Mono Equipment METRO Setup And Operation Instructions

METRO MOULDER

www.monoequip.com

Enter Serial No. here.____________________________

In the event of an enquiry please quote this serial number.

SET UP AND OPERATION INSTRUCTIONS

FG021- METRO RevA19 17-01-19

FILE 22

2

Failure to adhere to the cleaning and maintenance instructions

detailed in this booklet could affect the warranty of this

machine

FG021- METRO RevA19 17-01-19

3

SAFETY SYMBOLS

The following safety symbols are used throughout this product documentation and manual

(available at www.monoequip.com).

Before using your new equipment, read the instruction manual carefully and pay special

attention to information marked with the following symbols.

WARNING

WARNING

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

will result in electric shock.

CAUTION

Indicates a hazardous situation which, if not avoided,

will result in minor or moderate injury.

FG021- METRO RevA19 17-01-19

4

ELECTRICAL SAFETY AND ADVICE REGARDING

The supply to this machine must be protected by a

30mA RCD

SUPPLEMENTARY ELECTRICAL PROTECTION:

Commercial bakeries, kitchens and foodservice areas are environments where electrical

appliances may be located close to liquids or operate in and around damp conditions or

where restricted movement for installation and service is evident.

The installation and periodic inspection of the appliance should only be undertaken by a

qualified, skilled and competent electrician, and connected to the correct supply suitable for

the load as stipulated by the appliance data label.

The electrical installation and connections should meet the necessary requirements of the

local electrical wiring regulations and any electrical safety guidelines.

We Recommend:

− Supplementary electrical protection with the use of a residual current device (RCD)

− Fixed wiring appliances incorporate a locally situated switch disconnector to connect

to, which is easily accessible for switching off and safe isolation purposes. The switch

disconnector must meet the specification requirements of IEC 60947.

FG021- METRO RevA19 17-01-19

FG021- METRO RevA19 17-01-19

5

6

CONTENTS

1.0 Introduction

2.0 Dimensions

3.0 Specifications

4.0 Safety

5.0 Installation

6.0 Isolation

7.0 Cleaning

Daily

Weekly

8.0 Operating Instructions

How the Metro moulds dough.

Operating the moulder

o a. Hopper width adjustment

o b. Sheeting gap adjustment

o c. Side guides adjustment

o d. Moulding pressure adjustment

Starting the Metro

9.0 Trouble shooting

10.0 Service and spares

11.0 Electrical information

FG021- METRO RevA19 17-01-19

7

1.0 INTRODUCTION

The metro moulder has been designed with reliability and ease of operation in mind.

Fully interlocked guards and covers ensure that semi skilled personnel can safely operate

this versatile machine, which has a maximum output of 1200 dough pieces an hour.

The double sheeting rolls give a gentle two stage reduction of the dough and two curling

chains give greatly improved consistency of shape and size to the moulded dough piece.

Windows at the front and rear of the machine allow the operator to monitor the progress of

the dough right through the moulder.

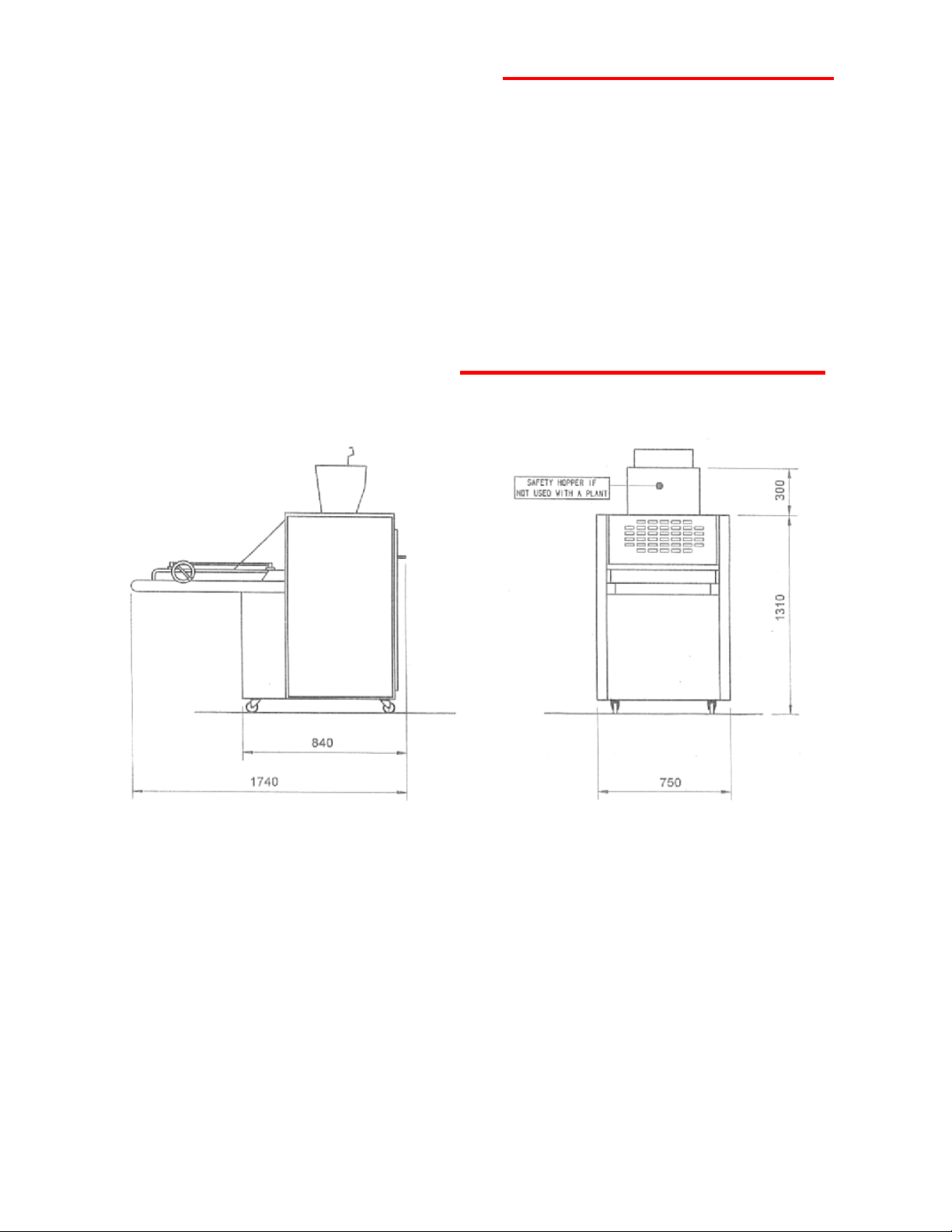

2.0 DIMENSIONS

HEIGHT 1310mm (WITHOUT HOPPER)

WIDTH 750mm

LENGTH 1740mm

FG021- METRO RevA19 17-01-19

8

3.0 SPECIFICATIONS

The supply to this machine must be protected by a

30mA RCD

CAPACITY: Dough piece weight range – 56grms to 1.8Kg – (2oz to 4lbs)

OUTPUT: Up to 1200 pieces per hour

POWER: 0.75kW, 3 phase and neutral

WEIGHT: 230kg (507lbs)

NOISE LEVEL: Less than 85dB

FG021- METRO RevA19 17-01-19

Loading...

Loading...