Mono Omega Plus 400, Omega Touch 450, Omega Plus 450, Omega Touch 400, Omega Plus 600 User guide

...Page 1

Innovative equipment

for traditional baking

Confectionery Depositors

Omega Touch | Omega Plus | Omega Plus with Wirecut

www.monoequip.com

Page 2

Page 3

The Omega Touch, Omega Plus and Omega

Plus with Wirecut Confectionery Depositors

Omega Plus with Wirecut Omega Touch

and Omega Plus

MONO Equipment is the longest established

confectionery depositor manufacturer in the world.

This proud history boasts a long line of depositing

machines from the original MK V, produced in the

1960s, to the state-of-the-art Omega Touch, Omega

Plus and Omega Plus with Wirecut machines

available today.

The Omega depositors are amongst the most

versatile and compact machines on the market with

an established reputation for the exceptional efciency,

accuracy and consistency of their depositing.

The Omega Plus is identical to the Omega Touch

but incorporates an enhanced motor which makes it

suitable to use with a wider range of mixes.

Ideal for bakers, confectioners, caterers and

10 Superb Features:

— User-friendly, large Colour Touch Screen with picture

programming

— Quick and easy one person set up and operation

— Single phase ‘Plug-&-Play’ means immediate productivity

— Small footprint which ts in most environments

— Exceptional accuracy of product weight, size and shape

— Quick and simple product, hopper and template change

over increases productivity

— Engineered in hygienic stainless steel for quick and

easy cleaning

— Trays removable from either side for true exibility

— Locking safety castors for effortless positioning and

genuine stability

— Extensive range of hoppers, templates, nozzles and

accessories available

hoteliers who need a competitive edge, the Omega

depositors are designed to produce an almost

endless array of high quality products by replicating

the traditional time-consuming hand movements of

the master confectioner - effortlessly - with speed

and reliability.

The Omega Plus with Wirecut also incorporates

an innovative nger frame mechanism which makes

clean and accurate cuts through hard mix to produce

the most delightful cookies and biscuits - even with

suspended ingredients.

The Omega Plus is available in three sizes to t

tray sizes up to 400mm, 450mm and 600mm while

the Omega Touch and Omega Plus with Wirecut are

available in 400mm and 450mm tray sizes.

10 Important Facts:

— Produces up to 35 deposits per cycle

— Up to 80mm automated vertical travel ideal for producing

tall products

— Provides total control of product weight, size, height,

length and shape

— Touch Screen incorporates 16 international languages

— Stores a total of 650 programmes

— Deposits on forward and reverse movements

— Deposits on upward and downward movements

— Deposits in a clockwise and anti–clockwise direction with

Rotary Template

— Creates complex and multiple-layered products

— Three sizes available to t up to 400mm, 450 mm and

600mm* wide trays

600mm only available on the Omega Plus with Wirecut

*

03 www.monoequip.com

Page 4

Unrivalled Specication

The Omega Confectionery Depositors take

the creation and production of cakes, biscuits

and confectionery to another level. The fast,

accurate, and consistent depositing

dramatically increases the volume and

complexity of items that can be produced,

compared with manual labour.

When using the automated continuous workow

function of the conveyor belt, this efciency can be

improved even further with an almost endless stream

of products being produced tray after tray; improving

output capacity and efciency as well as reducing

labour and production costs.

The painstaking craftsmanship that goes in to

each built-to-order Omega Depositor ensures that

these machines are built to last. The copious amount

of stainless steel used in their manufacture also

guarantees them to be durable, hygienic and easy

to clean.

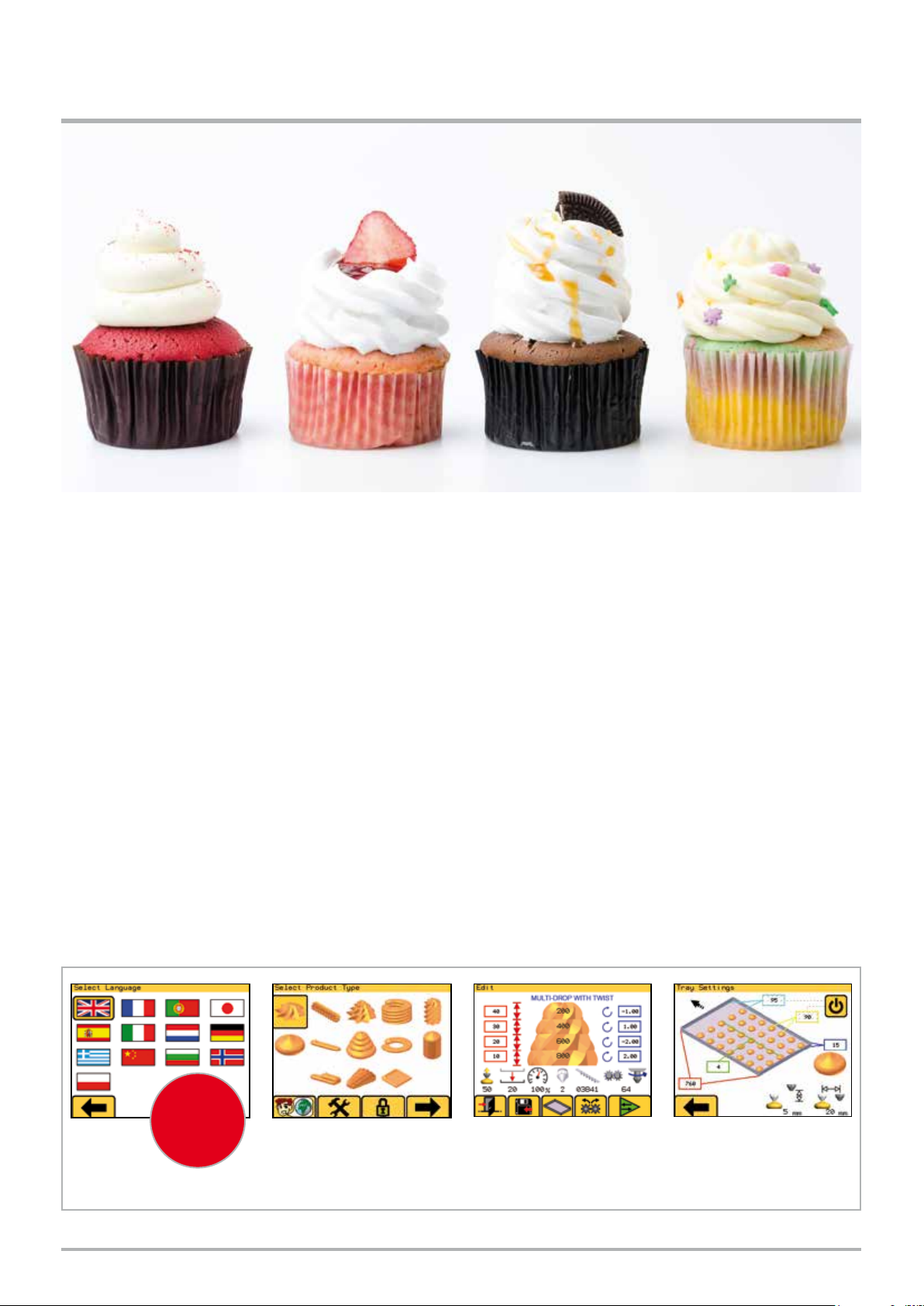

Innovative Touch Screen Controller

The user-friendly Colour Touch-Screen makes even

the most complex products simple to program and

easy to run, so that anyone can be creating the

most stunning confectionery within minutes – with

minimum training.

New programmes can be created with exceptional

ease and stored in the controller’s memory –

which stores up to 650 unique products – while

existing programmes can also be easily changed or

temporarily altered for a one-off session.

Every element of the product’s character can be

designed on screen using the colourful, icon-driven

menus; the product’s size, height, shape and volume,

along with the depositing speed, can all be dened

separately to create almost endless possibilities. A

graphical representation of the nished product along

with its dimensions can then be stored for future use.

Features

16 languages

Now

available

with Chinese

and Russian

languages

Simple icon-driven menu

for quick product selection

Each layer of the tower can

be deposited in alternate

clockwise and anticlockwise directions

04MONO Equipment

Programming the deposit

layout on a tray

Page 5

Hopper and Gear Options

The Omega Touch is available with a Soft Mix

Hopper in Standard size. The Hard Mix Hopper is

essential for the Omega Plus with Wirecut while

the Soft Mix Hopper is also offered as an optional

extra - both in extended capacity only.

The Omega Plus is available with a Hard or Soft

Mix Hopper in extended sizes.

1

Additional Soft or Hard Mix Hoppers can be

purchased to complement the original machine

specication to increase the variety and scope

of products produced.

*1

All Hoppers are crafted in the nest stainless

steel and aluminium to ensure they meet the most

stringent hygiene standards and have also been

designed for quick assembly and easy cleaning.

1

Soft Mix Hopper

The Soft Mix Hopper has been specially designed to deposit

a range of smooth mixes including batter, sponge, mufn,

choux and meringue along with any other mix with a

similarly smooth consistency.

The Soft Mix Hopper is available in a range of 6 different

capacities, depending on tray width, from the Standard

20 litre to the Extended 53 litre.

2

Particulate Gears

*1

2

3

4

The Particulate Gears have been designed to aid the

depositing of suspended ingredients, including chocolate

chips, fruit particles and small nuts (up to 8mm diameter).

Made from high-strength polyethylene and stainless steel,

the Particulate Gears simply replace the Standard Gears in

the Soft Mix Hopper to produce the perfect deposit of mixes

containing suspended particulates. Products include choc-

chip mufns, blueberry mufns, carrot cake and brownies.

3

Intermediate Gears

Designed to work in conjunction with the Standard Gears,

the Intermediate Gears help drive mixes of intermediate

consistency through the nozzles. Engineered from solid

stainless steel, the gears provide the perfect solution for

depositing Viennese biscuit dough, coconut macaroons

and any product that suffers with feeding issues.

4

Hard Mix Hopper

The Hard Mix Hopper is used where a traditional piping

bag will not sufce or when mixes of a stiffer consistency

are required; it is perfect for the production of traditional

shortbread on the Wirecut machine, along with petits fours,

biscuit mixes and other products of a similar consistency.

The Hard Mix Hopper is available in a range of 6

different capacities, depending on tray width, from the

Standard 21 litre to the Extended 45 litre.

*1

See Specications on Page 14 for details.

05 www.monoequip.com

*1

Page 6

Sheeting Templates

The Omega Confectionery Depositors remove

much of the manual labour traditionally

associated with the manufacture of sheet

products, providing increased production output

and greater product exibility. The precise

accuracy of the Omega Depositors also removes

human error to ensure that product consistency

of size, weight and quality is always guaranteed.

1

Suitable for:

— Sponge Sheets

— Swiss Roll

— Angel Cake

— Genoese

— Chocolate Brownies

— Battenburg

— Carrot Cake

2

Suitable for:

— All Tray Bakes

2

Multi-Sheeting Template -

Soft Mix

The Multi-Sheeting Template provides the perfect solution

when a number of separate deposits are required across

the baking tray.

The standard range of Multi-Sheeting Templates offers 16

variations based on the number of outlets across the template,

the slot length, the slot width and the pitch between outlets.

Outlet numbers vary from just 2 on the 400mm machine to a

maximum of 9 on the 580mm machine.

Non-standard Multi-Sheeting Templates can also be

produced to suit individual outlet number, slot length, width

and pitch requirements.

1

Sheeting Template -

Soft Mix

The Sheeting Template is perfect for laying down a single

deposit of mix onto a baking tray. The actual quantity of mix

deposited can be pre-programmed to achieve the desired

sheet thickness to create the ultimate Swiss rolls, Genoese

sponges and roulades.

Manufactured in light-weight aluminium, the Sheeting

Template is available in three standard sizes with a 385 mm,

435mm or 565mm slot length. Within each of the template

sizes there is a comprehensive range of standard slot widths,

in 1mm increments, from 2mm to 19mm to suit the vast

majority of requirements. A Reduced Drip Sheeting Template

is also available which minimises seepage between trays.

Non-standard Sheeting Templates can also be produced to

suit individual slot length, width and position requirements.

3

Suitable for:

— All 6” Sponge Tins

3

Staggered Template -

Soft Mix

The Staggered Template has been designed to make the

depositing of mixes like sponge in to round cake tins as

efcient as possible.

Round cake tins are usually arranged on a baking tray in a

staggered formation to maximise the use of space. The three

plastic nozzles attached to the aluminium Staggered Template

are set at forward facing and backward facing angles to

enable three tins to be lled simultaneously - effectively lling

two rows of cake tins in one pass.

The Staggered Template can also be produced to suit

individual requirements and non-standard tray widths.

06MONO Equipment

Page 7

Standard Template and Nozzles

The Omega Confectionery Depositors truly excel

in producing repetitive products with high speed,

accuracy and consistency. Each stage of the

deposit can be controlled to ensure the product’s

position, weight, height, length and diameter

meet the most exacting standards.

Suitable for:

— Drops

— Eclairs

— Cup Cakes

— Fairy Cakes

— Mufns

— Meringue Drops

— Macarons

— Lady Fingers

— Choux Buns

— Novelty Products

Plastic Nozzles -

Soft Mix

The Plastic Nozzles are simply screwed in to the Standard

Template to deposit soft mixes with a perfect nish and

are available in two different formats – Round and Star.

When depositing products like meringue drops and

sponge ngers, where a velvety smooth, even nish is

needed, the Round shaped nozzles should be used.

On the other hand, the Star shaped nozzles produce superb

striations on products like Viennese ngers and add depth

and character to multi-layered products like Christmas trees.

Each Plastic Nozzle is available individually and can

also be purchased in an 84-piece Nozzle Kit comprising

12 x each of the 7 different models.

Round: 13mmRound: 10mmRound: 6mm

Standard Template -

Soft & Hard Mix

One of the most widely used of all templates is the highly

versatile Standard Template which, when used in conjunction

with a comprehensive range of plastic or metal nozzles, can

produce a large variety of product formats including drops,

strips and shells along with cupcakes and multi-layered

novelty products like snowmen and Christmas trees.

The exibility of the Standard Template is illustrated by the

fact that there are 45 variants of the template for the three

machine sizes. The number of nozzles across the template

range from just 1 to a maximum of 18, depending on the

tray width, while some congurations also have a number of

different pitch options

Non-Standard Templates can also be produced to suit most

commercial moulded trays with specic nozzle quantities and

pitch requirements.

8-Star: 13mm8-Star: 10 mm8-Star: 6mm6-Star: 6mm

Metal Nozzles –

Soft & Hard Mix

A range of Metal Nozzles are available with the option

of Round or Star outlets.

Round: 6mm, 10mm, 13 mm, 16 mm, 18mm, 25mm

6-Star: 6mm, 10mm, 13 mm, 16 mm, 18mm, 20mm

8-Star: 6mm, 7mm, 10 mm, 12 mm, 13mm

Brass StarStainless Steel RoundBrass Round

07 www.monoequip.com

Page 8

Omega Touch / Omega Plus Confectionery Depositor

10 Most Popular Products our

Depositors can Produce

MONO Equipment’s depositors are designed to produce an

endless array of high quality products effortlessly with speed

and reliability.

Macarons

Roulades

Eclairs

Mufns

Meringues

Tray Bakes

Cookies

Cupcakes

Sponge Cakes

Viennese Whirls

08MONO Equipment

08MONO Equipment

Page 9

10 New Products you can Produce

With Your Depositor

MONO Equipment’s depositors can also easily produce

a wide variety of unusual products such as:

Soap Cakes

Duchess Potatoes

Animal Biscuits

Crispbreads

Gluten-Free Breads

Madeleines

Mouses and Desserts

Layered Sauces

09 www.monoequip.com

09 www.monoequip.com

Tartlet Fillings

Novelty Products

Page 10

Lady Finger and Injection Templates

Soft Mixes

1

Suitable for:

— Lady Fingers

1

Lady Finger / Budapest Template

Soft Mix

Ladyngers, called Savoiardi in Italian, meaning

‘from Savoy’, originated in the late 15th century at

the court of the Duchy of Savoy and were created

to mark the occasion of a visit of the King of

France. They also form a principal ingredient in

many French desserts recipes and are known as

‘Biscuits à la cuillère’.

Although these delicate sponge ngers can

be eaten on their own as a petit four or as an

accompaniment to ice creams, they are traditionally

soaked in syrup or liquor and used as part of more

complex desserts such as Tiramisu, English Tries

or Charlottes.

The Lady Finger Template deposits these

sophisticated sponge ngers speedily and effortlessly

by using a series of thin, tightly aligned depositing

tubes which perfectly reproduce their delightful shape

and texture. Before baking, powdered sugar is

usually sifted over the top of the ngers to give them

their characteristic crisp crust.

2

Suitable for:

— Doughnuts

— Cup Cakes

— Mufns

2

Injection Template

The Injection Template completely automates the

time-consuming process of injecting lling in to a

whole range of confectionery products. The exact

volume of lling along with the actual depth of

injection can both be programmed via the Colour

Touch Screen to ensure product quality and

lling consistency.

This precision piece of engineering injects the

exact amount of smooth lling into products such

as sponge cakes, choux buns and doughnuts. The

exact number of injector needles range from 4 to

7 across, depending on tray size. Multiple injector

needles can also be created for depositing in to

single products. The Injection Template can also be

designed to suit specic requirements.

The actual number of depositing tubes along the

template is completely congurable to individual

requirements, as is the diameter of the hole on the

tube’s outlet.

10MONO Equipment

Page 11

Rotary Template and Nozzles

Soft & Hard Mixes

Rotary Template

The Rotary Template truly adds an exciting

dimension to the confectioner’s product range by

effortlessly producing crescents, circles, pretzels

and nests with precision and consistency.

Engineered from stainless steel, the Rotary

Template contains an innovative mechanism that

enables the nozzles to rotate in both a clockwise

and anti-clockwise direction.

8-Star: 13mm8-Star: 10 mm8-Star: 6mm6-Star: 6mm

Suitable for:

— Viennese Whirls

— Viennese Fingers

— Towers

— Christmas Trees

— Meringue Swirls

— Novelty Products

Used with Star Nozzles

When used with Star Nozzles, the Rotary Template

creates beautifully dened deposits ideal for the production

of Viennese whirls and deeply textured ngers with

a characteristic twist – both of which look absolutely

irresistible when baked. The same setup can also be used

to add the nishing touches to cupcakes with an ornate

crown of coloured buttercream.

Brass Star

Used with Offset Nozzles

The Offset Nozzles work with the Rotary Template

to produce a variety of circular, semi-circular or

looped products.

There are 10 standard Offset Nozzle lengths available,

ranging from 5mm to 45mm, to create different diameter

products like meringue crescents, circles and nests with

either smooth or textured surfaces.

The tightness of the twist along with the height and

volume of deposit can all be programmed individually

using the Touch Screen Control Panel providing an almost

endless combination of possibilities.

Suitable for:

— Crescents

— Meringue Circles

— Meringue Nests

— Pretzels

11 www.monoequip.com

Page 12

Biscuit Template and Biscuit Dies

Hard Mix

An almost endless variety of mouth-watering

biscuits can be produced using the Biscuit

Template and intricate range of Brass Biscuit

Dies. The speed of the biscuit depositing and the

quality and denition of the patterns achieved is

second to none.

1

Suitable for:

— Biscuits

MONO Equipment does not recommend mixing different shapes and designs of dies across the template.

Just some of the Biscuit Dies available from the standard range:

2

1

Biscuit Die Template

The Biscuit Die Template is used in conjunction with the wide

variety of Biscuit Dies which are mounted on the ends of the

template’s depositing nozzles. Depending on the width of

the machine purchased, the number of tubes can vary from

5 to 10 across and bespoke options are also available to suit

specic requirements.

2

Brass Biscuit Dies

There are over 35 different standard Biscuit Dies available

including an assortment of delicate oral shapes and abstract

geometric patterns. Each die produces a perfectly shaped

biscuit which look absolutely mouth-watering when baked.

The brass Biscuit Dies can also be designed to meet

specic requirements in order to produce truly unique biscuit

shapes and textures.

12MONO Equipment

Page 13

Wirecut Finger Frame, Template and Dies

Hard Mix

1

The Wirecut facility is only available on the

Omega Plus with Wirecut machine and provides

the perfect solution when a traditional ‘hand

nished’ or ‘rustic’ look is required for hard

mix biscuits.

Three separate components work together in

perfect harmony to create the distinctive qualities

only associated with Wirecut products – the

Wirecut Finger Frame, the Wirecut Template and

the Wirecut Dies.

In addition to producing a range of traditional

biscuits like cookies, biscotti and shortbread,

the Wirecut also works perfectly with suspended

ingredients and mixes containing small particulates

eg. chocolate chips. Whilst the shape and diameter

of the biscuit is determined by the Die, the thickness

of the biscuit can be programmed via the Colour

Touch Screen.

3

1

Wirecut Finger Frame

A very strong, tensioned stainless steel wire runs through the

front edge of the Wirecut Finger Frame, connecting one nger

to the next, to create the sharp cutting edge used to slice

through the hard dough mix. The Finger Frame is easily tted

and locked in position behind the Safety Guard.

The number of ngers on the Finger Frame is variable,

depending on the size of the machine, as is the diameter

of the extrusion and the number of dies across the template.

2

Suitable for:

— Cookies

— Chocolate Chip Cookies

2

Wirecut Template

Manufactured from light-weight aluminium, the Wirecut

Template provides a solid base onto which the Wirecut

Dies are xed. The design of the template means that

a large variety of biscuits can be produced by simply

changing the dies.

MONO Equipment does not recommend mixing different dies across the template.

3

Wirecut Dies

The Wirecut Die forms the extruded dough into the required

shape before it is cut and drops onto the tray. Some of the

most popular die shapes include the Heart, Oval, Bloom

and Star; customised shapes and sizes are also available

on request.

13 www.monoequip.com

Page 14

Technical Specications

b

Omega Touch

and Omega Plus

a

b

a

Specications

d

c

Omega Touch & Omega Plus

Omega Plus

Omega Plus

with Wirecut

d

Omega Plus with Wirecut

400 450 580 400 450

c

Height (a) (mm) 1,541 1,541 1,541 1,541 1,541

Height to standard hopper (mm)

Height to extended hopper (b) (mm)

Height with lid open standard hopper (mm)

Height with lid open extended hopper (mm)

Touch 1,333

Plus na

Touch na

Plus 1,450

Touch 1,863

Plus na

Touch na

Plus 1,980

Touch 1,333

Plus na

Touch na

Plus 1,450

Touch 1,863

Plus na

Touch na

Plus 1,980

na na na

1,450 1,450 1,450

na na na

2,110 1,980 1,980

Depth (c) (mm) 869 869 999 881 881

Table Width (d) (mm) 1,200 1,200 1,200 1,200 1,200

Weight with soft mix standard hopper

tted (kg)

Weight with soft mix extended hopper

tted (kg)

Weight with hard mix extended hopper

tted (kg)

Approx. Cycles per minute

(mix dependant)*

Standard hopper capacity soft mix (litre)

Extended hopper capacity soft mix (litre)

Extended hopper capacity hard mix (litre)

Touch 183

Plus na

Touch na

Plus 180

Touch na

Plus 196

Touch 19

Plus 30

Touch 20

Plus na

Touch na

Plus 36

Touch na

Plus 31

Touch 192

Plus na

Touch na

Plus 185

Touch na

Plus 212

Touch 19

Plus 30

Touch 22.5

Plus na

Touch na

Plus 41

Touch na

Plus 35

200 197 204

200 197 204

235 210 224

30

Deposit 30

Wirecut 18

Deposit 30

Wirecut 18

na na na

53 36 41

45 31 35

Minimum distance between trays (mm) 50 50 50 50 50

Maximum vertical travel (mm) 80 80 80 80 80

Maximum programme storage 650 650 650 650 650

No of languages 16 16 16 16 16

Electrics

Power Supply Single phase, 13A maximum load. Suitable for 110v, 200v, 220v, 230v and 240v, 50-60Hz

Maximum power rating 2.5kW single phase fused at 13 A

Noise level Less than 85dB

* based on a 30g drop

Accessories

Mobile Tray RackAccessories Trolley Selection of Trays

The minimum deposit that can

be made depends on several

factors, the recipe, the mix, the

template size, the nozzle size

and deposit speed. As a guide

the following is the minimum that

should be attempted:

Macaroons 6g

Meringues 3g

Choux paste 5g

Viennese 4g

Sponge drops 4g

Specications correct at time of publication. MONO Equipment reserves the right to amend the specication without prior notice.

14MONO Equipment

Page 15

Page 16

MONO Equipment is one of the leading designers and

manufacturers of bakery equipment and confectionery

depositors in the United Kingdom. This proud heritage

of British craftsmanship, combined with a reputation for

creating high-quality, innovative products, can be traced

back to its origins in 1947.

MONO Equipment is the longest established

Confectionery Depositor manufacturer in the world.

This illustrious history boasts a long line of depositing

machines from the original MK V, produced in the 1960s,

to the state-of-the-art Omega Touch, Omega Plus and

Omega Plus with Wirecut machines available today.

MONO Equipment also supplies a comprehensive

range of specialist, innovative equipment to satisfy the

constantly developing needs of the bakery, foodservice

and confectionery markets.

Scan using your smart

phone to view the

Omega Confectionery

Depositor video.

MONO Equipment

Queensway

Swansea West Industrial Park

Swansea

SA5 4EB

United Kingdom

Tel: +44 (0)1792 561 234 (Switchboard)

Tel: +44 (0)1792 564 000 (UK Sales)

Tel: +44 (0)1792 564 004 (International Sales)

Tel: +44 (0)1792 564 048 / +44 (0)1792 564 039 (Spares)

Fax: +44 (0)1792 561 016

Email: sales@monoequip.com

Web: www.monoequip.com

Ofcial Distributor:

FM12346 EMS 595394

V6.0

Loading...

Loading...