Mono Epsilon 400, Epsilon 450 OPERATING AND MAINTENANCE MANUAL

Serial No.

Store this document safely and ensure it is available

at all times.

NOTE: THIS MACHINE IS FOR USE WITH SOFT DOUGH ONLY

Non-availability may affect the service / repair of your machine.

In the event of an enquiry please quote this serial number.

OPERATING AND MAINTENANCE MANUAL

Epsilon

07/12

3

Failure to adhere to the cleaning and

maintenance instructions detailed in this booklet

could affect the warranty of this machine.

FOR SAFE WORKING, PAY SPECIAL ATTENTION TO ITEMS MARKED

FG080 –EPSILON 07-12 RAC

4

CONTENTS

1.0 - INTRODUCTION

2.0 - DIMENSIONS

3.0 - SPECIFICATIONS

4.0 - SAFETY

5.0 - INSTALLATION

6.0 - ISOLATION

7.0 - CLEANING INSTRUCTIONS

8.0 - OPERATING CONDITIONS

9.0 - PREPARING FOR OPERATION

9A – FITTING THE HOPPER

9B – FITTING A TEMPLATE

EPSILON

10.0 - OPERATING INSTRUCTIONS

1 – SELECT PRODUCT TYPE

2 – SELECT SAVED PRODUCT TYPE

OR CHOOSE EMPTY SLOT TO CREATE A NEW PROGRAM

3 – OPERATOR SCREEN

4 – EDIT & SAVE SCREEN

4A – TRAY SETUP

5 – COPY

6 – DELETE

7 – PASSWORDS

8 – ENGINEERING SETTINGS

9 – FAULT INFORMATION SCREENS

11.0 - MAINTENANCE

12.0 - SPARES AND SERVICE

13.0 - SPARES LIST

14.0 - ELECTRICAL INFORMATION

FG080 –EPSILON 07-12 RAC

5

As it is our policy to improve our machines continuously, we reserve the right to change specifications without prior notice

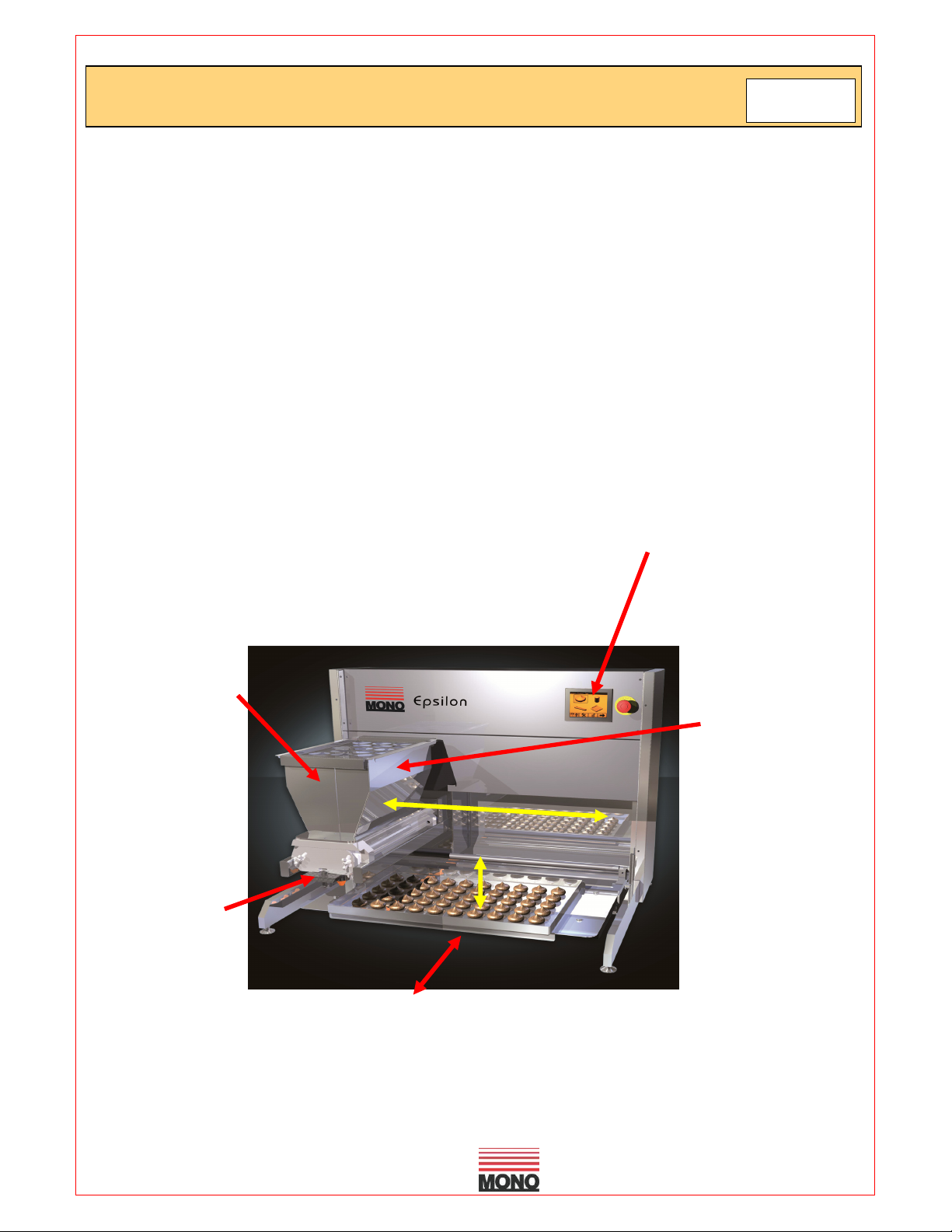

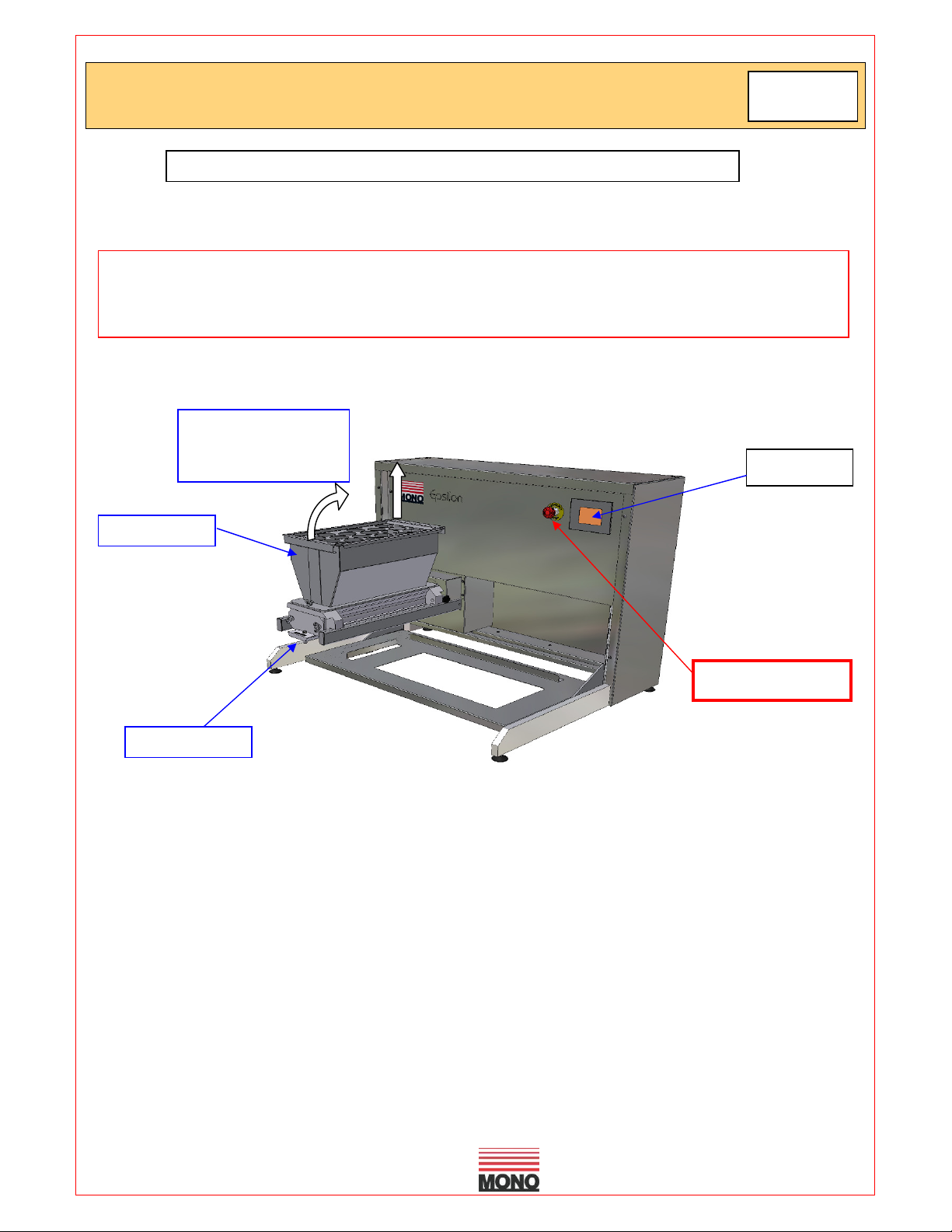

SOFT

EASY CHANGE

TRAVELLING HOPPER

LOAD FROM THE FRONT

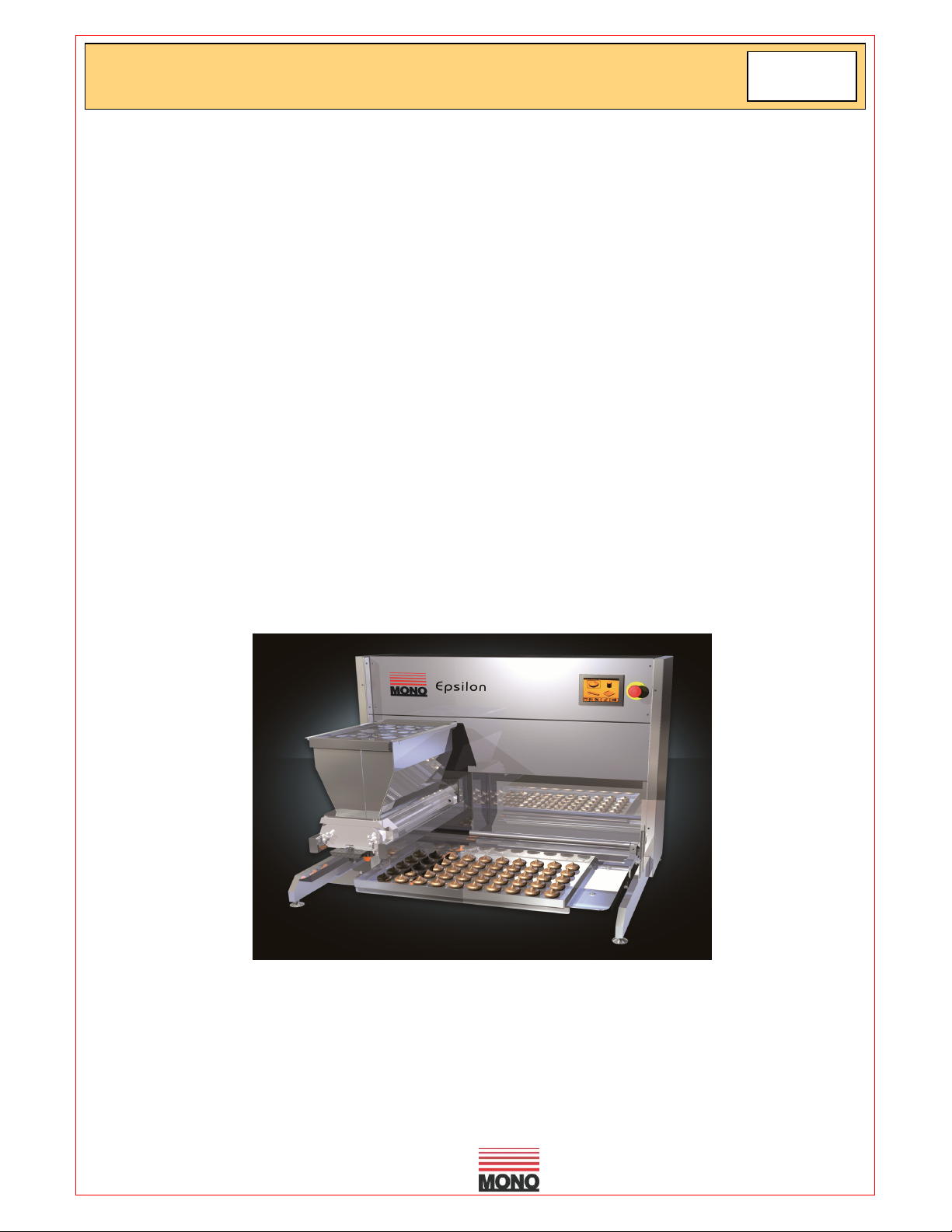

1.0 INTRODUCTION

EPSILON

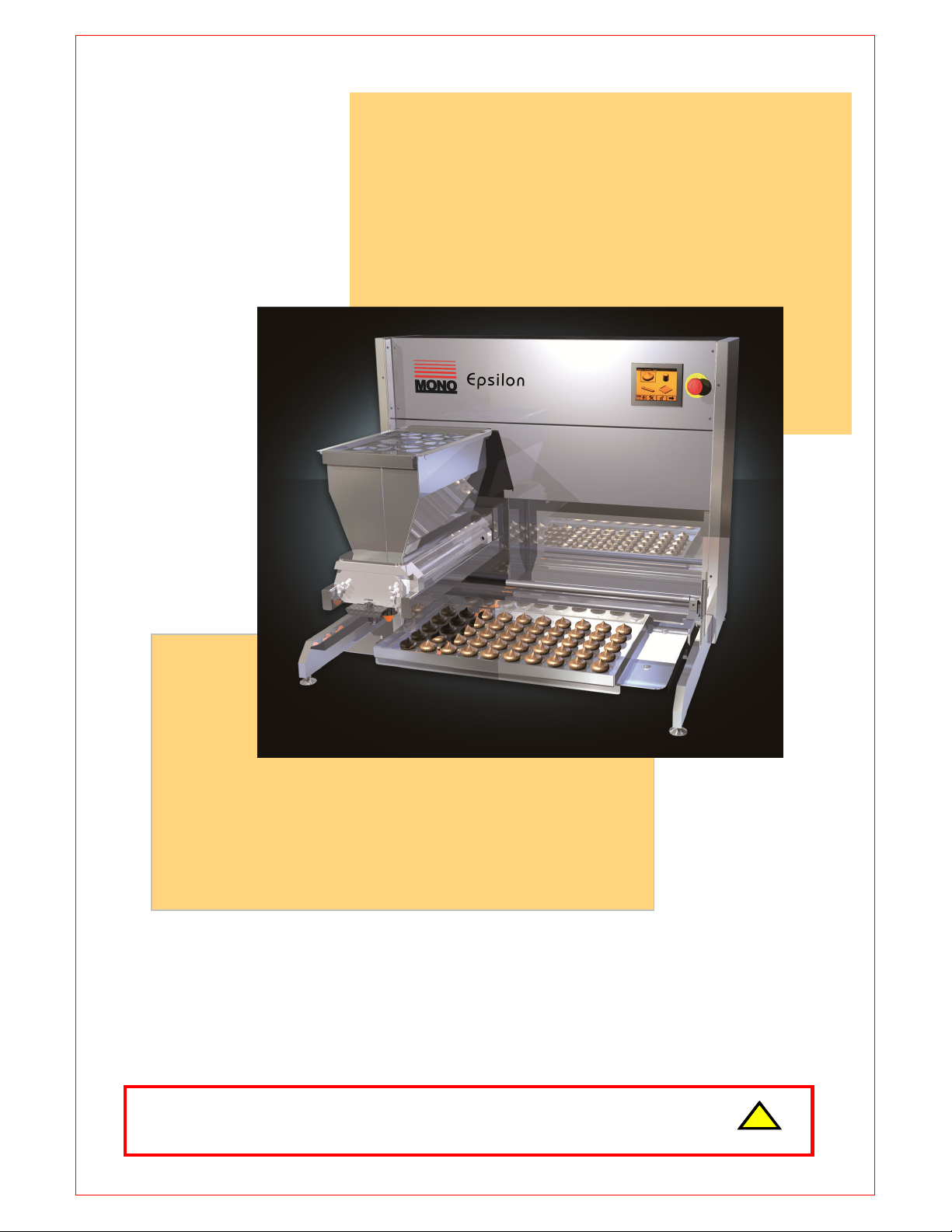

• The ground breaking EPSILON tabletop confectionary depositor requires less than 1 square

metre of space to operate.

• The unique travelling hopper system removes the need for a conveyor belt which means trays

can be loaded and unloaded in the most ergonomically efficient way – directly from the front.

• The EPSILON can be transported through a normal doorway and plugged into

a standard 13amp socket.

• Control is by a user friendly tri-colour touch screen (in 14 languages) and can be used

to store up to 96 programs.

• Robust stainless steel construction for durability and ease of cleaning.

• A matching stainless steel table is also available to make the EPSILON freestanding.

DOUGH HOPPER

TEMPLATES

TOUCH SCREEN CONTROL

SYSTEM

(NO CONVEYOR BELTS)

FG080 –EPSILON 07-12 RAC

6

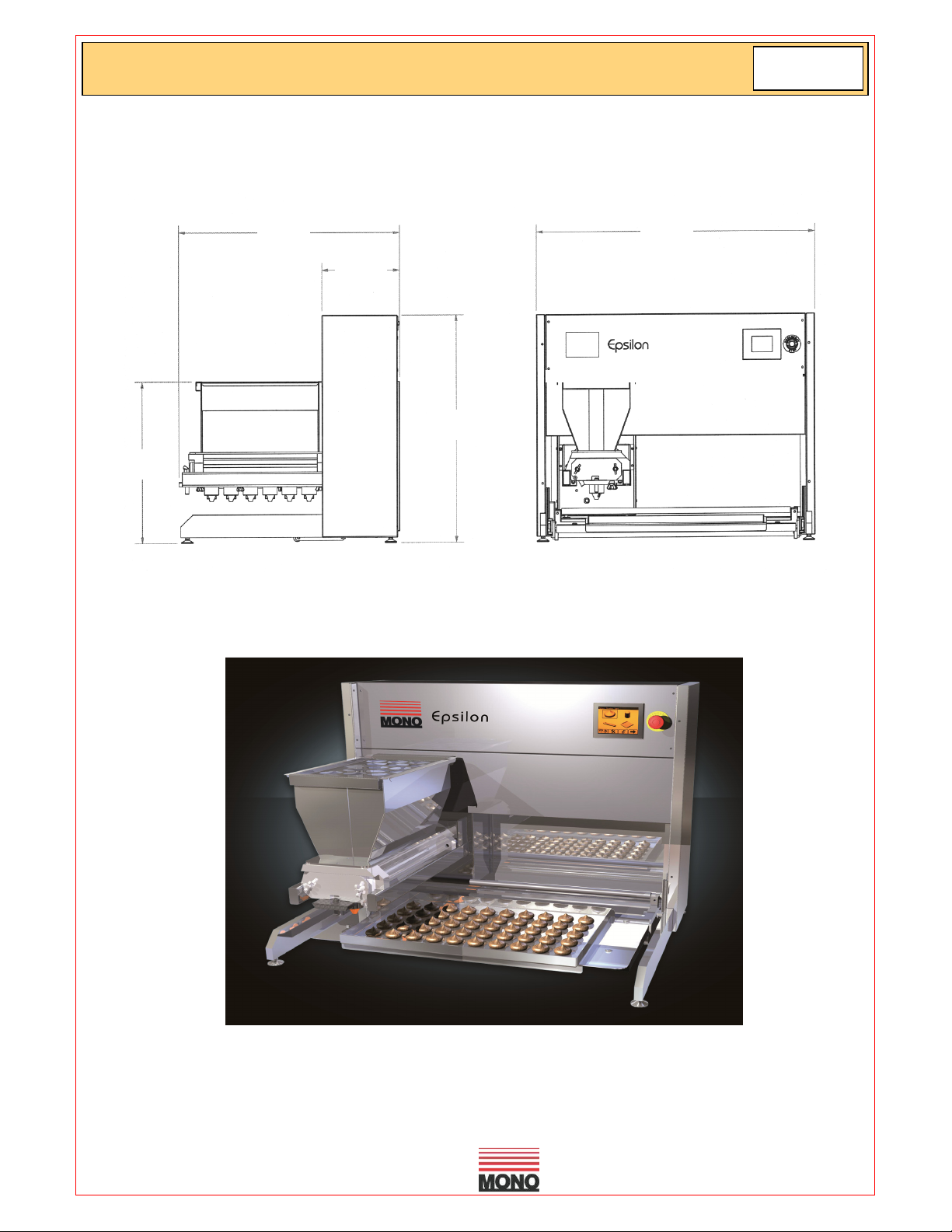

2.0 DIMENSIONS

265

774

548

EPSILON

FG080 –EPSILON 07-12 RAC

7

3.0 SPECIFICATIONS

However, consult

Mono Equipment

if

your intended product falls outside the above

EPSILON

SOFT DOUGH

MODEL 400 500

(Nom. hopper width (mm))

Weight (with hopper fitted) (Kg) : tba tba

Standard hopper 20 22.5

Capacity (litre) :

Power: Single phase, 13A max load. Suitable for 110v,200v,

220v, 230v, and 240v, 50-60 Hz supply.

MAX RATING 2.5kW single phase fused at 13A

Cycles per minute = Depends on product.

i.e. 5 across 30g drop = 16 per minute.

Max program storage = 96

Number of languages = 14

Noise level = Less than 85dB

Electronics = All microprocessor controlled

NOTE:

The minimum deposit that can be made depends on several factors - recipe, mixing

method, template size, nozzle size and deposit speed.

As a guide the following is the minimum that should be attempted:

Macaroons 6g,

Meringues 3g,

Choux Paste 5g,

Viennese 4g,

Sponge Drops 4g.

As it is our policy to improve our machines continuously, we reserve the right to change specifications without prior notice

general machine specification.

FG080 –EPSILON 07-12 RAC

8

4.0 SAFETY

EPSILON

1 Never use a machine in a faulty condition and always report any damage.

2 Only trained engineers may remove parts from this machine if a tool is required.

3 Always ensure hands are dry before touching any electrical appliance (including

cable, switch and plug). NEVER move machinery by pulling on the power cords

or cables.

4 Ensure that the floor area around the Epsilon is clean to avoid slipping –

especially if carrying heavy hopper and template components to and from the

machine.

5 All operatives must be fully trained.

Use of the machine can prove dangerous if:

the machine is operated by untrained or unskilled staff

the machine is not used for its intended purpose

the machine is not operated correctly

All safety devices applied to the machine during manufacture and the

operating instructions in this manual are required to operate this machine

safely. The owner and the operator are responsible for operating this machine

safely.

6 People undergoing training on the machine must be under direct supervision.

7 Do not operate the machine with any panels or guards removed.

8 No loose clothing or jewellery should be worn while operating the machine.

9 Switch off power at the mains isolator when machine is not in use and before

carrying out any cleaning or maintenance.

FG080 –EPSILON 07-12 RAC

9

ALL CLEANING AND MAI

NTENANCE OPERATIONS MUST

EPSILON

10 The bakery manager or the bakery supervisor should carry out daily safety

checks on the machine.

11 Do not operate machine without the hopper template fitted correctly.

12 Due to the essential requirement for handling heavy components during cleaning,

it is recommended that protective footwear be worn when carrying out such

procedures.

CAUTION:

The feed hopper and pump assembly can exceed 25kg and will need to be lifted off

by two people, or dismantled into smaller components while still on the machine.

BE MADE WITH MACHINE DISCONNECTED FROM THE

FG080 –EPSILON 07-12 RAC

POWER SUPPLY.

10

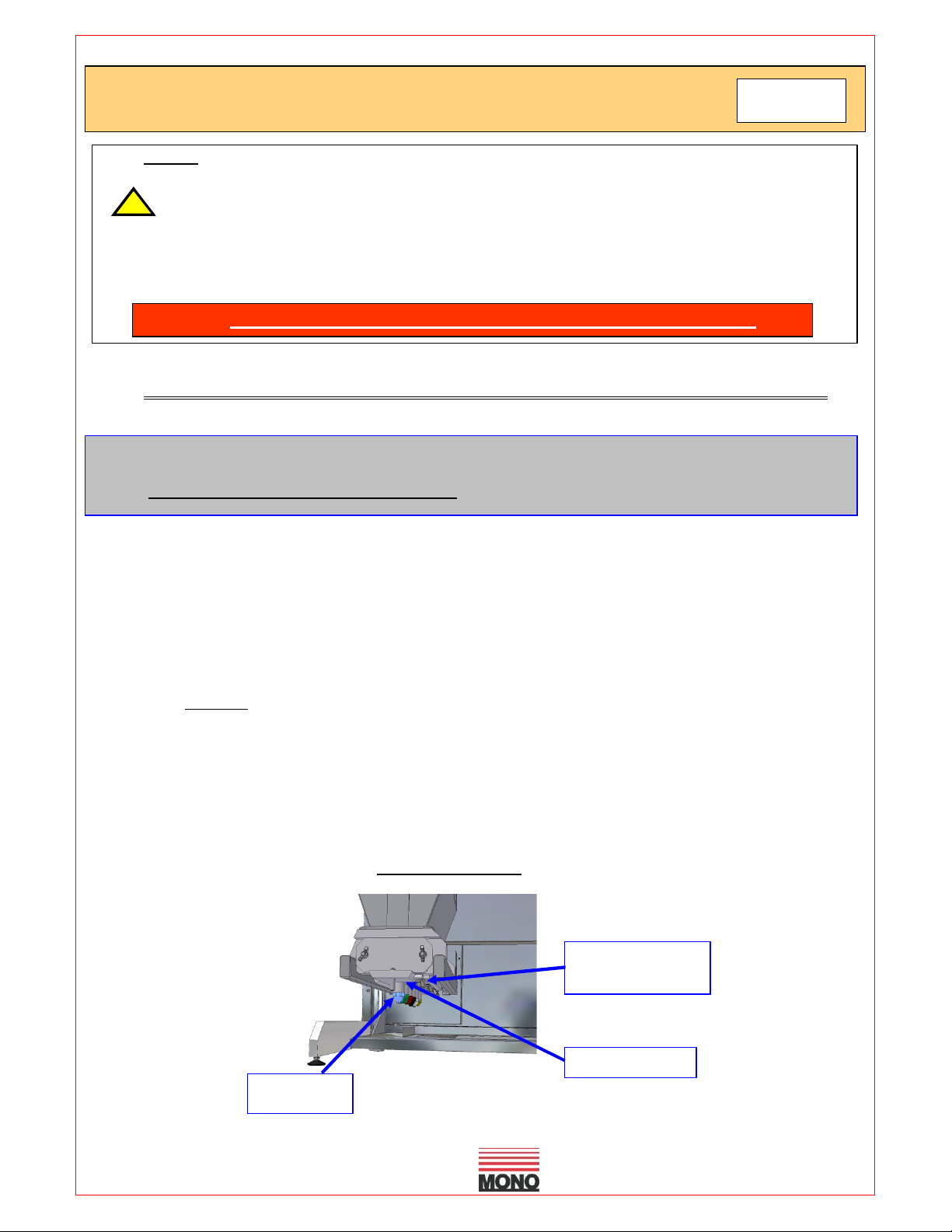

STOP BUTTON

EPSILON

5.0 INSTALLATION

1 Ensure that the depositor is connected to the correct electric supply as specified on

the serial number plate on the side of the machine.

2 Ensure that the correct fuse rating is fitted in the electrical supply.

3 The support table should be level and strong enough to support the machine and

loaded hopper.

4 This machine should be lifted by more than one person.

6.0 ISOLATION

IN AN EMERGENCY, SWITCH OFF AT THE MAINS

WALL ISOLATOR, OR PUSH EMERGENCY

STOP BUTTON.

To release the emergency stop button, turn clockwise.

FG080 –EPSILON 07-12 RAC

11

TEMPLATE

7.0 CLEANING INSTRUCTIONS

NOTE:

- Cleaning must be carried out by fully trained personnel only.

- Isolate machine from mains supply before carrying out any cleaning.

- Do not steam clean or use a jet of water.

-Do not use any form of caustic detergent or abrasive cleaners.-

All the outer surfaces of the machine should be wiped over daily with warm soapy water.

EPSILON

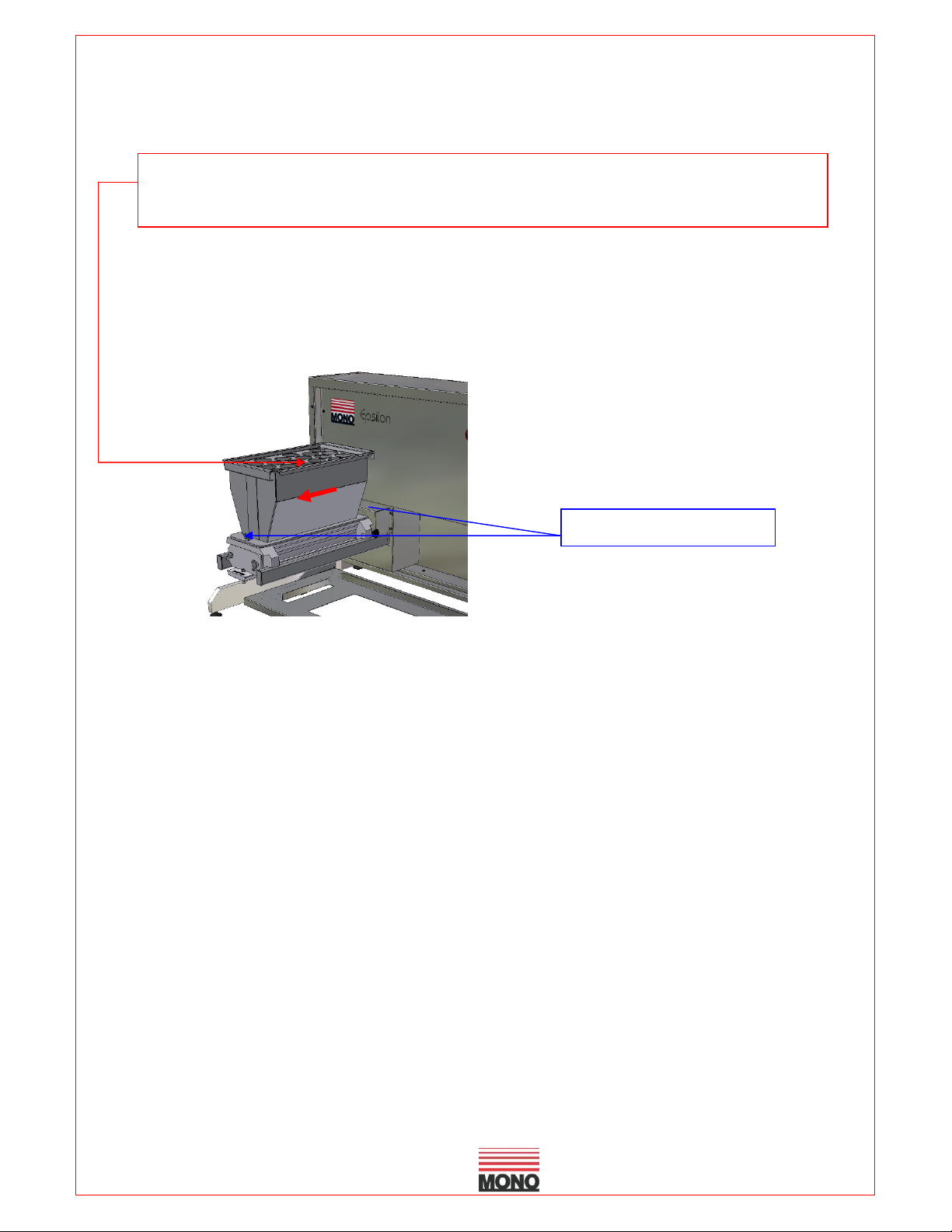

DOUGH HOPPERS

BETWEEN PRODUCT MIX CHANGES

The feed hopper, pump assembly, template, nozzles etc. should be removed from

the machine and dismantled for thorough cleaning between product mix changes.

1. Open top safety guard (lift front and unhook the back edge) and remove excess

mixture remaining in the feed hopper.

2. Slacken template clamp strip nuts and remove fitted template from pump assembly

by sliding out while supporting it to avoid damage.

NOTE.

Thumbscrews only need to be released slightly to allow the template to slide away

from the pump assembly. If loosened too much, the template will have to be supported.

NOZZLES

DOUGH HOPPER

CLAMP STRIP

AND NUTS

FG080 –EPSILON 07-12 RAC

12

3 To reduce weight and bulk, separate and remove the empty feed hopper from the

pump assembly, whilst still on the machine, by unscrewing the wing nuts.

To gain access to the inner wing nut, slide the complete hopper away from the machine

body slightly (keep on support bars) - this will also disengage the pump assembly from

the drive shaft.

HOPPER WINGNUTS

Ensure that the wing nuts are placed where they will not be lost.

FG080 –EPSILON 07-12 RAC

13

‘O’ RING IN GROOVE

(NOT SHOWN)

EPSILON

NOTE: THIS MACHINE IS FOR USE WITH SOFT DOUGH ONLY

DOUGH HOPPER

CAUTION:

The feed hopper and pump assembly can exceed 25kg and will need to be lifted off

by two people, or dismantled into smaller components while still on the machine.

Take care to avoid damage to the sealing surface of the feed hopper during removal,

cleaning, assembly and storage.

1. After removing the feed hopper, check condition of feed hopper seal.

2. Unscrew the end cap retaining nuts from the accessible side of the pump assembly.

Ensure that the nuts are placed where they will not be lost.

FEED HOPPER

SEALING SURFACE

3. Withdraw the end-cap with the pump gears.

Ensure that the ‘O’ sealing ring on the inside of the end-cap is not damaged during cleaning.

PUMP GEARS

REMOVE WITH END CAP

4. To fully dismantle pump assembly components for cleaning, remove remainder of

pump assembly from the machine and remove remaining end-cap.

PICTORIAL VIEWS SHOWN COULD BE DIFFERENT TO THE MACHINE BEING

WORKED ON BUT THE INSTRUCTIONS ARE THE SAME FOR ALL MODELS.

ENDCAP NUTS

END CAP

FG080 –EPSILON 07-12 RAC

14

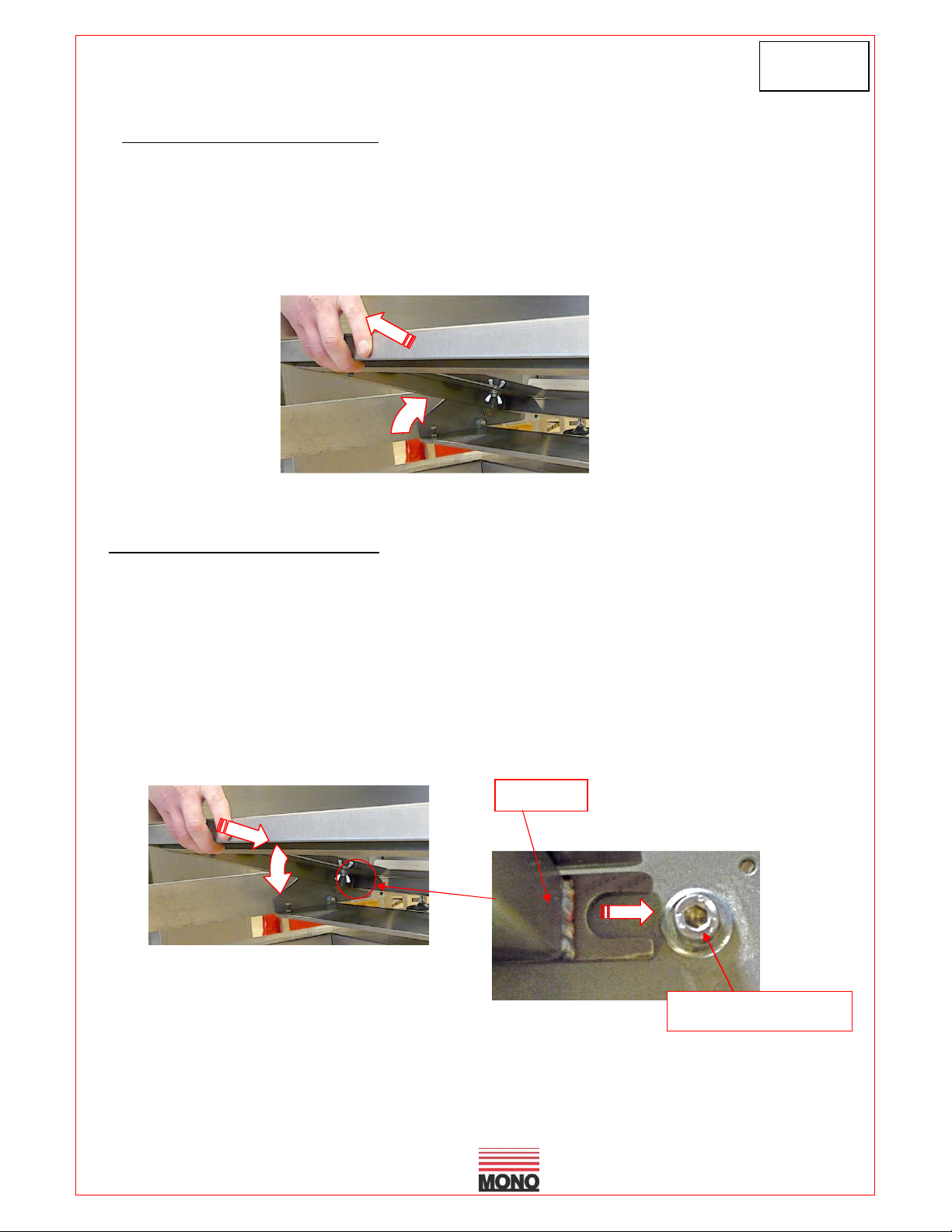

TABLE

To remove the table for cleaning:

1. Push the table down to its lowest level.

2. Lift the front edge and lift the table towards you.

The table will release from the back pins and can be placed in a washer for cleaning.

EPSILON

To replace the table after cleaning:

1. Hold table with the front edge raised and engage the slots over the pin on both sides.

2. Lower the table front edge.

When in the correct position the table will not slide forward.

LOCATING PIN

FG080 –EPSILON 07-12 RAC

15

8.0 OPERATING CONDITIONS

To obtain the best product results and consistent operation,

Make sure the depositor is used on a level surface.

(Adjust feet if required)

Ensure flat trays are used.

Ensure undamaged nozzles and templates are used.

Keep the machine clean.

EPSILON

Do not leave any components in the hopper.

FG080 –EPSILON 07-12 RAC

16

TEMPLATE

HOPPER

EPSILON

NOTE: THIS MACHINE IS FOR USE WITH SOFT DOUGH ONLY

9.0 PREPARING FOR OPERATION

1 Select template and nozzles required and fit as section 9a & 9b following.

Fill hopper with mix and close hopper guard.

It is recommended that when heavy mixes are used, the inside of the hopper should be

coated with vegetable oil and for lighter mixes such as meringue, dampen with water. The oil

or water will help the mix to settle down the hopper walls and prevent air being sucked in.

2 Connect power cable to the correct electrical supply.

Make sure stop button is in released position (turn clockwise if required).

3 Select an existing program or create a new program through the on-screen menus.

4 The machine is now ready for operation.

REMOVE GUARD TO FILL

HOPPER.

REPLACE CORRECTLY.

(MACHINE WILL NOT OPERATE WITHOUT

THIS GUARD IN POSITION)

(see section 10 operation)

SCREEN

STOP BUTTON

FG080 –EPSILON 07-12 RAC

Loading...

Loading...