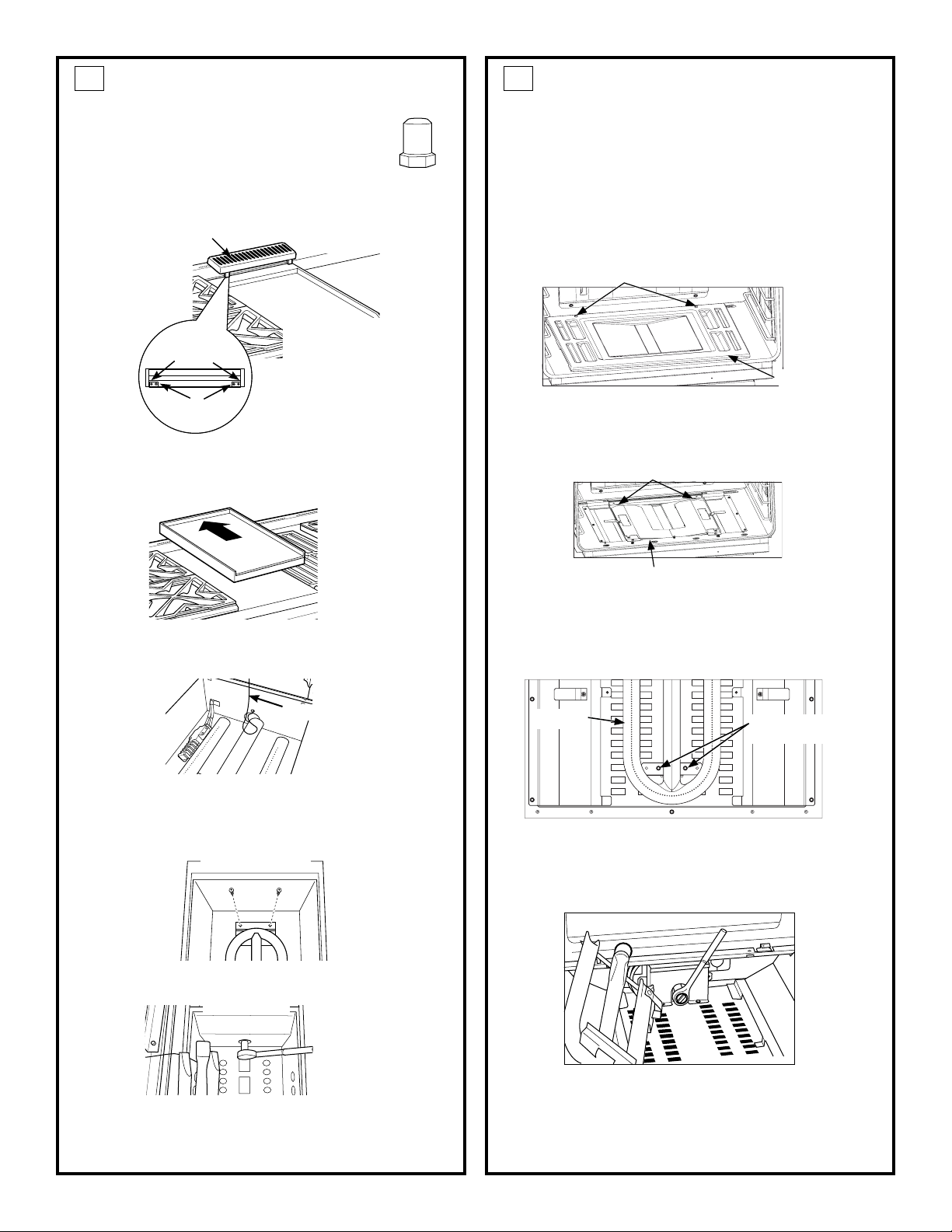

CHANGE GRIDDLE ORIFICE

3

(if present)

Locate the 3/4” long griddle orifice. Select the

proper orifice size for your gas and burner from the

conversion chart.

A. Lift off the griddle flue cover. Remove the 2 inside

clamping screws.

Griddle Flue Cover

NOTE: Remove

the 2 screws

Leveling Screws

Clamping Screws

positioned on

the inside only.

Do not remove

the outermost

screws—they

are for leveling.

B. Lift out the cast-iron grease trough. Slide the

griddle toward the rear and out of the hold-down

tabs along the bottom.

4A

CHANGE MAIN BAKE BURNER

ORIFICE (if present)

Locate the 3/4” long bake burner orifice.

Select the proper orifice size for your gas and burner from

the conversion chart.

A. Remove the oven door and set aside in a safe

location.

B. Remove the 2 oven bottom hold-down screws

from the rear of the cover.

Hold-Down Screws

Oven

Bottom

C. Slide the oven bottom forward and set aside.

D. Remove the burner diffuser screw.

Clips

C. Carefully lift and hold the griddle while pulling

additional length of the capillary from the entry

hole. Stand the griddle on end in the grease sump.

Capillary

D. Remove the 2 hold-down screws at the rear of the

burner.

Pull the burner straight back toward the rear and

out of the gas inlet.

Back of Range

E. Use a 1/2” deepwell socket to remove and replace

the orifice.

Front of Range

Diffuser screw

E. Lift the front of the burner diffuser up slightly and

slide it forward to disengage the clips at the rear.

Set the burner diffuser aside.

F. Remove the 2 burner retention screws.

Burner

Lift the front of the burner up slightly and slide for-

G.

Burner retention

screws

ward setting aside (careful not to damage the igniter.)

H. Use a 1/2” deepwell socket to remove and replace

the orifice.

Reverse these steps to reassemble the griddle.

Push excess capillary back into the entry hole.

Place the unused orifice in the holder for possible

future use.

I. Reverse these steps to reassemble the griddle.

Push excess capillary back into the entry hole.

Place the unused orifice in the holder for possible

future use.

2

Page 3

4B

CHANGE COMPANION BAKE BURNER

ORIFICE (if present)

Locate the 3/4” long bake burner orifice.

Select the proper orifice size for your gas and burner

from the conversion chart.

A. Remove the oven

door and set

aside in a safe

location.

B. Remove the 2

oven bottom

hold-down

screws from the

rear of the cover.

C. Slide the oven bottom forward and set asside.

D. Remove the burner diffuser screw.

E. Lift the front of the

burner diffuser up

slightly and slide it

forward to disengage the clips at

the rear. Set the

burner diffuser

aside.

F. Remove the 3

burner retension screws

(1 in front and 2 at the

rear)

G. Lift the front of the burner

up slightly and slide

leftward to remove.

H. Use a 1/2” deepwell

socket to remove and

replace the orifice.

I. Reverse these steps to

reassemble the griddle.

Push excess capillary

back into the entry hole.

Place the unused orifice

in the holder for possible future use.

Hold-Down

Screws

Oven

Bottom

Clips

Diffuser Screw

Burner

Retension

Screws

5

ADJUST BURNER FLAMES

Normally, burners do not need further adjustment.

Make adjustments only when necessary.

A. Turn on the gas. Plug in electrical cord.

B. Turn all burners on highest setting and check the

flames. They should be blue in color. When using

LP gas, the flames may have some yellow tipping

at the ends of the flame. Foreign particles in the

gas line may cause an orange flame at first, but

this will soon disappear.

C. Turn the burner knob to “LO” while observing the

flame.

Adjust the setting of the upper row of flames using

the valve bypass screw as follows:

Adjustments must be made with two other

burners in operation on a medium setting. This

prevents the upper row of flames from being set

too low, resulting in the flame being extinguished

when other burners are turned on.

D. To adjust the flame, remove the knobs. Insert a

small flat-blade screwdriver into the hole in the

center of the valve stem to engage screw.

• If the flames are too small

or flutter, turn the screw

counterclockwise.

• If the flames are too large,

turn the screw clockwise.

E. Make the adjustment by slowly turning the screw

until flame appearance is correct.

Once the conversion is complete and checked, fill out the

conversion label and affix the label near the rating label.

For ranges, place the label beneath the control panel. For

rangetops, place the label on the bottom of the unit.

3

Page 4

BURNER OUTPUT RATINGS: BTU/HR

NG (Natural) Gas, 5” W.C.P.

MODEL BURNER

ZDP48,

ZGP48,

ZGU48

ZDP36,

ZGP36,

ZGU36

ZDP304

ZGP304

ZDP304

ZGP304

ALL GRILL 15,000

ALL GRIDDLE 18,000

ZGP48,

ZGP36

ZGP30 BAKE MAIN 20,500

ZGP48 BAKE COMPANION 9,000

ZGP304,

ZGP36

ZGP48

ZGP48 BROIL COMPANION 9,000

ALL SURF. Main 16,800

BURNERS Simmer 1,200

RF BURNER

Simmer 1,200

RR, LR, LF

Simmer

BAKE MAIN 20,500

BROIL MAIN 12,500

Main 16,800

Main

BTU

RATE

8,800

1,200

ORIFICE

SIZE

0.075”

(1.90mm)

0.002”

(0.51mm)

0.075”

(1.90mm)

0.002”

(0.51mm)

0.050”

(1.26mm)

0.002”

(0.51mm)

0.0689”

(1.75mm)

0.067”

(1.70mm)

0.0807”

(2.05mm)

0.0807”

(2.05mm)

0.0492”

(1.25mm)

0.063”

(1.60mm)

0.052”

(1.32mm)

ID

175HXN

51SL

175HXN

51SN

126HXN

51SN

0.069

0.067

0.081

0.081

0.049

160

132

LP (Propane) Gas, 10” W.C.P.

MODEL BURNER

ZDP48,

ZGP48,

ZGU48

ZDP36,

ZGP36,

ZGU36

ZDP304

ZGP304

ZDP304

ZGP304

ALL GRILL 14,000

ALL GRIDDLE 16,000

ZGP48,

ZGP36

ZGP30 BAKE MAIN 20,000

ZGP48 BAKE COMPANION 9,000

ZGP304,

ZGP36

ZGP48

ZGP48 BROIL COMPANION 9,000

ALL SURF. Main 13,800

BURNERS Simmer 1,200

RF BURNER

Simmer 1,200

RR, LR, LF

Simmer

BAKE MAIN 20,000

BROIL MAIN 11,500

Main 13,800

Main

BTU

RATE

7,900

1,200

ORIFICE

SIZE

0.043”

(1.08mm)

0.013”

(0.34mm)

0.043”

(1.08mm)

0.013”

(0.34mm)

0.033”

(0.84mm)

0.013”

(0.34mm)

0.047”

(1.19mm)

0.047”

(1.19mm)

0.0512”

(1.45mm)

0.0512”

(1.45mm)

0.0354”

(0.90mm)

0.041”

(1.04mm)

0.0360”

(0.91mm)

ID

99HXL

34SL

99HXL

34SL

77HXL

34SL

0.047

0.042

0.051

0.051

0.035

104

91

4

Loading...

Loading...