Mono Omega Plus 400, Omega Touch 450, Omega Plus 450, Omega Touch 400, Omega Plus 600 User guide

...

Innovative equipment

for traditional baking

Confectionery Depositors

Omega Touch | Omega Plus | Omega Plus with Wirecut

www.monoequip.com

The Omega Touch, Omega Plus and Omega

Plus with Wirecut Confectionery Depositors

Omega Plus with Wirecut Omega Touch

and Omega Plus

MONO Equipment is the longest established

confectionery depositor manufacturer in the world.

This proud history boasts a long line of depositing

machines from the original MK V, produced in the

1960s, to the state-of-the-art Omega Touch, Omega

Plus and Omega Plus with Wirecut machines

available today.

The Omega depositors are amongst the most

versatile and compact machines on the market with

an established reputation for the exceptional efciency,

accuracy and consistency of their depositing.

The Omega Plus is identical to the Omega Touch

but incorporates an enhanced motor which makes it

suitable to use with a wider range of mixes.

Ideal for bakers, confectioners, caterers and

10 Superb Features:

— User-friendly, large Colour Touch Screen with picture

programming

— Quick and easy one person set up and operation

— Single phase ‘Plug-&-Play’ means immediate productivity

— Small footprint which ts in most environments

— Exceptional accuracy of product weight, size and shape

— Quick and simple product, hopper and template change

over increases productivity

— Engineered in hygienic stainless steel for quick and

easy cleaning

— Trays removable from either side for true exibility

— Locking safety castors for effortless positioning and

genuine stability

— Extensive range of hoppers, templates, nozzles and

accessories available

hoteliers who need a competitive edge, the Omega

depositors are designed to produce an almost

endless array of high quality products by replicating

the traditional time-consuming hand movements of

the master confectioner - effortlessly - with speed

and reliability.

The Omega Plus with Wirecut also incorporates

an innovative nger frame mechanism which makes

clean and accurate cuts through hard mix to produce

the most delightful cookies and biscuits - even with

suspended ingredients.

The Omega Plus is available in three sizes to t

tray sizes up to 400mm, 450mm and 600mm while

the Omega Touch and Omega Plus with Wirecut are

available in 400mm and 450mm tray sizes.

10 Important Facts:

— Produces up to 35 deposits per cycle

— Up to 80mm automated vertical travel ideal for producing

tall products

— Provides total control of product weight, size, height,

length and shape

— Touch Screen incorporates 16 international languages

— Stores a total of 650 programmes

— Deposits on forward and reverse movements

— Deposits on upward and downward movements

— Deposits in a clockwise and anti–clockwise direction with

Rotary Template

— Creates complex and multiple-layered products

— Three sizes available to t up to 400mm, 450 mm and

600mm* wide trays

600mm only available on the Omega Plus with Wirecut

*

03 www.monoequip.com

Unrivalled Specication

The Omega Confectionery Depositors take

the creation and production of cakes, biscuits

and confectionery to another level. The fast,

accurate, and consistent depositing

dramatically increases the volume and

complexity of items that can be produced,

compared with manual labour.

When using the automated continuous workow

function of the conveyor belt, this efciency can be

improved even further with an almost endless stream

of products being produced tray after tray; improving

output capacity and efciency as well as reducing

labour and production costs.

The painstaking craftsmanship that goes in to

each built-to-order Omega Depositor ensures that

these machines are built to last. The copious amount

of stainless steel used in their manufacture also

guarantees them to be durable, hygienic and easy

to clean.

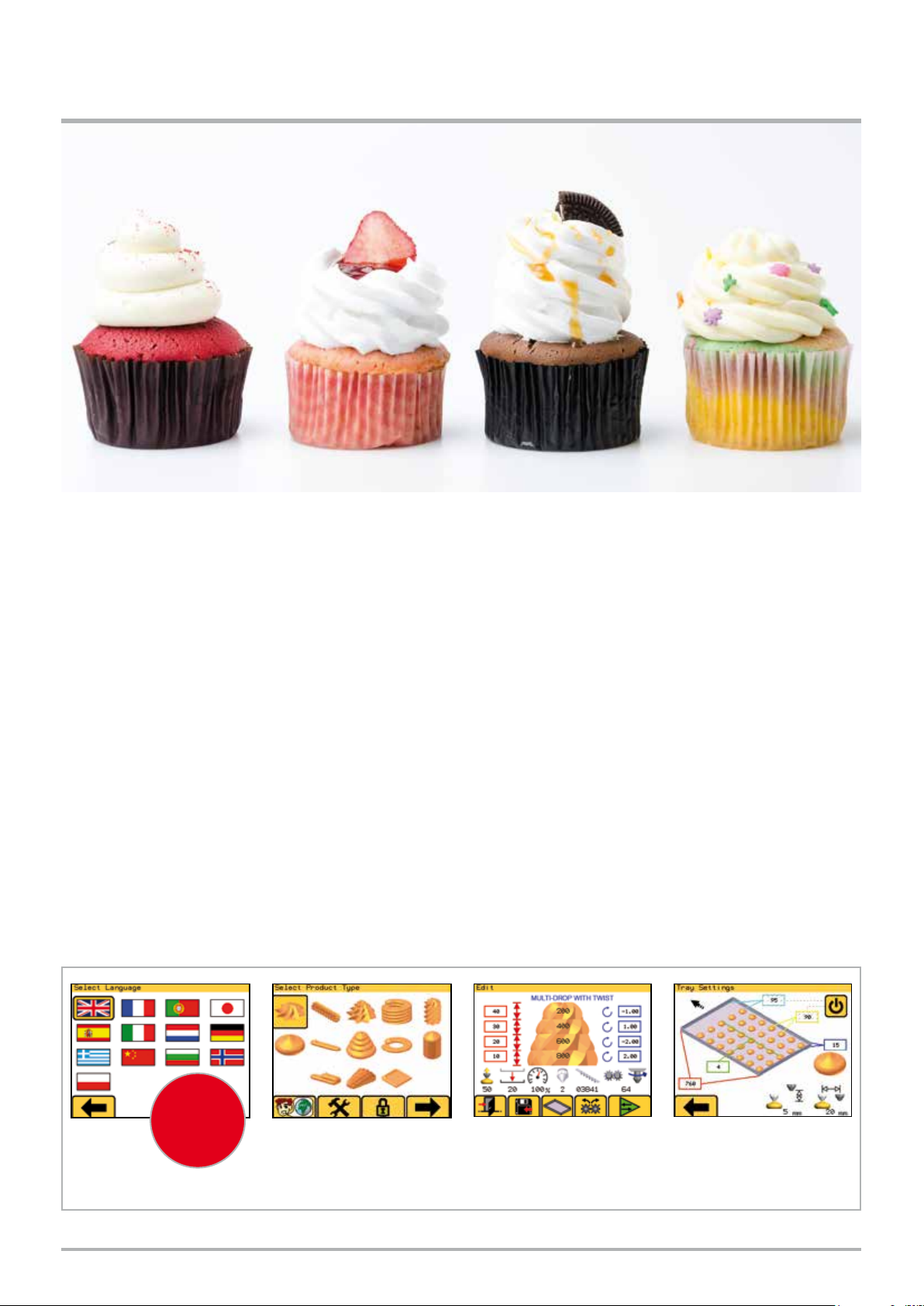

Innovative Touch Screen Controller

The user-friendly Colour Touch-Screen makes even

the most complex products simple to program and

easy to run, so that anyone can be creating the

most stunning confectionery within minutes – with

minimum training.

New programmes can be created with exceptional

ease and stored in the controller’s memory –

which stores up to 650 unique products – while

existing programmes can also be easily changed or

temporarily altered for a one-off session.

Every element of the product’s character can be

designed on screen using the colourful, icon-driven

menus; the product’s size, height, shape and volume,

along with the depositing speed, can all be dened

separately to create almost endless possibilities. A

graphical representation of the nished product along

with its dimensions can then be stored for future use.

Features

16 languages

Now

available

with Chinese

and Russian

languages

Simple icon-driven menu

for quick product selection

Each layer of the tower can

be deposited in alternate

clockwise and anticlockwise directions

04MONO Equipment

Programming the deposit

layout on a tray

Hopper and Gear Options

The Omega Touch is available with a Soft Mix

Hopper in Standard size. The Hard Mix Hopper is

essential for the Omega Plus with Wirecut while

the Soft Mix Hopper is also offered as an optional

extra - both in extended capacity only.

The Omega Plus is available with a Hard or Soft

Mix Hopper in extended sizes.

1

Additional Soft or Hard Mix Hoppers can be

purchased to complement the original machine

specication to increase the variety and scope

of products produced.

*1

All Hoppers are crafted in the nest stainless

steel and aluminium to ensure they meet the most

stringent hygiene standards and have also been

designed for quick assembly and easy cleaning.

1

Soft Mix Hopper

The Soft Mix Hopper has been specially designed to deposit

a range of smooth mixes including batter, sponge, mufn,

choux and meringue along with any other mix with a

similarly smooth consistency.

The Soft Mix Hopper is available in a range of 6 different

capacities, depending on tray width, from the Standard

20 litre to the Extended 53 litre.

2

Particulate Gears

*1

2

3

4

The Particulate Gears have been designed to aid the

depositing of suspended ingredients, including chocolate

chips, fruit particles and small nuts (up to 8mm diameter).

Made from high-strength polyethylene and stainless steel,

the Particulate Gears simply replace the Standard Gears in

the Soft Mix Hopper to produce the perfect deposit of mixes

containing suspended particulates. Products include choc-

chip mufns, blueberry mufns, carrot cake and brownies.

3

Intermediate Gears

Designed to work in conjunction with the Standard Gears,

the Intermediate Gears help drive mixes of intermediate

consistency through the nozzles. Engineered from solid

stainless steel, the gears provide the perfect solution for

depositing Viennese biscuit dough, coconut macaroons

and any product that suffers with feeding issues.

4

Hard Mix Hopper

The Hard Mix Hopper is used where a traditional piping

bag will not sufce or when mixes of a stiffer consistency

are required; it is perfect for the production of traditional

shortbread on the Wirecut machine, along with petits fours,

biscuit mixes and other products of a similar consistency.

The Hard Mix Hopper is available in a range of 6

different capacities, depending on tray width, from the

Standard 21 litre to the Extended 45 litre.

*1

See Specications on Page 14 for details.

05 www.monoequip.com

*1

Loading...

Loading...