Monarch TSP 3, TSP 2, TSP 4 Owner's Manual

OWNER'S

TSP SERIES

MANUAL

Self Priming Trash Pumps

PumpBiz.com

SAFETY WARNINGS

BEFORE OPERATING OR

INSTALLING THIS PUMP, READ

THIS MANUAL AND FOLLOW

ALL SAFETY RULES AND

OPERATING INSTRUCTIONS.

SAFETY

CAUTION

• DO NOT OPERATE THIS PUMP DRY!

• Review instructions before operating.

• Wear ear protection to reduce objectionable noise.

__________________________________________________

WARNING

• Turn off power before servicing.

• If fuel is spilled, avoid creating any source of ignition until the

fuel vapors have been cleaned up and removed.

CAREFULLY READ THESE SAFETY

MESSAGES IN THIS MANUAL AND

ON PUMP.

APPLICATION

This pump is suitable for installations where the vertical distance

from the pump to the water level does not exceed 25 ft. In off-set

PERFORMANCE

BASED ON 5’ SUCTION LIFT.

Total Head in Feet

Pump Pump Solids 30 40 50 60 70 80 90

Model Size Handling Capacity in U.S. Gallons per Minute

TSP 2 2” x 2” 1 1/8” 198 194 180 145 110 75 40

TSP 3 3” x 3” 1 1/2” 318 265 172 98 42

TSP 4 4” x 4” 2” 616 500 400 280 190 120 45

NOTE: This trash pump can handle pumping stones, leaves,

mud and other debris of sizes up to the listed solids handling for

the pump and up to 25% of the flow by volume.

installations, friction losses in the suction pipe must be taken into

consideration.

Total Head in Metres

Pump 9 12 15 18.5 21.5 23.5 27.5

Model Capacity in Litres per Minute

TSP 2 750 735 680 550 415 285 150

TSP 3 1205 1005 650 370 160

TSP 4 2330 1890 1515 1060 720 455 170

200162R3 0402

INSTALLATION

(a) LOCATION: The pump should be installed in a dry and well

ventilated location which provides adequate drainage, room

for servicing and protection from freezing temperatures. The

pump should be placed on a firm and level foundation. It

should be blocked and anchored, or if possible bolted down

to prevent creeping due to vibration. Locating the pump as

close as possible to the source of liquid supply reduces the

friction losses in the suction pipie and provides maximum

capacities.

CAUTION

• Always ensure there is adequate ventilation to prevent

asphyxiation.

(b) SUCTION HOSE: Use clean non-collapsible hose of the

same diameter as the pump suction piping. Where long

lengths of suction hose are used, the suction pipe diameter

should be increased by one size. This will increase the priming time. Check hose connections for leaks and the hose

for cuts and cracks. Repair any leaks, cuts or cracks as

they reduce pump capacity. The suction pipe must always

slope upwards from the liquid source to the pumps to avoid

air pockets in the line. In cases where the pump needs to

be reprimed often and it is not necessary that maximum

capacities be obtained, it is advisable to use a 90° or 45°

elbow in the suction line. This enables the pump to prime

more quickly and also prevents bending of the hose. In

cases where a maximum flow is required over a prolonged

period of time, the suction line should be led almost horizontally to the pump. Non-toxic thread compound should

be used on all pipe joints and connections should be thoroughly tightened. A strainer should be connected to the

bottom end of the suction pipe and it should be well submerged at all times.

OPERATION - PRIMING THE PUMP

WARNING: DO NOT RUN THE PUMP BEFORE PRIMING IT, SINCE THE SEAL AND IMPELLER COULD BE

PERMANENTLY DAMAGED.

(a) ENGINE: Check the engine manufacturer’s owner’s manual

supplied with the pump for instructions on engine preparation and start-up procedures. Make sure oil is added to

engine crankcase before starting the unit.

(b) PRIMING (NON-PRESSURIZED SYSTEM): Never oper-

ate the pump dry as this may damage the pump seal. Remove the priming plug from the top of the pump casing. Fill

the pump casing with water through the priming plug. Replace the priming plug and start the engine. The pump

should prime in 1/2 to 2 1/2 minutes, depending on the suction hose. If an exceptionally long suction line is used, the

water in the casing may become overheated and vapor

locked. If this occurs, replace the water in the casing with

cold water, using the priming and drain plugs. Continue to

prime the pump.

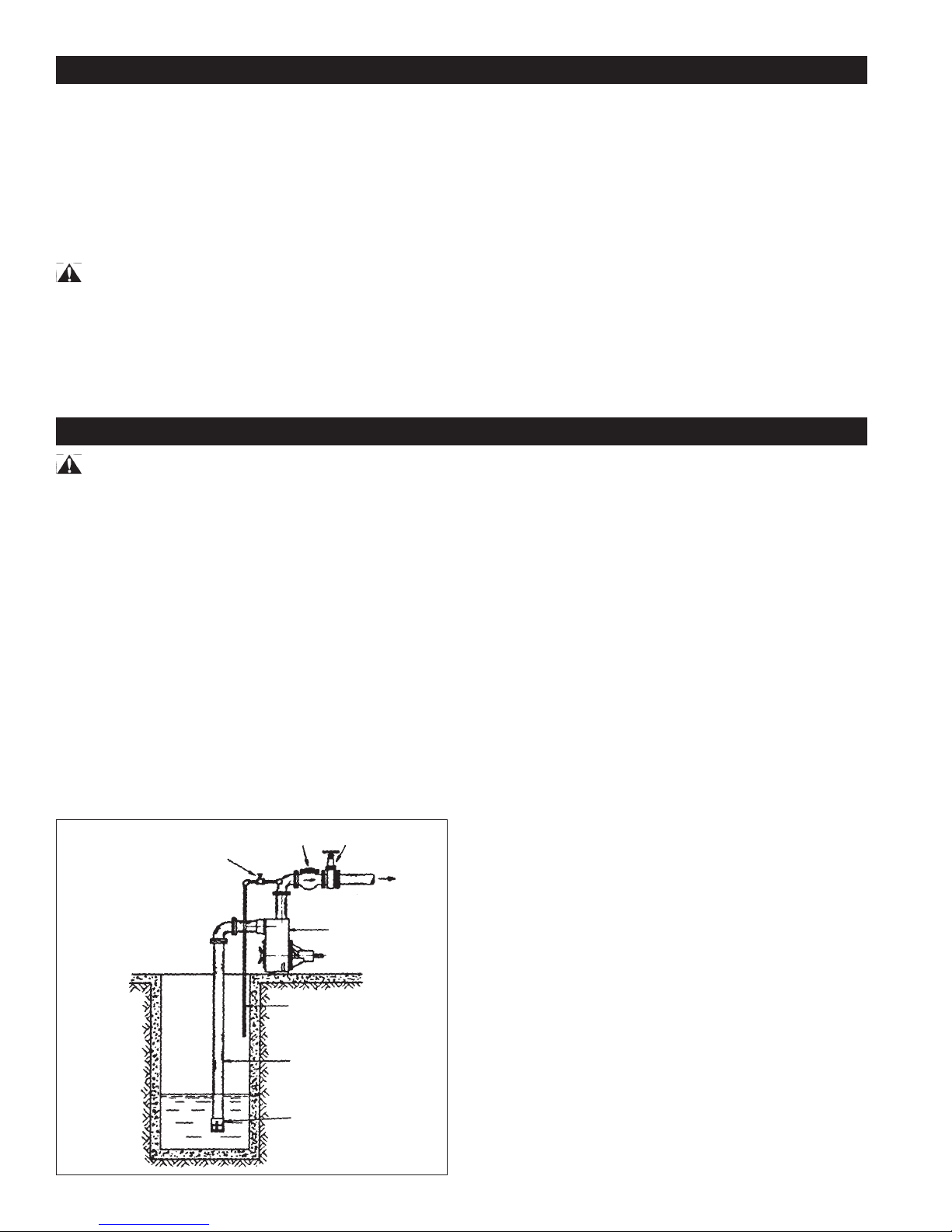

Figure 1

Gate Valve

(min. 3/4”)

Check Valve Gate Valve

Discharge

(c) PRIMING (PRESSURIZED SYSTEM): Place a check valve

on the discharge line of the pump. Place a pet cock or a ball

type air bleeder in place of the priming plug. Another alternative is to install an air bleed line with with gate valve onto

the discharge line, see Fig. 1. Open the priming port. Fill

the casing with water through the priming port. Replace the

plug or bleeder into the priming port. Open pet cock or ball

type air bleeder, and start engine. Once a continuous flow

of liquid emerges from the bleeder line, priming is complete

and the valve on pet cock can be closed off. The pump

should prime in 1/2 to 1 1 /2 minutes depending on suction

lift and the length and diameter of the suction hose. If an

exceptionally long suction line is used, the water in the casing may become overheated and vapor locked. If this occurs, replace the water in the casing with cold water using

the priming and drain plugs. Continue to prime the pump.

(d) UNCLOGGING: The pump is designed to enable the

impeller and volute to be unclogged without disconnecting

either suction or discharge hoses. Simply unbolt the four

large wing nuts and remove the front cover - suction hose

still attached. Remove the volute to expose the impeller.

All parts can then be readily cleaned.

Air Bleed Line

Suction Pipe

Strainer

Pump

(e) DRAINING: Should the pump be subject to freezing tem-

peratures, it will be necessary to drain the pump completely.

To drain, remove the drain plug located at the bottom of the

front casing and the priming plug and make sure that the

drain hold is not choked. After all of the water has been

drained out, operate the pump for a few seconds to ensure

that the impeller is devoid of water. Make sure that the suction line is also empty.

(f) STORAGE OF PUMP: Drain liquid from pump as explained

in the “Draining” section, to prevent freezing. It is recommended that a good rust inhibitor be put in the liquid end to

prevent excessive corrosion. Be sure motor is kept dry and

covered. When restoring the use of the pump, replace all

plugs and make sure all connections are tightly sealed. After a complete check, proceed with the initial prime according to the directions under the section “Priming”.

2

Loading...

Loading...