SOTTO™ Ice Machines

UG Models

Installation, Operation and Maintenance Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

Part Number: 040002628 8/13

We reserve the right to make product improvements at any time.

Specifications and design are subject to change without notice.

Safety Notices

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this manual.

Disregarding the notices may lead to serious injury and/

or damage to the equipment.

Throughout this manual, you will see the following types

of safety notices:

Procedural Notices

As you work on Manitowoc equipment, be sure to read

the procedural notices in this manual. These notices

supply helpful information which may assist you as you

work.

Throughout this manual, you will see the following types

of procedural notices:

NOTE: Text set off as a Note provides you with

simple, but useful, extra information about the

procedure you are performing.

Read These Before Proceeding:

NOTE: SAVE THESE INSTRUCTIONS.

! Warning

Text in a W arning bo x alerts yo u to a po tential

personal inju ry situ ation. Be su re to re ad th e

Warning st atement before pr oceeding, and wor k

carefully.

!

Caution

Text in a Ca ution b ox ale rts yo u to a s ituation in

which you could damage the equipment. Be sure to

read the Caution statement before proceeding, and

work carefully.

Important

Text in an Important box pr ovides yo u with

information that may help you perform a procedure

more ef ficiently. Disr egarding this information will

not cause damage or inju ry, bu t it m ay slow you

down as you work.

!

Caution

Proper ins tallation, ca re an d m aintenance a re

essential fo r ma ximum pe rformance an d tro ublefree operation of your Manitowoc equipment. Read

and understand this m anual. It con tains valuable

care and maintenance information. If you encounter

problems not cover ed by th is manual, do no t

proceed, co ntact Manitowoc Fo odservice Group.

We will be happy to provide assistance.

Important

Routine ad justments an d maintenance pr ocedures

outlined in th is ma nual are not co vered by th e

warranty.

! Warning

PERSONAL INJURY POTENTIAL

Do not operate e quipment that h as been misused,

abused, ne glected, da maged, or altered/modified

from that of original manufactured specifications.

Part Number 040003628 08/13 i

Table of Contents

Section 1

General Information

General................................................................................................................. 1-1

Model Numbers ................................................................................................ 1-1

Model Numbers Identification.................................................................... 1-1

Model/Serial Number Location................................................................... 1-2

Owner Warranty Registration Card.......................................................... 1-3

Section 2

Installation Instructions

General................................................................................................................. 2-1

Ice Machine Dimensions............................................................................... 2-1

Location of Ice Machine................................................................................ 2-2

Leveling the Ice Machine.............................................................................. 2-2

Electrical Service............................................................................................. 2-3

VOLTAGE ………………………………………………………………………… 2-3

FUSE/CIRCUIT BREAKER …………………………………………………… 2-3

TOTAL CIRCUIT AMPACITY ………………………………………………… 2-3

Water Service/Drains...................................................................................... 2-4

WATER SUPPLY ………………………………………………………………… 2-4

WATER INLET LINES…………………………………………………………… 2-4

DRAIN CONNECTIONS………………………………………………………… 2-4

WATER SUPPLY AND DRAIN LINE SIZING/CONNECTIONS …………… 2-4

Installation Checklist...................................................................................... 2-6

Before Starting the Ice Machine

................................................................ 2-6

Section 3

Operation

Component Identification............................................................................. 3-1

Component Removal...................................................................................... 3-2

Ice Making Sequence of Operation................................................ 3-5

Operational Checks........................................................................................ 3-6

Table of Contents (continued)

ii Part Number 040003628 08/13

Section 4

Maintenance

General................................................................................................................ 4-1

Cleaning the Condenser ............................................................................... 4-2

Interior Cleaning and Sanitizing................................................................ 4-3

GENERAL ……………………………………………………………………… 4-3

CLEANING & SANITIZING PROCEDURE ………………………………… 4-3

Exterior Cleaning............................................................................. 4-4

Removal from Service/Winterization

....................................................... 4-4

Section 5

Before Calling for Service

Checklist............................................................................................................. 5-1

Part Number 040003628 08/13 1-1

Section 1

General Information

General

It is recommended that this ice machine be inspected

and installed by a qualified service technician.

Follow all recommendations and instructions for proper

installation and safe operation of this ice machine.

Model Numbers:

This manual covers the following models:

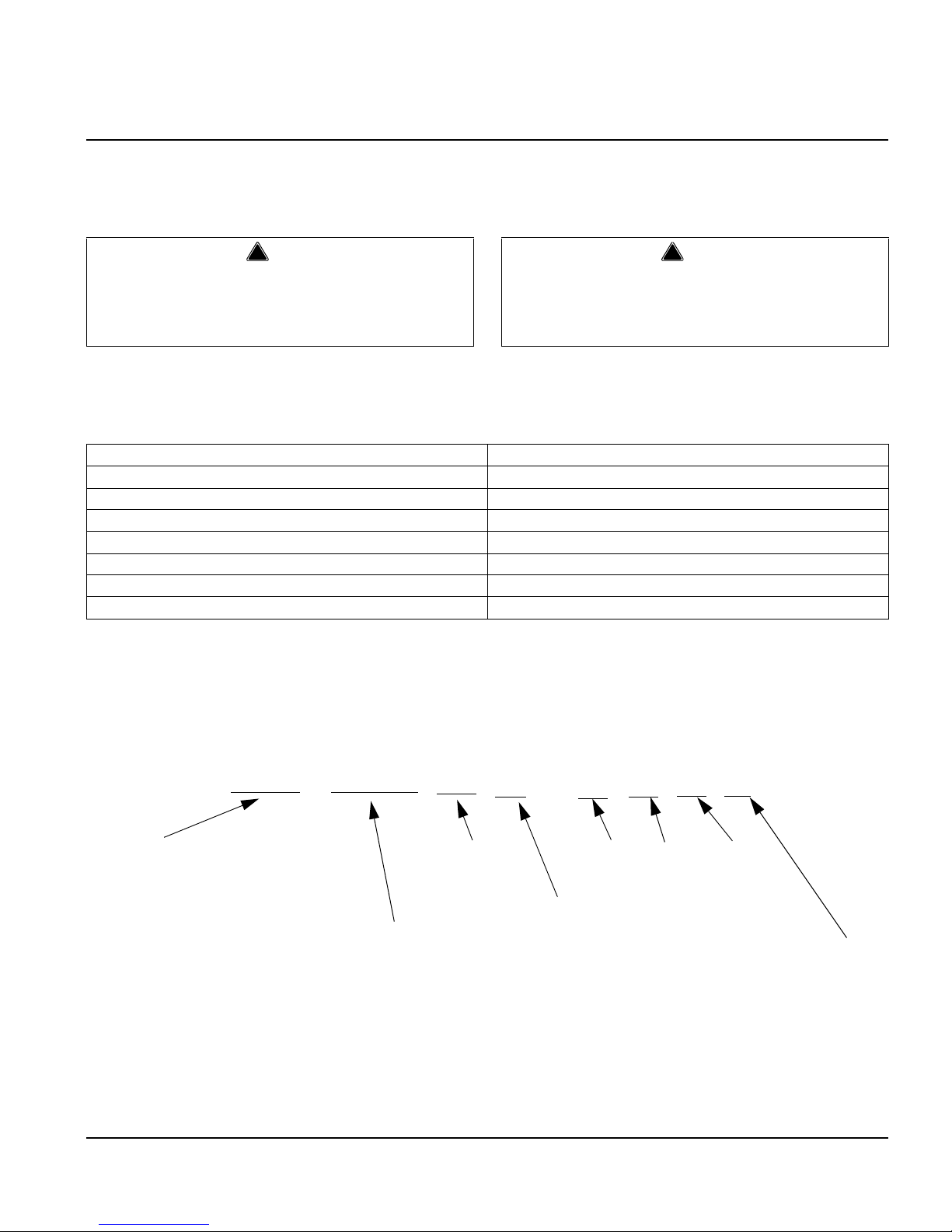

Model Numbers Identification:

UG 040 A C - 2 5 1 F

!

Warning

If you do not understand the procedures or the

safety precautions that must be followed, call your

local service representative to perform the

necessary installation procedures for you.

!

Warning

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

Self-Contained Air-Cooled Self-Contained Water-Cooled

UG018A N/A

UG020A N/A

UG030A UG030W

UG040A N/A

UG050A UG050W

UG065A N/A

UG080A N/A

Ice Machine Model

018= Model 18

020= Model 20

030= Model 30

040= Model 40

050= Model 50

065= Model 65

080= Model 80

A – Air Cooled

W – Water Cooled

Blank: Non-market specific

S: Saudi Arabic

K: Korea

C: China

G: GS approved

E : WRAS approved

B: Brazil

F= Schuko

G= Blade

Z= No Plug/Bare Lead

I= Oblique Flat Blades with Ground

B = 115V Grounded Power Cord

1= 115V

2= 230V

5= 50Hz

6= 60Hz

1= 1 Phase

General Information Section 1

1-2 Part Number 040003628 08/13

Model/Serial Number Location

Record the model and serial number of your ice machine

and bin or dispenser in the space provided below. These

numbers are required when requesting information from

your local Manitowoc distributor, or Manitowoc Ice, Inc.

The model and serial number are listed on the OWNER

WARRANTY REGISTRATION CARD. They are also

listed on the MODEL/SERIAL NUMBER DECAL affixed

to the ice machine, remote condenser and storage bin.

Model/Serial Number Location

Model:______________________ Serial Number:______________________

Model/Serial Number

Location

Section 1 General Information

Part Number 040003628 08/13 1-3

Owner Warranty Registration Card

GENERAL

The packet containing this manual also includes

warranty information. Warranty coverage begins the day

your new ice machine is installed.

If you do not return your OWNER WARRANTY

REGISTRATION CARD, Manitowoc will use the date of

sale to the Manitowoc Distributor as the first day of

warranty coverage for your new ice machine.

COMMERCIAL WARRANTY COVERAGE

General

The following Warranty outline is provided for your

convenience. For a detailed explanation, read the

warranty bond shipped with each product.

Contact your local Manitowoc representative or

Manitowoc Ice, Inc. if you need further warranty

information.

Parts

Manitowoc warrants the ice machine against defects in

materials and workmanship, under normal use and

service for two (2) years from the date of original

installation.

Labor

Labor required to repair or replace defective

components is covered for one (1) year from the date of

original installation.

Exclusions

The following items are not included in the ice machine’s

warranty coverage:

1. Normal maintenance, adjustments and cleaning as

outlined in this manual.

2. Repairs due to unauthorized modifications to the ice

machine or use of non-standard parts without prior

written approval from Manitowoc Ice, Inc.

3. Damage caused by improper installation of the ice

machine, electrical supply, water supply or drainage,

or damage caused by floods, storms, or other acts of

God.

4. Premium labor rates due to holidays, overtime, etc.;

travel time; flat rate service call charges; mileage

and miscellaneous tools and material charges not

listed on the payment schedule. Additional labor

charges resulting from the inaccessibility of

equipment are also excluded.

5. Parts or assemblies subjected to misuse, abuse,

neglect or accidents.

6. Damage or problems caused by installation,

cleaning and/or maintenance procedures

inconsistent with the technical instructions provided

in this manual.

Authorized Warranty Service

To comply with the provisions of the warranty, a

refrigeration service company, qualified and authorized

by your Manitowoc distributor, or a Contracted Service

Representative must perform the warranty repair.

NOTE: If the dealer you purchased the ice machine from

is not authorized to perform warranty service, contact

your Manitowoc distributor or Manitowoc Ice, Inc. for the

name of the nearest authorized service representative.

Service Calls

Normal maintenance, adjustments and cleaning as

outlined in this manual are not covered by the warranty.

If you have followed the procedures listed in this manual,

and the ice machine still does not perform properly, call

your authorized service company.

Important

Complete and mail the OWNER W ARRANTY

REGISTRATION CARD as s oon as pos sible to

validate the installation date.

General Information Section 1

1-4 Part Number 040003628 08/13

PAGE INTENTIONALLY LEFT BLANK

Part Number 040003628 08/13 2-1

Section 2

Installation Instructions

General

These instructions are provided to assist the qualified installer.

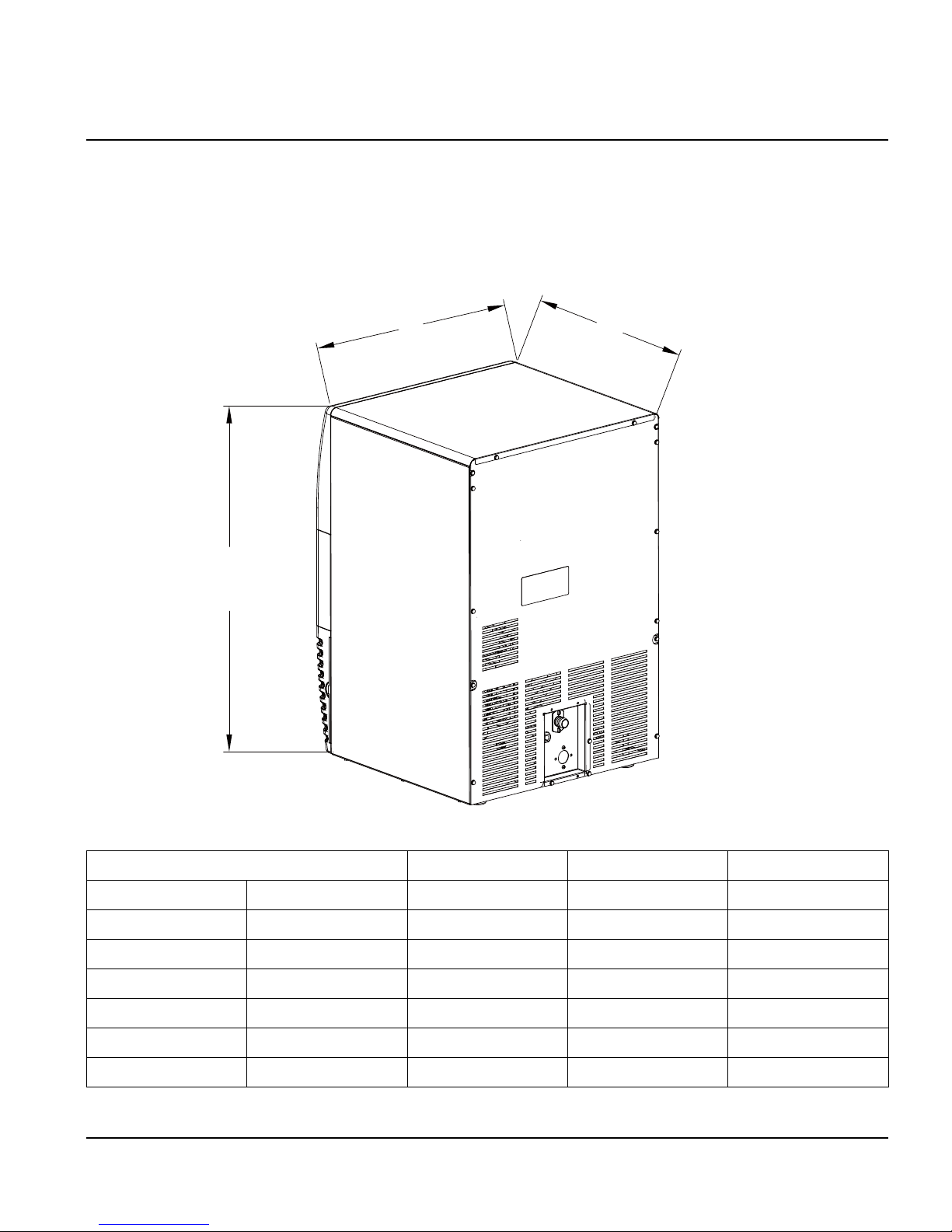

Ice Machine Dimensions

Model L W H

UG018 mm 343 450 635

UG020 mm 450 475 650

UG030 mm 450 475 650

UG040 mm 550 550 800

UG050 mm 550 550 800

UG065 mm 700 600 902

UG080 mm 700 600 902

/

+

:

Installation Instructions Section 2

2-2 Part Number 040003628 08/13

Location of Ice Machine

The location selected for the ice machine must meet the

following criteria. If any of these criteria are not met,

select another location.

• The location must be indoors.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 10C (50F), but

must not exceed 43C (110F).

• The location must not be near heat-generating

equipment or in direct sunlight.

• The location must be capable of supporting the

weight of the ice machine and a full bin of ice.

• The location must allow enough clearance for water,

drain and electrical connections in the rear of the ice

machine.

• The location must not obstruct airflow through or

around the ice machine (condenser airflow is in and

out the front). Refer to the chart below for clearance

recommendations:

NOTE: The ice machine may be built into a cabinet.

*There is no minimum clearance requirement for the top

or left and right sides of the ice machine. The listed

values are recommended for efficient operation and

servicing only.

Leveling the Ice Machine

Levelers are included with all ice machine. Legs are an

available option.

1. Screw the legs or levelers into the bottom of the ice

machine.

2. Screw the foot of each leg or leveler in as far as

possible. Move the ice machine into its final position.

Checking Ice Machine Level

3. Level the ice machine correctly. Use a level on top of

the ice machine. Turn each foot as necessary to

level the ice machine from front to back and side to

side.

Self-Contained

Air-Cooled

Self-Contained

Water-Cooled

Top/Sides 8” (203 mm)* 5” (127 mm)*

Back 5” (127 mm)* 5” (127 mm)*

!

Caution

The ice mac hine must be protec ted if it will be

subjected to temp eratures below 0 C (32 F).

Failure ca used by exposur e to fre ezing

temperatures is not covered by the warranty.

Section 2 Installation Instructions

Part Number 040003628 08/13 2-3

Electrical Service

VOLTAGE

The maximum allowable voltage variation is ±6% of the

rated voltage on the ice machine model/serial number

plate at start-up (when the electrical load is highest).

All ice machines are factory pre-wired with a 2 meter (6

ft) power cord, no plug is supplied.

FUSE/CIRCUIT BREAKER

A separate fuse/circuit breaker must be provided for

each ice machine. An electrical disconnect switch must

be provided if the ice machine is hard wired (wired

without a plug).

TOTAL CIRCUIT AMPACITY

The total circuit ampacity is used to help select the wire

size of the electrical supply.

The wire size (or gauge) is also dependent upon

location, materials used, length of run, etc., This must be

determined by a qualified electrician.

1. Connect –the three supply lead wires (Blue, Brown,

and Yellow/Green) to the field wiring terminal, “L”,

“N”, and “G”, the Yellow/Green wire must connect to

the “G”(ground).

2. After connecting the wiring to the terminal strip, the

supply lead must be secured to the cabinet with a

strain relief near the terminal strip.

3. Verify wiring is contained in the electrical wiring box.

!

Warning

All wiring must conform to local, state and national

codes.The ice machine must be grounded in

accordance with national and local electrical codes.

!

Warning

RISK OF ELECTRICAL SHOCK

FOR H ARD WIRED(WIRED WITHOUT A PLUG)

MACHINE, IT MUST BE PR OPERLY GROUNDED AND

CONNECTED T O THE FIELD WIRING TERMINAL IN

ACCORDANCE WITH ALL APPLICAB LE NA TIONAL

AND LOCAL ELECTRICAL CODES BY A QUALIFIED

ELECTRICIAN. BEFOR E CONNECTING WIRES,

DISCONNECT POWER AT THE ELECTRICAL

DISCONNECT AND LOCK OUT T O PREVENT

ACCIDENTALLY ENERGIZING .CONNECT AL L

ELECTRICAL WIRING BEFORE USE - DO NOT

ENERGIZE ICE MACHINE UNTIL INST ALLATION IS

COMPLETE.

Ice Machine

Air-Cooled Water-Cooled

Maximum Fuse/

Circuit Breaker

Tot a l A mp s

Maximum Fuse/

Circuit Breaker

Tot a l A mp s

UG018 230/1/50 10 2.0 N/A N/A

UG020

230/1/50 10 2.3 N/A N/A

230/1/

60 10 2.3 N

/A N/A

UG030

230/1/50 15 2.8 15 2.5

230/

1/60 15 2.8 N

/A N/A

1

15/1/

60 15 5.5 N/

A N/A

UG040

230

/1/50 15 3.0 N/A N/A

230/1/60 15 3.0 N/A N/A

UG050

230/1/50 15 4.0 15 2.8

230/1/60 15 4.0 N/A N/A

115/1/60 15 6.8

N/A N/A

UG065

230

/1/50 15 4.5 N/A N/A

230/1/60 15 4.5 N/A N/A

UG080

230/1/50 15 5.5 N/A N/A

230/1/60 15 5.5 N/A N/A

Installation Instructions Section 2

2-4 Part Number 040003628 08/13

Water Service/Drains

WATER SUPPLY

Local water conditions may require treatment of the

water to inhibit scale formation, filter sediment, remove

chlorine, and improve taste and clarity.

WATER INLET LINES

Follow these guidelines to install water inlet lines:

• Do not connect the ice machine to a hot water

supply. Be sure all hot water restrictors installed for

other equipment are working. (Check valves on sink

faucets, dishwashers, etc.)

• Water pressure to the machine should be between

1.4 to 5.5 bar (20 to 80 psi).

• If water pressure exceeds the maximum 5 bar

recommended pressure, obtain a water pressure

regulator from your Manitowoc distributor. Adjust

pressure to 2.5 bar (37 psi).

• Install a water shut-off valve.

• Connect to a potable water supply only.

DRAIN CONNECTIONS

Follow these guidelines when installing drain lines to

prevent drain water from flowing back into the ice

machine and storage bin:

• Drain lines must have a 3.8 cm (1.5 inch) drop of run

for each meter (3 feet), and must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• Run separate bin and water-cooled condenser drain

lines. Insulate them to prevent condensation by

temperature.

WATER SUPPLY AND DRAIN LINE SIZING/CONNECTIONS

* Water Inlet Hose Supplied With Machine.3/4” Female Pipe Thread/ 2 meters long.

** Drain Hose Supplied With Machine.7/8” (22.2mm) Hose/ 2 Meters Long.

Important

If you are inst alling a wa ter filter system, make

sure that you use a separate line for water-cooled

condenser. Filter life will be greatly reduced if

filtered water is used for water-cooled condenser.

Water

Temperature

Water

Pressure

Ice Machine

Fitting

Tubing Size Up to Ice

Machine Fitting

*Ice Making

Water Inlet

10ºC (50F) Min.

32.2ºC (90F) Max.

1.4 Bar (20 Psi) Min.

5.5 Bar (80 Psi) Max

3/4” Male Pipe

Thread

15mm (1/2”) Inside

Diameter Minimum

**Drain

Connection

Outlet

—— ——

7/8” Fitting Barbed 18mm (3/4”) Minimum

Inside Diameter

Condenser

Water Inlet

0.6ºC (33F) Min.

32.2ºC (90F) Max.

1.4 Bar (20 Psi) Min.

10.3 Bar (150 Psi) Max

3/8” Female pipe

Thread

15mm (1/2”) Inside

Diameter Minimum

Condenser

Water Outlet

—— ——

1/2” Female pipe

Thread

15mm (1/2”) Minimum

Inside Diameter

Section 2 Installation Instructions

Part Number 040003628 08/13 2-5

WATER SUPPLY AND DRAIN LINE CONNECTIONS

Water Cooled

Condenser Inlet

Water Cooled

Condenser Outlet

Ice Making Water Inlet

Drain

Electrical

Installation Instructions Section 2

2-6 Part Number 040003628 08/13

Installation Checklist Before Starting the Ice Machine

All ice machines are factory-operated and adjusted

before shipment. Normally, new installations do not

require any adjustment.

To ensure proper operation, follow the Operational

Checks in section 3 of this manual. Starting the ice

machine and completing the Operational Checks are the

responsibilities of the owner/operator.

Adjustments and maintenance procedures outlined

in this manual are not covered by the warranty.

Is the ice machine level?

Has all of the internal packing been removed?

Have all of the electrical and water connections

been made?

Has the supply voltage been tested and

checked against the rating on the nameplate?

Are all components installed

Has the ice machine been installed where

ambient temperatures will remain in the range

of 10 - 43C (50 - 110F)?

Has the ice machine been installed where the

incoming water temperature will remain in the

range of 10 - 32.2C (50 - 90F)?

Is there a separate drain line for the watercooled condenser?

Are all electrical leads free from contact with

refrigeration lines and moving equipment?

Has the owner/operator been instructed

regarding maintenance and the use of

Manitowoc Cleaner and Sanitizer?

Has the owner/operator completed the warranty

registration card?

Has the ice machine and bin been sanitized?

Has this manual been given to the owner/

operator?

Is the ice -off - wash switch set to the ice

position?

!

Warning

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, n eglected, damaged, or a ltered/modified

from that of original manufactured specifications.

Part Number 040003628 08/13 3-1

Section 3

Operation

Component Identification

Water Curtain

Water Sump

Trough

Air Cooled

Condenser

Evaporator

Ice Chute

Spray Bar

Spray

Nozzles

Toggle Switch

Control board

On/Off/Wash

Toggle Switch

Operation Section 3

3-2 Part Number 040003628 08/13

Component Removal

TOP COVER

For easiest access to the evaporator compartment, the

top cover can be removed.

1. Remove two screws on the rear of the ice machine.

2. Slide top cover back to disengage the three pins

from the front panel.

BIN DOOR

Allows access to the storage bin.

1. Remove top cover.

2. Slide door up until rear pins align with slot in door

tracks.

3. Lift rear door pins out and slide door up until front

door pins align with slot.

4. Lift door out of door track.

Remove Two Screws – Slide

Cover Back To Remove

Align Door Pins With Track Slots,

Then Lift Door Out Of Track

Section 3 Operation

Part Number 040003628 08/13 3-3

WATER CURTAIN

The water curtain is designed to keep the spraying water

from escaping the evaporator compartment. Removal of

the bin door is not required, but enhances access.

1. Grasp the ice curtain and lift up.

2. To re-install into ice machine,pivot the water curtain

and pull down into position. Make sure tabs are

secure in grooves.

ICE CHUTE

The ice chute is positioned over the spray nozzles and

allows the ice to easily fall into the bin. It must be firmly

positioned over the Spray Bar Assembly, with the front

edge inside the water trough or the spray nozzles will not

be aligned with the spray holes, and spray water will fall

into bin.

1. Grab protruding spray holes on one end and lift up.

2. Pivot ice chute and remove.

3. To re-install ice chute, grasp protruding spray holes

and position over Spray Bar Assembly. Make sure

rear supports are over Spray Bar Assembly, and

front edge is inside of water trough.

Water Curtain

Ice Chute

Operation Section 3

3-4 Part Number 040003628 08/13

SPRAY BAR

The spray bar supplies water to the individual icemaking cups. Water from the Water Pump sprays

through the nozzles, located on the upper portion of the

tubes.

1. Grasp one end of the spray bar, lift up and remove

from seat formed in water trough.

2. Remove both plastic clips on water inlet tubing by

grasping both ears on clip and separating.

3. Apply food grade lubricate to ease re-assembly of

spray bar components when necessary.

4. To re-install spray bar, position water inlet tubing on

inlet ports, and squeeze clips until tight.

5. Reposition assembly on water trough seat.

Nozzles and inserts can be removed for cleaning by

unscrewing nozzles. Inserts are located inside the spray

bar ports. The spray bar also disassembles for easy

cleaning.

SUMP DRAIN OVERFLOW TUBE

The sump drain overflow tube is located in the

evaporator water sump.

1. Remove shutters and ice chute.

2. Lift spray bar or disconnect and remove for easiest

access.

3. Pull up on over flow tube to remove.

4. To replace plug, insert in hole, and push with force to

make a tight seal.

Overflow Tube

Section 3 Operation

Part Number 040003628 08/13 3-5

Ice Making Sequence of Operation

INITIAL START-UP

1. Water Inlet and Pressure Equalization

Turn the toggle switch to”ON” positon,the water fill valve

and harvest valve are energized, 210 seconds later, the

water fill valve is de-energized. 20seconds after the

harvest valve solenoid is energized, the compressor is

energized. 300seconds after the compressor is

energized, the harvest valve solenoid is de-energized,

the water pumpand the fan motor are

energized,machine goes into freeze cycle.

2. Freeze Cycle

The pump sprays water into the inverted cups. The

water freezes layer by layer, until an ice cube forms in

each cup.

When the”water temperature”is equal to or less than 2

℃

for more than 5 seconds, control will read

the” liquid line temperature” and dip switch setting , get

the” freeze postpone time” and “fan shut off time”.Board

will shut the Fan before the end of the freeze cycle to

assist harvest. When the ” freeze postpone time” has

elapsed, the harvest cycle is initiated.

3. Harvest Cycle

The compressor continues to operate and the water

pump is de-energized. The hot gas valve energizes,

allowing hot gas to enter and warm the evaporator. The

water valve is also energized, aiding with harvest, as

well as filling up the sump with fresh water for a new

freeze cycle.

at the point of 2 minutes to freeze end , board will read

the ” liquid line temperature”again and calculate the

“harvest time”

The ice falls from the cups and is directed into the bin by

the ice chute. The harvest cycle continues until the

harvest time has elapsed,then machine goes into a new

freeze cycle

4. Automatic Shut-Off

When the storage bin is full, the ice will come in contact

with the bin thermostat which is located inside the bin.

The machine will stop after approximately 45seconds of

continuous ice contact with the bin thermostat probe.

The ice machine remains off until a 3 minutes delay has

elapsed and enough ice has been removed from the

storage bin to allow the ice to fall clear of the bin

thermostat probe. As the ice clears the probe, the bin

thermostat warms up and the machine starts another

freeze cycle.

Operation Section 3

3-6 Part Number 040003628 08/13

Operational Checks

GENERAL

Your ice machine was factory-operated and adjusted

before shipment. Normally, a newly installed ice machine

does not require any adjustment.

To ensure proper operation, always follow these

Operational Checks when starting the ice machine:

• for the first time

• after a prolonged out of service period

• after cleaning and sanitizing

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the warranty.

ICE CUBE THICKNESS CHECK

The ice cube thickness is factory-set to maintain the ice

cube thickness at the proper size and weight.

1. Allow the ice machine to operate for three complete

cycles. The cubes should have a small dimple in the

center.

2. Cycle times vary, according to surrounding air and

water inlet temperatures.

3. If cubes are not full (large dimple), raise the “dip

switch” level to increase cube size. Allow ice

machine to complete three cycles, then check cube.

4. If cubes are too full, ( no dimple), lower the “dip

switch” level to decrease cube size.Allow ice

machine to operate three complete cycles.

5. The “dip switch” can be adjusted to five levels: -2/-1/

0/+1/+2, and ensure that only one level switch is

pressed.

CUBE SHAPE

the standard cube has an average weight of 19 grams,

Notice the normal dimple in the center of the cube.

Important

It is recommended that adjustments made to this ice

machine be m ade by a qu alified te chnician.

Improper adjustment, may seriously affect the life of

this ice machine.

dip switch

Factory

Default

Setting

Decreas

e

Cube

Size

Increase

Cube

Size

Dimple

Standard Cube 19g

34

Part Number 040003628 08/13 4-1

Section 4

Maintenance

General

The end user is responsible for maintaining the ice

machine in accordance with the instructions in this

manual. Maintenance procedures are not covered by the

warranty.

Basic hygiene and maintenance of your Ice Machine, will

increase its reliability, increase performance, and help

save on water and power consumption. Ice production

will be maintained within the manufacturers guidelines,

and unwanted repairs due to maintenance issues will be

minimized.

The chart below is an overview of the maintenance that

the end user and service technician should perform, and

the frequency. These figures are the minimum required.

If the Ice Machine is supplied with hard water, more

frequent evaporator cleaning should be performed. If the

condenser air filter is totally blocked, after one week,

more frequent cleaning is recommended.

X=End User

S=Service Company

!

Caution

If you d o not understand the pr ocedures o r the

safety precautions th at must be followed, call yo ur

local service repres entative to perform the

necessary maintenance procedures for you.

Maintenance Weekly Monthly Semi Annual Annual After

prolonged

shutdown

At Start-up

Clean cabinet exterior X X X

Sanitize Ice Bin X X X

Clean Evaporator X S S

Sanitize Evaporator X S S S

Clean Condenser Coil X S S

Check Ice Quality X S S S

Maintenance Section 4

4-2 Part Number 040003628 08/13

Cleaning the Condenser

AIR-COOLED CONDENSER

A dirty condenser restricts airflow, resulting in

excessively high operating temperatures. This reduces

ice production and shortens component life.

Clean the condenser at least every six months.

1. Remove Plastic Front Grill removing two Phillips

head screws. Clean Grill openings before replacing.

2. Clean the outside of the condenser with a soft brush

or a vacuum with a brush attachment. Clean from

top to bottom, not side to side. Be careful not to

bend the condenser fins.

3. Shine a flashlight through the condenser to check

for dirt between the fins. If dirt remains:

A. Blow compressed air through the condenser

fins. Be careful not to bend the fan blades.

B. If dirt or grease remains between fins, consult

your service representative.

WATER-COOLED CONDENSER AND WATER

REGULATING VALVE

The water-cooled condenser and water-regulating valve

may require cleaning due to scale build-up.

Low ice production, high water consumption and high

operating temperatures and pressures all may be

symptoms of restrictions in the condenser water circuit.

Because the cleaning procedures require special pumps

and cleaning solutions, qualified maintenance or service

personnel must perform them.

!

Warning

Disconnect electric power to the ice machine at the

electric se rvice switch be fore pe rforming

maintenance on equipment.

!

Warning

The con denser fins ar e shar p. Use ca re wh en

cleaning them.

Section 4 Maintenance

Part Number 040003628 08/13 4-3

Interior Cleaning and Sanitizing

GENERAL

Clean and sanitize the ice machine every six months for

efficient operation. If the ice machine requires more

frequent cleaning and sanitizing, consult a qualified

service company to test the water quality and

recommend appropriate water treatment.

An extremely dirty ice machine must be taken apart for

cleaning and sanitizing.

CLEANING & SANITIZING PROCEDURE

Ice machine cleaner is used to remove lime scale or

other mineral deposits. Sanitizer is used to remove

algae or slime.

Mix 4 liters of water with 500 ml of cleaner in a plastic or

stainless container.

Step 1 Set the toggle switch to the OFF position at the

end of a Harvest Cycle, after ice releases from the

evaporator. Or, set the switch to the OFF position and

allow the ice to melt off the evaporator.

Step 2 Remove all ice from the bin.

Step 3 Remove all parts as described in Section 3,

Component Identification & Removal.

Step 4 Take all components to sink and with 2 liters

Cleaner/Water mixture clean all components with a soft

nylon brush. Disassemble spray bar, remove nozzles

and inserts and soak for 5 minutes. For heavily scaled

parts, soak in solution for 15–20 minutes. Rinse all

components with clean water.

Step 5 While components are soaking; use nylon brush

to scrub inside of ice bin. Scrub inside of door, door

track, bin, sump trough, and evaporator moldings. With

clean water, rinse all of these areas thoroughly.

Step 6 Replace sump overflow tube and pour remaining

2 liters of mixture into the water sump. Replace all parts.

Step 7 To start a cleaning cycle, set the toggle switch to

the WASH position.

Step 8 After 13.5 minutes, set the toggle switch to the

OFF position. Remove water curtain, ice chute and over

flow tube from the water sump. Allow all water to drain

from the sump. Replace drain plug . Set toggle switch to

WASH and circulate for 12minutes.

Step 9 Wait until the cleaning cycle(12 minutes) is

complete then place the toggle switch in the OFF

position.Remove water curtain, ice chute, water sump

over flow tube. Drain water from sump and replace tube.

Step 10 Mix 60 ml of sanitizer with 12 l of water in a

plastic or stainless steel container.

Step 11 Remove Water Curtain and Ice Chute as

described in Section 3, Component Identification &

Removal.

Step 12 Take all components to sink and with 10 liters

Sanitizer/Water mixture sanitize all components with a

soft nylon brush or cloth. Do not rinse components.

Step 13 Use brush or cloth to sanitize the inside of ice

bin. Scrub inside of door, door track, bin, water sump,

water distribution assembly and evaporator moldings.

Do not rinse.

Step 14 Replace sump drain over flow tube, and

transfer remaining 2 liters of solution to the sump trough.

Replace all components.

Step 15 To start a sanitizing cycle, set the toggle switch

to the WASH position.

Step 16 After 13.5 minutes, set the toggle switch to the

OFF position. Remove water curtain and ice chute

Remove over flow tube from water sump and allow all

water to drain from sump. Replace drain plug. Set toggle

switch to WASH and circulate for 12 minutes.

Step 17 Wait until the cleaning cycle (12 minutes) is

complete then place the toggle switch in the OFF

position. Remove water curtain, ice chute, water sump

over flow tube. Drain water from sump and replace tube.

!

Caution

Use only app roved Ice Ma chine Clean er and

Sanitizer. Read and understand all labels printed on

bottles before use. Do not mix Ice Machine Cleaner

and Sanitizer solutions together

!

Warning

Wear rubber gloves and safety goggles (and/or face

shield) when ha ndling Ice Machin e Clean er or

Sanitizer.

Cleaner Water

500 ml (16 oz) 4 l (1 gal)

!

Caution

Never use anything to force ice from the evaporator.

Damage may result.

Sanitizer Water

60 ml (2 oz) 12 l (3 gal)

Maintenance Section 4

4-4 Part Number 040003628 08/13

Step 18 Replace all parts.

Step 19 Place toggle switch to ON position,ice machine

will go into ice making cycle.

Exterior Cleaning

Clean the area around the ice machine as often as

necessary to maintain cleanliness and efficient

operation.

Sponge any dust and dirt off the outside of the ice

machine with mild soap and water. Wipe dry with a

clean, soft cloth.

A commercial grade stainless steel cleaner and polish

may be used.

Removal from Service/Winterization

GENERAL

Special precautions must be taken if the ice machine is

to be removed from service for an extended period of

time or exposed to ambient temperatures of 0C (32F)

or below.

Follow the applicable procedure below.

AIR-COOLED ICE MACHINES

1. Disconnect the electric power at the circuit breaker

or the electric service switch.

2. Turn off the water supply.

3. Drain the water from the water sump and water

pump by disconnecting the water pump tubing.

4. Disconnect and drain the incoming ice-making water

line and disconnect the tubing from the water inlet

valve outlet and allow water to drain.

5. Blow compressed air in the drain opening and water

valve outlet hose, then reattach.

6. Make sure water is not trapped in any of the water or

drain lines.

WATER-COOLED ICE MACHINES

1. Perform steps 1-6 under “Air-Cooled Ice Machines.”

2. Disconnect the incoming water and drain lines from

the water-cooled condenser.

3. Insert a large screwdriver between the bottom spring

coils of the water regulating valve. Pry upward to

open the valve.

4. Hold the valve open and blow compressed air

through the condenser until water no longer exits.

Pry Open the Water Regulating Valve

!

Caution

If water is allowed to re main in the ice mac hine in

freezing tem peratures, sever e d amage to some

components could result. Damage of this nature is not

covered by the warranty.

Part Number 040003628 08/13 5-1

Section 5

Before Calling for Service

Checklist

If a problem arises during operation of your ice machine, follow the chart below before calling for service. Routine

adjustments and maintenance procedures are not covered by the warranty.

Problem Cause Correction

Ice Machine Will Not Run No Power – Breaker off, fuse blown,

unplugged

Restore power

Toggle switch is not in ice position Place toggle switch in ice position

The storage bin is full Remove enough ice from the bin and wait

for 3 minutes delay to expire.

Ice machine runs and no ice is

produced

No water to ice machine Correct water supply

Water sump overflow tube out of position Reposition/install overflow tube

Water sump thermistor or liquid line

thermistor faulty

replace the thermistor

Control board problem Call for service

Freeze cycle long – low production Dirty condenser Clean condenser

Water temperature too high Connect to a cold water supply, verify

check valves in faucets and other

equipment work properly

Refrigeration problem Call for service

Shallow, incomplete or white ice

cubes

Ice machine is dirty Clean & sanitize the ice machine

Water pressure supply incorrect Verify water pressure is correct

Air temperature around ice machine is too

high

Vent area or move ice machine

Dip switch incorrectly adjusted Adjust Dip switch

Will not initiate a harvest cycle liquid line thermistor faulty replace the thermistor

Control board problem Call for service

Ice cubes do not release Ice machine is dirty Clean and sanitize the ice machine

Low ambient around ice machine move ice machine to warmer area

Dip switch incorrectly adjusted (cubes too

large)

Adjust Dip switch

Before Calling for Service Section 5

5-2 Part Number 040003628 08/13

PAGE INTENTIONALLY LEFT BLANK

PAGE INTENTIONALLY LEFT BLANK

MANITOWOC FOODSERVICE – ICE MACHINE DIVISION

2110 SOUTH 26TH STREET, MANITOWOC, WI 54220

800-545-5720

WWW.MANITOWOCICE.COM

Every new piece of Manitowoc Foodservice equipment comes with KitchenCare™ and you choose the level of service that meets

your operational needs from one restaurant to multiple locations.

StarCare – Warranty & lifetime service, certied OEM parts, global parts inventory, performance audited

ExtraCare — CareCode, 24/7 Support, online/mobile product information

LifeCare – Install & equipment orientation, planned maintenance, KitchenConnect™, MenuConnect

Talk with KitchenCare™ • 1-844-724-CARE • www.mtwkitchencare.com

To learn how Manitowoc Foodservice and its leading brands can equip you, visit our global web site at

www.manitowocfoodservice.com, then discover the regional or local resources available to you.

©2014 Manitowoc Foodservice except where explicitly stated otherwise. All rights reserved. Continuing product improvement may necessitate change of specications without notice.

Part Number: 040003628 8/13

Loading...

Loading...