Page 1

Page 2

Contents

Chapter 1 Overview ............................................................................................... 4

Chapter 2 Product Information .............................................................................. 6

2.1 Designation Rules ............................................................................................................6

2.2 Mounting Dimensions .......................................................................................................6

2.3 Electrical Specifications ....................................................................................................8

2.4 Braking Resistor .............................................................................................................11

2.5 Terminal Descriptions .....................................................................................................12

Chapter 3 Component Description ...................................................................... 16

3.1 Onboard Keypad Description .........................................................................................16

3.2 Use of the LED Operation Panel ....................................................................................18

3.3 CTB Board ......................................................................................................................20

3.4 Display Board (MCTC-HCB)...........................................................................................22

3.5 CCB Board .....................................................................................................................29

Chapter 4 Use of the NICE3000 .......................................................................... 32

4.1 Wiring Diagrams Under Default Parameter Settings ......................................................32

4.2 Description of Shaft Signals ...........................................................................................33

4.3 Typical Commissioning ...................................................................................................35

Chapter 5 Function Code Table ........................................................................... 52

Chapter 6 System Application ............................................................................. 72

6.1 Parallel Mode and Group Mode......................................................................................72

6.2 Emergency Evacuation at Power Failure .......................................................................75

6.3 Opposite Door Control ....................................................................................................78

Chapter 7 Troubleshooting .................................................................................. 82

7.1 Description of Fault Levels .............................................................................................82

7.2 Fault Information and Troubleshooting ...........................................................................83

Page 3

Page 4

1

Overview

Page 5

Overview Brief NICE3000 Instruction Manual

- 4 -

Chapter 1 Overview

To facilitate the users who use the NICE3000 control system for the first time to understand

how to commission the control system as quickly as possible, this manual briefly describes

the specifications, wiring, common parameter setting, and common commissioning of the

NICE3000.

The application range of the NICE3000 is as follows:

Maximum Number

of Floors

Maximum Elevator

Speed

Parallel/Group Mode Inputs Outputs

40 4 m/s 2 to 8 elevators 24 6

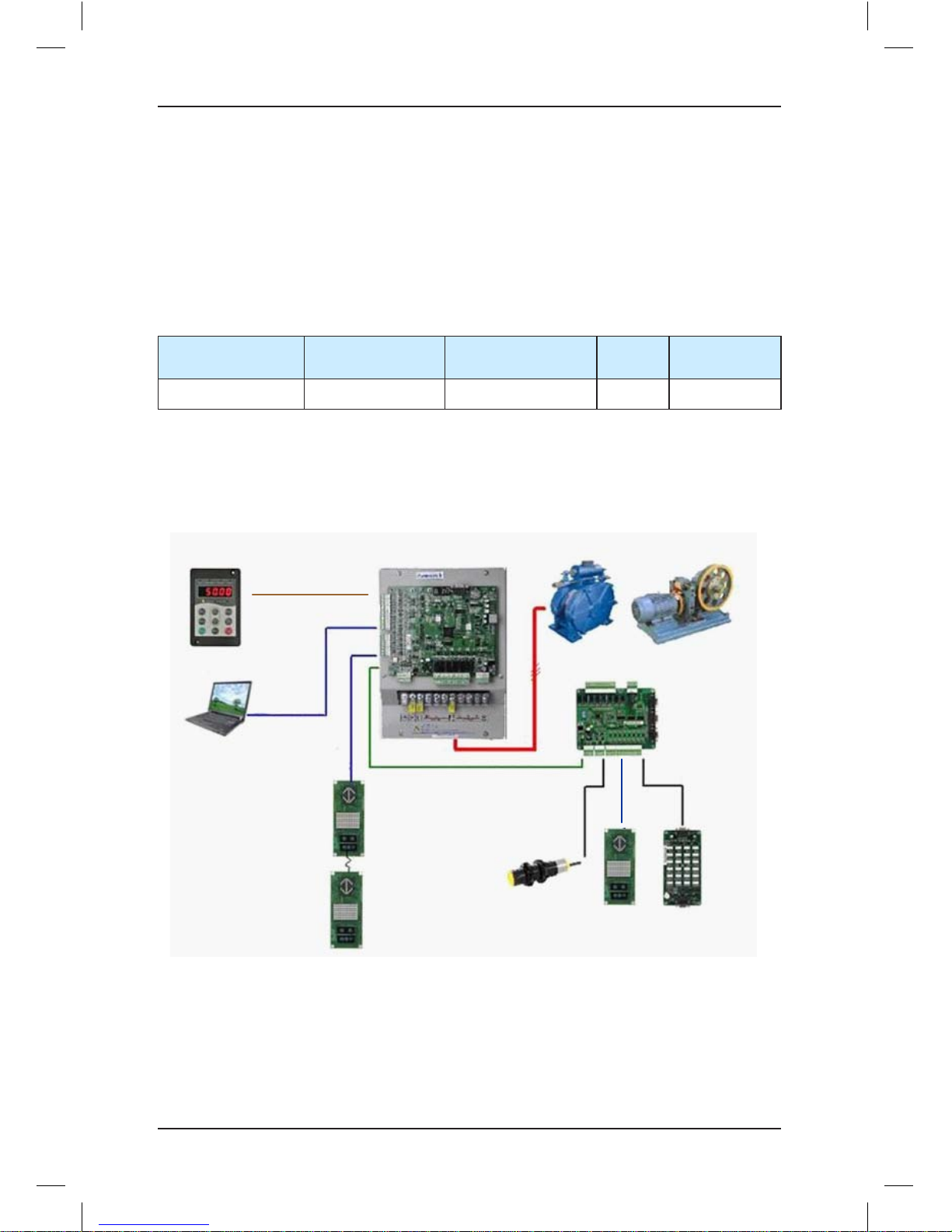

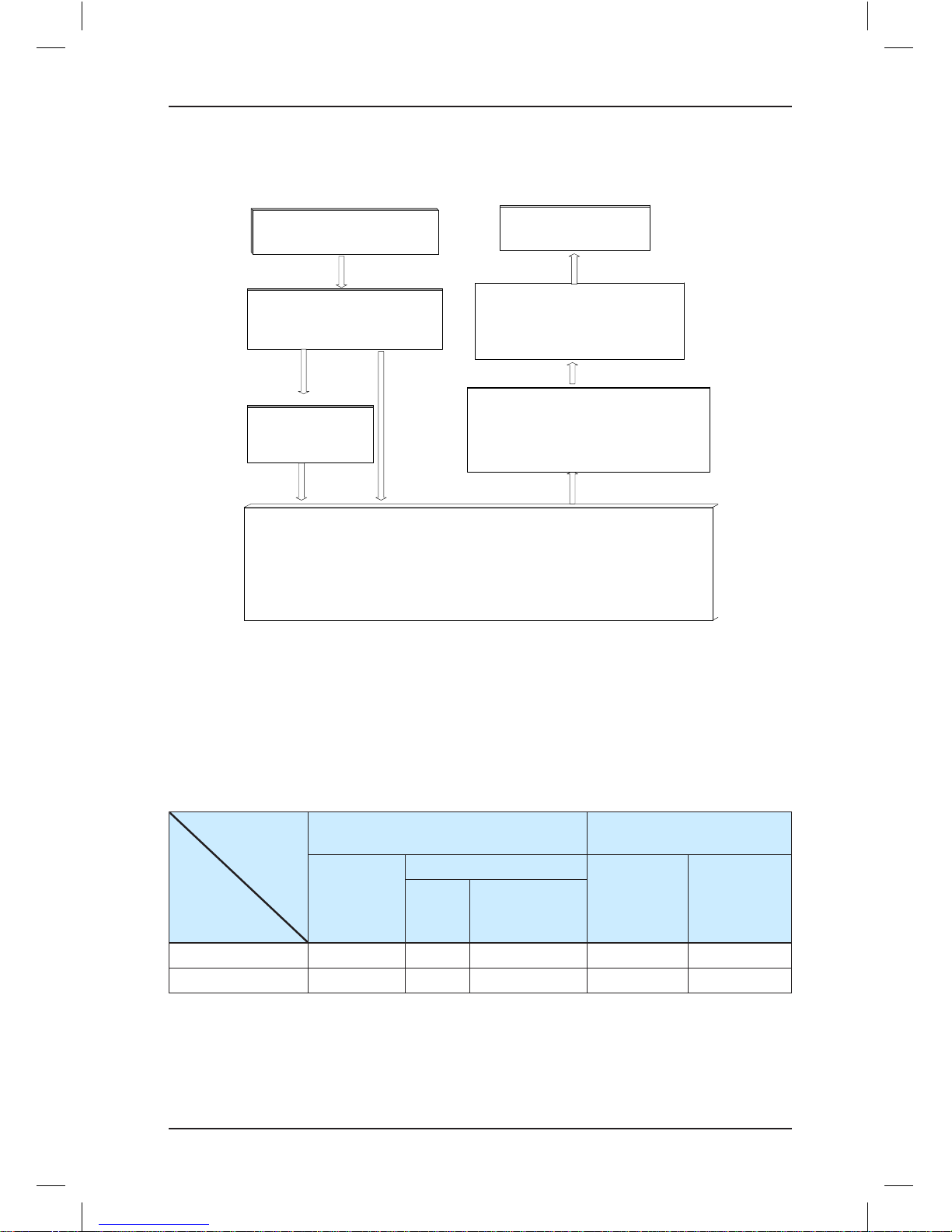

The NICE3000 series elevator integrated control system mainly includes the elevator

integrated controller, car top board (MCTC-CTB), hall call board (MCTC-HCB), car call

board (MCTC-CCB), and optional door pre-open module, and remote monitoring system.

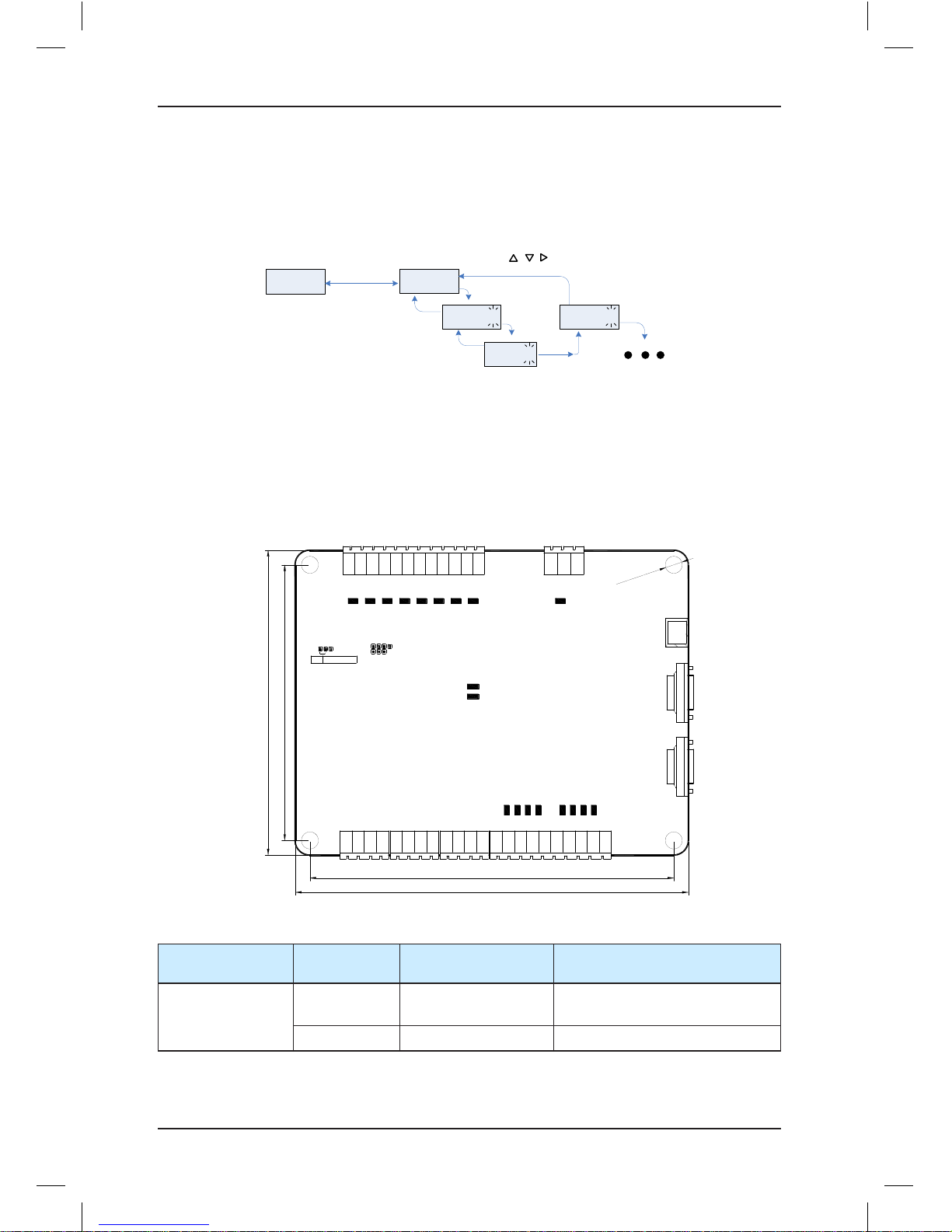

The following figure shows the system architecture.

Figure 1-1 System architecture of the NICE3000

LED operation

panel

Host

computer

CAN bus

MCTC-HCB

MCTC-HCB

Load cell

MCTC-HCB

Modbus

MCTC-CCB

MCTC-CTB

PMSM or

asynchronous motor

Page 6

2

Product Information

Page 7

Product Information Brief NICE3000 Instruction Manual

- 6 -

Chapter 2 Product Information

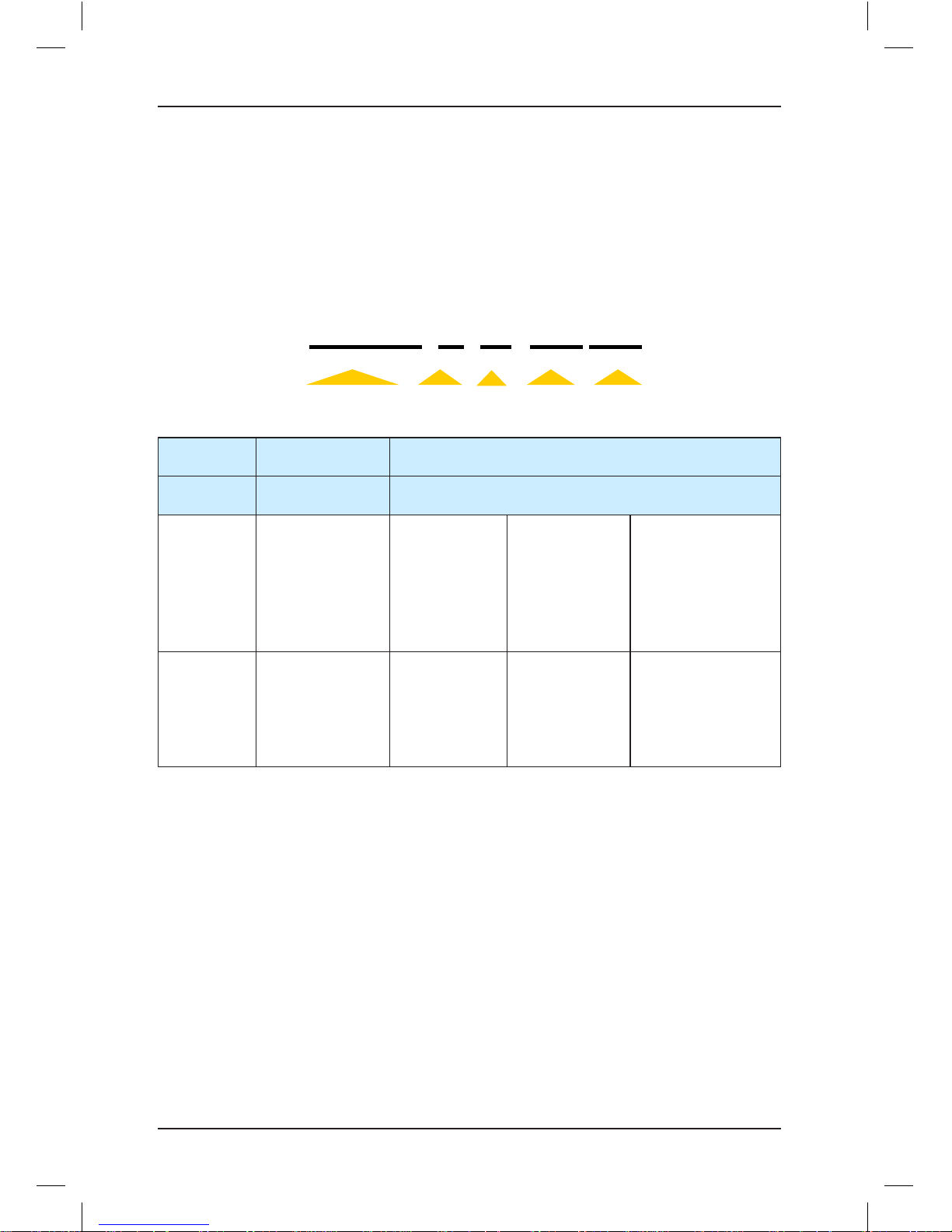

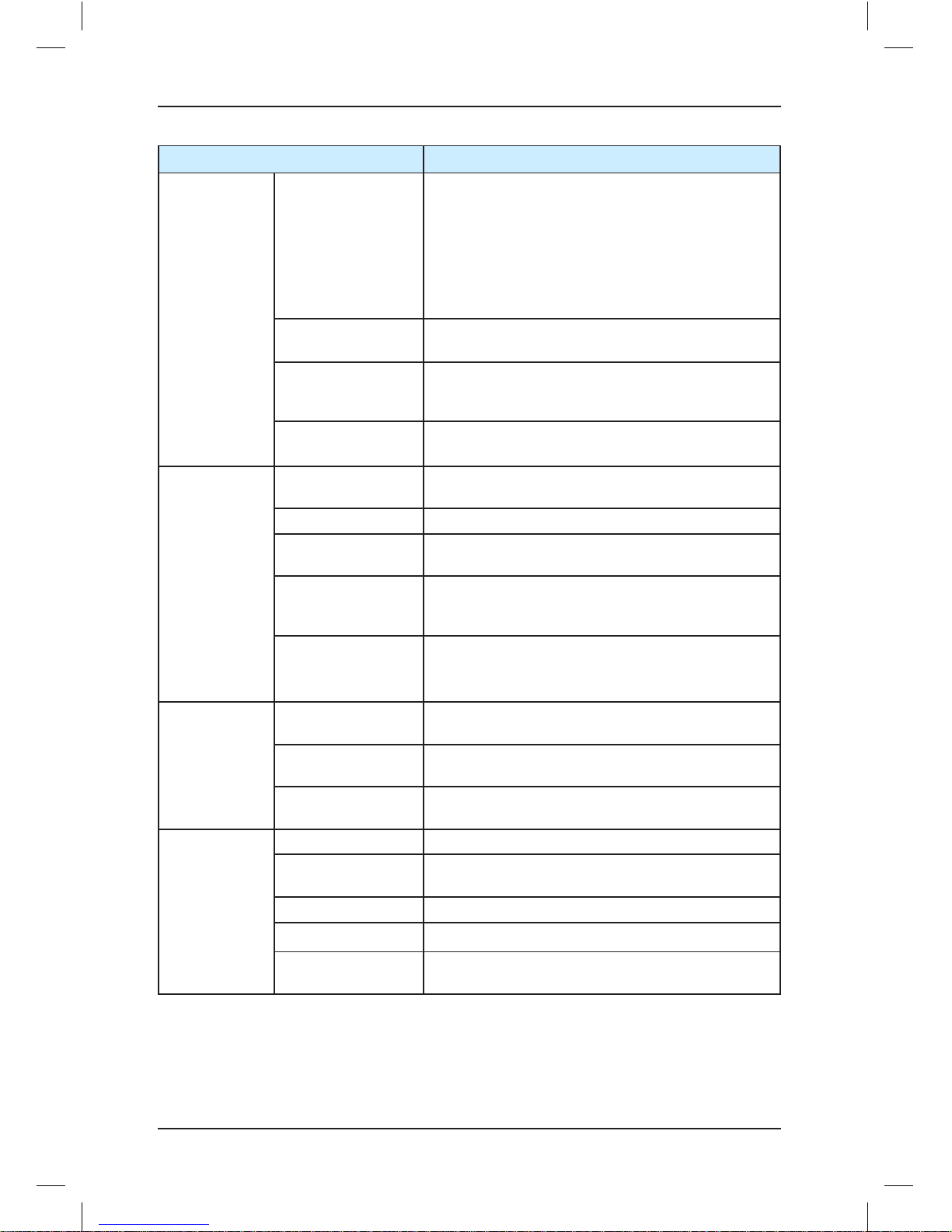

2.1 Designation Rules

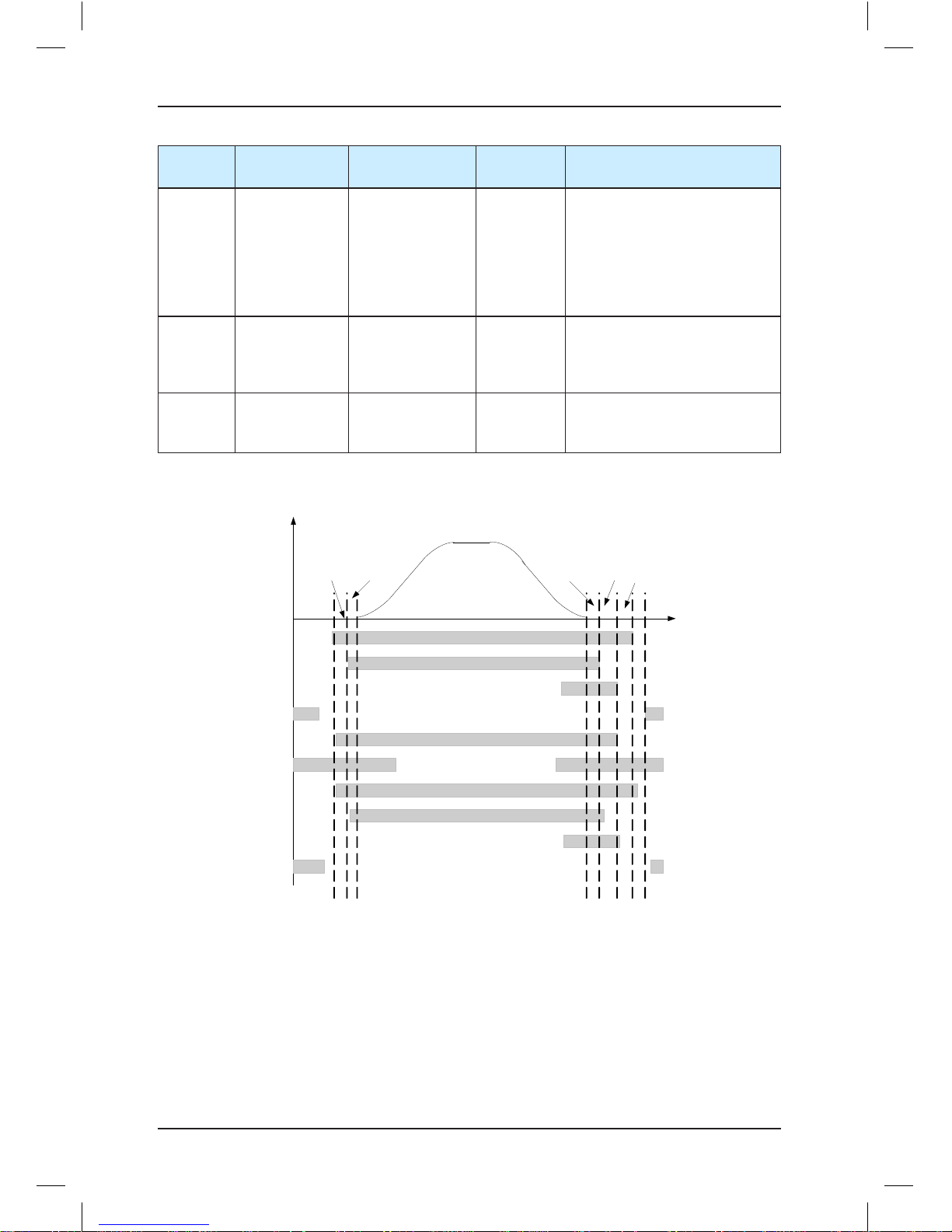

Figure 2-1 Designation rules of the NICE3000

NICE series

integrated controller

For lift

Controller

model

Three-phase

400 V

Motor power

NICE-L-A-40 11

Controller

Model

A B

Adaptable

Motor

Asynchronous

Motor

PMSM

Encoder

Incremental

encoder (pushpull output, opencollector output)

Incremental

encoder with

commutation

signals UVW

Incremental

SIN/COS

encoder with

sinusoidal

commutation

signals

Absolute SIN/

COS encoder

with EnDat serial

communications

protocol

(Heidenhain

ECN1313/413)

PG card

Main control

board (MCB)

integrating

the PG card,

requiring no

external one

MCTC-PG-B

MCTC-PG-D

MCTC-PG-C

MCTC-PG-E

MD32PG5

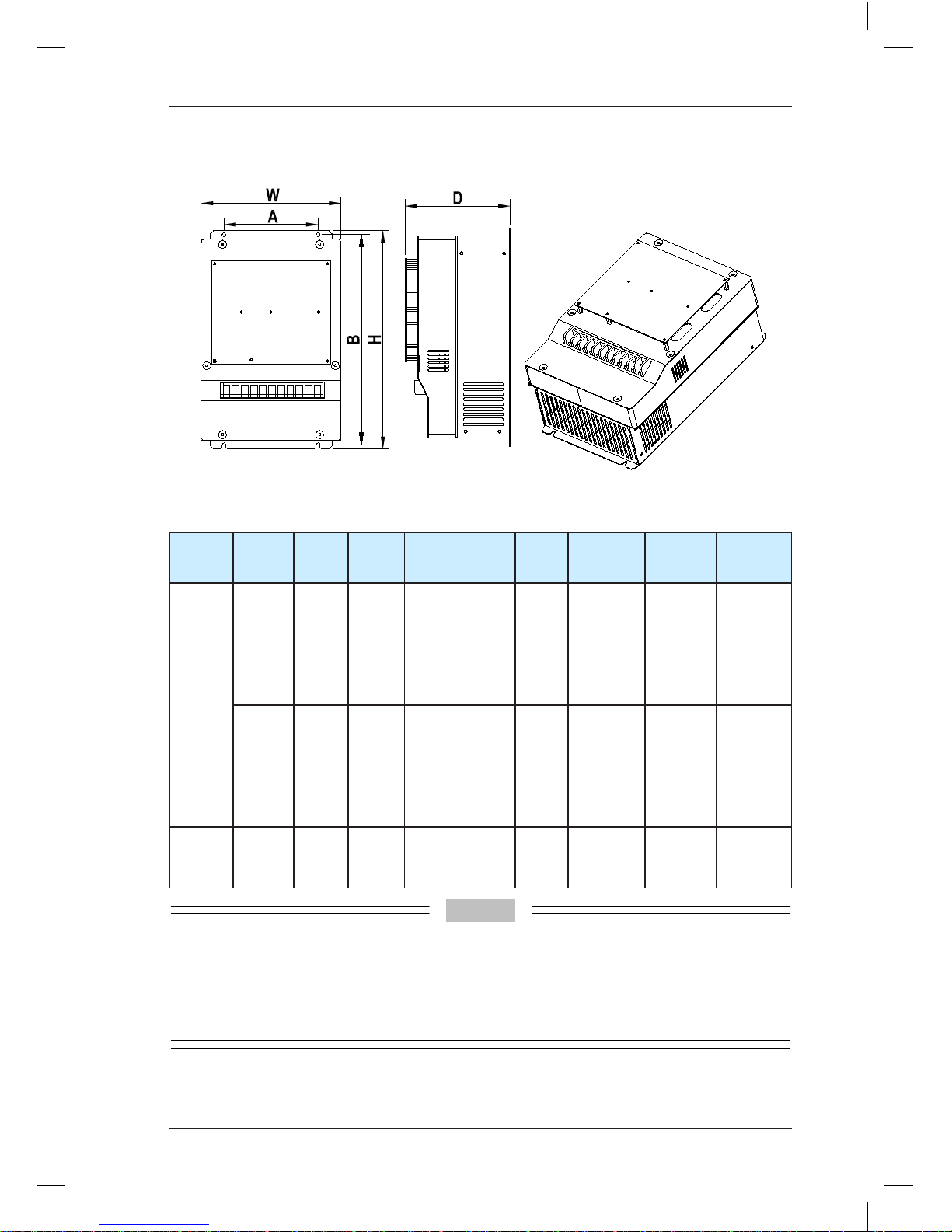

2.2 Mounting Dimensions

The NICE3000 controller has three sizes: SIZE-C, SIZE-D, and SIZE-E, as shown in the

following figure. SIZE-F is a customized model with different appearances but the same

installation mode.

The following figure and table show the appearance and physical dimensions of the

NICE3000 controller.

Page 8

Brief NICE3000 Instruction Manual Product Information

- 7 -

Figure 2-2 Appearance and mounting dimensions of the NICE3000 controller

Table 2-1 Sizes of the NICE3000 controller

Size Model

A

(mm)B (mm)H (mm)W (mm)D (mm)

Hole

Diameter

(mm)

Gross

Weight

(kg)

Structure

SIZE-C

P ≤ 5.5

kW

140 344 355 220 150 6.5 10 L

SIZE-D

5.5 kW

< P ≤

15 kW

150 334.5 347.5 223 167.5 6.5 12 L

5.5 kW

< P ≤

15 kW

190 305 322 208 212 6 6.5 L1

SIZE-E

15 kW

< P ≤

30 kW

235 541.5 554.5 289.6 223 6.5 14.5 L

SIZE-F

30 kW

< P ≤

45 kW

250 598 620

380

262 10 34 L

Note

1. The NICE3000 controller of other power ratings, such as above 45 kW is rarely applied in the

elevator, and therefore, specifications are not provided here. For future detail on the options and

availability, please contact Monarch.

2. SIZE-D has two types, sheet-metal (structure L) and plastic (structure L1), varying slightly in the

size.

Page 9

Product Information Brief NICE3000 Instruction Manual

- 8 -

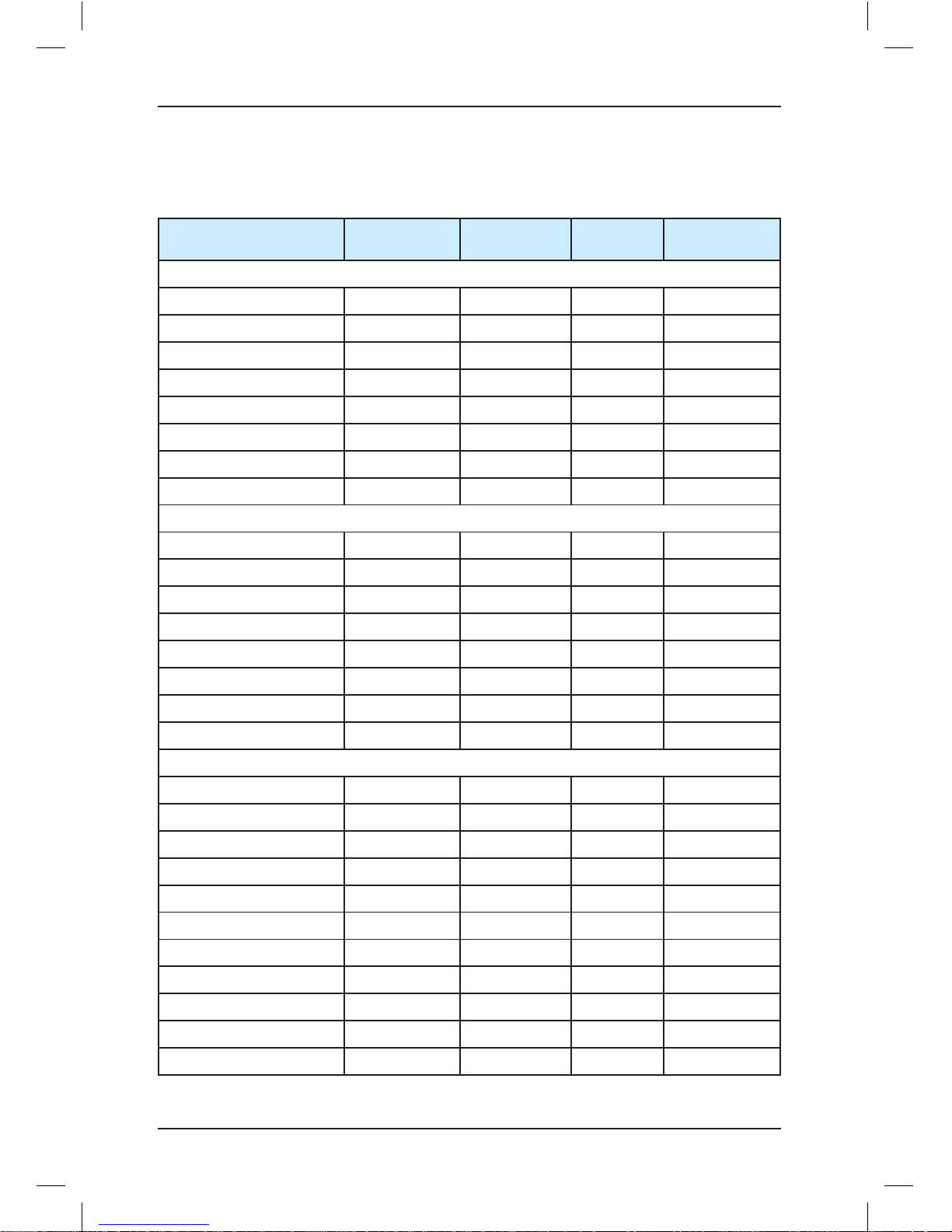

2.3 Electrical Specifications

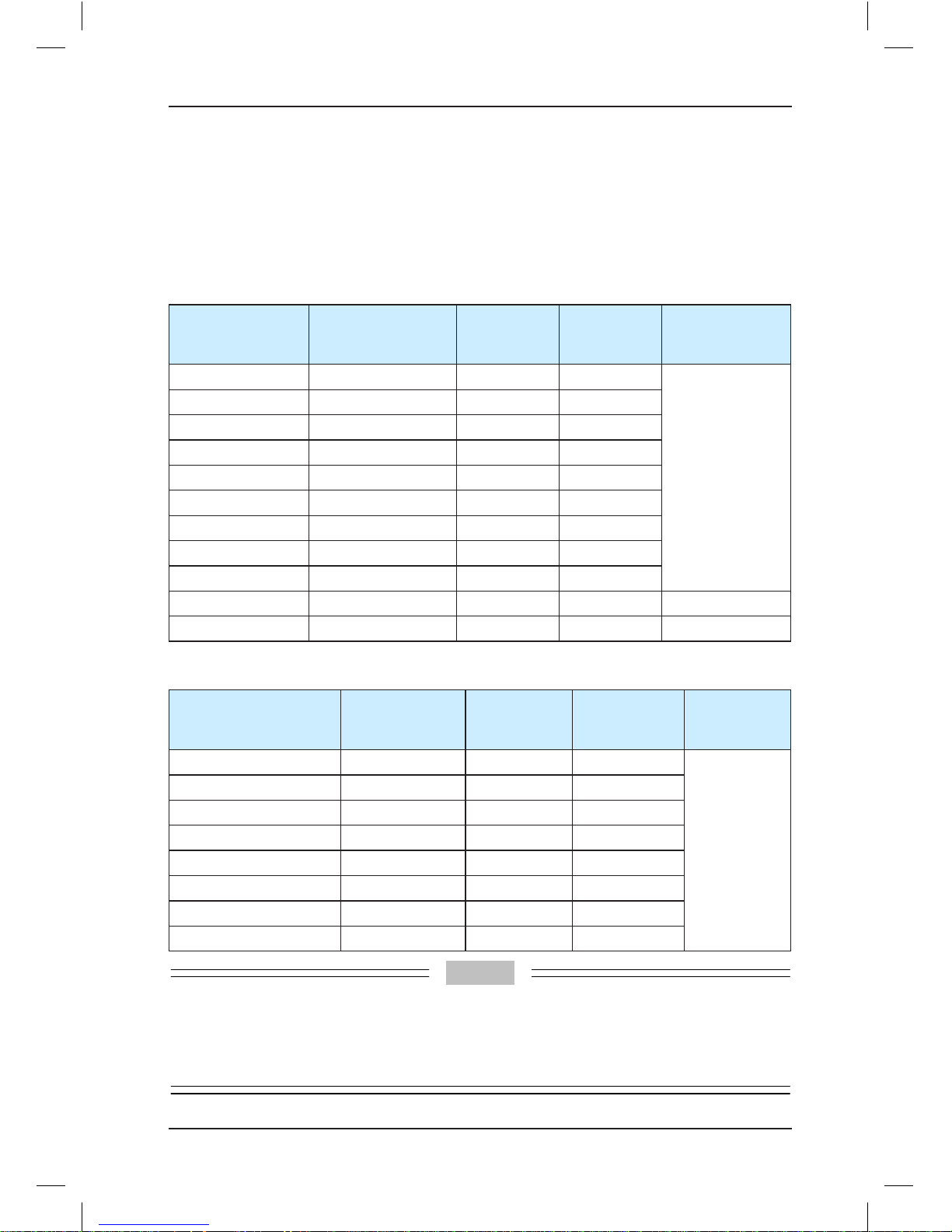

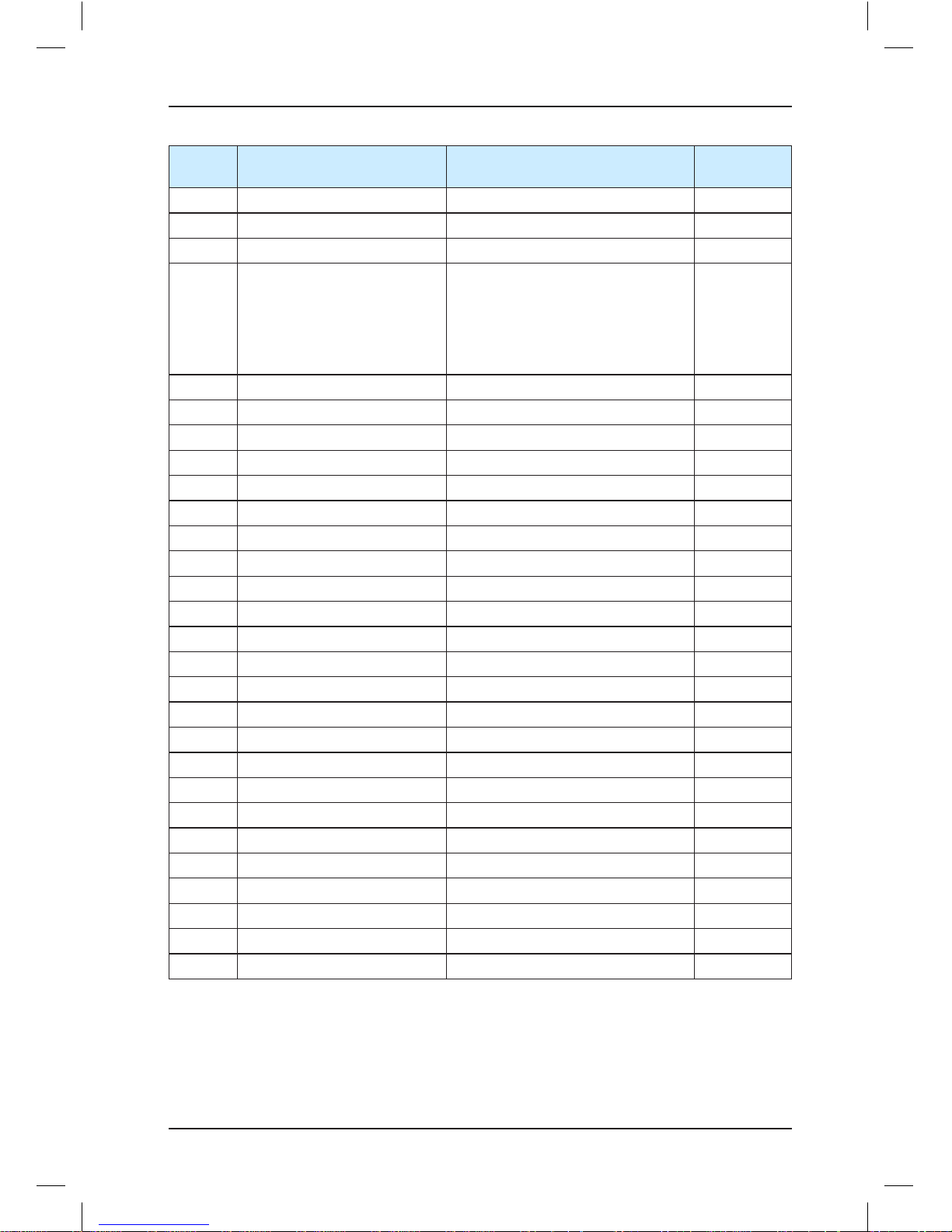

Table 2-2 NICE3000 models and electrical specifications

System Model

Power

Capacity (kVA)

Input Current

(A)

Output

Current (A)

Motor Power

(kW)

AC supply voltage: single-phase 220 V, range: –15% to 20%

NICE-L-A/B-2002 2.3 13.2 5.2 1.1

NICE-L-A/B-2003 3.4 17 7.5 1.5

220-NICE-L/L1-A/B-4007 9.8 29 10.3 2.2

220-NICE-L/L1-A/B-4011 12.1 36 15.5 3.7

220-NICE-L/L1-A/B-4015 13.9 41 19 4.0

220-NICE-L-A/B-4018 17.3 40 22.5 5.5

220-NICE-L-A/B-4022 23.1 49 27.7 11

220-NICE-L-A/B-4030 33 61 34.6 15

AC supply voltage: three-phase 220 V, range: –15% to 20%

NICE-L-A/B-2002 4.0 11.0 9.6 2.2

NICE-L-A/B-2003 5.9 17.0 14.0 3.7

220-NICE-L/L1-A/B-4007 17.0 29.0 18.0 4.0

220-NICE-L/L1-A/B-4011 21.0 36.0 27.0 5.5

220-NICE-L/L1-A/B-4015 24.0 41.0 33.0 7.5

220-NICE-L-A/B-4018 30.0 40.0 39.0 11.0

220-NICE-L-A/B-4022 40.0 49.0 48.0 15.0

220-NICE-L-A/B-4030 57.0 61.0 60.0 18.5

AC supply voltage: three-phase 380 V, range: –15% to 20%

NICE-L-A/B-4002 4.0 6.5 5.1 2.2

NICE-L-A/B-4003 5.9 10.5 9.0 3.7

NICE-L-A/B-4005 8.9 14.8 13.0 5.5

NICE-L/L1-A/B-4007 11.0 20.5 18.0 7.5

NICE-L/L1-A/B-4011 17.0 29.0 27.0 11.0

NICE-L/L1-A/B-4015 21.0 36.0 33.0 15.0

NICE-L-A/B-4018 24.0 41.0 39.0 18.5

NICE-L-A/B-4022 30.0 49.5 48.0 22.0

NICE-L-A/B-4030 40.0 62.0 60.0 30.0

NICE-L-A/B-4037 57.0 77.0 75.0 37.0

NICE-L-A/B-4045 69.0 93.0 91.0 45.0

Page 10

Brief NICE3000 Instruction Manual Product Information

- 9 -

Note

1. In terms of single-phase and three-phase 220 VAC, NICE-L-A/B-2002 and NICE-L-A/B-2003

are specially designed for 220 VAC. The other models that are marked by prefixing "220-" are

modified from the three-phase 380 VAC models.

2. Same models are available for single-phase 220 VAC and three-phase 220 VAC. Pay attention

to the power rating of the adaptable motor during the use.

3. Select the proper controller output current based on the motor rated current. Ensure that the

controller output current is equal to or greater than the motor rated current.

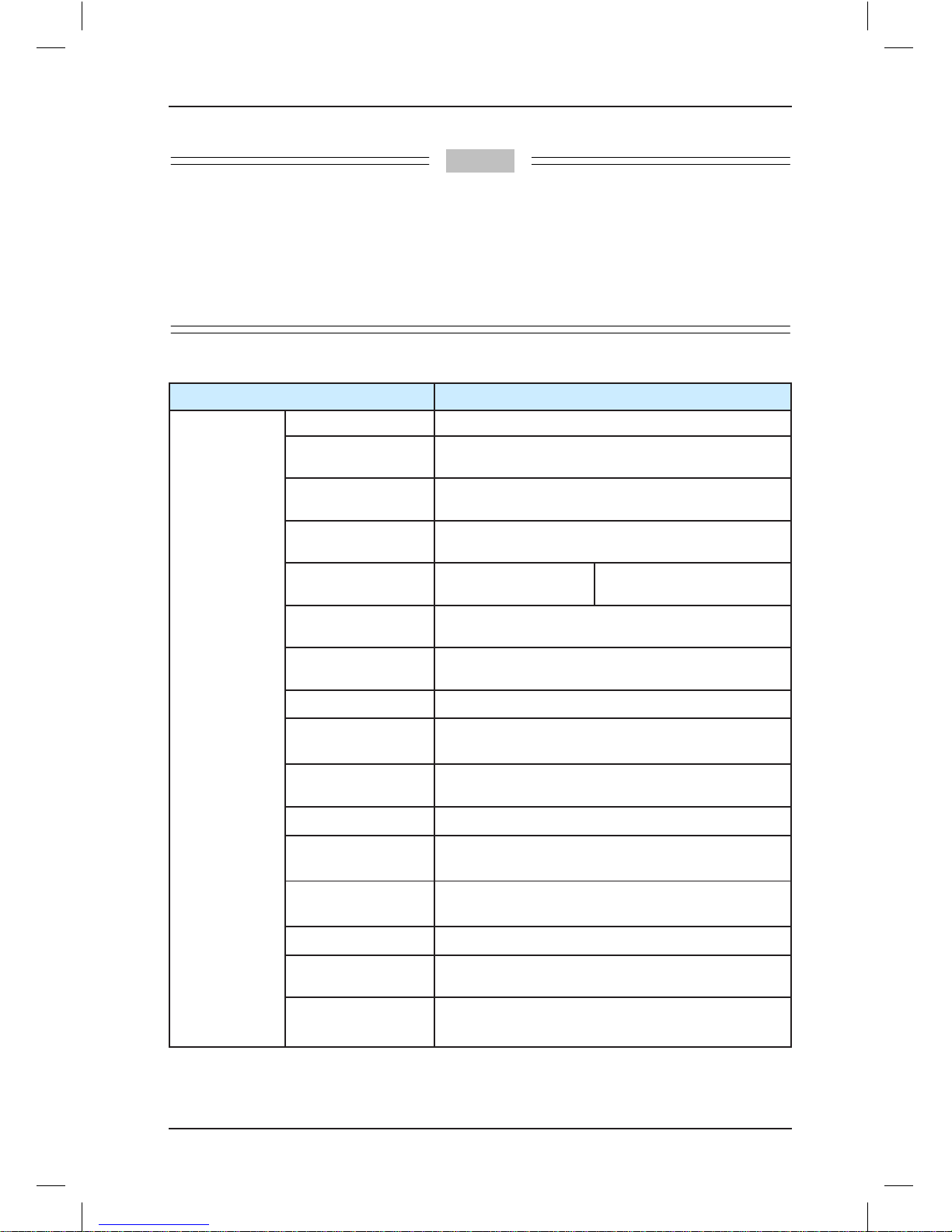

Table 2-3 Technical specifications of the NICE3000

Item Specification

Basic

specifications

Maximum frequency 99 Hz

Carrier frequency

0.5–16 kHz, adjusted automatically based on the

load features

Motor control mode

sensorless flux vector control (SFVC), closed-loop

vector control (CLVC)

Startup torque

0.5 Hz: 180% (SFVC)

0 Hz: 200% (CLVC)

Speed stability

accuracy

±0.5% (SFVC) ±0.05% (CLVC)

Torque control

accuracy

±5% (CLVC)

Overload

60s for 150% of the rated current, 1s for 200% of the

rated current

Motor auto-tuning With-load auto-tuning; no-load auto-tuning

Distance control

Direct flooring mode in which the leveling position

can be adjusted flexibly

Acceleration/

Deceleration curve

N curves generated automatically

Re-leveling Leveling re-adjustment after the car load changes

Slow-down

New reliable slow-down function, automatically

identifying the position of the slow-down shelf

Shaft auto-tuning

32-bit data, recording the position in the shaft

accurately

Leveling adjustment Flexible and easy leveling adjustment function

Startup torque

compensation

Humanized load cell auto-tuning

Real-time clock

Real-time clock for time-based floor service, peak

service and automatic password

Page 11

Product Information Brief NICE3000 Instruction Manual

- 10 -

Item Specification

Basic

specifications

Fault protection

Providing 57 protections such as:

• Power-on short circuit detection

• Protection at power phase loss and output phase

loss

• Over-current protection

• Door machine fault protection

• Encoder protection

• Protection on multiple levels of elevator faults

Intelligent

management

Remote monitoring, user management, and group

control adjustment

Security check of

peripheral devices

after power-on

Security check of peripheral devices, such as

grounding and short circuit, after power-on

Status monitor

Monitoring the state of feedback signals to ensure

that the elevator works properly

I/O feature

Digital input (DI)

24 x DI

Input specification: 24 V, 5 mA

Analog input (AI) AI (voltage range: –10 V to +10 V)

Communication port

CTB communication (CANbus)

Hall call communication (Modbus)

Output terminal

block

6 x Relay output

The terminals can be allocated with different

functions.

Encoder interface

Incremental encoder (push-pull output and open

collector output) by standard

Different encoders via PG card

Operation and

display

Operation panel

5-digit LED display, displaying parameters such as

running speed and bus voltage

Keypad

3-digit LED display, implementing some

commissioning functions

Status monitor

Monitoring the state of the elevator, including CTB

and HCB

Environment

Altitude Below 1000 m

Ambient

temperature

–10°C to +40°C (derated if the ambient

temperature is between 40°C and 50°C)

Humidity Maximum relative humidity 95%, non-condensing

Vibration Maximum vibration: 5.9 m/s2 (0.6 g)

Storage

temperature

–20°C to +60°C

Page 12

Brief NICE3000 Instruction Manual Product Information

- 11 -

2.4 Braking Resistor

The models of 30 kW or below have a built-in braking unit, and you only need to connect an

external braking resistor between PB and + terminals. For models above 30 kW, you need

to install a braking unit and a braking resistor externally.

Select the braking resistor based on the configuration listed in the following table.

Table 2-4 Braking resistor selection for the three-phase 380 V controller

System Model

Average Power

of the Braking

Resistor (W)

Maximum

Resistance

(Ω)

Minimum

Resistance

(Ω)

Braking Unit

NICE-L-A/B-4002 650 230 150

Built-in by

standard

NICE-L-A/B-4003 1100 135 100

NICE-L-A/B-4005 1600 90 80

NICE-L-A/B-4007 2500 65 50

NICE-L-A/B-4011 3500 45 35

NICE-L-A/B-4015 4500 30 25

NICE-L-A/B-4018 5500 25 20

NICE-L-A/B-4022 6500 20 15

NICE-L-A/B-4030 9000 15 15

NICE-L-A/B-4037 11000 13 12 MDBUN-45-T

NICE-L-A/B -4045 13500 11 11 MDBUN-60-T

Table 2-5 Braking resistor selection for the 220 V controller

System Model

Average Power

of the Braking

Resistor (W)

Maximum

Resistance

(Ω)

Minimum

Resistance

(Ω)

Braking Unit

NICE-L-A/B-2002 650 70 55

Built-in by

standard

NICE-L-A/B-2003 1100 40 30

220-NICE-L-A/B-4007 2500 20 18

220-NICE-L-A/B-4011 3500 14 10

220-NICE-L-A/B-4015 4500 10 8

220-NICE-L-A/B-4018 5500 8 7

220-NICE-L-A/B-4022 6500 7 6

220-NICE-L-A/B -4030 9000 7 6

Note

1. The preceding configuration takes the synchronous motor as an example. The asynchronous

motor has poor energy transfer efficiency, and you can reduce the power of the braking resistor or

increase the resistance of the braking resistor.

2. It is recommended that you select the braking resistor closest to the maximum resistance.

Page 13

Product Information Brief NICE3000 Instruction Manual

- 12 -

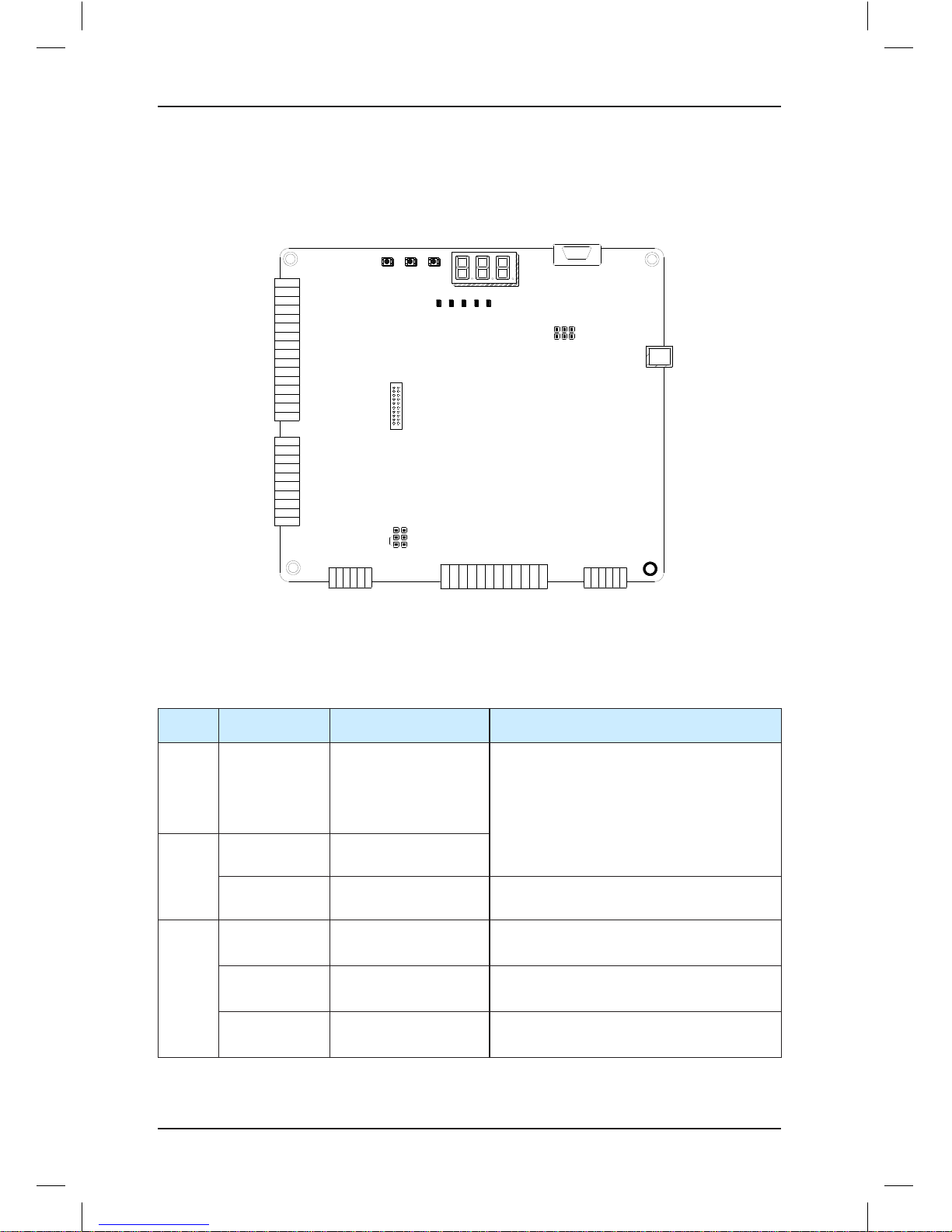

2.5 Terminal Descriptions

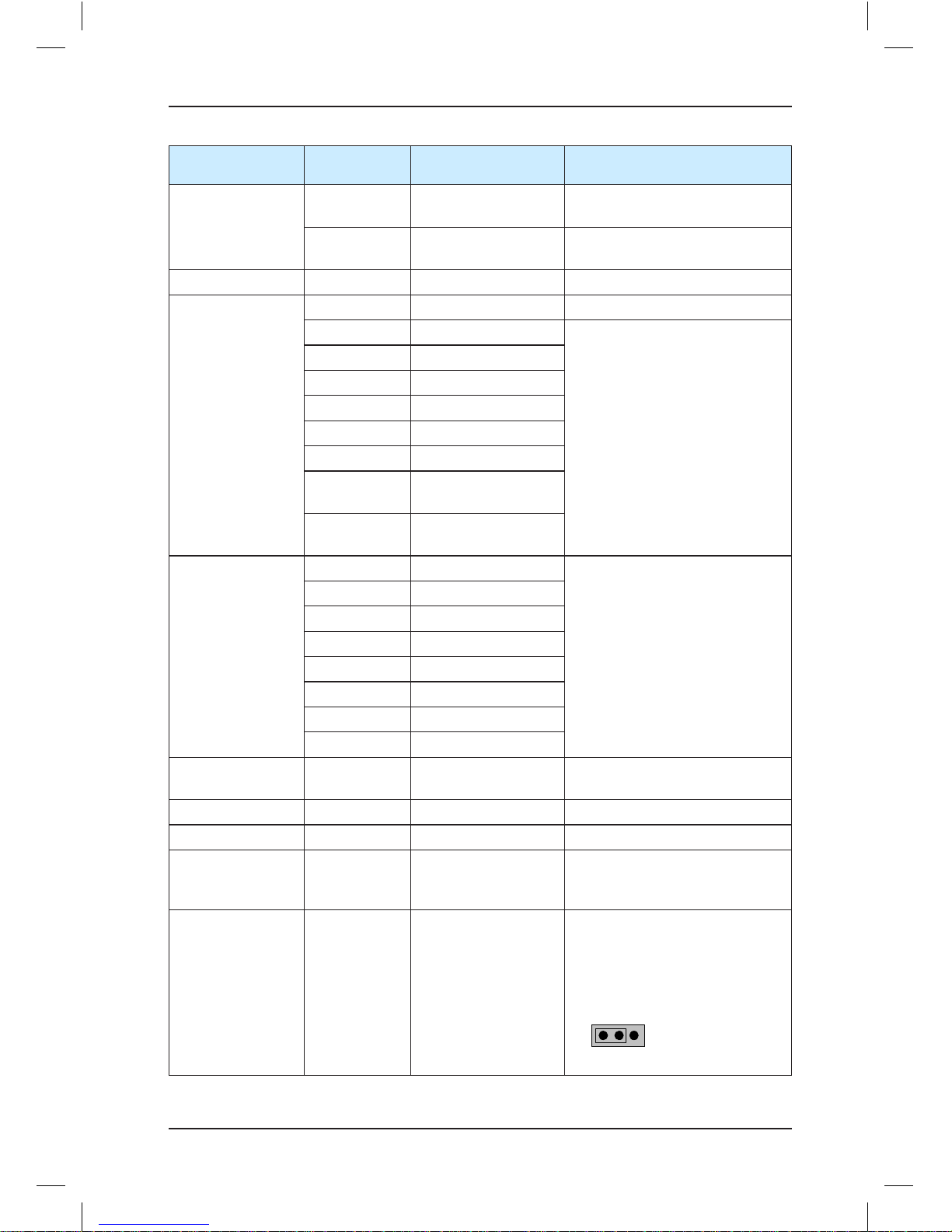

The following figure shows the structure of the MCB for the NICE3000.

Figure 2-3 Structure of the MCB

X1

X2

X3

X4

X5

X6

X7

X8

X9

X10

X11

X12

X13

X14

X15

X16

X17

X18

X19

X20

X21

X22

X23

X24

M

Ai

24V

COM

MOD+

MOD-

CAN+

CAN-

J9

RJ45

PRG UP SET

J10

Y1M1Y2M2Y3M3Y4M4Y5M5Y6

M6

CN7

CN3

CN9

CN1

ON

J6

CN5

CN12

J12

MCTC-MCB

J5

15V

PGM

PGA

PGB

PGM

PE

CN6

ER OK COP HOPMD BUS

The NICE3000 provides a keypad with three keys and three 7-segment LEDs for display,

and five LED status indicators. The NICE3000 also supports the external LED operation

panel.

Table 2-6 Terminal description and specifications

Mark Code Terminal Name Function Description

CN1 X1 to X16 DI

Input voltage range: 10–30 VDC

Input impedance: 4.7 kΩ

Optocoupler isolation

Input current limit: 5 mA

Functions set in F5-01 to F5-24.

CN9

X17 to X24 DI

Ai/M AI Used for the analog load cell device

CN3

24V/COM

External 24 VDC

power supply

24 VDC power supply for the entire board

MOD+/-

RS485 differential

signal

Standard isolated RS485 communication

interface, used for hall call and display

CAN+/-

CANbus differential

signal

CANbus communication interface,

communication with the CTB

Page 14

Brief NICE3000 Instruction Manual Product Information

- 13 -

Mark Code Terminal Name Function Description

CN7

Y1/M1 to Y6/

M6

Relay output

Normally-open (NO), maximum current

and voltage rating: 5A, 250 VAC. The

functions are set in F5-26 to F5-31.

CN6

15V/PGM/

PGA/PGB/PE

Encoder interface for

asynchronous motor

Connecting the incremental encoder

(push-pull output or open collector output)

CN5 DB9 interface

RS232

communication

interface

Used as the interface for commission

software, cell monitoring, RS232/RS485

parallel control, and software download for

the MCB and drive board

CN12

RJ45

interface

Operation panel

interface

Used to connect the digital operation panel

J5

Used to connect the terminal resistor for the CANbus communication control board;

the pins marked with "ON" connected to the terminal resistor

J6

Used to connect the terminal resistor for the Modbus communication control board;

the pins marked with "ON" connected to the terminal resistor

J9/

J10

Software writing jumper block (used by the manufacturer). Do not short the pins

randomly; otherwise, the controller cannot be used properly

J12 Interface for connecting the PG card.

Table 2-7 Description of indicators on the MCB

Mark Terminal Name Function Description

ER Fault indicator

When a fault occurs, the system reports an alarm and this

indicator is on (red).

OK OK indicator When there is no fault, this indicator is on (green).

COP

CTB communication

indicator

When communication between the MCB and the CTB is

normal, this indicator is on (green).

HOP

HCB communication

indicator

When communication between the MCB and the HCB is

normal, this indicator is on (green).

MDBUS

Parallel/Group mode

indicator

This indicator is steady on (green) when the

communication for parallel mode or group mode is

normal, and blinks when the running in parallel mode or

group mode is normal.

X1 to X24 Input signal indicator ON when the 24 VDC input is active.

Y1 to Y6 Output signal indicator ON when the relay output is active.

Page 15

Page 16

3

Component Description

Page 17

Component Description Brief NICE3000 Instruction Manual

- 16 -

Chapter 3 Component Description

3.1 Onboard Keypad Description

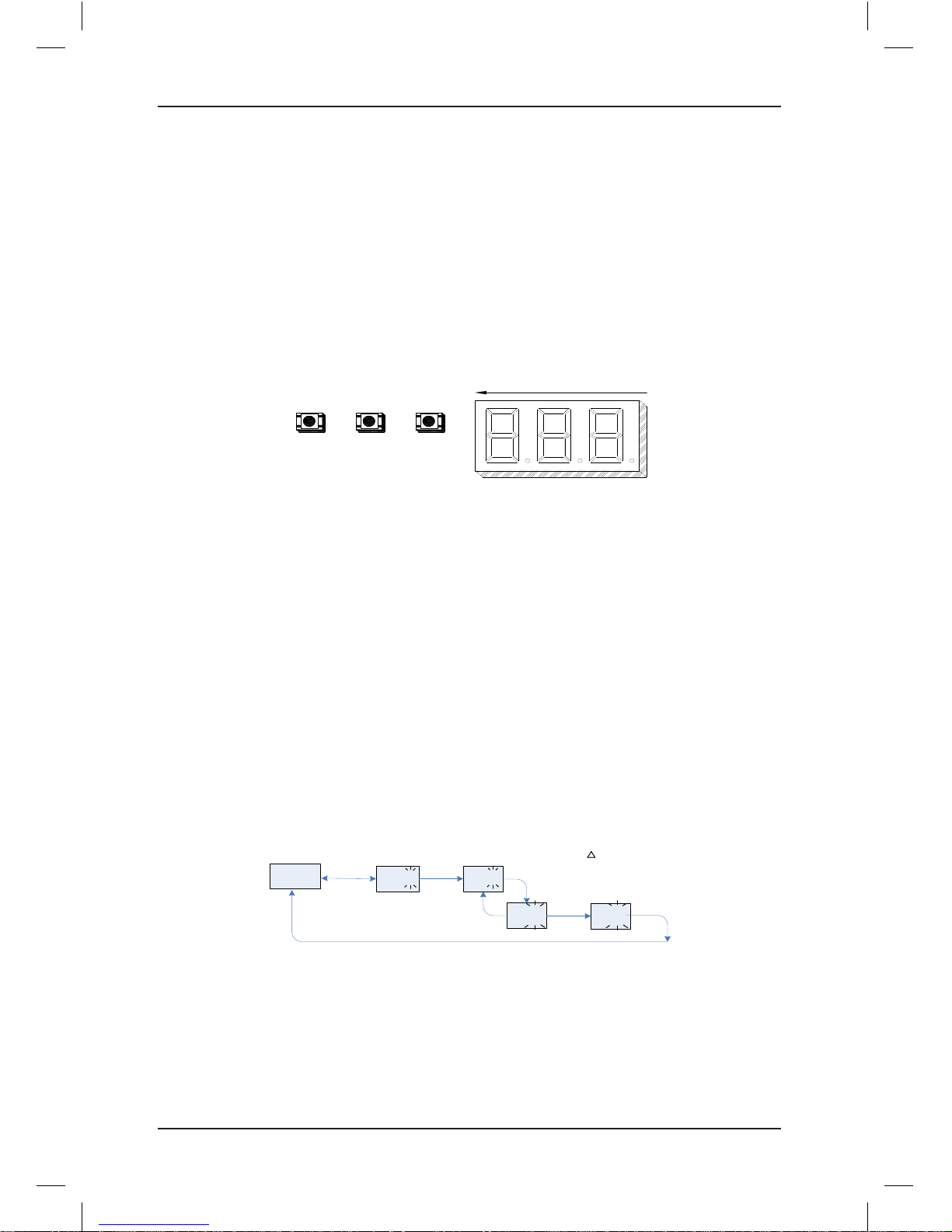

The onboard keypad consists of three 7-segment LEDs and three buttons. You can query

information about the controller and enter simple commands on the keypad.

The following figure shows the appearance of the keypad.

Figure 3-1 Appearance of the keypad

PRG UP

SET

3 2 1

As shown in the preceding figure, the three buttons are PRG, UP, and SET. The functions of

the three buttons are as follows:

• PRG: Press this button in any state to display the current function group number.

You can press the UP button to change the function group number.

• UP: Press this button to increase the function group number.

Currently, the MCB defines a total of nine function code groups, namely, F0 to F8. You

can press the UP button to display them in turn. In addition, in special function code

group menu, you can input simple references by using the UP button.

• SET: In the function code group menu, press this button to enter the menu of the

function code group.

In special function code group menu, after you input a simple reference and press this

button to save the setting, the keypad enters the F0 menu by default.

The following figure shows the setting of increasing the called floor to 5.

05

F0

04

(Select the function

code group )

(Set the

parameter value )

Level-I menu

Level-II menu

PRG

Without

saving

SET

Saving

When there is a blinking

digit, press to modify it.

01

SET

Enter

Current floor

UP

Increase

(default display )

F1

PRG

Switch

UP

Increase

Page 18

Brief NICE3000 Instruction Manual Component Description

- 17 -

The function code groups displayed on the keypad are described as follows:

1. F0: display of floor and running direction

The F0 menu is displayed on the keypad by default upon power-on. The first 7-segment

LED indicates the running direction, while the last two 7-segment LEDs indicate the

current floor of the elevator.

When the elevator stops, the first 7-segment LED has no display. When the elevator

runs, the 1st 7-segment LED indicates the running direction.

When a system fault occurs, the 7-segment LEDs automatically display the fault code

and blink. If the fault is reset, the F0 menu is displayed.

2. F1: command input of the running floor

After you enter the F1 menu, the 7-segment LEDs display the bottom floor (F6-01). You

can press the UP key to set the destination floor within the range of lowest to top and

then press the SET key to save the setting. The elevator runs to the destination floor,

and the 7-segment LEDs automatically switch over to the F0 menu at the same time.

3. F2: fault reset

After you enter the F2 menu, the 7-segment LEDs display 0. When you press the UP

button to select 1 and press the SET button, the system fault is reset. After the system

fault is reset, the 7-segment LEDs automatically switch over to the F0 menu.

4. F3: time display

After you enter the F3 menu, the 7-segment LEDs display the current system time

circularly.

5. F4: contract number display

After you enter the F4 menu, the 7-segment LEDs display the user's contract number.

6. F5: running times display

After you enter the F5 menu, the 7-segment LEDs display the elevator running times

circularly.

7. F6: reserved

User setting is prohibited.

8. F7: shaft auto-tuning command input

After you enter the F7 menu, the 7-segment LEDs display 0. You can select 0 or 1 here,

where 1 indicates the shaft auto-tuning command available. After you select 1 and press

the SET button, shaft auto-tuning is implemented if the conditions are met. Meanwhile,

the 7-segment LEDs switch over to the F0 menu. After shaft auto-tuning is complete, F7

is back to 0 automatically. If shaft auto-tuning conditions are not met, fault code "E35" is

displayed.

9. F8: test function

After you enter the F8 menu, the 7-segment LEDs display 00. The setting range of F8 is

1–4, described as follows:

Page 19

Component Description Brief NICE3000 Instruction Manual

- 18 -

1: Hall call forbidden

2: Door open forbidden

3: Overload forbidden

4: Limit switches disabled

After the setting is complete, press SET. Then the 7-segment LEDs display E88 and

blink, prompting that the elevator is being tested. When you press PRG to exit, F8 is

back to 0 automatically.

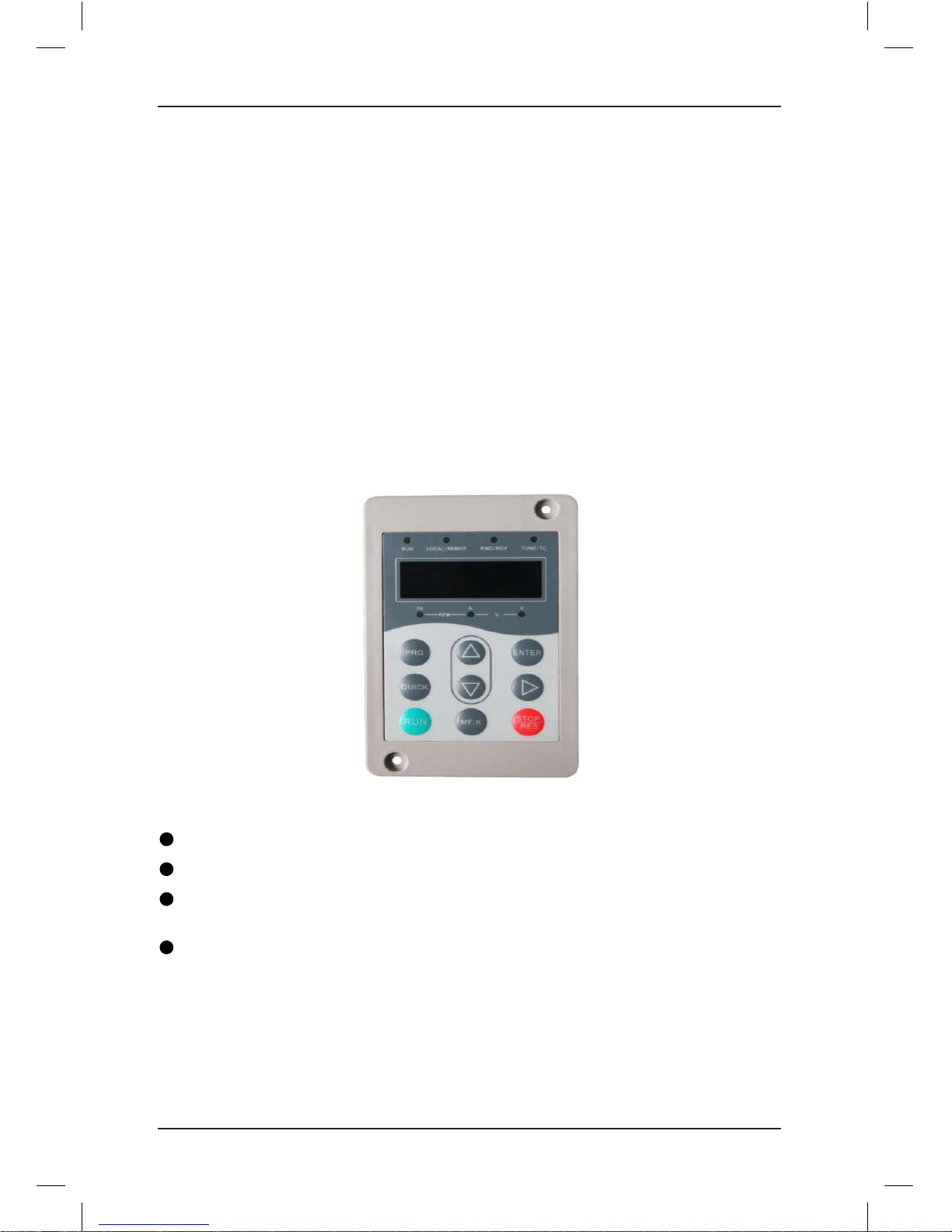

3.2 Use of the LED Operation Panel

The LED operation panel is connected to the RJ45 interface of the NICE3000 controller by

means of an 8-core flat cable. You can modify the function parameters, monitor the working

status, and run or stop the NICE3000 controller by using the LED operation panel. The

following figure shows the appearance of the LED operation panel.

Figure 3-2 Appearance of the LED operation panel

■ Function Indicators

RUN: This indicator is on when the NICE3000 is running.

LOCAL/REMOT: Reserved.

FWD/REV: It is the elevator direction indicator. ON indicates down direction, and OFF

indicates up direction.

TUNE/TC: It is the auto-tuning indicator. This indicator is on when the elevator is in auto-

tuning state.

Page 20

Brief NICE3000 Instruction Manual Component Description

- 19 -

■ Unit Indicators

indicates OFF, and indicates ON.

Hz A V

RPM %

Hz: unit of frequency

Hz A V

RPM %

A: unit of current

Hz A V

RPM %

V: unit of voltage

Hz A V

RPM %

RPM: unit of rotational speed

Hz A V

RPM %

%: percentage

■ Keys on the Operation Panel

Table 3-1 Keys on the operation panel

Key Name Function

PRG

Programming Enter or exit Level I menu.

ENTER

Confirm

Enter the menu interfaces level by level, and confirm the

parameter setting.

Increment Increase data or function code.

Decrement Decrease data or function code.

Shift

Select the displayed parameters in turn in the stop or running

state, and select the digit to be modified when modifying

parameters.

RUN

RUN

In operation panel control mode, press this key to run the

NICE3000.

STOP

RES

Stop/Reset

In operation panel control mode, press this key to stop the

running or reset the controller in fault state.

QUICK

Quick Enter or exit Level I shortcut menu.

MF.K

Fault display

Press this key to display or hide fault information in fault

state.

Page 21

Component Description Brief NICE3000 Instruction Manual

- 20 -

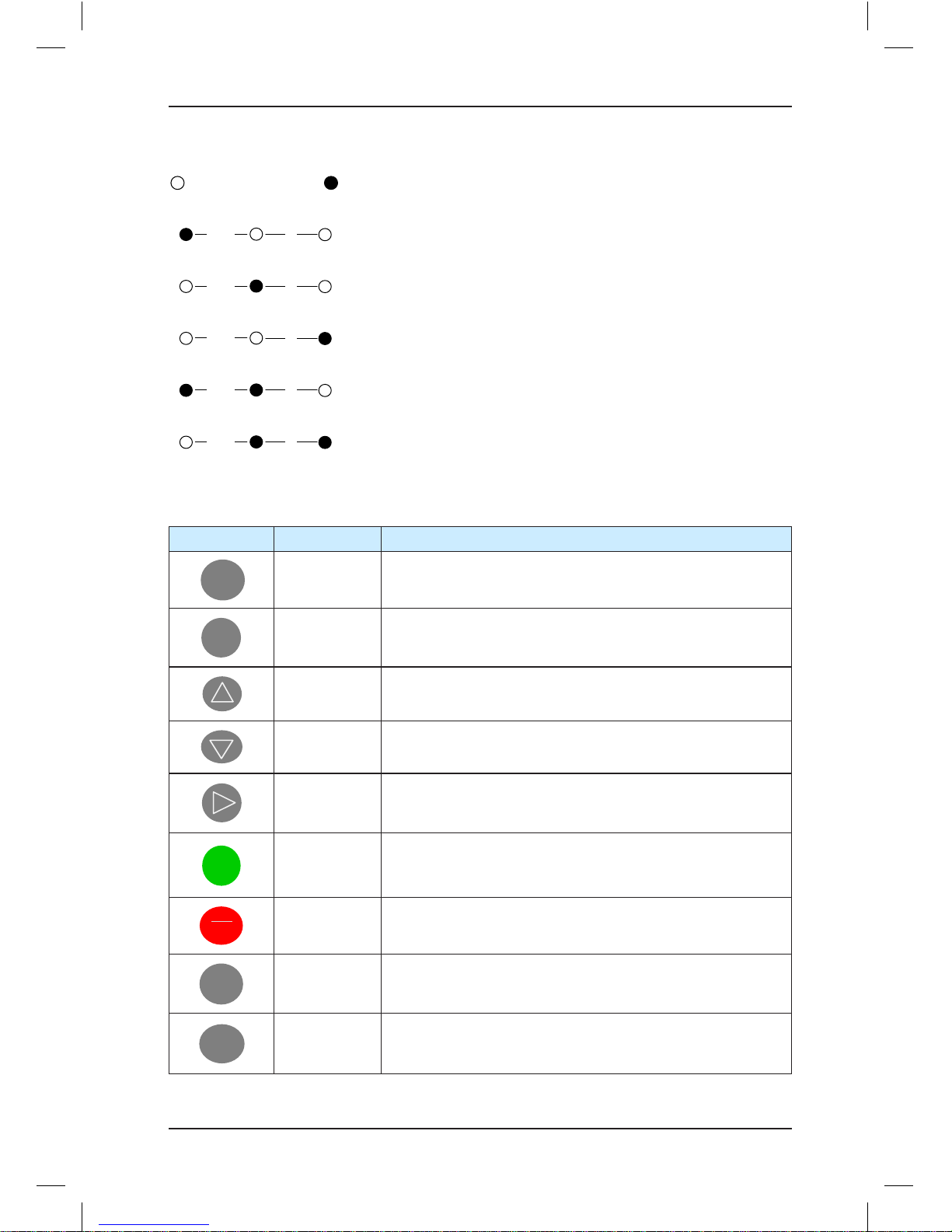

■ Operations on the Three-Level Menu

The following figure shows the operation procedure on the three-level menu.

Figure 3-3 Operation procedure on the three-level menu

F0

F0-06

50.00

(Select the functio n

code group)

(Select the

function code)

(Set the value o f

the function code)

Level-I menu

Level-II menu

Level-III menu

PRG

PRG

Not to save

the setting

ENTER

To save

the setting

ENTER

0.000

ENTER

Status parameter

PRG

F0-07

ENTER

PRG

Next function

code

(default di splay)

If there is a blinking digit , press

/ / to modify the digit .

3.3 CTB Board

The car top board (MCTC-CTB) is the elevator car control board of the NICE3000 controller.

It consists of eight DI terminals, one AI terminal, and nine relay output terminals. The CTB

can communicate with the CCB and HCB. The following figure shows the structure and size

of the CTB.

Figure 3-4 Structure and size of the CTB

J9

CAN

RESET

CN2 CN1 CN6 CN3

CN4 CN5

CN10

CN7

CN8

MCTC-

CTB

152 mm

162 mm

115 mm

125 mm

Φ

4

.

9

m

m

X1X2X3X4 X5X6X7X8

A1

B1

B2

B3

C2

C1

D2

D1

C3

24V

CAN+

CAN-

COM

24V

MOD+

MOD-

COM

24V

Ai

M

X1X2X3

X4

P24

P24

X5X6X7

X8

A

B

AM

CM

B3B2B1

BM

DM

C3

C3M

C2

C1

D2

D1

PARALLEL

ON

J2

Table 3-2 Description of CTB terminals

Type Terminal Name Description

CN2

(communication

with the MCB)

+24V/COM

External 24 V power

supply

24 VDC power supply to the

entire board

CAN+/CAN- CAN communication Connecting the MCB

Page 22

Brief NICE3000 Instruction Manual Component Description

- 21 -

Type Terminal Name Description

CN1

(communication

with the HCB)

+24V/COM 24 V power supply

24 VDC power supply to the

HCB

MOD+/MOD-

Modbus

communication

Communication with the HCB

CN6 (AI) Ai-M Load cell signal input 0–10 VDC

CN3 (DI)

P24 24 V power supply DI common terminal

X1 Light curtain 1

1. Photocoupler isolation,

unipolarity input

2. Input impedance: 3.3 kΩ

3. Positive logic

X2 Light curtain 2

X3 Door open limit 1

X4 Door open limit 2

X5 Door close limit 1

X6 Door close limit 2

X7

Full-load signal

(100%)

X8

Overload signal

(110%)

CN4 (relay

output)

B1-BM Door open signal 1

30 VDC, 1 A

B2-BM Door close signal 1

B3-BM Forced door close 1

C1-CM Door open signal 2

C2-CM Door close signal 2

C3-C3M Forced door close 2

D1-DM Up arrival signal

D2-DM Down arrival signal

CN5 A-AM

Car fan and lamp

control

250 VAC, 3 A; 30 VDC, 1 A

CN7/8 DB9 pin port CCB communication Connecting the CCB

CN10 RJ45 RJ45 Reserved

J9

Software

writing

interface

Software writing

interface

Used by the manufacturer

J2

ON/

PARALLEL

Address jumper

Setting the CTB addresses:

short PARALLEL for a single

elevator; short PARALLEL for

the master elevator and ON for

the slave elevator in parallel

mode.

J2

P ARA LLE LON

Page 23

Component Description Brief NICE3000 Instruction Manual

- 22 -

Type Terminal Name Description

CAN Indicator

Communication

indicator

This indicator blinks when the

CTB communicates with the

MCB.

RESET Indicator Fault indicator

This indicator blinks and the

CAN indicator is steady on

when a fault occurs during

communication between the

CTB and the MCB.

X1–X8 Indicator Input indicator

This indicator is on (green) when

the external input is active.

A–D Indicator Output indicator

This indicator is on (green) when

the system output is active.

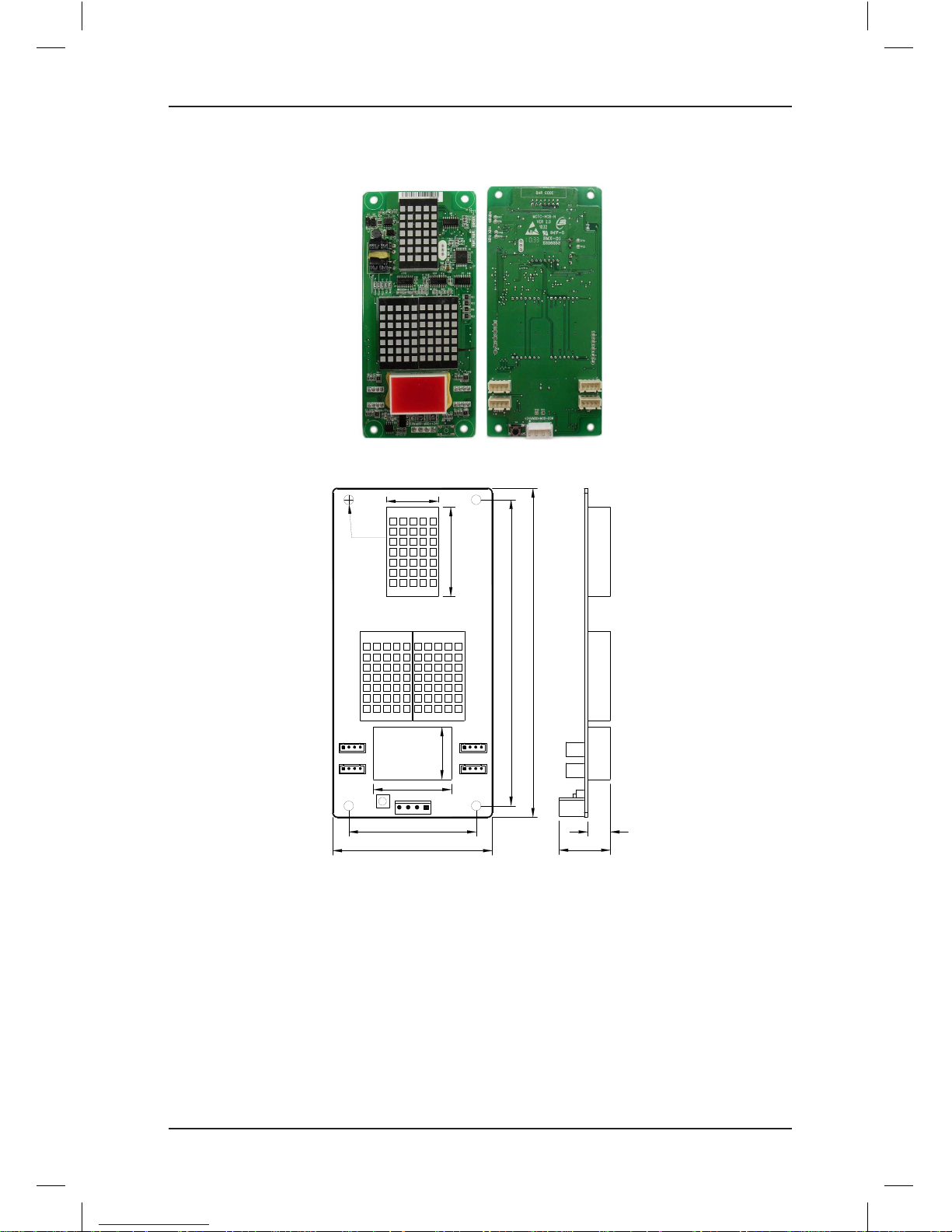

3.4 Display Board (MCTC-HCB)

As an important interface between users and the control system, the MCTC-HCB receives

hall calls and displays the current floor and running direction for the hall. This board can also

be used as car display board.

Monarch provides many types of display boards. The following describes only a few

common types. If you need other types, please contact Monarch.

The common types to be described are listed in the following table.

Table 3-3 Common types of HCB-H

Name Feature Size (mm)

HCB-H Dot-matrix display board (red) 144 x 70 x 18

HCB-R1 Ultrathin dot-matrix display board (red) 144 x 70 x 10

HCB-D2

Ultrathin segment LED display board (blue

background white display)

144 x 70 x 10

HCB-U1

4.3-inch segment LED display board (blue

background white display)

143.5 x 79.2 x 9.4

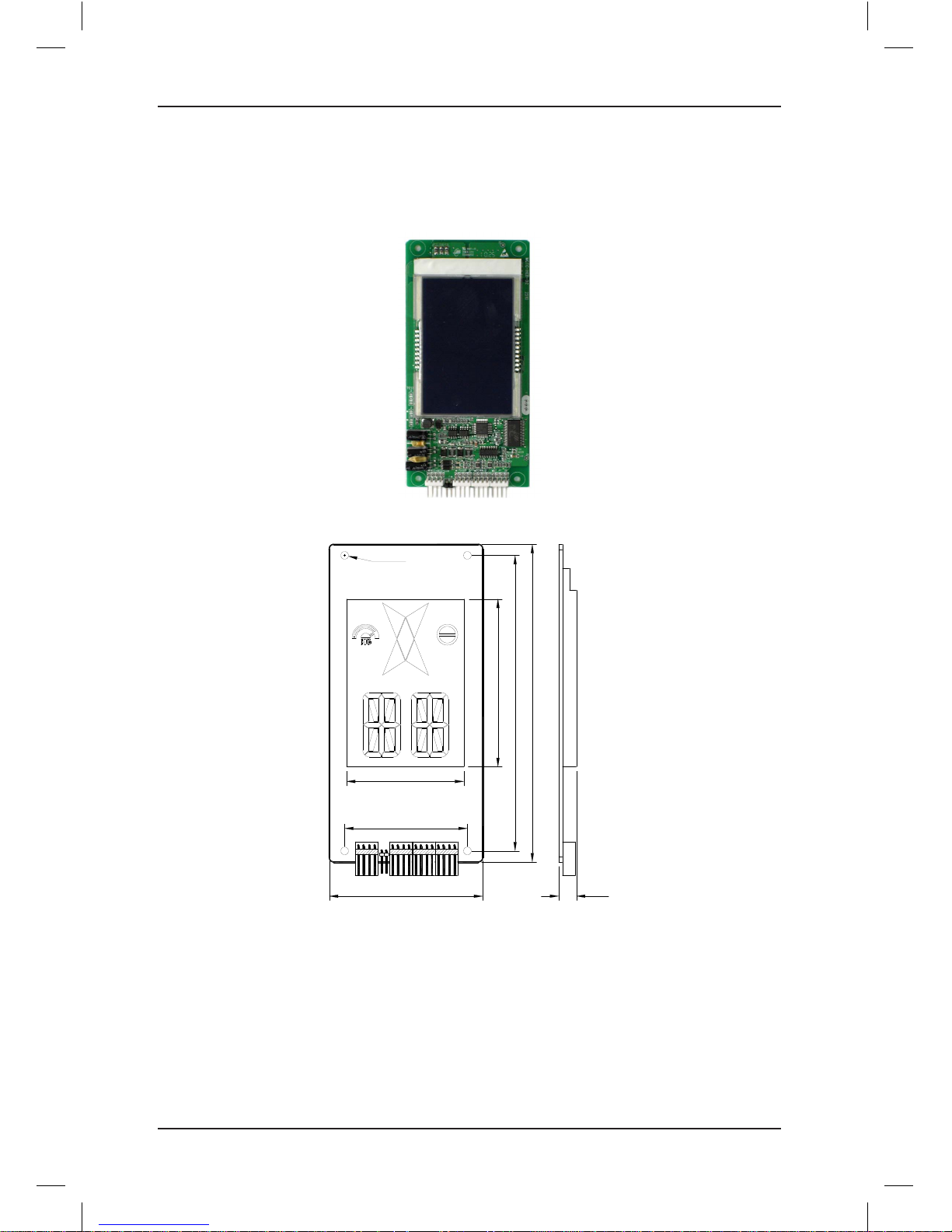

3.4.1 HCB-H (Dot-Matrix Display Board)

The following figures show the appearance and size of HCB-H.

Page 24

Brief NICE3000 Instruction Manual Component Description

- 23 -

Figure 3-5 Appearance of HCB-H

Figure 3-6 Size of HCB-H

4-Φ4.2 mm

56.0 mm

134.0 mm

70.0 mm

144.0 mm

9.9

mm

22.5 mm

22.9 mm

39.1 mm

34.3 mm

22.9 mm

S1

CN1

JP1 JP2

JP3 JP4

UP

DOWN

MCTC-HCB-H

Page 25

Component Description Brief NICE3000 Instruction Manual

- 24 -

The following table describes the input and output terminals.

Table 3-4 Input and output terminals of HCB-H

Terminal Name Function

JP1

Interface for the elevator locking switch and up arrival indicator

Pins 2 and 3 are for switch input. Pin 1 and 4 are power supply for the up

arrival indicator.

JP2

Interface for the fire-emergency switch and down arrival indicator

Pins 2 and 3 are for switch input. Pin 1 and 4 are power supply for the

down arrival indicator.

JP3

Interface for the up call button and indicator

Pins 2 and 3 are for up call input. Pins 1 and 4 are power supply for the up

call indicator.

JP4

Interface for the down call button and indicator

Pins 2 and 3 are for down call input. Pins 1 and 4 are power supply for the

down call indicator.

Note: Pins 1 and 2 are positive of power supply. The pin with white dot or that is rectangular

is pin 1.

S1

Button for setting the floor address.

Hold down the button to adjust the floor address. After you stop pressing,

the address number blinks three times, and therefore, the setting is

successful.

CN1

Modbus communication and power supply terminal

Pins 2 and 3 are for Modbus communication. Pins 1 and 4 are for DC

power supply.

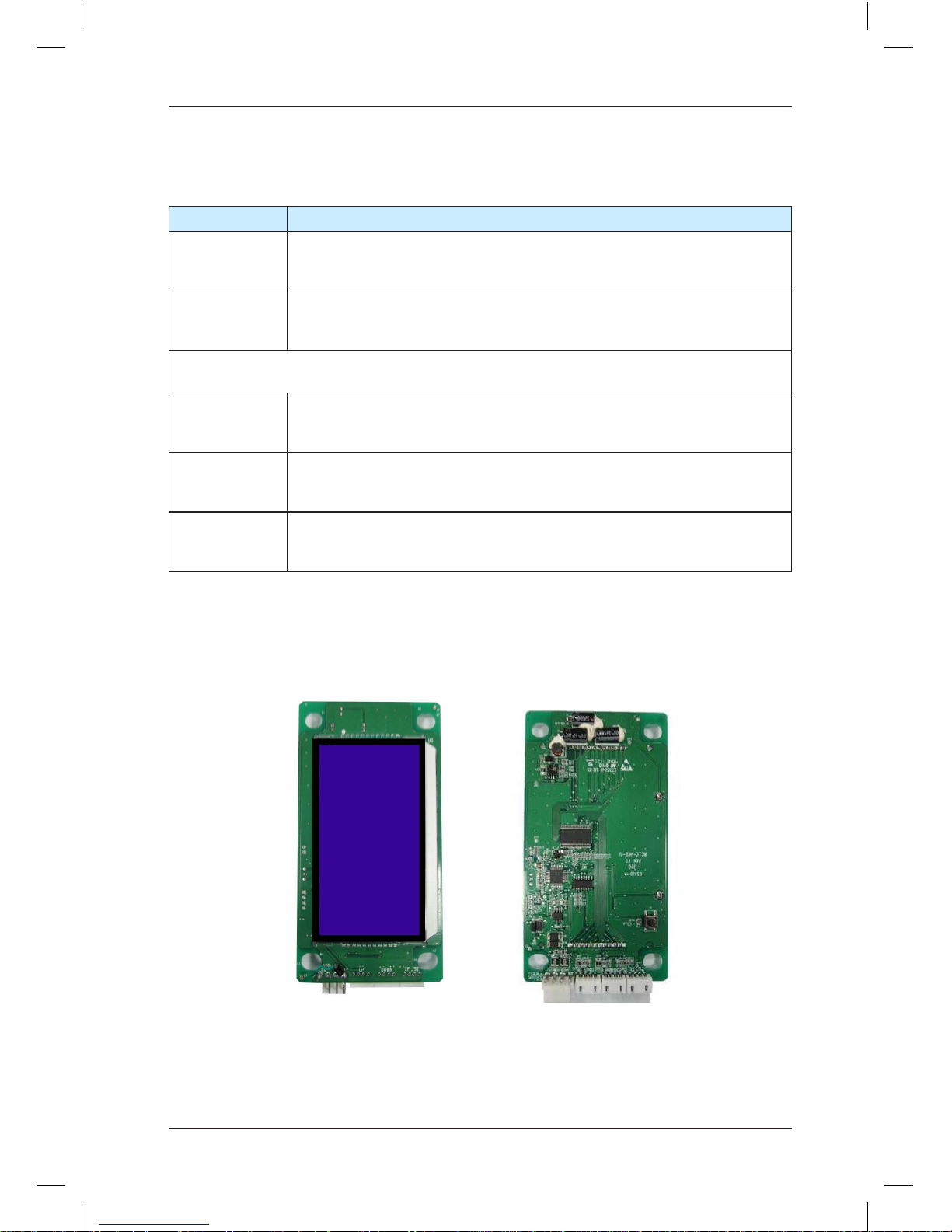

3.4.2 HCB-R1 (Ultrathin Dot-Matrix Display Board)

The following figures show the appearance and size of HCB-R1.

Figure 3-7 Appearance of HCB-R1

Page 26

Brief NICE3000 Instruction Manual Component Description

- 25 -

Figure 3-8 Size of HCB-R1

4-Φ3.5 mm

56.0 mm

134.0 m m

144.0 mm

6.7 mm

10 mm

22.8 mm

39.0 mm

CN1J1UP DOWN ST XF

70 mm

MCTC-HCB-R1

The following table describes the input and output terminals.

Table 3-5 Input and output terminals of HCB-R1

Terminal Name Function

UP

Interface for the up call button and indicator

Pins 2 and 3 are for up call input. Pins 1 and 4 are power supply for the up

call indicator.

DOWN

Interface for the down call button and indicator

Pins 2 and 3 are for down call input. Pins 1 and 4 are power supply for the

down call indicator.

Note: Pins 1 and 2 are positive of power supply. The pin with white dot mark or that is

rectangular is pin 1.

XF/ST

Interface for the fire-emergency and elevator locking switch

Pins 1 and 2 are for fire-emergency input. Pins 3 and 4 are for elevator

locking input.

J1

Terminal for setting the floor address.

Short J1, and press the UP button or DOWN button to set the floor address.

After the jumper cap is removed, the address is automatically stored.

CN1

Modbus communication and power supply terminal

Pins 2 and 3 are for Modbus communication. Pins 1 and 4 are for DC power

supply.

Page 27

Component Description Brief NICE3000 Instruction Manual

- 26 -

3.4.3 HCB-D2 (Ultrathin Segment LED Display Board)

The following figures show the appearance and size of HCB-D2.

Figure 3-9 Appearance of HCB-D2

Figure 3-10 Size of HCB-D2

4-Φ3.5 mm

56.0 mm

134.0 mm

70.0 mm

144.0 mm

10 mm

76.0 mm

49 mm

CN1J1UP DOWN ST XF

Page 28

Brief NICE3000 Instruction Manual Component Description

- 27 -

The following table describes the input and output terminals.

Table 3-6 Input and output terminals of HCB-D2

Terminal Name Function

JP2

Interface for the up call button and indicator

Pins 2 and 3 are for up call input. Pins 1 and 4 are power supply for the up

call indicator.

JP3

Interface for the down call button and indicator

Pins 2 and 3 are for down call input. Pins 1 and 4 are power supply for the

down call indicator.

Note: Pins 1 and 2 are positive of power supply. The pin with white dot mark or that is

rectangular is pin 1.

JP1

Interface for the fire-emergency and elevator locking switch

Pins 1 and 2 are for fire-emergency input, and pins 3 and 4 are for elevator

locking input.

J1

Terminal for setting the floor address.

Short J1, and press the UP button or DOWN button to set the floor address.

After the jumper cap is removed, the address is automatically stored.

CN1

Modbus communication and power supply terminal

Pins 2 and 3 are for Modbus communication. Pins 1 and 4 are for DC power

supply.

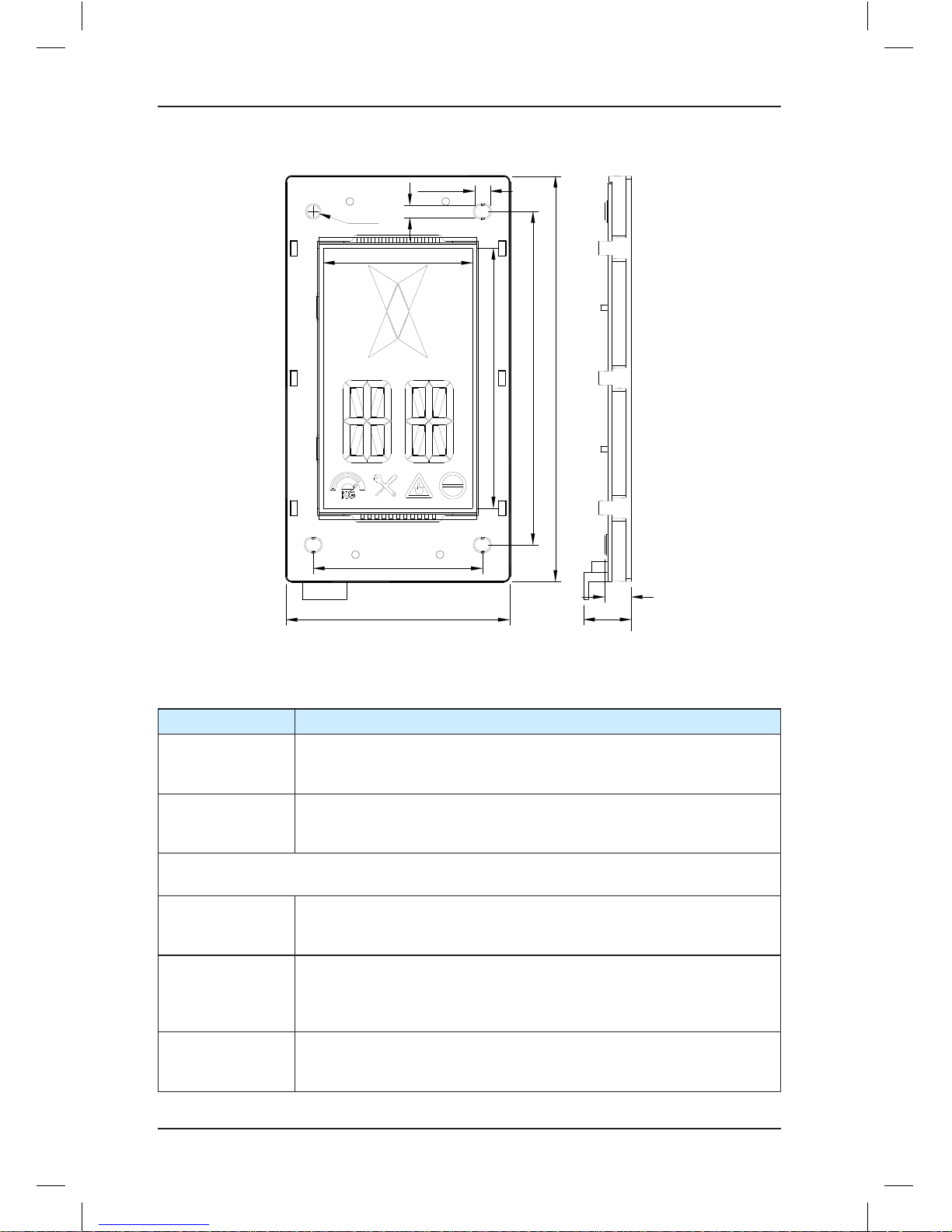

3.4.4 HCB-U1 (4.3-inch Segment LED Display Board)

The following figures show the appearance and size of HCB-U1.

Figure 3-11 Appearance of HCB-U1

Page 29

Component Description Brief NICE3000 Instruction Manual

- 28 -

Figure 3-12 Size of HCB-U1

3-5.5 mm

3-4.5 mm

9.4 mm

Φ4.5 mm

143.5 mm

79.2 mm

118.0 mm

60.0 mm

53.0 mm

92.0 mm

16.9 mm

The following table describes the input and output terminals.

Table 3-7 Input and output terminals of HCB-U1

Terminal Name Function

J1

Interface for the up call button and indicator

Pins 2 and 3 are for up call input. Pins 1 and 4 are power supply for the

up call indicator.

JP3

Interface for the down call button and indicator

Pins 2 and 3 are for down call input. Pins 1 and 4 are power supply for

the down call indicator.

Note: Pins 1 and 2 are positive of power supply. The pin with white dot mark or that is

rectangular is pin 1.

J3

Interface for the fire-emergency and elevator locking switch

Pins 1 and 2 are for fire-emergency input, and pins 3 and 4 are for

elevator locking input.

S1

Button for setting the floor address.

Hold down the button to adjust the floor address. After you stop pressing,

the address number blinks three times, and therefore the setting is

successful.

CN1

Modbus communication and power supply terminal

Pins 2 and 3 are for Modbus communication. Pins 1 and 4 are for DC

power supply.

Page 30

Brief NICE3000 Instruction Manual Component Description

- 29 -

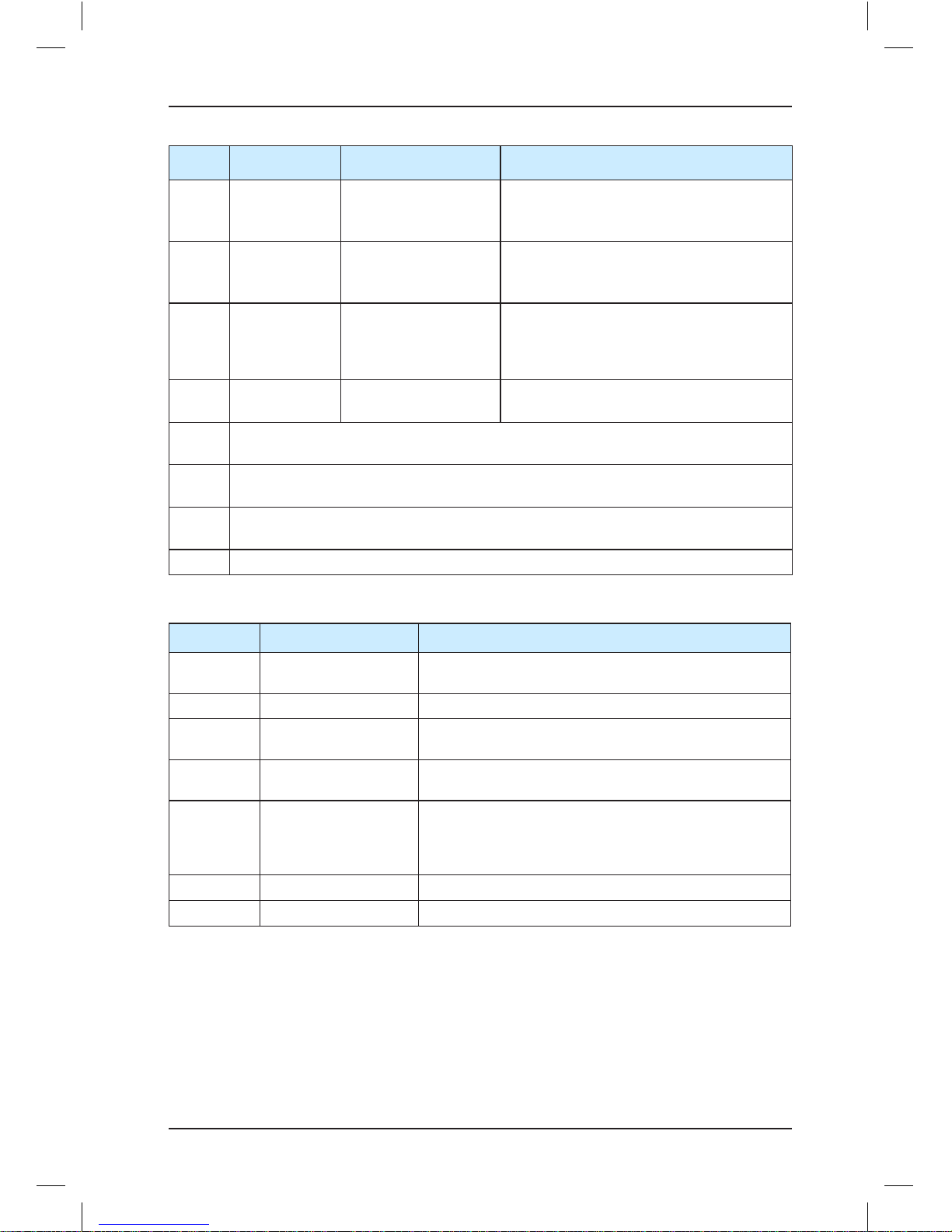

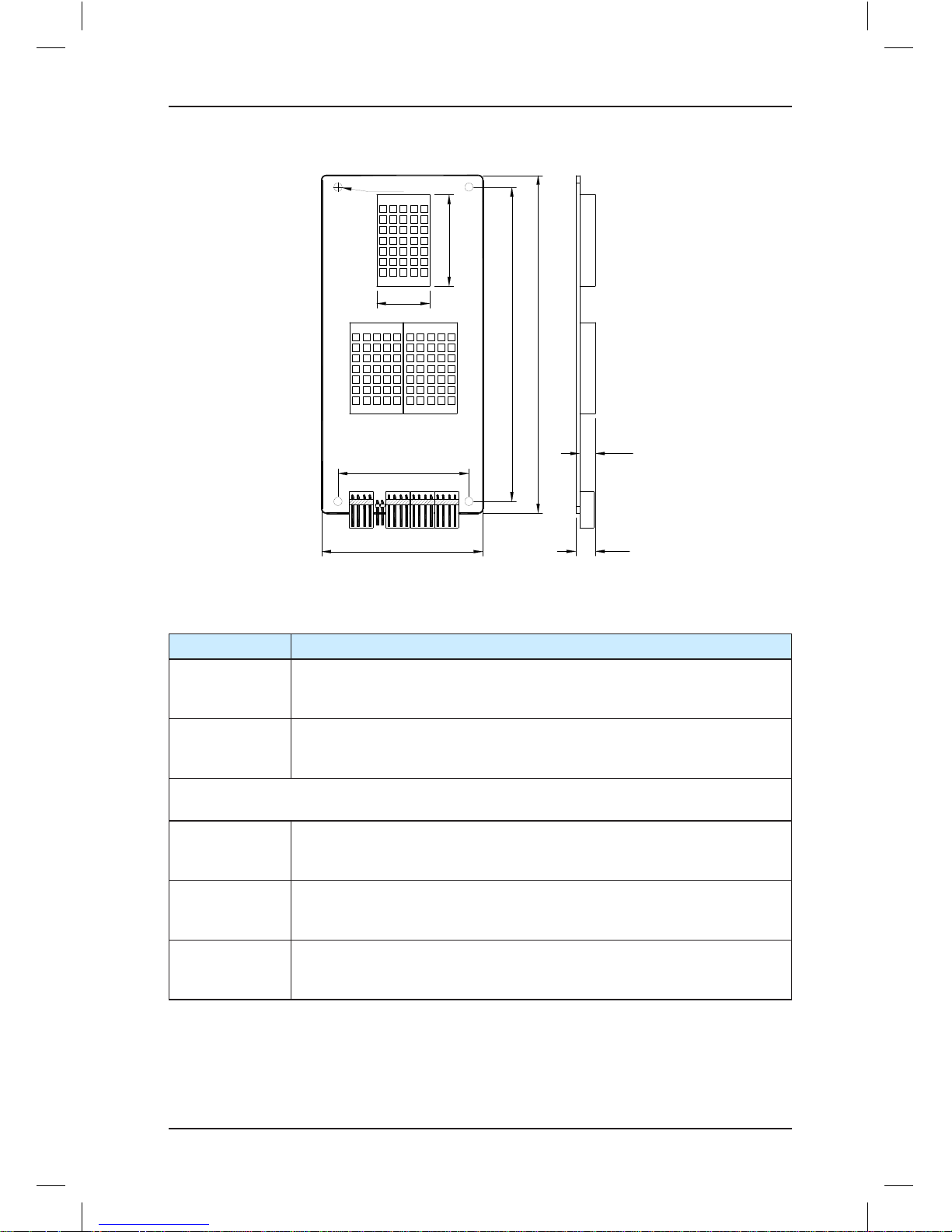

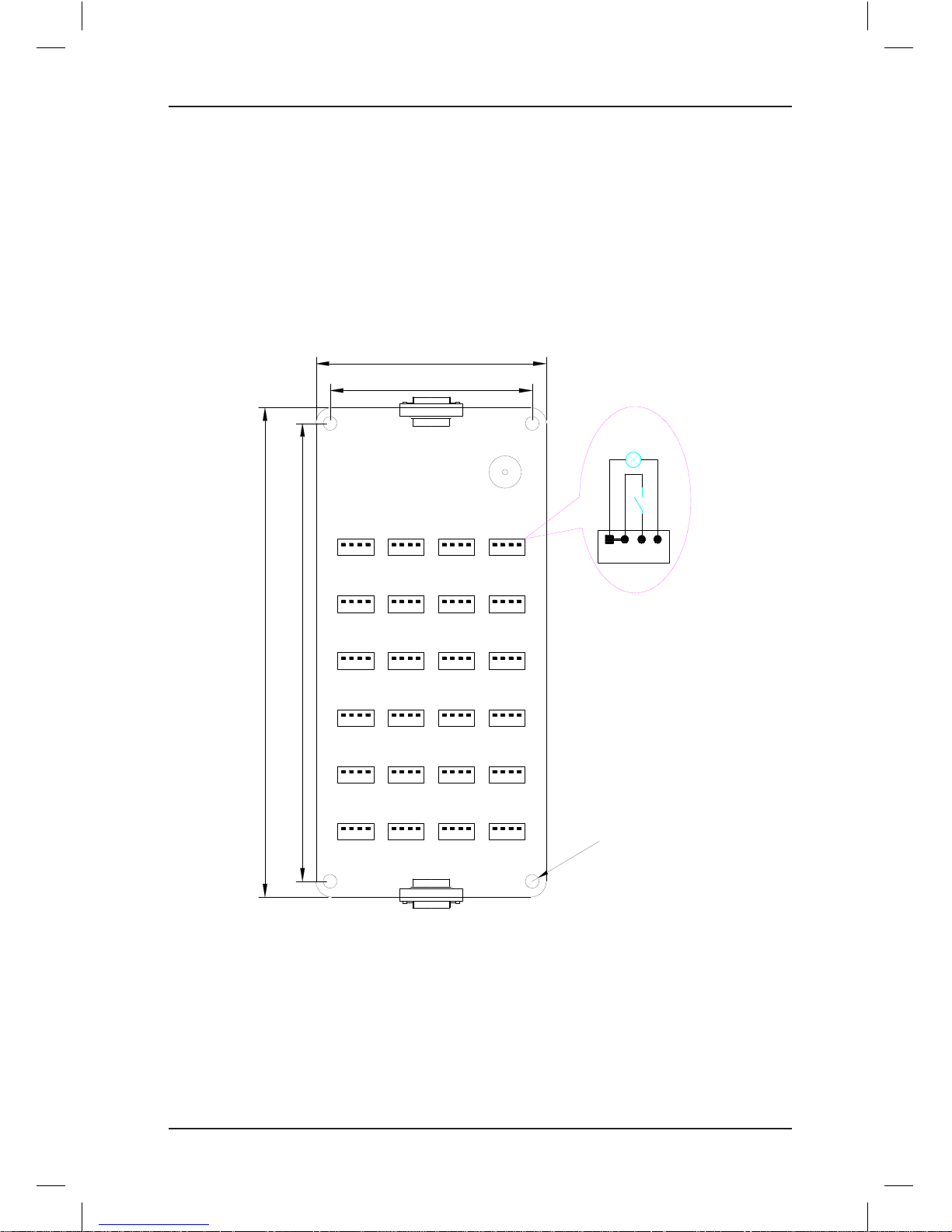

3.5 CCB Board

The car call board (MCTC-CCB) is another interface between users and the control

system. Each CCB comprises 24 inputs and 22 outputs, including 16 floor buttons and 8

functional signals. The CCB mainly collects button calls and outputs signals of the button

call indicators. The need for 31-floor use can be implemented through cascaded connection.

CN2 is an input connector and CN1 is a cascaded output connector.

The following figure shows the structure of the CCB.

Figure 3-13 Structure of the CCB

1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

JP1 JP2 JP3 JP4

JP5 JP6 JP7 JP8

JP9 JP10 JP11 JP12

JP13 JP14 JP15 JP16

JP17 JP18 JP19 JP20

JP21 JP22 JP23 JP24

CN1

Buzzer

Floor 1 Floor 2 Floor 3 Floor 4

Floor 5 Floor 6 Floor 7 Floor 8

Floor 9 Floor 10 Floor 11 Floor 12

Floor 13 Floor 14 Floor 15 Floor 16

Attendant

Direction

change

Independent

running

Fire

emergency

Door

open

Door

close

Door open

delay

Bypass

1 2 3 4

79 mm

69 mm

158 mm

148 mm

R

2

.

5

m

m

Output of the

button call

indicators

Button call

input

MCTC-CCB

CN2

Page 31

Component Description Brief NICE3000 Instruction Manual

- 30 -

The following table describes the input and output terminals.

Table 3-8 Input and output terminals of the CCB

No. Interface Pins 2 and 3 Pins 1 and 4 Remarks

1 JP1 Floor 1 button input Floor 1 display output

For CCB2, the

input signal of JPn

corresponds to floor

(16+n) button input.

2 JP2 Floor 2 button input Floor 2 display output

3 JP3 Floor 3 button input Floor 3 display output

4 JP4 Floor 4 button input Floor 4 display output

5 JP5 Floor 5 button input Floor 5 display output

6 JP6 Floor 6 button input Floor 6 display output

7 JP7 Floor 7 button input Floor 7 display output

8 JP8 Floor 8 button input Floor 8 display output

9 JP9 Floor 9 button input Floor 9 display output

10 JP10 Floor 10 button input Floor 10 display output

11 JP11 Floor 11 button input Floor 11 display output

12 JP12 Floor 12 button input Floor 12 display output

13 JP13 Floor 13 button input Floor 13 display output

14 JP14 Floor 14 button input Floor 14 display output

15 JP15 Floor 15 button input Floor 15 display output

16 JP16 Floor 16 button input Floor 16 display output

17 JP17

Door open button

input

Door open display

output

Invalid for CCB 2.

18 JP18

Door close button

input

Door close display

output

19 JP19

Door open delay

button input

Door open delay display

output

20 JP20 Bypass input Bypass display output

21 JP21 Attendant input Reserved

22 JP22

Direction change

input

Reserved

23 JP23

Independent running

input

Reserved

24 JP24 Firefighter input Reserved

Note: Pins 1 and 2 are positive of power supply. The pin with white dot mark or that is

rectangular is pin 1.

Page 32

4

Use of the NICE3000

Page 33

Use of the NICE3000 Brief NICE3000 Instruction Manual

- 32 -

Chapter 4 Use of the NICE3000

4.1 Wiring Diagrams Under Default Parameter Settings

4.1.1 Electric Wiring of the NICE3000

The following figure shows the electric wiring diagram of the NICE3000.

Figure 4-1 Electric wiring diagram of the NICE3000

X1

X2

X3

X4

X5

X6

X7

X8

X9

X10

X11

X12

X13

X14

X15

X16

X17

X18

X19

X20

X21

X22

X23

X24

M

Ai

R T+

-

U V W

PE

2 4V

COM

MOD+

M OD-

C AN+

C AN-

PG card

J9

PB

Up slow-down 1

Down leveling

Down slow-down 1

RUN contactor feedback

Safety circuit feedback

Door lock circuit feedback

S

Brake contactor feedback

RJ45

Encoder

Inspection

circuit

Analog weighing

Connect

to HCB

Connect

to CTB

PRG UP SET

Up leveling

Inspection signal

Up limit

Inspection up

Inspection down

Down limit

J10

Y1M1Y2M2Y3M3Y4M4Y5M5Y6

M6

CN7

CN3

CN9

CN1

ON

J5

24V

CN2

CN12

PE

24V

power

RUN output

Brake output

Encoder interface for

asynchronous motor

J6

15V

PGM

PGA

PGB

PGM

PE

CN6

Up slow-down 2

Up slow-down 3

Down slow-down 3

Down slow-down 2

1.5 m/s < elevator speed ≤ 2.4 m/s

2.4 m/s < elevator speed

Page 34

Brief NICE3000 Instruction Manual Use of the NICE3000

- 33 -

Note

The above wiring diagram shows the default I/O function setting of group F5. The braking resistor

is connected to PB and +.

4.1.2 Recommended CTB Wiring and Parameter Setting

The following wiring diagram shows the default function setting of the CTB. You can change

the input polarity (NO/NC) of the CTB terminals in F5-25.

Figure 4-2 Recommended CTB wiring

CN4

CN7

Door command common 1

CN3

Doo r 2 pen lim it

Force d doo r close 1

Overlo ad sign al

Doo r 1 ope n limit

CN2

Door open command 1

Up a rrival gong

C3 co mmon

Down arriva l gon g

Arrival gong

common

BM

B1

B2

B3

CM

C1

C2

C3M

DM

D1

D2

X1

X2

X3

X4

P24

P24

X5

X6

X7

X8

A

B

AM

P2 4

AI

M

+24 V

CAN+

CAN -

COM

+24V

MOD +

MOD-

COM

J1

J2

J3

Door 1 control circuit

503

501

AI2

AIM2

30 1

CN1

Comm unicate

with MCB

CN8

Overload

HCB

CTB

Full -loa d signa l

CN6

CN1

CN5

301

302

OFF

CN10

USB

CHM (voice

annou cement)

Door 2 control circuit

CCB: CN2

CCB: Opp osite ca r or special ca ll

Operation

pan el interfa ce

ON

J2

0V

B

A

+24V

COM

MO D-

MOD+

+24 V

Car fan and

lam p contro l

Doo r 1 close limi t

Doo r 2 close li mit

Doo r 1 light curta in

Doo r 2 light curta in

Door close command 1

Door command common 2

Door open command 2

Door close command 2

Wiri ng whe n appl ying

an alog weig hing de vice

C3

Force d doo r close 2

4.2 Description of Shaft Signals

In elevator control, the car position needs to be identified based on shaft position signals,

implementing stop at floors accurately and guaranteeing safe running.

These shaft position signals include the up final limit switch, down final limit switch, up limit

switch, down limit switch, up slow-down switch, low slow-down switch and leveling switches.

Page 35

Use of the NICE3000 Brief NICE3000 Instruction Manual

- 34 -

4.2.1 Limit Switch and Final Limit Switch

Stop the car at the top (or bottom) leveling position, and mount the limit switch 100 mm

away from the top (or bottom) leveling position. That is, the limit switch shall act when

the car continues to run upward (or downward) 100 mm from the top (or bottom) leveling

position.

The final limit switch is mounted above the up limit switch or below the down limit switch. It

is usually 100 to 150 mm away from the top (or bottom) leveling position.

4.2.2 Slow-Down Switch

Slow-down switch is one of the key protective components of the NICE3000, protecting

the elevator from over travel top terminal or over travel bottom terminal at maximum speed

when the elevator position becomes abnormal.

The default deceleration rate ("Special deceleration rate" in F3-08) of the NICE3000 system

is 0.9 m/s2. In the condition that the rated speed and the special deceleration rate are

certain, the slow-down distance can be obtained via the following formula:

Slow-down distance = Rated speed x Rated speed/(2 x special deceleration rate)

Then you can get the mounting positions of the slow-down switches that correspond to

various elevator speeds.

The recommended positions of slow-down switches are listed in the following table.

Table 4-1 Recommended positions of slow-down switches

Rated Elevator Speed V ≤ 1.5 m/s 1.5 m/s < V ≤2.4 m/s 2.4 m/s < V ≤3.7 m/s

Slow-down switch 1 1.3 m-L/2 1.3 m 1.3 m

Slow-down switch 2 3.2 m 3.2 m

Slow-down switch 3 8.0 m

Note

• "L" in the table indicates the landing height. The default special deceleration rate is 0.9 m/s2,

and the acceleration rate and deceleration rate are 0.6 m/s2.

• The positions of slow-down switches are calculated on the basis of default value (special

deceleration rate 0.9 m/s2, and acceleration rate and deceleration rate are 0.6 m/s2). Decreasing

the acceleration rate and deceleration rate or increasing the special deceleration rate does not

affect the safety, but increasing the acceleration rate and deceleration rate or decreasing the

special deceleration rate may bring safety hazard. If any value needs to be changed, calculate

proper slow-down distance for mounting the slow-down switches.

4.2.3 Leveling Switch

The NICE3000 system allows the use of 1 to 3 leveling switches. If only one leveling

sensor is used, the corresponding function code which is used for input of leveling signal is

allocated with function 03 (NO input of door zone signal).

There is no special requirement on the length of the flag. It is recommended to use a flag of

80–200 mm long. Ensure that flags at all landings have the same length and are mounted

vertically.

Page 36

Brief NICE3000 Instruction Manual Use of the NICE3000

- 35 -

You need to add two re-leveling switches if applying the door pre-open function. In this

case, you need to increase the length of the flag properly. For details on the door pre-open

module, contact Monarch or local agent for more information.

4.3 Typical Commissioning

4.3.1 Check Before Commissioning

■ Check Before Power-On

1. Check for the following wiring:

a. The wiring between the power cables RST of the elevator and the three-phase power

cables RST of the control cabinet is normal.

b. The wiring between the brake coils of the motor of the control cabinet is normal.

c. The wiring between UVW of the control cabinet and power cables of the motor is

normal.

d. The power and signal wiring between the motor encoder and the control cabinet is

normal.

e. The safety circuits are closed.

f. The door lock circuits are closed.

g. The wiring of the car top and CTB is normal.

h. The inspection circuit is normal.

i. The power and signal wiring of the door machine is normal.

j. The CAN communication wiring between the MCB and the CTB is normal.

k. The Modbus communication wiring between the HCB and the MCB is normal.

l. The wiring between the CCB and CTB is normal.

2. Check for the communication cables.

a. Check the impedance between the communication cables CAN+, CAN-, MOD+, and

MOD- and other control or power cables. It is better that the impedance is close to

infinity.

b. Check the impedance between the communication cables CAN+, CAN-, MOD+, and

MOD- and the grounding cable. It is better that the impedance is close to infinity.

c. Measure the resistance of the terminal resistor between CAN+ and CAN-, and between

MOD+ and MOD-. The correct value is close to 60 Ω.

3. Check for the motor's winding resistance and insulation to the ground.

4. Check for the cable grounding and measure the resistance.

1) Check that the resistance between the following points and the ground is close to infinity.

Page 37

Use of the NICE3000 Brief NICE3000 Instruction Manual

- 36 -

a. R, S, T, U, V, W

b. Input and output terminals of the controller and power supply for switches

c. Brake power coils and wiring terminals of the braking resistor

d. Nodes of various control signals

e. Encoder signal (note the grounding mode of the shielding layer and encoder body)

f. Various nodes of safety circuit

If any resistance is small, check the wiring immediately and find the fault. Otherwise,

transformer or power protection may result.

2) Check that the resistance between the following points and the ground is close to 0 (less

than 4 Ω).

a. Grounding cable of the power supply

b. Grounding cable of the motor

c. Shielding lay of the encoder

d. Grounding terminal of the controller

e. Grounding point of the control transformer

f. Grounding point of the switching power supply

g. Grounding point of the brake

h. Grounding point of various safety switches

The grounding and ground cable directly affect stability and reliability of the elevator

running. Ensure that the grounding points are tied to the ground reliably and the

grounding cable is reliable.

5. Check for the capacity of the power supply and switches, and the diameter of the power

cable.

6. Check that the power voltage complies with the regulation, including amplitude and

interphase deviation.

7. Confirm the following items:

a. All switches and fuses in the cabinet are in the off state.

b. The normal/emergency electric dial of the control cabinet is in the emergency electric

state.

c. The inspection switch of the car top or the car is in the normal state.

d. The shaft allows movement of the car.

8. After all the precedent check is complete and the power-on requirements are satisfied,

power on the controller.

■ Check After Power-On

1. Turn on the power switch and check the phase failure relay (PFR). If the PFR is

abnormal, turn off the power switch and then exchange any two power input phases.

Page 38

Brief NICE3000 Instruction Manual Use of the NICE3000

- 37 -

2. Check the input and output voltage of the control transformer in the cabinet.

Power 380 VAC input 110 VAC output 220 VAC output 110 VDC output

Measured voltage 380±15% 110±5% 220±5% 110±5% (DC)

3. If there is any problem, find the cause and solve the problem immediately.

4. If it is normal, turn on the MCCB in the cabinet and check the corresponding voltage and

circuit.

5. Check for the state of relays in the cabinet.

Relay State

Phase sequence relay Normal working status

Safety circuit relay Closed

Safety contactor Closed

Door lock contactor Closed

6. After ensuring that the circuits are normal, set the related parameters based on the

requirements and regulations on the use of the elevator to prepare for inspection-speed

commissioning.

4.3.2 Commissioning at Inspection Speed

To implement accurate control on the motor, motor auto-tuning must be performed

before the use of the NICE3000. Ensure that the installation and wiring satisfy the safety

requirements and technical specifications before the auto-tuning.

■ No-load Auto-tuning

1. Asynchronous motor

Note

For the asynchronous motor, after F1-11 is set to 2 (No-load auto-tuning), the motor will run. You

must take off the steel rope and release the brake manually.

To perform no-load auto-tuning for asynchronous motor, do as follows:

1) Set F0-01 (Command source selection) to 0 (Operation panel control) and press

STOP

RES

on the operation panel to reset the current faults.

2) Enter the motor nameplate parameters correctly.

• F1-01 (Rated motor power)

• F1-02 (Rated motor voltage)

• F1-03 (Rated motor current)

• F1-04 (Rated motor frequency)

• F1-05 (Rated motor rotational speed)

Page 39

Use of the NICE3000 Brief NICE3000 Instruction Manual

- 38 -

Then, set F1-12 (Encoder lines per revolution) based on the encoder nameplate.

3) Remove the load from the motor completely. Set F1-11 to 2 (No-load auto-tuning).

"TUNE" is displayed on the operation panel. Release the brake manually and press

RUN

on the operation panel. The motor enters the excitation state first, and starts

to rotate after about 2s. The motor accelerates to the full speed and then decelerates

to stop. Then the RUN contactor opens. After the motor stops rotating, apply the

brake manually. Then, the motor auto-tuning is complete. During the auto-tuning, the

controller automatically measures the motor parameters:

• F1-06 (Stator resistance)

• F1-07 (Rotor resistance)

• F1-08 (Leakage inductance)

• F1-09 (Mutual inductance)

• F1-10 (Motor magnetizing current)

4) Run the motor in operation panel control and set F0-02 (Speed reference in operation

panel control) to a proper value. For the consideration of safety, the system does not

output commands for the running contactor and brake contactor. You have to press

down the running contactor and release the brake manually.

If the motor jitters or E20 is reported in operation panel control, exchange any two

output power cables or exchange phases A and B of the encoder, and then perform the

motor auto-tuning again.

2. PMSM

Note

For PMSM, after F1-11 is set to 2 (No-load auto-tuning), the motor will run. You must take off the

steel rope and release the brake manually.

To perform no-load auto-tuning for PMSM, do as follows:

1) Check the motor power cables and encoder wiring.

Ensure that the UVW power cables of the motor are properly connected to the UVW

terminals of the controller, and the encoder's AB, UVW or CDZ signal wires are properly

connected to the AB, UVW or CDZ terminals of the PG card.

2) After the system is powered on, set F0-01 (Command source selection) to 0 (Operation

panel control) and press

STOP

RES

on the operation panel to reset the current faults.

3) Set the encoder parameters properly.

F1-00 (Encoder type selection)

Page 40

Brief NICE3000 Instruction Manual Use of the NICE3000

- 39 -

• 0: SIN/COS encoder

• 1: UVW encoder

F1-12 (Encoder lines per revolution)

If applying the Heidenhain ECN 1313 or 413 encoder with the MD32PG5 card, set F100 to 0.

4) Enter the motor nameplate parameters correctly.

• F1-01 (Rated motor power)

• F1-02 (Rated motor voltage)

• F1-03 (Rated motor current)

• F1-04 (Rated motor frequency)

• F1-05 (Rated motor rotational speed)

If applying the Heidenhain ERN 1387 SIN/COS encoder, set F1-10 (Selection of

encoder's signal check) to 1.

5) Remove the load from the motor completely. Set F1-11 to 2 (No-load auto-tuning).

"TUNE" is displayed on the operation panel. Release the brake manually and press

RUN

on the operation panel. The motor then starts to run and the controller

automatically calculates F1-06 (Encoder initial angle) and F1-08 (Wiring mode). After

three or more times of auto-tuning, compare the obtained values. The value deviation

of F1-06 shall be within ±5°. The values of F1-08 shall be the same.

Note

If the obtained value of F1-08 is an odd number, it indicates that the output phase sequence is

incorrect. In this case, you can run the motor but cannot complete with-load auto-tuning. If withload auto-tuning is required, exchange any two UVW phases of power output to ensure correct

phase sequence. Therefore, the value of F1-08 is an even number.

6) Run the motor in operation panel control and set F0-02 (Speed reference in operation

panel control) to a proper value. For the consideration of safety, the system does not

output commands for the RUN contactor and brake contactor. You have to press down

the running contactor and release the brake manually. The motor current is usually less

than 1 Amp in no load condition.

■ With-load Auto-tuning

1. Asynchronous motor

Note

For the asynchronous motor, after F1-11 is set to 1 (With-load auto-tuning), the motor keeps still.

You need not take off the steel rope. You can hear the motor current noise in the process of autotuning.

RUN

Page 41

Use of the NICE3000 Brief NICE3000 Instruction Manual

- 40 -

To perform with-load auto-tuning for asynchronous motor, do as follows:

1) Set F0-01 (Command source selection) to 0 (Operation panel control) and press

STOP

RES

on the operation panel to reset the current faults.

2) Enter the motor nameplate parameters correctly.

• F1-01 (Rated motor power)

• F1-02 (Rated motor voltage)

• F1-03 (Rated motor current)

• F1-04 (Rated motor frequency)

• F1-05 (Rated motor rotational speed)

Set F1-12 (Encoder lines per revolution) based on the encoder nameplate.

3) Set F1-11 to 1 (With-load auto-tuning) if the load cannot be removed from the motor

completely. Then "TUNE" is displayed on the operation panel. Press

RUN

on

the operation panel. The controller starts motor auto-tuning, measures the stator

resistance, rotor resistance and leakage inductance successively and automatically

calculates the motor's mutual inductance and no-load current. After the auto-tuning is

complete, the running contactor opens.

4) Run the motor at the inspection speed and check:

• Whether the running current is normal

• Whether the actual running direction of the elevator is consistent with the given

direction

• Whether the pulse direction is correct

Ensure that F4-03 (Low byte of current floor position) increases when you press the UP

key and decreases when you press the DOWN key.

The elevator running direction and pulse direction can be modified by F2-10 (Elevator

running direction).

2. PMSM

Note

• Ensure that the UVW power cables of the motor are connected to the UVW terminals of the

controller properly.

• Ensure that the AB, CDZ signal wires of the ERN1387 SIN/COS encoder are connected to the

AB, CDZ terminals of the PG card properly. The AB, UVW signal cables of the UVW encoder

are connected to the AB, UVW terminals of the PG card properly.

• Make sure that F8-01 (Pre-torque selection) is set to 0 (Pre-torque invalid). Otherwise, the

elevator runaway may result during the auto-tuning.

• If the auto-tuning still fails (the motor does not run or suddenly runs in one direction and then

stops) when the UVW power cables of the motor are correctly wired, exchange any two output

power cables of the controller and perform the motor auto-tuning again.

• Ensure that there is nobody in the shaft because the auto-tuning process is dangerous.

Page 42

Brief NICE3000 Instruction Manual Use of the NICE3000

- 41 -

To perform with-load auto-tuning for PMSM, do as follows:

1) Check the motor power cables and encoder wiring.

Ensure that the motor's UVW power cables are connected to the controller's UVW

terminals properly, and the encoder's AB, UVW or CDZ signal cables are connected to

the AB, UVW or CDZ terminals of the PG card properly.

2) Power on the system and set the inspection switch to the inspection position. Ensure

that F0-01 (Command source selection) to 1 (Distance control).

3) Set the encoder parameters properly.

F1-00 (Encoder type selection)

• 0: SIN/COS encoder

• 1: UVW encoder

F1-12 (Encoder lines per revolution)

4) Enter the motor nameplate parameters correctly.

• F1-01 (Rated motor power)

• F1-02 (Rated motor voltage)

• F1-03 (Rated motor current)

• F1-04 (Rated motor frequency)

• F1-05 (Rated motor rotational speed)

Make sure that F8-01 (Pre-torque selection) is set to 0 (Pre-torque invalid). If applying

the ERN1387 SIN/COS encoder, set F1-10 (Selection of encoder's signal check) to 1.

If applying the ECN 1313 or 413 encoder with the MD32PG5 card, set F1-00 to 0.

5) Reset the current faults and set F1-11 to 1 (With-load auto-tuning). Press the inspection

UP or DOWN button. The electromagnetic noise comes first. Then the motor runs one

turn in the given direction until the encoder original signal is detected.

When the TUNE indicator becomes off, the motor auto-tuning is complete. After three or

more times of auto-tuning, compare the obtained values. The value deviation of F1-06

shall be within ±5°. The values of F1-08 shall be the same.

6) If applying the ERN1387 SIN/COS encoder, set F1-10 (Selection of encoder's signal

check) to 2. Run the motor at the inspection speed and check:

• Whether the running current is normal

• Whether the actual running direction of the elevator is consistent with the given

direction

• Whether the pulse direction is correct

Ensure that F4-03 (Low byte of current floor position) increases when you press the UP

key and decreases when you press the DOWN key.

The elevator running direction and pulse direction can be modified by F2-10 (Elevator

running direction).

Page 43

Use of the NICE3000 Brief NICE3000 Instruction Manual

- 42 -

Note

After the motor auto-tuning is complete, the system prohibits inspection running for 8s and saves

parameters during the time.

4.3.3 Summary of Commissioning at Inspection Speed

■ Asynchronous Motor Auto-tuning Process

Figure 4-3 Auto-tuning process of the asynchronous motor

The motor does not run with electromagnetism

noise. The controller automatically meansures

F1-06, F1-07 and F1-08 and calculates F1-09

and F1-10.

The motor runs. The controller

automatically measures F1-06, F1-07,

F1-08, F1-09 and F1-10.

Set F1-01, F1-02, F1-03, F1-04 and F1-05 based on

motor nameplate parameters

The tuning is complete. Set F0-01 to 1 to restore distance control.

Set F0-01 to 0 (Operation panel control)

Lift the car up (take off the rope from the motor)

The TUNE indicator on the operation panel is

ON (the circuit from the output side to motor is

energized ). Open the brake manually and

press RUN. The RUN indicator is ON and

motor tuning begins.

F1-11 = 1 F1-11 = 2

The car need not be lifted up. The TUNE

indicator on the operation panel is ON (the

circuit from the output side to the motor is

energized ). Press RUN. The RUN indicator is

ON and motor tuning begins.

With-load

tuning

No-load

tuning

Page 44

Brief NICE3000 Instruction Manual Use of the NICE3000

- 43 -

■ PMSM Auto-tuning Process

Figure 4-4 Auto-tuning process of the PMSM

If no-load tuning is adopted , set F1-11 to 2. The TUNE indicator on the operation

panel is ON. Open the brake manually and press RUN . The RUN indicator on the

operation panel is ON . The motor tuning begins .

If with-load tuning is adopted , set F1-11 to 1. The TUNE indicator on the

operation panel is ON . Press the inspection key and then press the UP or DOWN

key. The RUN indicator on the operation panel is ON . The motor tuning begins .

Properly set encoder

parameters F 1-00 and F1-12,

and motor parameters F 1-01,

F1-02, F1-03, F1-04 and F 1-05

Tuning is complete. Press RUN to

check whether the motor runs

normally . If not, please reverse the

encoder signal direction and

perform motor tuning again .

Set F0-01 to 0 (N o-load tuning )

or 1 (With-load tuning )

Life the car up and

disconnect the

motor from load

Set F0-01 to 1 to restore

distance control.

Resume the rope .

No-load

tuning

With-load

tuning

Values of F1-06 and F 1-08 are obtained .

Three or more times of tuning is

suggested . The value deviation of F 1-06

shall be within ±5°. The values of F 1-08

shall be the same.

F1-11 = 1

F1-11 = 2

■ Output Status of RUN and Brake Contactors

For the sake of safety in different control modes, the system handles the output commands

to the RUN contactor or brake contactor differently. In some situations, it is necessary to

release the running contactor or the brake contactor manually.

The following table lists the output status of the running and brake contactors.

Table 4-2 Output status of the running and brake contactors

Control

Mode

Output

State

Motor Auto-tuning (F1-11 = 1, 2)

Controller Running

(Not Auto-tuning)

No-load

Auto-tuning

With-load Auto-tuning

Operation

Panel

Control

(F0-01 = 0)

Distance

Control

(F0-01 = 1)

PMSM

Asynchronous

Motor

RUN contactor Output Output Output Not output Output

Brake contactor Not output Output Not output Not output Output

Page 45

Use of the NICE3000 Brief NICE3000 Instruction Manual

- 44 -

4.3.4 Commissioning at Normal Speed

After ensuring that running at inspection speed is normal, you can start commissioning at

normal speed. Shaft auto-tuning is required before the commissioning at normal speed.

Ensure that the elevator satisfies the safety running requirements.

To perform shaft auto-tuning, the following conditions must be satisfied:

1. The signals of the encoder and leveling sensors (NC, NO) are correct and the position

switches are installed properly.

2. The elevator is at the bottom floor and the down slow-down switch acts.

3. The elevator is in the inspection state. The control mode is distance control and CLVC

(F0-00 = 1, F0-01 = 1).

4. The top floor number (F6-00) and bottom floor number (F6-01) are set correctly.

5. The NICE3000 system is not in the fault alarm state. If there is a fault at the moment,

press

STOP

RES

to reset the fault.

Then set F1-11 to 3 on the operation panel or set F7 to 1 on the keypad of the MCB, and

start shaft auto-tuning.

4.3.5 Riding Comfort

The riding comfort is an important factor of the elevator's overall performance. Improper

installation of mechanical parts and improper parameter settings will cause bad comfort.

Enhancing the riding comfort mainly involves adjustment of the controller output and the

elevator's mechanical construction.

■ Controller Output

The parameters that may influence the riding comfort are described in this part.

Function

Code

Parameter Name

Setting

Range

Default Description

F1-09

Current filter time

(PMSM)

0.00–40.00 0.00

It can reduce the lowerfrequency vertical jitter during

running.

F2-00

Speed loop

proportional gain 1

0–100 40

F2-00 and F2-01 are the PI

regulation parameters when

running frequency is lower

than F2-02 (Switchover

frequency 1). F2-03 and

F2-04 are the PI regulation

parameters when running

frequency is higher than F205 (Switchover frequency 2).

The regulation parameters

between F2-02 and F2-05 are

the weighted average value

of F2-00 & F2-01 and F2-03

& F2-04.

F2-01

Speed loop integral

time 1

0.01–10.00s 0.60s

F2-02

Switchover

frequency 1

0.00 to F2-05 2.00 Hz

F2-03

Speed loop

proportional gain 2

0–100 35

F2-04

Speed loop integral

time 2

0.01–10.00s 0.80s

F2-05

Switchover

frequency 2

F2-02 to

F0-06

5.00 Hz

Page 46

Brief NICE3000 Instruction Manual Use of the NICE3000

- 45 -

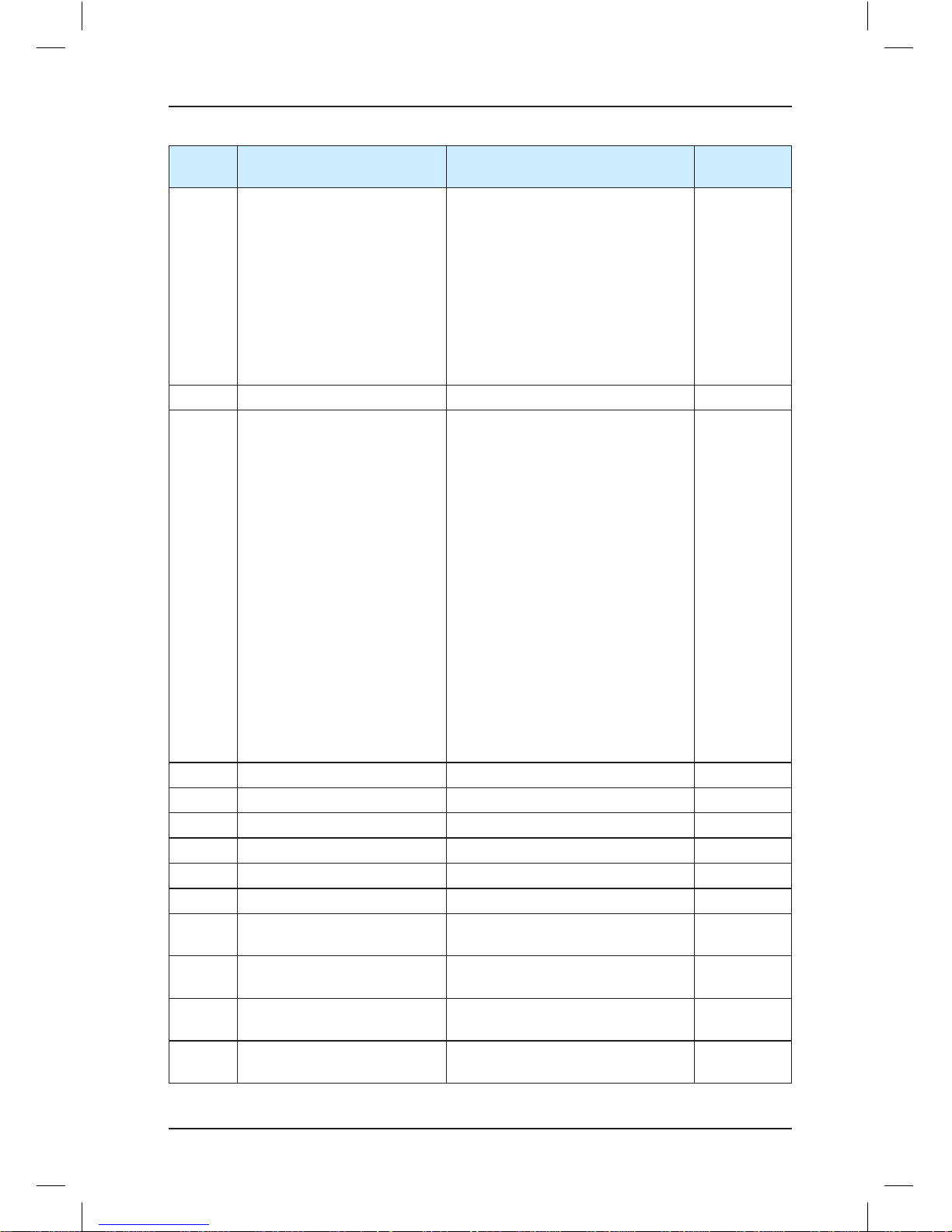

For a faster system response, increase the proportional gain and reduce the integral gain.

Be aware that a fast system response causes system oscillation.

Figure 4-5 Relationship between switchover frequencies

PI regulation

parameter

Frequency

reference

F2-05

F2-02

F2-03

F2-04

F2-00

F2-01

The recommended regulating method is as follows:

If the factory parameters cannot satisfy the requirements, make slight regulation. Increase

the proportion gain first to the biggest value under which the system does not oscillate. Then

decrease the integral time to ensure fast responsiveness and small overshoot.

If both F2-02 (Switchover frequency 1) and F2-05 (Switchover frequency 2) are set to 0

simultaneously, only F2-03 and F2-04 are valid.

Function

Code

Parameter

Name

Setting

Range

Default Description

F2-06

Current loop

proportion gain

10–500 60

F2-06 and F2-07 are the

current loop adjustment

parameters in the vector

control algorithm.

F2-07

Current loop

integral gain

10–500 30

Regulating the two parameters for PMSM has obvious effect on the riding comfort.

Appropriate regulation can restrain jitter during running. Generally, increase their default

value to 180 and 60 respectively for the PMSM.

Function

Code

Parameter

Name

Setting Range Default Description

F3-00 Startup speed 0.000–0.030 m/s 0.010 m/s

It can reduce improve the

terrace feeling at startup

caused by the breakout friction

of guide rail.

F3-01

Startup speed

holding time

0.000–0.500s 0.150s

F3-18

Zero-speed

control time at

startup

0.000–1.000s 0.200s

It specifies the zero speed

holding time before brake

output.

Page 47

Use of the NICE3000 Brief NICE3000 Instruction Manual

- 46 -

Function

Code

Parameter

Name

Setting Range Default Description

F3-19

Brake release

delay

0.000–1.000s

0.200s

0.600s

It specifies the time required

from when the system outputs

the open signal to when the

brake is completely released.

The value is automatically

changed to 0.0600s by the

system when F8-02 is 2.

F3-20

Brake apply

delay

0.000–1.000s 0.300s

It specifies the time from when

the system outputs the close

signal to when the brake is

completely applied.

F8-11

Zero-speed

control time at

end

0.200–1.500s 0.200s

It specifies the zero speed

holding time after the brake is

applied.

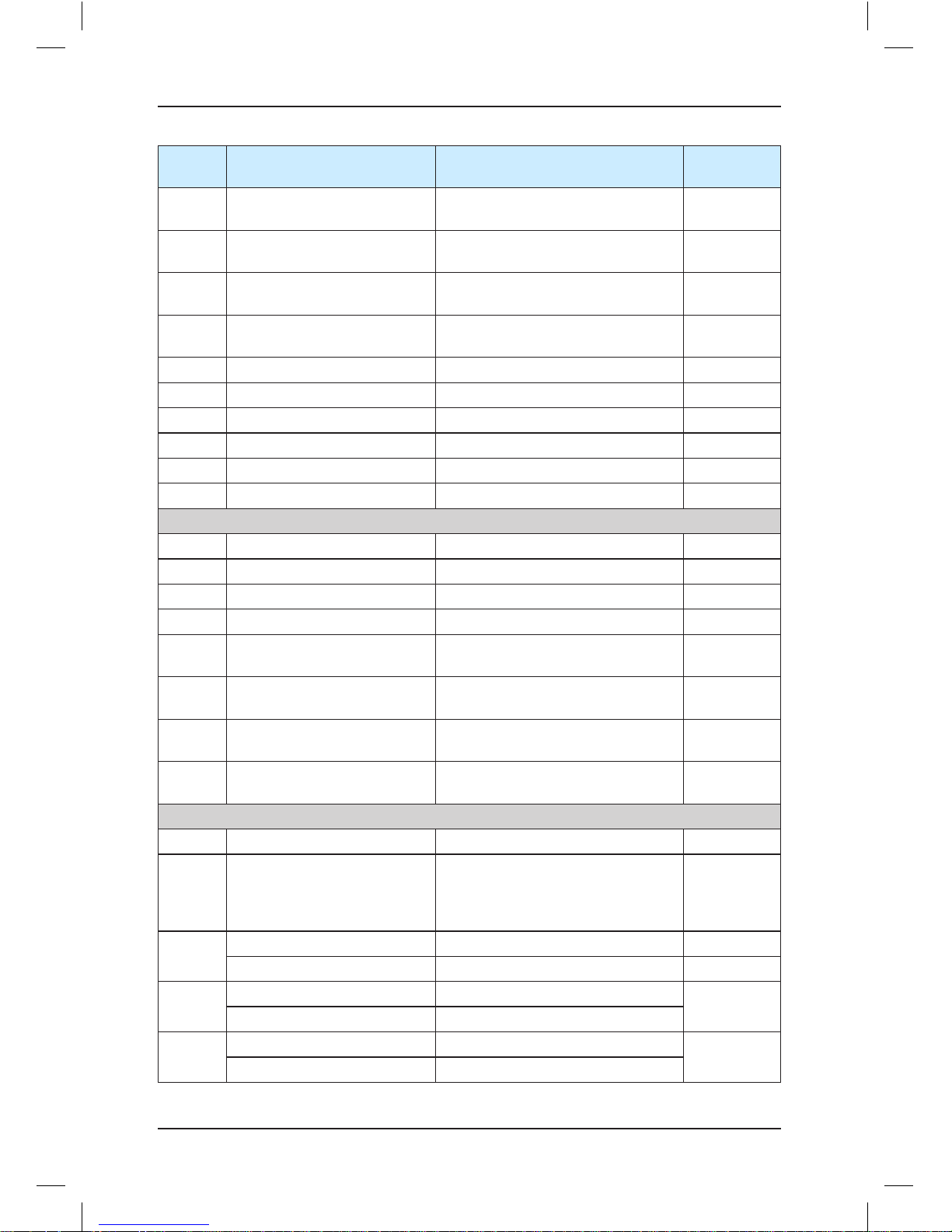

Figure 4-6 Running time sequence

V (speed )

RUN contactor

Brake contactor

Shorting door lock

circuit c ontactor

Shorting motor

stator contac tor

Internal

running status

Leveling signal

RUN contactor

feedback

Brake contactor

feedback

Shorting door lock circuit

contactor feedback

Shorting motor stator

contactor feedback

RUN contactor

Brake contactor

Shorting door lock

circuit c ontactor

Shorting motor

stator contac tor

Internal running status

Leveling signal

RUN contactor feedback

Brake contactor feedback

Shorting door lock circuit

contactor feedback

Shorting motor stator

contactor feedback

F3-18 F3-19 F3-20 F8-11

300 ms

The open time of the brakes varies according to the types and the response time of the

brakes is greatly influenced by the ambient temperature. Too high brake coil temperature

slows the brake responsiveness. Thus, when the riding comfort at startup or stop cannot

be improved by adjusting zero servo or load cell compensation parameters, appropriately

increase F3-19 and F3-20 to check whether the brake release time influences the riding

comfort.

Page 48

Brief NICE3000 Instruction Manual Use of the NICE3000

- 47 -

Function

Code

Parameter Name Setting Range Default

F8-01 Pre-torque selection

0: Pre-torque invalid

1: Load cell pre-torque

compensation

2: Automatic pre-torque

compensation

0

F8-02

Pre-torque offset

Zero servo current coefficient

0.0%–100.0%

0.20%–50.0%

50.0%

15.0%

F8-03

Drive gain

Zero servo speed loop KP

0.00–2.00

0.00–1.00

0.60

0.50

F8-04

Brake gain

Zero servo speed loop TI

0.00–2.00

0.00–2.00

0.60

0.60

1: Load cell pre-torque compensation

The controller with the load cell sensor pre-outputs the torque matched the load so as to

ensure the riding comfort of the elevator.

• Motor driving status: full-load up, no-load down

• Motor braking status: full-load down, no-load up

"Pre-torque offset" is actually the elevator balance coefficient, namely, the percentage of car

load to rated load when the car cage and counterweight are balanced.

The drive gain or brake gain scales the elevator's current pre-torque coefficient when the

motor runs at the drive or brake side. If the gain set is higher, then the calculated value of

startup pro-torque compensation is higher. The controller identifies the braking or driving

state according to the load cell sensor signal and automatically calculates the required

torque compensation value.

When an analog device is used to measure the load, these parameters are used to adjust

the elevator startup. To adjust the startup, do as follows:

• In the driving state, increasing the value of F8-03 could reduce the rollback during the

elevator startup, but a too high value could cause car lurch at start.

• In braking state, increasing the value of F8-04 could reduce the jerk in command

direction during the elevator startup, but a too high value could cause car lurch at start.

2: Automatic pre-torque compensation

This function is enabled only when the ERN1387 or ECN1313 encoder is applied. The

system automatically adjusts the compensated torque at startup.

a. Gradually increase F8-02 (Zero servo current coefficient) until that the rollback or jerk