Page 1

PH Gas Logs

INSTALLATION

BEFORE FULLY INSTALLING THE UNIT:

Turn OFF the gas supply to the replace or re-

•

box.

• Seal any fresh air vents and/or ash clean-out doors

located on the oor or wall of the replace. If left

unsealed, drafting may cause pilot outage or soot-

ing. Use a heat resistant sealant. Do not seal the

chimney ue damper.

Before installing in a solid fuel burning

fireplace, The chimney flue and firebox

must be cleaned of soot, creosote, ashes

and loose paint by a qualified chimney

WARNING

cleaner.

INSTALLING VENTED APPLICATIONS

Manual and millivolt controlled gas logs may be installed as

a vented decorative log set in compliance with ANSI Z21.60

and National Fuel Gas Code, Section 6.6 Since, the gas

logs are operated with the damper open, non-combustible

material and minimum mantel requirements do not apply.

NOTE: The use of a thermostat is prohibited in vented log

applications.

This appliance is for installation only in a solid

fuel burning replace (masonry replace or

manufactured fireplace) with a working

ue and constructed of noncombustible

material.

Exception: DO NOT install this appliance

in a factory-built fireplace that includes

WARNING

instructions stating that it has not been

tested or should not be used with unvented

gas logs. This log set may be installed as a

vented log set.

BEFORE INSTALLING THE APPLIANCE:

• Turn off gas supply to replace or rebox.

• Have the replace oor and chimney professionally

cleaned to remove ashes, soot, creosote or other

obstructions. Have this cleaning performed annually

after installation.

• Seal any fresh air vents or ash clean-out doors lo-

cated on oor or wall of replace. If not, drafting may

cause pilot outage or sooting. Use a heat-resistant

sealant. Do not seal chimney ue damper.

Install and operate the appliance as directed in this

manual.

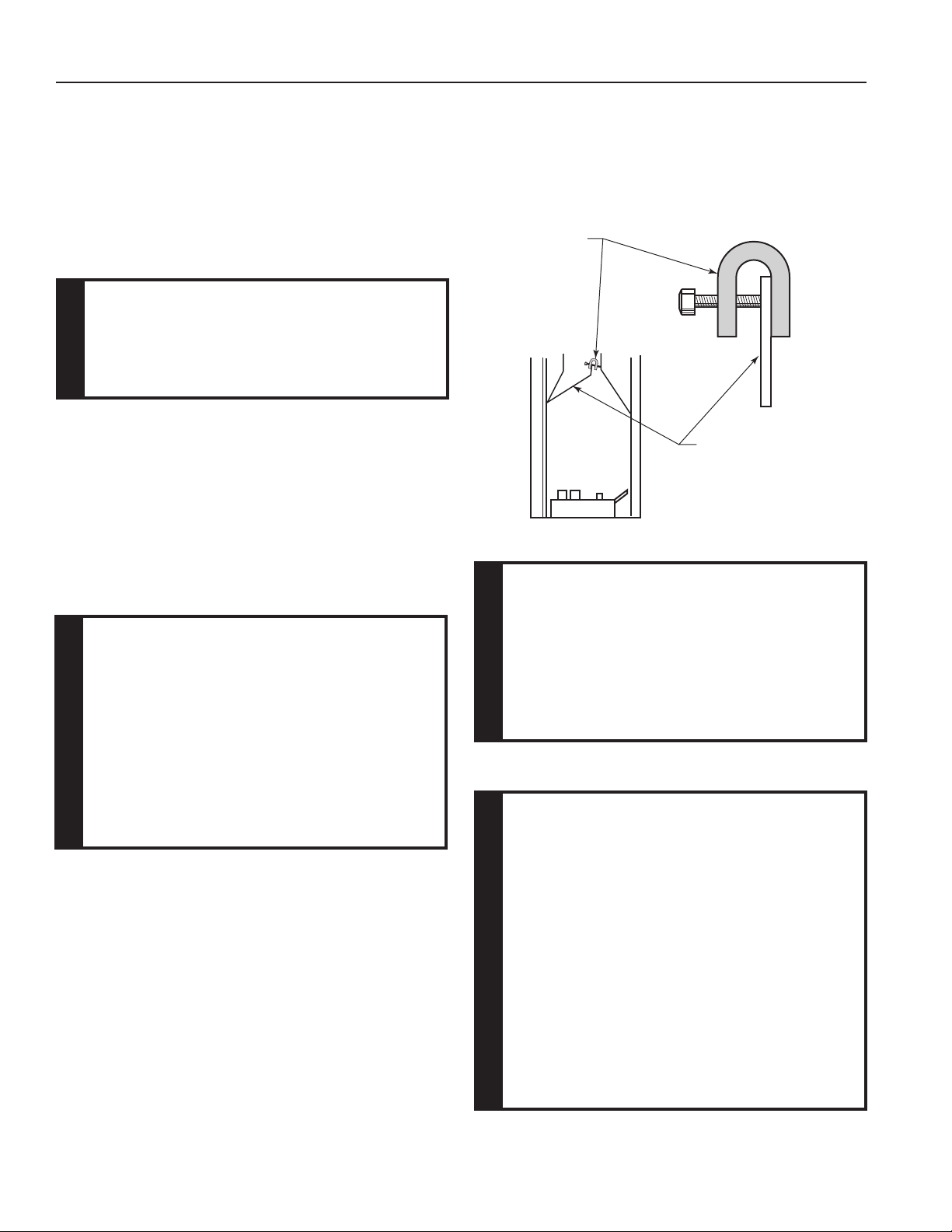

DAMPER STOP INSTALLATION:

A damper stop must be provided with the unit. Contact your

dealer to obtain one. The damper stop must be installed as

shown in Figure 11 to prevent full closure of the replace

damper blade and provide a minimum 29 square inch ue

opening.

Damper

Stop

Damper

FP2538

Figure 11 Damper Stop Installation

(See Warning)

The replace and gas logs function as a

system. If the replace is spilling into the

room (check with a match or a smoke stick),

reposition the damper clamp until a positive

draft is obtained by opening the damper. If

negative pressure in home prevents having

WARNING

a positive draft, contact your dealer for

assistance.

PLACE AND SECURE APPLIANCE

You must secure the gas log heater to

the replace oor. If not, the entire unit

may move when you adjust the controls.

Movement of unit may cause shifting of

the gas logs which leads to sooting and

improper burning.

Special care is required if you are installing

the unit into a sunken replace. You must

raise the replace oor to allow access to

WARNING

gas log controls. This will insure adequate

air ow and guard against sooting. Raise

the replace oor using noncombustible

materials, as described in Placement in a

Fireplace with Restrictive Barrier on Page

7.

12

Monessen • PH18/24 Installation/Owner's Manual • 65D2035 • Rev E • 01/19

Page 2

INSTALLATION

PH Gas Logs

ASSEMBLY PROCEDURE

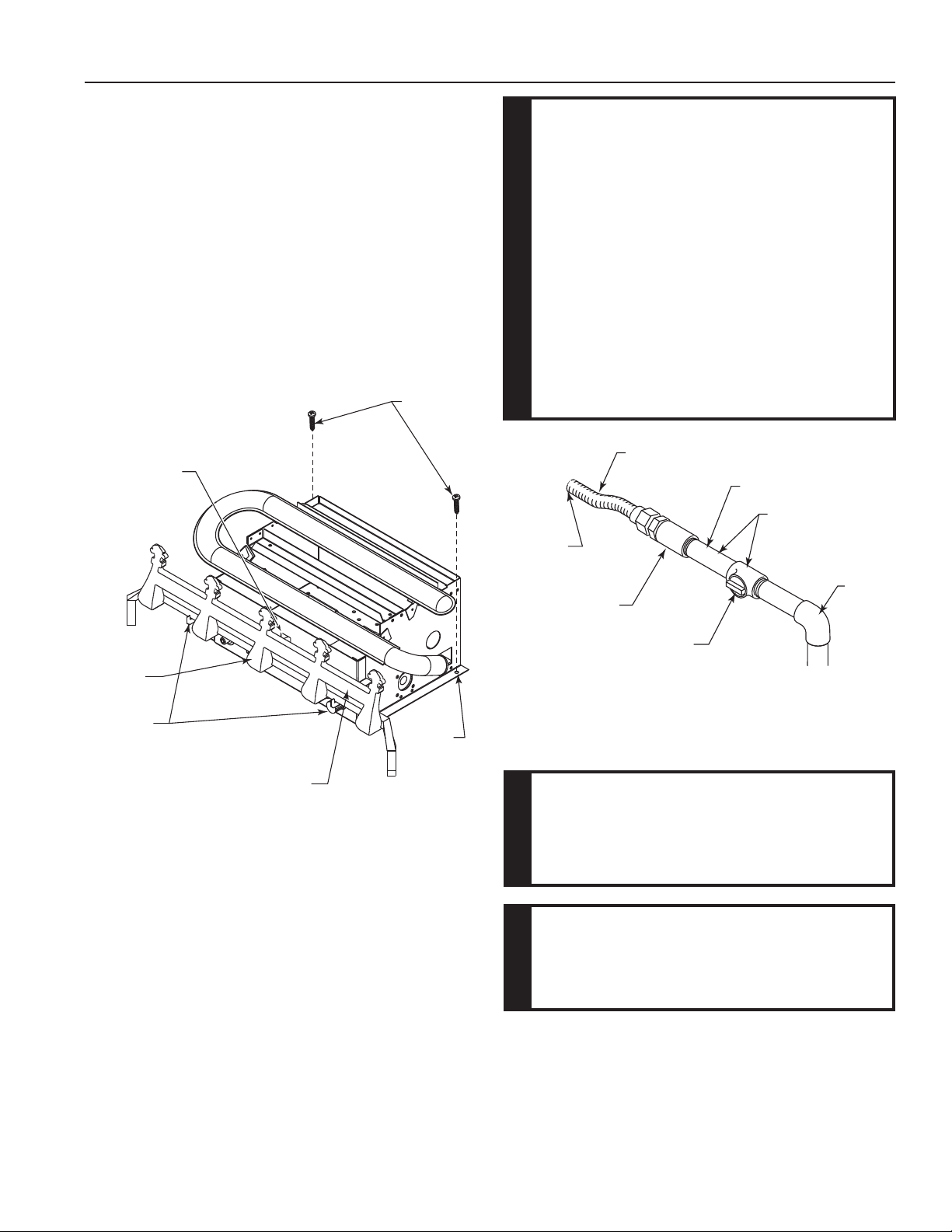

1. Center the gas log unit in the replace or rebox.

2. Install Grate: Insert longest middle grate bar in one of

the two square holes in control panel. Figure 12. Be sure

grate is centered. Sit horizontal bar inside two hooks

on front of control panel. Figure 12. Make certain front

feet of grate are located inside front edge of replace

or rebox.

3. Anchor holes are located on the ange of the unit. Figure

12. After centering the burner correctly, mark the hole

positions on the replace/rebox oor. Drill two (2) 5/32"

diameter holes approximately 11⁄2" deep.

4. Anchor the unit to the replace/rebox oor using the

screws provided. Figure 13.

Screws

Hole for

Grate Bar

Use new black iron or steel pipe. Internally

tinned copper or copper tubing can be

used per National Fuel Code, section 2.6.3,

providing gas meets hydrogen sulfide

limits, and where permitted by local codes.

Gas piping system must be sized to provide

minimum inlet pressure (Listed on Data

Plate) at the maximum ow rate (BTU/Hr).

Undue pressure loss will occur if the pipe

is too small.

CAUTION

A manual shutoff valve must be installed

upstream of the appliance. Union tee

and plugged 1/8" NPT pressure tapping

point should be installed upstream of the

appliance. Figure 13

Stainless

Flexible

Tube

To

Heater

Valve

Pipe

Possible Locations

for Pressure

Tapping Point

Middle

Grate Bar

Hooks for

Grate

Horizontal

Grate Bar

Figure 12 Install Grate and Secure Heater to Floor

of Fireplace/Firebox

Anchor

Hole

CONNECT THE GAS LINE

NOTICE: A qualied gas appliance installer must

connect the heater to the gas supply. Consult all local

codes.

Pipe

Coupling

Manual Shutoff

Valve

Figure 13 Gas Connection

Gas

Supply

Inlet

FP2371

IMPORTANT: Hold heater valve rmly with a wrench to

prevent movement when connecting to inlet pipe.

CHECK GAS TYPE: The gas supply must

be the same as stated on the heater’s rating plate. If the gas supply is different, DO

NOT INSTALL THE HEATER. Contact your

WARNING

dealer for the correct model.

Connecting directly to an unregulated propane/LPG tank can cause an explosion.

WARNING

Always use an external regulator for all propane/LPG

heaters and high pressure one to two-pound systems

only, to reduce the supply tank pressure to a maximum of

13" w.c. This is in addition to the internal regulator in the

heater valve.

Monessen • PH18/24 Installation/Owner's Manual • 65D2035 • Rev E • 01/19

13

Page 3

PH Gas Logs

INSTALLATION

CHECK GAS PRESSURE

The heater gas inlet connection is a 3/8" NPT at the valve.

All units have the inlet connection on the right side, when

you face the unit. To connect from the opposite side, route

the pipe under the rear portion of the unit.

When tightening up the joint to the valve, hold the valve

securely to prevent movement.

Test all gas joints from the gas meter to the heater valve

for leaks using a gas analyzer or soap and water solution

after completing connection. DO NOT USE AN OPEN

FLAME.

Check the gas pressure with the appliance burning and

the control set to HIGH.

MANUAL CONTROL

Figure 14

The pressure regulator is preset and locked to discourage tampering. If the pressure is not as specied,

replace the regulator with the correct part from the parts

list in this manual.

Remove 1/8" NPT plug, located on side of regulator body.

Install tting and tubing to pressure gauge. After taking

pressure reading, reinstall test plug. Check for gas leaks.

MILLIVOLT CONTROL

Figure 15

The valve regulator controls the burner pressure which

should be checked at the pressure test point.

Turn captured screw counter clockwise two or thre turns

and then place tubing to pressure gauge over test point

(Use test point “OUT” closest to control knob). After taking pressure reading, be sure and turn captured screw

clockwise rmly to re-seal. Do not over torque. Check for

gas leaks.

Test Port “Out”

FP2372

NPT Test Plug

Figure 14 Manual Control Pressure

Test Point Location

Figure 15 Millivolt Control Pressure

Test Point Location

FP2499

14

Monessen • PH18/24 Installation/Owner's Manual • 65D2035 • Rev E • 01/19

Loading...

Loading...