Page 1

Manual for LC6 / LC7

Page 2

Page 3

Monark Exercise AB ����������������������������������������������������������������������4

Product Information ����������������������������������������������������������������������6

Facts........................................................................................................... 6

PC software ................................................................................................ 6

Serial number ............................................................................................. 6

Settings ������������������������������������������������������������������������������������������8

User settings ..............................................................................................8

Initial operation ........................................................................................... 8

Cycle adjustments ...................................................................................... 8

Operating Instruction ��������������������������������������������������������������������9

Power on crank or ywheel ........................................................................ 9

Control of the bike ...................................................................................... 9

Measured quantities ................................................................................... 9

Meter instructions ..................................................................................... 10

Keys and functions ................................................................................... 10

Connection to controller ������������������������������������������������������������� 11

Setting command type (PC or ECG device) ............................................. 11

What command type (cmd type) is set? ................................................... 12

Connection to PC ..................................................................................... 12

Terminal Mode PC .................................................................................... 12

Management of connections .................................................................... 13

Validation �������������������������������������������������������������������������������������14

Checking the pulse function ..................................................................... 14

Validation of force ..................................................................................... 14

Zero adjustment of scale .......................................................................... 15

Calibration ................................................................................................ 15

Calibration ������������������������������������������������������������������������������������16

Calibration electronics .............................................................................. 16

Electronic calibration - with the pendulum ................................................ 16

Testing with LC6 / LC7 ����������������������������������������������������������������18

Heart Rate (telemetry) .............................................................................. 19

Test person enforcement .......................................................................... 19

Reviewing results ..................................................................................... 20

Troubleshooting guide ����������������������������������������������������������������21

Operation interferences ............................................................................ 22

Where to obtain additional information ������������������������������������23

Service ������������������������������������������������������������������������������������������24

Warning .................................................................................................... 24

Warranty ................................................................................................... 24

Service check and Maintenance .............................................................. 24

Batteries ................................................................................................... 25

Flywheel bearing ...................................................................................... 25

Crank bearing ........................................................................................... 25

Transportation .......................................................................................... 25

Replacement of brake belt .......................................................................25

Brake belt contact surface ........................................................................ 25

Chain 1/2“ x 1/8“ ....................................................................................... 26

Freewheel sprocket .................................................................................. 27

Spare parts list ����������������������������������������������������������������������������28

2014 MONARK EXERCISE AB, Vansbro, Sweden

Contents

Important

Read the manual carefully before using the cycle

and save it for future use.

Page 4

LC6 / LC7

4

Monark Exercise AB

Monark has 100 years’ experience of bicycle production. The Monark tradition has yielded

know-how, experience, and a real feel for the product and quality. Since the early 1900s,

Monark’s cycles have been living proof of precision, reliability, strength and service. Those

are the reasons why we are now the world leader in cycle ergometers and the market leader

in Scandinavia in transport cycles.

We manufacture, develop and market ergometers and exercise bikes, transport bikes and

specialized bicycles. Our largest customer groups are within health care, sports medicine,

public authorities, industry and postal services.

For more information: http://www.monarkexercise.se

Page 5

LC6 / LC7

5

Thank you for choosing a test cycle from Monark!

Ideal position is important for performance to reach its maximum. LC6/LC7 has a brand new frame

that is adjustable in all directions. The frame also allows the Q-factor to be reduced, which further

increases the possibilities for a perfect performance. The new setting options, along with an upgraded

braking system, make Monark's renowned bike even better.

LC6/LC7 gives the conditions; the rest is up to the rider.

In today's society we are used to customizing our machines and tools for our own needs. The

same applies to LC6/LC7. Through intelligent solutions parts can be customized according to user

requirements. LC6/LC7 is also prepared for additional equipment, channels behind the covers make it

easy to install different equipment for different needs. LC6/LC7 is a great bike as it is, with additional

equipment, it can be even better.

Force is a strong word which brings many associations. For us, force is interesting when it can be

measured and calibrated. For a brake-force to be correct, regardless of the system, it must be calibrated

and controlled. On LC6/LC7 the brake system and calibration have been updated so that it is safer

and more accurate. It is also quicker to adjust and has more options in that it is speed-independent,

but can be switched into constant braking force as an alternative.

Monark has always been known for the bikes measurement accuracy, now it's even better.

Page 6

LC6 / LC7

6

Facts

Technical data power adaptor, LC6 and LC7

Input voltage: 220-240 V AC; 650 mA; 50/60 Hz.

Output voltage: 24 V DC switching adapter alt. 18

V AC.

(Sweden, 18 V, Art. No: 9339-67, other countries

incl. USA, 24 V, Art. No: 9339-66)

Polarity: Optional AC

NOTE! The power adaptor must be CE-marked if

original adaptor is replaced.

Technical details

Length 1405-1630 mm

Width 640 mm

Height

(max at display) LC6 1530 mm

LC7 1500 mm

Height

(max at saddle) 1240 mm

Weight 77 kg

Weight flywheel 20 kg

Max user weight 180 kg

Painting Industrial powder coating

Rust protection Zinc-based basic powder

coating on exposed areas

Power output

Continuous (50-100 rpm) 4-700 W

Peak (at rpm) 1400 W (200 rpm)

Smallest increment 1 W

Features

VO•

2

submax test

Training/test protocols (custom)•

HRC•

VO•

2

controlled

External control via RS232 (USB with the includ-•

ed adaptor)

VO•

2

max test

ECG worktest•

Included

Calibration weight 4 kg•

Chest belt Polar T34, 5 kHz•

Tool kit•

Power adaptor•

USB-Serial converter•

0-modem cable (RS232)•

Product Information

LC6 is delivered with a document •

holder.

LC7 is delivered with an integrated •

computer with 10" touch screen,

Windows, Bluetooth and WiFi.

NOTE!

Use of the product may involve considerable physical

stress. It is therefore recommended that people who

are not accustomed to cardiovascular exercise or

who do not feel completely healthy, should consult

a physician for advice.

Serial number

The serial number is placed according to Fig: Overview

at page 7.

NOTE! Before you start using the bike - remember to

remove the pendulum locking devices and protective

tape on the flywheel.

The bike can be used at maximum load

without any time limit.

PC software

(not LC7)

If you need a PC software to do exercise tests on the

bike, our software is available for free download from

our website: www.monarkexercise.se.

Page 7

5

6

10

7

5

4

3

14b

14a

1

13

12

11

9a

2

16

17

18

19

9b

15

9

8

LC6 / LC7

7

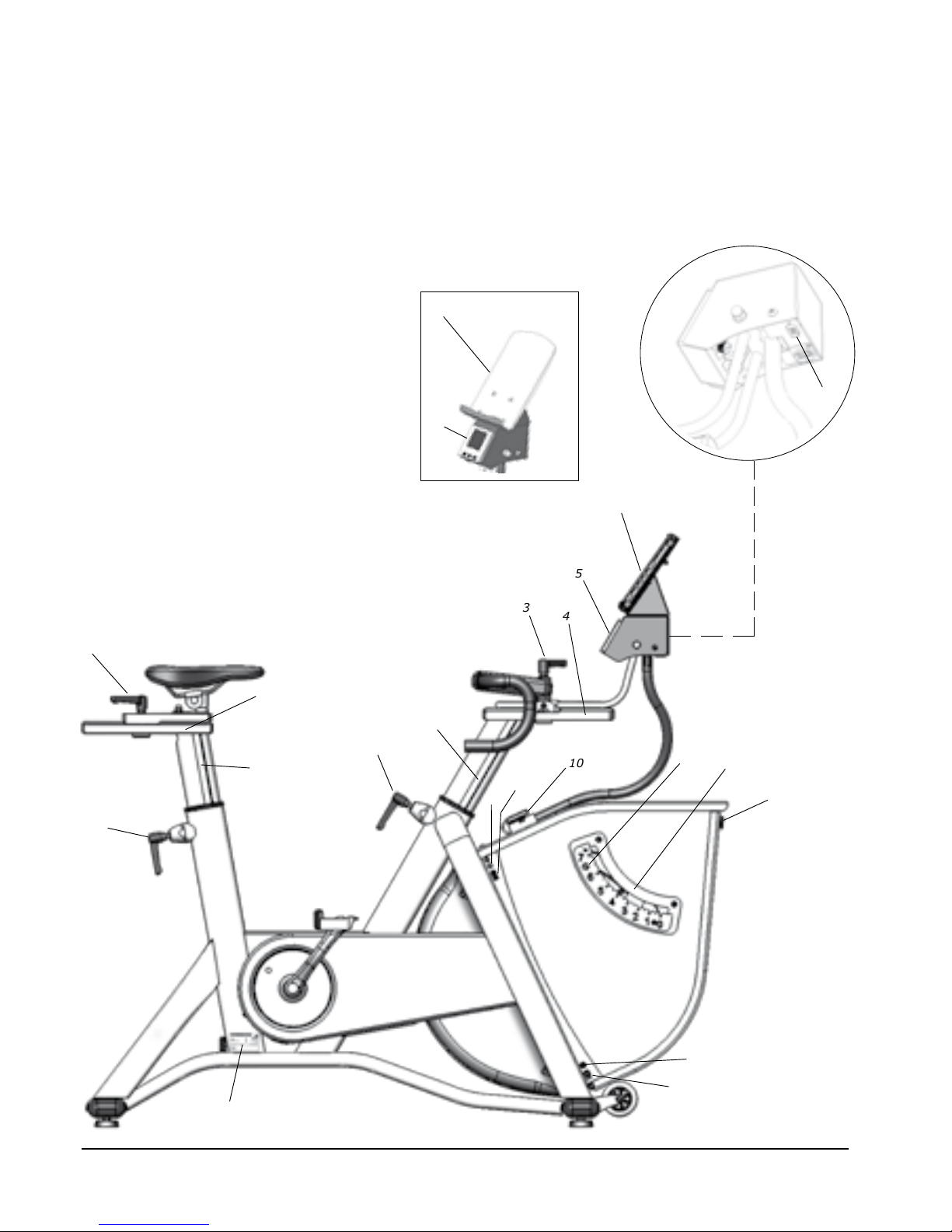

Fig: Overview

1) Knob for horizontal adjustment of saddle

2) Scale for horizontal adjustment of saddle

3) Knob for horizontal adjustment of handlebar and display

4) Scale for horizontal adjustment of handlebar

5) RPM meter

6) LC6 Document holder

7) LC7 Display with integrated computer

8) RS232 connection

9a) LED

9b) Power switch

10) Pulse receiver

11) Screw for adjustment Kp-scale

12) Kp-scale

13) Locking for front cover

14a) Power connection

14b) Locking for cable (power adaptor)

15) Serial number

16) Locking handle for height adjustment saddle

17) Scale for height adjustment saddle

18) Locking handle for height adjustment handlebar

19) Scale for height adjustment handlebar

Page 8

1

4

3

2

LC6 / LC7

8

Settings

User settings

Crank Steel, 170 mm standard,

172,5 mm optional

Pedals 9/16”, SPD/LOOK

compatible

Saddle Racing

Seat post Vertically: 530-940 mm

Horizontally: 200 mm

Handlebar Racing,

Ø31,8 mm at clamp

Handlebar stem Vertically: 500-910 mm

Horizontally: 200 mm

Distance saddle - handlebar 140-840 mm

Cycle adjustments

Seat height should be adjusted to a comfortable

position. The appropriate height is to have the knee

slightly bent when the sole of the foot is centred over

the pedal axle with the pedal in the bottom position.

When adjusting the saddle height and vertical

position, loosen the respective locking handles. See

Fig: Overview at page 7.

The handlebar setting should be in a comfortable

position when cycling. During longer exercise sessions

it is recommended to occasionally change handlebar

position. The handlebar can be adjusted both

horizontally and vertically. This is done by loosening

the respective locking handles. See Fig: Overview at

page 7.

NOTE! Be sure that the stem and seat post are inserted

to at least 100 mm in the frame. This is marked with

“MAX” on the stem.

Initial operation

LC6 / LC7 is mechanically calibrated in the factory.

The user may wish to verify this by performing the

mechanical calibration of the pendulum weight. See

”Electronic calibration”.

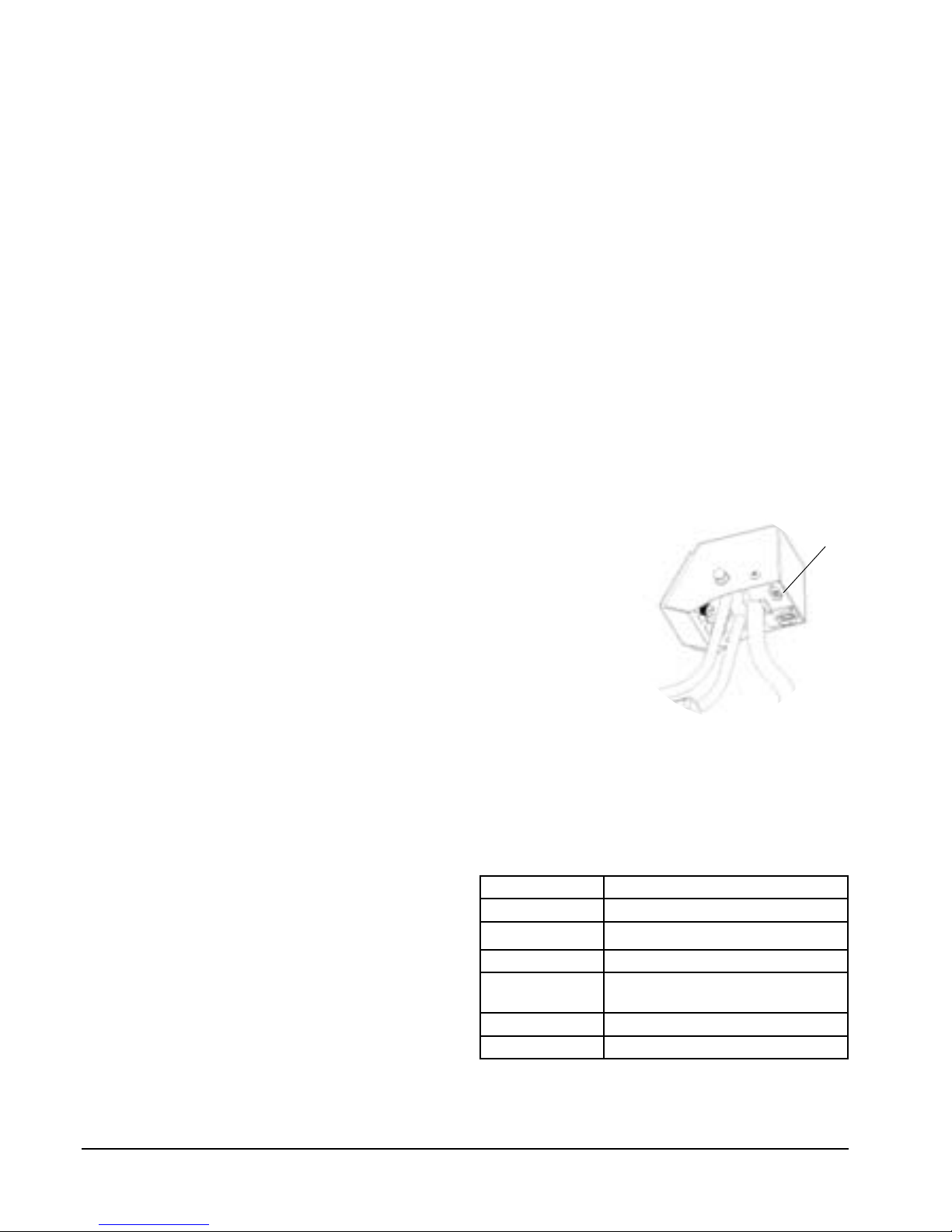

Apply power to the test bike by first connecting the

cable from the power adaptor to the test bike at the

power connector (3) at the right side of the bike, see

Fig: Front cover right. Then plug the power adaptor

into the wall outlet. Turn on the power switch (2) and

a green LED (1) lights up.

The cable from the power adaptor can be locked

with the clamp (4) which is placed below the power

connection.

Perform the electrical calibration as specified in section

"Calibration Electronics”. Test by pedalling the bike.

If the bike is working properly, it is ready for use.

Fig: Front cover right

1) LED (voltage indicator)

2) Power switch

3) Power input

4) Locking for cable (power adaptor)

Page 9

1

LC6 / LC7

9

Power on crank or ywheel

Monark bikes measure the effect of the flywheel, so it

will be a friction of 6-8% if you measure the impact

of the pedals (measure the effect of the crankshaft,

the difference is 4-5 %). These percentages will be

primarily due to friction in the chain, pedals and

bearings.

LC6 / LC7 is designed for fitness tests and is set for

power measurements on the flywheel. The bike can be

set to work with effect in the pedals / crankshaft (the

cycle constant).

Distance meter, miles

Energy kcal

Heart rate bpm

Force Newton (N), kp

Power Watts (W), kpm / min or

VO

2

ml/min/kg

Time min:sec

Weight kilogram (kg), pounds (lbs)

Measured quantities

The following units are normally used. Where multiple

units are specified, the user can select, see the software

documentation.

Control of the bike

LC6 / LC7 is built on a solid framework, a large

well-balanced flywheel, a brake belt and a pendulum

that measures the braking force. The pedals operate

around the brake wheel via a chain, while a stretch

mechanism tightens the brake belt to regulate the

braking force to affect the flywheel. This brake force

is given directly by the pendulum against the scale on

the right side of the bike.

The computer system consists of a main unit (built in

the bike) and a control unit (integrated computer on

the bike, PC, terminal or other external equipment).

The main unit reads pedal speed and braking force

and to determine the test subject's heart rate by a

chest belt, where applicable. In addition, the main

unit activates an actuator, which adjusts the brake belt

tension that regulates the braking force. This brake

force is varied automatically in relation to changes in

pedal speed, so that a constant power is maintained

The bike is as default rpm-independent.

For information about how respective control units

works, see respective sections.

The bike can be controlled externally by PC, terminal

or other external equipment.

Here are instructions for connection and options for

connection to external devices. If advanced technical

documentation / data protocol for system builders or

similar are required, contact Monark Exercise AB.

The control is performed over a serial line using ANSI/

ISO/ASCII format commands. Connector, a 9-pin

D-Sub (male) located below the RPM meter, see Fig:

Connector, is compatible with the RS232 standard.

The bike need not be switched off when connecting

external components, but it is recommended to prevent transmission of incorrect data between devices

over the connection.

Be careful when connecting different types of external

equipment to prevent flash-over and subsequent

injury. The user must ensure that the correct cables are

used, otherwise you risk serious injury or equipment

damage.

Operating Instruction

Fig: Connection

1) RS232 connection

Page 10

3

2

1

LC6 / LC7

10

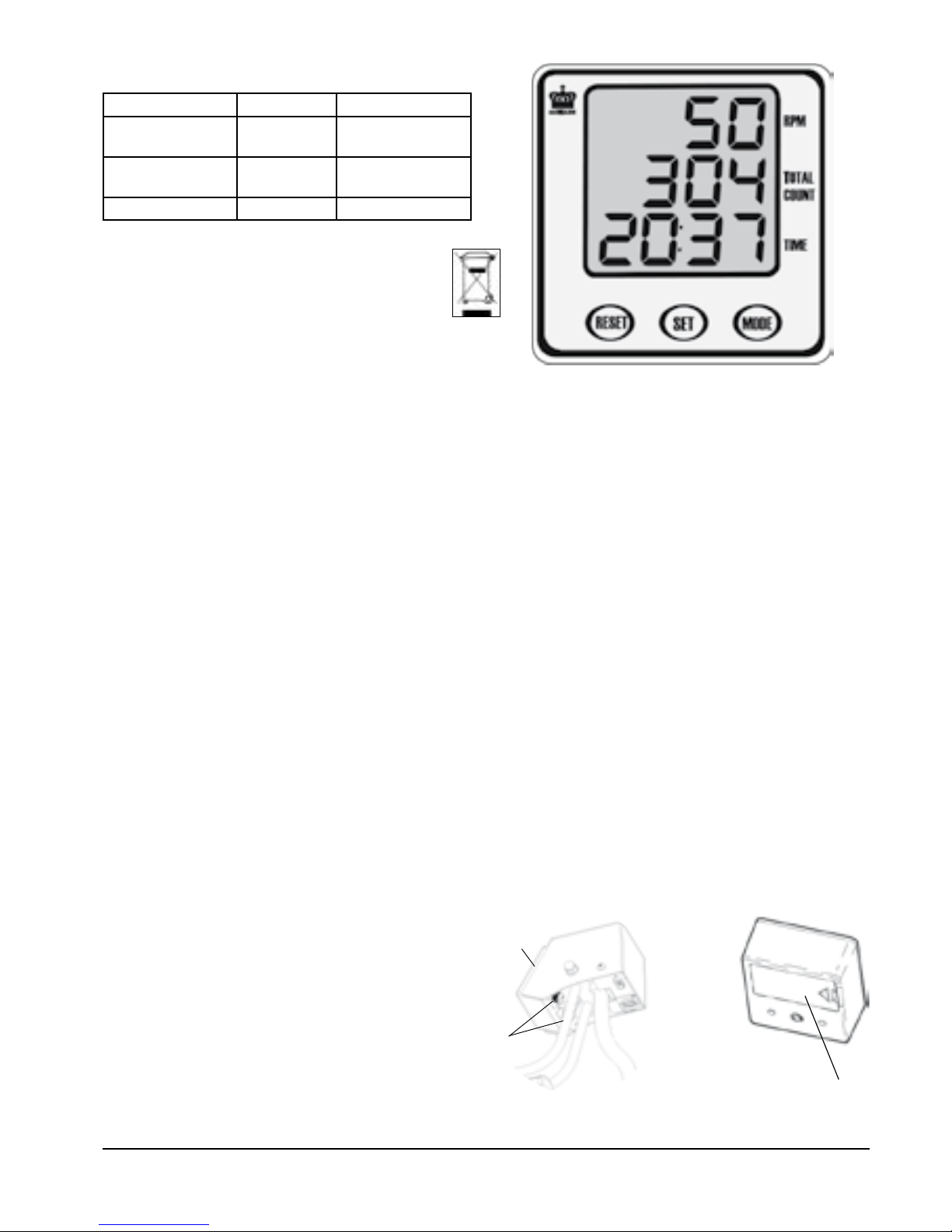

Meter instructions

Keys and functions

MODE key

Use MODE key to shift between the functions to set

TIME and TOTAL COUNT.

SET key

Pressing this key will make it possible to set TIME

and TOTAL COUNT. If you hold down this key for

two seconds you can advance the function value at a

faster rate.

Programming exercise time:

Push the MODE key until TIME flashes. Then use

SET to set the desired time. Each press of SET will

advance time by one minute. When the pedals are

rotated the countdown of time will start automatically

and count down to 0:00 and a beep will be heard for

five seconds.

Programming TOTAL COUNT:

Push the MODE key until TOTAL COUNT flashes.

Then use SET to set the desired value. Each press

of the SET will increase the value by 10. When the

pedals are rotated the countdown of number of turns

automatically start and count down to 0 and a beep

will be heard for five seconds.

RESET key

The RESET key will clear the values for TIME and

TOTAL COUNT individually.

NOTE!

Display will return to normal when not pressed •

any key for five seconds, or trainer is not used.

The meter starts automatically when a key is •

pushed, or if the bike is used and the meter gets

an indication of pedal movement.

Auto shut off function when not pressed any key •

or device not used for four minutes.

Do not expose the meter to direct sunlight or extremely

high temperature. Do not use any dissolvents when

cleaning. Use only dry cloth. For surface disinfection,

see the section "Regular service and maintenance".

Display

Pedal revolution

(RPM)

0 - 250 rev./min.

TOTAL COUNT

9999

Total number of

turns

TIME 0:00-99:59 min:sec

Batteries: 1.5 V x 2, R6 (AA)

Storing temperature: -10º C - +60º C

Operating temperature: 0º C - +50º C

Battery replacement

The batteries can be accessed from the back of the

RPM meter (2). Loosen the meter using the two

screws (1) on the back of the meter, under the meter

bracket.

Open the battery cover (3) and replace the batteries,

see Fig: Battery cover. Replace the meter and secure

it using the two screws.

Fig: Battery replacement

1) Screws

2) RPM meter

3) Battery cover

Page 11

1

5

4

3

2

LC6 / LC7

11

Setting command type (PC or ECG device)

Check that the brake belt is loose around the flywheel,

see Fig: Control loose brake belt. If the brake belt is

tight loosen it by moving the pendulum pointer to

4 kp and the servo releases the brake belt tension.

To be sure that indicator positions are correct, do a

calibration. See section "Calibration".

Turn off the power by turning the power switch 1.

(2), see Fig: Power switch. Disconnect the cable

from any connected external device.

Adjust the scale mechanically so that 0-index on 2.

the scale and indicator are in line. See section

"Zero adjustment of meter panel".

Move the indicator to 6 kp and hold it there.3.

Turn on the power again. The green LED (1) is lit 4.

when power is connected to the bike.

Hold the pendulum pointer at 6 kp until two 5.

beeps are heard.

Move the pendulum pointer to 6.

0 kp = mode for PC, terminal or some PC-

based external device.

1 kp = mode for ECG Siemens Megacart.

2 kp = mode for other ECG devices, alt 1.

3 kp = mode for other ECG devices, alt 2.

7. Keep at the selected position until two signals can

be heard. Then release the pointer to 0. The system

will now restart in the selected mode.

Alt. 1: ECG, Ergoline compatible command set,

requested load value.

Alt. 2: ECG, Ergoline compatible command set,

current load value.

Connection to controller

Fig: Control loose brake belt

Fig: Power switch

1) LED

2) Power switch

3) 6 kp

Page 12

1

LC6 / LC7

12

Connection to PC

To connect a PC to the bike, use a 0-modem cable

(RS232) with 9-pin D-sub connector (female) at both

ends. If no serial port is available on the computer,

use a USB-serial adaptor (included) for connection to

the USB port.

Before installing the Monark Software for your

ergometer, you must take the following steps.

Locate the USB adaptor. 1.

Inside the USB adaptor packaging, there is a mini-2.

CD.

Insert the mini-CD into the CD-ROM drive and 3.

install the driver software. If there is no CD drive

on your computer, driver software is available for

download from the website (http:www.vscom.de/

USB-CD).

Finalize the driver software installation by 4.

inserting the USB adaptor.

Install Monark software (can be downloaded 5.

from our website: www.monarkexercise.se).

Connect the USB Adaptor to the Serial Cable and 6.

proceed with testing.

To control the bike use the computer program "Monark

939 E Analysis Software" which is available for free

download from our website: www.monarkexercise.se.

The software is the same for the models 831 E, 839

E, 939 E and LC6 / LC7. Other external PC software

that are compatible with the bike can also be used.

Terminal Mode PC

A variety of settings can be made from the software.

For more information about this see the software's

help file.

Settings can also be made directly from the PC through

the terminal mode, see the Technichal Manual which

is available from Monark Exercise AB.

Fig: Connection

1) RS232 connection

When power is turned on to the bike it will beep, and

from the number of beeps the command type can be

determined.

Command type 0: A long beep. •

Command type 1: A long beep followed by a •

short beep.

Command type 2: A long beep followed by two •

short beeps.

Command type 3: A long beep followed by three •

short beeps.

What command type (cmd type) is set?

Page 13

1

LC6 / LC7

13

Management of connections

Display with integrated computer on the bike (LC7)

Make sure the power adaptor is connected to the bike

Make sure the USB cable is plugged into the bike

computer and the computer has power (needed if the

computer's internal battery is drained). The computer

can be powered from the bike power adaptor. Set

the bike power switch to "on" and then start the

computer.

Now you can start the computer software in the

computer. If you get a message that the connection

can not be obtained probably the wrong COM port

is registered in the software, see the manual to the

software.

Connecting an external computer (LC7)

Make sure the power adaptor is connected to the bike

Set the bike power switch to "off" and then remove

the USB cable from the bike computer.

NOTE! Det är viktigt att USB-kabeln är urtagen ur

It is important that the USB cable is disconnected from

the bike computer, otherwise there may be a conflict

between the external computer and the display with

integrated computer.

Insert the supplied RS232 cable to the RS232

connector (1) below the RPM meter. At the other end

of the RS232 cable, connect the USB serial adaptor.

Connect the USB connector into an available port

on the external computer. Set the bike power switch

to "on" and then start the software in the external

computer.

If you need a pc software to do exercise tests on the

bike, our software is available for free download from

our website: www.monarkexercise.se.

If you connect an external computer with an RS232

port you can connect the RS232 cable directly into

the serial port and do not need to use the USB serial

adaptor.

Connecting external equipment directly to the RS232

connector (LC6 / LC7)

Make sure the power adaptor is connected to the bike

Set the bike power switch to "off" then remove the

USB cable from the bike computer.

NOTE! NOTE! It is important that the USB cable is

disconnected from the bike computer. Otherwise there

may be a conflict between the external computer and

the display with integrated computer.

Insert the supplied RS232 cable to the RS232

connector below the RPM meter. Connect the other

end of the RS232 cable to the external equipment.

Set the bike power switch to "on" and then start the

external equipment.

Fig: Connection

1) RS232 connection

Page 14

1

2

3

1

LC6 / LC7

14

Checking the pulse function

This bike does not have a meter that shows the heart

rate. However, the heart rate is displayed in the

computer software or other external equipment.

While the patient rests, with the chest belt on, compare

heart rate in the software with the manually taken

pulse. If it does not correspond, check the chest belt

contact area and moisten if necessary the electrode

surfaces with water. Electrodes on the back of the

chest belt. If this fails, call customer service.

The following procedure ensures that the bike works

for daily use.

Check the pulse function, see section.•

Check the brake force, see section.•

Test by pedalling and check that a reasonable •

rpm is obtained - verify by a clock. Feel if the

pedals move smoothly. Listen for unusual sounds.

Remedy if necessary.

Adjust the handlebar and saddle and make sure •

they are securely attached and that the adjustment

is working properly.

Make sure the support legs are in position by •

rocking the bike. Tighten if necessary.

If something unusual is found during the daily

inspection that you cannot resolve, please call

customer service.

Fig: Placement of the chest belt

Validation

Validation of force

Start the PC software (it is available for free download

from our web site: www.monarkexercise.se) and

select a test programme from the menu "Test". In the

dialogue box that opens is a box showing the braking

force in Newton, see Fig: Force and HR display. You

do not have to press "Start" (1) to get the heart rate

showed (2), but you must press "Start" to show the

force (3).

With the pendulum pointer at 0, the display should 1.

read "00N".

Move the pendulum pointer to 4 kp and the display 2.

should now show "39N".

If the braking force is not displayed correctly, an

electronic calibration must be done. See section

"Calibration electronics".

NOTE!

After this verification, the brake belt will be loose,

which means that it takes about 15 seconds before the

regulating device has tense the brake belt to normal

again (5 N).

Fig: Force and HR display

1) Start

2) Heart rate display

3) Force in software (manual test)

Fig: Electrodes on the back of the chest belt (1)

Page 15

4 kg

1

3

4

2

1

2

3

1

2

3

LC6 / LC7

15

Zero adjustment of scale

Check that 0-index (3) on the scale (2) is in line with

the pendulum pointer when the bike is at a stand

still and the brake belt is loose. If not, an adjustment

must be done. Loosen the screw and adjust the scale.

Tighten the screw (1) after adjustment. See Fig:

Adjustment scale.

Calibration

All LC6 / LC7 are calibrated in the factory, but a

calibration of the pendulum can still be done to verify

this. If so, please do the following.

Open the front cover. Check that the brake belt (3) is

loose. If not, move the pendulum to 4 kp and hold it

there a while to loosen it. Unhook the brake belt from

the spring. Check that scale 0-index is in line with

the pointer. Adjust if necessary, see section "Zero

adjustment of scale".

Calibration weight 4 kg (Art. No: 9000-211) is

hooked on the spring.

NOTE!

The flywheel must be completely stopped before the

weight is hung on!

This weight (4 kg) can, when properly adjusted, be

read at the corresponding point on the scale. If there is

a deviation, adjust the pointer to the correct position

by adjusting the weight (2) inside the pendulum. To

change the adjustment weight loosen the adjustment

screw (1). If the pointer shows too low, the internal

weight must be moved upwards. If the pointer shows

too high, the adjustment weight is moved down.

This process is repeated until pointer is in the correct

position. Hook the brake belt in the spring and close

the front cover.

Check the calibration of the pendulum weight once a

year or when needed.

Fig: Calibration

1) Kp-scale

2) Pointer

3) Spring

4) Calibration weight 4 kg

Fig: Pendulum

1) Adjustment screw

2) Adjustment weight

3) Brake belt

Fig: Adjusting scale

1) Screw

2) Scale (Kp-scale)

3) 0-index

Page 16

LC6 / LC7

16

The following steps show how electronics are

calibrated against the pendulum.

Open the front cover. 1.

Check that the brake belt is loose on the flywheel, 2.

see Fig: Control loose brake belt. If not, move

the pendulum pointer to 4 kp and hold it there

for a few seconds. Move the pendulum pointer

to 0 again, and check again that the brake belt is

loose.

Adjust the scale, see "Zero adjustment of scale," 3.

so that the pendulum pointer is pointing at the

0-index of the scale, see Fig: Zero position.

Turn off the power to the bike and move the 4.

pendulum pointer to 4 kp, as shown in Fig: 4 kp.

Hold the pendulum pointer at 4 kp and turn the 5.

power on the bike again and wait for a beep.

Move the pendulum pointer to 0, see Fig: 0 kp.

Wait for a beep.

Move the pendulum pointer to 2 kp, see 6. Fig: 2 kp.

Wait for a beep.

Move the pendulum pointer to 4 kp, see 7. Fig: 4 kp.

Wait for a beep.

Move the pendulum pointer to 6 kp, see 8. Fig:

6 kp. Wait for two beeps. Move the pendulum to

0 again.

The calibration is complete. Close the front cover.

Electronic calibration - with the pendulum

Calibration electronics

Usually it is not necessary to recalibrate the cycle

electronically, but it should be done after each service,

change of electronic part, movement, if you adjusted

the 0-index, or after you have programmed the

"Reset" by default settings.

The calibration coefficient calculated by the computer

is stored in main memory. No matter when the power

is turned on, the last stored calibration will be placed

in main memory. New calibration automatically

replaces the old.

A check of the electronic calibration can be done in

the computer programme, see section "Validation of

force".

NOTE!

The pendulum must be kept still at the different

positions. This is done by pressing down the pointer

into the groove on the scale at each kp value.

Calibration

LC6 / LC7 has a mechanical brake and pendulum

weight, making performance validation a simple

procedure. Calibration is necessary so that the

electronic and the mechanical parts of the cycle

conform. The work carried out on the bike is a

result of the braking force (pendulum mode) and the

number of pedal revolutions (= distance). The effect

is then counted out by dividing the work done by the

time it took to accomplish it. Validation includes both

mechanical and electronic procedures. For detailed

information, see the computer programme's user

manual. If the bike fails to pass any section of the

validation, proceed to the calibration and/or service

menu.

After any repair or service, a "Daily Check" should

be done.

It is also possible to calibrate from the software. See

the menu "Monark Ergomedic" - Check calibration..." in the computer software.

Page 17

LC6 / LC7

17

Fig: Control loose brake belt

Fig: Zero position

Fig: 2 kp.

Fig: 4 kp.

Fig: 6 kp.

Fig: 0 kp.

Page 18

LC6 / LC7

18

Testing with LC6 / LC7

The versatility of the LC6 / LC7 enables it to be utilized

in a variety of testing environments. The precision

and reproducibility of the test values obtained with

the bike, along with the uncomplicated way to set up

the tests, means the bike can be used in clinical work

tests, in occupational health services for the fitness

tests as well as fitness centers, schools, sports clubs

and the like.

In general, one should note that stresses on the tested

person can become quite severe, whether in a clinical

work test or a simple fitness test in physical activity

contexts. As a precaution, it may be advisable, prior

to beginning an exercise protocol, that each subject

consults with a physician.

Before testing, the operator should review the entire

protocol operation with the test person, explaining

the work which will be required and the duration of

the procedure. One should also agree on how the test

person shall give signs of any fatigue, chest pain or

other abnormal physical reactions.

The test person should not engage in heavy physical

activity for several hours prior to testing to establish

maximum oxygen consumption. In addition, all

testing and exercise protocols should be performed

a reasonable time after meals. The test person should

also refrain from smoking within an hour of the

testing period.

The tested person shall also have the appropriate

clothing for a work test. Training suit or loosefitting clothing is best. More detailed instructions

are rarely needed, regarding the ride, but it may

still be appropriate for the test leader to give some

advice on pedalling, saddle height and position of

the handlebars. It should be comfortable to ride. The

appropriate height of the saddle is when the knee is

slightly bent when the sole of the foot is centred over

the pedal axle with the pedal in the bottom position.

Let the test subject try to ride with low workload and

see how it feels to hold a steady rpm.

Finally, the chest belt shall be put on, see Fig: Placement

heart rate belt in section "Heart Rate (telemetry)" for

correct placement. Check for a minute that a proper

heart rate is displayed. The baseline heart rate may

also be of assistance in determining the nervousness

of the test subject. It may be appropriate to let the test

person rest long enough before the test so a more or

less stable resting heart rate can be read.

Power calculation

1 rpm = that a point on the flywheel moves 6 meters

per minute.

50 rpm = 300 m

2 kp force makes 2 x 300 = 600 kpm/min

100 rpm= 600 m

1 kp force makes 1 x 600 = 600 kpm/min

Exact calculation:

Watts = rpm x kp x 0.98065

"Rule of thumb" calculation:

Watts = rpm x kp

(2% error, but may be good enough in many cases)

Page 19

1

LC6 / LC7

19

Test person enforcement

The bike performs automated tests virtually by itself,

requiring minimal intervention by the test operator.

This allows the operator to pay careful attention to

the test person without distraction. The response to

the exercise protocol can be accurately estimated and

appropriate action taken to assist the test person, if

necessary. Some programmes have sections where

the test person may develop significant physical

activity. The effect on the test person should not be

underestimated.

During the test it is important to observe the test

person's appearance and heart rate. The testing should

be stopped immediately if the test person reports chest

pain, difficulty in breathing, etc. A system of prompt

medical attention should be set up prior to testing, in

case of emergency.

The test person may also have difficulty in keeping a

steady pedalling speed. This is of minor importance

(except in cases where the program assumes a constant

braking force, since the effect is automatically adjusted

to the correct value as long as the pedal speed is at least

35 revolutions / min (rpm)). However, it is important

to consider what each test documentation says about

the pedal speed.

Heart Rate (telemetry)

A person's heart rate can be measured with a chest

belt that senses the electronic output of the heart. The

chest belt is standard equipment.

The bike does not have a meter that shows the heart

rate, however, the HR is displayed in the computer

programme or in other externally connected devices.

Fuss-free HR measurement requires that the belt is

correctly placed. When it is correctly fitted the logo

on the belt will be central and readable, outward

and upright, by another person. Before putting on

the belt, clean the skin where the belt is to be placed.

The chest belt should be secured at a comfortable

tension around the mid section, just below the breast

muscle, see Fig: Placement of the chest belt. Moisten

the electrodes before use, see Fig: Electrodes on the

back of the chest belt. To make contact with the HR

receiver on the bike, the distance should not be more

than 100 cm / 39 1/3". It is especially important when

first used to identify the chest belt with the sensor, by

standing close to get the HR (maximum 60 cm). This

relates especially to the Polar heart rate belt.

NOTE! Electromagnetic waves can interfere with the

telemetry system. Cellular phones are not allowed to

be used near the bike during test.

In case of problems, turn off WiFi, Bluetooth and

similar on computers nearby (including the display

with integrated computer on LC7).

Fig: Placement of the chest belt

Fig: Electrodes on the back of the chest belt (1)

Page 20

LC6 / LC7

20

Fitness Rating Index - Males

Maximum Oxygen Consumption ml/kg/min

Fitness Rating Index - Females

Maximum Oxygen Consumption ml/kg/min

Rating Rating

-36 yrs 36-45

yrs

45- yrs -36 yrs 36-45

yrs

45- yrs

Excellent 54 53 43 Excellent 55 49 46

Good 49 45 38 Good 45 43 38

Above aver-

age

46 39 34 Above aver-

age

39 37 32

Average 36 33 30 Average 34 33 27

Below aver-

age

32 29 27 Below aver-

age

30 29 24

Fair 28 25 24 Fair 26 26 20

Poor 24 23 20 Poor 20 22 18

See also table 7 in “ Work tests with the Bicycle Ergometer“ by P O Astrand.

Reviewing results

The maximum oxygen uptake is a

standard measure of the condition of the heart- and

lung-functions. Dependent on the linear relationship

between work and oxygen uptake and between work

and heart rate, the heart rate response to work may

be used to estimate the oxygen consumption. If the

maximum heart rate is considered, the maximum

oxygen consumption may be determined.

The YMCA and Åstrand protocols estimate

the maximum oxygen consumption, based on a

submaximal workload while all others report the

oxygen consumption required by the final workload.

The Bruce and Naughton protocols require that the

test subject exercise at a workload level for a minimum

of one minute to establish the oxygen consumption.

If less than one minute is observed, the previous

workload value is used.

The estimated maximum oxygen consumption

derived from some of the ergometer tests is subject

to the error of the “age related predicted maximum

heart rate“. Although there is a definite and linear

relationship between work and oxygen uptake, there

are some differences in actual oxygen uptake based

on individual work efficiency. Test persons who are

less familiar with bike exercise and those individuals

who are less fit, are more likely be less efficient than

those who ride bikes frequently.

It should be noted that these results are estimates or

predictions of maximal response and have a greater

chance of being in error than if the individual were

tested to their actual maximum value. Interpretation

should therefore be made more carefully with an

understanding of the possibility of errors in the

methodology.

A relative fitness index can be obtained from the

following tables:

Page 21

LC6 / LC7

21

Symptoms Probable Cause / Corrective Action

LED does not light up No current in the outlet. Check the fuses. •

Power switch turned off bike / main unit. •

Check cables and connections. •

Right AC adaptor? Check that the transformer information (voltage, current, po-•

larity, AC / DC) in section "Facts" complies with the transformer which is used.

No connection to PC Check cables (connections and type). •

Right COM-port (PC software or similar). •

Drivers missing when using the USB-serial adaptor. (CD with drivers is included •

with the USB-serial adaptor).

Right "cmd type", see section "Connection to controller". •

No workload Pendulum stuck. Contact service centre for action / replacement. •

Check that the pedal speed is higher than 35 rpm. No workload is put on if the •

actual pedal speed is lower than 35 rpm. See computer software menu - ’Monark

Ergomedic’ - ’Service program...’ - ’Service setup...’ - ’Pedal measurement’. The

default setting is 30 rpm but can be adjusted to the desired value.

Check calibration.•

Check that brake belt is hooked in the spring.•

No heart rate Check that the battery is alright in the chest belt, moisten your thumbs and click •

on the electrodes, a low clicking sound will be heard at the battery cover, alternatively that the heart rate is displayed in the computer software.

Make sure the belt fits correctly on the test person, see • Fig: Placement of chest belt

in section "Heart Rate (telemetry)", and that the strap is sufficiently tightened.

Moisten the electrodes, in severe cases it may be necessary to use gel alternative,

one drop of dish washing liquid mixed in water. Pulse signal strength varies from

person to person. Try the belt with a person known to have a good pulse wearing

a chest belt.

Check for loose cables or jack if you have a plug-in receiver. Use another HR re-•

ceiver (HR watch or test bike monitor) to check the chest belt.

Check that it is the correct receiver and that it is in the correct place. If it have a •

round Polar logo, the logo should be readable.

Uneven heart rate Use an external unit, for example a HR watch, to check if it also indicates an ir-•

regular pulse. If this is the case, there is probably disturbance in the room. The

disturbance may be electronic fields from power cables, elevators, lamps etc. or

other electronic devices which are too close (eg. cell phones). Move the bike to

a different location in the room or change rooms. If an irregular HR remains it

should be checked manually. If the HR remains irregular at work the person's

health should be examined.

No rpm reading Check cable.•

Unable to calibrate force The potentiometer shaft is not attached to the pendulum shaft, tighten the screw. •

The potentiometer is misadjusted. See the computer software menu - ’Monark •

Ergomedic’ - ’Service program...’ - ’Potentiometer’ and follow the instructions

that appear on the screen. Then calibrate the electronics again.

There is a click noise when pedal-

ling (increases with the weight)

The pedals are not tight. Tighten them or change pedals. •

The crank is loose. Check, tighten. •

The base bearing is loose. Contact your dealer for service. •

Scratching sound is heard when

pedalling

Check that the carriage block is taken off and that nothing is against the crank, •

chain, or wheel except the brake belt.

There’s a click noise and a squeak

noise when pedalling

Loosen the chain. •

Troubleshooting guide

Page 22

LC6 / LC7

22

Operation interferences

It is normally considered that about 70 % of all shutdowns on small computers are caused by mains interferences,

i.e. at short over voltage. These interferences can often be caused by different machinery, which is started or

stopped. The processor in the computer is then reacting incorrectly or is not working at all. The problems can

be solved by means of a mains interference protector, which is connected between the wall outlet and the AC

adaptor. .

Error message

Message Cause

"Test is aborted" An automatic test program has been stopped before it is

ready, or with values that are outside the tables so that no

result can be calculated. No test results can be obtained.

Page 23

LC6 / LC7

23

Where to obtain additional information

The user may require more information concerning several areas of the ergometer usage. This manual was

intended to instruct the reader primarily in the operation of the ergometer. References are made to related topics

in the discussions concerning the testing procedures and the protocol operation sections. The following literature

may provide some greater insight to ergometer-based testing without confusing the reader with technical medical

terms.

Åstrand P-O, ”Ergometri - konditionsprov”, Monark, Sverige. •

Golding L. A, Myers C. R, Sinning W. E, Y´s way to physical fitness“, YMCA of the USA, Rosemont, IL, •

1982

For more technical details, see the section entitled “Reference“.

References

Astrand I, ”Aerobic work capacity in men and women with special reference to age”, Acta Physiol Scand. 1.

49 (suppl. 169), 1960

Åstrand P-O, ”Experimental studies of physical working capacity in relation to sex and age”, Munksgaard, 2.

Köpenhamn, 1952.

Åstrand P-O, Rodahl K, ”Textbook of Work Physiology”, McGraw-Hill, New York, 1970.3.

Bruce RA, Kusumi F, Hosmer D, ”Maximal oxygen intake and nomographic assessment of functional aero-4.

bic impairment in cardiovascular disease”, Am Heart J 85:546-562,1973

Naughton J, ”Exercise Testing and Exercise Training in Coronary Heart Disease”, Academic Press, New 5.

York, 1973.

Golding LA. Myers CR, Sinning WE, ”Y´s way to physical fitness” YMCA of the USA, Rosemont, IL, 6.

1982

Wilson PK, Bell CW, Norton AC, ”Rehabilitation of the heart and lungs”, Beckman instruments, 19807.

Åstrand P-O, ”Ergometri - konditionsprov”, Monark, Sverige8.

Page 24

Service check and Maintenance

It is important to carry out a regular service on your

ergometer, to ensure it is kept in good condition.

Always keep the bike clean and well lubricated.

Service action:

We recommend isopropyl alcohol to disinfect the •

surface of the bike. Use a damp but not wet cloth to

clean the surface you wish to disinfect.

Surface treatment with a rust inhibitor, especially •

when the bike is clean and the surfaces are dry This

is done to protect the chrome and zinc parts as well

as the painted parts (4 times per year).

Check now and then that both pedals are firmly •

tightened. If not the threading in the pedal arms

will be damaged. When the Ergometer is new it

is important to tighten the pedals after 5 hours of

pedalling (4 times per year).

Check that the pedal crank is secure to the crank •

axle (4 times per year).

Be sure that the pedals are moving smoothly, and •

that the pedal axle is clear of dirt and fibres (4 times

per year).

When cleaning and lubricating be sure to check that •

all screws and nuts are properly tightened (twice a

year).

Check that the chain is snug and there is no play in •

the pedal crank (twice a year).

Check that pedals, chain and freewheel sprocket are •

lubricated (twice a year).

Be sure that the brake belt does not show significant •

signs of wear (twice a year).

Check that the handlebars and seat adjustment •

screws are lubricated (2 times per year).

Be sure that all moving parts, crank and flywheel •

are working normally and that no abnormal play

or sound exists. Play in bearings causes fast wearing

and with that follows a highly reduced lifetime.

Check that the flywheel is placed in the center and •

with plane rotation.

Grind the brake belt contact surface, see section •

"Brake belt contact surface" (once a year).

Service

Warning

Make sure the voltage indicated on the appliance

corresponds to the local mains voltage before making

connections.

Note that the text about service and maintenance is

universal and that all parts may not be relevant to

your bike.

Warranty

EU countries - Private use

If you are a consumer living in the EU you will have

a minimum level of protection against defects in

accordance with EC Directive 1999/44/EC. In short,

the directive states that your Monark dealer will be

liable for any defects, which existed at the time of

delivery. In case of defects, you will be entitled to have

the defect remedied within a reasonable time, free of

charge, by repair or replacement.

EU countries - Professional use

Monark Exercise products and parts are guaranteed

against defects in materials and workmanship for a

period of one year from the initial date of purchase

of the unit. In the event of a defect in material or

workmanship during that period, Monark Exercise

will repair or replace the product. Monark Exercise will

not, however, refund costs for labour or shipping.

Other countries

Monark Exercise products and parts are guaranteed

against defects in materials and workmanship for a

period of one year from the initial date of purchase

of the unit. In the event of a defect in material or

workmanship during that period above, Monark

Exercise will repair or replace (at its option) the

product. Monark Exercise will not, however, refund

costs for labour or shipping.

LC6 / LC7

24

Page 25

If the meter is battery-operated, the batteries are in a

separate package at delivery. If the storing time has

been long the battery power can be too low to make

the computer act correctly. Batteries must then be

changed.

Flywheel bearing

The flywheel bearing is long-term greased and requires no supplementary lubrication. If a problem

arises, please contact your Monark dealer.

Crank bearing

The crank bearing is greased and normally requires

no supplementary lubrication. If a problem arises,

please contact your Monark dealer.

Transportation

During transport the brake cord should be tightened

to prevent it from falling off the flywheel.

Replacement of brake belt

To replace the brake belt remove covers if necessary.

Make sure that the belt is loose.

Pendulum bike with engine:

To loosen the brake belt on pendulum bikes with

engine, connect power to the unit and raise the

pendulum to 4 kp. Hold it there until brake belt is

loose. Please note how the belt is assembled. Remove

it from the bike. Attach the new brake belt and

assemble the bike in reverse order.

Weight basket bike:

To loosen the brake cord on cycles with a weight

basket set the basket to its upper position. Loosen the

lock washer that is holding the cord and remove it

from the tension center. Loosen or cut off the knot on

the other end of the cord and then remove the whole

cord from the bike. When assembling a new brake

cord, first enter one end into the hole in the tension

center, and tie a knot and let the knot fall into the

bigger part of the hole. Lock the end of the cord with

the lock washer.

Brake belt contact surface

Deposits of dirt on the brake belt and on the contact

surface may cause the unit to operate unevenly and will

also wear down the brake belt. The contact surface of

the flywheel should be smoothed with fine sandpaper

and any dust removed with a clean dry cloth.

Remove any potential covers and all workload on

the brake belt and then remove it. Grind with a fine

sand paper. Grinding is easier to perform if a second

individual cautiously and carefully pedals the cycle.

Irregularities on the brake belt contact surface are

removed by means of a fine sand paper or an abrasive

cloth. Otherwise unnecessary wear on the brake belt

may occur and the unit can become noisy.

Always keep the brake belt contact surface clean and

dry. No lubricant should be used. We recommend

replacing the brake belt when cleaning the contact

surface. In regard to assembly and adjustment of the

brake belt, see ”Replacement of brake belt”.

Manual pendulum bike / exercise bike:

To loosen the brake belt on the bike remove all tension.

Please note how the belt is assembled. Remove it from

the bike. Attach the new brake belt and assemble the

bike in reverse order.

NOTE!

When replacing the brake belt it is recommended

to clean the brake surface. See ”Brake belt contact

surface”.

Batteries

LC6 / LC7

25

Fig: Brake belt contact surface

Page 26

Chain 1/2“ x 1/8“

Check the lubrication and tension of the chain at

regular intervals. In the middle of its free length the

chain should have a minimum play (3) of 10 mm (1/4

inch). See Fig: Chain adjustments. When the play in

the chain is about 20 mm (3/4 inch) the chain must

be tightened. Otherwise it will cause abnormal wear

of the chain and sprockets. Therefore it is always

recommended to keep the chain play as small as

possible. Loosen the hub nut (2) on both sides and

tense the chain with the chain adjuster (1) when

needed.

When the chain has become so long that it can no

longer be tightened with the chain adjusters it is worn

out and should be replaced with a new one.

To adjust or replace the chain, remove covers if

required.

To adjust the chain the hub nuts (2) should be

loosened. Loosening or tightening the nuts on the

chain adjusters (1) will then move the hub and axle

forward or backward. Then tighten the nuts on the

hub axle again. See Fig: Chain adjustments.

To replace the chain, loosen the chain adjusters as

much as possible. Dismantle the chain lock (6) and

remove the chain. Use pliers to both release the lock

washer and mount it again (4). Put on a new chain

and assemble the chain lock. The spring of the chain

lock should be assembled with the closed end in the

movement direction (5) of the chain. See Fig: Chain

replacement.

NOTE!

At assembly the flywheel has to be parallell with

the centerline of the frame. Otherwise the chain and

sprockets make a lot of noise and wear out rapidly.

kuggtoppar.

Then assemble the removed parts as above but in

reverse order.

4

6

5

3

2

1

LC6 / LC7

26

Fig: Chain replacement

4) Lock spring

5) Movement direction

6) Chain lock

Fig: Chain adjustments

1) Chain adjuster

2) Axle nut

3) Chain play

Page 27

Freewheel sprocket

When replacing the freewheel sprocket remove frame

covers if necessary. Remove the chain according to

section ”Chain 1/2” x 1/8””.

Loosen the axle nuts and lift off the flywheel. Remove

the axle nut, washer, chain adjuster and spacer on

the freewheel side. Replace sprocket-adaptor and

assemble the new parts in reverse order according to

the above.

NOTE! Do not tighten the axle nut completely. It

must be possible to loosen the adaptor-sprocket half

a turn.

The sprocket should be lubricated with a few drops of

oil once a year. Tilt the cycle to make it easier for the

oil to reach the bearing. See Fig: Lubrication.

LC6 / LC7

27

Fig: Lubrication

Fig: Hub assembly

Page 28

1

7

15

16

12

18

19

17

14

13

8

9

10

20

6

21

22

23

26

27

28

31

29

27

5

4

3

2

11

26

25

24

LC7

31

32

LC6

LC7

30

LC6 / LC7

28

Spare parts list

Page 29

LC6 / LC7

29

Fig: Chest belt

Pos. Qty. Art. No. Description Pos. Qty. Art. No. Description

1 1 9300-147 Saddle, racer with adaptor 1 9310-29 Handlebar with stem and

clamp, complete

1 C7100535 -Saddle Exeo Road white 21 1 9310-92 -Handlebar stem

1 9336-42 -Adaptor to race-/sport saddle 22 1 9310-24 -Handlebar clamp

2 1 9310-28 Sledge, complete 23 1

C2205419-120 -Reparto corse stem 120 mm Al

3 1 9311-24

-Locking handle black M10x32,

complete

24 1 C2305771-42 -Reparto corse handlebar

1 9310-281 -T-slot nut M10 1 C2600079 -Handlebar tape EVO black

4 1 9310-30 Seatpost with ruler 25 1 9311-74

-Locking handle black M10x80,

complete

5 8322-70 Pedal combi SPD/Look 1 9310-281 -T-slot nut M10L

6 1 9301-3 Support tube rear, complete 26 2 9310-27 Piston locking, complete

2 9328-51 -Plastic cap 2 9100-289 -Locking handle blue M10x50,

complete

2 9328-26 -Rubber foot with screw M8 27 2 9328-1315 Bushing with hole

7 1 9301-4

Support tube front, complete

1 9339-89 Chest belt Polar Wear-link

2 9328-51 -Plastic cap

2 9328-26 -Rubber foot with screw M8

2 9328-37 -Transport wheel, complete

8 1 9338-26 LED lamp LC7 9310-35-7 LC7 Display bracket, complete

9 1 9310-72 Switch (on / off) 28 1 9310-33 -Computer holder LC7

10 1 8243-7 Holder for cable 29 1 9310-32 -Locking strap for computer

11 1 9310-13

Pendulum scale 7 kp, complete

31 1 9371-68 -Digital meter

1 9310-152 -Scale 9000-103 -Screw M5x12

1 9000-103 -Screw M5x12 30 1 9310-96 Holder for Lenovo LC7

12 1 9310-595

Side cover rear, right (outer

chain guard)

1 9339-66 Power adaptor, export

13 1 9310-620 Side cover front, right, with

recess for pendulum scale

1 9339-67 Power adaptor, SE

14 1 9310-20 Front cover LC6 9310-35-6 LC6 Display bracket, complete

15 1 9310-71 Lock to front cover 32 1 9310-77 -Document holder LC6

16 1 9310-630 Side cover front, left 31 1 9371-68 -Digital meter

17 1 9310-89 Bracket plate pulse receiver 2 9000-103 -Screw M5x12

18 1 9338-21

Pulse receiver Polar, complete

1 9339-66 Power adaptor, export

19 1 9310-605 Side cover rear, left 1 9339-67 Power adaptor, SE

20 1 9000-103 -Screw M5x12

Page 30

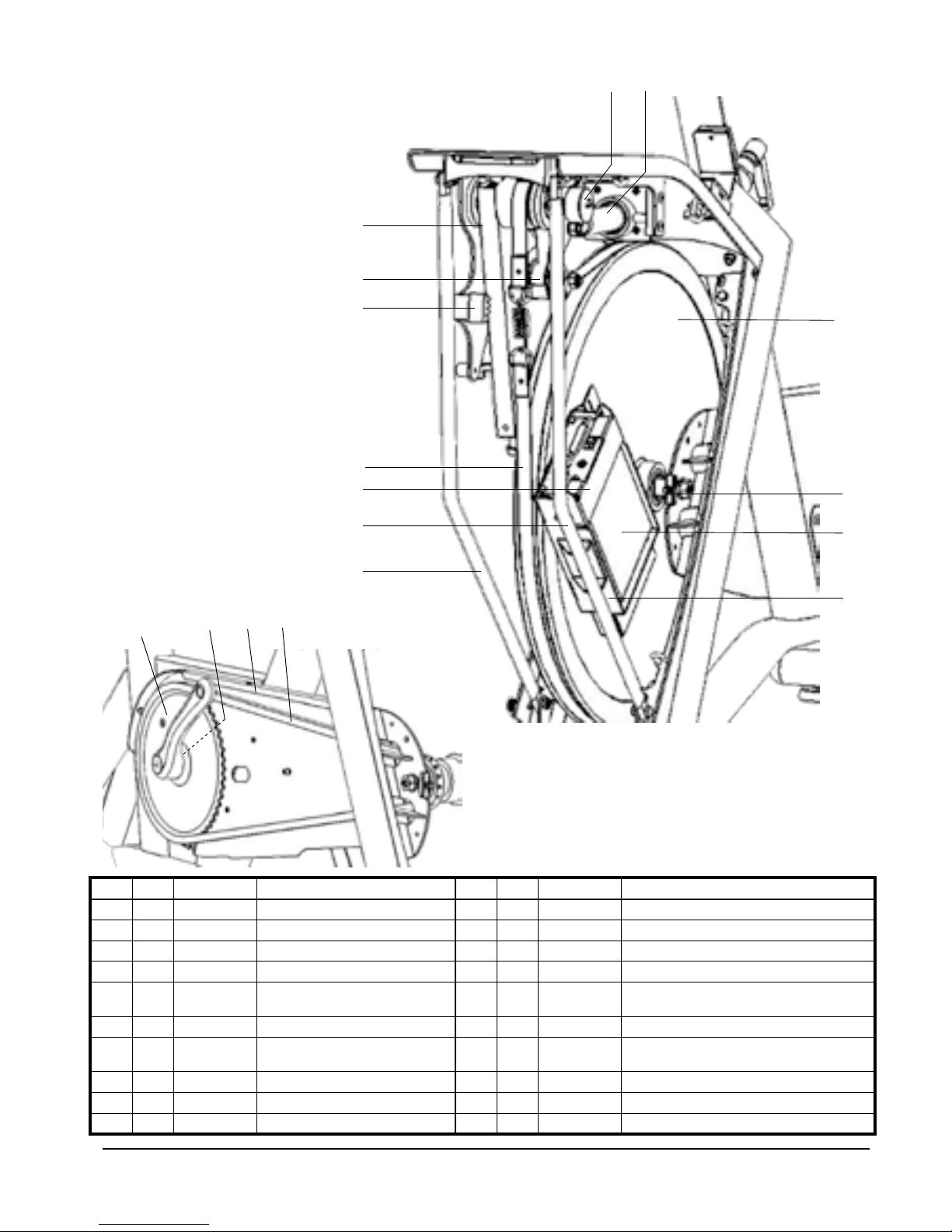

11

8

7

6

10

4

5

3

2

1

9

14

17

15 16

13

12

LC6 / LC7

30

Pos. Qty. Art. No. Description Pos. Qty. Art. No. Description

1 1 9310-45 Pendulum 7 kp, complete 9 1 9338-24 Electronic box

1 9310-43 -Pointer 10 1 9300-3 Flywheel, complete

1 9326-88 -Spring 11 1 9300-24 -Flywheel suspension, complete

2 1 9100-26 Tension cylinder 12 1 9310-57 Motor, complete

3 2 9300-99 Stop 13 1 9310-88 Potentiometer with data card and

cable

4 1 9310-94 Brake belt, complete 14 1 9300-478 Crank set 52 T with 13 magnets

5 1 9310-48 Locking strap for electronic

box

15 1 9300-480 Bottom bracket 68/110 mm

6 1 9310-64 Strut with bracket 16 1 9310-90 Inner chain guard

7 1 9310-65 Strut without bracket 17 1 9310-118 Chain 9300, 120 L, with chain lock

8 1 9310-46 Frame for electronic box

Page 31

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

LC6 / LC7

31

Notes

Page 32

KROONS VÄG 1, SE-780 50 VANSBRO, SWEDEN | WWW.MONARKEXERCISE.SE | TEL: +46(0)281 59 49 40 | FAX: +46(0)281 719 81

Version 1402

Art. No: 7950-359

Loading...

Loading...