Page 1

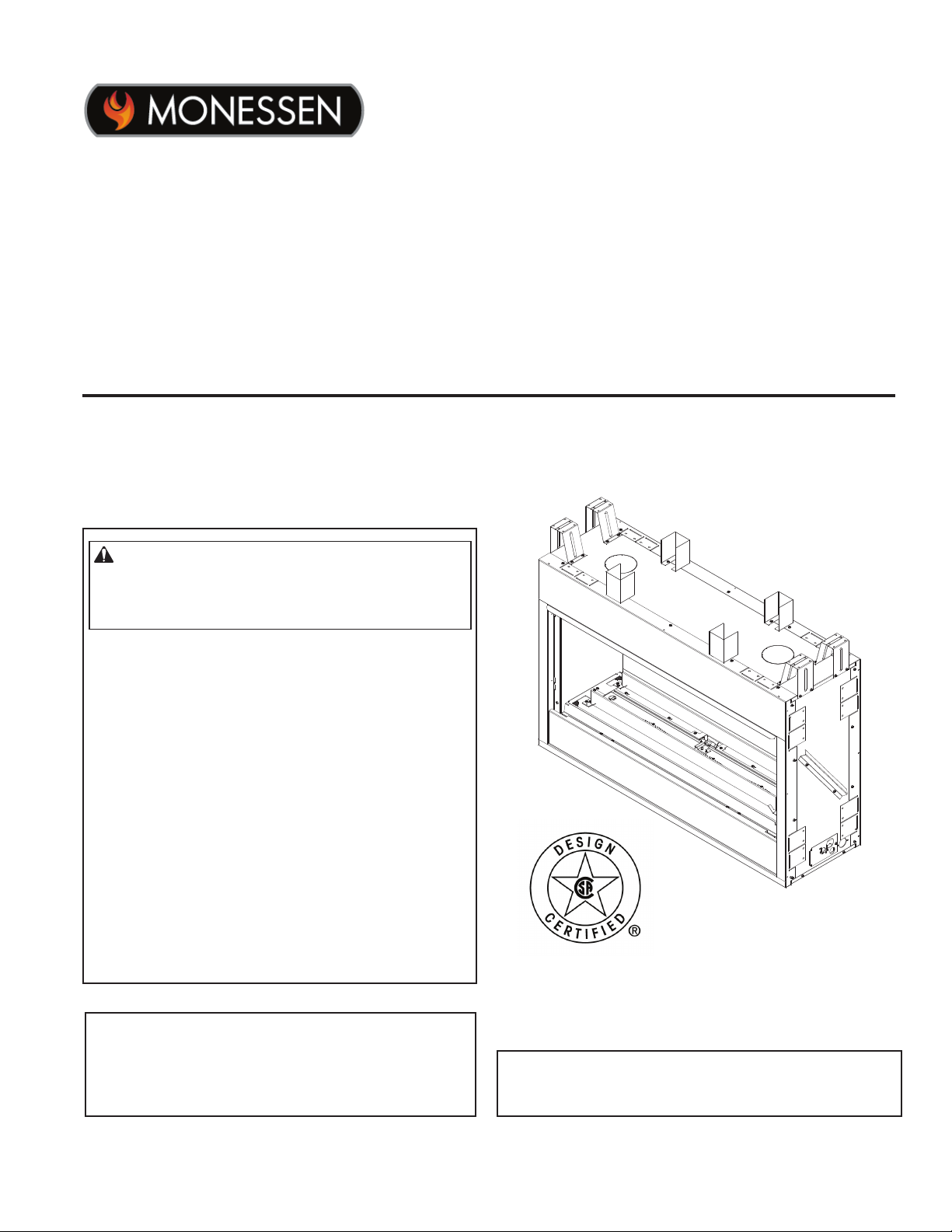

AVFLST Vent Free See Through

Fireplace System

Installation & Operating Instructions

Models: AVFLST42NIP and AVFLST42PIP

WARNING! If the information in this manual

is not followed exactly, a re or explosion may

result causing property damage, personal

injury or loss of life.

• Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS

– Do not try to light any appliance.

– Do not touch any electrical switch; do

not use any phone in your building.

– Leave the building immediately.

– Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier's instructions.

– If you cannot reach your gas supplier,

call the re department.

• Installation and service must be performed

by a qualied installer, service agency or

the gas supplier.

This is an unvented replace. It uses air (oxygen)

from the room in which it is installed. Provisions

for adequate combustion and ventilation air must

be provided. Refer to Page 8.

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Page 2

CONTENTS

AVFLST Vent Free Fireplace

Thank you and congratulations on your purchase of a Monessen replace.

PLEASE READ THE INSTALLATION AND OPERATION INSTRUCTIONS BEFORE USING THE APPLIANCE!

IMPORTANT: Read all instructions and warnings carefully before starting installation.

Failure to follow these instructions may result in a possible re hazard and will void the warranty.

STANDARD WORK CHECKLIST .................................. 3

IMPORTANT SAFETY INFORMATION ......................... 4

Building code information ............................................ 5

PRODUCT FEATURES .................................................. 6

AVFLST42 controls ..................................................... 6

Gas specications & orice size .................................. 6

Gas pressures ............................................................. 6

FIREPLACE and FRAMING DIMENSIONS .................. 7

PRE-INSTALLATION INFORMATION ........................... 8

Getting started ............................................................. 8

What you will need for installation ............................... 8

Planning the installation .............................................. 8

Adequate combustion and ventilation air .................... 8

Fireplace location ........................................................ 9

Clearances and height requirements ........................ 10

FIREPLACE INSTALLATION ...................................... 12

Secure replace to framing ....................................... 12

Finishing material ...................................................... 12

Noncombustible facing installation ............................ 12

Connect the gas ........................................................ 13

►

Check gas pressure .................................................. 14

Gas pressures ........................................................... 14

ELECTRICAL INSTALLATION .................................... 15

►

Wiring junction box .................................................... 15

Wiring Requirements ................................................. 16

►

FINAL INSTALLATION ................................................ 18

Installation of air deection glass .............................. 18

Fireglass only placement .......................................... 18

Glass and optional stone kit placement .................... 18

OPERATING INSTRUCTIONS .................................... 19

For your safety read before lighting .......................... 19

Heat Management ..................................................... 20

Operation During a Power Outage ............................ 20

Intellire™ Plus ODS SYSTEM OPERATION ............ 21

FLAME APPEARANCE & LED CONTROL ................. 28

Flame appearance .................................................... 28

Check the pilot ame ................................................. 28

Check the burner ame ............................................. 28

LED Control ............................................................... 28

MAINTENANCE and CLEANING ................................ 29

Cleaning and servicing .............................................. 29

Replacing top light bulb ............................................. 29

Replacing led strips ................................................... 29

Porcelain Panel Removal .......................................... 30

OPERATION AND OPTIONAL ACCESSORIES ......... 31

Operating information ................................................ 31

Optional accessories ................................................. 31

TROUBLESHOOTING ................................................. 32

Intellire™ Plus ODS System ................................... 34

SERVICE PARTS ......................................................... 36

►

LIMITED LIFETIME WARRANTY ................................ 38

2

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Page 3

AVFLST Vent Free Fireplace

STANDARD WORK CHECKLIST

ATTENTION INSTALLER:

This standard work checklist is to be used by the installer in conjunction with, not instead of, the instructions contained in this

installation manual.

Customer:

Lot/Address:

Model

(circle one): AVFLST42NIP, AVFLST42PIP

WARNING! Risk of Fire or Explosion! Failure to install appliance according to these instructions could

lead to a fire or explosion.

Appliance Install (Pg. 7-12)

Verified that the chase is insulated and sealed.

Required non-combustible board is installed.

Fireplace is leveled and secured.

Adequate provisions for combustion and ventilation air have been verified.

Verified clearances to combustibles.

Gas (Pg 13-14)

Proper appliance for fuel type.

Leak check performed and inlet pressure verified.

Verified proper air shutter setting for installation type.

Follow this Standard Work Checklist

Date Installed:

Location of Fireplace:

Installer:

Dealer/Distributor Phone #

Serial #:

?YHW , ON F I SEY

___________________________

___________________________

___________________________

___________________________

___________________________

___________________________

___________________________

___________________________

Electrical (Pg 15)

Unswitched power (110-120 VAC) provided to the appliance.

Switch wires properly installed.

Media & Accessories (Pg 18)

All packaging and protective materials removed (inside & outside of

appliance). Media installed correctly.

Accessories installed properly.

Finishing (Pg 10 & 12)

Verifi ed all clearances meet installation manual requirements.

Mantels and wall projections comply with installation manual requirements.

Manual bag and all of its contents are removed from inside/

under the appliance and given to party responsible for use and operation.

Started appliance and veried no gas leaks exist.

___________________________

___________________________

___________________________

___________________________

___________________________

___________________________

___________________________

___________________________

___________________________

Hearth & Home Technologies recommends the following:

• Photographing the installation and copying this checklist for your file.

• That this checklist remain visible at all times on the appliance until the installation is complete.

Comments: Further description of the issues, who is responsible (Installer/ Builder/ Other Trades, etc) and corrective

action needed _____________________________________________________________________________________

Comments Communicated to party responsible ____________________ by ______________________on ___________

= Contains updated information.

(Builder / Gen. Contractor/) (Installer) (Date)

4118-982A 04/20

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

3

Page 4

IMPORTANT SAFETY INFORMATION

AVFLST Vent Free Fireplace

INSTALLER

Please leave these instructions with the appliance.

OWNER

Please retain these instructions for future reference

.

WARNING!

• Any change to this heater or its controls can be dangerous.

• Improper installation or use of the heater can cause serious injury or death from re, burns,

explosion or carbon monoxide poisoning.

• Do not allow fans to blow directly into the replace. Avoid any drafts that alter burner ame patterns.

• Do not use a blower insert, heat exchanger insert or other accessory, not approved for use with

this heater where applicable.

1. Due to high temperatures, the appliance should be

located out of trac and away from furniture and

draperies.

2. Children and adults should be alerted to the hazard

of high surface temperature and should stay away

to avoid burns or clothing ignition.

3. Young children should be carefully supervised when

they are in the same room with the appliance.

4. Do not place clothing or other ammable material

on or near the appliance.

5. Any safety screen or guard removed for servicing

an appliance, must be replaced prior to operating

the heater.

6. Installation and repair should be done by a qualied

service person. To prevent malfunction and/or sooting, an unvented replace should be cleaned before

use and at least annually by a professional service

person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding materials, etc. It is imperative that control compartments,

burners and circulating air passageways be kept

clean.

7. WARNING! Any change to this heater or its controls

can be dangerous.

8. Unvented fireplaces are a supplemental zone

heater. They are not intended to be the primary

heating appliance.

9. CARBON MONOXIDE POISONING: Early signs of

carbon monoxide poisoning are similar to the u with

headaches, dizziness and/or nausea. If you have these

signs, obtain fresh air immediately. Have the heater

serviced as it may not be operating properly.

10. The installation must conform with local codes or, in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.l/NFPA54.

11. This unit complies with ANSI Z21.11.2:19 Unvented

Heaters.

12. Do not install the heaters in a bathroom or bedroom.

13. Proper location of the heater, and annual cleaning are

necessary to avoid potential problems with sooting.

Sooting, resulting from improper installation or operation, can settle on surfaces outside the replace.

14. Avoid any drafts that alter burner ame patterns. Do not

allow fans to blow directly into replace. Do not place

a blower inside burn area of rebox. Ceiling fans may

create drafts that alter burner ame patterns. Sooting

and improper burning will occur.

15. Caution: Candles, incense, oil lamps, etc. produce

combustion byproducts including soot. Vent-free

appliances will not lter or clean soot produced by

these types of products. In addition, the smoke and/or

aromatics (scents) may be re-burned in the vent-free

appliance which can produce odors. It is recommended

to minimize the use of candles, incense, etc. while the

vent-free appliance is in operation.

16. This is an unvented replace. It uses air (oxygen) from

the room in which it is installed. Provisions for adequate

combustion and ventilation air must be provided. Refer

to Page 8.

17. This heater shall not be installed in a room or space

unless the required volume of indoor combustion air is

provided by the method described in the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, the International

Fuel Gas Code or applicable local codes.

18. Keep room area clear and free from combustible materials, gasoline and other ammable vapors and liquids.

19. Unvented replaces emit moisture into the living area.

In most homes of average construction, this does not

pose a problem. In houses of extremely tight construction, additional mechanical ventilation is recommended.

20. During manufacturing, fabricating and shipping, various

components of this appliance are treated with certain

oils, lms or bonding agents. These chemicals are not

harmful but may produce annoying smoke and smells

4

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Page 5

AVFLST Vent Free Fireplace

as they are burned o during the initial operation of the

appliance; possibly causing headaches or eye or lung

irritation. This is a normal and temporary occurrence.

The initial break-in operation should last two to three

hours with the burner at the highest setting. Provide

maximum ventilation by opening windows or doors to

allow odors to dissipate. Any odors remaining after this

initial break-in period will be slight and will disappear

with continued use.

21. Input ratings are shown in BTU per hour and are for

elevations up to 2,000 feet. For elevations above 2,000

feet, input ratings should be reduced 4 percent for each

1,000 feet above sea level. Refer to the National Fuel

Gas Code.

22. The appliance and its appliance main gas valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1⁄2 psig (3.5 kPa).

23. The appliance must be isolated from gas supply piping

system by closing its equipment shuto valve during

any pressure testing of the gas supply piping system at

test pressures equal to or less than 1⁄2 psig (3.5 kPa).

24. Do not use this room heater if any part has been under

water. Immediately call a qualied service technician

to inspect the room heater and to replace any part of

the control system and any gas control which has been

under water.

25. Never burn solid fuels in a replace where a unvented

room heater is installed.

IMPORTANT SAFETY INFORMATION

This appliance may be installed in an aftermarket, permanently located, manufactured

(mobile) home, where not prohibited by local

codes.

This appliance is only for use with the type of

gas indicated on the rating plate. This appliance

is not convertible for use with other gases.

BUILDING CODE INFORMATION

Adhere to all local codes or, in their absence, the latest

edition of THE NATIONAL FUEL GAS CODE ANSI Z223.1

or NFPA54 which can be obtained from:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

or

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

WARNING: This product and the

fuels used to operate this product (liquid

propane or natural gas), and the products

of combustion of such fuels, can expose

you to chemicals including benzene, which

is known to the State of California to cause

cancer and reproductive harm. For more

information go to: www.P65Warnings.

ca.gov.

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

5

Page 6

PRODUCT FEATURES

AVFLST Vent Free Fireplace

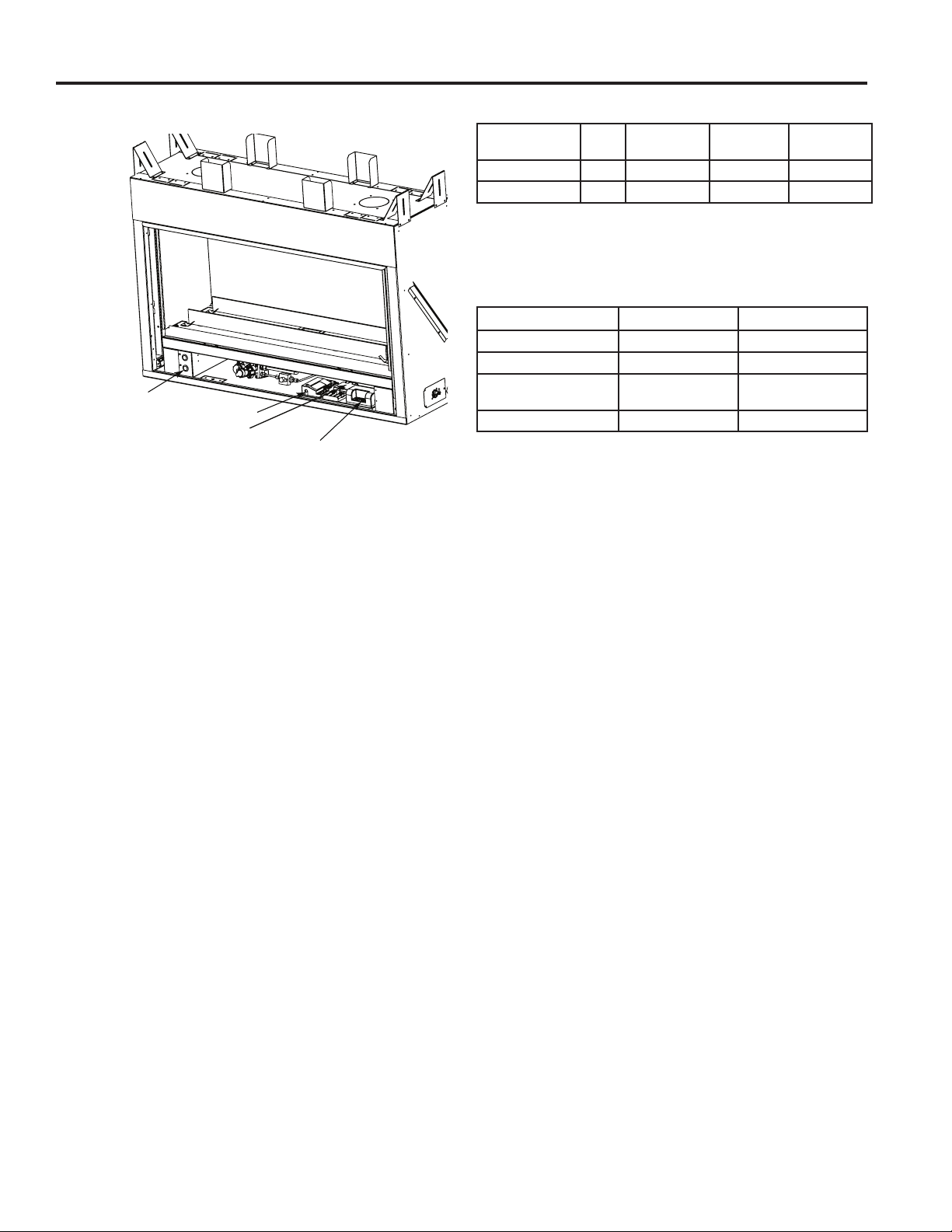

AVFLST42 CONTROLS

LED Switches

Control Module

Thermocouple Module

Aux Module

Figure 1. AVFLST42 Controls (Control Access Door Shown Open)

GAS SPECIFICATIONS & ORIFICE SIZE

MODEL FUEL

AVFLST42NIP NAT. 37,000 24,500 2.20 mm

AVFLST42PIP L P. 36,000 28,500 #55

MAX. INPUT

(BTU/h)

NOTE: For LP models an external regulator is required

to reduce supply pressure to a maximum of 13" w.c.

MIN. INPUT

(BTU/h)

ORIFICE

SIZE

GAS PRESSURES

NATURAL PROPANE (LP)

Inlet Minimum 5.0" w.c. 11.0" w.c.

Inlet Maximum 10.5" w.c. 13.0" w.c.

Regulator Pressure

Setting

Pilot Regulator 3.5" w.c. —

3.5" w.c. 10" w.c.

6

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Page 7

AVFLST Vent Free Fireplace

33 ½" *

[851mm]

32"

[813mm]

Minimum

Rough

Framing

Height

37½"

[953mm]

39¾"

[1010mm]

43"

[1092mm]

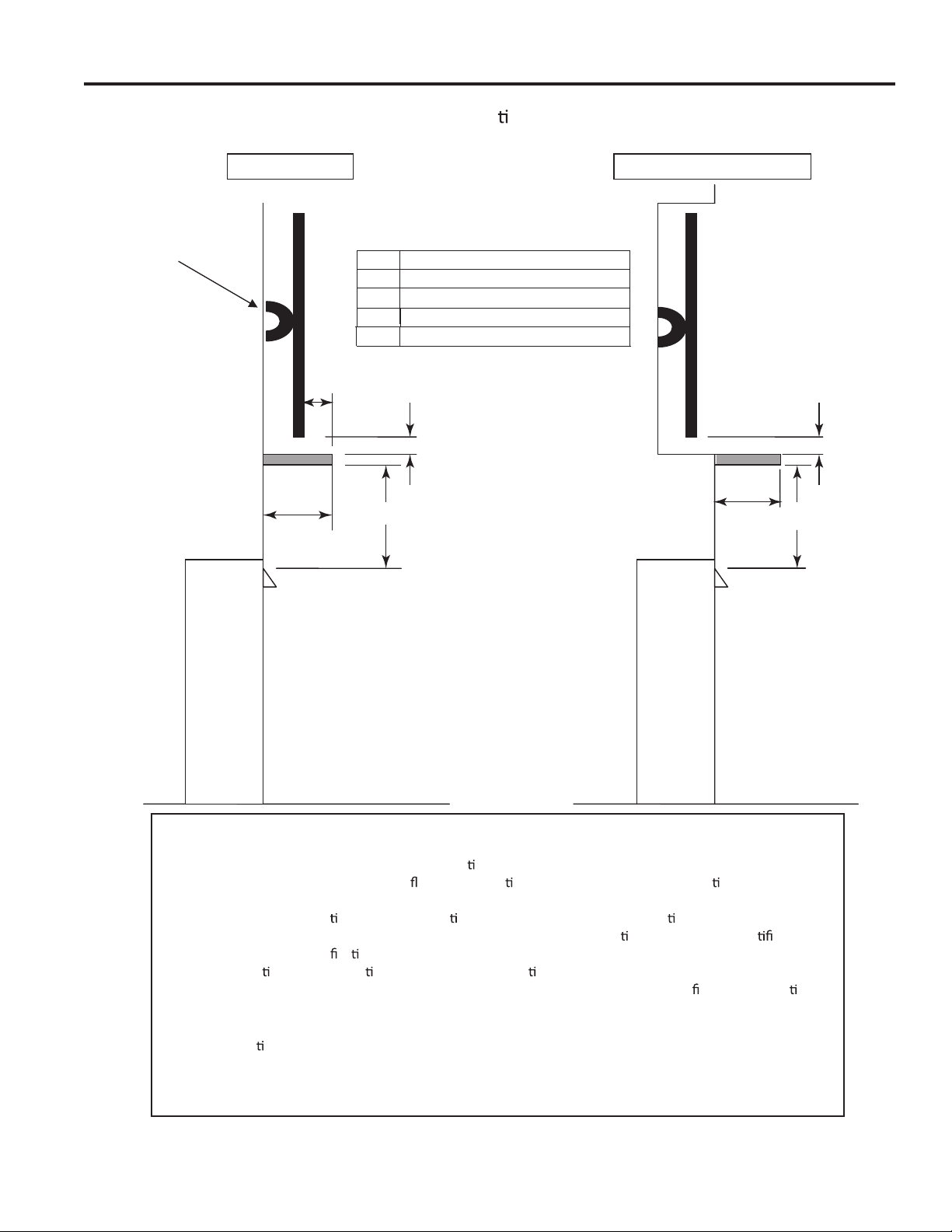

FIREPLACE AND FRAMING DIMENSIONS

15⁄"

[386mm]

6⁄"

[154mm]

28"

[711mm]

13⁄"

[333mm]

*NOTE: The AVFLST42 unit must be raised at least 1.5 inches above the top surface of the nished oor when

using the AVFL42WFBT-A or AVFL42WCSS-A wide contemporary face.

32"

[813mm]

Figure 2. Fireplace dimensions

Interior wall

installation

Wall cover

thickness

Exterior wall

installation

Wall cover

thickness

½"[13mm]

⁄"[16mm]

½"[13mm]

or

⁄"[16mm]

Minimum rough

or

Minimum Rough

Framing Width

44"

[1118mm]

44"

[1118mm]

opening depth

for 5/8" wall thickness

12"

[305mm]

Minimum rough

opening depth

for 5/8" wall thickness

14⁄"

[378mm]

Figure 3. Framing dimensions with outdoor kit installed (AVFLSTSSODK)

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

48½"

[1232mm]

7

Page 8

PRE-INSTALLATION INFORMATION

AVFLST Vent Free Fireplace

GETTING STARTED

Check to verify that all listed parts have been received.

You should have the following:

• One (1) Unvented replace

• Two (2) Anchoring screws

• One (1)Installation/operating instructions

• Two (2) 5" noncombustible board

• Two (2) 2" x 32" deector glass

• Two (2) Bags reglass

• One (1) 90 watt bulb

• One (1) RC300 remote control

Carefully inspect the contents for shipping damage. If any

parts are missing or damaged, immediately inform the

dealer from whom you purchased the appliance. Do not

attempt to install any part of the appliance unless you

have all parts in good condition.

WHAT YOU WILL NEED FOR INSTALLATION

You must have the following items available before proceeding with installation:

• External regulator (for propane/LPG only)

• Manual shuto valve

• Piping which complies with local codes

• Sediment trap

• Phillips head screwdriver

• Tee joint.

• Pipe sealant approved for use with propane/LPG

(Resistant to sulfur compounds)

• Pipe wrench

WARNING!

Do not install the heater:

• Where curtains, furniture, clothing, or

other ammable objects are less than 36"

from the front of the heater.

• In high trac areas.

• In windy or drafty areas.

PLANNING THE INSTALLATION

In planning the installation for the replace it is necessary

to determine where the unit is to be installed and whether

optional accessories are desired. Gas supply piping should

also be planned. The following steps represent the normal

sequence of installation. Each installation is unique, however, and might require a dierent sequence.

1. Position fireplace in desired location. Refer to the

Fireplace and Framing Dimensions (page 7, Figures 2

and 3,) Fireplace Location (page 9, Figure 5) and

Clearances and Height Requirements (page 10, Figures

6 and 7.)

NOTE: Be sure all cardboard packing material has been

removed from under the unit.

2. Install following the instructions found in this manual.

3. Field wire main power supply to junction box. Refer to

the Electrical Installation section (page 15). (Electrical

connections should only be performed by an experienced, licensed certied service person).

4. Plumb gas line. Refer to the Connect the Gas (page

13, Figure 10) section found in this manual. (Gas

connections should only be performed by an experienced, licensed/certied service person).

5. Complete nish wall material and/or surround.

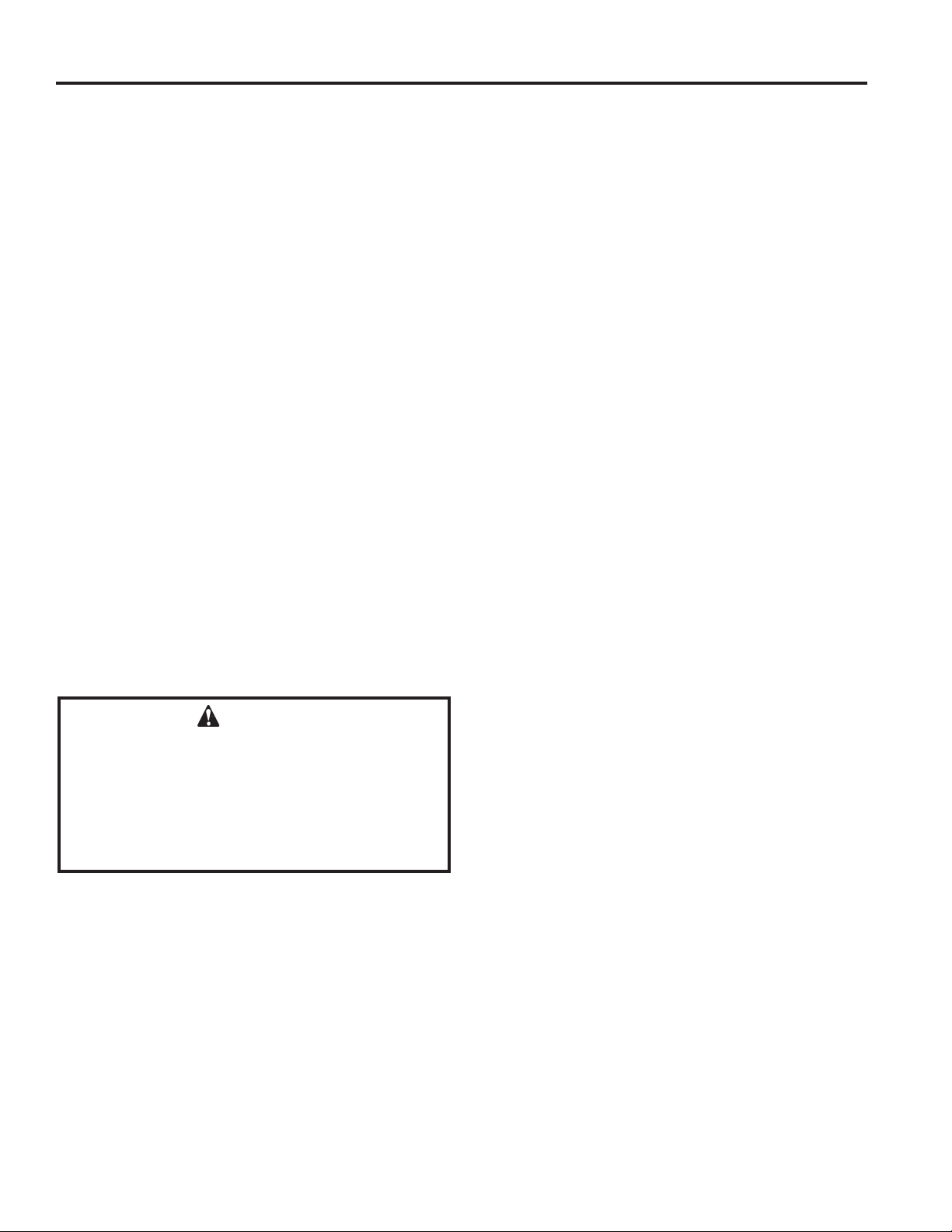

ADEQUATE COMBUSTION AND

VENTILATION AIR

This heater shall not be installed in a conned space or

unusually tight construction unless provisions are provided

for adequate combustion and ventilation air.

The National Fuel Gas Code, (ANSI Z223.1/NFPA54),

denes a conned space as a space whose volume is less

than 50 cubic feet per 1,000 BTU per hour (4.8m3 per kw)

of the aggregate input rating of all appliances installed in

that space, and an unconned space as a space whose

volume is not less than 50 cubic feet per 1,000 BTU per

hour (4.8 m3 per kw) of the aggregate input rating of all

appliances installed in that space. Rooms communicating

directly with the space in which the appliances are installed,

through openings not furnished with doors, are considered

a part of a conned space.

Unusually tight construction is dened as construction

where:

a. Walls and ceilings exposed to the outside atmosphere

have a continuous water vapor retarder with a rating of

1 perm (6 x 10

gasketed or sealed, and

b. Weather stripping has been added on openable win-

dows and doors, and

11

kg per pa/sec-m2) or less with openings

8

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Page 9

AVFLST Vent Free Fireplace

Indoor application

Exterior wall application

with AVFLSTSSODK installed

PRE-INSTALLATION INFORMATION

c. Caulking or sealants are applied to areas such as joints

around window and door frames, between sole plates

and oors, between wall-ceiling joints, between wall

panels, at penetrations for plumbing, electrical and gas

lines and other openings.

The following formula can be used to determine the maximum heater rating per the denition of unconned space:

BTU/Hr = (L1 + L2) Ft x (W) Ft x (H) Ft

50

Consider two connecting rooms with an open area

between, with the following dimensions:

L1 = 151/2 Ft., L2 = 12 Ft., W = 12 Ft., H = 8 Ft.

BTU/Hr = (151/2 + 12) x (12) x (8)

50

If there were a door between the two rooms the calculation

would be based only on the room with the heater.

BTU/Hr = (151/2) x (12) x (8)

50

Counter

Fireplace

H

W

FIREPLACE LOCATION

This unvented replace requires no outside venting and

burns cleanly and eciency. As a zero-clearance unvented

replace, it can be installed recessed into any wall that is

accessible to a gas line, except in a bedroom or bathroom.

Carefully select the best location for installation of your

unvented replace. The following factors should be taken

into consideration.

• Clearance to side wall, ceiling, woodwork and window

or other combustibles. Refer to Clearance and Height

Requirements section on Page 10. Minimum clearances to combustibles must be maintained.

• Location must not be aected by drafts caused by

kitchen exhaust fans, ceiling fans, return air registers

for forced air furnaces / air conditioners, windows or

doors.

• Installation must provide adequate ventilation and

combustion air.

• DO NOT INSTALL THIS MODEL IN A BEDROOM

OR BATHROOM.

• Location should be out of high trac areas and

away from furniture and draperies due to heat from

rebox.

• Never obstruct the front opening of the unvented re-

place or restrict the ow of combustion and ventilation

air.

• Minimize modications to existing construction. Refer

to Figure 5 below for location suggestions.

• Do not install in the vicinity where gasoline or other

ammable liquids may be stored. The unvented rebox must be kept clear and free from the combustible

materials.

Figure 4.

WARNING!

If the area in which the heater may be operated

does not meet the required volume for indoor

combustion air, combustion and ventilation

air shall be provided by one of the methods

described in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, the International Fuel Gas

Code or applicable local codes.

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Figure 5. Possible Fireplace Locations

FP3029

9

Page 10

PRE-INSTALLATION INFORMATION

AVFLST Vent Free Fireplace

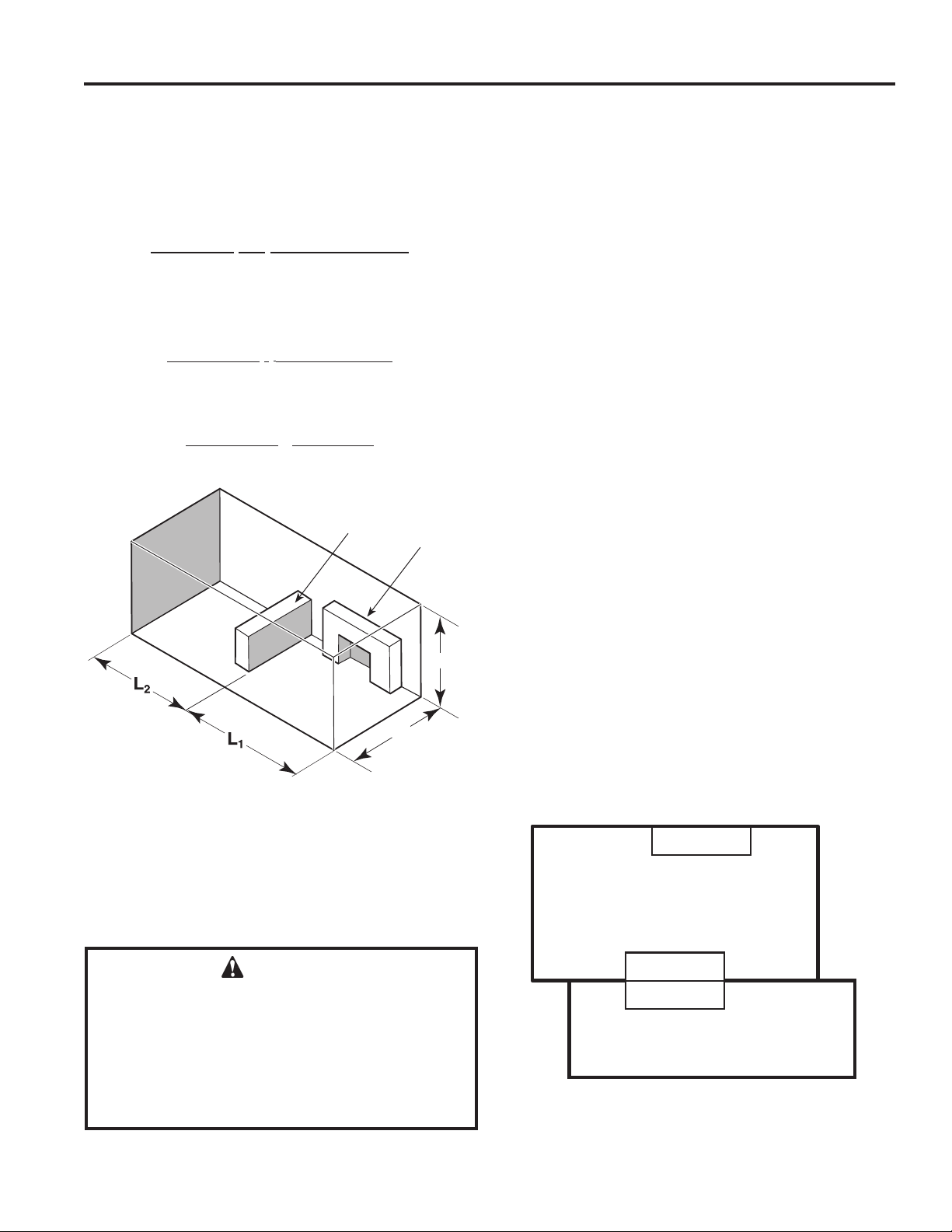

CLEARANCES AND HEIGHT

REQUIREMENTS

Ensure that minimum clearances shown in Figures 6 and

7 are maintained. Left and right clearances are determined

when facing the front of the rebox.

Follow these instructions carefully to ensure safe installation. Failure to follow these requirements may create a

re hazard.

Sidewall Clearances — The clearance from the inside of

the appliance to any combustible adjacent wall should not

be less than 6". Figure 6

Ceiling Clearance — The ceiling must be at least 36" from

the rebox opening. Figure 6

WARNING!

The dimensions shown in Figures 6 and 7

are minimum clearances to maintain when

installing this heater. Left and right clearances

are determined when facing the front of the

heater.

Follow these instructions carefully to ensure

safe installation. Failure to follow instructions

exactly can create a re hazard.

Floor Clearance — The replace may be installed directly

on a combustible oor or a raised platform of an appropriate

height. Do not place replace on carpeting, vinyl, tile or

other soft oor coverings. It may, however, be placed on at

wood, plywood, particle board or other hard surfaces. Be

sure replace rests on a solid continuous oor or platform

with appropriate framing for support so that no cold air can

enter from under the rebox. See note below regarding

oor installation with wide contemporary faces.

Mantel clearances — Must meet the clearance requirements detailed in Figures 6 and 7.

Wall

Stud

Mantel Clearances shown apply to both sides

of the See Through Unit.

36" Minimum

From Opening

12

" Max.

Depth

" Min.

6

1

2

/2" Max

Depth

28

" Min.

From Opening

18

" Min.

From Opening

FP3006

28"

Top of Fireplace

Opening

SIDE VIEW

Fireplace

Opening

TOP VIEW

12"

23"

6"

18"

1"

2¹⁄₂"

3"

Insulation

Board

Stando

1

2

/2"

FP3007

1¹⁄₂"

3¹⁄₂"

4¹⁄₂"

45°

5"

6"

FP3008

Figure 6. Sidewall and Ceiling Clearances

10

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Figure 7. Mantel Clearances

Page 11

AVFLST Vent Free Fireplace

Good Faith Guidelines for TV Installa ons above a Typical Gas Fireplace

TV on the wall

PRE-INSTALLATION INFORMATION

TV recessed into the wall

TV Wall

Bracket

TV

A

Mantel

D

Mantel and TV Clearances shown apply to both

sides of the See Through Unit.

Item Minimum Dimensions

A 6 inches

4 inches

B

C 28 inches

D

12 inches

C

BB

D

C

Fireplace

Notes:

1. These are good faith recommended clearances only and not a guarantee of compliance with all TV

manufacturers’ maximum allowable opera

2. Since every home has unique air

can vary from manufacturer to manufacturer and from model to model, actual TV temperatures should

be validated at the

temperature exceeds the manufacturers’ maximum allowable opera

TV’s technical speci

informa

3. Mantel height and depth must conform to mantle requirements specified in the

manual.

on or have ques ons regarding the informa

me of each installa on. TVs should not be used in situa ons where the actual TV

ons. Contact the TV’s manufacturer directly if you cannot locate this

ca

ow characteris

ng temperatures.

cs and maximum allowable opera ng temperatures

on.

Fireplace

ng temperatures iden ed in the

replace installa

4. “C” dimension taken from the top of the hood or fireplace opening.

Sugges ons on how to further reduce TV temperatures:

5.

a. Increase “A” dimension.

b. Increase “C” dimension, however, increasing “B” dimension beyond maximum recommended

typically results in higher temperatures.

on

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

11

Page 12

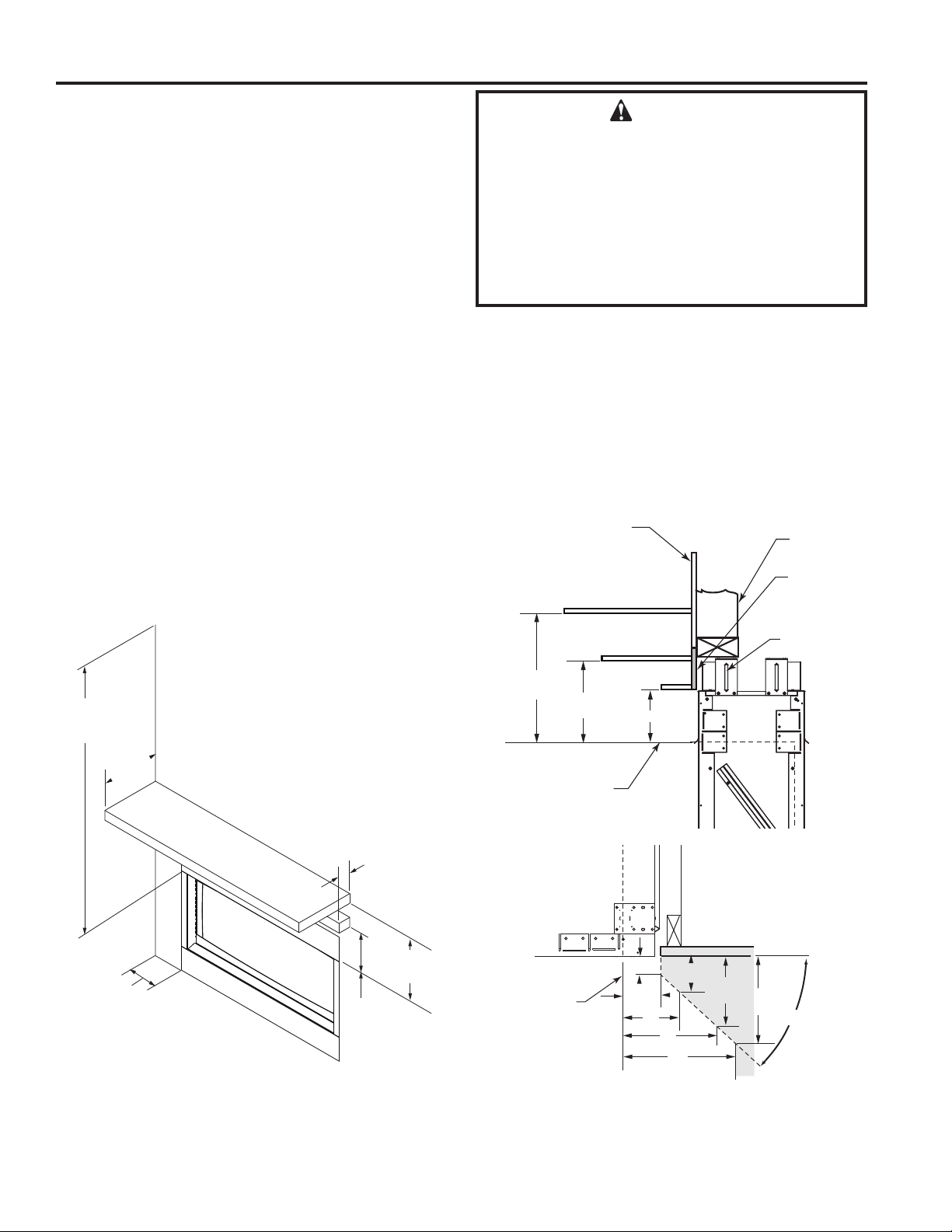

FIREPLACE INSTALLATION

44"

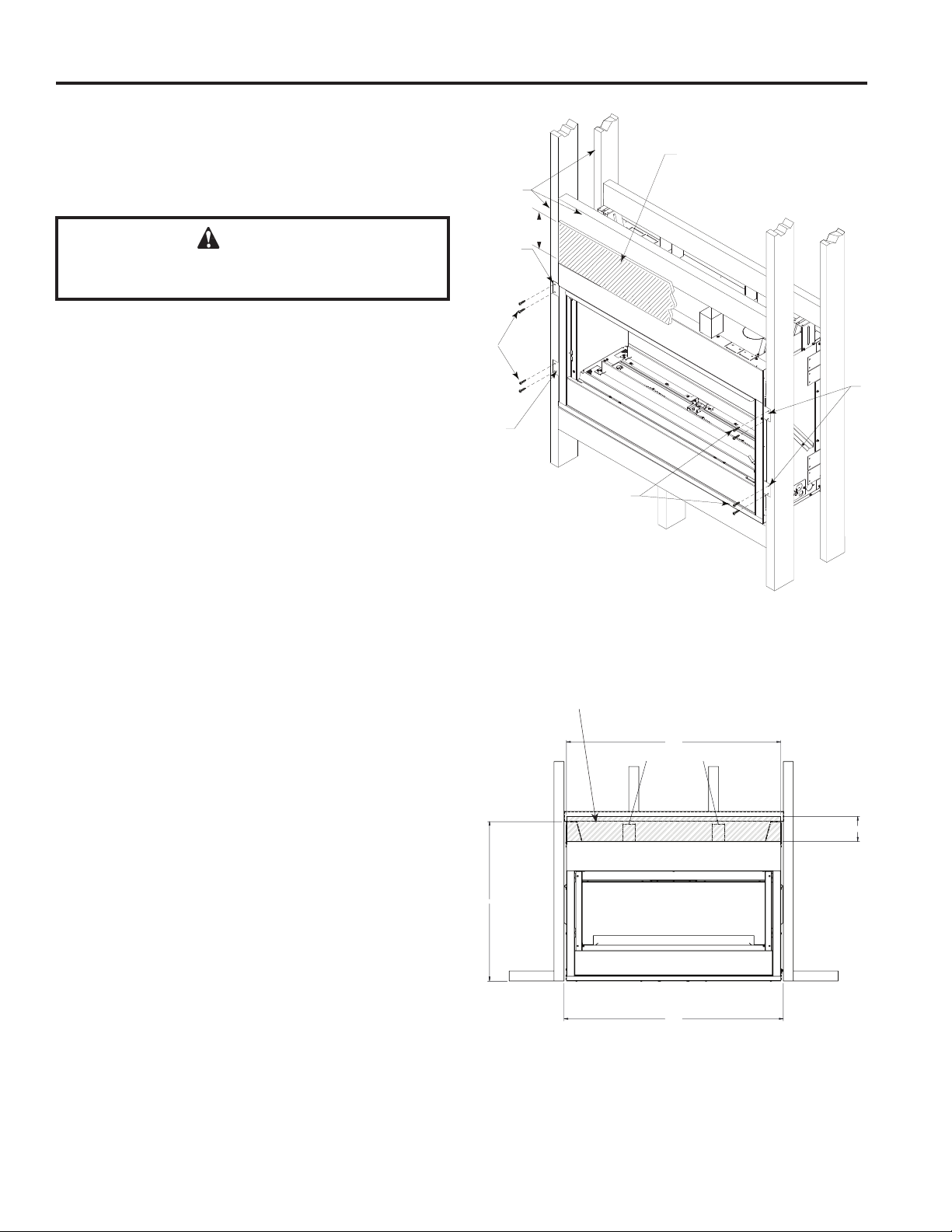

SECURE FIREPLACE TO FRAMING

AVFLST Vent Free Fireplace

The replace must be secured to the framing studs as

shown in Figure 8. Use eight (8) screws to attach replace

to framing. The side nailing anges are 1⁄2" or 5⁄8" to accommodate dierent wall thickness.

WARNING!

Never install combustible materials over front

face of replace.

FINISHING MATERIAL

NOTE: Any remote wiring (i.e. remote control, wall

switch), must be done prior to nal nishing to avoid costly

reconstruction.

Only noncombustible materials (i.e. brick, tile, slate, steel,

or other materials with a UL re rating of Zero) may be

used to cover the black painted face of the appliance. It is

permissible to bring combustible wall board to the top of

the standos on the top and to the wall board stand-os

on the sides of the unit. A 300°F minimum adhesive may

be used to attach facing materials to the black surface. If

joints between the nished wall and the replace surround

are sealed, a 300°F minimum sealant material (General

Electric RTV103 or equivalent) must be used.

NOTE: Fireplace may be installed on top of framing or

platform constructed of combustible materials which do

not protrude beyond the face.

Noncombustible Material

Framing

Members

Nailing

Flange

Screws

Nailing

Flange

Figure 8. Secure Fireplace to Framing Studs

5”

Screws

Nailing

Flange

NONCOMBUSTIBLE FACING INSTALLATION

CAUTION: The noncombustible wall board supplied with

this unit can be damaged if dropped or struck. Handle

with care.

1. Using drywall screws, secure the noncombustible board

to the two brackets on top of the unit. IMPORTANT: To

avoid cracking the board, pre-drill holes prior to securing

to the unit/framing.

2. Wipe any debris or dust from the noncombustible board

and drywall.

3. It is highly recommended to prime the facing using a

quality primer prior to taping and mudding. This will

ensure proper adhesion of both the tape and mud. The

supplied board is very porous.

4. Tape the seams using a mesh type tape.

5. Mud seams as normal. We recommend using a product

called Durabond high strength compound for the rst

coat. This product can be purchased at any hardware

store. Follow manufacturer's recommendations for curing

the mud. NOTE: Depending upon the nal nishing

method, use a minimum rated 300 degree sealant, drywall compound or thin set to seal the side and top joints.

6. Prime wall for a second time for proper adhesion of paint.

Supplied noncombustible board

43"

MOUNTING POINTS

32"

Figure 9. Noncombustible board installation

5"

12

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Page 13

AVFLST Vent Free Fireplace

CONNECT THE GAS

NOTICE: A qualied gas appliance installer must connect

the heater to the gas supply. Consult all local codes.

►

Note: Gas line may be installed on the left or right side of

the appliance.

WARNING!

This appliance is equipped for either natural or propane

gas. Field conversion is not permitted.

WARNING!

Use new black iron or steel pipe. Internally

tinned copper or copper tubing can be used

per National Fuel Code, section 2.6.3, providing

gas meets hydrogen sulde limits, and where

permitted by local codes. Gas piping system

must be sized to provide minimum inlet

pressure (Listed on Data Plate) at the maximum

ow rate (BTU/hr). Undue pressure loss will

occur if the pipe is too small.

A manual shutoff valve must be installed

upstream of the appliance. Union tee and

plugged 1⁄8" NPT pressure tapping point should

be installed upstream of the appliance. Figure

10

A sediment trap should be installed upstream

to prevent moisture and contaminants from

passing through the pipe to appliance controls

and burners. Failure to do so could prevent the

appliance from operating reliably. Figure 10

FIREPLACE INSTALLATION

WARNING!

CHECK GAS TYPE: The gas supply must be the

same as stated on the heater’s rating plate. If the

gas supply is dierent, DO NOT INSTALL THE

HEATER. Contact your dealer for the correct

model.

IMPORTANT: Loosen the pipe adapter on the ex tube

before installing to the system piping.

Always use an external regulator for all propane/LPG heaters only, to reduce the supply tank pressure to a maximum

of 13" w.c. This is in addition to the internal regulator in the

heater valve.

When tightening the joint to the valve, hold the valve

securely to prevent movement.

Test all gas joints from the gas meter to the heater valve for

leaks using a gas analyzer or soap and water solution after

completing connection. DO NOT USE AN OPEN FLAME.

WARNING!

Connecting directly to an unregulated

propane/LP tank can cause an explosion.

WARNING!

DO NOT USE OPEN FLAME TO CHECK FOR

GAS LEAKS.

Figure 10. Gas Connection

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

To Fireplace

Stainless

Flexible Tube

Manual Shuto

Valve

Sediment

Trap

Pipe

Coupling

Pipe

Locations Pressure Tapping

Point Installation

Gas Supply Inlet

Tee Joint

3” Min.

Pipe Nipple

Cap

13

Page 14

FIREPLACE INSTALLATION

CHECK GAS PRESSURE

Figure 11

Check the gas pressure with the appliance burning and

the control set to HIGH.

The valve regulator controls the burner pressure which

should be checked at the pressure test point.

Open control access door at bottom front of unit to nd

valve and regulator.

Turn captured screw counterclockwise two or three turns

and then place tubing to pressure gauge over test point.

Use test point “A” closest to gas inlet. If the pressure is not

within the range listed for your gas type turn the valve regulator until it is within range. After taking pressure reading,

be sure and turn captured screw clockwise rmly to reseal.

Do not over torque. Check for gas leaks.

GAS PRESSURES

NATURAL PROPANE (LP)

Inlet Minimum 5.0" w.c. 11.0" w.c.

Inlet Maximum 10.5" w.c. 13.0" w.c.

Regulator Pressure

Setting

Pilot Regulator 3.5" w.c. —

3.5" w.c. 10" w.c.

AVFLST Vent Free Fireplace

TEST PORT 'A'

Figure 11. Pressure Test Point Location

14

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Page 15

AVFLST Vent Free Fireplace

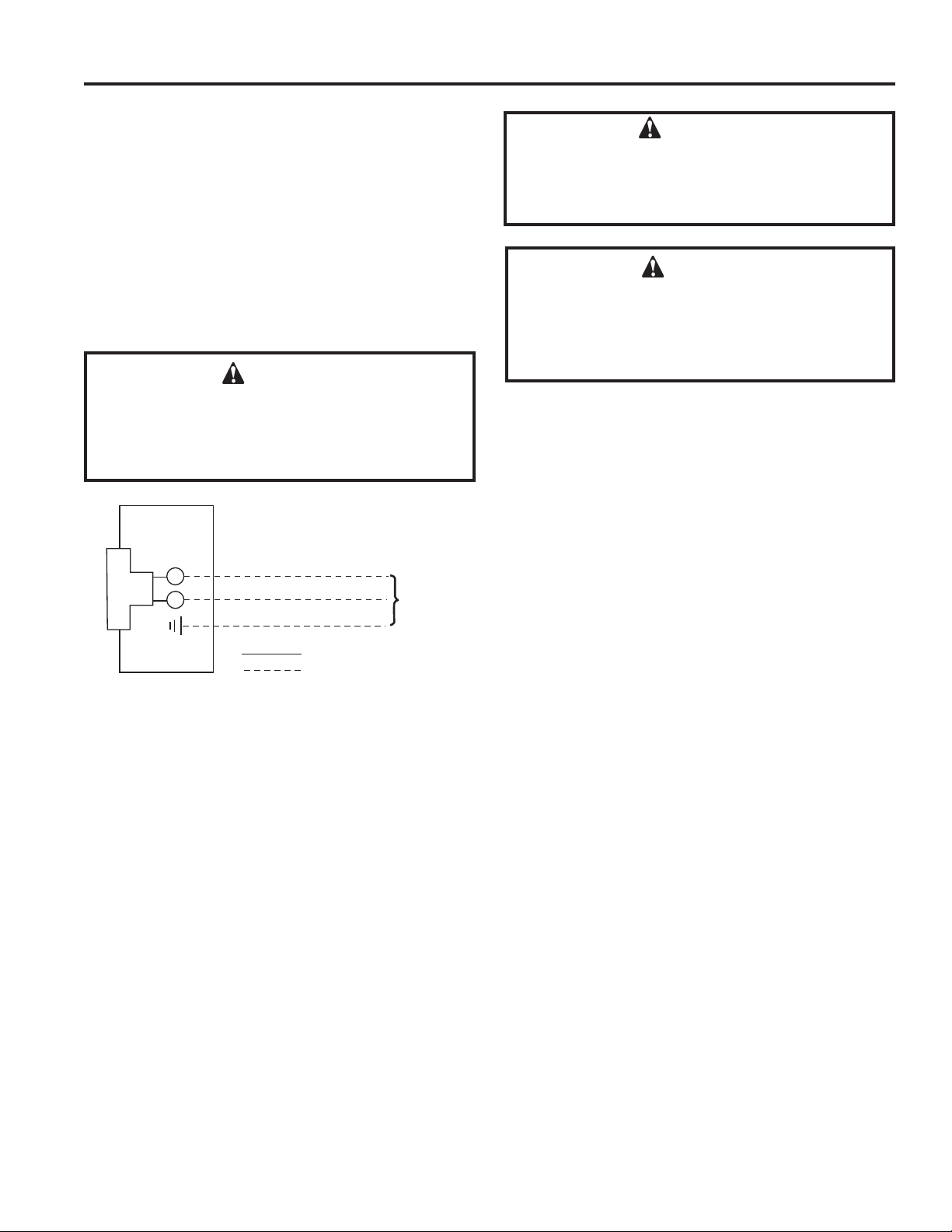

WIRING JUNCTION BOX

1. Before installing, wire the receptacle into an electrical

circuit. This should be done before framing the replace. Wire with minimum 60° C wire in accordance

with prevailing codes.

2. Remove the cover plate located on the outer shell-

►

right side.

3. Loosen two screws on the Romex connector, feed the

necessary length of wire through the connector and

tighten the screws.

4. Make all necessary wire connections and reattach the

cover plate to the outer shell.

WARNING!

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify

proper operation after servicing.

ELECTRICAL INSTALLATION

WARNING!

Electrical connections should only be performed by

a qualied licensed electrician. Main power supply

must be turned o before connecting to the main

electrical power supply or performing service.

WARNING!

Electrical Grounding Instructions:

This appliance is equipped with a three-prong

(grounding) plug for your protection against shock

hazard and should be plugged directly into a

properly grounded three prong receptacle.

IMPORTANT: Always check local building codes. This installation must comply with local regulations as well as

the National Electric Code.

Junction Box

Figure 12. Junction Box Wiring Diagram

120V AC

60Hz

Factory Supplied

Not Supplied

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

15

Page 16

ELECTRICAL INSTALLATION

TO JUNCTION

AVFLST Vent Free Fireplace

Wiring Requirements

Intellire™ Plus ODS Ignition System Wiring

• Wire the appliance junction box to 110-120 VAC for

proper operation of the appliance.

WARNING! Risk of Shock or Explosion! DO NOT wire

IFP ODS controlled appliance junction box to a switched

circuit. Incorrect wiring will override IFP ODS safety lockout.

• Refer to Figure 13 and 14, IFP ODS Wiring Diagram.

• This appliance is equipped with an Intellire™ Plus

control valve which operates on a 6 volt/1.5 AMP system.

• Plug the 6 volt transformer plug into the appliance junction

box to supply power to the unit OR install 4 AA cell

batteries (not included) into the battery pack before use.

PILOT

THERMOCOUPLE MODULE

NOTICE: Batteries should only be used as a power source

in the event of an emergency power outage. Batteries

should not be used as a primary long-term power source.

Battery polarity must be correct when installing batteries.

When using batteries as a power source, the 6-volt

transformer must be unplugged from the receptacle.

Do not store batteries in the battery pack when the

appliance is powered by the 6 volt transformer connected

to permanent electrical service.

Accessories Requirements

• This appliance ships standard with a remote control.

Wiring for optional Hearth & Home Technologies approved

accessories should be done now to avoid reconstruction.

Follow instructions that come with those accessories.

THERMOCOUPLE

TO Y CORD

(120VAC) SEE

FIGURE 14 ON

NEXT PAGE

ORANGE

(PILOT)

Thermocouple Module Wire Assembly

6V DC

SUPPLY

CONTROL MODULE

FLAME

MODULATION

GREEN

(MAIN)

I

S

8K-1 Adapter Box Wire Assembly

RED

BLACK

BROWN

BROWN/RED

OPTIONAL ON/OFF

SWITCH

GROUND

THERMOCOUPLE

SENSOR

WHITE

BATTERY PACK

SENSOR

ORANGE

6V DC

ODS Adapter Box

ODS to Adapter Box Wire Assembly

AUX300 MODULE

AUX 1

FAN

AUX 2

TO TOP DOME

RC300 4.5V DC

(AAA X 3)

BOX 120VAC

LIGHT

Figure 13. IntelliFire™ Plus ODS Wiring Diagram

►

16

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Page 17

AVFLST Vent Free Fireplace

6V DC Supply

(See Figure 13 on previous

page)

To Junction

Box 120VAC

Use Y cord supplied in install bag to plug in 6V

DC supply for control module and LED

transformer.

LED STRIP

LED STRIP

TRANSFORMER

TOP BUTTON

ON/HI/MED/LO/OFF

BLACK

BLACK

GREEN

RED

BOTTOM BUTTON

BLACK

Color Selection

BLACK

Figure 14. LED Wiring Diagram

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

CONTROL

MODULE

RED

GREEN

YELLOW

BLUE

17

Page 18

FINAL INSTALLATION

AVFLST Vent Free Fireplace

INSTALLATION OF AIR DEFLECTION

GLASS

NOTE: The 32" deector glass must be installed prior

to placing any reglass or stone media on the burner.

To install the air deection glass simply place the tabs

(located at the bottom of the glass) into the slots at

either end of the burner oor, in front of the burner ports.

The glass should stand upright, neither leaning forward

nor backward. Repeat for the second glass deector

installation.

FIREGLASS ONLY PLACEMENT

NOTE: Two (2) bags of reglass are supplied with the

replace. Both bags may be used to cover the entire oor

and burner. We advise against using additional reglass

as too much can cut o the proper amount of air the burner

needs to burn cleanly. This may cause sooting.

1. Spread reglass evenly in one layer over the entire oor

and burner. It is important to not have the reglass too

thick on ported area (single layer only).

2. Turn burner on and adjust reglass over ported areas

to achieve an even, clean ame.

GLASS AND OPTIONAL STONE KIT

PLACEMENT

1. For best results, spread reglass evenly over the entire

oor and burner making sure the reglass is not too

thick over the burner ports (single layer only).

2. Place the stones randomly in front of and behind the

air deection glass. CAUTION: Do not allow stones to

sit directly on burner or in ame. Figure 17.

3. Turn burner on and adjust reglass over the ported area

to achieve an even, clean ame. (page 28, Figure

22.)

Figure 15. Air Deection Glass Placement (before) Figure 16. Air Deection Glass Placement (after)

Burner Surface

Examples of

Stone Placement

Figure 17. Air Deection Glass and Stone Placement

18

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Page 19

AVFLST Vent Free Fireplace

WARNI NG : If you do not follow these instructions exactly, a fi re or explosion may result causing property damage, personal injury or loss of life.

A. This appliance is equipped with an intermittent pilot ignition (IPI) device which

automatically lights the burner. DO NOT try to light the burner by hand.

B. BEFORE LIGHTING, smell all around the appliance area for gas. Be sure to smell

next to the fl oor because some gas is heavier than air and will settle on the fl oor.

WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electric switch; do not use any phone in your building.

1. This appliance is equipped with an ignition device which automatically

lights the burner. DO NOT try to light the burner by hand.

GAS

VALVE

1. Equipped with wall switch: Turn ON/OFF switch to OFF.

Equipped with remote or wall control: Press OFF button.

Equipped with thermostat: Set temperature to lowest setting.

IPI LIGHTING INSTRUCTIONS

FOR YOUR SAFETY READ BEFORE LIGHTING

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fi re department.

C. DO NOT use this appliance if any part has been under water. Immediately call

a qualifi ed service technician to inspect the appliance and to replace any part of

the control system and any gas control which has been under water.

LIGHTING INSTRUCTIONS (IPI)

2. Wait fi ve (5) minutes to clear out any gas. Then smell for gas, including near the

fl oor. If you smell gas, STOP! Follow “B” in the Safety Information located on the

top of this label. If you do not smell gas, go to next step.

3. To light the burner:

Equipped

Equipped with remote or wall control: Press ON or FLAME button.

4. If the appliance does not light after three tries, call your service technician or gas

TO TURN OFF GAS TO APPLIANCE

2. Service technician should turn off electric power to the control when performing

with wall switch: Turn ON/OFF switch to ON.

Equipped with thermostat: Set temperature to desired setting.

supplier.

service.

4604-200

WARNING:

DO NOT CONNECT LINE VOLTAGE (110/120 VAC OR 220/240 VAC) TO THE CONTROL VALVE.

Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Refer to the owner’s information manual provided with

this appliance. For assistance or additional information, consult a qualifi ed installer,

service agency or the gas supplier.

This appliance needs fresh air for safe operation and must be installed so there are

provisions for adequate combustion and ventilation air.

CAUTION:

Keep burner and control compartment clean. See installation and operating instructions accompanying appliance.

Hot while in operation. DO NOT touch. Keep children, clothing, furniture, gasoline

and other liquids having fl ammable vapors away.

NOT FOR USE WITH SOLID FUEL

follow the National Fuel Gas Code, ANSIZ223.1/ NFPA 54, or the National Gas and

Propane Installation code, CSA B149.1.

For additional information on operating your

Hearth & Home Technologies fi replace, please refer to www.fi replaces.com.

.

,enon fi ;yna fi ,sedoc lacol htiw ecnadrocca ni dellatsni eb tsum ecnailppa sihT

4604-201

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

19

Page 20

OPERATING INSTRUCTIONS

AVFLST Vent Free Fireplace

Initial Use

Initial Break-in Procedure

• The replace should run three to four hours continuously

on high.

• Turn the replace o and allow it to completely cool.

This cures the materials used to manufacture the replace.

• Some people may be sensitive to smoke and odors.

• Smoke detectors may activate.

Heat Management

Burn Rate

The Artisan model has a variable burn rate which is controlled by the remote control. Therefore the ame height

is adjustable.

The ame height may be adjusted as desired by locating

the ame option on the remote control and adjusting up or

down to desired ame height.

Operation During A Power Outage

The IntelliFire™ Plus ODS intermittent pilot ignition system

comes with a battery backup system that enables the

system to operate in a power outage. The system oers

seamless transition from household AC power to battery

backup. A factory-installed battery pack is located in the

control cavity of the appliance. See Figure 18. Battery

longevity and performance will be aected by long term

exposure to the service temperatures of this appliance.

• Remote receiver is integrated into the ignition module

• Use the remote to turn the appliance on.

• To preserve battery life, do not use the HI/LO ame or

THERMOSTAT options.

Ignition Module:

• Locate the ignition module in the control cavity.

• Slide the ON/REMOTE/OFF switch to the ON position.

NOTICE: Some functionality will be lost when using

battery backup including remote control, lights, or any

other auxiliary functions that require household 110-120

VAC power.

To Return to Operation Using Electrical (AC) Power

Standard Wall Switch or Factory-Installed ON/OFF

Switch:

• Toggle the switch to OFF.

• Remove the batteries from the battery tray.

Wireless Remote:

• Slide the ON/REMOTE/OFF switch to the REMOTE

position.

• Remove the batteries from the battery tray.

Ignition Module:

• Slide the ON/REMOTE/OFF switch to the REMOTE

position.

• Remove the batteries from the battery tray.

NOTICE: Batteries should only be used as a power source

in the event of an emergency power outage. Batteries

should not be used as a primary long-term power source.

To Operate Fireplace Using Battery Power (DC):

1. Access the control cavity of the appliance. See Figure 18

for location. Lift the barrier screen o of the appliance.

2. Locate the battery tray and insert four AA cell batteries.

See Figure 18. Battery polarity must be correct or

module damage will occur. A complete wiring diagram

is included in the electrical section of the appliance

installation manual.

3. Turn the appliance on according to the instructions

below for the appropriate type of control:

Standard Wall Switch or Factory-Installed ON/OFF

Switch:

• Toggle the switch as you would under normal

circumstances.

Wireless Remote:

20

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Gas Valve

Control Module

Battery Tray

Figure 18. Control Cavity Location

Page 21

AVFLST Vent Free Fireplace

IntelliFire™ Plus ODS

Hearth & Home Technologies disclaims any responsibility

for, and the warranty will be voided by, the following actions:

• Installation and use of any damaged system component.

• Modication of the system component.

• Installation other than as instructed by Hearth & Home

Technologies.

• Installation and/or use of any component part not approved

by Hearth & Home Technologies.

Any such action may cause a re hazard.

• Read, understand and follow these instructions for safe

installation and operation.

Introduction

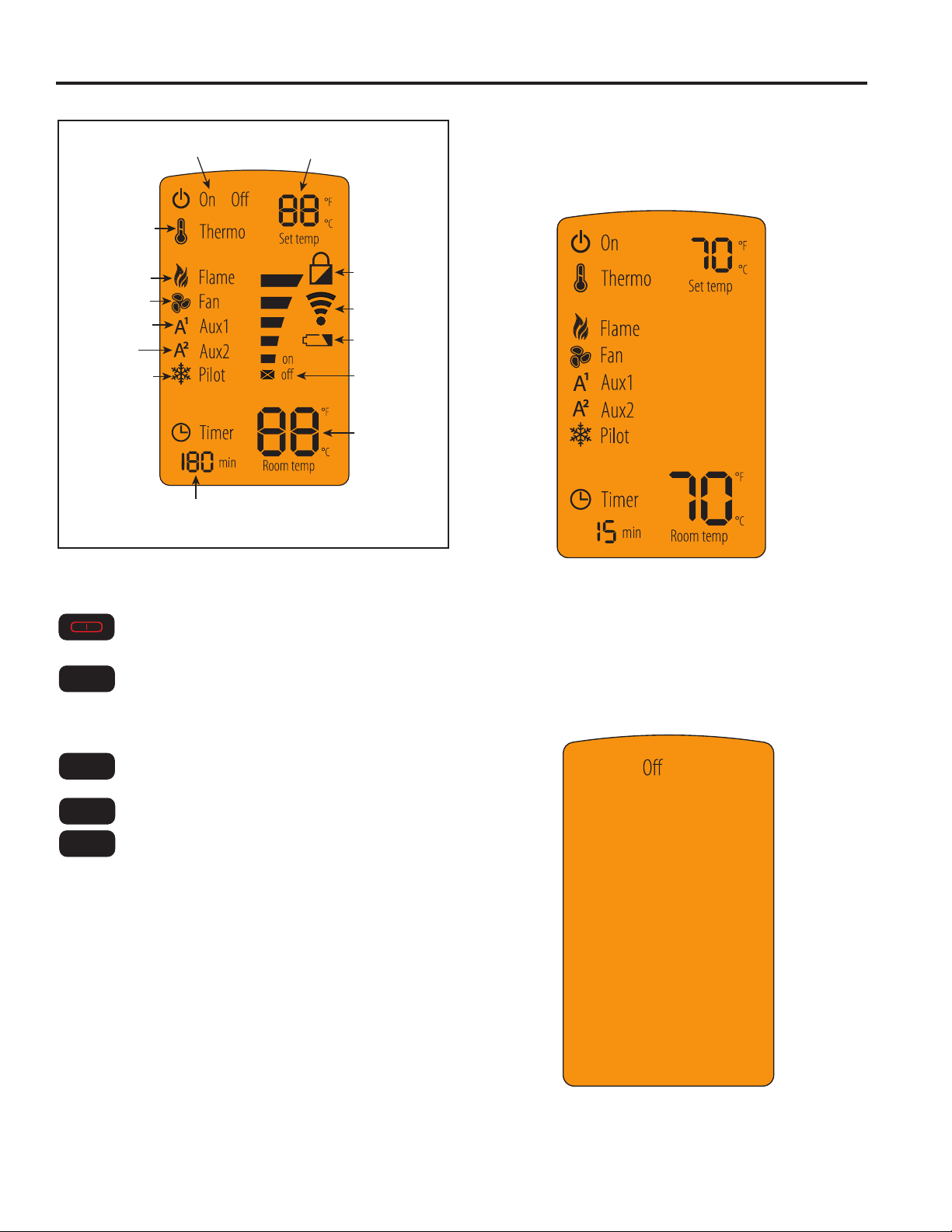

The RC300 multifunctional remote control is designed

to control light, ame height and interior dome lighting. The RC300 is equipped with thermostat functions

which can automatically control the temperature in the

room in which it is installed. The control is only for use

with the Hearth & Home Technologies IntelliFire Plus™

system (IPI). The AUX300 module is rated for 120 VAC,

60 Hz, and is required for operation of this remote control

device.

Installation Precautions

This remote control is tested and safe when installed in

accordance with this installation manual. Do not install

any components that may be damaged.

Do not modify, disassemble, or substitute any of the components included with this kit. Installation of this unit must

be done by a qualied service technician.

Placement of this remote control may aect performance.

An assessment of the space should be done prior to installation for optimum performance.

Determine Location

Determine the location for the remote control. The selected

location should be in the same space as the gas replace.

Never place this unit in a separate room. The remote control

must be placed within 30 feet (9.14 m) of the replace but

should not be exposed to extreme heat.

The RC300 is approved for interior installation and should

not be used in exterior applications.

• Keep remote control out of reach of children.

FCC Requirements

Warning! Risk of Fire! Changes or modication to

this unit not expressly approved by the party responsible

for compliance could void the user's authority to operate

the equipment.

Note: This equipment has been tested and found to

comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against

harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can

be determined by turning the equipment o and on, the

user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a circuit

dierent from that to which the receiver is connected.

• Contact the dealer or an experienced radio TV technician for help.

Changing Temperature Scale

To change the temperature display between Celsius and

Fahrenheit, remove the battery cover from the back of the

remote control and slide the switch to your desired temperature scale (see Figure 1). The screen will automatically change the indicators on the room temperature and

set temperature portion.

Figure 1. Temperature scale

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

21

Page 22

IntelliFire™ Plus ODS

Installation of Remote Control Housing

Caution! Risk of Fire! DO NOT install damaged or mod-

ied components. Warranty will be voided if damaged or

modied components are installed.

Kit components: One remote control, two #6 screws, two

wall anchors, 3 AAA batteries and one AUX300 module. If

batteries are properly installed the remote will turn on

1. Remove remote control components from packaging.

2. Remove battery cover from the back of the remote by

sliding it down and install 3 AAA batteries.

To prevent unintended operation when not using your replace for an extended period of time (summer months,

vacation, trips, etc):

• Remove batteries from remote control.

• Unplug switching adapter and remove back-up batteries.

3. Secure the remote control housing on a at wall surface using the two screws and wall anchors provided.

See Figure 2.

AVFLST Vent Free Fireplace

Figure 3. Remote in Housing

5. Close the housing door. See Figure 4.

Figure 2. Mounting Remote Control Housing

4. Place remote control inside housing. See Figure 3.

22

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Figure 4. Mounting Remote Control Housingng

Page 23

AVFLST Vent Free Fireplace

Programming the RC300 to the Control Module

Caution! Risk of burns! DO NOT program the

remote control to the control module when replace

is hot.

• Verify the ON/OFF/REMOTE switch is in the REMOTE

position. Green LED light will blink three times and wall

switch will beep once 5 seconds later when ready. See

Figure 5.

• Using a small item (such as a paper clip) press and

release the LEARN button located near the ON/OFF/

REMOTE switch. See Figure 5.

• Control module will beep once and LED will blink green

for 10 seconds.

• While the LED is blinking, press the POWER button on

the remote control. A double beep will come out of the

control module to indicate that it has been programmed

successfully.

NOTICE: Up to three remote controls can be programmed

into the control module. Simply press a button on the other

remote controls during the 10 second programming process

to add another remote into the system. It is recommended

to program only one RC300 remote control.

To clear memory in the control module, use a small item

(such as a paper clip) to press and release the LEARN

button. Control module will beep once and LED will blink

green for 10 seconds DO NOT press any buttons on the

remote during the ten seconds that the green LED blinks.

The memory will be cleared. Note that the RC300 will not

be programmed if it’s in STANDBY mode. Press the ON/

OFF button twice to switch to IDLE mode.

IntelliFire™ Plus ODS

REMOTE POSITION

Figure 5. Programming RC300 (Control Module is located under

unit.)

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

23

Page 24

IntelliFire™ Plus ODS

V

Menu

V

V

V

AVFLST Vent Free Fireplace

Display Screen

FIREPLACE STATUS

THERMOSTAT

FLAME HEIGHT

FAN SPEED

ADJUSTABLE

AUXILIARY

ADJUSTABLE

OUTPUT (ON/OFF)

CONSTANT PILOT

TIMER DISPLAY/FUNCTION

Figure 8. RC300 Display Screen

THERMOSTAT DESIRED

TEMP SETTING

CHILD LOCK

INDICATOR

TRANSMISSION

INDICATOR

LOW BATTERY

INDICATOR

FUNCTION LEVEL

INDICATOR

ROOM TEMP

DISPLAY

Idle When Remote is in ON Mode

The remote control will go into an idle mode if no buttons

are pressed within 5 seconds. Press any button to resume full functionality. In idle mode, only active functions

will show on the screen.

Function Buttons

Use POWER button to turn the unit on and o.

Menu

Use MENU button to display the menu functions.

Only functions that can be activated will be

displayed. For example: Flame Height will not

be displayed when the remote status is OFF.

Select

Use the SELECT button to select the current

feature.

V

Use the UP and DOWN arrows to toggle

through the menu functions and value selec-

V

tions in the submenus.

Figure 9. RC300 Idle Mode

Standby mode

The remote control will go into a standby mode if no buttons are pressed within 5 minutes. Press the POWER

button to reactivate the remote control to ON mode. Active functions will be displayed

24

Figure 10. RC300 Standby Mode

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Page 25

AVFLST Vent Free Fireplace

IntelliFire™ Plus ODS

About ON Mode

• All functions can be accessed when the remote control

is in the ON mode.

• Only active functions will be displayed when the remote

control is in the ON mode.

About OFF Mode

Only the following functions can be accessed in the OFF

mode:

• AUX1

• AUX2-Top Dome Light

Only active functions will be displayed when the remote

control is in the OFF mode.

Turning On the Fireplace

• Press the POWER button to turn the replace ON. The

replace will rst ignite the pilot. Once the pilot ame is

established the main burner will be lit.

NOTICE: Whenever the replace is cycled from OFF to

ON, the main burner will light on high for 10 seconds before

returning to the previous user setting.

Adjusting Flame Height

• Press the MENU button to activate the menu.

• Using the UP and DOWN arrows highlight the FLAME

icon and press SELECT.

• Use the UP and DOWN arrows to adjust the FLAME

HEIGHT, then press SELECT. The FLAME HEIGHT

can be adjusted to 5 dierent settings.

NOTICE: FLAME HEIGHT will not be adjustable for rst

ten seconds when replace is turned on.

NOTICE: The system will remember the previous FLAME

HEIGHT setting and will automatically adjust after 10

seconds.

Adjusting Thermostat

• Press the MENU button to activate the menu.

• Using the UP and DOWN arrows highlight the THERMO

icon and press SELECT.

• Use the UP and DOWN arrows to turn the THERMO ON

or OFF, then press SELECT (the SET TEMP will start

blinking). Using the UP and DOWN arrows select the

desired temperature and press SELECT.

NOTICE: If the THERMO function is on, the SET TEMP

can be adjusted at any time by pressing the UP and DOWN

arrows.

NOTICE: As the ROOM TEMP (RT) approaches SET

TEMP (ST), the remote system will automatically adjust

the ame height. If the RT rises above ST, the replace

will shut down the main burner. After this, the replace will

turn back on after the RT drops below the ST.

NOTICE: The system requires a two degree Fahrenheit

or higher temperature dierence between RT and ST for

the replace to turn on.

NOTICE: The system will remember the previous TEMPERATURE setting when THERMOSTAT mode is cycled

ON or OFF.

NOTICE: If your installation includes an optional wired

ON/OFF wall switch, it should be in the OFF position when

using the RC300 in thermostat mode.

Adjusting Timer

• Press the MENU button to activate the menu.

• Using the UP and DOWN arrows highlight the TIMER

icon and press SELECT.

• Use the UP and DOWN arrows to turn the TIMER ON

or OFF, then press SELECT. Using the UP and DOWN

arrows select the desired set time and press SELECT.

Timer operates in increments of 15, 30, 45, 60, 90, 120

and 180 minutes.

NOTICE: Some models use xed valves, which cannot

be adjusted.

AUX2 Function (Top Dome Light)

• Press the MENU button to activate the menu.

• Using the UP and DOWN arrows highlight the AUX1 icon

and press SELECT.

• Use the UP and DOWN arrows to adjust the AUX1 output,

then press SELECT. The AUX1 function can be adjusted

to 4 dierent settings: HI, MED, LOW and OFF.

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Setting the Child Lock

• Press and hold the MENU and UP arrow buttons simul-

taneously for 4 seconds to enable or disable the child

lock feature.

NOTICE: No functions will be usable until child lock feature

is disabled.

25

Page 26

IntelliFire™ Plus ODS

Power Outage

• If replace battery backup system IS installed at time of

power outage, replace operation will not be interrupted.

• If replace battery backup system IS NOT installed at

time of power outage, replace will shut o. To resume

replace operation, install battery backup.

NOTICE: Battery polarity must be correct or module

damage will occur.

Manual Fireplace Shuto

In the unlikely event that the remote wall switch malfunctions and will not turn o the replace, call your dealer

for service assistance. In the meantime, you may choose

one of the following actions to turn o the replace:

CAUTION! Risk of burns! Fireplace surfaces are hot

when operating and during cool down. Use care and wear

gloves when opening the front and accessing components inside the replace.

Check remote screen for battery level indicator, replace

the batteries if low battery is indicated (See Figure 8,

page 24).

The replace may be manually shut down by one of the

following methods:

Turn o the control module:

• Open or remove the decorative front to access the control

module.

• Move switch to OFF (See Figure19, page 27).

Disconnect power to the control module:

• Open or remove the decorative front to access power

cord to the junction box and/or back-up batteries.

• Unplug the control module and/or remove back-up

batteries.

Shut o gas to the control:

• Open or remove the decorative front and locate the gas

shut-o valve to the left of the gas control.

• Rotate the valve 90 degrees to turn o gas supply.

Turn o power to the replace (if back-up batteries are

not installed):

• Unplug unit from electrical source, if you cannot unplug

then:

• Locate house circuit breaker for replace.

• Turn o the circuit breaker.

AVFLST Vent Free Fireplace

26

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Page 27

AVFLST Vent Free Fireplace

IntelliFire™ Plus ODS

Detailed Component Operating Instructions— Intellire™ Plus ODS

Control Module Operation

1. The control module has an ON/OFF/REMOTE selector

switch that must be set. See Figure 19.

OFF Position: Appliance will ignore all power inputs and

will not respond to any commands from a wall switch or

remote. The unit should be in the OFF position during

installation, service, battery installation, fuel conversion,

and in the event that the control goes into LOCK-OUT

mode as a result of an error code.

ON Position: Appliance will ignite and run continuously

in the HI ame setting, with no adjustment in ame

output. This mode of operation is primarily used for

initial installation or power outage operation with battery

backup.

REMOTE Position: Appliance will initiate commands

from an optional wired wall switch and/or the wireless

remote (RC300).

2. If using a wired wall switch with the module in REMOTE

mode, the ame output can be adjusted with the HI/LO

selector switch on the module. See Figure 19. Note

that the ame HI/LO selector switch will become inactive

once a remote control (RC300) is programmed to the

control module. Note that the control module will always

ignite the replace on HI and remain so for the initial 10

seconds of operation. If the HI/LO is switched to the

LO position, the ame output will automatically drop to

the lowest setting after the ame has been established

for 10 sec. After this 10 second period, the ame can

be adjusted from HI to LO with the switch.

3. The control module has safety feature that automatically

shuts down the replace after 9 hours of continuous

operation without receiving a command from the RC300

remote.

4. If you intend to use both an optional wired wall switch

and the RC300 remote control to operate your replace,

the wall switch will override any commands given by

the remote.

5. Module Reset

This module may lock-out under certain conditions.

When this occurs, the appliance will not ignite or

respond to commands. The module will go into

lock-out mode by emitting three audible beeps, then

continuously displaying a RED/GREEN error code at

its status indicator LED.

• Check battery tray. Remove batteries if installed.

Batteries should only be installed for use during power

outages.

• Locate the module selector switch. (See Figure 19).

MODULE

SELECTOR

SWITCH

FLAME HI/LOW

SWITCH

Figure 19. Control Module

STATUS

INDICATOR LED

NG/LP GAS-TYPE

SELECTOR SWITCH

• Set the module selector switch to the OFF position.

• Wait ve (5) minutes to allow possible accumulated gas

to clear.

• Set the module selector switch to ON or REMOTE

position.

• Start the appliance.

WARNING! Risk of Explosion! DO NOT press the

module reset switch more than one time within a ve

minute time period. Gas could accumulate in rebox. Call

a qualied service technician.

Nine Hour Safety Shutdown Feature

The appliance has a safety feature that automatically

shuts down the replace after nine hours of continuous

operation without receiving a command from the wall

switch or optional remote.

Appliance ON/OFF

Use the IntelliFire™ Plus Remote Control to control the ON/

OFF function of the appliance. Follow instructions included

with the remote control. If desired, a wall switch may be

installed to control the ON/OFF function of the appliance.

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

27

Page 28

FLAME APPEARANCE & LED CONTROL

FLAME APPEARANCE

Flames from the pilot, front and rear burner should be

visually checked as soon as the heater is installed.

In addition, periodically check the ames visually during

operation.

CHECK THE PILOT FLAME

The pilot ame must always be present when the

heater is in operation. It should just touch the top of the

thermocouple tip for natural gas. Refer to Figure 20 for

correct pilot ame.

If the pilot ame does not touch the thermocouple, then

the main burner cannot function reliably. Refer to Figure

21 for incorrect shape of pilot ame.

AVFLST Vent Free Fireplace

Figure 22. AVFLST42 Burner Flame Appearance

(Shown with reglass only)

CHECK THE BURNER FLAME

In normal operation, at full rate after 15 minutes, the ames

should appear as shown in Figure 22.

Thermocouple

for Natural Gas

Figure 20. Correct ODS Pilot Flame Appearance

Thermocouple

for Natural Gas

Thermocouple

for LP

Thermocouple

for LP

LED CONTROL

– Multi-colored LED lights — Two buttons turn LEDs

On (Hi/Med/Lo) and Off and cycles through the color

selection.

– Color selection options — Using the color selection

button, you can choose from ten (10) dierent lighting

options.

1. Color fade – This selection will cycle through the range

of colors listed below.

2. Color fade (slow) – This selection is the same as the

previous selection; only at a slower rate.

3. Pause color – This selection will allow the user to

choose a custom color through the hues of colors of

the slow fade.

• Blue

• Violet

• Red

• Yellow

• Green

• Cyan

• White

4. Pushing the color selection button again cycles back

to the rst color fade selection.

Figure 21. Incorrect Pilot Flame Appearance

28

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

ON (Hi/Med/Lo)

O button

Screws

Figure 23. LED Controls

Color selection

button

Page 29

AVFLST Vent Free Fireplace

MAINTENANCE AND CLEANING

CLEANING AND SERVICING

Annual inspection and cleaning by your dealer or qualied service technician is recommended to prevent

malfunction and/or sooting.

WARNING!

Turn off heater and allow to cool before

cleaning. Disconnect electrical power before

cleaning or servicing.

Remove reglass and/or stones as applicable.

PERIODIC CLEANING – Refer to parts diagram for

location of items discussed below.

• Do not use cleaning uid to clean any part of heater.

• Brush stones with soft bristle brush or vacuum with

brush attachment.

• Remove glass media and rinse with clean water.

Spread media out on paper towel or equivalent and

allow to dry completely.

• Vacuum loose particles and dust from the burner,

controls.

• Inspect and clean burner air intake holes. Remove

lint or particles with vacuum, brush, or pipe cleaners.

Failure to keep air intake holes clean will result

in sooting and poor combustion.

• The replace face should be dusted and wiped with

a wet soapy cloth.

Top light

Figure 24. Top Light Position; Porcelain Panel Screw Location

REPLACING TOP LIGHT BULB

TOP LIGHT BULB INSTALLATION

1. Remove three screws holding light cover in place

(as shown in Figure 25.)

2. Insert (1) 90W bulb provided into socket.

3. Replace top light cover with three screws.

Light cover

screws

ANNUAL CLEANING/INSPECTION – Refer to parts

diagram for location of items discussed below.

• Inspect and clean burner air intake holes. Remove

lint or particles with vacuum, brush or pipe cleaners.

Failure to keep air intake holes clean will result in

sooting and poor combustion.

• Inspect and clean all burner ports.

• Inspect ODS pilot for operation and accumulation of

lint at air intake holes. (Figure 20)

• Verify ame pattern for proper operation.

• Verify smooth and responsive ignition of main burner

and rear burner.

• Replace batteries in remote control device.

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Figure 25. Top Light Screws

REPLACING LED STRIPS

1. Remove two air deection glass pieces.

2. Remove glass media from hearth and burner area.

3. Remove nineteen (19) screws holding front and rear

hearth. Remove both and set aside. See Figure 29.

Figure 26. LED Control Assembly Screws

29

Page 30

MAINTENANCE AND CLEANING

AVFLST Vent Free Fireplace

4. Remove two screws holding LED control assembly

in place. See Figure 26. Turn at and pull forward.

5. Remove the two black LED connectors.

6. From inside unit, start at one end of the strip and

begin to peel from base.

7. Repeat with second strip.

8. Peel paper from adhesive back on new LED strip

and place in track. Feed wire through hole on left

end of unit.

9. Reconnect strips to control module and replace control module with two screws.

10. Reinstall front and rear hearth with nineteen (19)

screws.

11. Install two (2) air deection glass panels and glass

media.

Porcelain

panel screws

PORCELAIN PANEL REMOVAL

1. Remove two (2) air deection glass panels.

2. Remove glass media from hearth and burner area.

3. Remove two (2) screws holding top of panel in place.

See Figure 27.

4. Remove single retainer clip at base of panel. See

Figure 28.

5. Tilt panel out from top and remove.

6. To reinstall panel, insert at an angle with bottom

rst. Tilt top in aligning holes at top and install two

retainer screws.

7. Install retainer bracket at base.

Retainer clip

Figure 27. Porcelain Panel Screw Location

Figure 29. Hearth Screw Locations

30

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

Figure 28. Porcelain Panel Clip Location

Ten Rear Hearth Screws

Nine Front Hearth Screws

Page 31

AVFLST Vent Free Fireplace

Figure 30. LED Strip Location

OPERATION AND OPTIONAL ACCESSORIES

LED strips

OPERATING INFORMATION

Avoid any drafts that alter burner ame patterns. Do

not allow fans to blow directly into the replace. Do not

place a blower inside the burn area of the rebox. Ceiling

fans may create drafts that alter ame patterns. Sooting

and improper burning will result.

During manufacturing, fabricating and shipping, various

components of this appliance are treated with certain oils,

lms, or bonding agents. These chemicals are not harmful, but may produce annoying smoke and smells as they

are burned o during the initial operation of the appliance

possibly causing headaches or eye or lung irritation. This

is a normal and temporary occurrence.

The initial break-in operation should last two to three hours

with the burner at the highest setting. Provide maximum

ventilation by opening windows or doors to allow odors to

dissipate. Any odors remaining after this initial break-in

period will be slight and will disappear with continued use.

This appliance must not be used with glass doors.

Faces and Trim Kits

Wide Contemporary Textured Black Face AVFL42WFBT-A

Wide Contemporary Stainless Steel Face AVFL42WCSS-A

Black Textured Inside Fit Trim Kit AVFL42TKI

Stone Kit SKAVFL42

Glass Kits

Glass Kit Bronze GKB

Glass Kit Diamond GKD

Glass Kit Onyx GKO

Glass Kit Sapphire GKS

Outdoor Kit AVFLSTSSODK

OPTIONAL ACCESSORIES

There are a wide range of optional accessories available

for the AVFL Vent Free Fireplace. A variety of face and

trim kits can change the appearance of the replace. The

outdoor kit brings the outdoors inside.

Choose the stylish rustic stone kit or go minimalist with just

a coating of glass media and transform the replace to suit

your space.

Monessen • AVFLST42 Installation Instructions • 4118-900 Rev. B • 05/2020

31

Page 32

TROUBLESHOOTING

AVFLST Vent Free Fireplace

WARNING!

• Turn appliance OFF and allow to cool before

servicing.

• Only a qualified service person should

service and repair the heater.