MTN/VM220

High performance Vibration Meter

Monitran Ltd

| Monitor House | 33 Hazlemere Road | Penn | Bucks | UK | HP10 8AD

Telephone

+44 (0)1494 816569 | E-mail info@monitran.com | Website www.monitran.com

We reserve the right to alter specifications without prior notice.

HB039.3

Instruction Manual

0.

Contents

Page

1.

Introduction

1

2.

Precautions

1

3.

Equipment details

1

4.

Preparation for use

2

5.

Buttons

3

6.

Display

3

7.

Connections

4

8.

Battery status

4

9.

Charging the unit

4

10.

Connecting sensor

5

11.

Measurement modes

6

12.

Calculation modes

6

13.

Memory recall mode

7

14.

Settings menu

8

15.

Setting the clock

8

16.

Setting units

8

17.

Setting low pass filter

9

18.

Setting ISO10816 group

9

19.

Clearing memories

9

20.

ISO10816

10

21.

Physical

11

22.

Specifications

12

23.

Troubleshooting

14

24.

After sales support

14

A.

Main operations

15

B.

Conversions and formulae

16

1

1.

Introduction

The MTN/VM220 Vibration Meter is a rechargeable, portable instrument designed to operate with a constant current

type accelerometer to provide accurate vibration measurements.

Conforming to ISO10816-3/7, MTN/VM220 will display RMS, peak, peak-peak, crest factor and bearing condition on its

colour screen. Up to 100 time-stamped readings can be stored to non-volatile memory.

The MTN/VM220 is an invaluable trouble-shooting tool for instrumentation engineers familiar with the problems of

plant vibration monitoring, providing an instant readout of the condition of bearings and rotating parts.

2.

Precautions

• Only use the unit as directed in this manual.

• Protect the unit from shocks and extremes of temperature, humidity and harsh environments (such as high salt).

• Use only a soft clean cloth. Do not use solvents or harsh cleaning agents.

• The unit contains no user serviceable parts. Do not attempt to disassemble or repair the unit, as this will invalidate

your warranty.

• To ensure continued performance, have the unit checked and serviced at regular intervals.

3.

Equipment Details

Purchase date:

Vibration meter serial number:

Cable serial number:

Sensor serial number:

Software version:

2

4.

Preparation for use

Carefully remove the instrument from the transit packaging and ensure all accessories supplied agree with the delivery

note.

Visually inspect for transit damage.

3

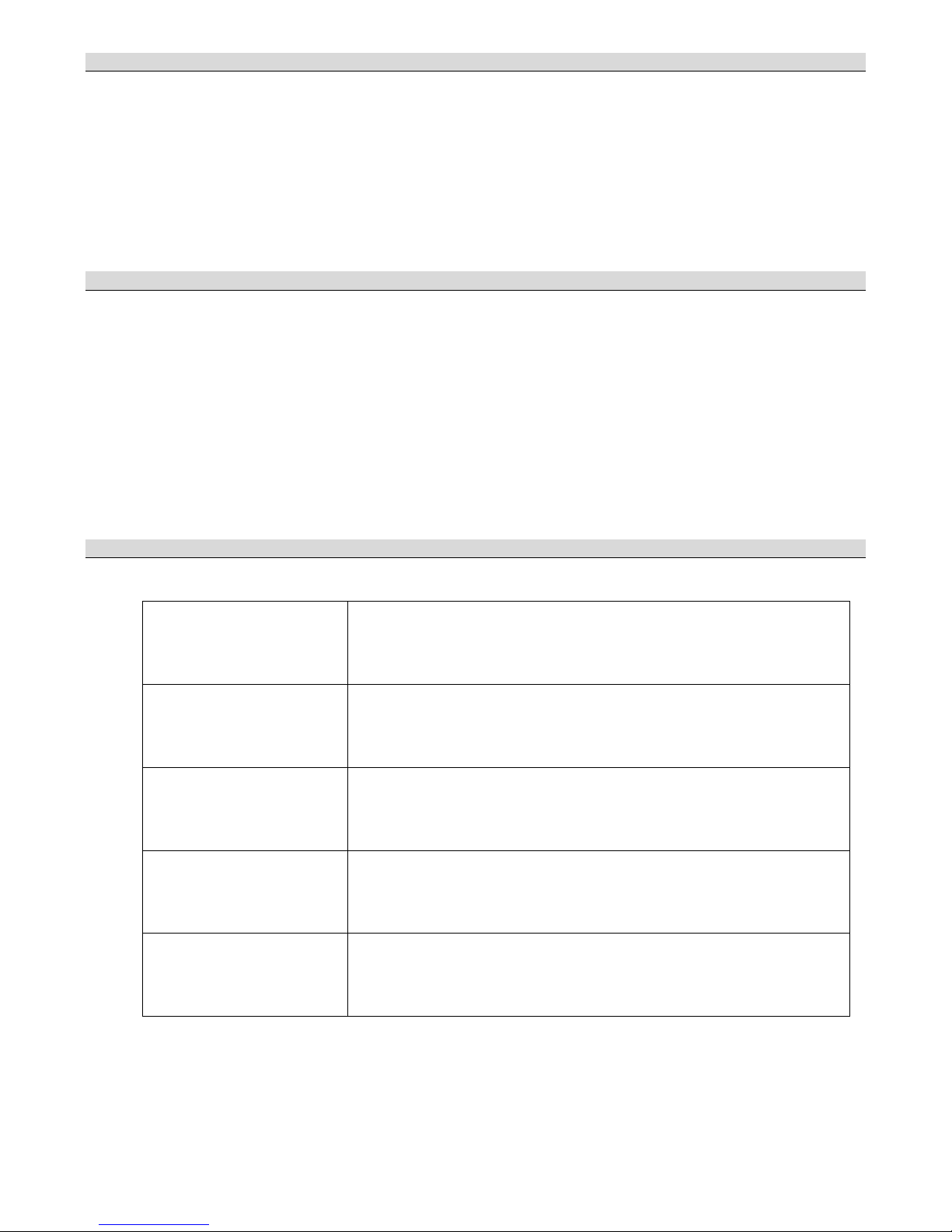

5.

Buttons

• Power on

• Power off

• Previous operating mode

• Value increase

• Next operating mode

• Value decrease

• Previous calculation mode

• Previous memory slot

• Next calculation mode

• Next memory slot

• Store value to memory slot

• Select parameter

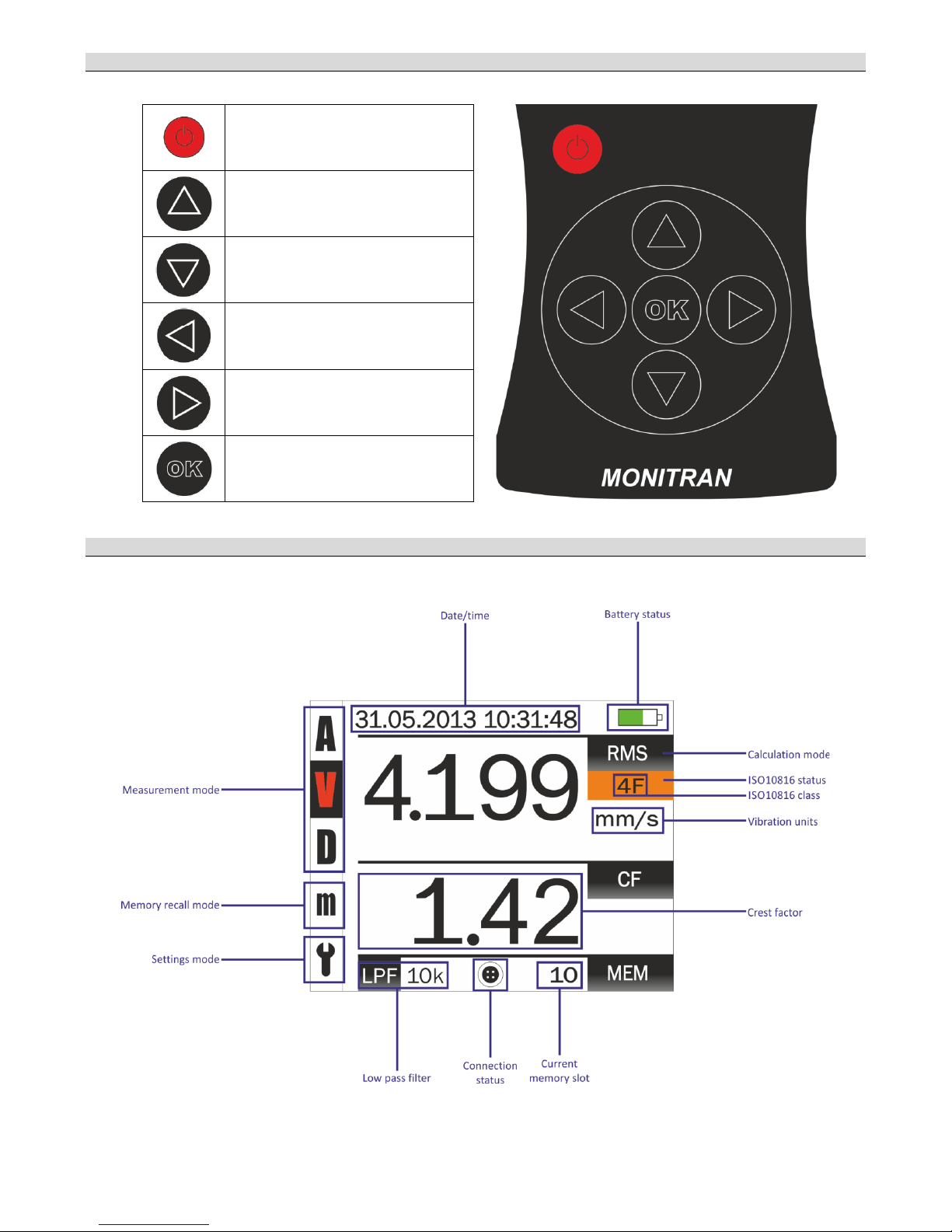

6.

Display

4

7.

Connections

The headphone jack

will accept a 3.5mm stereo jack plug. Headphones (not included) may be used to listen to the vibration

directly.

To avoid hearing damage, use of headphones with an inline volume adjustment is recommended. Ensure the volume is turned

down before connectin

g your headphones. After placing headphones in your ears, gradually turn up the volume until you reach a

comfortable listening level. Do not use headphones when it's unsafe to do so - while operating a vehicle, or during any activity or in

an environment where your full attention to your surroundings is required.

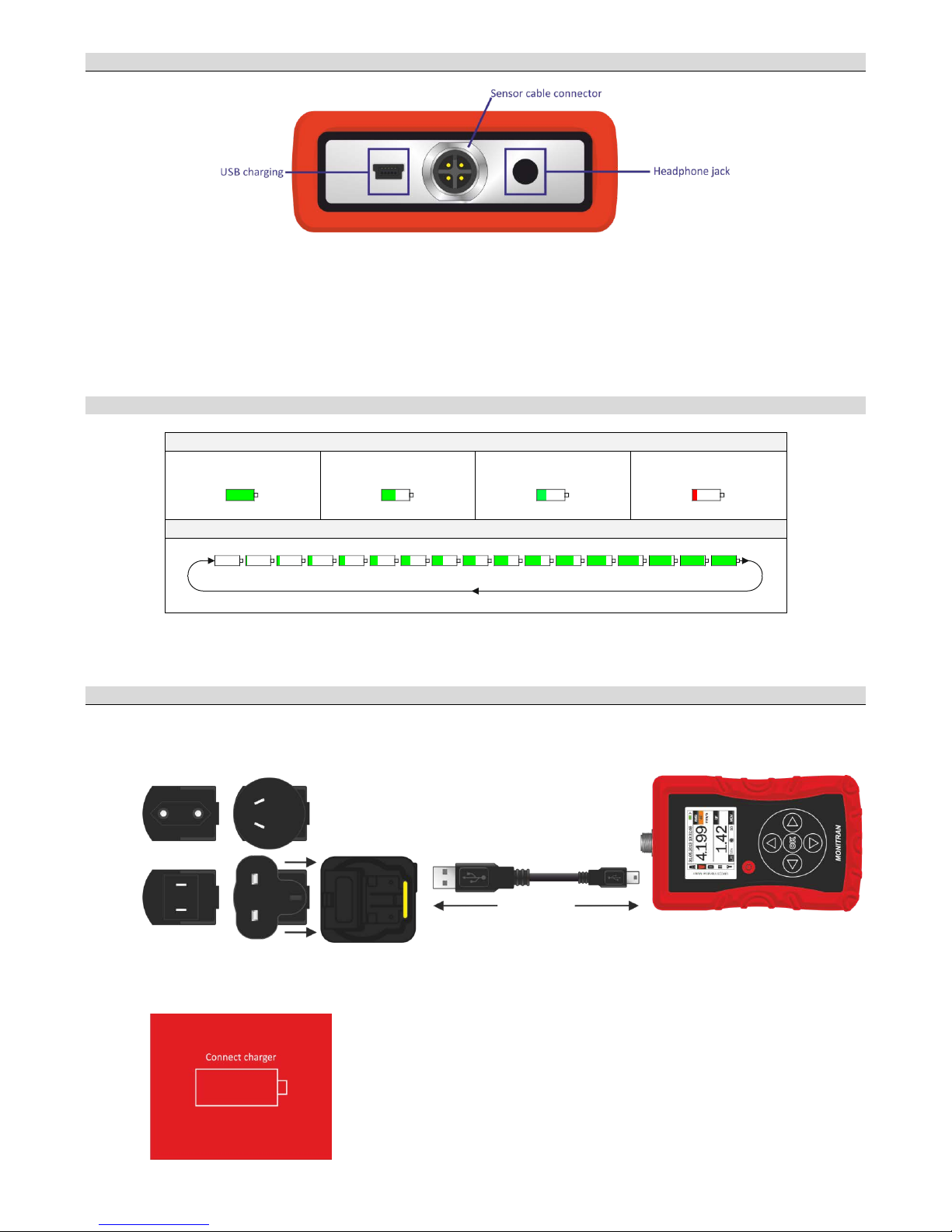

8.

Battery status

Normal operation

100%

50%

25%

10%

Charging

The meter will automatically turn-off after 15 minutes of inactivity (5 minutes if sensor not connected).

9.

Charging the unit

The supplied multi-voltage charger comes with 4 adaptors and is suitable for use worldwide.

Connect the correct adaptor for your region, plug into mains and connect the mini USB to the MTN/VM220.

The unit should reach full charge within 4 hours. The battery status icon will indicate charging is in progress (see 6.

Display & 8. Battery status).

When the battery is level is low, a warning screen (see left) will display for 5

seconds and the unit will power off.

5

10.

Connecting sensor

• The sensor and cable can be connected/disconnected at any time.

• Once fully charged, briefly press the power button to switch the unit on.

1 2 3

Connect either end of the cable to

the unit by rotating the connector

to align the key.

Once in the correct position, the

connector will drop into the socket

and the knurl can be tightened to

hold the connector in place. Do

not overtighten.

• Repeat this process to connect the sensor to the other end of the cable.

Notes:

The connection status icon (see 6. Display) will change accordingly.

No connection

Cable connected

Sensor connected

• Attach spike or magnet, if required.

6

11.

Measurement modes

Press buttons to switch between measurement modes.

The current mode will be highlighted.

Units for each measurement mode can be set (see 16. Setting units)

MODE UNITS

Acceleration mode g m/s²

Velocity mode mm/s in/s

Displacement mode µm mils

Memory recall mode (see 13. Memory recall mode)

Settings (see 14. Settings menu)

12.

Calculation modes

When the unit is in one of the measurement modes (acceleration, velocity, displacement), press buttons to

switch between RMS, peak-peak and 0-peak displays. An additional bearing display is available in both acceleration and

velocity measurement modes. The bearing mode passes the vibration signal through a 1kHz-10kHz band-pass filter to

attenuate non-bearing vibration found at lower frequencies, and is used for more precise monitoring of bearings.

Display

Calculation mode

RMS

Root mean square

PK-PK

Peak to peak

0-PK

Zero to peak

B

Bearing (RMS)

Press

to store the displayed value in the current memory slot. The current memory number will automatically move

to the next slot.

• Current time

• Current date

• Measurement mode

• Calculation mode

• Crest factor value

• Vibration value & units

The Crest Factor is equal to the peak amplitude of a waveform divided by the RMS value. The purpose of the

crest factor calculation is to give an analyst a quick idea of how much impacting is occurring in a waveform.

Impacting is often associated with roller bearing wear, cavitation and gear tooth wear.

7

13.

Memory recall mode

Using buttons , select memory recall mode. Press buttons to navigate through memory slots.

When returning to the measurement mode, the selected memory slot will be the current memory slot for the next

store.

It is possible to quickly clear all memory slots (see 18. Clearing memories).

There are 100 memory slots in total. The blue fields shown in the above figure are saved into memory

Provided the unit is returned to Monitran for service, the memories will remain intact, even after battery replacement

and calibration (see 24. After Sales Support)

8

14.

Settings menu

• Using buttons , select .

• Press button

to enter settings menu.

• Use buttons

to navigate and press to select option.

• Use button

to navigate back to the main menu.

15.

Setting the clock

•

Enter settings menu (see

14. Settings menu

)

• Press button twice to highlight CLOCK and press to enter clock mode.

• Use buttons

to set DAY/MONTH/YEAR/HOUR/MINUTE settings.

• Press buttons

to change between DAY/MONTH/YEAR/HOUR/MINUTE.

• Press

at any time to save and return to settings menu.

16.

Setting units

•

Enter settings menu (see

14. Settings menu

)

• Press to select UNITS.

• Use buttons

to choose between acceleration (A), velocity (V), displacement

(D).

• Use buttons

to select units.

• Press

to save and return to settings menu.

9

17.

Setting low pass filter

• Enter settings menu (see 14. Settings menu)

• Press to select FILTER.

• Use buttons

to choose between 1, 5, 10 kHz.

• Press

to save and return to settings menu.

18.

Clearing memories

• Enter settings menu (see 14. Settings menu)

• Press to select RESET.

• A red bar will appear under the button to indicate progress.

NOTE: The clock and unit settings will be unaffected.

19.

Setting ISO10816 group

•

Enter settings menu (see

14. Settings menu

)

• Press to select ISO10816 (see 20. ISO10816).

• Use buttons

to select group (1F, 1R, 2F, 2R, 1<, 1>, 2<, 2>).

• Press

to save and return to settings menu.

1F

ISO10816-3 Group 1 (300kW-50MW) flexible foundation

1R

ISO10816-3 Group 1 (300kW-50MW) rigid foundation

2F

ISO10816-3 Group 1 (15kW-300kW) flexible foundation

2R

ISO10816-3 Group 1 (15kw-300kW) rigid foundation

1<

ISO10816-7 Category 1 (<200kW)

1>

ISO10816-7 Category 1 (>200kW)

2<

ISO10816-7 Category 2 (<200kW)

2>

ISO10816-7 Category 2 (>200kW)

See 20. ISO10816

10

20.

ISO10816

ISO10816-3:2009

Industrial machines with nominal power above 15kW and

nominal speeds between 120rpm and15000rpm when

measured in situ.

1F

ISO10816-3 Group 1 (300kW-50MW)

flexible foundation

1R

ISO10816-3 Group 1 (300kW-50MW)

rigid foundation

2F

ISO10816-3 Group 1 (15kW-300kW)

flexible foundation

2R

ISO10816-3 Group 1 (15kw-300kW)

rigid foundation

ISO10816-7:2009

Rotodynamic pumps for industrial applications, including

measurements on rotating shafts.

1< ISO10816-7 Category 1 (<200kW)

1> ISO10816-7 Category 1 (>200kW)

2< ISO10816-7 Category 2 (<200kW)

2> ISO10816-7 Category 2 (>200kW)

Sufficient severity to cause damage to the machine

Restricted operation until remedial action can be taken

Unrestricted long-term operation

Newly commissioned machines

Please consult ISO10816 standards for more information.

11

21.

Physical

All dimensions in mm, unless stated otherwise.

12

22. Specifications

Measurement ranges

Acceleration

Velocity

Displacement

20g

200mm/s

2000 µm

Different ranges available

Modes

RMS

Peak

Peak

-peak

Crest factor

Bearing acceleration

Bearing velocity

ISO10816

• ISO10816-3: 4 modes

ISO10816-3 Group 1 (300kW-50MW) flexible foundation

ISO10816-3 Group 1 (300kW-50MW) rigid foundation

ISO10816-3 Group 1 (15kW-300kW) flexible foundation

ISO10816-3 Group 1 (15kw-300kW) rigid foundation

• ISO10816-7: 4 modes

ISO10816-7 Category 1 (<200kW)

ISO10816-7 Category 1 (>200kW)

ISO10816-7 Category 2 (<200kW)

ISO10816-7 Category 2 (>200kW)

•

Visual indication of machine status:

Severe

Restricted

Unrestricted

Good

Frequency range

Low pass filters

Band

-pass filter

1kHz, 5kHz, 10kHz

1

-10kHz

Units

Acceleration

Velocity

Displacement

g, m/sec²

mm/sec, in/sec

µm, mils

Display

Type

Resolution

Viewing angle

Viewable size

TFT 16bit colour

160 x 128

100°

35 x 28mm

Memory

Size

100 slots storing vibration, time, date, filter, units, crest factor

Connections

Power

Headphones/AC signal

Sensor

USB mini-B

3.5mm stereo

4 pin Lumberg

13

Environmental

Operating temperature

0 to +45°C

Storage temperature

-20 to +60°C

Protection:

IP54

Power

Charger

100-240V/5V 1A USB with 4 adaptors

Battery

Li-ion 3.7V

Battery life

>20 hours

Power status

Battery icon indicates charging status, battery level

Dimensions

Size (L x W x H)

Weight

(meter only)

(complete kit)

130 x 78 x 28mm

0.215kg

1.427kg

Accessories

MTN/VM220

MTN/2100

-X

MTN/MM001

MTN/PS002

MTN/CA476

MTN/CA477

MTN/BT004

MTN/HE016

MTN/HB039

Vibration meter

Probe

Magnet

4" ¼"

-28UNF Spike

Coiled sensor cable

USB A to mini

USB B cable

Worldwide adaptor with 4 adaptors

Carry case

Handbook

14

23.

Troubleshooting

The unit will not power on

• Recharge battery.

The battery will not charge

• Try a different charger.

• Check charger cable for signs of damage.

•

Return the unit to Monitran for service.

The unit has frozen

• Hold the button for at least 10 seconds to force the unit to perform a hard

shutdown. Wait a few seconds, then restart as usual.

The unit is displaying

unexpected readings

• Ensure connectors are securely fastened at both ends of the cable.

•

Check cable and connectors for signs of damage.

24.

After Sales Support

Warranty

All products are guaranteed against defects in materials and workmanship for a period of 24 months from

the date of purchase. In the event of failure within 24 months of the original purchase the Company will

promptly repair or replace any defective products without charge.

This warranty is void if repair has been attempted by unauthorised persons or agents, if the products have

been used for purposes for which they were not intended, if they have been subjected to abuse or wilful

neglect or if the user has in any way failed to take sufficient precautions to safeguard the products.

No liability will be accepted for loss of items or component parts.

Recalibration

It is recommended that the Vibration Meter is recalibrated annually to maintain optimum performance.

Monitran are pleased to provide this service. Please contact our Sales Office for details.

15

Appendix A – Main operations

16

Appendix B – Conversions and formulae

A V D

F

ACCELERATION

m/s² g in/s² ft/s²

1 0.102 39.37 3.281

9.807 1 386.1 32.17

0.0254 0.00259 1 0.08333

0.3048 0.03108 12 1

VELOCITY

mm/s

m/s

in/s

ft/s

1 0.001 0.03937 0.003281

1000 1 39.37 3.281

25.4 0.0254 1 0.08333

304.8 0.3048 12 1

DISPLACEMENT

µm mm mils in

1 0.001 0.03937 0.0000394

1000 1 39.37 0.03937

0.0254 0.0000254 1 0.001

25400 25.4 1000 1

FREQUENCY

Hz CPS RPM CPM

1 1 60 60

1 1 60 60

0.01667 0.01667 1 1

0.01667 0.01667 1 1

𝐀 = 𝐕. 𝟐𝛑𝐅

= 𝐃. (𝟐𝛑𝐅)²

m/s²

m/s m Hz

𝐀 =

𝐕. 𝟐𝛑𝐅

𝟏𝟎𝟎𝟎

=

𝐃. (𝟐𝛑𝐅)²

𝟏𝟎𝟎𝟎𝟎𝟎𝟎

m/s²

mm/s

µm

Hz

𝐀 =

𝐕. 𝟐𝛑𝐅

𝟗𝟖𝟎𝟕

=

𝐃. (𝟐𝛑𝐅)²

𝟗𝟖𝟎𝟔𝟔𝟓𝟎

g

mm/s

µm

Hz

𝐕 =

𝐀

𝟐𝛑𝐅

= 𝐃. 𝟐𝛑𝐅

m/s²

m/s m Hz

𝐕 =

𝟏𝟎𝟎𝟎. 𝐀

𝟐𝛑𝐅

= 𝐃.

𝟐𝛑𝐅

𝟏𝟎𝟎𝟎

m/s²

mm/s

µm

Hz

𝐕 =

𝟗𝟖𝟏𝟎. 𝐀

𝟐𝛑𝐅

= 𝐃.

𝟐𝛑𝐅

𝟏𝟎𝟎𝟎

g

mm/s

µm

Hz

𝐃 =

𝐀

(𝟐𝛑𝐅)²

=

𝐕

𝟐𝛑𝐅

m/s²

m/s m Hz

𝐃 =

𝟏𝟎𝟎𝟎𝟎𝟎𝟎. 𝐀

(𝟐𝛑𝐅)²

=

𝟏𝟎𝟎𝟎. 𝐕

𝟐𝛑𝐅

m/s²

mm/s

µm

Hz

𝐃 =

𝟗𝟖𝟎𝟔𝟔𝟓𝟎. 𝐀

(𝟐𝛑𝐅)²

=

𝟏𝟎𝟎𝟎. 𝐕

𝟐𝛑𝐅

g

mm/s

µm

Hz

Where:

A = Acceleration

V = Velocity

D = Displacement

F = Frequency

Waveform

RMS value

Crest factor

Sine wave

𝟏

√

𝟐

≈ 𝟎. 𝟕𝟎𝟕

√

𝟐 ≈ 𝟏. 𝟒𝟏𝟒

Triangle wave

𝟏

√

𝟑

≈ 𝟎. 𝟓𝟕𝟕

√

𝟑 ≈ 𝟏. 𝟕𝟑𝟐

Sawtooth wave

𝟏

√

𝟑

≈ 𝟎. 𝟓𝟕𝟕

√

𝟑 ≈ 𝟏. 𝟕𝟑𝟐

Square wave 1 1

Where: Peak-peak = 1

17

Notes

© Monitran Limited 2016 HB039.3 11/2016

Right of modification reserved.

ALPINE

COMPONENTS

Postal Address

Alpine Components Ltd

Innovation Centre, Highfield Drive

Churchfields

St. Leonards-on-

Sea

TN38 9UH

United Kingdom

Telephone

01424 858118

Website Address

www.alpine-

components.co.uk

"Alpine Components" is the abbreviated trading name for "Alpine Components Limited"

The company has been trading since 1991 and was incorporated on 13/11/2006 in the United Kingdom

Company Registration Number: 05996485

VAT Number: GB583598190

Loading...

Loading...