Page 1

MONARCH INSTRUMENT

Instruction Manual

Printed in the U.S.A. © Monarch Instrument 2002 all rights reserved

1071-4800-121

Vibration Strobe

15 Columbia Drive

Amherst, NH 03031-2334 USA

Phone: (603) 883-3390

Fax: (603) 886-3300

E-mail: support@monarchinstrument.com

Website: www.monarchinstrument.com

Page 2

Safeguards and Precautions

1. Read and follow all instructions in this manual carefully, and retain

this manual for future reference.

2. Do not use this instrument in any manner inconsistent with these

operating instructions or under any conditions that exceed the

environmental specifications stated.

3. Use of this product may induce an epileptic seizure in persons prone

to this type of attack.

4. Objects viewed with this product may appear to be stationary when

in fact they are moving at high speeds. Always keep a safe distance

from moving machinery and do no touch the target.

5. There are lethal voltages present inside this product. Refer to the

section on Lamp Replacement before attempting to open this product.

6. The ventilation holes must remain unrestricted (well exposed) when

the unit is in operation to allow heat to escape.

7. Do not allow liquids or metallic objects to enter the ventilation holes

on the stroboscope as this may cause permanent damage and void

the warranty.

8. Do not allow cables extending from unit to come into contact with

rotating machinery, as serious damage to the equipment, or severe

personal injury or death may occur as a result.

9. Do not direct strobe flash toward certain data collectors, as it may

temporarily interrupt data collector operation, and could result in loss

of stored data.

10. This instrument may not be safe for use in certain hazardous

environments, and serious personal injury or death could occur as a

result of improper use. Please refer to your facility’s safety program

for proper precautions.

11. Do not attempt to operate the unit while charging. To do so may

cause permanent damage to the charger and the strobe light.

PRODUCT WARRANTY POLICY

SELLER warrants the Vibration Strobe to be free from defects in workmanship on all parts

except as noted below, for a period not to exceed 12 months from date of shipment to

BUYER. The warranty period for battery defects and flash tube defects shall be 6 months

from date of shipment to BUYER. SELLER’s entire liability and BUYER’s sole and exclusive

remedy resulting from any defect in workmanship or material in the hardware product covered

by this limited warranty shall be limited to and fully discharged by the SELLER’s option of

replacement or repair of such item without charge. The limited warranty provided in this

clause is in lieu of all other warranties, expressed or implied, arising by law or otherwise.

ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE EXCLUDED. This limited warranty shall not be modified except by an

arrangement signed by both parties specifically referencing this clause.

Product failure or damage caused by misuse or abnormal operating conditions are not

covered by this warranty. If the malfunction, or a portion thereof, is determined by SELLER

to have been caused by misuse or abnormal conditions of operation, or otherwise is not a

warranty item, an estimate of cost to repair will be submitted to the BUYER for approval

before any such repairs are performed.

NO OTHER WARRANTY IS HEREBY EXPRESSED OR IMPLIED. IN NO EVENT SHALL

SELLER BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, CONSEQUENTIAL,

OR PUNITIVE LOSSES OR DAMAGES (INCLUDING, BUT NOT LIMITED TO, LOSSES

OR DAMAGES FOR ANY LOST PROFITS OR LOST DATA) AS THE RESULT OF ANY

BREACH OR DEFAULT BY SELLER WITH RESPECT TO THE HARDWARE OR

SOFTWARE, EVEN IF SELLER HAS BEEN ADVISED OR MADE AWARE OF THE

POSSIBILITY OF ANY SUCH LOSSES OR DAMAGES AND REGARDLESS OF WHETHER

THE CLAIM IS BASED ON CONTRACT, TORT, STRICT LIABILITY, OR OTHER THEORY

OF LIABILITY.

Liability under this warranty is limited to servicing and adjusting the instrument returned to

Monarch Instrument factory, with transportation charges prepaid by the BUYER. THE USER

SHOULD NOT UNDERTAKE ANY STROBE REPAIRS. OPENING THE CASING WILL

CAUSE THE WARRANTY TO BE NULL AND VOID.

If a malfunction develops, notify the Customer Support Department of Monarch Instrument,

or its representative in your area, giving details of the problem, and the name, model and

serial number of the unit. Upon receipt of this information, service data or shipping instructions

will be provided. Please do not ship product prior to contacting Monarch Instrument, or its

local representative, for a Return Material Authorization (RMA) Number, to insure

proper handling.

12. This product contains sealed lead acid batteries which must be

disposed of in accordance with Federal, State, & Local Regulations.

Do not incinerate. Batteries should be shipped to a reclamation facility

for recovery of the metal and plastic components as the proper method

of waste management. Contact distributor for appropriate product

return procedures.

13. This instrument is not user serviceable. For technical assistance,

contact the sales organization from which you purchased the product

or Monarch Instrument directly.

Page 3

DECLARATION OF CONFORMITY

TABLE OF CONTENTS

TABLE OF CONTENTS

INTRODUCTION ....................................................................................... 1

As Manufacturer:

Monarch Instrument

Division of Monarch International Inc.

15 Columbia Drive, Amherst NH 03031 USA

declares under Monarch’s sole responsibility that the product:

Name: Vibration Stroboscope

Model: VB 115/230

to which this declaration relates is in conformity with the following standards:

EMC: EN50082-2:1995

EN55011:1991 Group 1, Class A

EN61000-4-2

ENV50140

EN61000-4-4

ENV50142

ENV50141

and therefore conforms with the requirements of Council Directive

89/336/EEC relating to electromagnetic compatibility. Retlif Testing

Laboratories performed the testing of this product. (Report No R-2700N).

27th March 1996

Manufacturer (Amherst, NH) Alan Woolfson, VP Engineering (Authorized Signature)

PREPARATION FOR USE ........................................................................ 2

OPERATION ............................................................................................. 3

MEASURING RPM WITH THE Vibration Strobe ....................................... 4

BALANCING AND PHASE MEASUREMENT ........................................... 4

PHASE ANALYSIS ................................................................................... 6

MOTION STUDIES ................................................................................... 7

POWER REQUIREMENTS AND BATTERY CHARGING ........................ 8

LAMP REPLACEMENT ............................................................................. 8

REPAIR/SERVICE/PARTS ..................................................................... 10

SPECIFICATIONS

Flash Rate Range: 100-12,000 FPM (Flashes Per Minute)

Locking Range: Wide Mode: 600 to 10,000 RPM

Narrow Mode: 200 to 8,000 RPM

Accuracy: ± 1 FPM (RPM)

Resolution: 1 FPM

Display: 5-Digit Liquid Crystal Display, Low Battery Indication

Input: Connector: 3.5 mm Stereo Plug

2.5 to 12 volt pulse in External (EXT) mode

100mV/g accelerometer in Tracking (LOCK/TRACK) mode,

externally powered

Output: Connector: 3.5 mm Mono Plug

Approx 6 Volt positive pulse

Power: 6.0 Vdc, Internal Rechargeable Sealed Lead Acid Battery

Charger: 115 Vac (Optional 230 Vac)

Operating Time: In excess of 60 minutes at 1800 FPM (on full charge)

Flash Duration: 30 microseconds

Flash Tube (Lamp) Life: 100 million flashes

Operating Temperature: 0-40° C (May be operated for short time periods, slightly beyond stated

temperature range.)

Weight: 2.5 lbs.

Page 4

INTRODUCTION

The Vibration Strobe is a truly portable, battery-operated stroboscope that is suited for a wide range

of industrial, institutional, and educational applications, and is able to interface with several of the

Vibration Data Collectors that are currently available. Several interface cables are available. Sturdy

and compact, the strobe can be operated anywhere in the plant or field to permit visual inspection

(freeze motion), and digital measurement of rotary, reciprocating, or linear motions of various

equipment while it is in operation.

The Vibration Strobe has a special “tuning” circuit that allows it to track vibration transducer

(accelerometer) signals. This capability makes it different from general-purpose strobe lights. It

also has a Narrow and Wide Bandwidth filter selection to discriminate fundamentals from harmonics.

The Narrow Bandwidth filter limits the influence of harmonics around the selected frequency,

providing a more stable phase reading.

The Vibration Strobe requires an input signal to synchronize the flash rate with an external source,

typically a vibration transducer in the tracking mode or optical pickup in the external mode. This

signal is applied, using a special cable, to the Input (! pointing into socket) jack connector on the

side of the strobe light. The Vibration Strobe generates a tachometer signal that is on the Output ("

pointing away from socket) jack. Information about the use of these signals is given in other sections

of this manual. Special adapter cables are available to suit several commercially available

Vibration Analyzers.

The Vibration Strobe is ideally suited for:

1. Balancing

2. Inspection of High Speed Rotating Parts

3. Motion Analyses, or Phase Measurement

4. Over speed Trip Tests

5. Online coupling Inspections

The Vibration Strobe can also be used as a highly accurate, remote electronic digital tachometer for

direct measurement of RPM (speed) without special reflective tape or markings. RPM results are

updated and displayed approximately every 1 second on a 5-digit LCD display.

The display panel consists of a backlit liquid crystal display with five alphanumeric digits (see Figure

1). Below the display is a knob that controls the phase shifting, the Mode Selector Switch and the

Bandwidth Switch.

REPAIR/SERVICE/PARTS

Repair:

In accordance with the warranty and replacement provisions, the user ordinarily would undertake

no strobe repairs. Possible exceptions involve minor malfunctions, i.e., cables, plugs, and

attachment items.

Assembling the Vibration Strobe is a critical procedure. It should NOT be dismantled. However,

the reflector lens is removable for lamp replacement. Refer to the section on Lamp Replacement

for instructions.

Service:

Notes should be kept regarding field troubles, whether or not any of the equipment is returned at

that time. A brief history or record of symptoms, or of pre-fault behavior is of substantial aid to the

factory. This is especially true of intermittent malfunctions that might call for a schedule of extended

scrutiny at the repair site.

Disposal:

Prior to disposing of this product, the user must remove the sealed lead acid batteries. To do this,

remove the lens as detailed above in lamp replacement, remove the reflector and lamp. This will

expose 4 screws that must be removed so the reflector housing can be dismantled. There are four

additional screws in the case half opposite the input and output jacks that must be removed. The

case halves can now be separated, exposing the batteries. Remove the cables from the batteries and

place tape over the battery terminals to prevent them from shorting. The batteries should be sent to

a recycling center or returned to the factory. The rest of the parts may now be disposed of.

Parts:

The following parts are available for field replacement, and can be ordered directly from

Monarch Instrument.

Model Description

CC-7 Latching Carrying Case for Strobe with provision for accessories

FR-3CE Fast Charger, 115Vac, 50/60Hz (3 hour)

FR-4CE Fast Charger, 230Vac, 50/60Hz (3 hour)

L-1903 Vibration Strobe replacement lamp (flash tube)

50192 Cable, BNC to miniature phone jack, External trigger input

Figure 1 Display Panel

1

10

Page 5

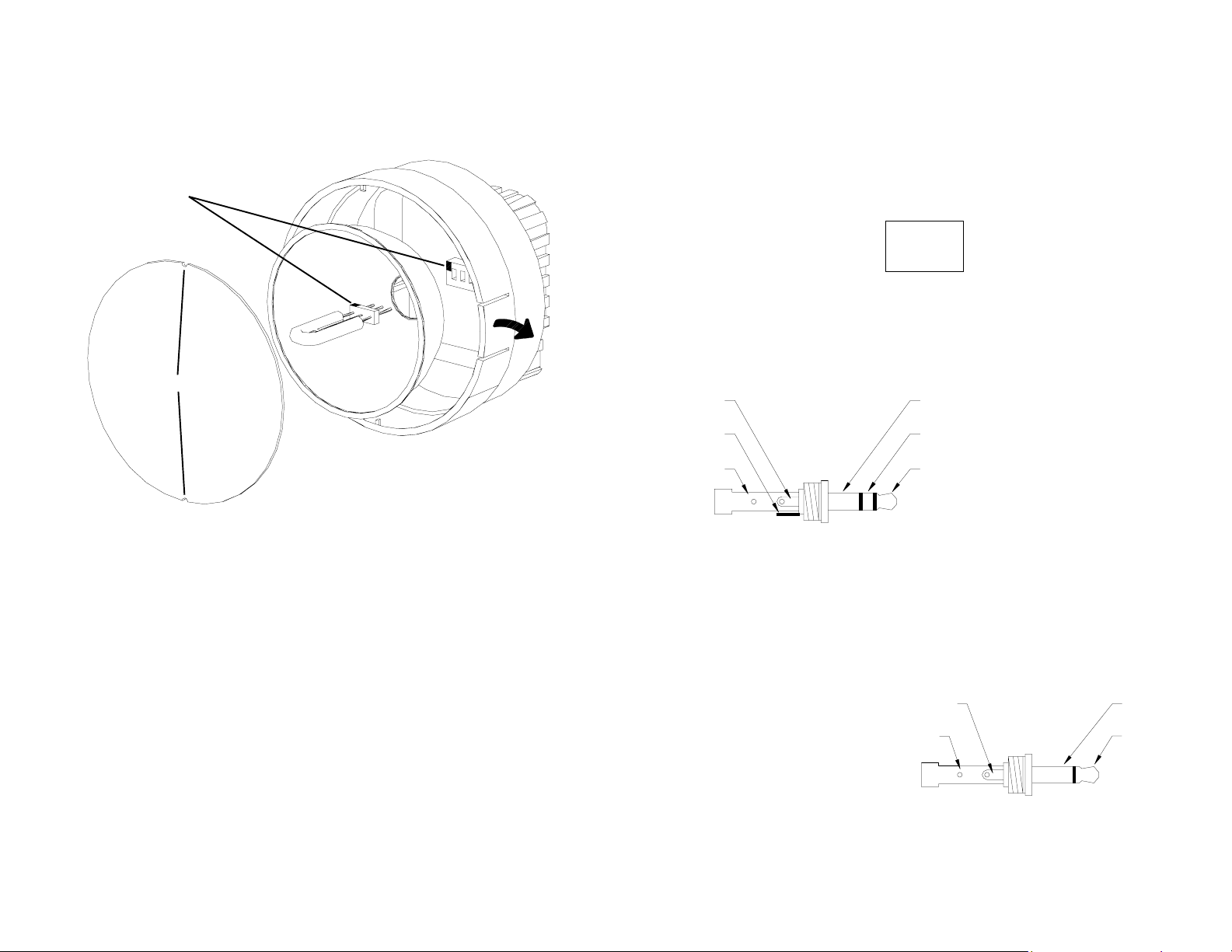

3. The lamps are polarized and must be put into the socket matching polarity. Using a lint

free cloth, match up the red dot on the plug with the red dot on the socket and

gently rock the lamp back and forth while pushing it into place (see Figure 5). Make sure

the lamp is in straight and centered in the reflector hole.

CAUTION: Do NOT allow the reflector to contact the lamp.

Red Dots

Notches

Figure 5 Lamp Replacement

4. Reinstall the reflector and then position the front lens in place matching up the notches on

the lens with the two small tabs on the housing to prevent lens rotation (see Figure 5).

Push the tabs on the front rim outward and press the lens into place.

PREPARATION FOR USE

The Vibration Strobe is a portable lightweight strobe flash unit with internal battery that will flash for

more than 1 hour at 1800 FPM (Flashes Per Minute) before recharging is required. The unit should

be fully charged prior to each use. See the Power Requirements and Battery Charging section later

in this manual for details.

The unit may be either hand-held, or mounted to a tripod or other user-supplied bracket using the

1/4" - 20 UNC bushing at the base of the handle.

The strobe has input and output jacks on the left side of the stroboscope (see Figure 2). These jacks

accept 3.5 mm plugs (input – stereo, output – mono).

! !! !

! !

! !! !

""

!!

"

!

""

!!

Out In

Figure 2 Input/Output Jacks

Input

The input ring is for the accelerometer input. The accelerometer must be powered externally and

this input is decoupled internally, so that the positive or signal from the transducer can be applied

Signal Input

Sensor Input

Common

(GND)

Figure 3 Input Connector Connection Detail

minute). There is typically a 5 µsec delay from trigger input to flash. The trigger source should

provide a pulse with a minimum duration (width) of 20 µsec in the range 2.5 to 12 volts dc.

Output

In the Internal (INT) mode, the output provides a TTL compatible pulse from the strobe’s internal

oscillator in synch with the flash. In the External (EXT) mode, the output pulse mimics the input

pulse. This output pulse may be

used to trigger a second stroboscope

synchronously to illuminate larger

areas. In the Tracking (LOCK/

TRACK) mode, this output is a pulse

at the tracking or lock frequency, at

the strobe flash rate, and may be

phase shifted ±180° from the

reference point.

Common

(GND)

Sensor Input

(100 mV/g)

Signal Input

(TTL Pulse)

Signal Input

Common

(GND)

Figure 4 Output Connector Connection Detail

directly. The unit is optimized

for 100mV/g accelerometers,

but any signal above 5mVac will

activate the unit.

The input tip is for an external

digital signal from a remote

sensor or another strobe. The

range for triggering is from 0

flashes per second to 200 flashes

per second (12,000 flashes per

Common

(GND)

Signal Input

9

2

Page 6

OPERATION

To turn on the stroboscope, depress and hold the trigger. When the strobe is powered up in the

Internal (INT) mode, it will begin flashing immediately. The trigger may be locked in position using

the side-locking button. To lock the trigger on, hold the unit in the right hand, depress the trigger as

far as it will go, and then use your thumb to press the locking button. You may release the trigger

and the trigger will be held in place. To release the trigger lock, simply depress the trigger and

then release.

There are three Operating Modes that are controlled by the Mode Selector Switch at the front of the

unit. The Operating Modes are:

EXT: External - an external tachometer signal (TTL level pulse) controls

the flash rate, i.e. an optical sensor or second strobe.

INT: Internal - the internal oscillator controls the flash rate

LOCK/TRACK: Locking - when properly set, the vibration transducer (accelerometer)

controls the flash rate

Internal Mode – Standard Strobe Operation

In the Internal Mode the stroboscope generates its own signals and functions like an adjustable

stroboscope. The strobe is in the Internal Mode when the Mode Selector Switch is set to INT.

To operate in the Internal Mode:

1. Push the Mode Selector Switch to the INT (Internal Mode) position.

2. Depress and hold the trigger. The unit will begin to flash at the rate displayed on the LCD

display until the trigger is released.

3. Turn the control knob, located on the left side of the strobe to adjust the flash rate.

4. For continuous operation, squeeze the trigger once again, then depress the small “trigger

lock” button (just above the trigger, on the side of the unit) and the unit will continue to

flash with finger-free operation until the trigger is depressed again, which releases

the lock.

External Mode

In the External Mode the flash rate is a function of the input signal, and the user cannot make flash

rate adjustments. This mode is used to synchronize the flash to an external event (for example,

from an optical sensor) to stop or freeze motion. The flash will be triggered on the rising edge of the

external input pulse. The strobe is in the External Mode when the Mode Selector Switch is set to

EXT. The LCD will display the current Flash Rate.

Locking Mode

In the Locking Mode the vibration transducer (accelerometer) controls the flash rate. The strobe

is in the Locking Mode when the Mode Selector Switch is set to LOCK/TRACK.

Prior to setting the LOCK/TRACK mode, the strobe MUST be operated in the Internal

mode. The accelerometer must be properly connected and powered, usually by the external Vibration

Analyzer, and must be mounted in place. Special cable assemblies are available for several

commercially available Vibration Analyzers, or you may “steal” the accelerometer signal and feed

it into the strobe input as detailed above.

Once set up, you have to tune the strobe to set the center frequency of the filters to work with the

accelerometer. Using the Internal mode, adjust the flash rate of the strobe to stop motion of the

target of interest. Switch the Mode Selector Switch to LOCK/TRACK, and the strobe will now use

the signal from the accelerometer to control the flash rate.

3

POWER REQUIREMENTS AND BATTERY CHARGING

The Vibration Strobe has internal rechargeable batteries and can operate continuously in excess of

60 minutes at 1800 flashes per minute. The strobe has a protection feature to prevent it from

operating if the battery charge becomes too low. All decimal points on in the LCD display indicate

this condition. When this occurs, the battery is in need of recharging. The actual operating time of

the battery depends on the flash rate and duty cycle of operation.

NOTE: Do not attempt to operate the unit while charging. To do so may incur permanent damage

to the charger and the stroboscope.

The unit may be recharged at any time. You do not need to wait until the low battery condition is

indicated.

To charge the battery:

1. Release the trigger so the strobe is off.

2. Plug the recharger cable into the recharger socket (located below the display panel behind

the handle).

3. Plug the recharger into a mains wall outlet.

CAUTION: Use of rechargers other than the one supplied (FR-3A for 115 Vac or

FR-4 for 230 Vac) may damage the stroboscope and void

the warranty.

4. Press the black button on the front panel of the supplied recharger to begin a charge cycle.

The red LED “charge light” on the panel will illuminate.

The recharger will fast charge the batteries for up to 5 hours (typically 3½ - 4 hours). Once the fast

charge is completed, the recharger will trickle charge the batteries (as indicated by the red LED light

turning off). The unit may be left on charge overnight, and it requires 14 hours to reach a full

charge, from a low battery condition. The unit may be left on charge indefinitely.

The battery voltage can be measured at the charger socked on the strobe using a high impedance

voltmeter. A fully charged set of batteries should measure around 6.6 Vdc.

LAMP REPLACEMENT

WARNING: Before attempting to remove the lamp, make sure the stroboscope is

turned off and that the battery recharger and all other cabling are

disconnected from the unit. Allow the lamp to cool waiting at least

1 minute.

The stroboscope is designed to discharge the internal high voltages within 30 seconds. However,

caution should be exercised when replacing the lamp.

The lamp can be replaced by using just a pocket screwdriver. It is not necessary to remove any

screws to replace the lamp. A new spare lamp is supplied with each new Vibration Strobe Kit.

To change the lamp:

1. Push apart the two tabs on the side of the reflector housing and remove the front lens

using a small screwdriver to help pry one tab and lift the lens. Take care not to pry the tab

any more than is necessary to free the lens. The reflector is held in place by the front lens

and will come loose, but is not necessary to remove the reflector.

2. Hold the lamp with a cloth between your forefinger and thumb and rock it back and forth

gently while pulling out. Do not attempt to rotate the lamp. The lamp is socketed and

will come out easily when pulled.

WARNING: Do NOT touch the new lamp with bare fingers.

8

Page 7

Checking for unbalance:

1. If the vibration transducer is moved from the vertical position on the bearing to another

radial position, the reference mark will move to the new position if there is a significant

amount of unbalance. The reference mark will follow the vibration transducer around the

clock only if the once per turn vibration is caused by unbalance.

Checking for alignment:

1. Alignment checks can be made by moving the vibration transducer to each end of the

machines in a train. The vibration transducer is positioned axially at these locations for

these measurements. Keep track of the phase for each measurement location.

2. As the vibration transducer is moved to each location, it’s direction keeps changing from

North to South, for example. When it changes direction, phase will shift from 12:00

o’clock to 6:00 o’clock.

3. If you move across a coupling and phase does not change as expected, a misalignment

condition can be the cause.

MOTION STUDIES

The Vibration Strobe can be a useful tool to determine how a mechanical support or a piping system

is moving. It allows the user to find points of maximum motion as well as minimum motion. This is

important if a new pipe hanger is to be installed or if a brace is going to be added to dampen a

vibration condition.

For these tests the strobe light should be set on a tripod. A long cable will be needed for the sensor.

The sensor should be mounted on a magnetic base.

Follow the same 5 steps outlined in the previous section for General Preparation for phase analysis,

and then follow these steps:

1. Mark the piping system off in given intervals and note the location of supports or hangers.

For example, use 6-foot intervals. Draw a simple diagram on paper.

2. Start at the machine end, adjust the strobe light to running speed, and note the phase

reading using the clock face method. (For reference, adjust the phase marker to the 12:00

o’clock). Move the vibration transducer to each location, noting the phase reading

at each.

NOTE: Do not move the strobe light, just the vibration sensor. Do not change the Phase Angle

control knob after the initial reference has been set.

3. The phase markings should “walk” around the clock face as the sensor is moved to each

location. Each time the marking is at or near 12:00 o’clock, the motion is at or near

maximum and is in phase with the reference point. Each time the marking is at or near

6:00 o’clock, the motion is at or near maximum in the opposite direction and is out of

phase with the reference point.

The Narrow and Wide Bandwidth selector on the strobe’s front panel can be used to optimize its’

ability to lock onto the vibration signal at any speed. The Wide bandwidth will allow the strobe to

track the signal over a fairly wide range of speed change and should be used when tracking the

fundamental frequency (in simple systems).

On machines such as a gear drives, reciprocating engines, or any drive with multiple fundamental

frequency excitation, the strobe could encounter difficulty tracking the designated signal, due to the

tracking filter’s normal bandwidth. If substantial levels of multiple fundamental frequencies, or

fundamentals with harmonics occur within a selected bandwidth, the shaft reference may appear to

oscillate, or drift substantially, when viewed with the Vibration Strobe. Also, if the accelerometer

cannot be positioned on the primary point of interest, a fundamental frequency of something other

than that of the primary point of interest may be predominant. In these cases, use the Internal (INT)

mode and flash rate adjust to stop the motion of the primary point of interest, switch the Bandwidth

switch to Narrow, and then switch to the Locking (LOCK/TRACK) mode. The filter is far more

sensitive and will better be able to discriminate the required signal. However, it will not be able to

track over widely varying speed changes, which will require retuning in the Internal (INT) mode.

After the image has been locked and the Narrow or Wide Bandwidth has been optimized for the

speed and/or background noise on the sensor signal, the Phase knob can be used to adjust the phase

of the output pulse (and image) - refer to the Phase Analysis section later in this manual for adjusting

the Phase Angle control.

MEASURING RPM WITH THE Vibration Strobe

To read and measure RPM (speed) with the Vibration Strobe, select a permanent or semi-permanent

object or mark on the shaft to use as a visual reference. Most technicians choose to select an

unopposed shaft keyway, or other marking on the shaft, that is not duplicated on the opposite side

(180 degrees) of the shaft. If it is possible to stop the machine, mark the shaft with a center punch,

paint or permanent marker, liquid correction fluid, etc. When marking, it is a good idea to use

marks on the shaft 180 degrees apart, such as a horizontal line (-) at one point, and a vertical line (I)

180 degrees away. This will give an indication of a “+” when the flash rate (and LCD display) is at

two times actual running speed. This serves as a useful indicator.

It is suggested that the shaft mark/object should be observed at as much of a 360 degree rotation as

possible, however, normally a range of 180-200 degrees is sufficient. After placing the Mode

Selector Switch to INT, direct the flash toward the mark/object on the shaft. If the speed of rotation

is within the range of the strobe, start at the highest flash rate and adjust the flash rate slower until a

single image of the dedicated reference is observed. Note that at a flash rate twice the speed of the

image, that two images may be observed 180 degrees apart from each other. As you near the

correct speed you will see 3, 4 or more images at harmonics of the running speed. The first single

image you observe should be the true running speed. To verify this, simply slow the flash rate to half

of what was noted at one times speed. A single image should again appear. Readjust the flash rate

again, as closely as possible back to running speed, the next higher single image. As the mark is

locked-in, the LCD display will read out the true RPM (speed) of the machine part being observed.

BALANCING AND PHASE MEASUREMENT

The Vibration Strobe contains an internally tuned filter that is incorporated in a phase shifting

network, which allows the shaft reference mark to be directed at any convenient location on the

machine while balancing or performing motion studies (phase measurement) along a machine’s

casing or along a machine train. Examples of a convenient location are the machine’s horizontal

split line, top or bottom dead center, or the plane of the reference transducer.

NOTE: It is advisable to “LOG” this reference location, so that it may be utilized in future studies

or balancing procedures.

7

4

Page 8

To set-up for balancing or phase measurement, a data collector or vibration analyzer must be used

that is capable of interfacing with the Vibration Strobe. The instrument must then be set up to obtain

and record the phase information supplied to it from the strobe and the reference transducer.

As a general set-up guideline for the data collector or analyzer, in order to be triggered properly and

to read phase properly, check the following:

1. Set the instrument to accept an external tachometer trigger signal. The strobe light will

provide this signal.

2. Set the frequency range for order analysis (10 orders full scale works best). This insures

the 1X frequency will be centered in the 1X (first order) filter which is a must for repeatable

phase measurements.

3. Set the instrument to display averaged spectrum and phase data (4 or 8 averages).

4. Set transducer power to On.

NOTE: Application Notes are available for some data collectors that describe their particular set-

up configurations. Check the Owners Manual for your data collector for proper setup

configurations.

Connect the proper interconnect cable between the strobe and the data collector or analyzer. See

wiring diagram to build the cable. The Input (Up Arrow) and Output (Down Arrow) jacks are

located on the left side of the strobe. Connect the vibration transducer (this may be a separate cable

or an integral cable) to the strobe cable.

NOTE: The vibration transducer provides the signal the strobe uses as a phase trigger source and

therefore is the input to the strobe. The vibration transducer also provides the vibration

signal to the data collector or analyzer. The interconnect cable provides a “TEE” connection

to both. The strobe provides the phase referenced tachometer signal (output) which is

used as an input to the data collector or analyzer for triggering.

Now you are ready to go to work!

Follow the operating instructions outlined at the beginning of this section for tuning the strobe to 1X

running speed. After the reference mark has been “frozen” (as nearly as possible, but slight rotation

is acceptable), place the Mode Selector Switch in the LOCK/TRACK position. The flash rate is

now derived from the vibration transducer. Phase information is only valid when operating in

the Locking (LOCK/TRACK) mode.

Select the Phase Angle orientation that is desired (0-360 or ±180 degrees) by pulling or pushing the

Phase Angle control knob. Using the Phase Angle control knob, position the reference mark to a

“convenient viewing location”. The data collector can now be employed to receive and process the

phase information as supplied to it by the strobe and the transducer. After the information is received,

simply release the trigger on the strobe, proceed to the next point, and then repeat the process.

NOTE: The trigger must stay depressed until the data collector or analyzer is through processing

the data.

For certain data collectors that do not provide constant power out to transducers that so

require, it may be necessary to command the analyzer to begin taking the data before the

phase image becomes stable enough to allow it to be placed at a reference location. It

may also be noted that slight adjustment of the Phase Angle control knob may be required

before each measurement, to assure that the reference location is repeated.

If the data collector you are using does not respond to the phase reference signal supplied to it by

the strobe, it is possible that the Trigger Set-up in the data collector may be reversed. If so, change

the set-up from “positive” trigger slope to “negative”, or vice versa, and try again.

When the strobe is tuned in the Internal (INT) mode, and then switched to LOCK/TRACK, the filter

in the strobe will track slight changes in speed. If the speed changes too much or too fast, the strobe

will lose LOCK/TRACK and stop flashing. It will be necessary to switch back to Internal (INT)

mode and repeat the adjustments. Also, try switching the Narrow and Wide Bandwidth switch to

optimize results. Generally, the Wide Bandwidth will give best tracking results but the Narrow

Bandwidth will give better stabilization.

NOTE: When it is necessary to have repeatable phase measurements, it is necessary to write

down the transducer locations used. Also, the transducer mounting method should be the

written down. Stud mounting or magnetic base mounting is preferred since data taken

with hand-held transducers may lead to significant phase differences.

PHASE ANALYSIS

The Vibration Strobe can be used to measure movement of parts of a machine, couplings and

machine cases in a machine train. The direction of movement (Phase) reveals important information

about looseness, unbalance and alignment.

This section is not intended to be a comprehensive review of these measurements. Refer to one of

the many training notes and application notes written over the years on these techniques.

This section outlines the preparations and use of the strobe light in order to be assured the

measurements you are making are correct.

NOTE: A data collector or vibration analyzer is not needed in order to do phase analysis. You do

need a method of powering the vibration transducer, or you can use a self-generating

velocity transducer to “drive” the strobe light.

General preparation for phase analysis is as follows:

1. It is important to use a magnetic mounting base on the vibration transducer.

2. Use a transducer cable that is long enough to allow you to get some distance away from

the strobe light.

3. Mount the strobe light on a tripod so it can be left standing.

4. Connect the vibration transducer to the strobe light (using a power source or a

data collector).

5. Start all measurements with the vibration transducer mounted on a bearing housing in the

vertical direction. (This is a good habit to get into). Aim the strobe light at the selected

reference mark and turn it on. Adjust the flash rate to running speed and then set it to the

Locking (LOCK/TRACK) mode. Using the Phase Angle control, position the reference

mark to the 12:00 o’clock position.

Do not move the strobe between measurements.

Checking for looseness:

1. Keeping the vibration transducer in the vertical direction, move the vibration transducer

from the foundation, to the base plate, to a foot, to an area above any split line, to the

bearing cap. Note the phase at each of these locations.

2. The reference mark should stay at the 12:00 o’clock position for each of these

measurements. If phase changes (probably to 6:00 o’clock) at any of these measurement

points, there is looseness at the mechanical joint.

5

6

Loading...

Loading...