Monessen Hearth LO-RIDER LSTF36, LPF36, LO-RIDER LRCF36, LO-RIDER LLCF36, LO-RIDER LPF36 Installation And Operating Instructions Manual

Page 1

LO-RIDER

DESIGNER VENT-

FREE FIREBOXES

INST ALLATION AND OPERA TING

INSTRUCTIONS

MODELS: LSTF36, LPF36, LRCF36, LLCF36

If the information in this manual is not followed exactly , a fi re

or explosion may result causing property damage, personal

injury or loss of life.

WARNINGS

For use only with a listed gas-fi red

unvented decorative room heater

not to exceed 40,000 BTU/hr. DO

NOT BUILD A WOOD FIRE.

Carefully review the instructions

supplied with the decorative

type unvented room heater

for the minimum fi replace size

requirement.

DO NOT INST ALL AN APPLIANCE

IN THIS FIREBOX UNLESS THIS

FIREBOX MEETS THE MINIMUM

DIMENSIONS REQUIRED FOR

THE INSTALLATION.

READ AND SAVE THESE INSTRUCTIONS

– Do not store or use gasoline or other fl ammable vapors and

liquids in the vicinity of this or any other appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the

fi re department.

– Installation and service must be performed by a qualifi ed

installer, service agency or the gas supplier.

WARNING: Improper installation, adjustment, alteration, service

or maintenance can cause injury or property damage. Refer to

this manual. For assistance or additional information consult

a qualifi ed installer, service agency, or the gas supplier.

Page 2

CONTENTS

IMPORTANT SAFETY INFORMATION ................................................................................................. 3

PLANNING the INSTALLATION ............................................................................................................ 4

LOCATION of FIREBOX ........................................................................................................................ 5

CLEARANCES and HEIGHT REQUIREMENTS ................................................................................... 7

FIREPLACE FRAMING ........................................................................................................................ 9

FIREPLACE INSTALLATION ..............................................................................................................11

GAS LINE INSTALLATION .................................................................................................................. 14

CANOPY INSTALLATION ................................................................................................................... 15

WIRING to JUNCTION BOX ............................................................................................................... 16

GLASS CLEANING ........................................................................................................................... 16

ILLUSTRATED PARTS LIST ............................................................................................................... 17

USING OPTIONAL OUTSIDE AIR KIT ................................................................................................18

WARRANTY .....................................................................................................................BACK COVER

2 79D0004

Page 3

IMPORTANT SAFETY INFORMATION

INSTALLER

Please leave this manual with the appliance.

IMPORTANT

Read these instructions carefully before installing this vent-free fi rebox.

• Improper installation or use of the fi rebox can cause serious injury or death from

fi re, burns, explosion or carbon monoxide poisoning.

• Do not allow fans to blow directly into the fi replace. Avoid drafts that alter burner

fl ame patterns.

• Do not use a blower insert, heat exchanger insert or other accessory, not approved

WARNING

for use with this fi rebox where applicable.

1. Due to high temperatures, the firebox should be

located out of traffic and away from furniture

and draperies.

2. Children and adults should be alerted to the hazard

of high surface temperature and should stay away

to avoid burns or clothing ignition.

3. Young children should be carefully supervised

when they are in the same room with the firebox.

4. Do not place clothing or other flammable material

near the fireplace when the firebox is in use.

5. Any safety screen or guard removed for servicing,

must be replaced prior to operating a heater within

the firebox.

6. Installation and repair should be done by a qualified

service person.

7. To prevent malfunction and/or sooting, an unvented

gas heater/firebox should be cleaned at least

annually by a professional service person. More

frequent cleaning may be required due to excessive

lint from carpeting, etc. It is imperative that

control compartments, burners and circulating air

passageways be kept clean.

8. The installation must conform with local codes or, in

the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.l/NFPA 54.

9. This unit complies with Z21-91 Ventless Firebox

Enclosures for gas-fired unvented decorative room

heaters.

10. Do not install the firebox in a bathroom or bedroom.

OWNER

Please retain this manual for future reference

11. Avoid any drafts that alter burner flame patterns. Do not

allow fans to blow directly into fireplace. Do not place

a blower inside burn area of firebox. Ceiling fans may

create drafts that alter burner flame patterns. Sooting

and improper burning will occur.

12. Caution: Candles, incense, oil lamps, etc. produce

combustion byproducts including soot. Vent-free appliances will not filter or clean soot produced by these types

of products. In addition, the smoke and/or aromatics

(scents) may be reburnt in the vent-free appliance which

can produce odors. It is recommended to minimize the

use of candles, incense, etc. while the vent-free appliance

is in operation.

13. Keep room area clear and free from combustible

materials, gasoline and other flammable vapors and

liquids.

14. During manufacturing, fabricating and shipping, various

components of this appliance are treated with certain

oils, films or bonding agents. These chemicals are not

harmful but may produce annoying smoke and smells

as they are burned off during the initial operation

of the appliance; possibly causing headaches or eye

or lung irritation. This is a normal and temporary

occurrence.

The initial break-in operation should last 2-3 hours with

the burner at the highest setting. Provide maximum

ventilation by opening windows or doors to allow odors

to dissipate. Any odors remaining after this initial

break-in period will be slight and will disappear with

continued use.

15. Always have a fireplace screen in place when the

appliance is in operation and, unless other provisions

for combustion air are provided, the screen shall have an

opening(s) for induction of combustion air.

.

79D0004 3

Page 4

GENERAL INSTALLATION INFORMATION

DO NOT ATTEMPT TO BURN SOLID WOOD FUELS, VENTED GAS LOG SETS, OR ANY OTHER COMBUSTIBLE IN THIS UNVENTED FIREBOX. ALSO, DO NOT INSTALL A VENT-FREE GAS LOG SET IN THIS

FIREBOX IF THE MINIMUM CLEARANCE AND HEIGHT REQUIREMENTS OF THE LOG SET ARE TOO

LARGE FOR THE FIREBOX.

The LSTF36, LPF36, LRCF36, and LLCF36 Series are vent-free fireboxes. They feature a self-contained heat-circulating

system. These units also feature a 2-in-1 flexible-face system (except for corner unit) that converts the circulating system

into a radiant system in seconds.

This installation manual will enable you to obtain a safe, efficient, and dependable installation of your vent-free

fireplace system.

Do not alter or modify the firebox or its components under any circumstances. Any modification or alteration of the firebox

system, including but not limited to the firebox and accessories, may void the warranty, listings and approvals of this system

and could result in an unsafe and potentially dangerous installation.

BEFORE YOU START:

CHECK YOUR PACKING LIST TO VERIFY THAT ALL LISTED PARTS HAVE BEEN RECEIVED.

ALSO INSPECT THE CONTENTS FOR SHIPPING DAMAGE AND IMMEDIA TEL Y INFORM YOUR DEALER

IF ANY DAMAGE IS FOUND.

You should have the following:

1. Vent-Free Gas Firebox

2. One (1) - 36" Canopy (LRCF36/LLCF36)

One (1) - 20" Canopy (LRCF36/LLCF36)

Two (2) - 36" Canopys (LSTF36/LPF36)

3. Installation and Operating Instructions

4. Five (5) drywall spacers

ITEMS REQUIRED FOR INSTALLATION

TOOLS: BUILDING SUPPLIES:

Phillips screwdriver Square Framing materials

Hammer Piping complying with local codes Wall finishing materials

Saw and/or saber saw Tee joint Caulking material (noncombustible)

Level Pipe wrench Fireplace surround materials (noncombustible)

Measuring tape Pliers

Electric drill and bits Pipe sealant approved for use

with propane/LPG (resistant to sulfur compounds)

Refer to the installation instructions provided with the log sets for items required for log set installation.

Illustrations shown in this manual refl ect “typical” installations with nominal

dimensions and are for design and framing reference only . Actual installations may

vary due to individual design preferences. However, always maintain minimum

clearances to combustible materials and do not violate any specifi c installation

NOTICE

requirements.

4 79D0004

Page 5

PLANNING THE INSTALLATION

In planning the installation for the appliance it is necessary to determine where the unit is to be installed and whether optional

accessories are desired. Gas supply piping should also be planned. The following steps represent the normal sequence of

installation. Each installation is unique, however, and might require a different sequence.

1. Position firebox prior to framing or into prepared framing.

2. Field wire main power supply to circulating models with fan kit. (Electrical connections should only be performed

by an experienced, licensed/certified tradesman).

3. Plumb gas line. (Gas connections should only be performed by an experienced, licensed/certified tradesman).

4. Install vent-free gas log heater per the instructions provided with the vent-free gas log heater.

5. Complete finish wall material and surround to your individual taste.

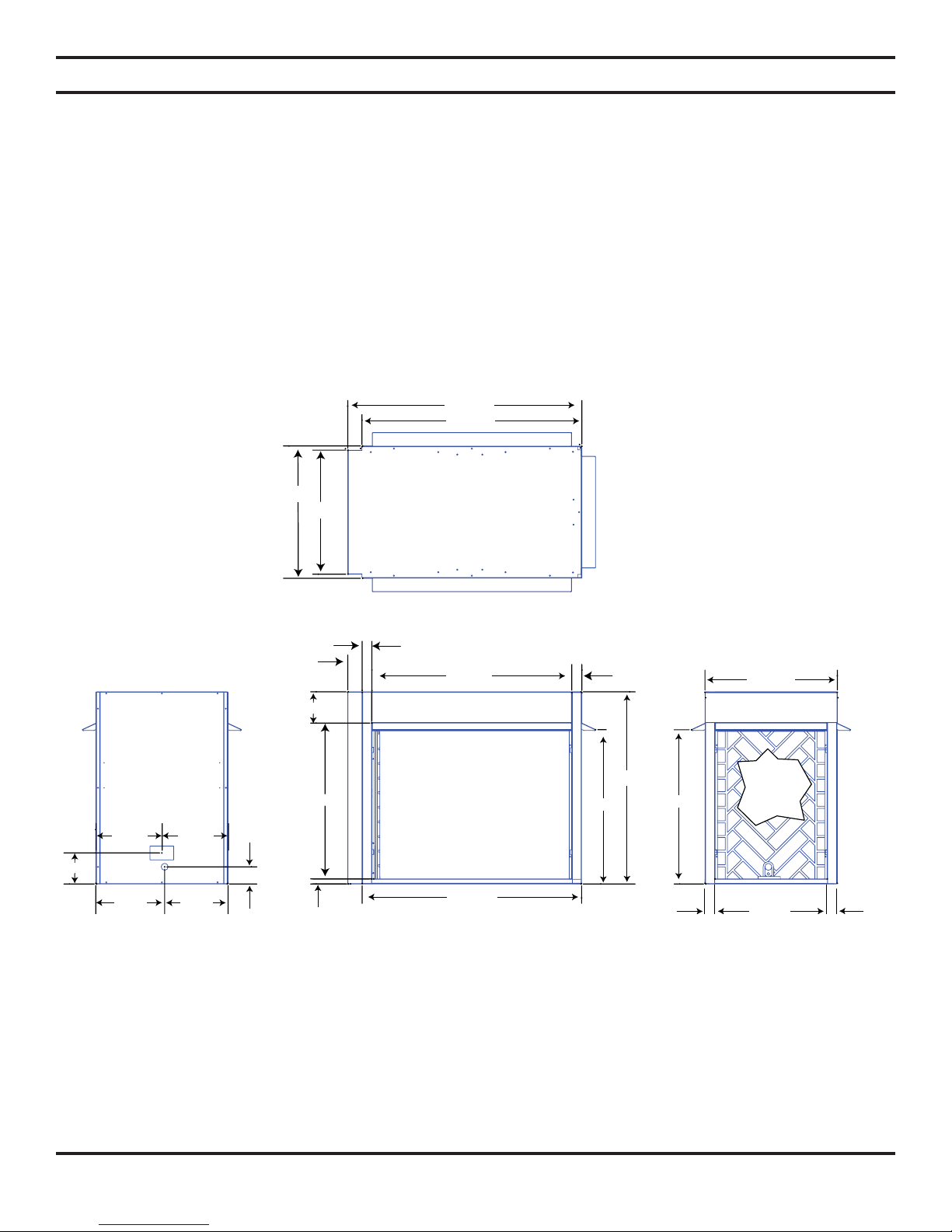

42 3/16"

39 9/16"

23 13/16"

22 5/16"

TOP

5 5/8"

12 3/8"

11 7/8"11 7/8"

11 3/8"

3 3/16"

2 5/8"

5 5/8"

1 3/4"

35 15/16"

FRONTREAR

28 1/16"

39 9/16"

"

Figure 1 - Firebox Dimensions

27 3/4"

1 13/16"

35 9/16"

27 3/4"

"

23 13/16"

OPEN

SIDE

"

"

79D0004 5

Page 6

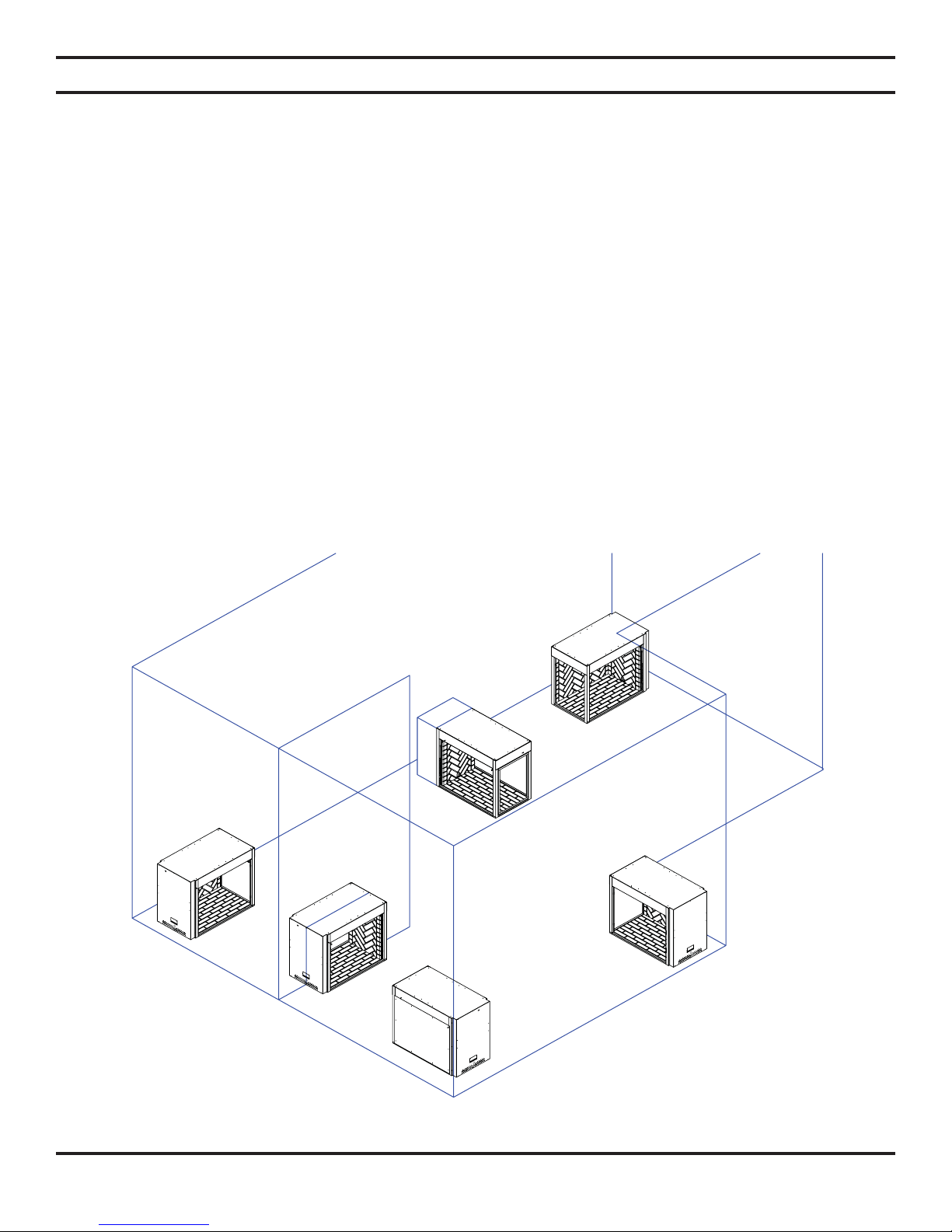

LOCATION OF FIREBOX

Carefully select the best location for installation of your vent-free firebox. The following factors should be taken into consideration.

• Clearance to side wall, ceiling, woodwork, and windows. Refer to “CLEARANCES and HEIGHT REQUIREMENTS”

section below and on pages 8 and 9. Minimum clearances to combustibles must be maintained.

• Location must not be affected by drafts caused by kitchen exhaust fans, ceiling fans, return air registers for forced air

furnaces/air conditioners, windows, or doors.

• Installation must provide adequate ventilation and combustion air.

• DO NOT INSTALL THIS FIREBOX IN A BATHROOM.

• This firebox enclosure is approved for bedrooms on the condition that the unvented room heater does not exceed 10,000

BTUs input and the room is properly sized for combustion air.

• Location should be out of high traffic or windy or drafty areas.

• DO NOT INSTALL WHERE CURTAINS, FURNITURE, CLOTHING OR OTHER FLAMMABLE OBJECTS

ARE LESS THAN 36" FROM FRONT OF HEATER.

• Never obstruct the front opening of the vent-free firebox or restrict the flow of combustion and ventilation air.

• Minimize modifications to existing construction. Refer to Figure 2 for location suggestions.

• Do not install in the vicinity where gasoline or other flammable liquids may be stored. The vent-free firebox must be

kept clear and free from these combustible materials.

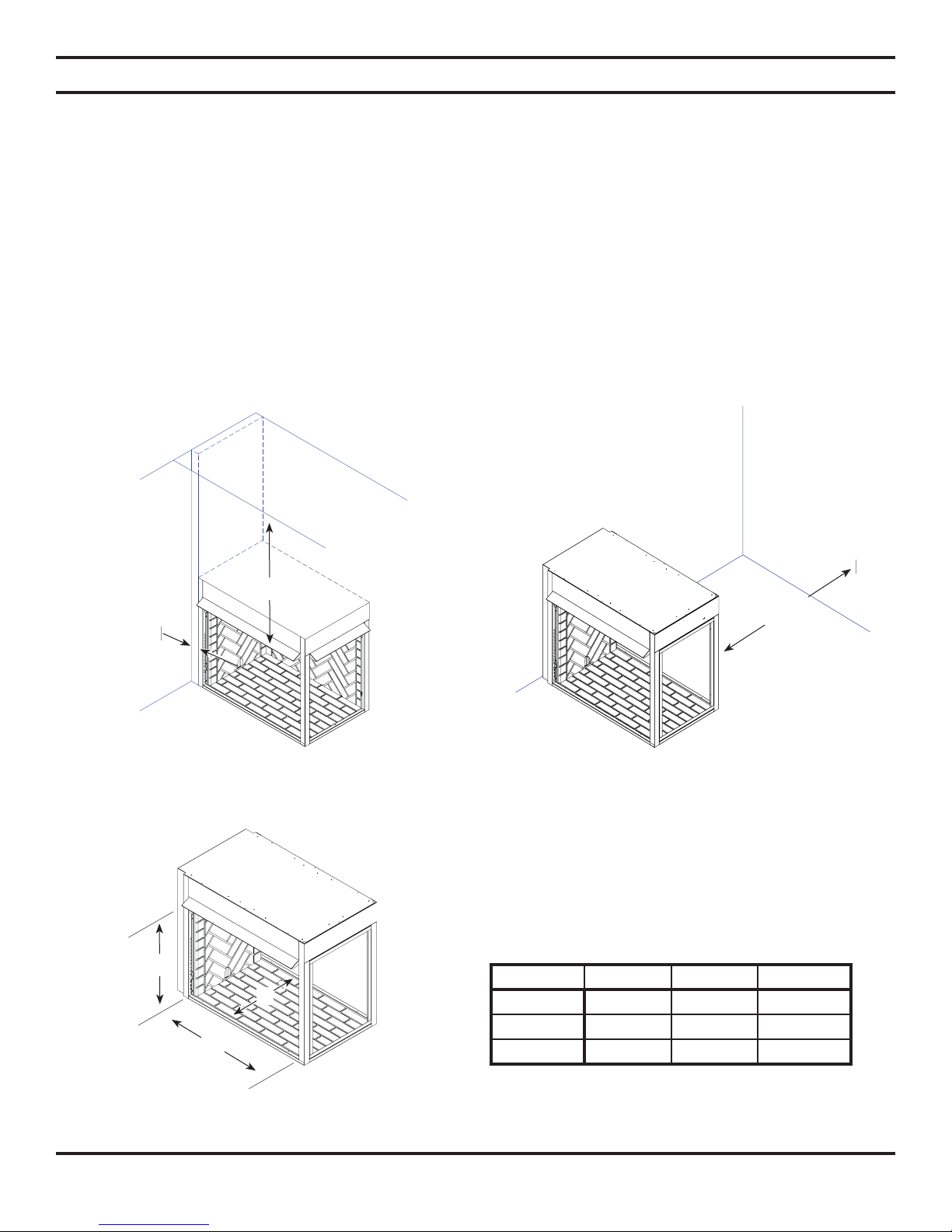

CORNER RIGHT

CORNER LEFT

PENINSULA

CORNER LEFT

SEE-THROUGH

CORNER RIGHT

Figure 2 - Suggested Firebox Locations

6 79D0004

Page 7

CLEARANCES and HEIGHT REQUIREMENTS

CLEARANCES and HEIGHT REQUIREMENTS

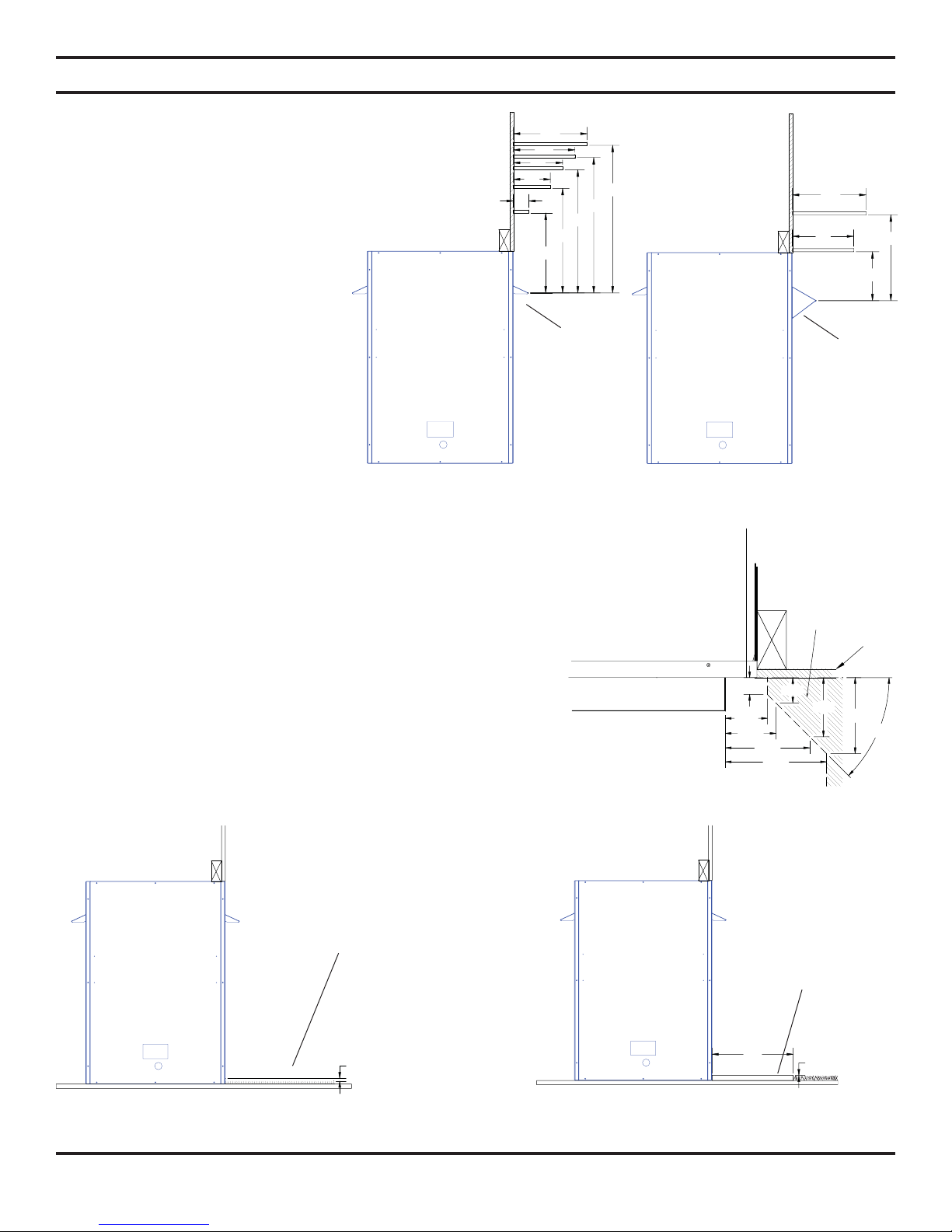

Ensure that minimum clearances shown in Figures 3 through 7 are maintained. Left and right clearances are determined

when facing the front of the firebox.

Follow these instructions carefully to ensure safe installation. Failure to follow these requirements may create a

fire hazard.

1. Sidewall Clearances — The clearance from the inside of the appliance to any combustible adjacent wall should not

be less than 2

2. Ceiling Clearance — The ceiling must be at least 42" from the top of the firebox opening (bottom of hood). Refer

to Figure 3.

3. Back Wall Clearance — The appliance may be placed against a combustible back wall.

4. Parallel Wall Clearance — The clearance from the opening of the firebox to any wall that is parallel to the opening

should not be less than 36" (LSTF36 and LPF36 models only). Refer to Figure 4.

7

/8". Refer to Figure 3.

42"

36"

55/8"

Figure 3 - Sidewall and Ceiling Clearances

C

B

A

Figure 5 - Minimum Hearth Dimensions

79D0004 7

Figure 4 - Parallel Wall Clearance

(LSTF36 and LPF36 Models Only)

Minimum Hearth Dimensions

AB C

See-Thru 33 3/16" 27 3/4" 21 15/16"

Corner 35 5/16" 27 3/4" 21 15/16"

Peninsula 35 5/16" 27 3/4" 21 15/16"

Page 8

CLEARANCES and HEIGHT REQUIREMENTS

5. Mantel clearances — The canopy supplied with

the unit must be installed. If a combustible mantel

is installed, it must meet the clearance requirements

detailed in Figure 6.

2.5"

6. Floor clearance — This fi rebox hearth opening

(inter-chamber fl oor) must be installed

1

at least

/ 2" above any combustible

fl ooring material or, the fi rebox hearth

may be installed fl ush with the fl oor

if noncombustible material such as

slate or marble is installed between

the base of the fi rebox and the com-

bustible fl ooring. The firebox may be

installed directly on a combustible

floor or raised on a platform of an

appropriate height. Do not place firebox on carpeting, vinyl, or other soft

floor coverings. It may, however, be

Figure 6 a&b - Minimum Mantel Clearances for Canopy

placed on a flat wood, plywood, particle board, or other hard surfaces. Be

sure firebox rests on a solid continuous floor or platform with

appropriate framing for support so that no cold air can enter room

from under the firebox. Refer to Figure 8.

NOTE: The combustible area above the facing must

not protrude more than 3/4" from the facing. If it does,

it is considered a mantel and must meet the mantel

requirements listed in this manual.

Figure 6c - Minimum Mantel Clearances

12"

10"

8"

6"

17"

13"

24"

22"

20"

Canopy

and Wide Profi le Canopy

FIREPLACE

HOOD

TOP VIEW

2.50

1.00

3.00

COMBUSTIBLE

1.50

5.00

5.63

12"

8"

14"

8"

Wide Profi le

Canopy

MATERIAL

AREA

WALL

3.50

4.50

45°

Combustible Material

Figure 7 - Floor Clearance above Combustible

Flooring Material

8 79D0004

1/2"

MIN.

Noncombustible

Material

14"

MIN.

0"

Figure 8 - Floor Clearance above Noncombustible

Flooring Material

Page 9

FIREPLACE FRAMING

Firebox framing can be built before or after the appliance is set in place. Construct firebox framing following Figures 9

through 14 on pages 9 and 10 for your specific installation requirements. Refer to Figure 1 on Page 5 for firebox dimensions.

The framing headers may rest on the top of the firebox standoffs.

The firebox may be installed directly on a combustible floor or raised on a platform of an appropriate height. Do not place

firebox on carpeting, vinyl, or other soft floor coverings. It may, however, be placed on a flat wood, plywood, particle board,

or other hard surfaces. Be sure firebox rests on a solid continuous floor or platform with appropriate framing for support so

that no cold air can enter room from under the firebox.

The classification “noncombustible material” includes, but is not limited to: stone, brick, and mortar. Noncombustibles are

safe to overlay the black-painted metal face, including radiant plates, and

do not pose a fire hazard. Any noncombustible finish material must not

Do not fi ll spaces around

fi rebox with insulation or

other materials. This could

cause a fi re.

WARNING

10 9/16"

11 9/16"

extend past or interfere with the fireplace opening.

The classification “combustible material” includes, but is not limited to:

plywood, drywall, and particle board. Combustible materials may contact

the sides, bottom, or back of the firebox. Do not overlay the black painted

face with combustible materials.

10 9/16"

12 5/8"

GAS

CONNECTION

NOTE:

All dimensions are based on

Two by Four

41 9/16"

1/2" drywall. If 5/8" drywall

is used, dimensions must be

changed accordingly.

22 3/16"

Figure 9 - Top View of Framing Specifi cations for

Peninsula Units (Model LPF36)

GAS

CONNECTION

41 9/16"

23 1/4"

Figure 10 - Top View of Framing Specifi cations for

Corner Units (Model LRCF36/LLCF36)

3413/16"

419/16"

Figure 11 - Framing Specifi cations for

Peninsula Units (Model LPF36)

79D0004 9

231/4"

223/16"

3413/16"

419/16"

Figure 12 - Framing Specifi cations

for Corner Units (Model LRCF36/LLCF36)

Page 10

FIREPLACE FRAMING

42 9/16"

10 9/16"

GAS

CONNECTION

22 3/16"

11 9/16"

Two by (2x)

fi ller to be

installed after

fi replace is set

in place

Two by Four

223/16"

3413/16"

425/8"

Figure 13 - Top View of Framing Specifi cations for

See-Through Unit (Model LSTF36)

The fi replace must be installed giving

full consideration to the clearance and

height requirements identifi ed in this

manual.

WARNING

Figure 14 - Framing Specifi cations for

See-Through Unit (Model LSTF36)

10 79D0004

Page 11

PENINSULA UNIT (LPF36)

INSTALLATION

1. Attach nailing flanges in desired position. See Figure

16.

2. Slide firebox into prepared framing or position firebox

in its final position and frame later.

3. Level and plumb firebox by checking edges of firebox.

Shim if necessary.

4. Attach nailing flanges to studs. See Figure 15.

5. Install canopy. Refer to page 15 for canopy installation.

FIREPLACE INSTALLATION

Nailing Flange

Figure 15 - Location of Nailing Flanges and

Floor Screws

Figure 16a - 1/2 drywall position Figure 16b - 5/8 drywall position

79D0004 11

Page 12

FIREPLACE INSTALLATION

SEE-THROUGH UNIT (LSTF36) INSTALLATION

1. Attach nailing flanges in desired position. See Figure 16.

3. Slide firebox into prepared framing or position firebox in its final position and frame later.

4. Level and plumb firebox by checking edges of firebox. Shim if necessary.

5. Attach nailing flanges to studs. See Figure 17.

6. Install canopy. Refer to page 15 for canopy installation.

Nailing Flange

Figure 17 - Location of Nailing Flanges and Floor Screws

12 79D0004

Page 13

FIREPLACE INSTALLATION

RIGHT (LRCF36) AND LEFT (LLCF36) CORNER INSTALLATION

1. Attach nailing fl anges in desired position. See Figure 16.

2. Slide firebox into prepared framing or position firebox in its final position and frame later.

3. Level and plumb firebox by checking edges of firebox. Shim if necessary.

4. Attach nailing flanges to studs. See Figure 18.

5. Install canopy. Refer to page 15 for canopy installation.

Figure 18 - Location of Nailing Flanges and

79D0004 13

Floor Screws

Page 14

GAS LINE INSTALLATION

Plumbing connections should only be performed by a

qualifi ed, licensed plumber. Main gas supply must be

off when plumbing gas line to fi replace or performing

service.

CAUTION

Consult all local codes. All gas piping must be installed to comply with local codes, or in the absence of local codes, with

the latest edition of the National Fuel Gas Code, ANSI Z223.1/NFPA54.

The gas supply line must have an ANSI approved manual shutoff valve, upstream of the appliance. Either a recessed valve

with a key should be mounted to the wall or floor outside the firebox, or an on/off appliance-style valve with union can be

placed inside the firebox. A plugged 1/8" NPT pressure taping point is recommended for service and may be incorporated

to the valve assembly. Bring a minimum 1/2" gas supply line through the knockout hole provided in the firebox.

A sediment trap may be upstream of the heater to prevent moisture and contaminants from passing through trap to

the heater controls and burners. Failure to do so could prevent the heater from operating reliably. Consult applicable

codes.

In addition to the regulator fitted to the heater, an external regulator must be used on all propane/LPG heaters to reduce

the supply tank pressure to 13" w.c. (maximum). Any copper tubing used to supply propane/LPG from the tank must be

internally tinned. Note: When connecting propane/LPG vent-free room heaters, you must use pipe sealant

resistant to propane/LPG.

Check gas type: The gas supply must be the same as stated on the heater’s rating plate. If the gas supply is different,

DO NOT INSTALL THE HEATER. Contact your dealer for the correct model.

Connecting directly to an unregulated

propane/LPG tank can cause an

explosion.

WARNING

After completing connection, test all gas joints from the gas meter to the gas heater regulator for leaks. Using soap and

water solution or a gas sniffer. DO NOT USE AN OPEN FLAME

Do not connect directly to natural

gas 1/2 PSI or 2 PSI systems. Always

make sure natural gas pressure is

regulated 10.5 w.c. (maximum before

WARNING

operating the unit).

14 79D0004

Page 15

CANOPY INSTALLATION

A canopy is furnished with each firebox and MUST be installed for safe operation. Refer to Figure 19.

The firebox canopy must not be

modifi ed or replaced with a canopy

that may be provided with the

unvented decorative room heater.

WARNING

Close fi replace screen panel before

operating decorative type unvented

room heater.

WARNING

1. Align the canopy with the holes in the top frame.

2. Secure canopy with five (5) screws provided.

3 Repeat on other side for See-Through Unit (LSTF36) and

Peninsula Unit (LPF36). Install the 20" canopy on the

shorter end with two (2) screws (LRCF36/LLCF36).

Figure 19 - Canopy Installation

79D0004 15

Page 16

WIRING TO JUNCTION BOX & GLASS CLEANING

FORCED AIR KIT

If you are installing the forced air kit Model BLOTDL on the LSTF36, LPF36, GCRF36 or GCLF36 units, see the installation instructions below supplied with kit.

Electrical connections should only be performed by a qualifi ed, licensed electrician,

main power must be off when connecting to main electrical power supply or

performing service.

The blower when installed, must be electrically grounded in accordance with local

codes or in the absence of local codes, with the National Electrical Code ANSI/NFP A

CAUTION

70.

WIRING TO JUNCTION BOX

NOTE: The wire must be run to the junction box before framing the fi rebox.

1. Wire the receptacle into an electrical circuit. Use minimum 60°C wire in accordance to prevailing codes.

2. The junction box is preinstalled at the factory. Remove junction box cover by removing the screw from the out

side firebox wall.

3. The junction box cover has a factory-installed “romex” style strain relief connector. Connect the wires according

to the wiring diagram below. Route the connected wire leads through the strain relief connector. See Figure 20.

120VAC

Receptacle

Junction Box

BLACK

GREEN

TANTANWHITEBLACKBLACK

Figure 20a - Wiring Diagram for Junction

GLASS CLEANING

NOTE: Glass should not be removed for cleaning

Speed Control

Figure 20b - Wiring Diagram for Blower

NOTE: For see thru and peninsula

models, two blower kits may be used

Optional Thermostatic Switch

and will be controlled independently.

When Cleaning Glass

• Allow glass to cool before cleaning.

• Never use abrasive cleaning materials on glass.

• Keep children and pets at safe distance away.

• Never operate fireplace if glass is broken. Replace any glass that is chipped, cracked or broken. Replacement

glass frame assemblies MUST be supplied by the fireplace manufacturer. Do not substitute other materials.

• Handle glass frame with care. Avoid striking or scratching glass on hard objects.

16 79D0004

Page 17

ILLUSTRATED PARTS LIST

Figure 21 - Exploded View

6

1

3

8

7

2

5

10

4

STANDARD FEATURES

ITEM DESCRIPTION LST LPF LRCF/LLCF

1 36” Canopy 71D0500 71D0500 71D0500

2 20” Canopy - - 79D0082(1)

3 Screen Panel 79D0001(4) 79D0001(4) 79D0001(3)

4 Screen Rod Side 26D0138(4) 26D0138(4) 26D0138(2)

5 Screen Rod End - - 43D0116(1)

6 Brick Panel Common 79D0093(1) 79D0093(1) 79D0093(1)

6 Brick Panel Corner - - 79D0094(1)

6 Brick Panel Hearth 79D0095(1) 79D0095(1) 79D0095(1)

6 Brick Panel See Thru 79D0096(1) - 7 Door Assembly - 79D0034(1) 8 Nailing Flange 79D0091(5) 79D0091(5) 79D0091(5)

9 Outside Air Kit* AK-4(1) AK-4(1) AK-4(1)

10 Blower Kit BLOTDL BLOTDL BLOTDL

3

ACCESSORIES

*Not shown

79D0004 17

Page 18

USE OF OPTIONAL AK-4 OUTSIDE AIR KIT

COMBUSTION AIR

1. Locate combustion air assembly at an exterior location which is not likely to be accidentally blocked in any manner.

Locate assembly amin. of 12" above the snow line to prevent blockage by snow accumulation.

2. Never mount the combustion air inlet assembly in a garage or storage area where combustible fumes such as gasoline

might be drawn into the fi replace.

3. Combustion air can be drawn from the crawl space under a house when an adequate supply of air is provided by open

ventilation.

4. CAUTION: Do not take combustion air from attic space or garage space.

5. locate air supply at least 3' away from any appliance vent terminal.

6. Avoid extremely long runs and numerous turns in the duct leading from the fi replace to the combustion air assembly.

These conditions increase the resistance to the free fl ow of air through the duct. See Figur es 22 through 25 for methods

of installing the outside air for combustion assemblies.

Note: Fireplace model in illustrations may not be representative of your appliance.

Above

Snow

Level

Ground

Level

Figure 22 - Basement Installation

Duct Extended

to Miss Joist

Basement

Wall

8'max.

Inlet Grill in

Soffi t

(Overhang)

Figure 23 - Concrete Slab Installation

(Optional Outside Air Runs)

Inside Wall

To Outside Wall

Figure 24 - Installation Above Basement or

Crawl Space

18 79D0004

Outside

Wall

Figure 25 - 45° Corner Installation on

Slab Floor

Page 19

USE OF OPTIONAL AK-4 OUTSIDE AIR KIT

The use of outside air for combustion is optional unless required by building codes. It is only necessary to supply outside

combustion air to one side of the fi replace. Use the model AK4 combustion air kit.

MODEL AK-4 COMBUSTION AIR ASSEMBL Y

1. Remove the cover plate from the 4" outlet opening location on the left or

right outside of the fi replace.

2. Place the insulation ring between the AK-4 starting collar and fireplace wall.

3. Place the starting collar (4") into the hole on the side of fi replace. Fasten it in place with the four sheet metal screws

provided. See Figures 26 and 28.

Note: The air starting collar extends through the fi replace outer wrap. When the air starting collar is

securely attached, it will form a seal against the fi replace wall.

4. Attach outside duct to starting collar with duct clamp or screws. See Figure 27.

DO NOT remove the

cover if the outside air

will not be connected.

WARNING

Left Side of

Fireplace

Shorter End

of Air Starting

Figure 26 - Attaching Outside Air Starting Collar

and Insulation Ring to Left Side of Fireplace

5. Cut a 6-inch diameter opening for model AK-4 in the outside

wall covering where the outside vent is to be located. See

Figure 28.

6. Select and cut a piece of duct long enough to attach to the

fi replace and stick out at least 3" beyond the face of the wall

to which the AK-4 inlet air vent will be attached. See Figur e

27.

Insulation Ring

AK-4 Starting

Collar

Sheet

Meal

Screws

Collar

6" Diameter

Hole

Duct

Extending

3"min.

Screws

Left Side of

Fireplace

Figure 27 - Attaching Outside Duct

to Starting Collar

Air Starting

Collar

Screw

Duct

Nail

Holes

Use FP-4 U duct for maximum effi ciency

and safety. Do not use a combustible

duct. Always use UL Listed Class 0 or

1 duct material.

WARNING

79D0004 19

AK-4 Inlet

Air Vent

Figure 28 - Combustion Air Assembly for

Model No. AK-4

Screws

Continued

Page 20

USE OF OPTIONAL AK-4 OUTSIDE AIR KIT

MODEL AK-4 COMBUSTION AIR ASSEMBL Y (CONTINUED)

7. If the duct is the insulated type, push the insulation back from one end of

the duct approximately 2". See Figure 29.

8. Slip the exposed end of the duct over the starting collar on the fi replace.

9. Using the sheet metal screws provided, secure the duct end to the collar

attached to the fi replace.

Duct

Connector

Approximately

2"

10. Nail or screw the combustion air assembly to the surface of the wall.

Note: If the wall covering is brick or stone, use appropriate

masonry fasteners. If necessary, splice the duct. Use a model

403-duct connector to splice duct sections.

INSTALLING MODEL 403 DUCT CONNECTOR

1. Push insulation back approximately 2" from the end of each duct.

2. Slip each duct over duct connector until an equal length of connector extends into each duct.

3. Place duck clamp over the end of each duct. Tighten duct clamp down snuggly.

4. Push insulation back into place and over duct clamp.

Figure 29 - Installing Duct

Connector 403

Insulation

Duct Clamp

20 79D0004

Page 21

NOTES

79D0004 21

Page 22

NOTES

22 79D0004

Page 23

NOTES

79D0004 23

Page 24

LIMITED LIFETIME WARRANTY POLICY

LIFETIME WARRANTY

The following components are warranted for life to the original owner, subject of proof of purchase: Firebox,

Combustion Chamber, Heat Exchanger, Grate, and Stainless Steel Burners.

FIVE YEAR WARRANTY

The following components are warranted for 5 years to the original owner, subject of proof of purchase: Vent Free

Ceramic Fiber Logs, Catalytic Filter and Aluminized Burners.

BASIC WARRANTY

Monessen Hearth Systems (MHS) warrants the components and materials in your gas appliance to be free from

manufacturing and material defects for a period of two years from date of installation. After installation, if any of

the components manufactured by MHS in the appliance are found to be defective in materials or workmanship,

MHS will, at its option, replace or repair the defective components at no charge to the original owner. MHS will

also pay for reasonable labor costs incurred in replacing or repairing such components for a period of two years

from the date of installation. Any products presented for warranty repair must be accompanied by a dated proof

of purchase.

This Limited Lifetime Warranty will be void if the appliance is not installed by a qualified installer in accordance

with the installation instructions. The Limited Lifetime Warranty will also be void if the appliance is not operated

and maintained according to the operating instructions supplied with the appliance, and does not extend to (1)

firebox/burner assembly damage by accident, neglect, misuse, abuse, alteration, negligence of others, including

the installation thereof by unqualified installers, (2) the costs of removal, reinstallation or transportation of

defective parts on the appliance, or (3) incidental or consequential damage. All service work must be performed

by an authorized service representative.

This warranty is expressly in lieu of other warranties, express or implied, including the warranty of merchantability

of fitness for purpose and of all other obligations or liabilities. Monessen Hearth Systems, Inc. does not

assume for it any other obligations or liability in connection with the sale or use of the appliance. In states

that do not allow limitations on how long an implied warranty lasts, or do not allow exclusion of indirect

damage, those limitations of exclusions may not apply to you. You may also have additional rights not covered

in this Limited Lifetime Warranty.

MHS reserves the right to investigate any and all claims against the Limited Lifetime Warranty and decide

upon method of settlement.

For information about this warranty, contact:

Technical Services

Monessen Hearth Systems

149 Cleveland Drive

Paris, Kentucky 40361

24 43D0121

MAY 2008 P/N 79D0004 • Rev. 2

Loading...

Loading...