MONITOR HEATING SYSTEMS

Table

of

Contents

Section

1:

Description

1-1

Specifications

(M-2400)

1-2

Special Features (M-2400)

1

-3

Safety Features (M-2400)

1-4

Specifications (M-2200)

1-5

Special

Features (M-2200)

1-6

Safety Features (M-2200)

1-7

Description

1-8

Spill

Tray

1-9

Heater Cabinet

1-10 Combustion System

1-11

Combustion Chamber

1-12 Burner

Pot

1-13

Combustion

Ring Assembly

1-14 Flame Sensor

1-15

Igniter

1-16 Combustion

Air

System

1-17

Flue

Pipe

1-18

Combustion

Blower

Motor (M-2400)

1-19 Heat Exchanger

1-20

Air

Circulation

Fan

Page

1~10

1-21

Air

Pressure Switch

1-22 Fuel Delivery System

1-23 External Fuel Tank

1-24

Fusible Link Valve

1-25 Fuel Constant Level Valve

1-26

Solenoid Pump

1-27

Electrical System

1-28

Microprocessor

1-29 Temperature Sensor

1-30 Safety Mechanism

1-31 Cloth Covered Exhaust Pipe

1-32

Air

Circulation

Fan

Guard

1-33 Fuse

1-34

Overheat Protector Switches (M-2400)

1-35

Revolution control

of

combustion blower motor

1-36

Combustion Blower Motor (M-2200)

1-37

Overheat Protector Switches (M-2200)

Elements

of

combustion system (M-2400)

Elements

of

combustion system (M-2200)

Section

2:

Installation

2-1

Introduction

2-2

Physical Placement

of

Heater

2-3

Drilling Requirements

2-4

Power Requirements

2-5

Fuel Tank Requirements

2-6

Temperature Sensor Wiring

Requirements

2-7

Building Codes

2-8

Un-packing

2-9

Heater Installation

Installation

Classification (M-2400)

Page

11~27

Installation Classification (M-2200)

Applicable Wall Thickness

of

Flue Pipe

Flue Pipe Clearances

2-10

Installing

an

Extension

Kit

2-11

Typical Monitor Lifter Pump Installations

2-12

Uses

for the

Elbow Adapter

Kit

2-13 Fuel Tank

Installation

2-14 Heater

Installation

Typical fuel line connections

Back

guard (M-2400)

Back guard (M-2200)

Section

3:

Operation

•

3-1

Introduction

(M-2400)

3-2

Operating Specifications (M-2400)

3-3

Introduction (M-2200)

3-4

Operating Specifications (M-2200)

3-5

Operating

Controls

and

Indicators

3-6

Pre-operation

Check List

3-7

Operation

3-8

Manual Heater Operation

3-9

Automatic

Heater

Operation

Page

28~38

3-10

Programming

the

weekly timer

for

automatic heater operation

3-11

Heat Sensor

3-12

Monitor Shutdown

3-13

Out

of

Fuel

3-14

Recovery from a Power

Failure

3-15

Recovery from Overheat Condition

3-16

Recovery from Blown Fuse

3-17 Operation

Control

system

M-2400/2200

Operation timing chart

MONITOR HEATING SYSTEMS

Table

of

Contents

Section

4:

Maintenance

Page

39—42

4-1

Introduction

4-6

Cleaning Fusible Link

Valve

Intake

4-2

Periodic Maintenance

4-7

Corrective Maintenance

4-3

Inspect Exhaust

/Air

Piping

4-8

Replacement

of

Fuses

4-4

Verify

Igniter

Operation

4-9

Fuel Contamination

4-5

Clean Fuel Constant Level

Valve

Filter

Section

5:

Servicing

Page

43—47

5-1

Introduction

5-2

Measurement

of

Fuel Flow rate

5-3

Removal

of

Water Deposits

and

Contaminants

from

Fuel Constant Level Valve

and

Fuel Lines

5-4

Cleaning

the

Burn Chamber & Burner

Pot

(M-2400)

5-5

Cleaning

the

Fuel Inlet (M-2400)

5-6

Cleaning

the

Burn Chamber & Burner

Pot

(M-2200)

5-7

Cleaning

the

Fuel Inlet (M-2200)

Section

6 :

Troubleshooting

Page

49~62

Resistance Values (M-2400)

Component Voltage Readings (M-2400)

Resistance

Values (M-2200)

Component Voltage Readings (M-2200)

Test

Point Voltage

Troubleshooting Diagrams (Mechanical)

Troubleshooting Diagrams (Electrical)

Indication

of

Failure

mode

Section

7 :

Electrical

System

Page

63—66

Schematics

Schematics (since February 2004)

Monitor 2400 Printed Circuit Board Wiring Diagram

Monitor 2200 Printed Circuit Board Wiring Diagram

SERVICE

PARTS

LIST

•

Page

67-70

Monitor 2400 Service parts list

Exploded views (M-2400)

Monitor 2200 Service parts

list

Exploded

views

(M-2200)

MONITOR

HEATING

SYSTEMS

1-1

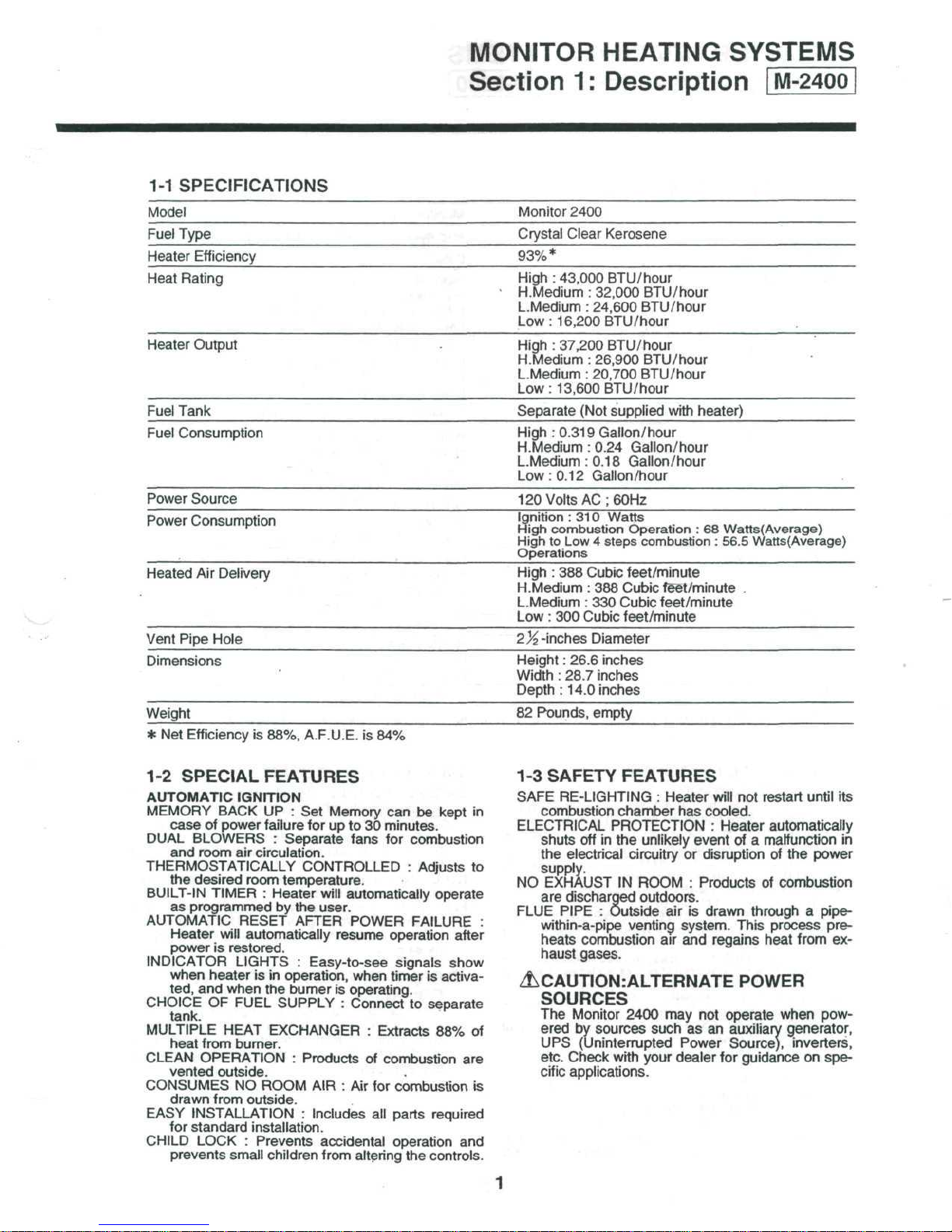

SPECIFICATIONS

Model

Fuel Type

Heater

Efficiency

Heat

Rating

Heater

Output

Fuel Tank

Fuel

Consumption

Power

Source

Power

Consumption

Heated

Vent

Dimensions

Weight

* Net

Air

Delivery

Pipe Hole

Efficiency

is

88%, A.F.U.E.

is 84%

Section

Monitor

Crystal

93%*

High : 43,000 BTU/hour

H.Medium : 32,000

L.Medium : 24,600 BTU/hour

Low:

High : 37,200 BTU/hour

H.Medium:

L.Medium:

Low:

Separate

High : 0.319

H.Medium:

L.Medium:

Low:

120

Volts

Ignition

High combustion Operation

High

to Low 4

Operations

High

: 388

H.Medium

L.Medium

Low

: 300

-inches Diameter

Height:

Width:

Depth : 14.0

82

Pounds, empty

1:

Description

2400

Clear

Kerosene

BTU/hour

16,200

13,600

0.12 Gallon/hour

BTU/hour

26,900 BTU/hour

20,700 BTU/hour

BTU/hour

(Not supplied with heater)

Gallon/hour

0.24 Gallon/hour

0.18

Gallon/hour

AC

;60Hz

: 310

Watts

steps

combustion : 56.5

Cubic feet/minute

: 388

Cubic feet/minute

: 330

Cubic feet/minute

Cubic feet/minute

26.6 inches

28.7 inches

inches

: 68

Watts(Average)

Watts(Average)

1-2

SPECIAL FEATURES

AUTOMATIC

MEMORY

case

DUAL

BLOWERS : Separate fans

and

THERMOSTATICALLY

the

BUILT-IN TIMER : Heater

as

programmed

AUTOMATIC

Heater

power

INDICATOR

when heater

ted,

CHOICE

tank.

MULTIPLE HEAT EXCHANGER : Extracts

heat

CLEAN

vented outside.

CONSUMES

drawn

EASY

INSTALLATION : Includes

for

standard

CHILD

prevents

IGNITION

BACK

of

room

desired room temperature.

is

and

OF

from burner.

OPERATION : Products

from

LOCK : Prevents accidental operation

UP : Set

power

failure

for up to 30

air

circulation.

CONTROLLED : Adjusts

will

by the

RESET AFTER POWER FAILURE

will

automatically resume operation after

restored.

LIGHTS : Easy-to-see

is in

when

the

FUEL SUPPLY : Connect

NO

RpOM

outside.

installation.

small

children

user.

operation, when timer

burner

AIR : Air for

from

Memory

is

can be

minutes.

for

automatically operate

operating.

of

combustion

all

altering

kept

combustion

signals show

is

to

separate

88% of

combustion

parts required

the

controls.

in

to

activa-

are

is

and

1-3

SAFETY FEATURES

SAFE

RE-LIGHTING : Heater

combustion chamber

ELECTRICAL

shuts

the

supply.

NO

EXHAUST

are

FLUE PIPE : Outside

:

within-a-pipe

heats

haust gases.

PROTECTION : Heater automatically

off in the

electrical

discharged outdoors.

combustion

circuitry

IN

venting system. This process

ZLCAUTIONiALTERNATE

SOURCES

The

Monitor 2400

ered

by

UPS

etc. Check with your dealer

cific

sources such

(Uninterrupted Power Source), inverters,

applications.

will

has

unlikely

or

ROOM : Products

air is

air

and

not

cooled.

event

of a

disruption

drawn through a pipe-

regains heat from

POWER

may not

operate when pow-

as an

auxiliary generator,

for

guidance

restart

until

malfunction

of the

power

of

combustion

on

its

in

pre-

ex-

spe-

MONITOR

HEATING

SYSTEMS

Section

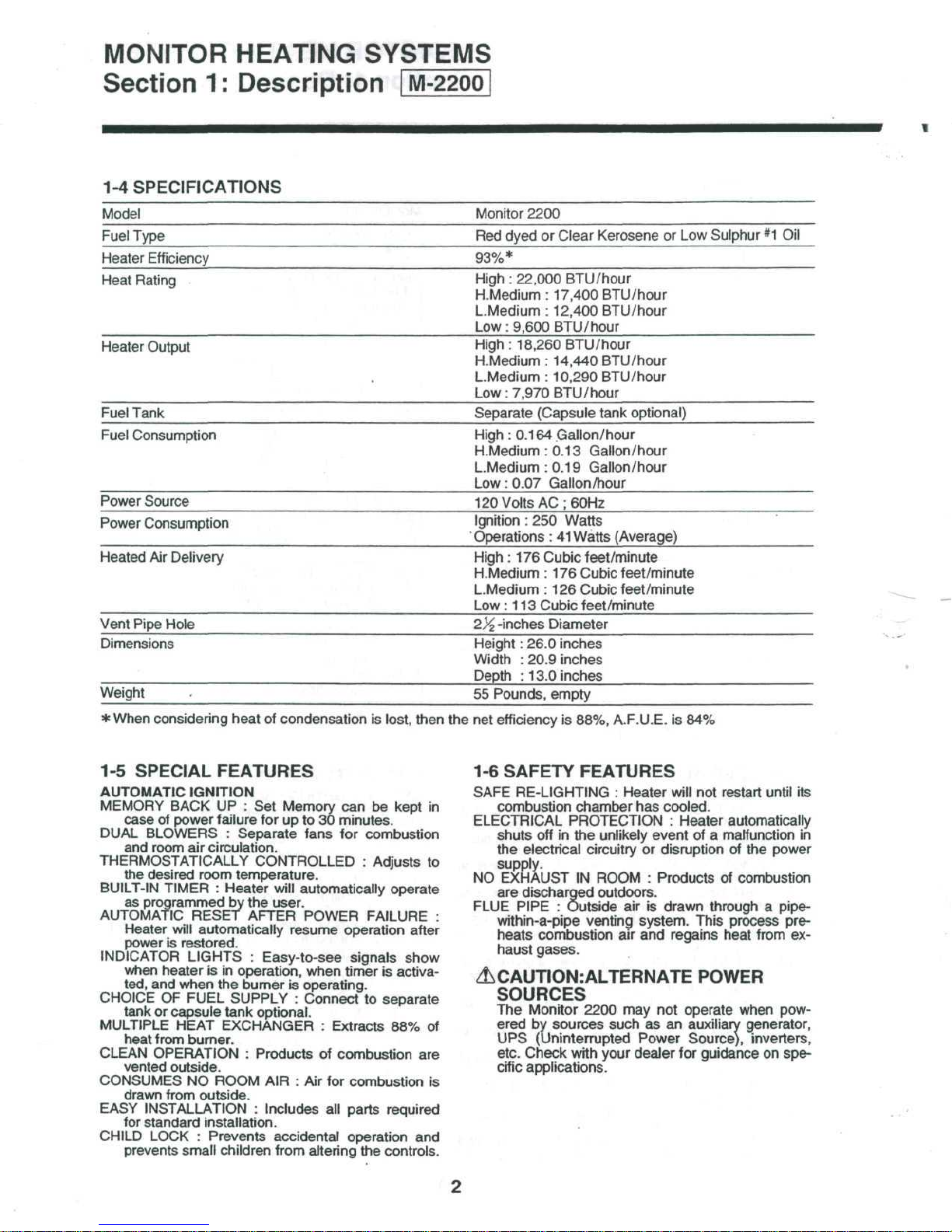

1-4

SPECIFICATIONS

Model

Fuel Type

Heater

Efficiency

Heat

Rating

Heater

Output

Fuel

Tank

Fuel Consumption

Power

Source

Power

Consumption

Heated

Air

Vent

Pipe Hole

Dimensions

Weight

*

When

1:

Delivery

considering heat

Description

of

condensation

is

lost, then

Monitor

Red

2200

dyed

or

Clear Kerosene

93%*

High : 22,000

H.Medium : 17,400

L.Medium : 12,400 BTU/hour

Low:

9,600 BTU/hour

High:

18,260 BTU/hour

H.Medium : 14,440 BTU/hour

L.Medium : 10,290 BTU/hour

Low:

7,970 BTU/hour

Separate

High:

0.164

H.Medium : 0.13 Gallon/hour

L.Medium : 0.19

Low:

0.07

120

Volts

Ignition

Operations

High : 176

H.Medium : 176

L.Medium

Low : 113

inches

Height:

Width : 20.9 inches

Depth : 13.0

55

Pounds, empty

the net

efficiency

BTU/hour

(Capsule

Gallon/hour

Gallon/hour

Gallon/hour

AC ;

60Hz

: 250

Watts

: 41

Watts (Average)

Cubic feet/minute

Cubic feet/minute

: 126

Cubic feet/minute

Cubic feet/minute

Diameter

26.0 inches

inches

is

88%, A.F.U.E.

or Low

BTU/hour

tank optional)

is 84%

Sulphur

*1 Oil

1-5

SPECIAL FEATURES

AUTOMATIC

MEMORY

case

DUAL

BLOWERS : Separate fans

and

THERMOSTATICALLY

the

BUILT-IN TIMER : Heater

as

AUTOMATIC

Heater

power

INDICATOR

when

ted,

CHOICE

tank

MULTIPLE HEAT EXCHANGER : Extracts

heat from

CLEAN

vented

CONSUMES

drawn

EASY

INSTALLATION : Includes

for

CHILD LOCK : Prevents accidental operation

prevents

IGNITION

BACK

of

room

desired room temperature.

programmed

is

heater

and

OF

or

OPERATION : Products

from outside.

standard

UP : Set

power failure

air

circulation.

by the

RESET AFTER

will

automatically resume operation after

restored.

LIGHTS : Easy-to-see

is in

when

the

FUEL SUPPLY : Connect

capsule tank

burner.

outside.

NO

RpOM

installation.

small children from

Memory

for up to 30

CONTROLLED : Adjusts

will

automatically operate

user.

POWER

operation, when timer

burner

is

optional.

AIR : Air for

operating.

of

all

altering

can be

minutes.

for

combustion

parts required

kept

combustion

FAILURE

signals

combustion

is

to

separate

88% of

the

controls.

show

activa-

and

in

to

are

is

1-6

SAFETY FEATURES

SAFE

RE-LIGHTING : Heater

combustion chamber

:

ELECTRICAL

shuts

the

supply.

NO

EXHAUST

are

FLUE

PIPE : Outside

within-a-pipe

heats

haust gases.

PROTECTION : Heater automatically

off in the

electrical circuitry

IN

discharged

venting system. This process

combustion

&CAUTION:ALTERNATE

SOURCES

The

Monitor 2200

ered

by

UPS

etc. Check with your dealer

cific applications.

sources such

(Uninterrupted

will

has

unlikely event

or

ROOM : Products

outdoors.

air is

air and

not

cooled.

of a

disruption

drawn through a pipe-

regains heat from

POWER

may not

operate when pow-

as an

Power

auxiliary generator,

Source),

for

guidance

restart

until

malfunction

of the

power

of

combustion

inverters,

on

its

in

pre-

ex-

spe-

MONITOR

HEATING SYSTEMS

Section

1:

Description

1-7

DESCRIPTION

The

Monitor heaters

are

composed

of the

following:

a

spill

tray, a cabinet, a combustion system,

an air

circulation system, a fuel delivery system, electrical

and

electronics systems

and a

variety

of

safety

mechanisms.

1-8

SPILL

TRAY

The

Spill

Tray:

—

Protects

the

floor from damage resulting from

fuel

spillage.

—

Provides a secure,

tip-resistant

heater base.

Metal retainers

(2)

secure

the

heater

to the

Spill

Tray.

The

legs

are

positioned with

in the

circular indenta-

tions.

1-9

HEATER CABINET

A

steel

cabinet

holds

and

protects

all

internal

com-

ponents.

A

number

of

primary parts

are

assembled

to

form

this

housing.

1-10 CMBUSTION SYSTEM

The

Combustion System

is

responsible

for the

pro-

duction

of

heat which

is

circulated into

the

room

.

In the

Combustion Systems a mixture

of

fuel

and air

is

burned

to

produce

heat.

Air is

drawn from outside

the

dwelling

into

the

Combustion

Chamber.

At the

same

time, fuel

is

metered

from a storage cavity into

this same Combustion Chamber.

Within

the

cham-

ber,

the

air/fuel mixture

is

ignited

to

produce heat.

The

Monitor combustion systems

are

safeguarded

by a pair

of

overheat protector switches; They

will

shut down

the

heater

(to

protect

it

from damage)

in

the

event

of

excessive heat

build-up.

The

overheat

protector

switches reset automatically after

cooling

down.

1-11 COMBUSTION CHAMBER

This

tall

cylinder

is

positioned

on the

Heater Base.

It

is

secured

to the

base

by

phillips

head screws.

Connected

to the

Combustion Chamber

are the ig-

niter, (located within

the

chamber) a fuel

line,

the

Heat

Exchanger,

and a

Flame Sensor.

Within

the

Combustion Chamber

are the

Burner Pot,

the

Combustion Ring Assembly. Access

to

those

in-

ternally-located parts

is

facilitated

by a

removable

Service

panel.

A

Window

on the

panel

lets

the

technician

visually

examine

the

combustion

process(i.e.

glowing igniter

or

proper flame color).

An

airway,

in the

Cabinet Base, extends from

the in-

take

fan of the

Combustion Blower

to the

hollow

base

of the

Combustion Chamber.

This

airway chan-

nels

air to the

Combustion Chamber.

The

Flame Sensor

is

mounted with

two (2)

phillips

head screws onto

the

wall

of the

Combustion

Cham-

ber.

1-12

BURNER

POT

Designed specifically

to

support combustion,

the

Burner

Pot

(refer

to

Figure

1-2/1-3)

contains a series

of

air

holes,

an

igniter tube

(to

accommodate

the Ig-

niter),

and a

fuel

inlet

fitting

(interconnects

the

fuel

line).

It

is

secured

to a

mounting plate near

the

bot-

tom

of the

Combustion Chamber.

The

Combustion Ring Assembly

is

seated

on

three

(3)

screws

or

pins

in the

Burner Pot.

1-13 COMBUSTION RING

ASSEMBLY

This assembly

is a

special structure, designed

to

promote efficient combustion.

1-14 FLAME

SENSOR

Mounted

on the

outside wall

of

Combustion Cham-

ber,

the

Flame Sensor always supervises

the

flame.

1-15 IGNITER

Located within

the

igniter tube

of the

Burner Pot,

the

Igniter

is

designed

to

pre-heat

the

Burner

Pot and to

vaporize

and

ignite

the

air/fuel mixture

to

start

the

combustion process.

The

Igniter

is

secured

by a

bracket

and

screw

to the

igniter tube.

The

cover plate

is

secured

to the

com-

bustion chamber

by

three

(3)

phillips

head screws.

1-16 COMBUSTION

AIR

SYSTEM

The

Combustion

Air

System channels

air to and

from

the

heater.

Outside

air is

drawn into

the

heater

by the

Combus-

tion

Blower through

an

airway

to the

Combustion

Chamber.

A

Combustion Blower draws

the

intake

air in

through a Flue Pipe. This

air

enters

the

Combustion

Chamber

at the

Burner

Pot and

mixes with

the

fuel

to

support

combustion,

Remaining

air is

heated

and

is

drawn

into

the

Heat Exchanger.

As

the

heated

air

passes through

the

Heat Exchan-

ger,

an Air

Circulation

Fan

blows room

air

past

the

Heat

Exchanger

and out

again into

the

room, heating

passing

air by

convection. Exhaust vapors

exiting

from

the

Heat Exchanger

are

vented through

the

Flue

Pipe.

A

deterioration

of air

pressure

at the Air

Pressure

Switch

is an

abnormal condition;

the

heater

is

shut

down

by the

malfunction.

MONITOR

HEATING

SYSTEMS

Section

1:

Description

1-17

FLUE

PIPE

The

Flue Pipes

is

adaptable

in

three

(3)

sizes. This

provides

the

flexibility

to

meet

the

installation

re-

quirements

for

walls

of

various thicknesses.

The

Flue Pipe

is two

Sections, Flue pipe

A and

Flue

pipeB.

The

Flue Pipe A contains a "T"-shaped

fitting con-

sisting

of

four

ports. This side

is

mounted

on the in-

terior

wall

of the

dwelling.

The

Flue Pipe

B is

vented

outside

the

dwelling.

The

Flue

Pipe

Assembly con-

sists

of two

concentric tubes. Outside

air is

drawn

through

the

cylindrical space between

the

tubes.

Combustion by-products

are

vented through

the in-

ner

tube.

As

the

cool

air

enters,

it is

heated

by the hot air

that

is

exiting

the

system.

A

large-bore,

flexible

hose connects

the air

inlet

port

on

the

Flue Pipe A with

the

Combustion Blower;

a

cloth-covered metal pipe connects

the

Combustion

Blower

with

the

exhaust outlet

on the

Flue Pipe

A.

IMPORTANT:

If

extension kits

are

utilized,

use the

correct

damper

in

accordance

with

the

instructions

in

table

2-1 of

page

14

1-18 COMBUSTION

BLOWER

MOTOR

The

combustion

blower

has a

four stage intake

fan

Burner modes control

fan

speeds.

The

combustion

air

controls

are as

follows:

Table

1-1

COMBUSTION

AIR

CONTROL

(M-2400)

Burn

Mode

Fan

Speed

(r.p.m.)

High

2,800

Medium-High

2,300

Medium-Low

1,900

Low

1,500

Please refer

to

paragraph

1 -35 in

page?

for the

de-

tails

of the

combustion blower motor control.

1-19

HEAT

EXCHANGER

An

inlet

at the top of the

Heat Exchanger permits

the

heated

air to

travel from

the

Combustion Chamber

into

the

exchanger.

An

outlet,

at the

bottom

of the

exchanger, permits

combustion by-products

to be

vented

to the

Flue

Pipe.

air

within

the

exchanger heats

the

outside metal

walls.

The hot

metal walls,

in

turn, heat

air

that

is

pushed

past

the

exchanger

and is

circulated into

the

room.

An air

baffle, directly

in

front

of the

exchanger,

deflects

the

heated

air

upwards,

and

out, through

the

louver

assembly.

A

pair

of

Over-Heat Protector Switches protect

the

heater

from

damage

due to

excessive heat built-up.

1-20

AIR

CIRCULATION

FAN

Circulation fans

are

driven

by

three-speed motors

and are

designed

to

circulate

the

heated room air.

If

the

heater

is

running

in low

burn modes,

the fan

also

runs

at

low-speed;

in

medium-low burn mode,

the fan

runs

at

medium-speed;

in

medium-high

or

high burn modes,

the fan

advances

to

high speed.

Operation

of the fan is

controlled

by the

micropro-

cessor

and fan

thermostat switch.

Physically assembled with a protective wire cage

for

the

heater,

the

entire

fan

assembly

is

secured

to a

bracket

on the

rear

of the

Heater Cabinet.

A

metal conduit,

at the

rear

of the

heater, protects

the

fan

wiring from damage.

1-21

AIR

PRESSURE

SWITCH

This

switch consists

of a

rubber diaphragm which

senses

changes

in air

pressure(it

is

connected

to the

Combustion Blower)

and is a

normally open, micro

switch.

Should

an

abnormal pressure differential exist,

the

switch opens

to

disable

the

circuitry that controls

the

supply

of

fuel.

Since

the

flow

of

fuel

to the

Burner

Pot

is cut

off,

the

flame

extinguishes

(after

all

fuel

currently

in the

line

has

been consumed),

and the

code

fE14jis

indicated

in the

digital

display.

This

safety

mechanism

can be

triggered

by

several

conditions:

—

Leak

or

loose

connection

in air

line

—

Leak, loose,

or

broken

tubing

which connects

the

Air

Pressure Switch with

the

Combustion Blower

—

Clogged

or

blocked

Air

Line

—

Blocked

or

clogged Flue Pipe

—

Intake port Combustion Blower

is

blocked.

—

Combustion Blower

is

inoperable

—

Clogged

or

block

air/intake

hose.

While moving through

the

Heat Exchanger,

the hot

MONITOR HEATING SYSTEMS

Section

1:

Description

1-22

FUEL

DEUVERY

SYSTEM

Fuel

Delivery

is a

very

important

aspect

of the

Monitor's

operation.

The

fuel

flow must

be

maintained

at a

level corre-

sponding

to the

burn mode,

so

that

combustion

can

be

conducted efficiently.

Fuel moves

by

gravity-flow

from

the

external fuel

storage

tank

or the

capsule fuel tank

to the

Fuel

Constant Level Valve.

The

Solenoid Pump meters

the

flow

of

fuel from

the

Fuel Constant Level Valve

to the

Burner Pot.

The

metered flow

of

fuel

is

carried

to the

Burner

Pot

by a copper fuel

line.

1-23

EXTERNAL

FUEL TANK

Fuel

for the

Monitors

can be

stored

in,

and fed

from

an

external storage

tank.

The

tank,

which generally

is

dealer

installed,

should

contain a shutoff

valve,

a

fuel

filter

and a

vent.

Installation

of the

tank should

conform

to

local

regulations

and to the

specifica-

tions

and

guidelines

documented

in

this

Service

Manual.

1-24 FUSIBLE LINK

VALVE

Basically,

the

Fusible Link Valve

is a

safety mecha-

nism that

cuts-off

fuel

to the

heater

in the

event

of

an

overheat

condition

at the

valve.

In

M-2400/M-2200,

Fusible

Link

Valve

is not

instal-

led,

If

necessary,

it can be

installed

outside

of the

appliance.

The

Fusible Link Valve

is a

springloaded

device that

cuts

off the

supply

of

fuel

to the

heater when

the

temperature level

(at the

valve)

exceeds a predefined maximum

limit.

An

inlet

on the

bottom

of the

valve

allows

fuel

to

pass

into

the

heater.

The

handle-which

can

also

manually

be

opened

or

closed-sits

on a

springloaded stem which contains a low-melting point

alloy.

Fuel

enters

the

Fuel Constant

Level

Valve

through

an

inlet

at the

bottom

of the

reservoir.

As the

level

of

fuel rises,

it

passes through a filter (which

removes

most

particles

and

foreign matter

from

the

fuel),

flows

up

through

an

open inlet valve

and

enters

the

tank.

IMPORTANT:

The

Fuel

Constant

Level

Valve

filter

should

be

cleaned

or

replaced peri-

odically.

Time

intervals

will depend

on

purity

and

quality

of

fuel.

Within

the

Valve, a float mechanism controls

the

level

of

fuel that will

be

permitted

to the

reservoir.

As

the

fuel level drops,

the

float drops down

to

increase

the

inlet

valve opening

to

admit

more

fuel

into

the

valve.

When

the

fuel level reaches

its

maximum

volume,

the

float

rises

to

shut

the

inlet valve.

In the

event

that

fuel

within

the

reservoir

rises

to an

abnormally high level, a float within

the

reservoir

rises

to

trip a safety magnet. This safety magnet

locks

out the

float

to

prevent fuel from entering

in the

reservoir.

Should a foreign substance cause

the

inlet

valve

to

stick

(or

prevent

it

from opening),

the

Fuel

Set

Lever

is

utilized

to

free

the

valve

and to

admit fuel

to the

reservoir.

A

CAUTION:

Care

must

be

taken

to

prevent

dust,

dirt,

or

other debris from

clogging

or

blocking

the

inlet

valve.

If

debris collects

on the

seat

of the

inlet

valve

it may

cause

tripping

of the

safety

lever

and

will

require cleaning.

1-25

FUEL

CONSTANT

LEVEL

VALVE

This valve

has an

automatic shutoff safety mecha-

nism

and a

Fuel

Set

Lever.

The

safety mechanism

prevents

fuel from flooding

or

overflowing

from

the

fuel

reservoir.

The

Fuel

Set

Lever resets

the

float

so

the

Fuel Constant Level Valve

can

resume opera-

tion.

The

fuel reservoir

is a

tank which contains a float

assembly, a safety mechanism,

and a

priming lever.

MONITOR HEATING SYSTEMS

Section

1:

Description

1-26

SOLENOID

PUMP

The

Solenoid Pump, mounted

on the

Fuel

Constant

Level

Valve,

and

controlled

by a

microprocessor,

delivers

four

fuel flow modes (High, Medium-High,

Medium-Low,

Low)

to the

Burner Pot.

1-27

ELECTRICAL

SYSTEM

Electrical

power

is

supplied

to the

Monitor

to run the

Microprocessor

and the

other

electrically-energized

component.

Electrical operation

of the

Monitor

can be

thought

of

as

having

the

following

eight(8)

distinct

phases.plug

in;

turn-on;

pre-purge/pre-heat;

ignition; pre-

combustion;

heating;

Shutdown

and

post-purge.

All

electronic diagrams, Such

as

wiring diagram,

circuit

board layout,

and

electrical

schematic

can be

found

in

Section

7 of

this Service Manual.

1-28

MICROPROCESSOR

Principally consisting

of a

64-pin

Integrated

Circuit,

the

Microprocessor provides safety timings, controls

relays

and

provides

clock

and

thermostat functions

for

the

Monitor heater. A component layout

of the

Printed

Circuit Board

is

found

in

Section

7 of

this

Service

Manual.

1-29

TEMPERATURE

SENSOR

The

sensor

which

is

capable

of

sensing

room

tem-

perature

within a range

of

42"F

to

96°F,

can be

left

mounted

on the

back

of the

heater cabinet

or be

wall mounted.

Approximately

4/^'(about

140 cm) of No. 22 AWG

Wire

is

supplied with

the

sensor

to

facilitate wall

mounting

the

sensor

in a

favorable location.

1-30

SAFETY

MECHANISMS

Several

safety mechanisms have been built into

the

Monitor

Heating System. These devices protect

the

user

against personal

injury,

protect

the

heater

against

damage,

and

shutdown

the

heater

if a

malfunction occurs.

During

installation make

sure

that

all

Exhaust

Lines

are

tight.

Do not

operate

the

heater

without

the

insulating covers.

1-32

AIR

CIRCULATION

FAN

GUARD

This guard

is an

integral

part

of the fan

assembly.

The

guard protects

the

user

against physical injury

which could occur

from

accidental contact with

revolving

metal

fan

blade.

1-33

FUSE

2-amp.

and

10-amp.,

125VAC,

fuses protect

the

heater

from

damage resulting

from

power overloads.

In

the

event

of a

power surge

or

internal wiring

hazards,

the

fuse

opens

and

power

to the

heater

is

cut

off.

The

electrical outlet into which

the

heater

is

con-

nected should

be

protected

by at

least a 15-amp.

fuse

or

circuit breaker.

1-34

OVERHEAT PROTECTOR

SWITCHES

(M-2400)

Connected

in

series,

two (2)

normally-closed Over-

heat

Protector Switches safeguard

the

heaters

against damage

due to

overheating.

The

switches

are

rated

115'C

(239'F).

Should

a

Monitor overheat (internal temperatures

rise

beyond

115'C

(239'F)). either

or

both switches will open

to

shut down

the

heater.

After

extinguishing

the

flame,

the

code

FE14J

is

indicated

in the

digital display.

The

Overheat Protector Switches

will

automatically

reset

after

cooling down.

Once

the

heater

has

cooled

to

90'C

(194*F),

the

system

can be

restarted.

To

restart

the

Monitor,

proceed

as

follows:

A.

Press ON/OFF Switch

to

OFF.

B.

Allow heater

to

cool.

C.

Troubleshoot

the

cause

of the

overheat.

D.

Press

ON/OFF switch

to ON

E.

Proceed with normal operation.

1-31

CLOTH COVERED EXHAUST

PIPE

Insulating cloth covers

are to be

placed

over

all

metal surfaces

of the

Exhaust

Line

during

installa-

tion.

Since

combustion by-products

are

vented

at

ele-

vated

temperatures,

the

Exhaust Pipe will become

hot

during operation.

The

insulating

cloth

covers

protect

the

user from burn hazards associated with

accidental contact with these heated metal surfaces.

6

MONITOR

HEATING SYSTEMS

Section

1:

Description

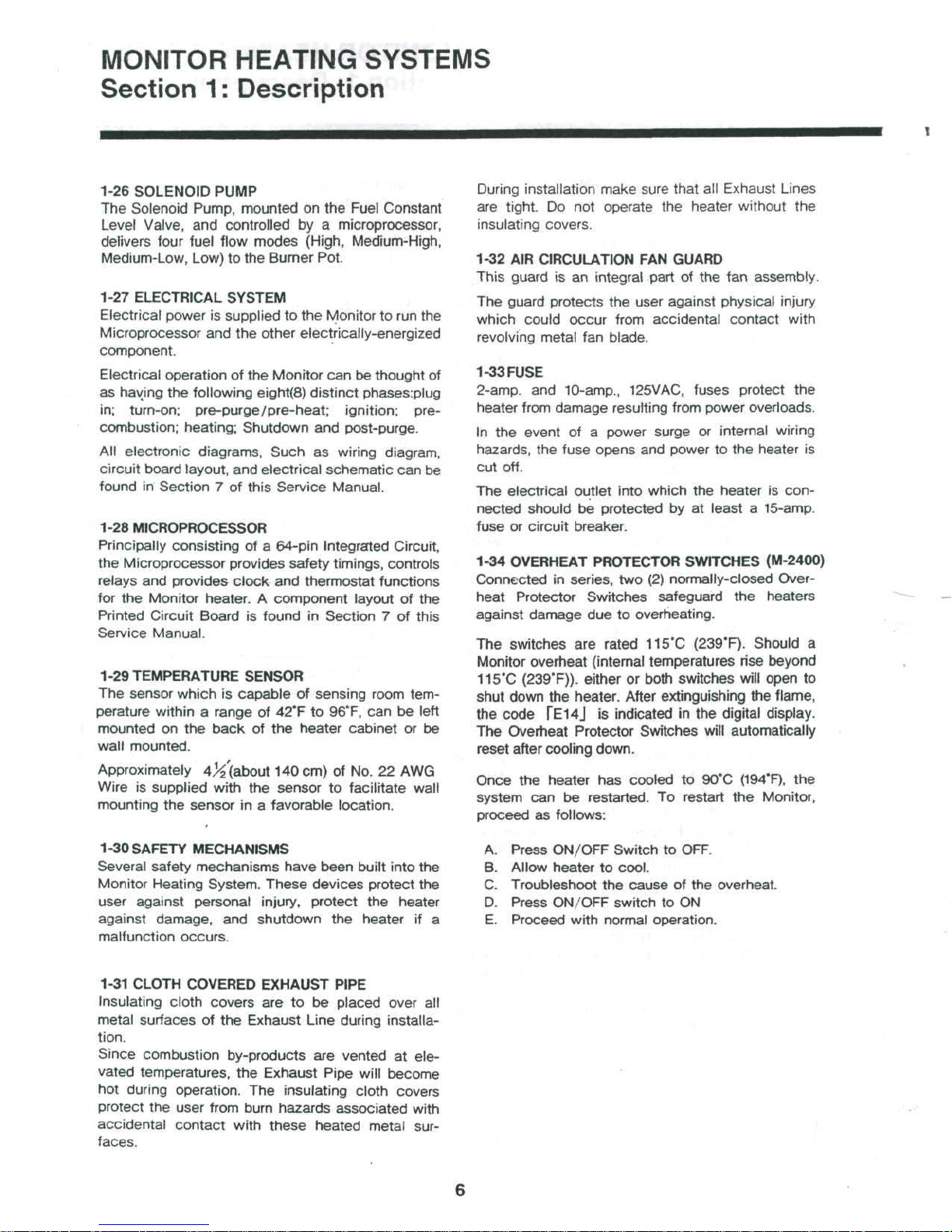

1-35

Revolution

control

of

combustion

blower

motor

IC4

TRIAC L fSfj

1

Hole

1C

01

JT

Fig.

1-1

-o

5V

microprocessor

As

shown

in

Fig.1-1,

the

current-carrying

ratio

for the

combustion blower motor shall

be

performed

by the

phase

control,

TRIAC,

Q1.

The

combustion blower motor

has a

built-in

hole

1C

of

which input signal

is

entered

to the

microproces-

sor

through

the

comparator IC8.

The

hole

1C

outputs

the

pulse signal

by 6

pulse

ev-

ery

one

revolution

of the

motor.

The

microprocessor

counts this pulse

signal

to

obtain

the

number

of

pulse, frequency

per one

second,

and

then compute

the

motor

revolution

-per

one

minute

by

this

frequen-

cy.

In

order

to

achieve

the

target control revolutions

shown

in

Table 1-1/1-2, Page 4/8,

the

current-carry-

ing

ratio

to the

motor shall

be

controlled

by

TRIAC,

Q1

to

make

the

revolution

of the

combustion blower

motor

constant.

If

the

revolution

of the

combustion blower

has

slowed down

to

less than 1200

(rpm),

an

abnormal

revolution

will

be

sensed

and

then

the

heater opera-

tion

will

be

stopped

indicating

the

error code

of

(EOS)

in the

display window.

MONITOR

HEATING SYSTEMS

Section

1:

Description

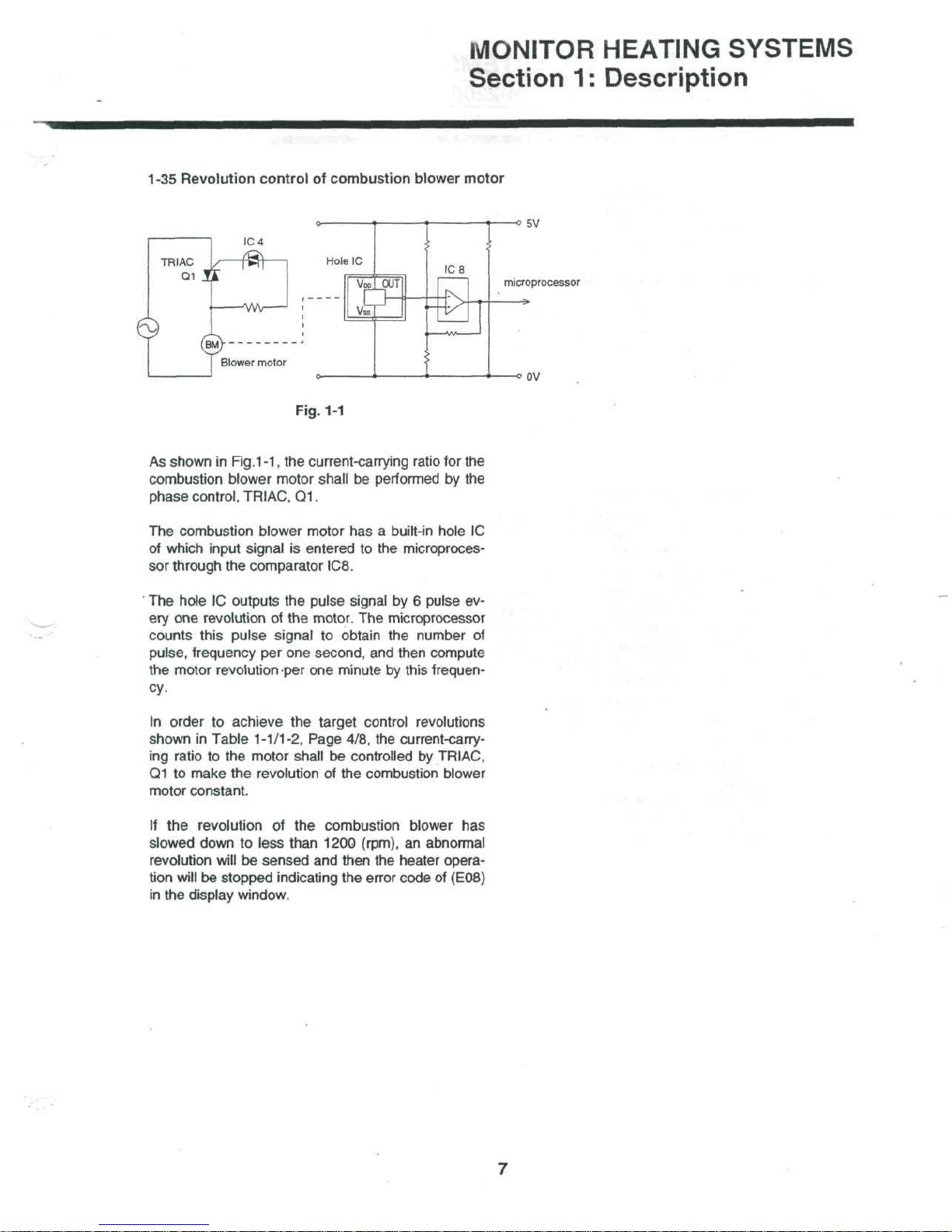

1-36

COMBUSTION

BLOWER

MOTOR

The

combustion blower

has a

four stage intake

fan

Burner

modes control

fan

speeds.

The

combustion

air

controls

are as

follows:

Table

1-2

COMBUSTION

AIR

CONTROL

Burn

Mode

Fan

Speed

(r.p.m.)

High 2,975

Medium-High

2,550

Medium-Low 2,025

Low

1,800

1-37

OVERHEAT

PROTECTOR

SWITCHES

Connected

in

series,

two (2)

normally-closed

Over-

heat

Protector Switches safeguard

the

heaters

against damage

due to

overheating.

The

switches

are

rated

110'C

(230T)

and

105'C

(221

'F).

Should a Monitor overheat

(internal

temper-

atures

rise

beyond 105'C

(221'F).

either

or

both

switches

will

open

to

shut down

the

heater.

After

ex-

tinguishing

the

flame,

the

code

[EOS]

is

indicated

in

the

digital

display.

The

Overheat Protector Switches

will

automatically reset after

cooling

down.

Once

the

heater

has

cooled

to

90'C

(194T),

the

system

can be

restarted.

To

restart

the

Monitor,

proceed

as

follows:

A.

Press ON/OFF Switch

to

OFF.

B.

Allow heater

to

cool.

C.

Troubleshoot

the

cause

of the

overheat.

D.

Press

ON/OFF

switch

to ON

E.

Proceed with normal

operation.

8

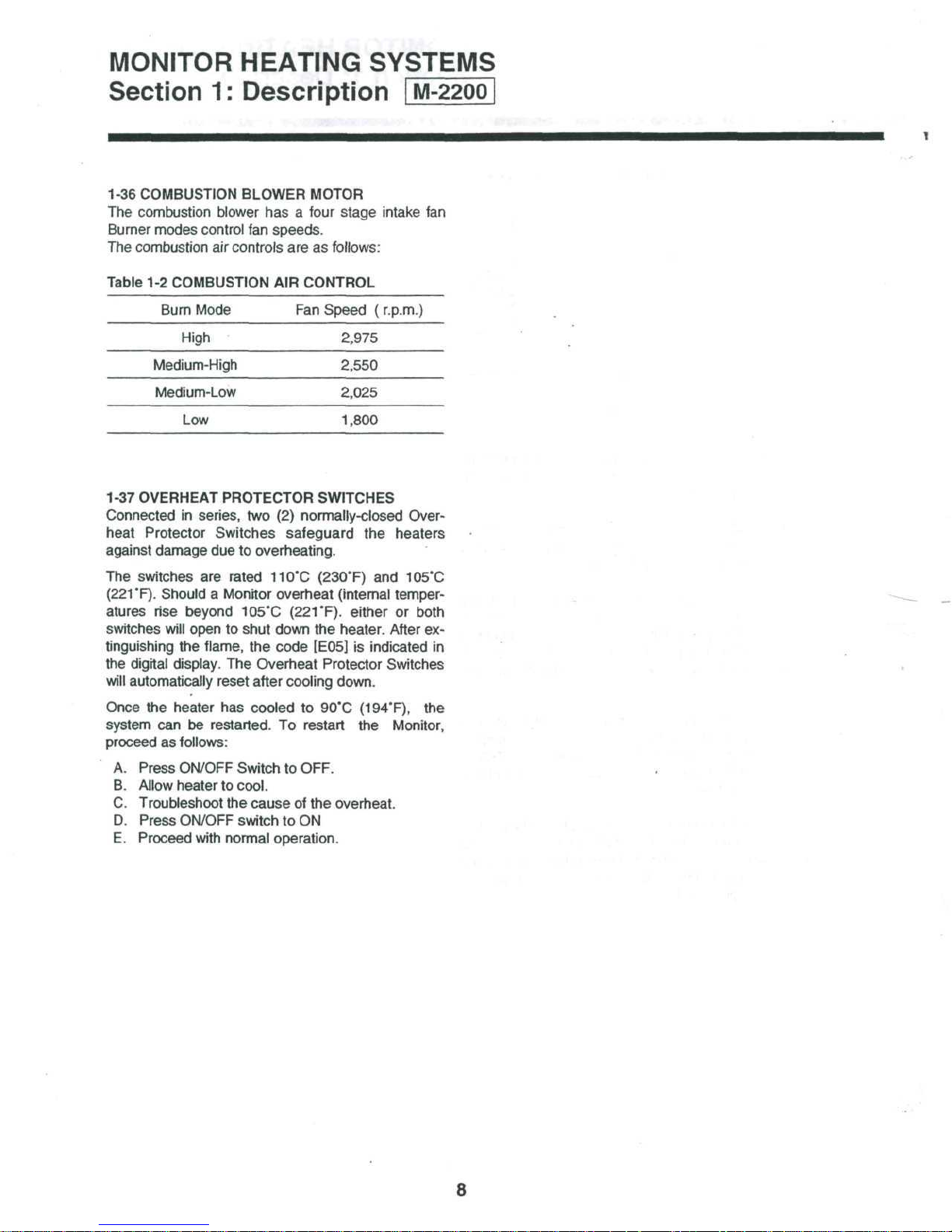

MONITOR HEATING SYSTEMS

Section

1:

Description

UJ

en

z

o

CO

m

S.

o

o

LL

O

CO

UJ

UJ

2

9

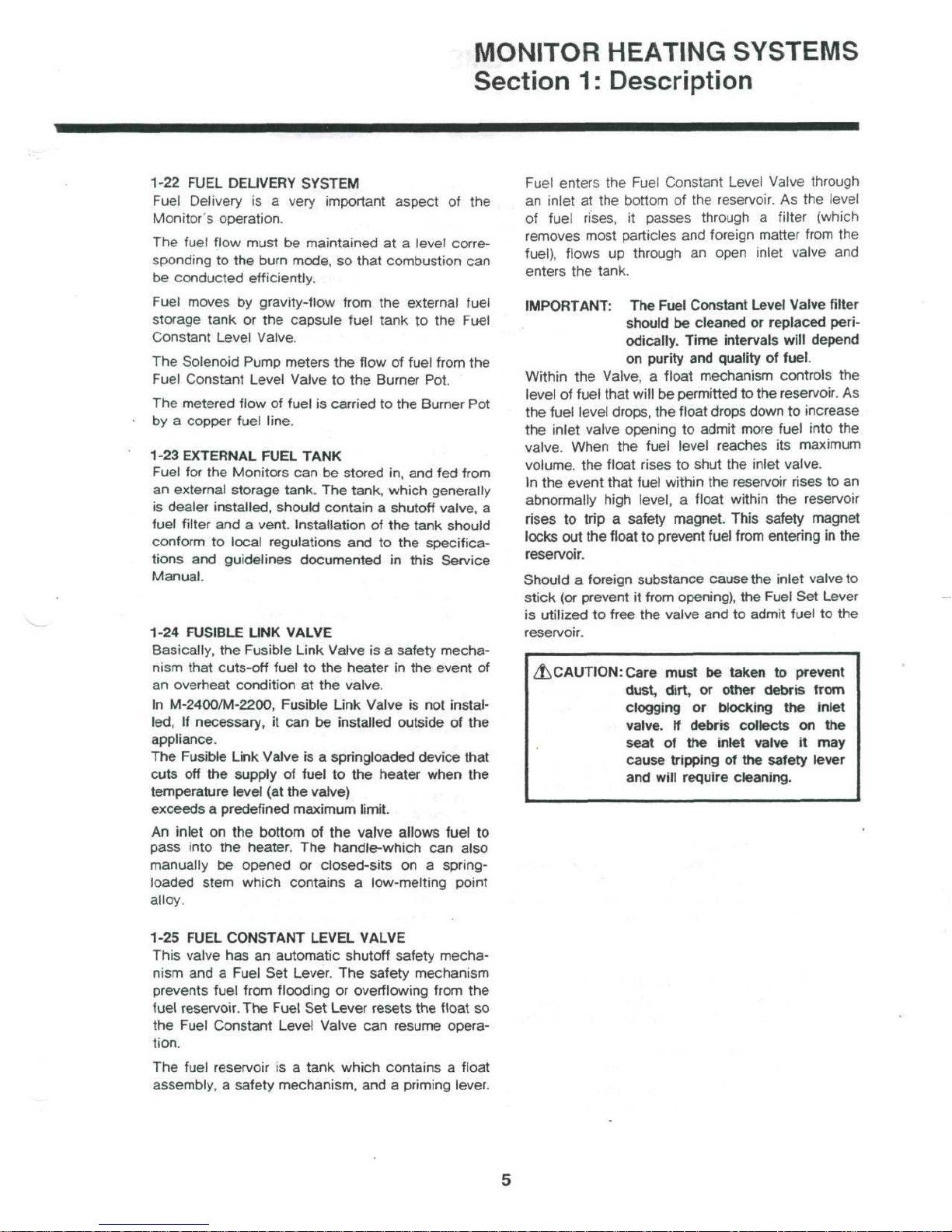

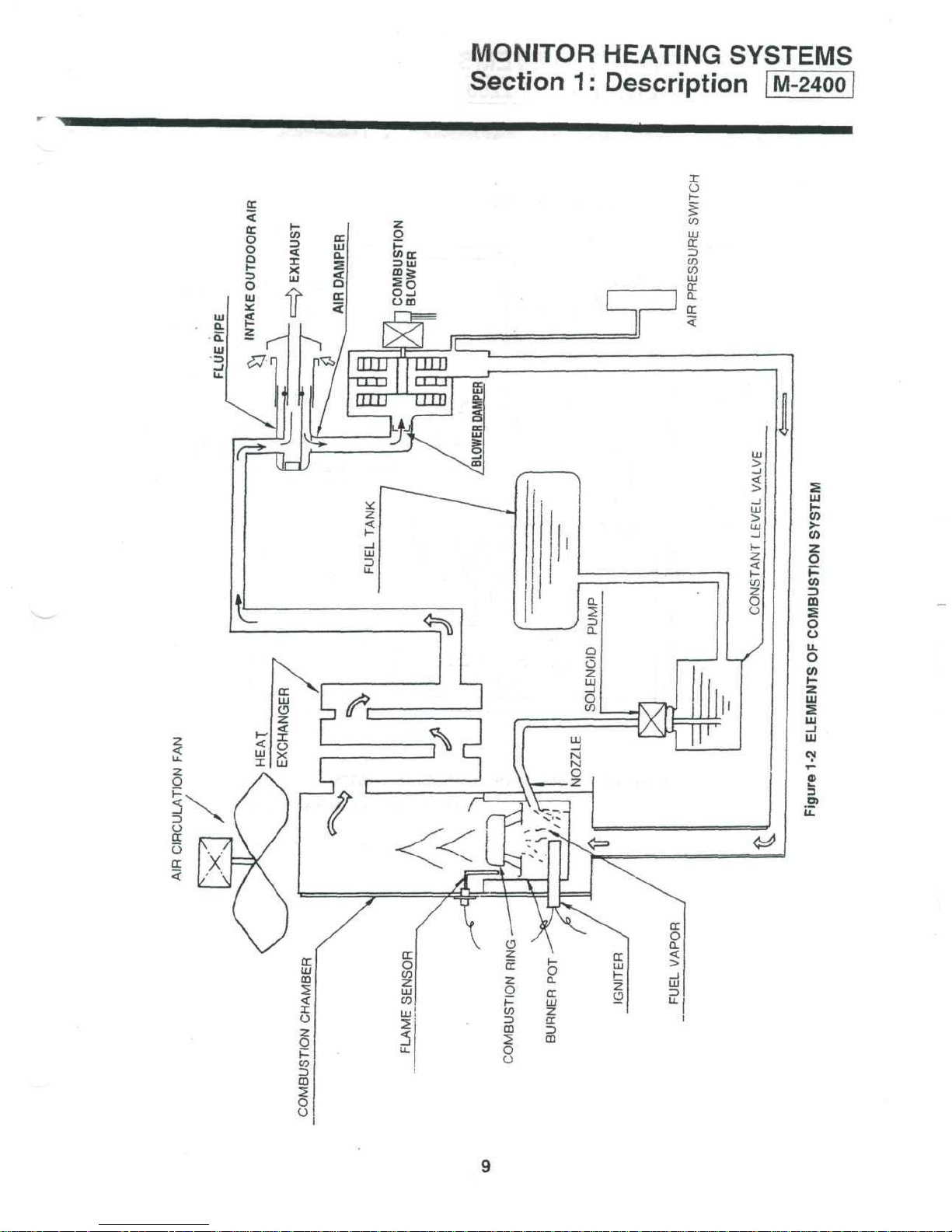

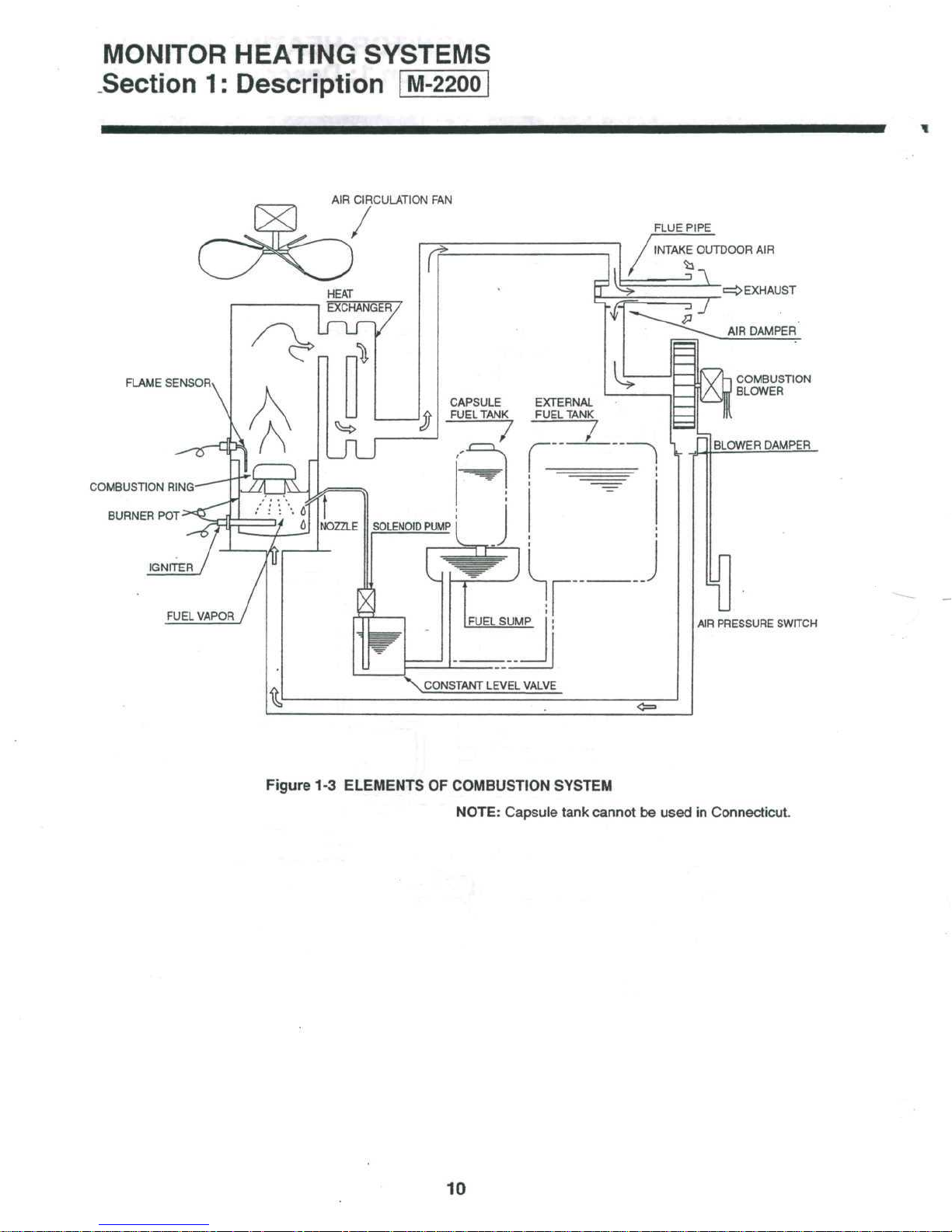

MONITOR HEATING SYSTEMS

Section

1:

Description | M-2200

AIR

CIRCULATION

FAN

FLAME

SENSOR

FLUE PIPE

COMBUSTION RING

BURNER

POT

^•^U^-S

CAPSULE EXTERNAL

FUEL

TANK

FUEL

TANK

\CONSTANT

LEVEL

VALVE

AIR

PRESSURE

SWITCH

Figure

1-3

ELEMENTS

OF

COMBUSTION

SYSTEM

NOTE:

Capsule tank cannot

be

used

in

Connecticut.

10

MONITOR

HEATING

SYSTEMS

Section

2:

Installation

2-1

INTRODUCTION

Installing

the

Monitor

System

at the

user's

location

can

be

performed

quickly

and

economically.

The

Monitor

2400/2200 model

is

strictly a remotely

fueled

system

and is

externally vented.

As

such

it

needs

the

installation

of an

externally vented

intake/

exhaust

system

and if

remotely

fueled,

will

need

the

installation

of a

remote fuel storage tank.

By

completing each step

of the

easy-to-follow

installation

instructions

(each step should

be

com-

pleted

in the

exact order

specified),

the

Technician

is

directed through

the

installation

process.

This section

contains

all

relevant

installation

infor-

mation

including:

—

Installation

specifications

—

List

of

installation

tools

—

Alternative types

of

venting systems (and

in-

stallation

procedures

for

each)

—

Basic requirements

for

fuel

tank

installation

—

Instructions

to

install

the

Monitor

System

IMPORTANT:

Before

beginning installation

of the

Monitor

vented

heating

system

(in-

cluding

any

electrical

wiring

and

fuel

supply

equipment), check local

building,electrical,

mechanical

and

fire

codes.

The

requirements

of

these

codes

must

be

followed

to

insure

lawful installation

and

use.

The

heater

can be

located

almost anywhere within

the

dwelling provided

that

electrical,

fuel,

and ex-

haust

specifications

are

met.

2-2

PHYSICAL PLACEMENT

OF

HEATER

In

addition

to the

space

taken

up by the

heater,

interior space must also

be

reserved

for

free

air

circulation.

Remove

all

combustibles

from

the

heat-

ing

area.

Unless

building

or

fire codes

dictate

otherwise,

the

Monitor system

can be

placed

on any

floor surface

(including

carpeting

or

other combustible material)

and

provide safe

operation.

2-3

DRILLING REQUIREMENTS

Through-the-wall

Flue Pipe

installation

requires that

a 2

Vz"

(65mm)

hole

be

drilled

through

the

dwelling

wall (interior

to

exterior).

The

hole must

be

pitched

downward

toward

the

outside

at an

approximate

angle

of

2"(about l/2"

per

foot).

The

appropriate

wall

area

(in

which hole

will

be

drilled)

must

contain

no

internal

obstacles

such

as

piping,

wiring,

air

ducts,

or

studs.

RECOMMENDED

TOOL

KIT FOR

MONITOR

HEATER

SERVICE

TECHNICIANS

1)

#2

Phillips

Head

Screwdriver

2)

Steel Tape Measure

3)

Felt

Tip Pen or

Pencil

4)

Caulking

Material (exterior

grade)

5)

Electrical Drill

(reverse

capability

recommended)

6)

Hole Saw, Saber (Jig) Saw,

or

other appropriate

tool

for

cutting a 2.5" diameter hole

for

flue pipe

7)

Rubber Clipping Tool

8)

Long

Drill

Bit—'//'

9)

#2

Standard Screwdriver

10)

Adjustable Wrenches

(various

sizes)

11)

Copper Tubing Cutter

12)

Copper Tubing Flaring Tool

13)

V.O.M.(Volt.

OHM. Meter with shielded

probes)

14)

Level

15)

Plumber's

Pipe Thread Tape

16)

Small assortment

of

Self-Tappeng

Screws

17)

Assorted Pliers (Slip

Joint,

Needlenose, Cutting,

Lock

Joint)

18)

Phenolic

Probe

or

Insulated

Screwdriver

19)

Supply

of

125V,

2 and 10 Amp

fuses

20)

Floor

mat to

cover

carpeting

21)

Quart size

pan for

draining fuel

2-4

POWER

REQUIREMENTS

WARNING:

THE

MONITOR

POWER

CORD

MUST

BE

PLUGGED

INTO A DIRECTLY ACCESSIBLE

WALL

OUTLET.

DO

NOT USE AN

EXTENSION

CORD

TO

MAKE

THIS

ELECTRICAL CONNECTION.

Line

current

to the

system

should

be 120 VAC at 60

Hz.

The

electrical

system should

be

protected

against

current

overload

by

means

of at

least

a

15-ampere

fuse

or

circuit

breaker.

NOTE:

The

wall

outlet

should supply electricity

for

the

Monitor system only.

Do not

connect

any

other

electrical

appliance

to it.

^CAUTION:

In

some installations,

it may be

best

to

hard-wire

the

heater

to the

house

circuits. A competent,

licensed electrician

should

do

this.

11

MONITOR

HEATING SYSTEMS

Section

2-5

FUEL

2:

TANK

REQUIREMENTS

Installation

WARNING:

INSTALLATION

FUEL

TANKS

STANDARDS

Heater

fuel (crystal clear kerosene only)

stored

in

from

55

gallon drums

using

large tanks a pressure regulator with a max.

2.5

PSI

should

(if top of

unit.)

/JK.CAUTION:

2-6

TEMPERATURE

MENTS

A

wall-mounted temperature Sensor gauges

temperature

cycles

of the

The

standard sensor wire

left mounted

If

this

is not

a

wall.

OF ANY

MUST

AND/OR

remotely located storage tanks ranging

be

installed near heater

tank

is

going

In

some

ter to

plumbing. A licensed plumber

oil

dealer should

and

automatically regulates

Monitor System.

on the

practical

REMOTELY

COMPLY

BUILDING CODES.

to 275

to be

installations,

install permanent

SENSOR

back

the

WITH

gallon tanks. When

8'

higher

do

WIRING

is

4/£'

long

of the

cabinet

sensor

can be

LOCATED

ALL

inlet,

than

it may be

fuel

this.

REQUIRE-

the

and can be

as

mounted

LOCAL

can be

base

of

bet-

tank

or

room

heating

shipped.

on

of

NOTE:

The

tion

return

as

possible.

D.

Remove

remove

E.

Remove

F.

Remove

parts.and

G.

Remove

heater.

H.

Firmly

of

board

I.

Check

Guide.

IMPORTANT:

the

When

Pipe

from cardboard packing materials.

grasp cabinet

heater cabinet)

shipping base.

for

Dealer should complete

Card

at

time

of

customer

it to

Monitor

the

spill

plastic bag.

the

plastic

the

plastic

set it

aside.

the

Flue Pipe from

ready

parts

Only

is

shipped with

Monitor

longer

pipe, Window Kits, Extension

Kits,

may

be

installations.

Products, Inc.

tray

from

bag

covering

bag

containing

to

install, separate Flue

handles

and

lift

heater

as

listed

the

standard-size Flue Pipe

dealer

Flue pipe

and

other accessories that

required

the

purchase

shipping

the

(one

in

Monitor

the

will

also stock

B and a

for

non-standard

Registra-

as

carton,

the

heater.

the

rear

of

each side

off the

Owners

heater.

and

soon

and

heater

of the

card-

The

a

Relay

il\CAUTION:

2-7

BUILDING CODES

Fire regulations,

codes

may

vented heater

installation,

2-8

UNPACKING

Save

all

been completely

A.

Cut the

ping carton together.

B.

Remove

C.

Remove

(drilling) Template

If

,

motely

direct

exterior

as

temperature

electrical

govern

and

check

shipping

three plastic

the

from

sensor

installed

top.

is to be

be

careful

sunlight,

walls

in

this will create

reading.

and

the

installation

related

and

materials

the

fueling

comply

until

and is

ribbons

shipping carton

and the

on

drafty

other

with

Owner's

mounted

not to

uninsulated

areas etc.,

an

inaccurate

local

and use of a

systems. Prior

all

the

Monitor

working properly.

that hold

the

re-

place

it in

building

codes.

the

Cardboard

'Guide.

has

ship-

to

12

MONITOR

HEATING SYSTEMS

Section

2:

Installation

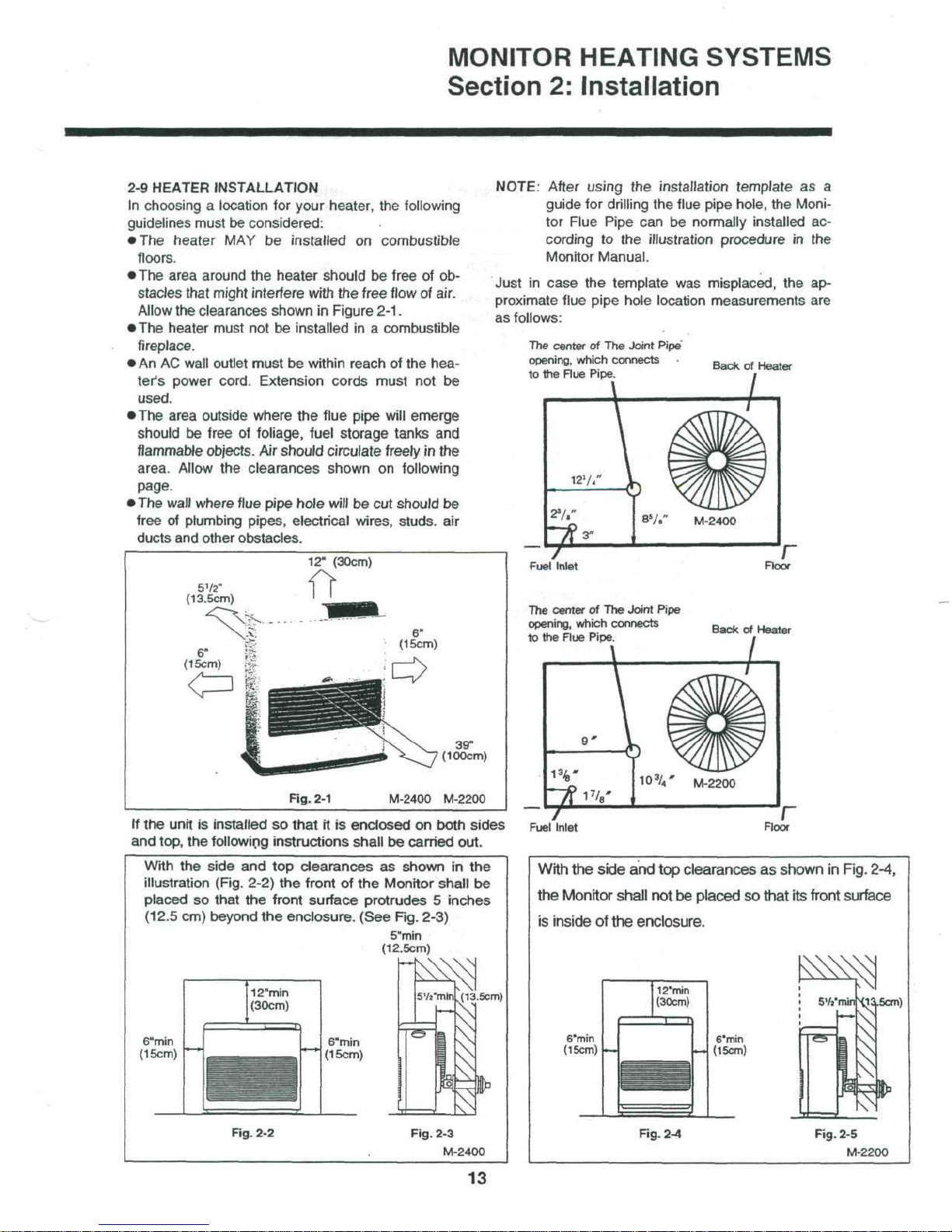

2-9

HEATER INSTALLATION

In

choosing a location

for

your

heater,

the

following

guidelines

must

be

considered:

•

The

heater

MAY be

installed

on

combustible

floors.

•

The

area

around

the

heater should

be

free

of ob-

stacles that might interfere

with

the

free flow

of

air.

Allow

the

clearances shown

in

Figure

2-1.

•

The

heater must

not be

installed

in a

combustible

fireplace.

• An AC

wall outlet must

be

within reach

of the

hea-

ter's

power cord. Extension cords must

not be

used.

•

The

area outside where

the

flue

pipe

will

emerge

should

be

free

of

foliage, fuel storage tanks

and

flammable

objects.

Air

should

circulate

freely

in the

area.

Allow

the

clearances shown

on

following

page.

•

The

wall where

flue

pipe

hole

will

be cut

should

be

free

of

plumbing pipes, electrical wires,

studs,

air

ducts

and

other obstacles.

NOTE: After

using

the

installation

template

as a

guide

for

drilling

the

flue pipe hole,

the

Moni-

tor

Flue Pipe

can be

normally installed

ac-

cording

to the

illustration

procedure

in the

Monitor

Manual.

Just

in

case

the

template

was

misplaced,

the

ap-

proximate

flue pipe hole location measurements

are

as

follows:

12"

(30cm)

5V2"

(13.5cm)

Fig.

2-1

39"

(100cm)

M-2400

M-2200

If

the

unit

is

installed

so

that

it is

enclosed

on

both

sides

and

top,

the

following

instructions

shall

be

carried

out.

With

the

side

and top

clearances

as

shown

in the

illustration

(Fig.

2-2)

the

front

of the

Monitor

shall

be

placed

so

that

the

front surface protrudes 5 inches

(12.5

cm)

beyond

the

enclosure.

(See

Rg.

2-3)

5"min

(12.5cm)

(13.5cm)

6"min

(15cm)

6"min

(15cm)

Rg. 2-2

Fig.

2-3

M-2400

13

The

center

of The

Joint

Pipe'

opening,

which

connects

to

the

Flue

Pipe.

Back

of

Heater

The

center

of The

Joint

Pipe

opening,

which

connects

to

the

Flue

Pipe.

Back

of

Heater

With

the

side

and top

clearances

as

shown

in

Fig.

2-4,

the

Monitor

shall

not be

placed

so

that

its

front surface

is

inside

of the

enclosure.

6"min

(15cm)

.115cm)

6'min

(15cm)

Fig.

2-4

Fig.

2-5

M-2200

MONITOR

HEATING

SYSTEMS

Section

2:

Installation

Table

2-1

Installation

Classification

for

using

Damper

Diameter

and

Processing

of

P.W.B.

Jumper

Wire

CJ

Installation

Classification

Up

to 1

bend(90°elbows) with

no

extension

Up

to 1

bend(90'elbows)

with

extension

kit

length : 0-73"

2

bends with extension

kit

length

:

exceed

20" or 3

bends

P.W.B.

Jumper Wire

CJ

Altitude (feet)

0~3,000

Air

Damper

STANDARD

Used

EXTENSION

Used

Blower

Damper

Used

Used

No

Cut

3,000—5,000

Air

Damper

STANDARD

Used

Not

Used

Not

Used

Blower

Damper

Used

Used

Not

Used

5,000-7,000

Air

Damper

EXTENSION

Used

Not

Used

Blower

Damper

Used

Not

Used

THIS

UNIT

CAN NOT BE

USED

FOR

THIS

APPLICATION.

Cut

The

blower

damper

is fixed

with

suction

case

B of

the

combustion

blower

ass'y,

as

shown

in

Fig.

2-6.

To

remove

the

blower

damper

from

suction

case

B,

remove

the air

hose

supply

ass'y,

first and

then

loosen

the

screw

holding

the

blower

damper.

After

the

blower

damper

has

been

removed,

insert

air

supply hose

ass'y

into

the

suction

case

B and

tighten

by the

hose

band.

Suction

case

B

Combustion blower assy

Blower damper

Hose band

Screw

Air

supply hose assy

[Position

of

P.W.B. jumper wire

CJ and

reset

push-

button switch]

Reset

push-button

-

switch

^

Jumper wire

CJ

D

P.W.B.

IMPORTANT:

After

cutting

the

jumper wire

CJ,

please

be

sure

to

press

the

reset push-button switch

on the

P.W.B.

two

to

three

times,

with

the

power

plug

inserted

in

the

socket.

If

the

reset button

has

been pressed, settings such

as

the

current

time,

current

day of the

week,

economy

plus

and

child lock

functions

will

be

cancelled,

and

these programs must

be set

again.

Fig.

2-6

14

MONITOR

HEATING SYSTEMS

Section

2:

Installation

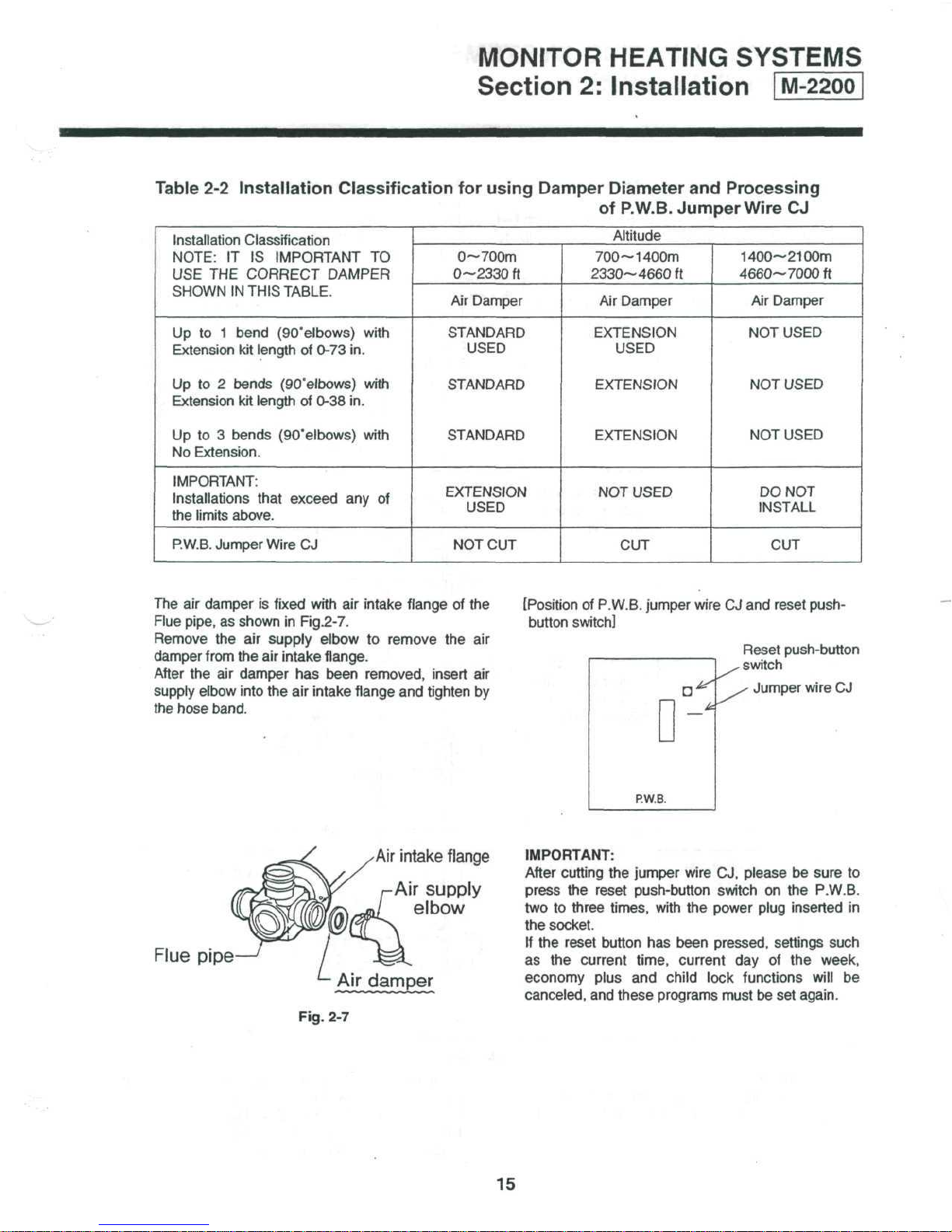

Table

2-2

Installation Classification

for

using Damper Diameter

and

Processing

of

P.W.B.

Jumper Wire

CJ

Installation Classification

NOTE:

IT IS

IMPORTANT

TO

USE THE

CORRECT DAMPER

SHOWN

IN

THIS TABLE.

Up

to 1

bend

(90'elbows)

with

Extension

kit

length

of

0-73

in.

Up

to 2

bends

(90°elbows)

with

Extension

kit

length

of

0-38

in.

Up

to 3

bends

(90'elbows)

with

No

Extension.

IMPORTANT:

Installations

that exceed

any of

the

limits

above.

P.W.B.

Jumper Wire

CJ

Altitude

0~700m

0—2330

ft

Air

Damper

STANDARD

USED

STANDARD

STANDARD

EXTENSION

USED

NOT

CUT

700—

1400m

2330—

4660ft

Air

Damper

EXTENSION

USED

EXTENSION

EXTENSION

NOT

USED

CUT

1400—

2100m

4660—

7000ft

Air

Damper

NOT

USED

NOT

USED

NOT

USED

DO

NOT

INSTALL

CUT

The

air

damper

is

fixed

with

air

intake

flange

of the

Flue pipe,

as

shown

in

Fig.2-7.

Remove

the air

supply

elbow

to

remove

the air

damper

from

the air

intake

flange.

After

the air

damper

has

been removed, insert

air

supply elbow into

the air

intake flange

and

tighten

by

the

hose band.

[Position

of

P.W.B. jumper wire

CJ and

reset push-

button switch]

Reset

push-button

.

switch

^

Jumper wire

CJ

D'

o-

P.W.B.

Flue

pipe

Air

intake

flange

Air

supply

elbow

A|r

damper

Fig.

2-7

IMPORTANT:

After

cutting

the

jumper wire

CJ,

please

be

sure

to

press

the

reset push-button switch

on the

P.W.B.

two

to

three times, with

the

power plug inserted

in

the

socket.

If

the

reset button

has

been pressed, settings such

as

the

current

time,

current

day of the

week,

economy plus

and

child

lock functions

will

be

canceled,

and

these programs must

be set

again.

15

MONITOR HEATING SYSTEMS

Section

2:

Installation

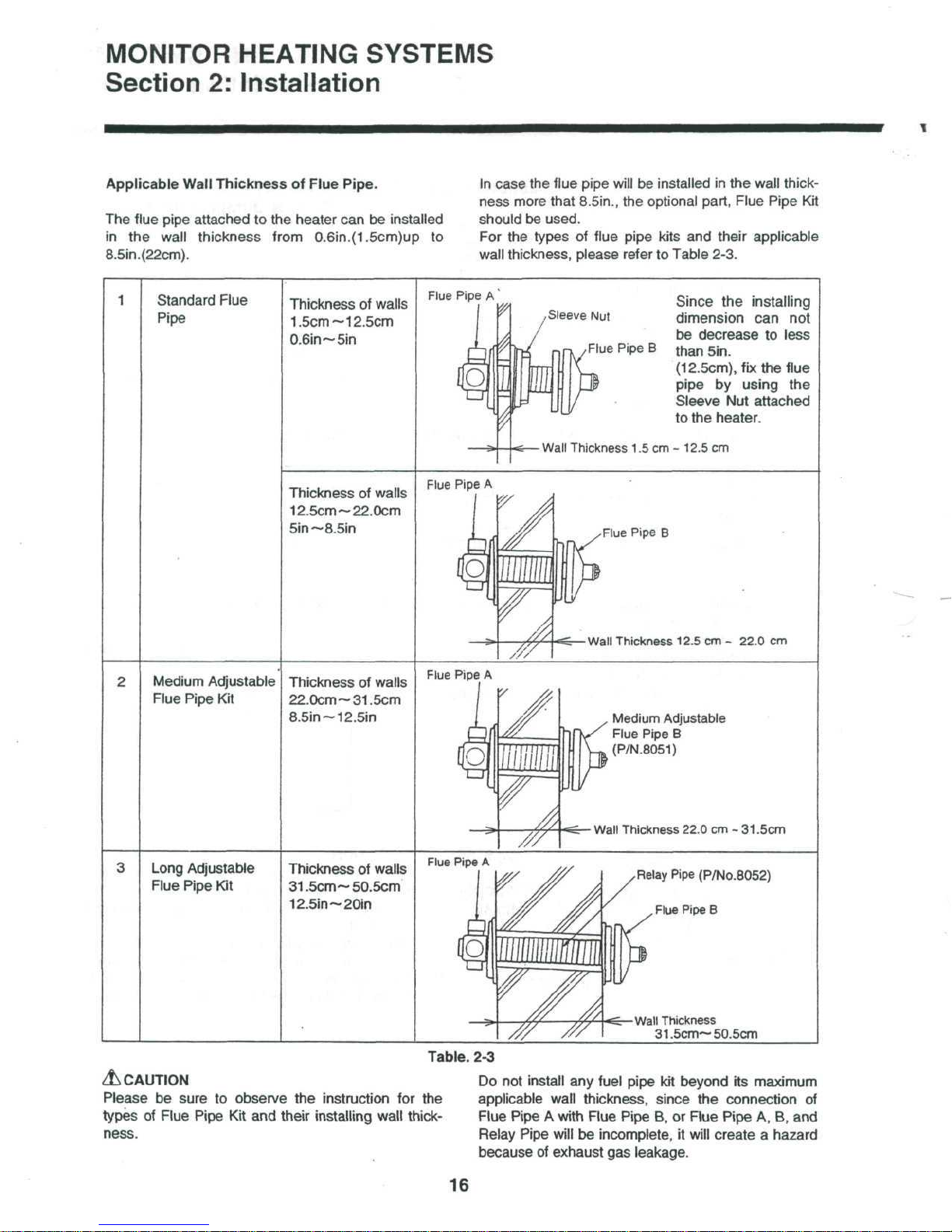

Applicable

Wall

Thickness

of

Flue Pipe.

The

flue

pipe

attached

to the

heater

can be

installed

in the

wall thickness from

0.6in.(1.5cm)up

to

8.5in.(22cm).

In

case

the

flue pipe will

be

installed

in the

wall thick-

ness

more

that

8.5in.,

the

optional part, Flue Pipe

Kit

should

be

used.

For

the

types

of

flue pipe kits

and

their applicable

wall

thickness, please

refer

to

Table 2-3.

Standard

Flue

Pipe

Thickness

of

walls

1.5cm ~ 12.5cm

0.6in~5in

Thickness

of

walls

12.5cm~22.0cm

Sin

~8.5in

Flue

Pipe

A

,Sleeve

Nut

nrK

/Flue

Pipe

B

Since

the

installing

dimension

can not

be

decrease

to

less

than

Sin.

(12.5cm),

fix

the

flue

pipe

by

using

the

Sleeve

Nut

attached

to

the

heater.

s—

Wall Thickness

1.5

cm -

12.5

cm

Flue Pipe

A

Flue Pipe

B

y/\<Z.

Wall Thickness

12.5

cm -

22.0

cm

Medium

Adjustable

Flue

Pipe

Kit

Thickness

of

walls

22.0cm~31.5cm

8.5in~12.5in

Flue

Pipe

A

A

Medium

Adjustable

Flue

Pipe

B

(P/N.8051)

s£r-

Wall Thickness 22.0

cm -

31.5cm

Long

Adjustable

Flue Pipe

Kit

Thickness

of

walls

31.5cm ~ 50.5cm

12.5in~20in

Flue

Pipe

A

Relay

Pipe

(P/No.8052)

Flue Pipe

B

Wall Thickness

31.5cm~

50.5cm

Table.

2-3

A

CAUTION

Please

be

sure

to

observe

the

instruction

for the

types

of

Flue

Pipe

Kit and

their

installing

wall

thick-

ness.

Do

not

install

any

fuel pipe

kit

beyond

its

maximum

applicable wall thickness, since

the

connection

of

Flue

Pipe A with

Flue

Pipe

B, or

Flue

Pipe

A, B, and

Relay

Pipe

will

be

incomplete,

it

will

create a hazard

because

of

exhaust

gas

leakage.

16

MONITOR

HEATING

SYSTEMS

Section

2:

Installation

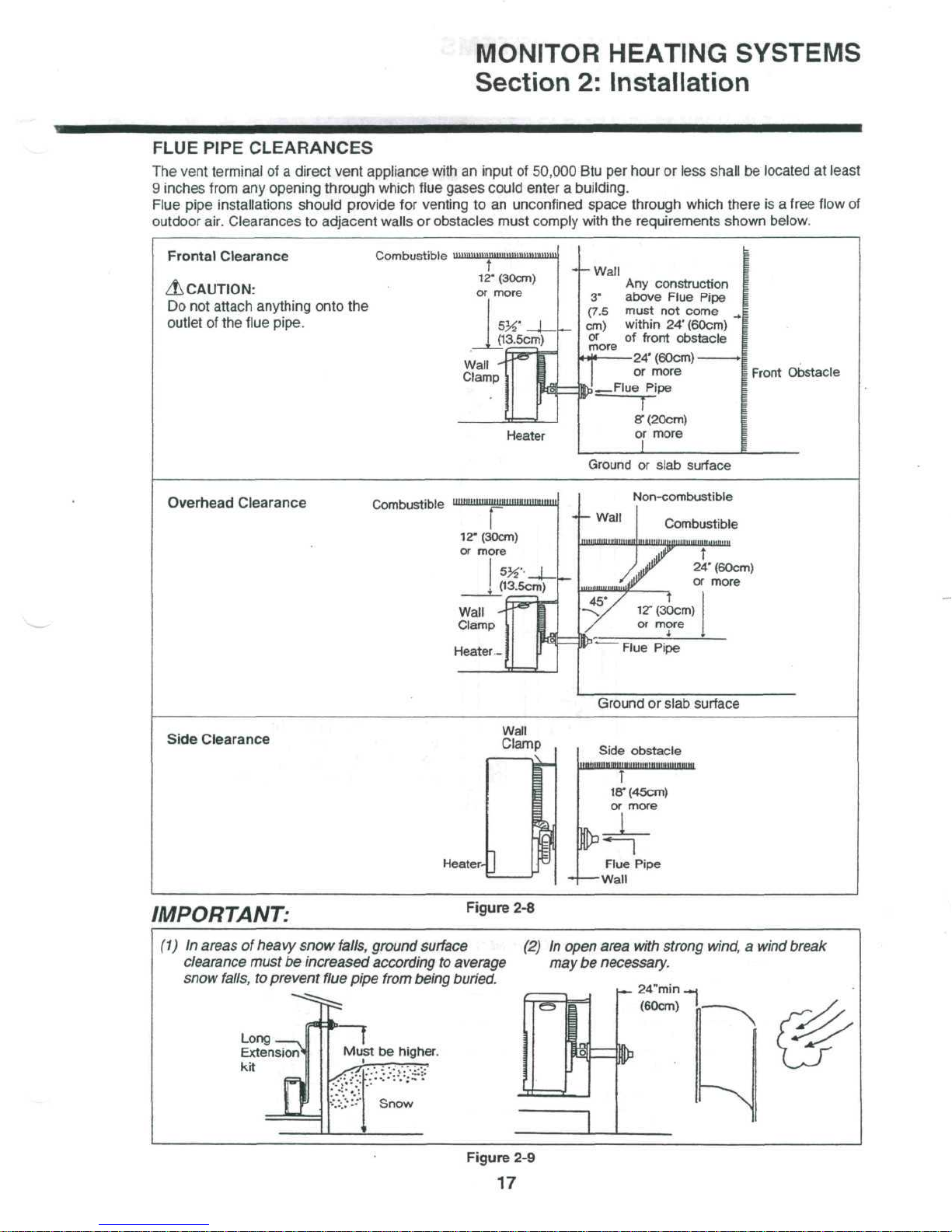

FLUE

PIPE

CLEARANCES

The

vent terminal

of a

direct

vent appliance with

an

input

of

50,000

Btu per

hour

or

less

shall

be

located

at

least

9

inches from

any

opening

through

which flue gases could enter a building.

Flue pipe installations

should

provide

for

venting

to an

unconfined space through which there

is a

free

flow

of

outdoor

air. Clearances

to

adjacent walls

or

obstacles must comply with

the

requirements shown below.

Frontal

Clearance

Combustible

iiiiniiiiminimiiinintiiniiniiii

12"

(30cm)

A

CAUTION:

or

more

Do

not

attach anything onto

the

outlet

of the

flue

pipe.

J13.5cm)

Wall

-

Clamp

-f-Wall

Any

construction

3"

above

Flue Pipe

(7.5

must

not

come

cm)

within

24'(60cm)

or

of

front obstacle

-24'(60cm)

or

more

i-—Flue

Pipe

~T~

8T(20cm)

or

more

more

I

Front

Obstacle

Ground

or

slab

surface

Overhead

Clearance

Combustible

Non-combustible

Ground

or

slab

surface

Side Clearance

Wall

Clamp

Heater-

Side

obstacle

T

18"

(45cm)

or

more

Flue

Pipe

-Wall

IMPORTANT:

Figure

2-8

(1) In

areas

of

heavy

snow

falls,

ground

surface

(2) In

open area

with

strong

wind, a wind

break

clearance

must

be

increased according

to

average

may be

necessary,

snow

falls,

to

prevent

flue

pipe

from

being buried.

Long

Extension

kit

u»-

=»

24"min

.

(60cm)

Figure

2-9

17

MONITOR

HEATING SYSTEMS

Section

2:

Installation

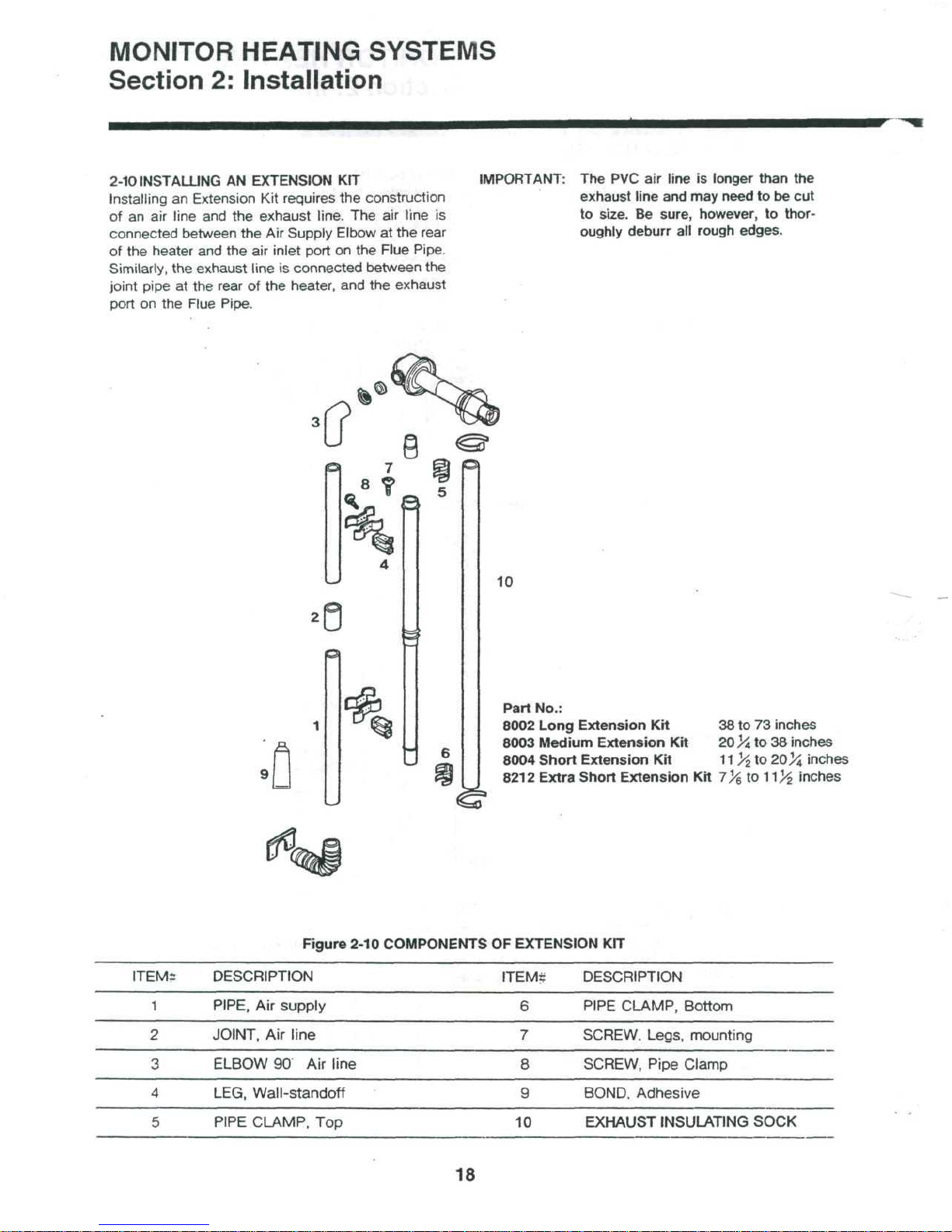

2-10 INSTALLING

AN

EXTENSION

KIT

Installing

an

Extension

Kit

requires

the

construction

of

an air

line

and the

exhaust

line.

The air

line

is

connected between

the Air

Supply Elbow

at the

rear

of

the

heater

and the air

inlet port

on the

Flue

Pipe.

Similarly,

the

exhaust

line

is

connected

between

the

joint pipe

at the

rear

of the

heater,

and the

exhaust

port

on the

Flue Pipe.

IMPORTANT:

The PVC air

line

is

longer

than

the

exhaust

line

and may

need

to be cut

to

size.

Be

sure,

however,

to

thor-

oughly

deburr

all

rough

edges.

10

Part

No.:

8002 Long Extension

Kit 38 to 73

inches

8003 Medium Extension

Kit

20

^A,

to 38

inches

8004 Short Extension

Kit

11

>£

to

20

>J

inches

8212

Extra Short Extension

Kit

7^

to

1l)i

inches

Figure

2-10 COMPONENTS

OF

EXTENSION

KIT

ITEM?

DESCRIPTION

1

PIPE,

Air

supply

2

JOINT,

Air

line

3

ELBOW

90

Air

line

4

LEG,

Wall-standoff

5

PIPE

CLAMP,

Top

ITEM;

6

7

8

9

10

DESCRIPTION

PIPE

CLAMP,

Bottom

SCREW.

Legs,

mounting

SCREW,

Pipe

Clamp

BOND. Adhesive

EXHAUST

INSULATING

SOCK

18

MONITOR HEATING SYSTEMS

Section

2:

Installation

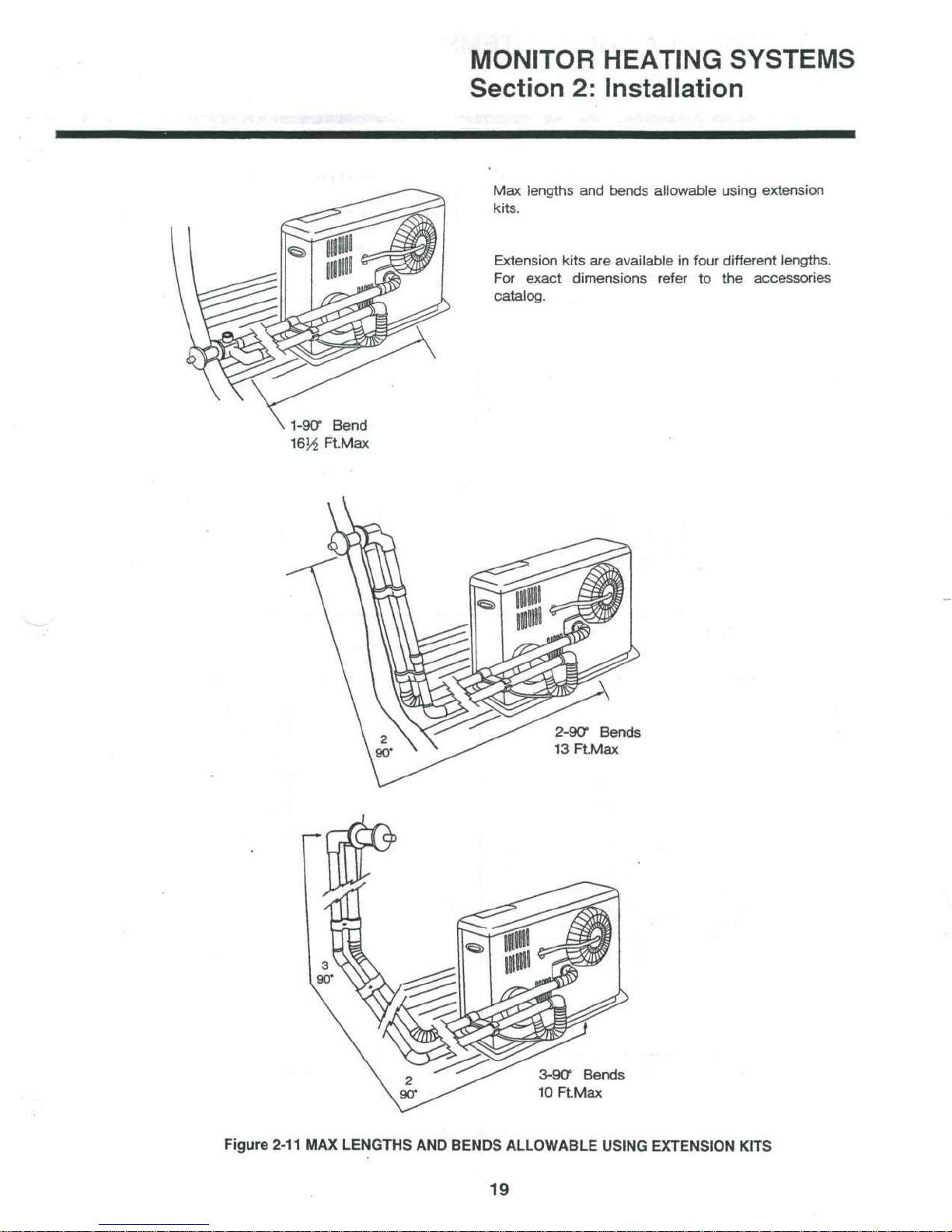

Max

lengths

and

bends

allowable

using extension

kits.

Extension

kits

are

available

in

four different

lengths.

For

exact

dimensions

refer

to the

accessories

catalog.

1-90° Bend

FtMax

3-90°

Bends

10

FtMax

Figure

2-11

MAX

LENGTHS

AND

BENDS

ALLOWABLE

USING EXTENSION KITS

19

MONITOR

HEATING SYSTEMS

Section

2:

Installation

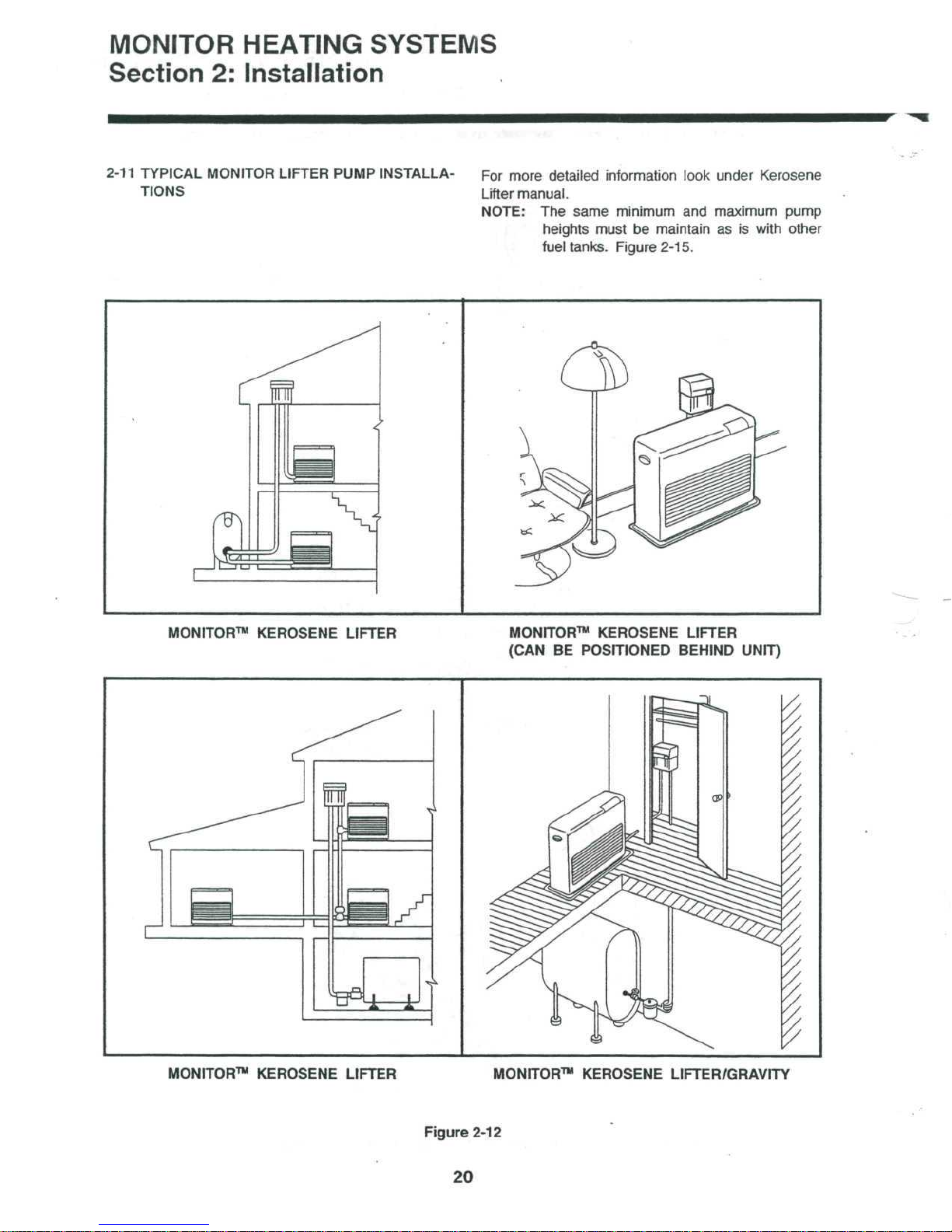

2-11 TYPICAL MONITOR LIFTER PUMP INSTALLA-

TIONS

For

more

detailed

information look under Kerosene

Lifter

manual.

NOTE:

The

same

minimum

and

maximum

pump

heights

must

be

maintain

as is

with other

fuel

tanks.

Figure

2-15.

MONITOR™

KEROSENE LIFTER

MONITOR™ KEROSENE LIFTER

(CAN

BE

POSITIONED BEHIND

UNIT)

MONITOR™ KEROSENE LIFTER

MONITOR™ KEROSENE LIFTER/GRAVITY

Figure

2-12

20

MONITOR

HEATING

SYSTEMS

Section

2:

Installation

2-12

USES

FOR THE

ELBOW

ADAPTER

KIT

F

Convert

from

Monitor

20/30

to

2200/2400

using

an

elbow

adapter

Kit

(part#8213A)

and

utilizing

existing

flue

pipe

installation.

PARTS

UST

EXPLODED

Name

No

Ref.

of , in

No.

Part

Unit

1

Exhaust Pipe Clamp

2

Exhaust Elbow

1

3

Exhaust Joint

1

4

Joint

Supporter

1

5

Heat

Insulation

Cover

1

6

Self-Tapping Screws

2

7

Hose Clamp (this part comes

with

your

Monitor""

Heater)

8 Air

Damper (this part comes with

your

Monitor™

Heater)

9

Flue Pipe (this part comes with your

Monitor™ Heater)

A.

Remove Monitor

20/30

heater

and

flue

pipe.

B.

Install

Monitor

2200/2400

fluo

pipe

into

sleeve.

C.

Slide

the

exhaust elbow onto

the

exhaust port

opening

on the

rear

of the

heater.

(To

locate

exhaust

port

opening,

see

your Monitor

Owner'

s

Guide.)

D.

Secure

the

exhaust elbow

by

attaching

the

exhaust

pipe clamp

to the

heater cabinet

with

two

self-tapping screws.

E.

Cover

the

adjustable exhaust

pipe

with heat

insulation

cover.

Remove

metal

cap on

side mounted

exhaust

port

of

flue pipe

and

replace into

the

port.

NOTE:

Be

sure

the

exhaust elbow

is

firmly

fixed

on

the

flue

pipe with a joint supporter.

G.

Insert

air

supply elbow opening

over

flue pipe

air

intake flange

and

secure with hose clamp.

NOTE:

The

Standard

Air

Damper

is

installed

over

the

flue pipe "air intake flange."

(To

locate

flue

pipe

"air

intake

flange",

see

your

Monitor™ Owner's Guide.)

Elbow

adapter kits

may

also

be

used

to

raise a flue

pipe high enough

to

clear certain base board heat-

ing

systems.

2-13 FUEL

TANK

INSTALLATION

Pictorial

views

of

alternative types

of

storage facil-

ities

and

delivery

systems

are

illustrated

(Figure

2-15).

Since fuel storage tank

installation