Monnit ALTA, ALTA WirelessCarbon Monoxide Sensor, ALTA Wireless Temperature Sensor, ALTA Wireless Carbon Dioxide Sensor User Manual

Page 1

by

ALTA Wireless 150 Amp Current Meter

User Guide

Page 2

Table of Contents

I. ABOUT THE WIRELESS 150 AMP AC CURRENT METER 1

ALTA WIRELESS 150 AMP AC CURRENT METER FEATURES 1

EXAMPLE APPLICATIONS 1

2

2

III. REGISTRATION

REGISTERING A CURRENT METER

IV. SETTING UP THE 150 AMP AC CURRENT METER

INSTALLING BATTERIES

V. SENSOR OVERVIEW

MENU SYSTEM

SUPPORT

WARRANTY INFORMATION

PAGE II

2

3

3

4

4

6

6

II. CURRENT METER SECURITY

CURRENT METER COMMUNICATION SECURITY

DATA SECURITY ON THE GATEWAY

iMONNIT SECURITY 2

MOUNTING THE SENSOR 5

ANTENNA ORIENTATION 5

13

13

CERTIFICATIONS 15

Page 3

I. ABOUT THE WIRELESSS 150 AMP AC CURRENT METER

The ALTA wireless AC Current Meter measures the RMS current of an alternating current

(AC) system using a current transformer (CT) that wraps around the “hot” wire of a two wire

(hot, common, ground(optional)) power system. The sensor reports Minimum RMS current,

maximum RMS current, average RMS current, and amp hours to the iMonnit system. The

iMonnit system is capable of generating watt hour or kilowatt hour readings as well.

PAGE 1

ALTA WIRELESS 150 AMP AC CURRENT METER FEATURES

• Wireless range of 1,200+ feet through 12+ walls *

• Frequency-Hopping Spread Spectrum (FHSS)

• Interference immunity

• Power management for longer battery life **(12+ years on AA batteries)

• Encrypt-RF® Security (Die-Hellman Key Exchange + AES-128 CBC for sensor

data messages)

• Onboard data memory stores up to hundreds of readings per sensor:

- 10-minute heartbeats = 3.5 days

- 2-hour heartbeats = 42 days

• Over-the-air updates (future proof)

• Free iMonnit basic online wireless sensor monitoring and notication system to

congure sensors, view data and set alerts via SMS text and email

* Actual range may vary depending on environment.

** Battery life is determined by sensor reporting frequency and other variables. Other power options are also

available.

EXAMPLE APPLICATIONS

• Current Monitoring

• Current Usage

• Amperage Monitoring

• Amp Hour Meter

• Measures amp hours, max RMS current, min RMS current, and average RMS current

• Two dierent current transducers available:

• Low Current: 0-20 amp

• High Current: 0-150 amp

• Capable of generating watt hour or kilowatt hour readings using iMonnit

• Data logging for accumulated amp hour readings

• Can notify based on current levels or changes in current levels

• Simple and safe installation of current/power

measurement hardware, no rewiring required

To measure current, clip the CT around only a single wire of the AC system (clipping around

a hot and neutral wire at the same time will result in 0 current readings). After the sensor

powers on and connects to the gateway it will begin taking measurements based on the

averaging interval (5 seconds default). It will report data to iMonnit every heartbeat or if the

current goes outside of the aware thresholds set in iMonnit. The sensor reports amp hours,

max RMS current, min RMS current, and average RMS current. iMonnit can also generate

watt hour or kilowatt hour readings if a default RMS voltage is set in iMonnit.

Page 4

iMONNIT SECURITY

iMonnit is the online software and central hub for conguring your device settings. All

data is secured on dedicated servers operating Microsoft SQL Server. Access is granted

through the iMonnit user interface, or an Application Programming Interface (API)

safeguarded by 256-bit Transport Layer Security (TLS 1.2) encryption. TLS is blanket of

protection to encrypt all data exchanged between iMonnit and you. The same encryption

is available to you whether you are a Basic user of Premiere user of iMonnit. You can rest

assured that your data is safe with iMonnit.

PAGE 2

II. CURRENT METER SECURITY

The ALTA Wireless 150 Amp AC Current Meter has been designed and built to securely manage data from sensors monitoring your environment and equipment. Hacking from botnets

are in the headlines, Monnit Corporation has taken extreme measures to ensure your data

security is handled with the utmost care and attention to detail. The same methods utilized by

nancial institutions to transmit data are also used in Monnit security infrastructure. Security

features of the gateway include tamper proof network interfaces, data encryption, and bankgrade security.

Monnit’s proprietary sensor protocol uses low transmit power and specialized radio

equipment to transmit application data. Wireless devices listening on open communication

protocols cannot eavesdrop on sensors. Packet level encryption and verication is key

to ensuring trac isn’t altered between sensors and gateways. Paired with best-in-class

range and power consumption protocol, all data is transmitted securely from your devices.

Thereby ensuring a smooth, worry-free, experience.

CURRENT METER COMMUNICATION SECURITY

Monnit current meter to gateway secure wireless tunnel is generated using ECDH-256

(Elliptic Curve Die-Hellman) public key exchange to generate a unique symmetric key

between each pair of devices. Meters and gateways use this link specic key to process

packet level data with hardware accelerated 128-bit AES encryption which minimizes

power consumption to provide industry best battery life. Thanks to this combination,

Monnit proudly oers robust bank-grade security at every level.

DATA SECURITY ON THE GATEWAY

The ALTA gateways are designed to prevent prying eyes from accessing the data that is

stored on the sensors. Gateways do not run on an o the shelf multi-function OS (operating

system). Instead they run a purpose specic real-time embedded state machine that cannot

be hacked to run malicious processes. There are also no active interface listeners that

can be used to gain access to the device over the network. The fortied gateway secures

your data from attackers and secures the gateway from becoming a relay for malicious

programs.

Page 5

III. REGISTRATION

PAGE 3

If this is your rst time using the iMonnit online portal, you will need to create a new

account. If you have already created an account, start by logging in. For instructions on

how to register for an iMonnit account, please consult the iMonnit User Guide viewable at

monnit.com/support/documentation.

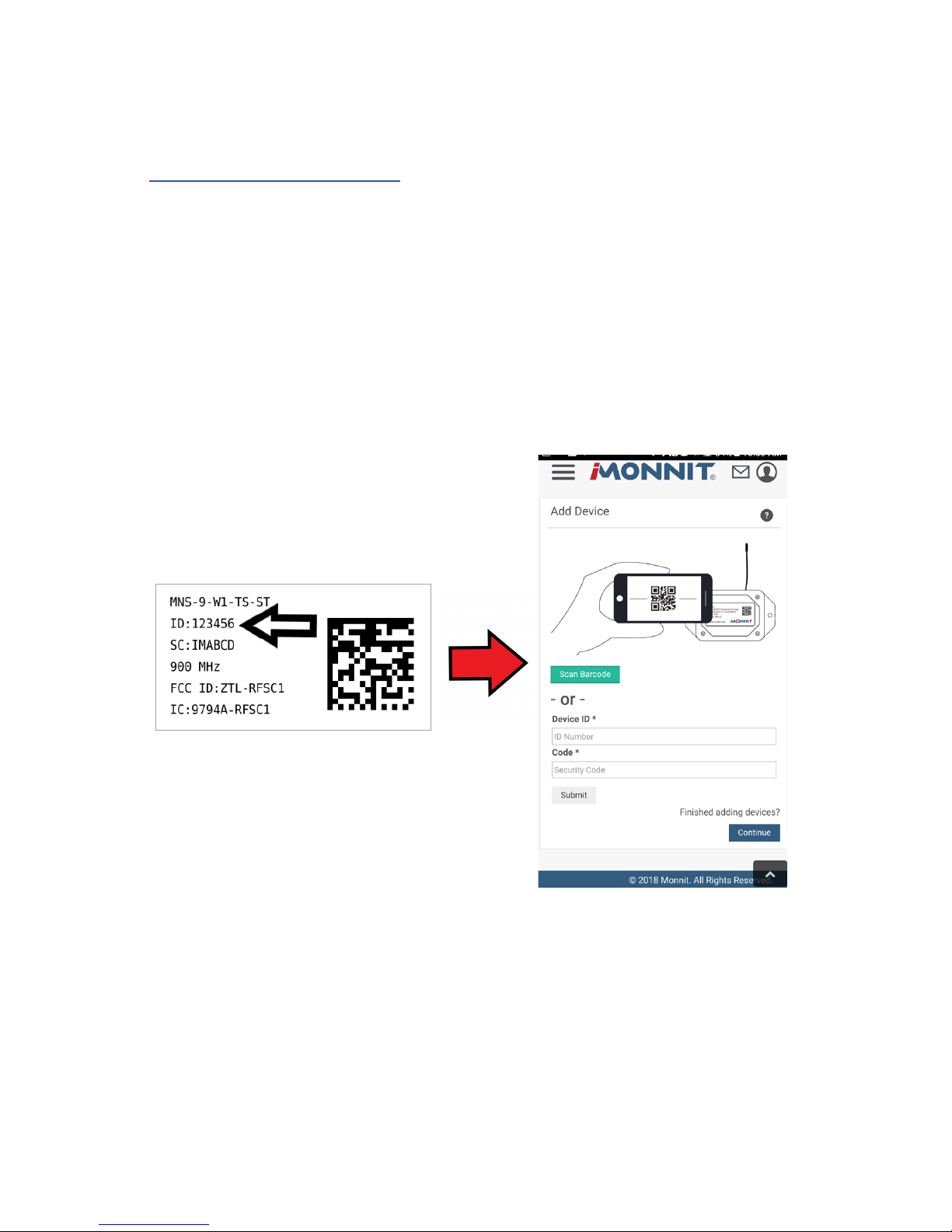

REGISTERING THE CURRENT METER

You will need to enter the Device ID and the Security Code from your 150 Amp AC Current

Meter in the corresponding text boxes. Use the camera on your smartphone to scan the

QR code on your sensor and gateway. If you do not have a camera on your phone, or the

system is not accepting the QR code, you may enter the Device ID and Security Code

manually.

• The Device ID is a unique number located on each device label.

• Next you’ll be asked to enter the Security Code (SC) on your device. A security

code will be all letters and must be entered in upper case, no numbers. It can also

be found on the barcode label of your gateway.

When completed, select the “Submit” button.

Page 6

IV. SETTING UP YOUR 150 AMP AC CURRENT METER

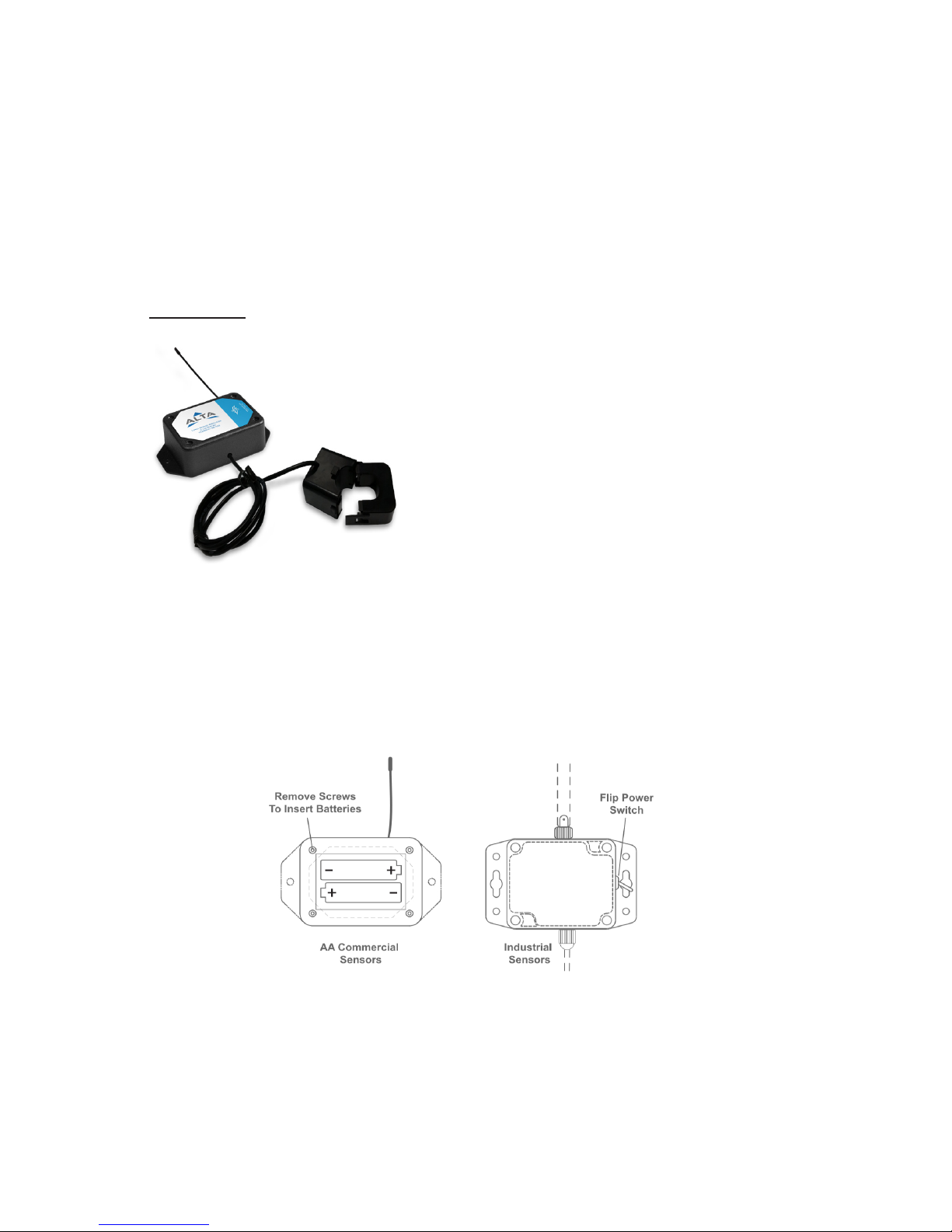

INSTALLING BATTERIES

ALTA commercial current meters are powered by AA batteries. Industrial sensors need a

3.6V Lithium battery supplied from Monnit or another industrial battery supplier. Monnit

encourages customers to recycle all old batteries.

When you are nished adding the sensor to your account, the next step is to insert the

battery. The type of battery you use will depend on the category of your sensor. ALTA

Wireless 150 Amp AC Current Meter will either be powered by commecial coin cell, AA, or

an industrial battery.

AA Batteries

The standard version of this current meter is powered by

two replaceable 1.5 V AA sized batteries (included with

purchase). The typical battery life is 10 -12 years.

This current meter is also available with a line power

option. The line powered version of this meter has a

barrel power connector allowing it to be powered by

a standard 3.0–3.6 V power supply. The line powered

version also uses two standard 1.5 V AA batteries as

backup for uninterrupted operation in the event of line

power outage.

Power options must be selected at time of purchase,

as the internal hardware of the meter must be changed to support the selected power

requirements.

Place batteries in the device by rst taking the meter and sliding the battery door open.

Insert fresh AA batteries in the carriage, then shut the battery door.

Complete the process by opening up iMonnit and selecting Sensors from the main

navigation menu. Verify that iMonnit is showing the meter has a full battery level.

PAGE 4

Page 7

Industrial Batteries

3.6V Lithium batteries for the Industrial Wireless 150 Amp AC

Current Meter is supplied by Monnit. The ALTA battery life for

the Industrial battery is 10 – 12 years.

Install the battery by taking the sensor and unscrewing the

four screws at the corners. Tuck-in a fresh battery in the

carriage, then adjust clips to hold the battery in place.

Open iMonnit and select Sensors from the main navigation

menu. Verify that iMonnit is showing the sensor has a full

battery level. Replace the battery door by screwing in the

four corners.

In order for the meter to function properly, you will need to attach the included antenna.

Simply screw the antenna onto the barrel connector on the top of the device. Make sure

to snug the antenna connection, but do not over tighten. When placing the meter, make

sure to mount the sensor with the antenna oriented straight up (vertical) to ensure the best

wireless radio signal.

Since the electronics are sealed within the meter housing, we have added an "On/O"

switch to the unit for your convenience. If you are not using the meter, simply leave the

button in the o position to preserve battery life. If the meter needs to be reset for any

reason, you can simply cycle the power by turning the switch to the "O" position and

waiting 30 seconds before powering back on.

PAGE 5

ANTENNA ORIENTATION

In order to get the best performance out of your ALTA Wireless Current Meter, it is important

to note proper antenna orientation and sensor positioning. Antennas should all be oriented

in the same direction, pointing vertically from the sensor. If the sensor is mounted at on its

back on a horizontal surface, you should bend the antenna as close to the sensor housing

as possible giving you the most amount of antenna pointing vertical. You should make the

antenna wire as straight as possible, avoiding any kinks and curving of the wire. Sensors

must be at least 3 ft. away from other sensors and the wireless gateway to function.

More Signal

Less Signal

Page 8

PAGE 6

V. CURRENT METER OVERVIEW

Select Sensors from the main navigation menu on iMonnit to access the sensor overview

page and begin making adjustments to your 150 Amp AC Current Meter.

MENU SYSTEM

Details - Displays a graph of recent current meter data.

History - List of all past heartbeats and readings.

Events - List of all events attached to this current meter.

Settings - Editable levels for your current meter.

Calibrate - Reset readings for your current meter.

Scale - Change the scale of readings for your current meter.

Directly under the tab bar is an overview of your current meter. This allows you to see the

signal strength and the battery level of the selected meter.

• indicates the meter is checking in and within user dened safe parameters.

• indicates the meter has met or exceeded a user dened threshold or triggered event.

• indicates that no meter readings are being recorded, rendering the meter inactive.

Details View

The Details View will be the rst page you see upon selecting which meter you would like to

modify.

A. The meter overview section will be

above every page. This will display

the present reading, signal strength,

battery level, and status.

B. This graph charts how the meter

uctuates throughout a set date

range. To change the date range

displayed in the graph, navigate up to

the top of the Readings Chart section

on the right-hand corner to change

the from and/or to date.

C. The Recent Readings section

below the chart shows your most

recent data received by the meter.

D. Battery Life displays the current

battery percentage remaining.

E. The Average Signal shows the

most common signal strength of your

meter. Low signal strength could be

a sign the placement of your sensor

Page 9

should be adjusted.

F. The pie chart in the Aware or Not Aware Section displays the percentage of aware states

your meter has entered since activation.

History View

Selecting the “History” tab within the tab bar allows you to view the meter’s data history as

time stamped data.

• On the far right of the meter history data is a cloud icon. Selecting this icon will

export an excel le for your sensor into your download folder.

Note: Make sure you have the date range for the data you need input in the “From” and “To” text boxes. This will be

the most recent week by default. Only the rst 2,500 entries in the selected date range will be exported.

The data le will have the following elds:

MessageID: Unique identier of the message in our database.

SensorID: If multiple meters or sensors are exported you can distinguish which reading

was from which using this number even if the names for some reason are the same.

Sensor Name: The name you have given the meter.

Date: The date the message was transmitted from the meter.

Value: Data presented with transformations applied but without additional labels.

Formatted Value: Data transformed and presented as it is shown in the monitoring portal.

Battery: Estimated life remaining of the battery.

Raw Data: Raw data as it is stored from the sensor.

Sensor State: Binary eld represented as an integer containing information about the state

or the meter when the message was transmitted. (See “Sensor State Explained” below).

Gateway ID: The Identier of the gateway that relayed the data from the meter.

Alert Sent: Boolean indicating if this reading triggered a notication to be sent from the

system.

Signal Strength: Strength of communication signal between the meter and the gateway,

shown as percentage value.

PAGE 7

Page 10

Voltage: Actual voltage measured at the meter battery used to calculate battery percentage,

similar to Received Signal you can use one or the other or both if they help you.

State

The integer presented here is generated from a single byte of stored data. A byte consists

of 8 bits of data that we read as Boolean (True (1)/False (0)) elds.

Using a temperature sensor as an example.

If the sensor is using factory calibrations the Calibrate Active eld is set True (1) so the bit

values are 00010000 and it is represented as 16.

If the sensor is outside the Min or Max threshold, the Aware State is set True (1) so the bit

values are 00000010 and it is represented as 2.

If the customer has calibrated the sensor this eld the Calibrate Active eld is set False

(0) AND the sensor is operating inside the Min and Max Thresholds, the bits look like

00000000 this is represented as 0.

If the sensor is using factory calibrations and it is outside the threshold the bit values are

00010010 and it is represented as 18 (16 + 2 because both the bit in the 16 value is set

and the bit in the 2 value is set).

Note: These two are the only bits that typically observed outside of our testing procedures.

PAGE 8

Page 11

Settings View

To edit the operational settings for a sensor, choose the “Sensor” option in the main

navigation menu then select the “Settings” tab to access the conguration page.

A. Sensor Name is a unique name you

give the meter to easily identify it in a list

and in any notications.

B. The Heartbeat Interval is how often

the meter communicates with the gateway

if no activity is recorded.

C. Aware State Heartbeat is how often

the meter communicates with the gateway

while in an Aware State.

D. Sensor is on is the time of day the

sensor is actively working. No signal

communication will be sent while meter is

hibernating.

E. Minimum Threshold is the lowest

amp threshold allowable. Assessments

below this value will cause the sensor to

enter the Aware State.

F. Maximum Threshold is the highest

reading the meter should record before

entering an Aware State.

G. The Aware State Buer is a buer

to prevent the sensor from bouncing

between Standard Operation and Aware

State when the assessments are very

close to a threshold.

H. Averaging Interval is the average time in seconds when data is reported to iMonnit on

every heartbeat.

I. Accumulate will accumulate the readings heartbeat after heartbeat. Accumulation rolls

over at 65535 (2^16 or 0xFFFF).

J. Show Full Data Value when on, will not cut o data value and show the full reading.

K. In small sensor networks the sensors can be set to synchronize their communications.

The default setting o allows the sensors to randomize their communications therefore

maximizing communication robustness. Setting this will synchronize the communication of

the sensors.

L. Failed transmissions before link mode is the number of transmissions the sensor

sends without response from a gateway before it goes to battery saving link mode. In link

mode, The sensor will scan and Join a gateway at the following intervals: @ 0 Seconds, 3

sec, 6 sec, 9 sec, 15 sec, 30 sec, 1 min, 2 min, 5 min, 15 min, 30 min, and 60 min, then 60

minutes thereafter. While attempting to link, the sensor will continue to measure. A lower

number will allow sensors to nd new gateways with fewer missed readings. High numbers

will enable the sensor to remain with its current gateway in a noisy RF environment better.

PAGE 9

Page 12

The default heartbeat interval is 120 minutes or two hours. It is recommended that you do

not lower your heartbeat level too much because it will drain the battery.

Finish by selecting the “Save” button.

Note: Be sure to select the “Save” button anytime you make a change to any of the sensor parameters. All

changes made to the sensor settings will be downloaded to the sensor on the next sensor heartbeat (check-

in). Once a change has been made and saved, you will not be able to edit that sensor’s conguration again

until it has downloaded the new setting.

Calibrate View

To calibrate a meter, you will want to ensure that the environment of the meter and other

calibration device is stable. Note the “Expected Next Check-in” time for the sensor you are

calibrating and take a reading from your calibration device a few minutes prior to the next

check-in.

Enter the actual (accurate) reading from the calibration device into the text elds for

“Observed Sensor Reading” and “Actual Input”.

Press “Calibrate”.

When the meter checks-in, it will send the pre-calibration reading to the gateway, then

receive the calibration command and update it’s conguration. When the process is

completed, it will send a “Calibration Successful” message. The server will display the

sensor’s last pre-calibrated reading for this check-in, then all future readings from the

sensor will be based on the new calibration setting.

It is important to note that after calibrating the sensor, the sensor reading returned to the

server is based on pre-calibration settings. The new calibration settings will take eect on

the next sensor heartbeat.

Note: If you would like to send the changes to the sensor right away, please remove the battery(s) for a full 60

seconds, then re-insert the battery(s). This forces the communication from the sensor to the gateway and this the

message to make a change from the gateway back to the sensor. (If the sensors are industrial sensors, turn the

sensor o for a full minute, rather than removing the battery).

If the meter readings need to be reset, the “Calibrate” tab will be available for selection in

the tab bar.

PAGE 10

Page 13

Creating a Calibration Certicate

Creating a calibration certicate will mask the calibration tab from those who should not

have permissions to adjust these settings. Permissions for self-certifying a calibration must

be enabled in user permissions.

Directly below the calibrate button is the selection to "Create Calibration Certicate.

A. The Calibration Facility Field will be lled. Select the dropdown menu to change your

facility.

B. The date for "Certicate Valid Until" must be set one day in the future after the date

contained in the "Date Certied" eld.

C. "Calibration Number" and "Calibration Type" are unique values to your certicate.

D. Choose the "Save" button before moving on.

When the new certicate is accepted, the Calibration tab will change to a Certicate tab.

You will still be able to edit the certicate by choosing the Certicate Tab and navigating

down to "Edit Calibration Certicate."

The tab will revert back to "Calibrate" after the period for the certicate ends.

PAGE 11

Page 14

Scale View

The scale option will be available in the tab bar. To change the amp label and volts, select

the Scale tab.

Press the “Save” button to complete your adjustment.

PAGE 12

Page 15

SUPPORT

For technical support and troubleshooting tips please visit our support library online at

monnit.com/support/. If you are unable to solve your issue using our online support, email

Monnit support at support@monnit.com with your contact information and a description of

the problem, and a support representative will call you within one business day.

For error reporting, please email a full description of the error to support@monnit.com.

WARRANTY INFORMATION

(a) Monnit warrants that Monnit-branded products (Products) will be free from defects

in materials and workmanship for a period of one (1) year from the date of delivery with

respect to hardware and will materially conform to their published specications for a period

of one (1) year with respect to software. Monnit may resell sensors manufactured by other

entities and are subject to their individual warranties; Monnit will not enhance or extend

those warranties. Monnit does not warrant that the software or any portion thereof is error

free. Monnit will have no warranty obligation with respect to Products subjected to abuse,

misuse, negligence or accident. If any software or rmware incorporated in any Product

fails to conform to the warranty set forth in this Section, Monnit shall provide a bug x or

software patch correcting such non-conformance within a reasonable period after Monnit

receives from Customer (i) notice of such non-conformance, and (ii) sucient information

regarding such non-conformance so as to permit Monnit to create such bug x or software

patch. If any hardware component of any Product fails to conform to the warranty in this

Section, Monnit shall, at its option, refund the purchase price less any discounts, or repair

or replace nonconforming Products with conforming Products or Products having substan-

tially identical form, t, and function and deliver the repaired or replacement Product to a

carrier for land shipment to customer within a reasonable period after Monnit receives from

Customer (i) notice of such non-conformance, and (ii) the non-conforming Product provided; however, if, in its opinion, Monnit cannot repair or replace on commercially reasonable

terms it may choose to refund the purchase price. Repair parts and replacement Products

may be reconditioned or new. All replacement Products and parts become the property of

Monnit. Repaired or replacement Products shall be subject to the warranty, if any remains,

originally applicable to the product repaired or replaced. Customer must obtain from Monnit

a Return Material Authorization Number (RMA) prior to returning any Products to Monnit.

Products returned under this Warranty must be unmodied.

Customer may return all Products for repair or replacement due to defects in original

materials and workmanship if Monnit is notied within one year of customer’s receipt of the

product. Monnit reserves the right to repair or replace Products at its own and complete discretion. Customer must obtain from Monnit a Return Material Authorization Number (RMA)

prior to returning any Products to Monnit. Products returned under this Warranty must be

unmodied and in original packaging. Monnit reserves the right to refuse warranty repairs

or replacements for any Products that are damaged or not in original form. For Products

outside the one year warranty period repair services are available at Monnit at standard

labor rates for a period of one year from the Customer’s original date of receipt.

(b) As a condition to Monnit’s obligations under the immediately preceding paragraphs,

Customer shall return Products to be examined and replaced to Monnit’s facilities, in

shipping cartons which clearly display a valid RMA number provided by Monnit. Customer

acknowledges that replacement Products may be repaired, refurbished or tested and found

to be complying. Customer shall bear the risk of loss for such return shipment and shall

bear all shipping costs. Monnit shall deliver replacements for Products determined by Monnit to be properly returned, shall bear the risk of loss and such costs of shipment of repaired

Products or replacements, and shall credit Customer’s reasonable costs of shipping such

returned Products against future purchases.

PAGE 13

Page 16

(c) Monnit’s sole obligation under the warranty described or set forth here shall be to repair

or replace non-conforming products as set forth in the immediately preceding paragraph, or

to refund the documented purchase price for non-conforming Products to Customer. Monnit’s warranty obligations shall run solely to Customer, and Monnit shall have no obligation

to customers of Customer or other users of the Products.

Limitation of Warranty and Remedies.

THE WARRANTY SET FORTH HEREIN IS THE ONLY WARRANTY APPLICABLE TO

PRODUCTS PURCHASED BY CUSTOMER. ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY

DISCLAIMED. MONNIT’S LIABIITY WHETHER IN CONTRACT, IN TORT, UNDER ANY

WARRANTY, IN NEGLIGENCE OR OTHERWISE SHALL NOT EXCEED THE PURCHASE

PRICE PAID BY CUSTOMER FOR THE PRODUCT. UNDER NO CIRCUMSTANCES

SHALL MONNIT BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES. THE PRICE STATED FOR THE PRODUCTS IS A CONSIDERATION IN LIMITING

MONNIT’S LIABILITY. NO ACTION, REGARDLESS OF FORM, ARISING OUT OF THIS

AGREEMENT MAY BE BROUGHT BY CUSTOMER MORE THAN ONE YEAR AFTER

THE CAUSE OF ACTION HAS ACCRUED.

IN ADDITION TO THE WARRANTIES DISCLAIMED ABOVE, MONNIT SPECIFICALLY

DISCLAIMS ANY AND ALL LIABILITY AND WARRANTIES, IMPLIED OR EXPRESSED,

FOR USES REQUIRING FAIL-SAFE PERFORMANCE IN WHICH FAILURE OF A PRODUCT COULD LEAD TO DEATH, SERIOUS PERSONAL INJURY, OR SEVERE PHYSICAL

OR ENVIRONMENTAL DAMAGE SUCH AS, BUT NOT LIMITED TO, LIFE SUPPORT OR

MEDICAL DEVICES OR NUCLEAR APPLICATIONS. PRODUCTS ARE NOT DESIGNED

FOR AND SHOULD NOT BE USED IN ANY OF THESE APPLICATIONS.

PAGE 14

Page 17

CERTIFICATIONS

United States FCC

This equipment has been tested and found to comply with the limits for a Class B digital

devices, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television recep-

tion, which can be determined by turning the equipment o and on, the user is encouraged

to try to correct the interference by one of more of the following measures:

• Reorient or relocate the recieving antenna.

• Increase the separtation between the equipment and reciever

• Connect the equipment into an outlet on a circuit dierent from that to which the

reciever is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Warning: Changes or modications not expressly approved by Monnit could void

the user’s authority to operate the equipment.

RF Exposure

WARNING: To satisfy FCC RF exposure requirements for mobile

transmitting devices, the antenna used for this transmitter must not be

co-located in conjunction with any antenna or transmitter.

Monnit and ALTA Wireless Sensors:

This equipment complies with the radiation exposure limits prescribed for an uncontrolled

environment for xed and mobile use conditions. This equipment should be installed and

operated with a minimum distance of 20 cm between the radiator and the body of the user

or nearby persons.

All ALTA Wireless Sensors Contain FCC ID: ZTL-G2SC1. Approved Antennas

ALTA devices have been designed to operate with an approved antenna listed below, and

having a maximum gain of 14 dBi. Antennas having a gain greater than 14 dBi are strictly

prohibited for use with this device. The required antenna impedance is 50 ohms.

• Xianzi XQZ-900E (5 dBi Dipole Omnidirectional)

• HyperLink HG908U-PRO (8 dBi Fiberglass Omnidirectional)

• HyperLink HG8909P (9 dBd Flat Panel Antenna)

• HyperLink HG914YE-NF (14 dBd Yagi)

• Specialized Manufacturing MC-ANT-20/4.0C (1 dBi 4” whip)

PAGE 15

Page 18

Canada (IC)

English

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum (or lesser) gain approved for the transmitter by Industry Canada.

To reduce potential radio interference to other users, the antenna type and its gain should

be so chosen that the Equivalent Isotropically Radiated Power (E.I.R.P.) is not more than

that necessary for successful communication.

The radio transmitters (IC: 9794A-RFSC1, IC: 9794A-G2SC1, IC: 4160a-CNN0301, IC:

5131A-CE910DUAL, IC: 5131A-HE910NA, IC: 5131A-GE910 and IC: 8595A2AGQN4NNN)

have been approved by Industry Canada to operate with the antenna types listed on previous page with the maximum permissible gain and required antenna impedance for each

antenna type indicated. Antenna types not included in this list, having a gain greater than

the maximum gain indicated for that type, are strictly prohibited for use with this device.

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this device may not cause interference, and (2)

this device must accept any interference, including interference that may cause undesired

operation of the device.

French

Conformément à la réglementation d’Industrie Canada, le présent émetteur radio peut

fonctionner avec une antenne d’un type et d’un gain maximal (ou inférieur) approuvé pour

l’émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à l’intention des autres utilisateurs, il faut choisir le type d’antenne et son gain de

sorte que la Puissance Isotrope Rayonnée Èquivalente (P.I.R.È) ne dépasse pas l’intensité

nécessaire à l’établissement d’une communication satisfaisante.

Le présent émetteurs radio (IC: 9794A-RFSC1, IC: 9794A-G2SC1, IC: 4160a-CNN0301,

IC: 5131A-CE910DUAL, IC: 5131A-HE910NA, IC: 5131A-GE910 et IC: 8595A2AGQN4NNN) a été approuvé par Industrie Canada pour fonctionner avec les types d’antenne

gurant sur la page précédente et ayant un gain admissible maximal et l’impédance requise

pour chaque type d’antenne. Les types d’antenne non inclus dans cette liste, ou dont le

gain est supérieur au gain maximal indiqué, sont strictement interdits pour l’exploitation de

l’émetteur.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils

radio exempts de licence. L’exploitation est autorisée aux deux conditions suivantes : (1)

l’appareil ne doit pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter

tout brouillage radioélectrique subi, méme si le brouillage est susceptible d’en compromettre le fonctionnement.

PAGE 18

Page 19

SAFETY RECOMMENDATIONS

READ CAREFULLY

Be sure the use of this product is allowed in the country and in the environment required.

The use of this product may be dangerous and has to be avoided in the following areas:

• Where it can interfere with other electronic devices in environments such as hospitals

airports, aircrafts, etc.

• Where there is risk of explosion such as gasoline stations, oil reneries, etc.

It is responsibility of the user to enforce the country regulation and the specic environment

regulation.

Do not disassemble the product; any mark of tampering will compromise the warranty

validity. We recommend following the instructions of this user guide for correct setup and

use of the product.

Please handle the product with care, avoiding any dropping and contact with the internal

circuit board as electrostatic discharges may damage the product itself. The same precau-

tions should be taken if manually inserting a SIM card, checking carefully the instruction for

its use. Do not insert or remove the SIM when the product is in power saving mode.

Every device has to be equipped with a proper antenna with specic characteristics. The

antenna has to be installed with care in order to avoid any interference with other electronic

devices and has to guarantee a minimum distance from the body (23 cm). In case this re-

quirement cannot be satised, the system integrator has to assess the nal product against

the SAR regulation.

The European Community provides some Directives for the electronic equipments introduced on the market. All the relevant information’s is available on the European Community

website: http://ec.europa.eu/enterprise/sectors/rtte/documents/

Additional Information and Support

For additional information or more detailed instructions on how to use your Monnit Wireless

Sensors or the iMonnit Online System, please visit us on the web at monnit.com/support.

Monnit, Monnit Logo and all other trademarks are property of Monnit, Corp.

© 2019 Monnit Corp. All Rights Reserved.

Monnit Corporation

3400 South West Temple

Salt Lake City, UT 84115

801-561-5555

www.monnit.com

AUG-012 (02/19)

Loading...

Loading...