Page 1

Page 2

“In developing Platinum we’ve created the definitive

Monitor Audio loudspeaker. There is no finer

expression of the dedication to sound quality, design

and engineering that has driven our adventure and

innovation for over three decades. We’ve proved once

again that there is no preconception that cannot be

challenged, no rule beyond question. By refining new

materials and technologies, we’re getting closer to

perfection.”

Dean Hartley

Technical Director

Page 3

T e c h n i c a l E x p e r t i s e

I n n o v a t i o n

S u p e r i o r D e s i g n

P e r f o r m a n c e

P r i d e o f O w n e r s h i p

Page 4

S P R E Z Z A T U R A

Famous for his ‘Il Libro Del Cortegiano’ (The Book of

the Courtier, 1528), Renaissance humanist Baldesar

Castiglione coined the word ‘sprezzatura’ to describe

the ideal for courtly behaviour. He insisted that in

order to be worthy, exceptional virtuosity should be

conveyed with an unaffected, effortless dignity. In

essence, sprezzatura is the art of making something

difficult look easy.

Created from the finest materials and complex

technologies, our superlative Platinum loudspeakers

are a sophisticated blend of craftsmanship and

science, but make music so gracefully that it sounds

naturally effortless.

Page 5

Page 6

A U D I T I O N

Introducing genuinely esoteric yet affordable

performance and quality, Monitor Audio’s Platinum

loudspeakers are engineered to achieve the most

natural sound possible. In our quest for true

fidelity, we’ve harnessed new materials, developed

innovative new technologies, tested, refined and

optimised every last design detail, and verified the

science with plenty of good old-fashioned listening.

Every component part is produced to exacting

standards and each speaker is carefully hand-built

by our small team of technicians. The new Platinum

Series represents the epitome of British design and

quality, demonstrating Monitor Audio’s devotion

to music and film sound reproduction.

Page 7

Page 8

C r a f t s m a n s h i p

a n d Q u a l i t y

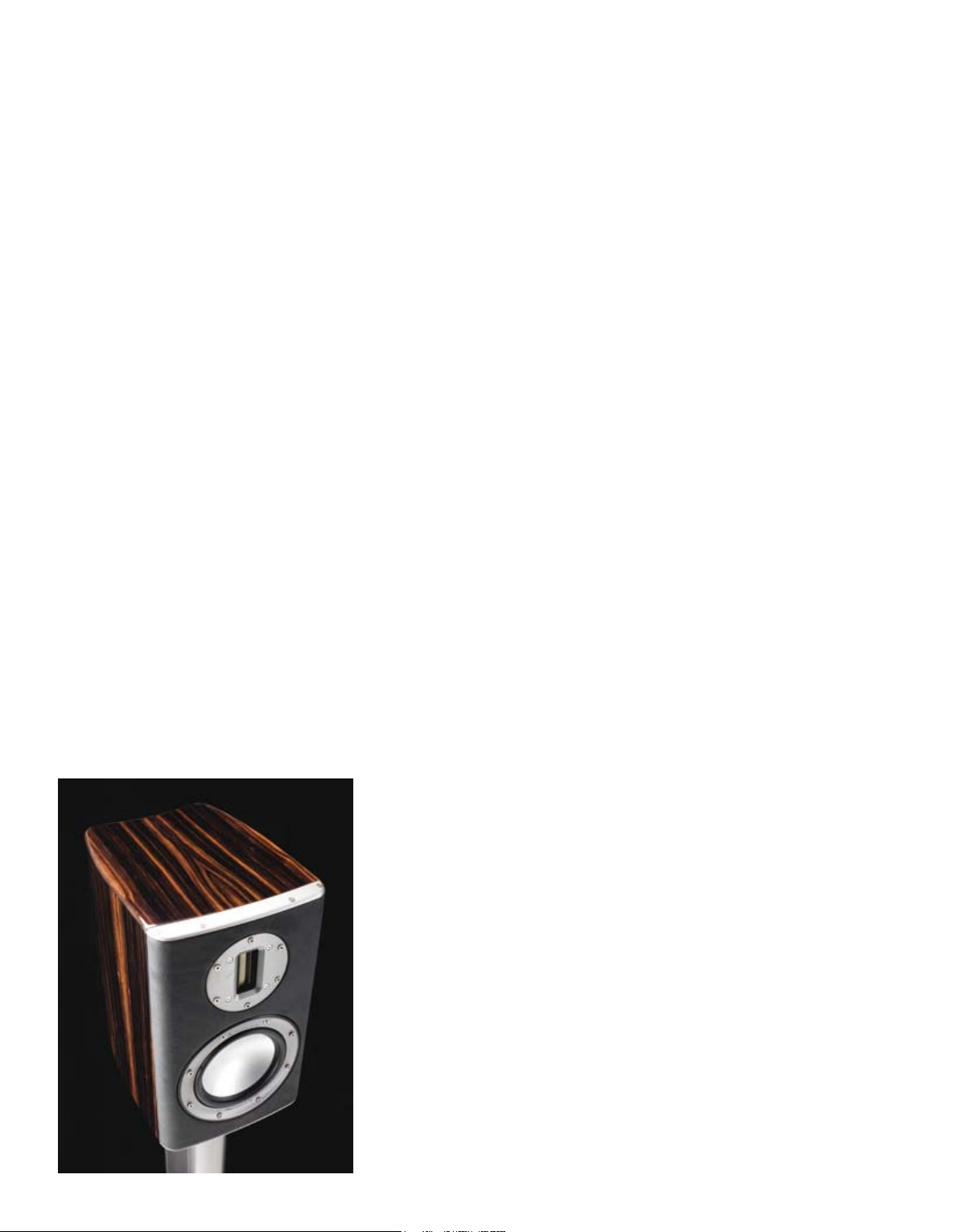

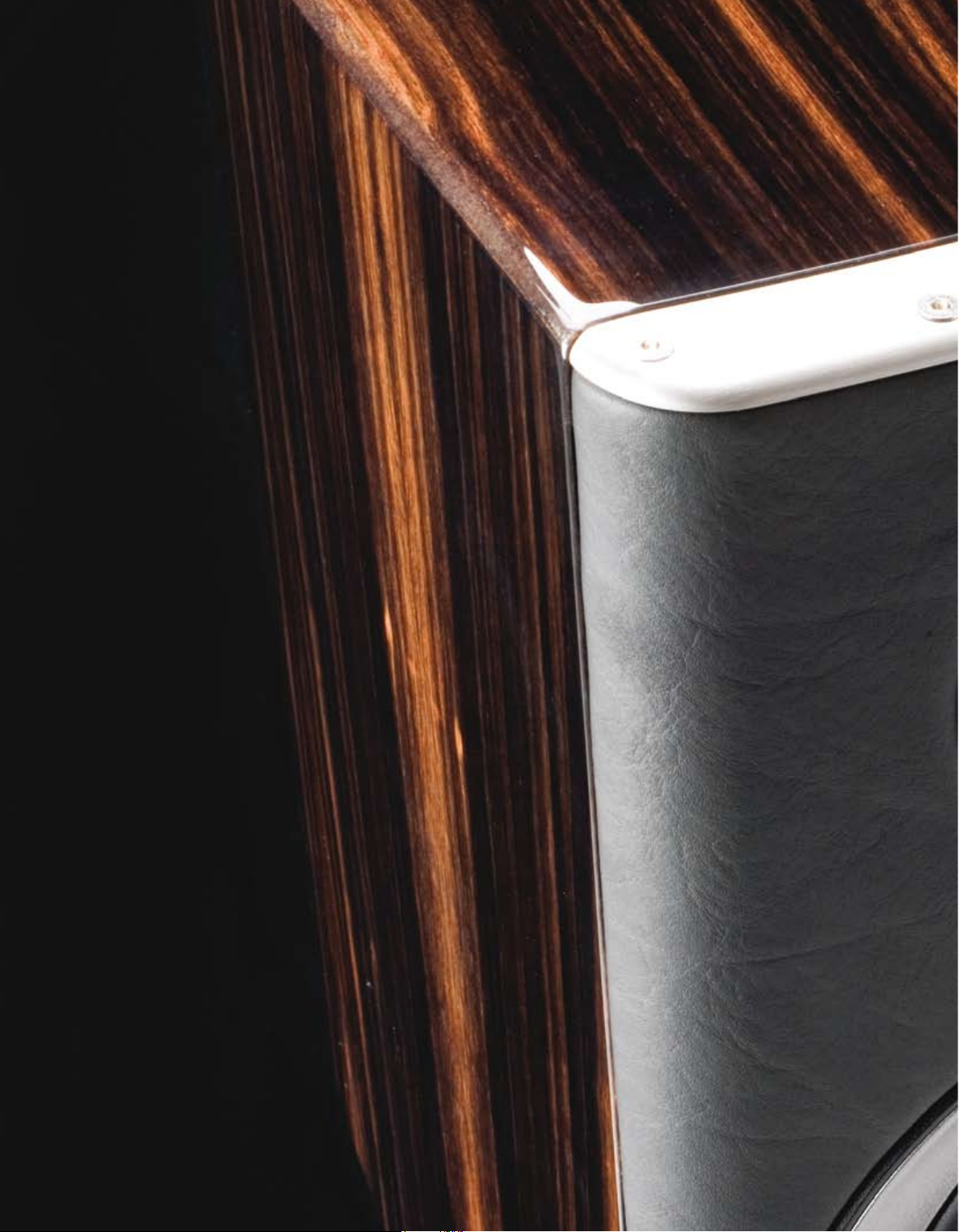

Each pair of Platinum loudspeakers is an original

work of art. Monitor Audio’s cabinet makers hand

select uniquely matching sets of exotic natural wood

veneer in Santos Rosewood or Ebony for every pair.

The veneers are applied by hand after the cabinet

is made to ensure that the grain match is precise

and that no joints are visible. After meticulous

inspection, no fewer than eleven layers of clear gloss

piano lacquer are applied to enhance the exquisite

grain definition and rich variety of colour within each

veneer.

The front baffles are hand-upholstered using

Strathspey leather supplied by Andrew Muirhead.

Strathspey’s natural leather is of the very highest

quality and is associated with many respected

British brands from the furniture, automotive and

marine industries. It conveys a tactile sense of luxury

which blends with the lustrous beauty of Platinum’s

lacquered veneer finishes to impart an immediate

impression of excellence in any room, however lavish

its décor.

Platinum promises a depth of beauty, quality and

performance that will inspire an intense pride of

ownership in lovers of music and design.

Page 9

Page 10

T e c h n o l o g i e s

Ceramic-Coated Aluminium/Magnesium (C-CAM®)

Since 1972, Monitor Audio’s near fanatical

commitment to excellence and innovation has

received global recognition and acclaim. When

we launched our R352MD loudspeaker - the first

model to incorporate a metal dome tweeter - it caused

quite a stir. Until that time, most metal domes were

single-metal types made from copper or titanium and

virtually all sounded unconvincing. The R352 used

an aluminium/magnesium alloy dome and sounded

significantly better and smoother than all of its

single-metal rivals. This radical design formed the

blueprint for successive generations of our C-CAM

metal domes.

All the radiating surfaces of the Platinum drivers are

formed from C-CAM, a material originally developed

by the aerospace industry for jet engine components.

Its properties are ideal for loudspeaker cones:

extremely rigid, yet light enough to yield high overall

efficiency. In manufacture, aluminium/magnesium

alloy undergoes stress-relieving processes to

remove surface deformation and molecular weakness.

Once formed, the alloy cone is subjected to a high

temperature anodic coating process, in which a

layer of pure ceramic alumina is depleted onto its

surfaces to give a completely rigid exterior.

Conventional cone materials are liable to flex or

twist in operation, producing a significant level of

audible distortion. C-CAM cones have a much higher

resistance to bending stress and therefore exhibit

much greater fidelity.

Page 11

Page 12

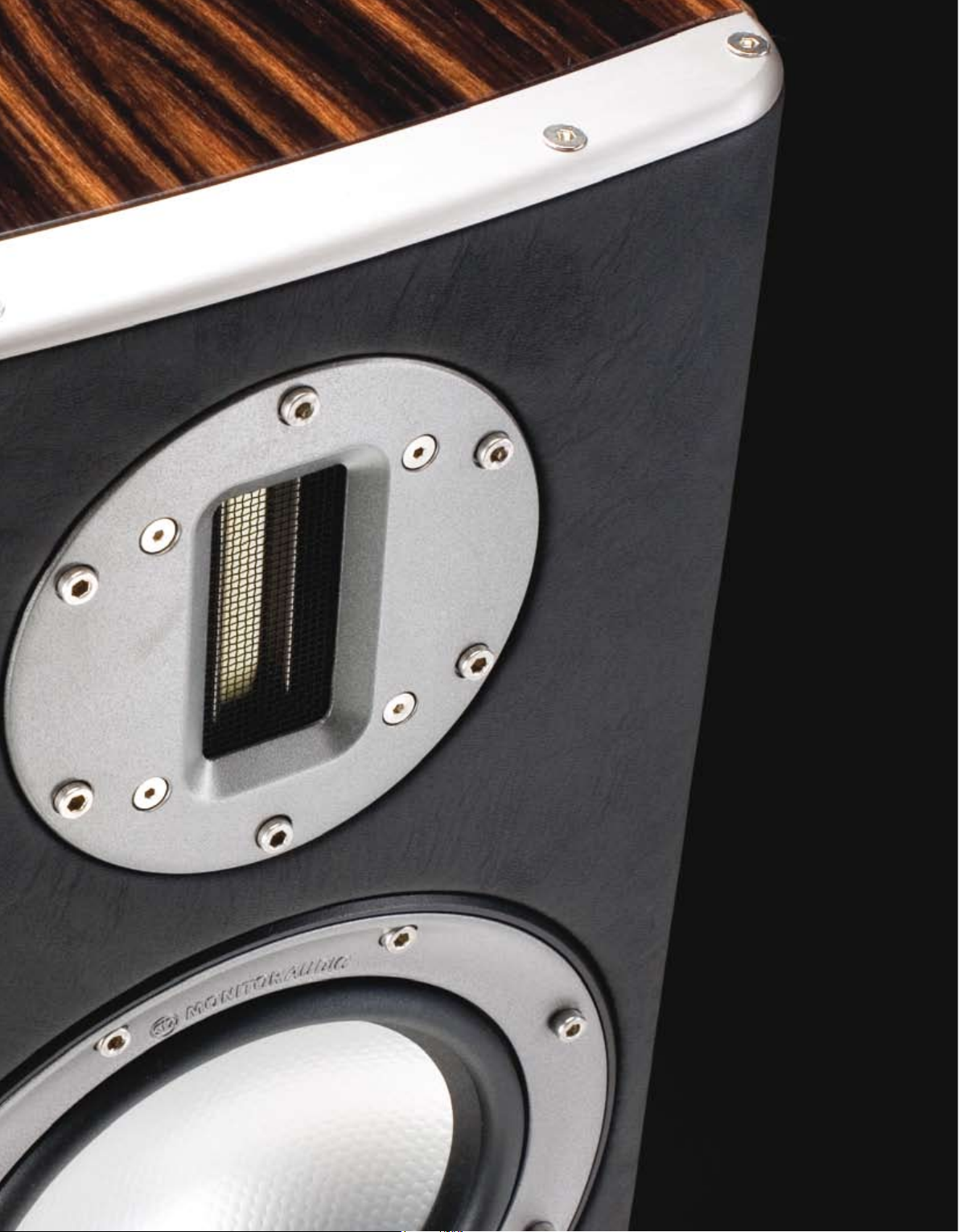

Platinum C-CAM high frequency ribbon transducer.

A pure ribbon tweeter is highly regarded in the world

of high-end audio as being the best way to reproduce

ultra-high frequencies and provide the most lifelike

transient response. While this belief is well supported

by fundamental physics, one listen will tell you that

this driver is very special indeed.

Platinum’s ribbon tweeter design uses an ultra-thin

sandwich of C-CAM alloy suspended in a powerful

transverse magnetic field of high energy NeFeB rare

earth magnets. The ribbon serves as both voice coil

and radiating diaphragm, with every part of the ribbon

driven directly and simultaneously without energy

storage. Having a mass of just 18mg, its diaphragm

is able to start and stop in an instant, producing a

transient response capable of defining the leading

edge and natural harmonic resonance of complex

musical sounds. Specified to reach ultra-high

frequencies up to an elusive 100 kHz, Platinum’s

magical ribbon tweeter will reproduce with ease

every last nuance and detail from vinyl, CD, DVD-A

and SACD, together with the wider bandwidth of

HD-DVD and Blu-ray.

Page 13

Page 14

Rigid Diaphragm Technology (RDT®) mid-range and

bass drivers

Bass and mid-range driver cones use RDT, a unique

technology developed specifically by Monitor Audio’s

engineers for the Platinum series of loudspeakers*.

Designed to reduce mass and increase cone stiffness,

RDT applies ultra-thin skins of C-CAM to a core of

honeycomb Nomex®** material, creating a structure

which is extremely light but incredibly rigid. At only

40μm thick, the C-CAM skins are half the thickness

of a human hair, yet when bonded to the hexagonal

honeycomb core they form an RDT cone, which is 150

times more rigid than a single layer of 200μm C-CAM

alloy, but has a fraction of the overall mass. These

properties allow the cone to operate as a lightning-

fast piston for a clearer more natural sound. The

cone’s new concave geometry has been refined by FEA

analysis to provide a smooth frequency response and

eradicate break-up.

To optimise the performance of the RDT cone,

Monitor Audio has developed motor systems in

which a focused magnetic gap and copper eddy

rings work together to produce a higher level of

linearity and lower distortion than was previously

possible. Magnet plates and poles are CNC machined

to very precise standards, ensuring consistency.

The Platinum mid-range driver utilises an ‘under hung’

voice coil design to further optimise linearity and

reduce distortion. High energy NeFeB rare earth

magnets are used for high efficiency, and a large

2” (50mm) voice coil is specified to handle powerful

dynamic impulses. Its RDT cone is driven directly

by the voice coil to provide an extremely articulate

mid-range response and seamless integration

with the other drivers.

Platinum’s bass drivers use long-throw voice coil

windings for long excursions at high power levels,

giving deeper, more controlled and potent bass.

The larger 8” (200mm) drivers employ dual spider

arrangements for extra stability. Their direct-drive

RDT cones have no dust cap or joints to interfere

with the driver response over the working band.

* PLW-15’s driver is C-CAM only

** Nomex® is a registered trademark of E.I DuPont de

Nemours and Company

Page 15

Page 16

Anti-Resonance Composite (ARC) baffles, plinths and

mid-range driver housings

The front baffles, plinths and mid-range driver

housings for the Platinum series of loudspeakers

are cast from ARC material, a thermo-set polymer

loaded with minerals to provide very inert,

optimally-damped components. Refined for Platinum

by Monitor Audio’s engineers, this type of material

is used for leading-edge automotive design and is

ideal for acoustic applications where a high degree

of structural rigidity and vibration damping is

required. ARC material is cast to form a Tapered Line

Enclosure (TLE) for Platinum’s mid-range drivers.

The TLE is designed to prevent the propagation of

standing waves and modal resonances.

HiVe® II High Velocity reflex port

Platinum employs a new type of port technology,

which uses a straight rifled design to accelerate air

flow and reduce turbulence. HiVe II technology has

the ability to move air in and out of the cabinet more

quickly than a conventional port, bringing powerful

bass and a superior transient response.

Page 17

HiVe II (High Velocity reflex port)

TLE (Tapered Line Enclosure)

ARC (Anti-Resonance Composite)

ARC (Anti-Resonance Composite)

Page 18

Cabinet construction

The cabinets are of multiple laminations of wood

veneer in a rigid plywood-type construction shaped

to form a one piece shell. Internally, the sides are

non-regular, preventing the formation of standing

waves, which undermine the accuracy of the system.

Monitor Audio has developed a unique ‘pin-hole’

bracing structure for the Platinum series, positioned

to provide rigidity and integrity. Cabinet bracing is

further enhanced by steel bolts that tie front and

back panels to the ‘pin-hole’ brace and are tightened

to a specific torque in order to tune out undesirable

resonances. Bitumastic damping material is applied

to all internal cabinet walls to produce a heightened

level of resonance damping.

Every last detail

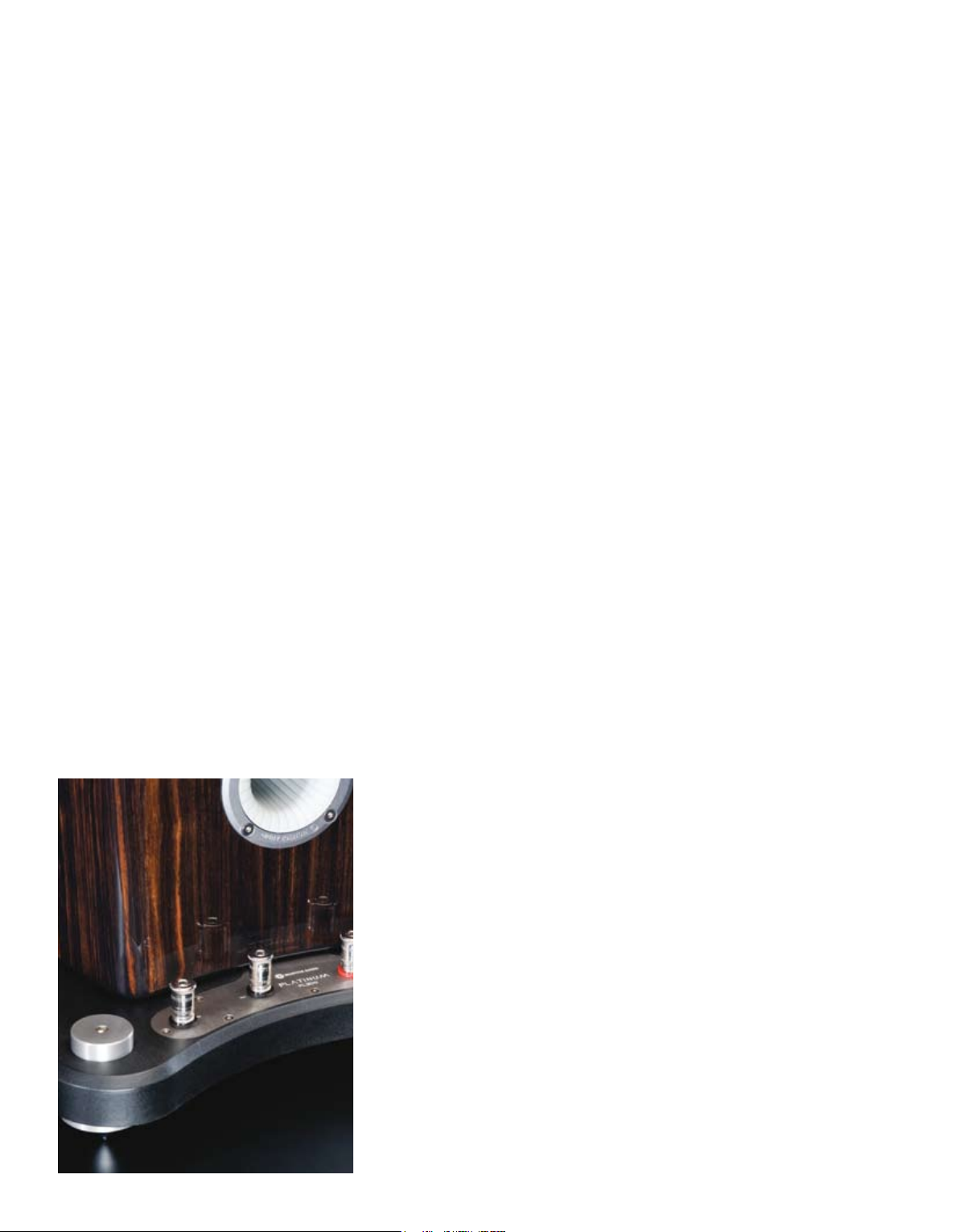

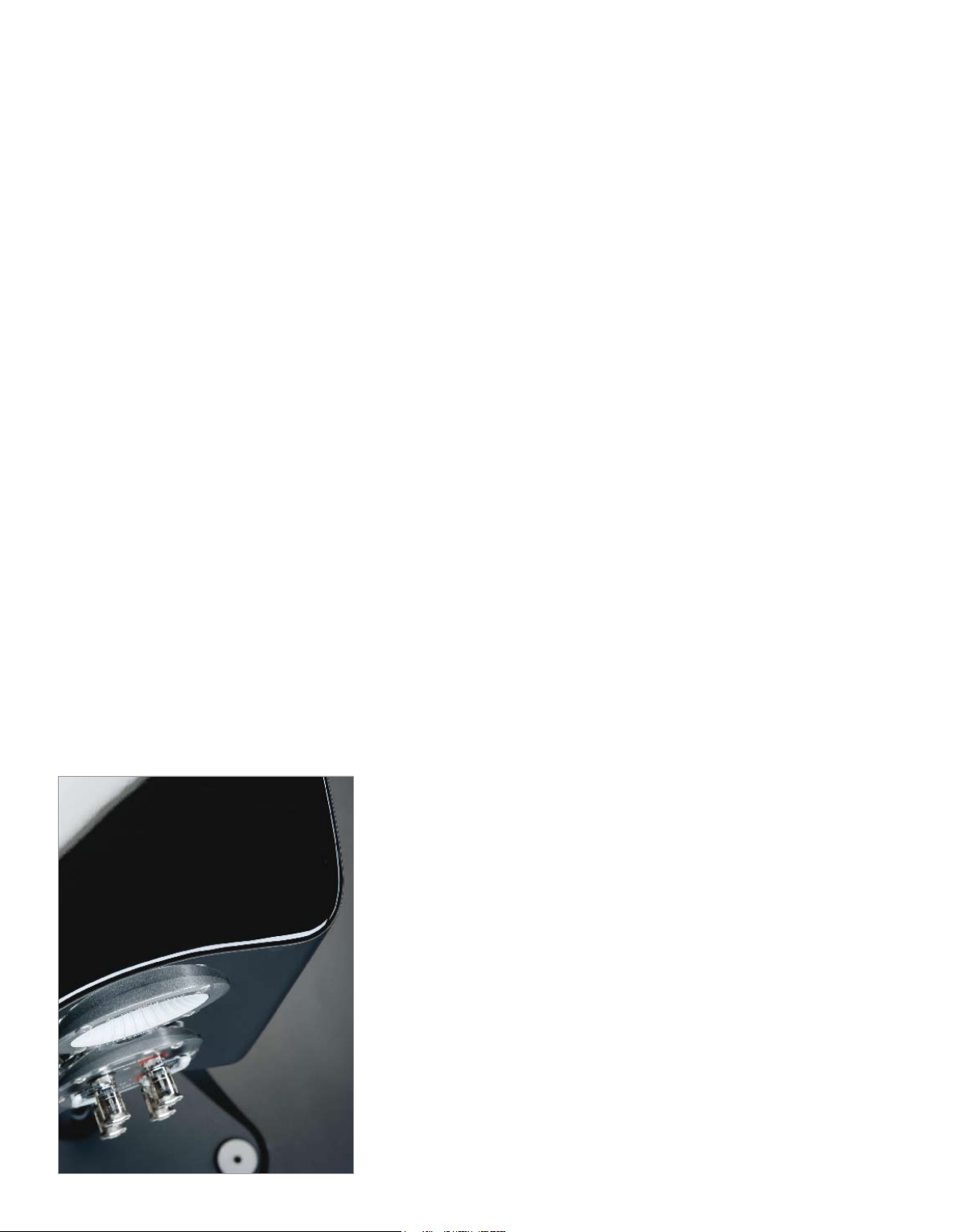

WBT* Platinum signature Binding Pots are

considered to be of the highest quality available.

Precision-machined and plated with pure platinum,

they offer a very low contact resistance and the best

possible reliability. Featuring accurate fine-pitch

adjustment, the terminals are suitable for heavy

duty cables with spade, 4mm plug or bare wire

connections.

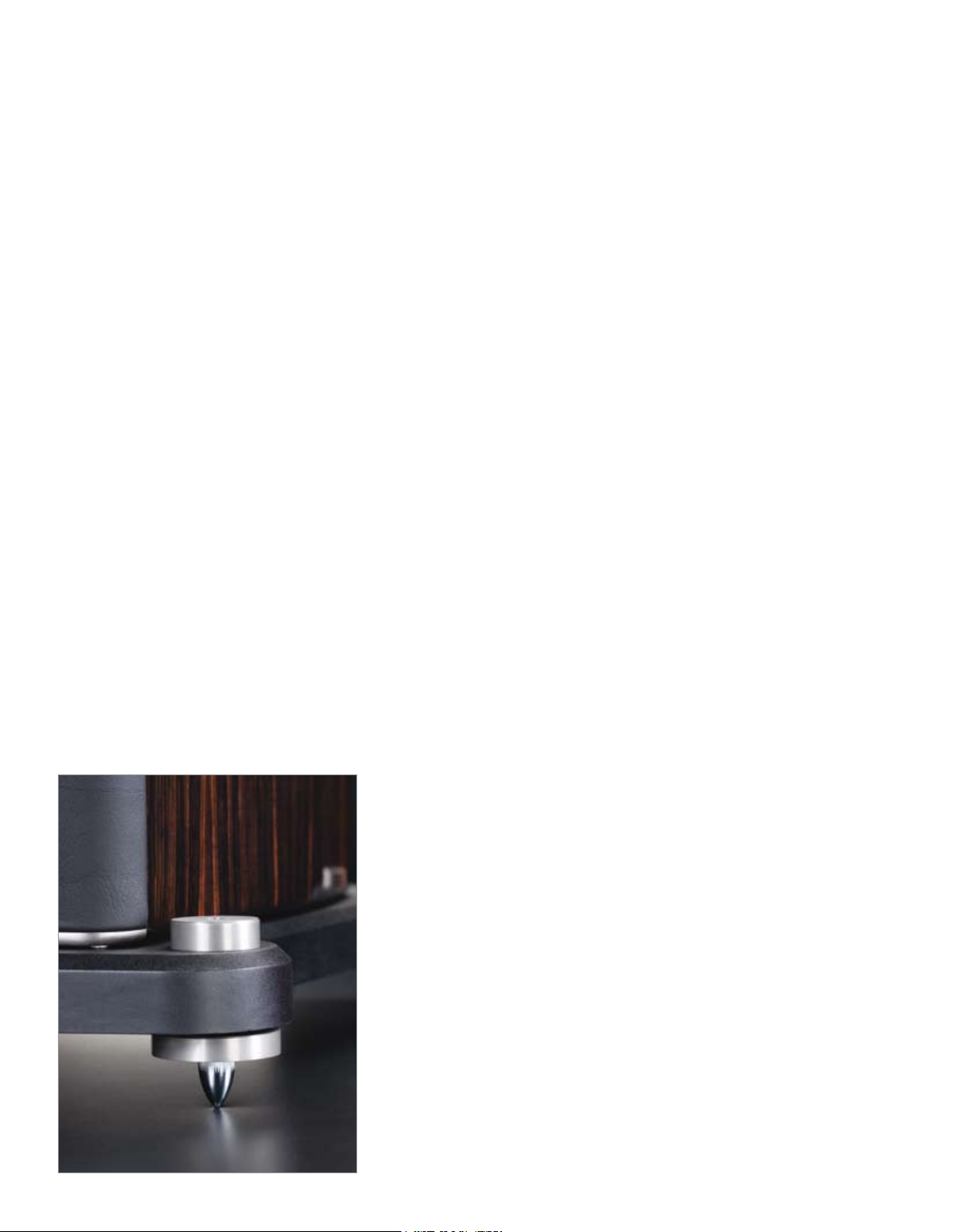

To provide a secure contact with the floor,

adjustable spiked feet are used. Machined to the

finest tolerances from high-grade alloy and anodised

to the most exacting standards, the feet accept

‘bullet’ spikes of high-tensile steel, chrome-plated

to a mirror finish. For hard or solid wood flooring,

a non-slip rubber pad is integrated with the foot

design.

* WBT Trademark of WBT GMbh, Germany

Page 19

Page 20

P L 1 0 0

A compact two-way loudspeaker featuring one

6.5” (165mm) RDT bass-mid driver and C-CAM

ribbon transducer. The PL100 has the superior

bass definition and detailed mid-range response

of the most accurate studio monitors; and its

ability to generate the deepest bass frequencies

will redefine expectations of a small speaker. A

rigid cabinet construction, proprietary bracing

techniques and advanced damping technologies

combine to provide the optimum environment

for its ultra-low distortion drivers. The PL100’s

C-CAM ribbon tweeter extends way beyond

the auditory threshold to reveal the ultra-high

harmonic frequencies that are part of the

natural spectrum of sound. Consistency of

phase is secured by the lightning-fast RDT bass

driver, which reproduces the power and scale of

dramatic passages with a breathtaking fidelity.

The PL100 is a wideband speaker capable of

expressing the entire micro-dynamic texture

of every performance, drawing a rich, natural

radiance from the most demanding of music and

film scores. Optional, dedicated floor stands

are available, which can be bolted directly to

the PL100 cabinet for increased stability and

performance. The PL100 stand allows for an

increased level of tilt to facilitate set up and

positioning.

Page 21

Page 22

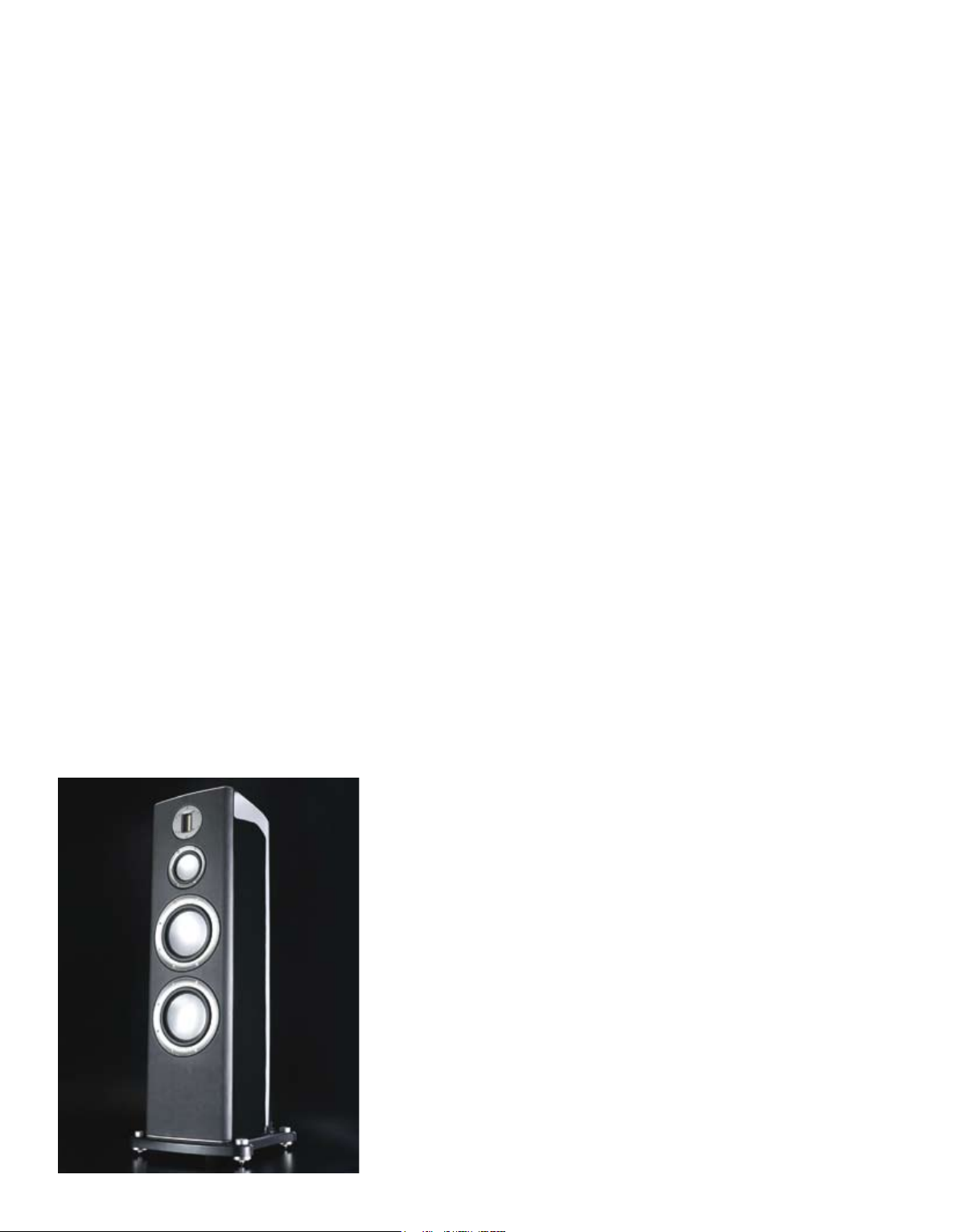

P L 3 0 0

Standing at nearly 1.2m tall, the PL300 is a

majestic three-way floor standing loudspeaker

comprising two 8” (200mm) RDT bass drivers,

one 4” (100mm) RDT mid-range driver and a

C-CAM high frequency ribbon transducer. It

possesses the ability to generate the power

and scale required to fill a larger room with

awe-inspiring sound. Jaw-dropping dynamics,

combined with supreme agility give the

PL300 the power to paint the widest and most

luminous of sonic pictures. Through the

application of advanced technologies, the

sound is neutral, lifelike and totally refined.

With a range from 28Hz to 100kHz, the PL300

is a true wide bandwidth speaker system which

is unrivalled in its class. Between 550Hz and

4kHz, the PL300’s ultra-light and rigid RDT

mid-range driver operates with lightning-fast

precision to provide an utterly lucid transient

response, aided by its dedicated, proprietary

Tapered Line Enclosure (TLE). Precision cast

from ARC material, the TLE provides a very

inert chamber, whose shape is designed to

prevent the formation of standing waves.

Rubber isolation materials decouple the

chamber from the surrounding cabinet to

inhibit the release of residual energy. Below

the mid-range transducer, the PL300’s twin

RDT bass drivers are engineered for long

excursions with extremely low signal

distortion. Even at high power levels the

PL300 will remain free from any signs of

distortion or fatigue to deliver a sound of

immense potency and integrity. Further

evidence of Platinum’s no compromise

design philosophy is revealed by the

‘outboard’ location of the PL300’s crossover,

which is mounted in the cast ARC plinth to

eliminate magnetic interference and provide

acoustic de-coupling from the speaker itself.

The ARC plinth also houses the bi-wire WBT

terminals and offers convenient floor level

access.

Page 23

Page 24

P L C 3 5 0

PLC350 is a substantial three–way, four driver

centre channel speaker with the same driver

complement as the PL300. Armed with the

drivers and technologies of the Platinum series,

the PLC350 is able to illuminate frequencies

from 32Hz to 100 kHz - arguably the widest

bandwidth of any centre speaker available.

A purely neutral tonal balance in concert

with vanishingly low distortion and cabinet

colouration make it perfect for reproducing

crystal clear dialogue. Furthermore, given that

at least sixty per cent of the information

generated by a home theatre system is

reproduced by the centre channel speaker, the

value of having as accomplished a design as

the PLC350 in the role cannot be exaggerated.

For a seamless transition of audio within the

front soundstage of a Platinum home

theatre system, the PLC350’s tonal character

and performance matches perfectly with that

of the PL300, to generate a truly immersive,

dynamic and enriching multichannel experience.

A dedicated two pillar stand for the PLC350 is

available to provide straight or tilted positioning

for optimum set up.

Page 25

Page 26

P L W - 1 5

Underpinning the drama and scintillating

musical vitality of a Platinum multichannel

speaker system is the PLW-15, a range-

matching sub-bass engine endowed with all

the quality, virtuosity and excellence that

defines the marque. Capable of releasing the

deepest frequencies recorded on disc, the

PLW-15 will drive performances of music and

film with an utterly breathtaking authority. Its

15” (381mm) long-throw C-CAM driver is triple-

suspended in a rigid die-cast alloy chassis. A

massive double-stack magnet motor system

with a 4” (101.6mm) voice coil provides the

ultimate linearity and control required to

reproduce the clean seismic 16Hz tones that

you feel more than you hear. Powered by the

staggering continuous force of 1000 watts from

the onboard Class D amplifier, the driver has

the speed and integrity to complement the

performance of its range counterparts, creating

the foundation for a seamless wideband sound

field, rich in natural dynamism, texture and

tonality.

With the convenience of remote control, the

PLW-15’s subterranean potency can be

fine-tuned to the loudspeaker system using

sophisticated digital filters, and to room

acoustics with a range of advanced DSP

adjustments, including a ten band parametric

EQ and no fewer than four preset EQ positions.

Its response can be optimised to meet the

specific demands of music and film sound

through individual input settings.

The PLW-15’s talent for room-matching is

also expressed by the lustre of its beautifully

compact curvaceous cabinet, resplendent in a

choice of Platinum veneers and radially braced

and damped to enhance structural integrity.

Blending power and finesse with superb

aesthetics, the PLW-15 introduces a sensational

new dimension to the experience of sound in

the home, which celebrates the raw energy and

compelling quality of genuinely deep bass.

Page 27

Page 28

MODEL PL100

Frequency Response 42Hz - 100kHz

Sensitivity (1W@1m). dB 88

Nominal Impedance. ohms 4

Maximum S.P.L dBA (per pair) 112.6

Power Handling (RMS) watts 120

Recommended Amplier Requirements (RMS) watts 50-120

Bass Alignment Ported. HiVe® II technology

Mid/ H.F Crossover Frequency 2800Hz

Bass Low Pass Crossover Frequency N/A

Drive Unit Complement 1 x 6.5” RDT® Bass/mid-range driver

1 x C-CAM® high frequency ribbon transducer

External Dimensions - Excluding Stand Height: 370mm (14 9/16 inches)

Width: 225mm (8 7/8 inches)

Depth: 285mm (11 1/4 inches)

Weight (each) 13 Kg (28.6lbs)

Stand External Dimensions Height: 615mm (24 3/16 inches)

Width: 340mm (13 3/8 inches)

Depth: 365mm (14 3/8 inches)

Finishes Available 1. Santos Rosewood veneer with clear gloss piano lacquer

2. Ebony veneer with clear gloss piano lacquer

3. Piano black gloss

All cabinet nishes have hand-upholstered front bafes in Black Strathspey

premium grade leather by Andrew Muirhead

1.

GENUINE LEATHER

2.

3.

Page 29

MODEL PL300

Frequency Response 28Hz - 100kHz

Sensitivity (1W@1m). dB 90

Nominal Impedance. ohms 4

Maximum S.P.L dBA (per pair) 118.6

Power Handling (RMS) watts 300

Recommended Amplier Requirements (RMS) watts 100-300

Bass Alignment Twin Ported HiVe® II technology

Sealed Mid-range TLE®

Mid/ H.F Crossover Frequency 4000Hz

Bass Low Pass Crossover Frequency 550Hz

Drive Unit Complement 2 x 8” long-throw RDT® bass drivers

1 x 4” RDT® mid-range driver

1 x C-CAM® high frequency ribbon transducer

External Dimensions – Including Fixed Plinth & Feet Height: 1113mm (43 13/16 inches)

Width: 410mm (16 1/8 inches)

Depth: 470 mm (18 1/2 inches)

Weight (each) Including Plinth 43.8 Kg (96.4 lbs)

Finishes Available 1. Santos Rosewood veneer with clear gloss piano lacquer

2. Ebony veneer with clear gloss piano lacquer

3. Piano black gloss

All cabinet nishes have hand-upholstered front bafes in Black Strathspey

premium grade leather by Andrew Muirhead

1.

GENUINE LEATHER

2.

3.

Page 30

MODEL PLC350

Frequency Response 32Hz- 100kHz

Sensitivity (1W@1m). dB 90

Nominal Impedance. ohms 4

Maximum S.P.L dBA (per pair) 117.8

Power Handling (RMS) watts 250

Recommended Amplier Requirements (RMS) watts 100-250

Bass Alignment Twin Ported HiVe®II technology

Sealed Mid-range TLE®

Mid/ H.F Crossover Frequency 4000Hz

Bass Low Pass Crossover Frequency 550Hz

Drive Unit Complement 2 x 8” long-throw RDT® bass drivers

1 x 4” RDT® mid-range driver

1 x C-CAM® high frequency ribbon transducer

External Dimensions - Excluding Stand Width: 800mm (31 1/2 inches)

Height: 288mm (11 5/16 inches)

Depth: 368mm (14 1/2 inches)

Weight 33.5 Kg (73.8 lbs)

Stand External Dimensions – Including Plinth & Feet Width: 610mm (24 inches)

Height: 335mm (13 13/16 inches)

Depth: 463mm (18 1/4 inches)

Finishes Available 1. Santos Rosewood veneer with clear gloss piano lacquer

2. Ebony veneer with clear gloss piano lacquer

3. Piano black gloss

All cabinet nishes have hand-upholstered front bafes in Black Strathspey

premium grade leather by Andrew Muirhead

1.

GENUINE LEATHER

2.

3.

Page 31

MODEL PLW-15

The PLW-15 subwoofer is scheduled to be introduced in 2008. All information and specications will be available on its release.

External Dimensions - Excluding Plinth. Width: 485mm (16 inches)

Height: 455mm (18 Inches)

Depth: 475mm (18 3/4 Inches)

Weight (each) Including Plinth 50 Kg (110 lbs)

Mains input Voltage 100 - 240 Vac (50 / 60 Factory Set)

Trigger Input 3.5mm Jack input, +12Vdc = On State

Finishes Available 1. Santos Rosewood veneer with clear gloss piano lacquer

2. Ebony veneer with clear gloss piano lacquer

3. Piano black gloss

1.

2.

3.

Page 32

Page 33

Page 34

Monitor Audio Ltd

24 Brook Road, Rayleigh

Essex, SS6 7XL

England

Tel: + 44 (0)1268 740580

Fax: + 44 (0)1268 740589

Email: info@monitoraudio.co.uk

monitoraudio.co.uk

Designed in the United Kingdom

Loading...

Loading...