OPERATING AND MAINTENANCE

MANUAL

Enter Serial No. here._____________________________________

In the event of an enquiry please quote this serial number.

www.monoequip.com

FLEXI MULTI-MOULDER (HAND FEED)

Flexi moulder RevA19 10-01-19

FG105

1

Flexi moulder RevA19 10-01-19

2

The supply to this machine must be protected by a

30mA RCD

IMPORTANT NOTES

ELECTRICAL SAFETY AND ADVICE REGARDING

SUPPLEMENTARY ELECTRICAL PROTECTION:

Commercial bakeries, kitchens and foodservice areas are environments where electrical

appliances may be located close to liquids or operate in and around damp conditions or where

restricted movement for installation and service is evident.

The installation and periodic inspection of the appliance should only be undertaken by a

qualified, skilled and competent electrician, and connected to the correct supply suitable for

the load as stipulated by the appliance data label.

The electrical installation and connections should meet the necessary requirements of the

local electrical wiring regulations and any electrical safety guidelines.

We Recommend:

− Supplementary electrical protection with the use of a residual current device (RCD)

− Fixed wiring appliances incorporate a locally situated switch disconnector to connect to,

which is easily accessible for switching off and safe isolation purposes. The switch

disconnector must meet the specification requirements of IEC 60947.

Flexi moulder RevA19 10-01-19

3

The supply to this machine must be protected by a

30mA RCD

SAFETY SYMBOLS

The following safety symbols are used throughout this product documentation and manual

(available at www.monoequip.com).

Before using your new equipment, read the instruction manual carefully and pay special

attention to information marked with the following symbols

ENSURE THE MOULDER IS SET UP AND ADEQUATE TINS AND TRAYS ARE AVAILABLE

BEFORE STARTING.

WARNING

WARNING

CAUTION

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

will result in electric shock.

Indicates a hazardous situation which, if not avoided,

will result in minor or moderate injury.

FAILURE TO ADHERE TO THE CLEANING AND MAINTENANCE INSTRUCTIONS

DETAILED IN THIS BOOKLET COULD AFFECT THE WARRANTY OF THIS MACHINE.

Flexi moulder RevA19 10-01-19

4

CONTENTS

Section - 1.0 Introduction

Section - 2.0 Overall Dimensions

Section - 3.0 Specifications

Section - 4.0 Safety

Section - 5.0 Installation

Section - 6.0 Isolation

Section - 7.0 Cleaning

o Daily

o Weekly

Section - 8.0 Operating Information

Section - 9.0 Operating Machine

o Moulding between belts (French stick and petit pan)

o Moulding Between Rear Belt & Pressure Board (Tin and Bloomers)

Section - 10.0 Maintenance

Section - 11.0 Troubleshooting

Section - 12.0 Service and Spares

Section - 13.0 Electrical Information

Flexi moulder RevA19 10-01-19

5

1.0 INTRODUCTION

MONO’s 105 Moulder combines the capabilities of traditional bread and French stick moulding

machines. Its small footprint and simple controls are of particular benefit in small bakeries.

The 105 Moulder will process up to 900 dough pieces an hour.

2.0 OVERALL DIMENSIONS

Height: 1825mm.

Depth: 1205mm.

Width: 1020mm.

Flexi moulder RevA19 10-01-19

6

The supply to this machine must be protected by a

30mA RCD

3.0 SPECIFICATIONS

Total power: 0.75kW three phase

Capacity: Up to 900 dough pieces processed every hour, between 250g (9oz) and 0.9kg (2lb)

in weight and between 125mm (5”) and 760mm (30”)

Weight: 430kg

Noise level: Less than 85dB.

Flexi moulder RevA19 10-01-19

7

4.0 SAFETY

1 Never use a machine in a faulty condition and always report damage.

2 No one under 16 may operate this machine.

3 No one under 18 may clean this machine.

4 Only trained and authorised persons may remove any part that requires a tool to do so.

5 Always ensure hands are dry before touching any electrical appliance (including cable and

plug).

6 All operatives must be fully trained.

7 People undergoing training on the machine must be under direct supervision of a trainer.

8 Do not operate with any panels removed.

9 All guards must be fixed in place with bolts or screws unless protected by a

safety switch.

10 No loose clothing or jewellery to be worn while operating the machine.

11 Switch off power at the mains isolate switch or isolate at the main control box

12 The Bakery Manager or the bakery Supervisor must carry out daily safety checks.

13 Warning: Do not attempt to scrape moulding belts when moulder is running.

14 Any internal maintenance must be by fully trained maintenance personnel.

WARNING: Hand or bodily contact with moving belt surfaces may cause friction burns to skin.

This situation need not occur to successfully operate moulder

Flexi moulder RevA19 10-01-19

8

5.0 INSTALLATION

1 Ensure machine is standing on a solid level floor. Lock the two front castors into place.

2 Check machine after installation to ensure drive motor rotation is in the direction of arrow.

This should be done with drive V-belt removed. If motor rotation is incorrect, change round

any two of the three phase carrying wires. Drive motor should be travelling in an anticlockwise direction.

Flexi moulder RevA19 10-01-19

9

To stop the moulder in an emergency

EMERGENCY STOP BUTTON

6.0

ISOLATION

switch off at the main isolator,

or use the emergency stop button on the front of the machine

,

Flexi moulder RevA19 10-01-19

(TWIST TO RELEASE)

10

SIDE DOOR

LARGE FRONT SHEET

SMALL FRONT SHEET

7.0 CLEANING

DAILY CLEANING INSTRUCTIONS

NOTE! - USE PLASTIC SCRAPERS TO REMOVE SUBSTANTIAL DOUGH PIECES PRIOR TO

CLEANING.

1. Isolate the mains supply.

2. Brush infeed hopper area.

3. Pull out and down, large hopper area sheeting to expose rollers.

INFEED HOPPER

REAR DOOR

(BOTH SIDES)

Flexi moulder RevA19 10-01-19

11

4. Set sheeting gap to the widest mark and brush out residue from the area, using a plastic

scrapper on the rollers if required.

5. Clean any residue that has been trapped at the bottom of the belt.

Scrape exposed surface of the dough-moulding belt with plastic scraper.

6. Close cover and then remove bottom cover by lifting up slightly and lowering down.

7. Brush/vacuum the area and close cover.

Flexi moulder RevA19 10-01-19

12

CLOSED

OPEN

PIN

SLOT

To refit scraper.

CLIP

SCRAPER REMOVAL

To remove scraper.

Slide clips sideways and drop bar down

to disengage (one each side).

Feed under chute and remove.

Feed scraper into position under

chute and lift locating slot on to pin.

Slide clip over protruding bolt to hold

in position. Both sides.

Flexi moulder RevA19 10-01-19

13

LIFT

CURLING CHAIN CLEANING

1. Remove scraper as previous section.

2. Lift black knob on right and slide square shaft to the left while lifting out of location.

3. Place bar diagonally and work out through the top of the machine after unclipping

opposite end of chain at the rear.

Lift clamps/chain off top bar and remove curling chain

4. Clean and replace chain by dropping down conveyor from the back and clipping in

place at the front. (Reverse of removal).

Flexi moulder RevA19 10-01-19

14

A

B

PRESSURE BOARD

Pressure Board Removal

SET TO 400

1. Fully lower the rear-moulding belt using lever (A) and fully lower the pressure board

by adjusting handle (B) to setting “400” on the counter. Open rear door.

2. Remove the pressure board by gripping the handle provided,

and then lift up and out .

3. Wash dough contact surfaces of the pressure board and side guides with

disinfecting solution and hot water. Dry with cloth.

4. Remove any dough from the bottom belt with a plastic scraper.

5. Replace the pressure board, making sure the hooks on the board are fully engaged.

Close the rear door firmly to make the interlock connection.

REAR

BELT

PRESSURE

BOARD

HANDLE

Flexi moulder RevA19 10-01-19

15

OFF TAKE TRAY

This should be scraped clean with a plastic scraper.

OFF TAKE TRAY

• Brush down all external surfaces of the machine including the stand.

• Sweep under machine to remove all debris from the floor.

• Spot clean with cloth dampened, disinfecting solution and hot water, paying particular

attention to handles, levers and controls.

Flexi moulder RevA19 10-01-19

16

WEEKLY CLEANING INSTRUCTIONS

AS DAILY INSTRUCTIONS AND ALSO:

1. Disconnect power (mains plug).

2. Pull machine away from obstructions.

3 Wipe the stand with a cloth dampened with disinfecting solution and hot water.

4 Scrape and scrub the wheels on the machine.

5 Wipe down all internal surfaces with disinfecting solution and hot water.

Dry with a cloth.

Flexi moulder RevA19 10-01-19

17

8.0 OPERATING INFORMATION

1 The Moulder should be used on a level floor for the best results.

2 All control levers, handles, etc are best adjusted when moulder is running, although they

can be adjusted with the machine stationary.

Machine cycle information.

1 The moulding elements consist of two dough guides, two differential sheeting

rollers, a guide roller, a stripper roller, a removable curling chain, two endless

polyurethane belts rotating in the same direction, a two position deflector, a

pressure board, a pair of dough guides and an offtake tray.

2 Dough is delivered from the prover conveyor. The dough is then sheeted through

the two differential rollers into a pancake shape.

3 The dough piece is taken off the rollers by means of a stripper roller and guided

by the remaining roller onto the endless polyurethane belt. Upon making contact

with the belt the dough piece is immediately pressurised by the curling chain mat.

The light pressure produced by the chain causes the dough piece to roll over on

its self and produce a sausage shape.

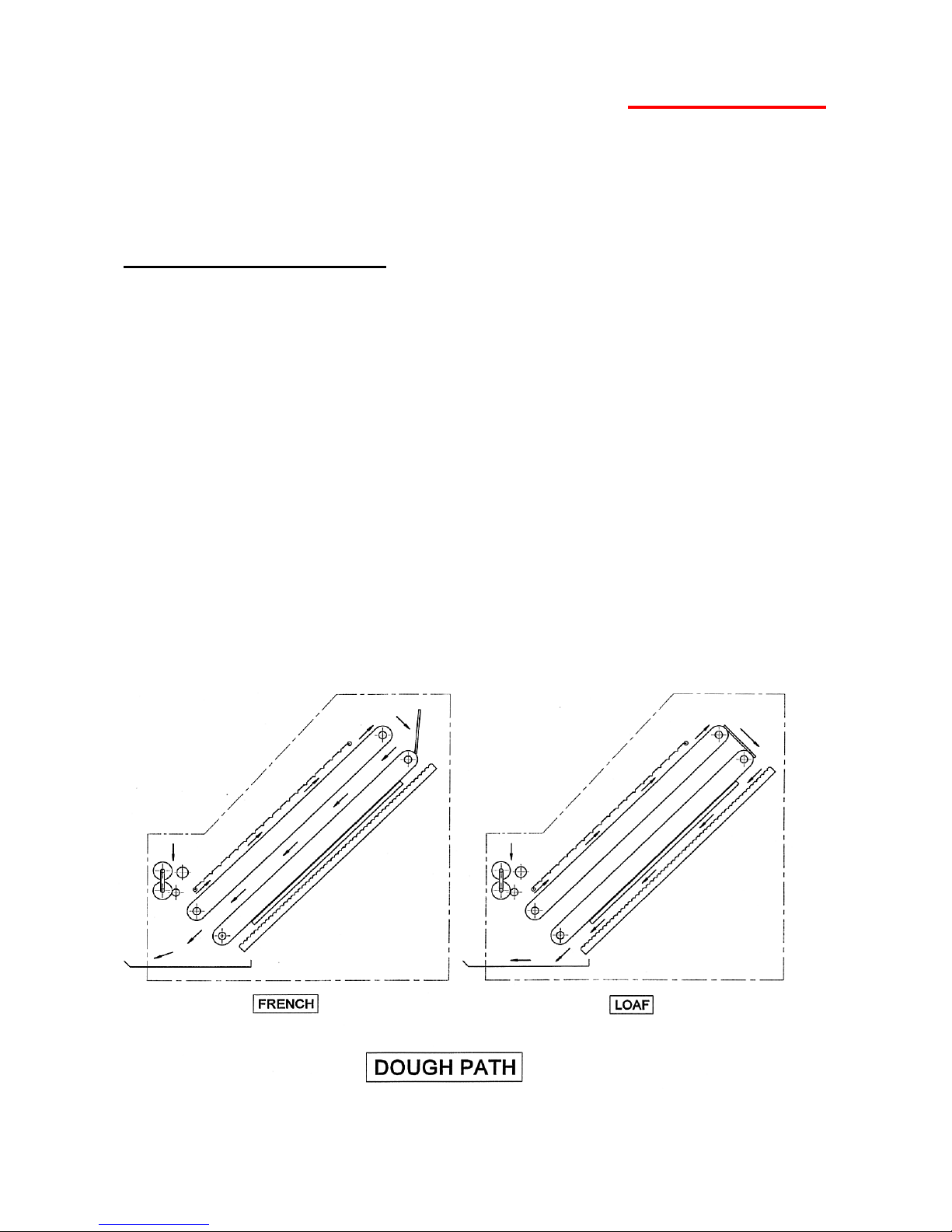

4 At this stage in the moulding process the dough path can be selected, via pushrod

to be further processed either between front and rear belts or between the rear

belt and pressure board.

5 Both of the moulding routes chosen will deposit the finished dough piece onto an

offtake tray.

Flexi moulder RevA19 10-01-19

18

9.0 OPERATING INSTRUCTIONS

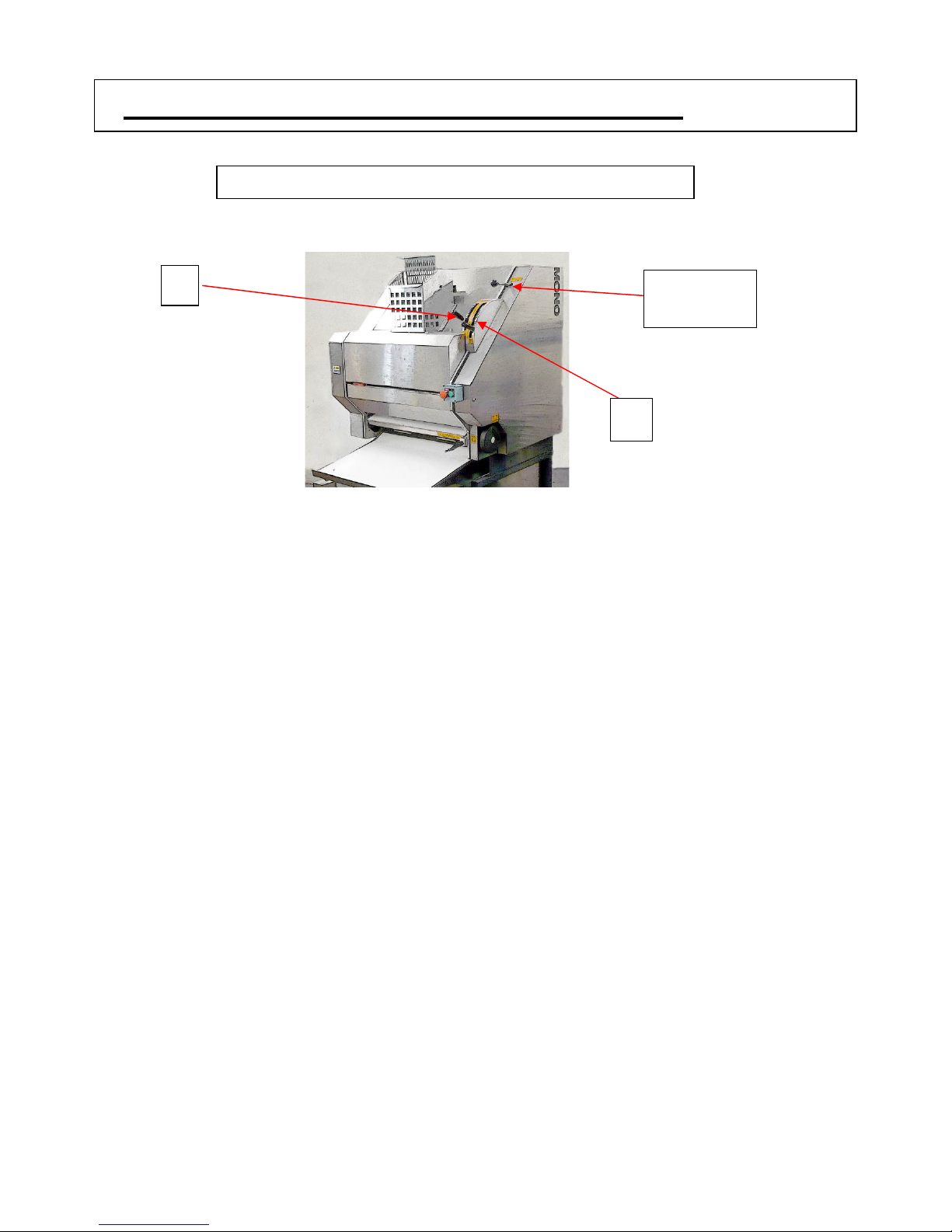

E A

STOP/START BUTTONS

B

Ensure the moulder is set up and adequate tins and trays

are available before starting.

D

C

All control levers, handles, etc are best adjusted when moulder is

running, although they can be adjusted with the machine stationary.

Flexi moulder RevA19 10-01-19

19

D

FRENCH STICK AND PETIT PAN PRODUCTS.

E

1 Set lever “A” to control the length of the dough piece required.

2 Adjust “E” to open or close the sheeting gap of the two infeed rollers.

• Control settings will vary according to user, dough mixes, product, machine

• It is advisable for the Bakery Manager to inform staff of settings required for all

Push in pushrod “D” until it engages in locating plate.

PUSHROD

A

construction etc, and are best established by the user.

French range once established. This will result in consistent product, assuming

dough condition is constant.

Flexi moulder RevA19 10-01-19

20

D

TIN BREAD & BLOOMERS.

Pull out pushrod “D” until it engages in locating plate.

1 Position control lever “A” to position 0 – this ensures the correct transfer of the dough

piece after curling and correct discharge of product onto the return conveyor.

2 Adjust handle “E” for the infeed sheeting gap.

E

Scale to show distance

between dough guides

When using hand wheel “C”

3 Adjust handle “B” for the pressure board.

Anti-clockwise will mean the numbers on the digital counter will increase and therefore the

pressure on the dough will decrease. Clockwise will be the opposite. The number on the

digital counter should be noted so it can be reproduced at a later date.

4 Adjust hand wheel “C” to control the length of the loaf.

Hand wheel simultaneously positions the dough side guides equally about the centreline of

the moulder. The distance between the dough guides is indicated by the metal pointer and

the scale

5 After moulding, the dough piece should be transferred from the offtake to a waiting tray.

B

PUSHROD

A

C

Flexi moulder RevA19 10-01-19

21

10.0 MAINTENANCE

1 Refer to cleaning instructions.

2 Maintenance other than cleaning must be carried out by trained maintenance personnel.

3 It is recommended that the bearings, chain, motor, etc. be greased every six months

4 If a belt is tracking to the left or the right. Call in maintenance contractor immediately

before any permanent damage can occur.

MAINTENANCE ENGINEER NOTES

Moulding belts should be no tighter than necessary to eliminate slippage.

Over tensioning can lead to belt and/or bearing failure.

The belt should be adjusted by means of the adjustment tensioning screws (shown below).

The belts should run with equal clearance between its edges and the unit side frames. If

one edge of the belt is tighter than the other, it will tend to run towards the slack side. This

tracking defect can be eliminated by individual adjustment of the tensioning screws.

Caution

Adjustment screws should not be continually tightened (this will cause bearing failure or the

moulding belt to stretch and break). It may be that one side is too tight so should be eased

off a little.

Bearings and bearing grub screws (2 per bearing) should also be checked as a seized

bearing may be the cause of the moulding belt needing adjustment.

If a bearing is replaced, the grub screws should be tightened and liquid thread lock applied.

(On later models the grub screws should also be aligned with dimples in the roller shaft).

Flexi moulder RevA19 10-01-19

ADJUSTMENT TENSIONING

SCREWS

(one side shown.)

22

11.0 TROUBLESHOOTING

MONO

• The final dough temperature, after mixing, should not exceed the ideal.

(typically 25 - 26 º C).

• A dough conditioner containing a good relaxant is required.

• French dough should be soft but not sticky.

• Curling chain should be kept clean.

12.0 SERVICE AND SPARES

If a fault arises, please do not hesitate to contact the

Customer Service Department, quoting the machine serial number

on the silver information plate of the machine and on the front cover of this manual

Swansea West Industrial Estate

email:spares@monoequip.com

Web site:www.monoequip.com

Spares Tel. +44(0)1792 564039

Main Tel. +44(0)1792 561234

Fax. 01792 561016

Queensway

Swansea.

SA5 4EB

UK

Flexi moulder RevA19 10-01-19

23

UNDER

“V” BELT AND DRIVE INFORMATION

DUE TO CONTINUAL IMPROVEMENTS

METALWORK MAY BE SLIGHTLY

DIFFERENT ON THE MODEL YOU HAVE

A900-09-108

Main Pulley

A900-06-259

Bearing

A900-06-242

Bearing

A900-06-227

Bearing

A900-06-259

Bearing

A900-06-259

Bearing

A900-09-105

Motor drive Pulley

Flexi moulder RevA19 10-01-19

A900-21-109

Main drive V belt

24

MOULDING BELT DRIVE INFORMATION

PART NO

.

UNDER

UNDER

UNDER

A900

-09-

104

A900

-06-

259

A900

-09-

098

A900

-06-

227

UNDER

A900-09-097

24T PULLEY

A900-06-259

BEARING

30T PULLEY

BEARING

PULLEY 48T A900-09-093

34T A900-09-094

28T A900-09-095

26T A900-09-096

BELT -- DOUBLE SIDED LARGE A900-21-092

-- TIMING BELT A900-21-093

A900-06-259

BEARING

A900-09-096

26T PULLEY

A900-21-092

TIMING BELT

A900-06-242

BEARING

A900-09-104

40T PULLEY

A900-09-095

28T PULLEY

A900-21-093

TIMING BELT

40T PULLEY

A900-09-094

34T PULLEY

A900-09-096

26T PULLEY

A900-06-227

BEARING

BEARING

A900-06-259

BEARING

A900-09-093

48T PULLEY

Flexi moulder RevA19 10-01-19

25

13.0 MOULDER ELECTRICAL

INFORMATION

Flexi moulder RevA19 10-01-19

26

Flexi moulder RevA19 10-01-19

27

Flexi moulder RevA19 10-01-19

28

Flexi moulder RevA19 10-01-19

29

DISPOSAL

MONO Equipment

Queensway,

Swansea West Industrial Park,

Swansea,

SA5 4EB

UK

Tel. +44(0)1792 561234

Fax. 01792 561016

Spares Tel. +44(0)1792 564039

Email:mono@monoequip.com

www.monoequip.com

As it is our policy to improve our machines continuously, we reserve the right

to change specifications without prior notice.

CARE SHOULD BE TAKEN WHEN THE MACHINE COMES TO THE END OF ITS WORKING LIFE. ALL

PARTS SHOULD BE DISPOSED OF IN THE APPROPRIATE PLACE, EITHER RECYCLING OR OTHER

MEANS AS THE LAW PERMITS AT THE TIME.

Flexi moulder RevA19 10-01-19

30

Loading...

Loading...