INSTRUCTION MANUAL

Model CC-8946

Rev. 04.16

Magnetic Lock with

Display Panel

Moniteq, Inc.

2

INSTRUCTION MANUAL

Model CC-8946

Rev. 1.1

Magnetic Lock with Display Panel

Table of contents

1. Introduction 3

2. Specifications 4

3. Supplied equipment 5

4. Functions of controls and indicators 6

5. Installation 7

6. Operation 12

7. Theory of operation and troubleshooting 13

3

1. INTRODUCTION

The Model CC-8946 is a magnetic door lock with an integrated display panel intended for use on

doors that are monitored and controlled from a remote location. The unit includes a magnetic lock

rated at 1200lbs and a display panel that is readily viewed by personnel on the secure side of the door.

The display panel includes red, green and amber lamps that indicate the door status, and a key switch

that can be used to manually release the door. Internal tamper, magnetic bond, and door contact

switches are used to provide output status signals. All connections to the CC-8946 are made via an

attached 20 ft. cable. The integration of the display panel with the magnetic lock simplifies the

installation by eliminating the multiple cables required when installing separate magnetic locks, door

contacts and a display panel. The CC-8946’s cable is typically connected to a terminal block which in

turn is connected to a door control module located within a security information center (SIC).

The CC-8946 can be used in new installations and to retrofit existing installations presently equipped

with a separate magnetic lock and display panel.

4

2. SPECIFICATIONS

Operating Voltage: 24Vdc

Magnetic lock:

Holding force: 1200 lbs.

Operating Voltage: 24Vdc

Operating Current: 290 mA

Display Panel:

Indicator lamps: Replaceable LEDs

Key switch: Medico high security cylinder w/two keys

Internal Functions:

Tamper switch

Magnetic door contact switch

Dual Magnetic bond sensing switches

Piezo-electric audible alarm

Lamp/alarm test switch

Dimensions

Magnetic lock with display panel: 14.0” W x 2.0”H x 4.25”D

Magnet armature: 10.0” W x 1.74” H x 0.625”D

Supplied cable: 20 ft., 15-conductor., #22

5

3. SUPPLIED EQUIPMENT

QTY

ITEM

PURPOSE

1

Magnetic Lock with

Display Panel

Mounts on the door header to secure the door and display

the door status

Magnetic Armature

Mounts on the door so as to align with and bond to the

magnetic lock when the door is secured.

1

Mounting Template

Used to accurately locate both the Magnetic Lock and

Armature.

1

Sex bolt/nut and roll pin

kit

Used to mount the Armature to the door

1

Mounting screw kit

Used to mount Magnetic Lock with Display Panel to the

door frame

2

Key for key switch

Used to manually release the magnetic lock using the key

switch on the Display Panel

1

Instruction Manual

Installation, operation and troubleshooting instructions

The CC-8946 consists of the Magnetic Lock with Display Panel, Magnetic Armature and various

accessories and mounting hardware to facilitate installation. The table below lists all of the items

that comprise the Model CC-8946 along with a brief description of each to aid in identification

and use.

6

4. FUNCTIONS OF CONTROLS AND

INDICATORS

The functions of the items on the display panel are described below:

Key switch - Used to release the magnetic lock by momentarily turning the key clockwise. The

key cannot be removed in this released position.

Red Lamp - Indicates that the door is open. (Controlled by the internal door contact switch.)

Green Lamp – Indicates that the door is secured (controlled by the internal magnetic bond

sensor switch.)

Amber Lamp - Indicates that the door is not secure (controlled by the internal magnetic bond

sensor switch and the control module in the SIC). When flashing, indicates that the push bar has

been pressed and that the countdown timer (typically set to 15 seconds) has been activated.

Audible Alarm - When sounding continuously indicates that the tamper switch within the CC8946 has opened. (controlled by the internal tamper switch and by the control module in the

SIC.) When sounding on-and-off indicates that the push bar has been pressed and that the 15

second count down timer has been activated. When sounding continuously indicates that the

unit’s cover has been opened.

Test switch - When pressed illuminates all three indicator lamps and sounds the audible alarm

and the corresponding items on the Control Module in the SIC. (Accessed using a paper clip or

similar item through the small hole located near the center of the underside of the Display Panel.)

7

5. INSTALLATION

Installation of the CC-8946 consists of mounting the Magnetic Lock/Display Panel and the

Armature, and then connecting the attached cable (via a terminal block) to the cable that runs to

the associated Door Control Module.

5.1 Mechanical Installation

Figure 5-1, Elevation View

READ THOROUGHLY BEFORE INSTALLING

Handle electro-magnets and armatures carefully. Any damage to the mating surfaces may

significantly reduce holding efficiency.

The Electro-magnet assembly mounts firmly and rigidly to the underside of the header on the

stop side of the door. The armature mounts to the face of the door with special hardware for

proper floating action to assure total mating with the face of the electro-magnet.

Note from the supplied template that a 2-1/2” minimum reveal is required to assure rigid

mounting of the electro-magnet assembly. If this minimum is not met see Fig. 1 to determine the

need for either a filler Plate or an angle bracket.

Mark the door and frame for drilling in accordance with the supplied template dimensions. All

measurements are to be made with the door in the closed position.

Follow this 4-step mounting process:

8

STEP 1 - FRAME PREPARATION

Remove the housing cover prior to lock installation (see Figure 5-5 Exploded View). Prepare the

frame for the electro-magnetic lock assembly by drilling for #14 sheet metal screws or drilling

and tapping for 1/4-20 machine screws and external tooth lock washers, (use the large slotted

holes only) tightening the screws just enough to hold unit in place. Route the attached 20 ft.

cable through the frame to the location where it will be connected to the cable going to the SIC.

STEP 2 - ARMATURE PREPARATION (Figure 3)

Prepare armature for mounting: Note that the armature has two 3/16 dia. holes open from the back

only. Press the two spring pins provided into these holes. Tap pins gently until they are firmly seated

in the holes being extremely careful not to mar the face of the armature.

Insert one spring washer on the 5/16 #18 shoulder screw and then insert the screw thru the armature.

Add three conical spring washers over shoulder and flat stop washer. (Per diagram enclosed in

armature kit.)

STEP 3 - ARMATURE MOUNTING

THRU BOLT MOUNTING IN HOLLOW METAL DOORS (Figure 5-2A)

(Dimensions shown are for standard 1-3/4” thick doors)

Drill an 11/32” hole through the door. Enlarge the hole in the outside face to ½” for the knurled sex

nut. Be sure that the spring pins pocket and float freely in the ¼” holes in the door. If not, remove the

armature and enlarge the holes in the door. Insert the shoulder screw/armature assembly thru the face

of the door, being sure that the spring washers remain over the shoulder, and hold firmly against the

door by pushing directly on the head of screw. Insert the sex nut from the opposite face and assemble.

When the armature is floating freely, tighten the 5/16 #18 shoulder screw fully and securely with a

5/32 Allen wrench.

THRU BOLT MOUNTING IN SOLID CORE WOODEN DOOR (Figure 5-2B)

Drill a ½” hole through the door. Insert the shoulder screw/armature assembly thru the face of the

door, being sure that spring washers remain over the shoulder, and hold firmly against the door by

pushing directly on the head of the screw. Insert the sex nut from the opposite face and assemble.

When the armature is floating freely, tighten the 5/16 #18 shoulder screw fully and securely with a

5/32 Allen wrench.

MACHINE SCREW MOUNTING (Figure 5-2C)

The door must be properly reinforced to a 3/8” minimum thickness and structured for a 1200 lb. load.

Drill and tap thru the reinforcing for a 1/15 #18 machine screw. Insert the shoulder screw/armature

assembly, being sure that the spring washers remain over the shoulder and the flat washer is between

the shoulder and the face of door. When the armature is floating freely, tighten the 5/16 #18 shoulder

screw fully and securely with a 5/32 Allen wrench.

9

STEP 4 - LOCK & ARMATURE ALIGNMENT

figure 2-A

HOLLOW

METAL

DOOR

1-3/4"

figure 2-B

WOOD

DOOR

figure 2-C

Min. 3/8"

Reinforcing

REINFORCED

DOOR

ROLL PINS

DOOR

ARMATURE

DRILL 1/4" DIA . 1/2" DEE P

INTO DOOR FOR ROLL PINS

figure 3

TAP 2 ROLL PINS INTO HOLES IN ARMATURE.

MAKING SURE PINS BOTTOM OUT IN HOLES

Figure 5-2A

Figure 5-2B

Figure 5-2C

Figure 5-3

With the electro-magnet energized and the armature fully engaged, position the Lock so that the door

is snug against stops and then tighten the #14 Sheet Metal Screws or the ¼ #20 machine screws

securely.

Using the 3/16” dia. holes in the mounting plate behind the electro-magnet as a physical template, drill

two .159 dia. holes (# 21 drill) and tap the frame for # 10/32 machine screws, or drill two 11/64” dia.

holes in the frame for # 190 sheet metal screws. Secure the mounting plate with the #10 screws and

lock washers.

THE USE OF THESE #10 SCREWS IS IMPORTANT, as they provide resistance to shear rotation

and assure maximum system holding efficiency of the system.

10

VIO

GRY

BLU

GRN

YEL

ORG

RED

BRN

BLK

Common

+24Vdc

Push Bar Switch

WHT

Red Lamp

Green Lamp

Yellow Lamp

Buzzer

3 kOhm Sense

Lock Power In

Terminal

block at door

(Not supplied)

RED/BLK

RED/YEL

RED/GRN

ALPHA 1181/15C cable

(20 ft. supplied)

Push Bar

Switch (N/C)

Direct to magnet

N/C

Common

Magnetic Bond

Status Output

Relay

N/O

2

1

3

4

5

6

8

7

9

10

PAIR

11

12

13

14

PAIRPAIRPAIRPAIRPAIR

15

16

Cable to Control

Module

BLK

WHT

RED

BLK

YEL

BLK

BLU

GRN

BLK

BLK

BRN

BLK

Not used

CC-8946

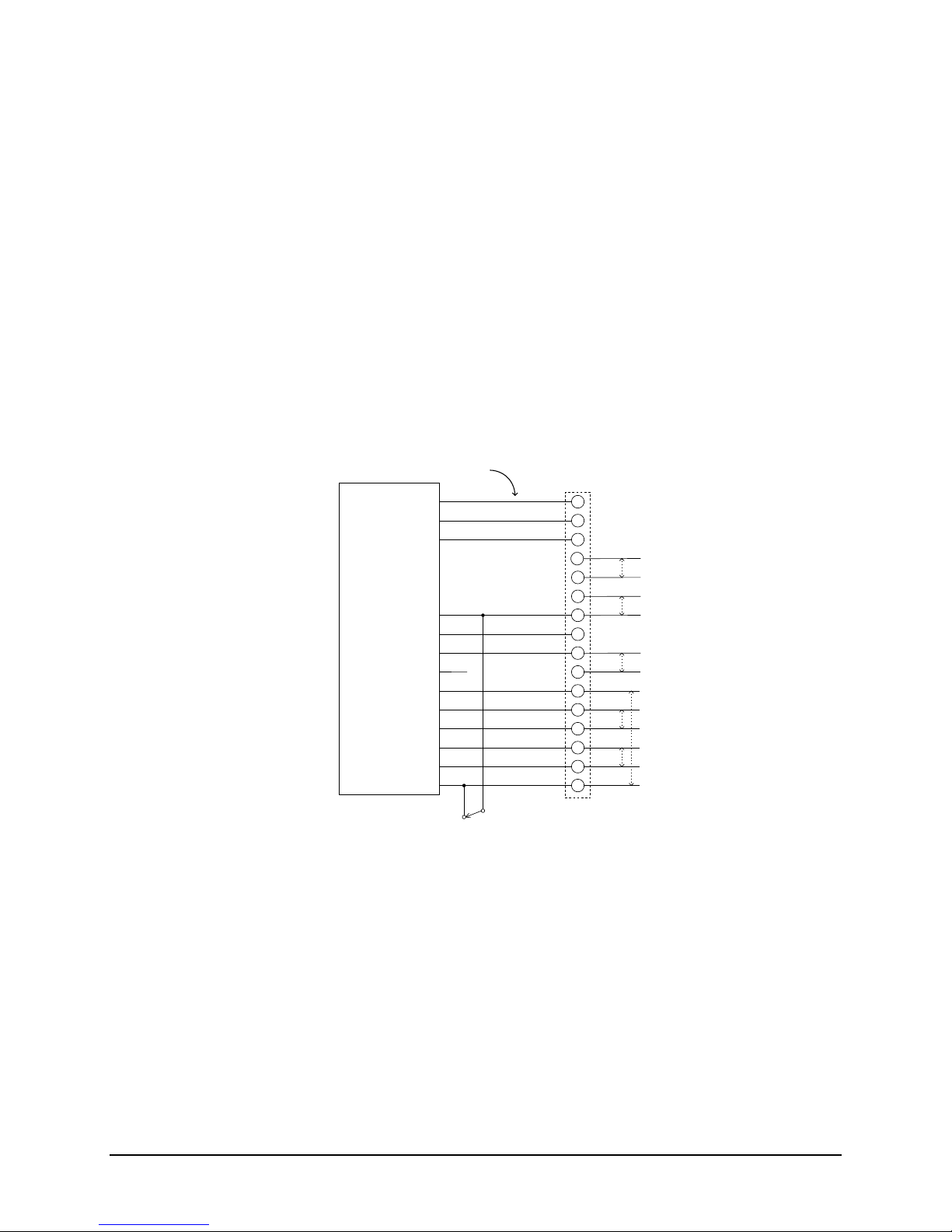

5.2 Electrical Installation

All external connections to the CC-8946 are made through the attached 15-conductor cable. The

supplied cable is 20 ft. long and may be cut as necessary. A terminal block within or near the

door frame is normally used to interconnect the CC-8946 with the cable that connects with the

associated Door Control Module in the SIC.

The diagram below illustrates a typical interconnection using a 16-position terminal block. Note

that the wire colors shown for the cable that connects to the Door Control Module are typical and

may be different in any particular installation.

Figure 5-4, Interconnection Wiring Diagram

Check the installation and alignment of the armature and electro-magnet by opening and closing

door while energizing and de-energizing the electromagnet. The armature mounting surface must

be in full contact with the top and bottom rails of electro-magnet, with the center line of armature

slightly above the center line of the magnet as shown on elevation profile drawings. When all

checks out satisfactory, replace the housing cover.

Figure 5-4, Interconnection Wiring Diagram

Figure 5-4, Interconnection Wiring Diagram

11

Figure 5-5, Exploded View of the CC-8946

12

6. OPERATION

General

During normal operation the CC-8946 remains in a Secure Mode until someone requests egress

by pressing on the Push Bar. This causes a timing sequence to begin which when completed,

releases the door. An operator stationed at the SIC may intervene at any time by using controls

on the Control Module associated with that door.

Secure Mode

The CC-8946 is normally in the Secure Mode. In this mode the Green and Amber lamps are on,

indicating that the door is closed and the magnet is bonded to the armature.

Egress Request Mode

When an individual presses the push bar a signal is sent from the CC-8946 to the control module

in the SIC. The control module then begins a timing sequence, typically 15 seconds long. The

amber lamp begins flashing and the audible alarm sounds an on-off pattern. The duration of the

Egress Request Mode is set within the control module.

Released Mode

Upon completion of the Egress Request Mode the Control Module removes the power to the

magnetic lock, releasing the door. The door may then be opened to provide egress. When the

door re-closes the system returns to the Secure Mode.

Operator Intervention

The operator at the SIC may intervene at any time using controls on the Control Module to

change the sequence of events. Refer to the documentation for the Control Module for details.

13

7. THEORY OF OPERATION AND

TROUBLESHOOTING

General

The CC-8946 operates together with a Control Module located in a Security Information Center

(SIC). Figure 7-1 is a schematic diagram of the Model CC-8946 showing the interconnections to

the Control Module in the SIC. It is supplied as an aid to understanding both the operation of the

CC-8946 itself and its connections to the Control Module.

Power to the magnetic lock is routed from the Control Module through T1, Pin 8, then through

the Key Switch S5 to the magnet.

Sensors within the CC-8946 monitor the status of the door, magnetic lock and push bar and route

this information to the control unit through T1 and the interconnecting cable. The Control

Module uses this information to control the magnetic lock and the status of the indicator lamps

and audible alarm on the CC-8946’s display panel.

Indicators and Audible Alarm

The three indicator lamps and the audible alarm all have one side connected to +24 Vdc from Pin

2 of T1. The other side of each device is controlled by both external connections to the Control

Module and by sensing switches within the CC-8946.

The Red lamp is controlled by the internal Door Switch (S4). When the door is open this switch

is closed, connecting the common return path to the red lamp.

The Green and Amber lamps are connected to the Magnetic Bond Switch S3. When the magnet

is energized and bonded to the armature, S3 connects the common return path to the Green lamp

L2. When the magnet and armature are not bonded, S3 connects the common return path to the

Amber lamp L3. The Control Module may also activate the Amber Lamp L3 by applying the

common return path through T1, Pin 5. This occurs during the Egress Request Mode.

Fuse F1 protects the magnetic bond reed switches against currents in excess of 200mA. These

reed switches are susceptible to damage if a voltage source is inadvertently applied during

installation. F1 automatically resets itself after the voltage causing the excess current to be

removed.

The Audible Alarm B1 is controlled by the Tamper Switch S2 and by the Control Module

through T1, Pin 6. The Tamper Switch S2 connects the common return path to B1 when the

cover of the CC-8946 is removed.

Test Switch - Applies the common return path to all three lamps and B1 (through diodes D3,

D4, D5 and D6). This provides a means of testing the lamps and audible alarm. Note that this test

also activates the lamps and audible alarm on the Control Module.

Relay K1 - is controlled by the power to the magnet and its contacts shunt the external push bar

switch when the magnet is energized.

14

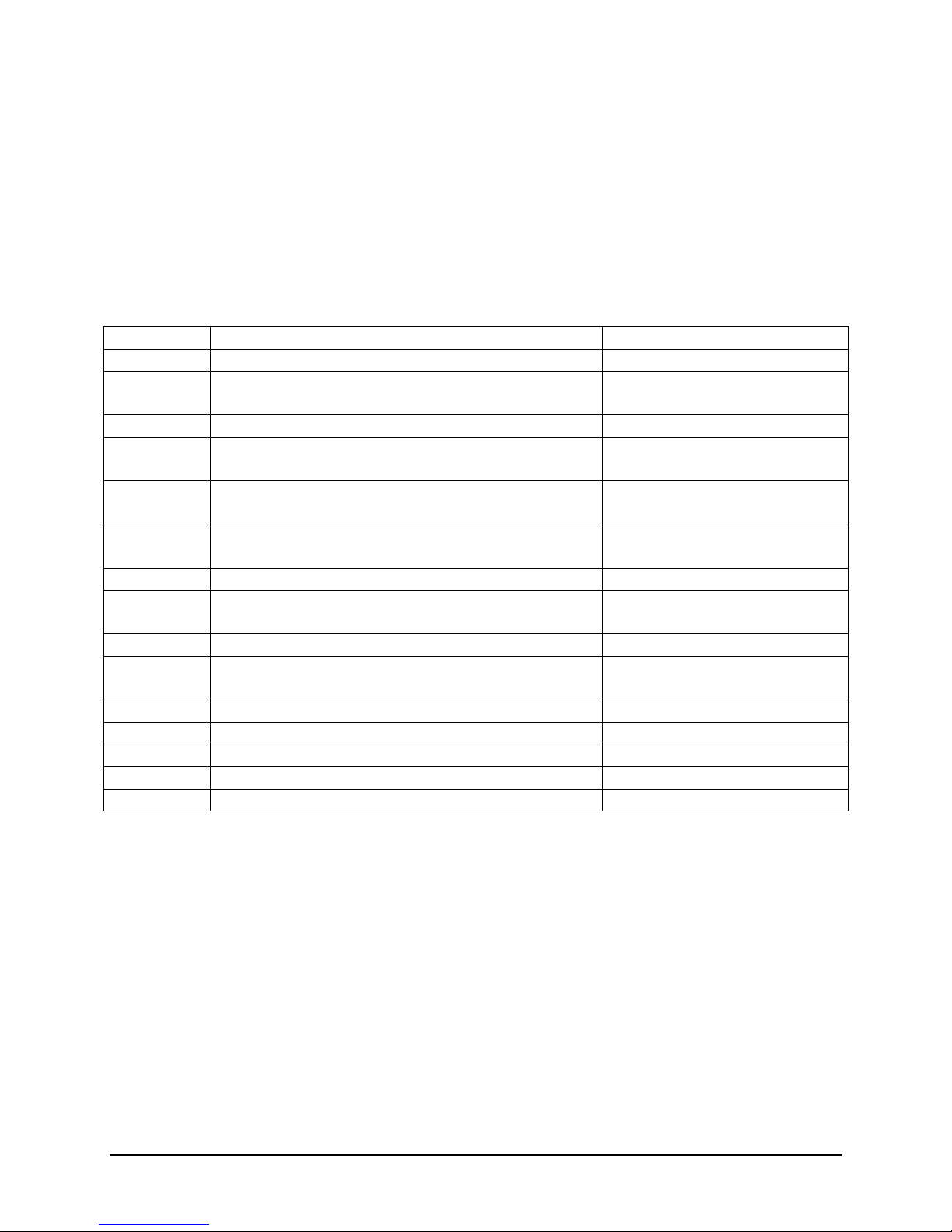

Wire Color

Function

Signal status in Secure Mode

Brown

Common reference for all signals

0 Vdc

Red

Fixed +24 Vdc supply voltage from control

module

+24 Vdc

Orange

Red lamp, controlled by internal door switch

0 Vdc

Yellow

Green lamp, controlled by internal magnetic bond

switch

0 Vdc

Green

Yellow lamp, controlled by internal magnetic

bond switch and control module

+24 Vdc

Blue

Audible alarm, controlled by internal tamper

switch and control module

+24Vdc

Violet

3kohn supervised door switch output

3kohm

Gray

Switched +24 Vdc magnet power from the

control module

+24 Vdc

White

Direct input to magnet, Not used

n/a

Black

Push bar switch output, controlled by push bar

and relay K1

0 Vdc

Red/Black

MBS Status Output - Common relay contact

Connected to Red/Green wire

Red/Yellow

MBS Status Output - N/C relay contact

Open

Red/Green

MBS Status Output - N/O relay contact

Connected to Red/Black wire

Pink

Spare

Gray

Spare

Relay K2 - is controlled by the Magnetic Bond Switch S3. The output contacts of K2 are

connected to the red/green, red/yellow and red/black wires in the interconnecting cable. These

outputs are intended for use with an external device such as an automatic door opener.

Electromagnet – The electromagnet operates on a nominal 24Vdc and draws approximately 300

mA when energized. Diode D8 is across the magnet terminals to suppress voltage spikes that can

be generated when the magnet de-energizes.

Table 2, Status of the Signals on the interconnecting cable in the Secure Mode.

15

Figure 7-1, Schematic and External Wiring

2

1

3

4

5

6

8

7

9

10

RED

GRN

AMB

BUZZ

BLK

BLK

24Vdc P.S.

+

-

GRN

BLU

BLK

YEL

WHT

11

2

1

3

4

5

6

8

7

9

10

Isolated Fire Control

Relay (if used)

Tamper

Switch

Mag. Bond

Switch

VIO

GRY

BLU

GRN

YEL

ORG

RED

BRN

BLK

WHT

GRN

RED

RED

BLK

WHT

Fire Bus

(24 Vdc)

SW2

K

2

Emerg.

Bus

(24Vdc)

AES 945

Note:

1. All switches and relays are shown

as when system is de-energized and

door is closed.

LE12/13/03

Common

+24Vdc

T1

2

1

3

4

5

6

8

7

R5

BEEP

B1

R

4

D2

D3

D4 D6D5

Test

S1

Mag Lock

2

1

T3

Push Bar Switch

RED

BLK

WHT

9

10

T2

WHT

Red Lamp

Green Lamp

Yellow

Lamp

Buzzer

3 kOhm Sense

Lock Power In

Medeco Key

Switch

PAIR

RED

Terminal

block at door

K1

D1

K2

D7

F1

MBS Status

Output

11

12

13

14

15

16

1

2

3

RED/BLK

RED/YEL

RED/GRN

BLK

BLK

BLK

BRN

Printed Circuit Board

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

P1J1

ALPHA 1181/15C cable

20 ft. supplied

PAIR

PAIR

PAIR

PAIR

PAIR

1 2 3

4 75 6 8

109

1 2 3

4 75 6 8

109

P1

J1

RED

GRN YEL

D8

Push Bar

Switch (N/C)

3k

1k

Door

Switch

16

MONITEQ Inc.

213 Church St.

Greensboro , MD 21639

Tel: 1-800-989-9891

1-410-827-8870

Fax: 1-703-549-1090

Email: info@moniteq.com

12/03-25

One Year Limited Warranty

MONITEQ products are warranted to be free from factory defects

for a period of one year from the date of shipment. The repair or

replacement of a defective part shall be at the option of the

factory when the product is shipped prepaid and insured by the

owner. This warranty is void in cases of abuse, misuse,

mishandling, or repair by unauthorized persons. This warranty is

given in lieu of all other warranties expressed or implied.

MONITEQ is not liable for incidental or consequential damages

resulting from the operation or failure of this product. The

warranty recognizes any and all rights you may have under

appropriate state law.

Loading...

Loading...