Page 1

MONARCH INSTRUMENT

Instruction Manual

Data-Chart Data-Chart

Data-Chart

Data-Chart Data-Chart

Paperless Recorder

IMPORTANT!

Please format all floppy disks in

the Recorder prior to use.

Because floppy disks are volatile,

do not use disks for more than

2-3 months. Also, use a floppy

cleaning disk every 4 months to

clean the heads.

®

2000 2000

2000

2000 2000

15 Columbia Drive

Amherst, NH 03031-2334 USA

Phone: (603) 883-3390

Fax: (603) 886-3300

E-mail: support@monarchinstrument.com

Website: www.monarchinstrument.com

Page 2

Page 3

MONARCH INSTRUMENT

Instruction Manual

®

Data-Chart Data-Chart

Data-Chart

Data-Chart Data-Chart

2000 2000

2000

2000 2000

Overview

Chapter 1 .................... General Information

Chapter 2 .................... Installation and Wiring

Chapter 3 .................... Getting Started

Chapter 4 .................... Operation

Chapter 5 .................... Programming

Chapter 6 .................... Calibration

Chapter 7 .................... Get Data Software

Appendix A ................. Configuring a 1-5 Vdc input for a 0-250

psig pressure transducer

Appendix B ................. Configuring a 4-20 mA input to equal

0 to 150 gpm

Appendix C ................. Configuring a J type T/C input for a

100-750° C range

Appendix D ................. Configuring the Totalizer

Warranty

Return Information

Page 4

Page 5

SAFETY NOTICE

This Safety Notice has been included to emphasize the DANGER OF HAZARDOUS VOLTAGES on the

REAR TERMINAL PANEL of your instrument. USE EXTREME CAUTION WHEN INSTALLING OR

SERVICING your instrument. Please read the entire contents of the Installation and Wiring Chapter of

this manual before attempting to install or service your instrument.

WARNING

Use Extreme caution when servicing the rear terminal of your instrument.

Page 6

Page 7

Chapter 1 General Description

Introduction ..................................................................................................................................................... 1-1

1.1 Recorder Description ...............................................................................................................................1-2

1.1.1 Inputs ............................................................................................................................................. 1-2

1.1.2 Instrument Size .............................................................................................................................. 1-2

1.1.3 Menus ............................................................................................................................................ 1-2

1.1.3.1 Display Menu ........................................................................................................................ 1-3

1.1.3.2 Program Menu ...................................................................................................................... 1-3

1.1.3.3 Function Menu ......................................................................................................................1-3

1.1.3.4 Hidden Menu ........................................................................................................................1-3

1.1.4 Memory ..........................................................................................................................................1-3

1.1.5 Clock ..............................................................................................................................................1-3

1.1.6 Recorder Construction ...................................................................................................................1-3

1.2 Recording Options ...................................................................................................................................1-4

1.2.1 Floppy Disk Drive ...........................................................................................................................1-4

1.2.2 PCMCIA Memory Card ................................................................................................................... 1-4

1.2.3 Zip Drive .........................................................................................................................................1-4

1.3 Recorder Options ....................................................................................................................................1-4

1.3.1 Digital Input and Output .................................................................................................................. 1-4

1.3.2 Communications Interface ..............................................................................................................1-4

1.4 Specifications ..........................................................................................................................................1-5

Page 8

Page 9

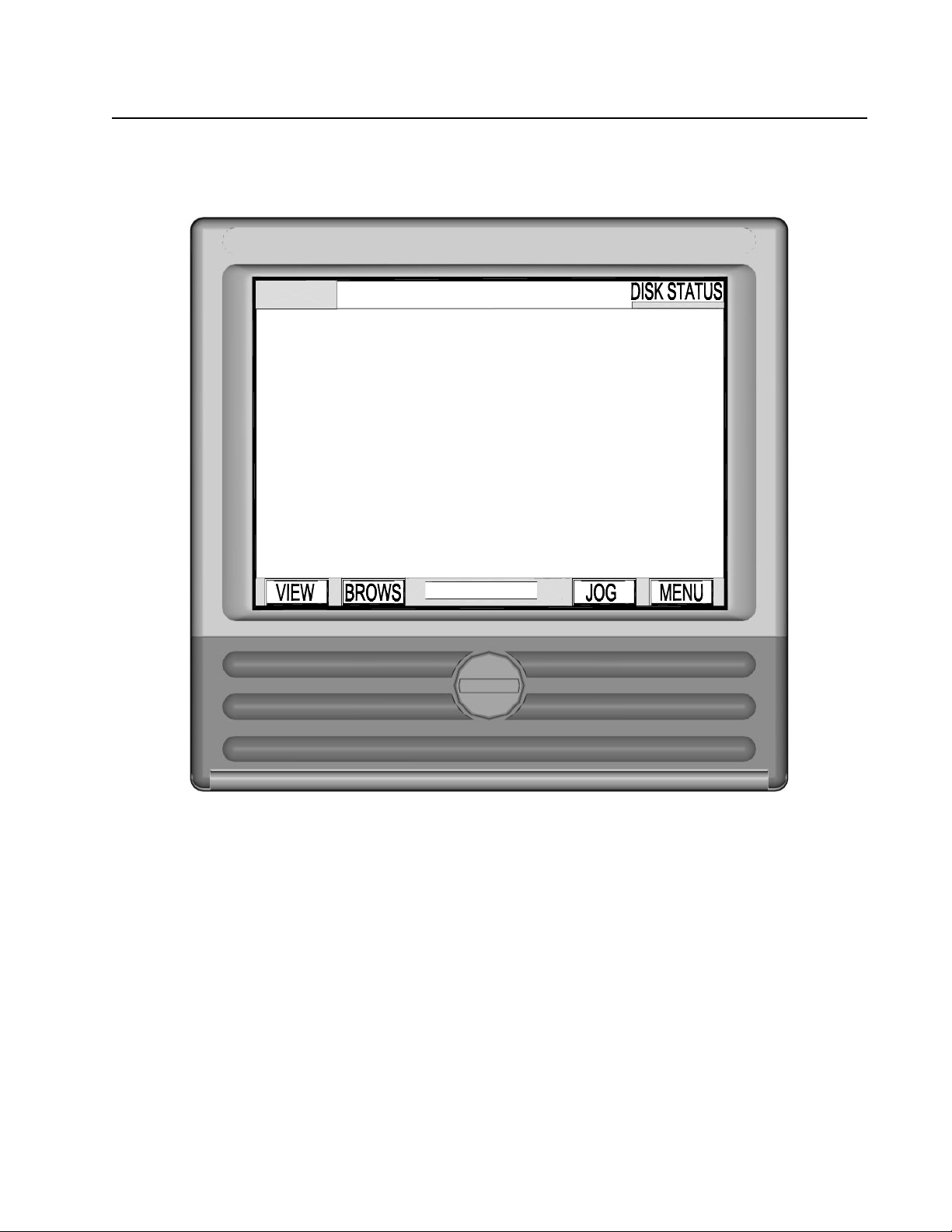

Chapter 1 General Description

CHAPTER 1

STATUS LINE

GRAPHICS AREA

4/17/01 15:52:35

Figure 1-1 Solid State Data Recorder

This manual is a user reference guide for the Solid State Paperless Data Recorder (Figure 1-1). The manual

provides detailed instruction for installation, operation, programming, calibration and maintenance of the instrument.

The recorder is a sophisticated piece of equipment that requires some level of programming before use. The user is

advised to read this manual in its entirety before proceeding with the installation and programming. Refer to Chapter

3, Getting Started for minimum configuration. Step by step instructions for a few sample applications are included

in Appedixes A-D.

Page 1-1

Page 10

Chapter 1 General Description

1.1 Recorder Description

The Solid State Data Recorder is a Paperless Recording instrument. Data is stored on either an internal floppy

disk, a removable PCMCIA memory card or a Zip Drive.

All data is stored in MSDOS format and may be archived or analyzed on any IBM compatible PC running Microsoft

Windows 3.1 or Windows 95/98 using the available Companion Software. The instrument retains all the features of

a traditional Paper Chart Recorder by virtue of its large STN monochrome or TFT color Liquid Crystal Display (LCD)

which presents the data in the traditional chart mode as well as in bar graph or digital numeric form.

The unit has many features and functions which are unique and cannot be performed on traditional paper recorders,

such as data compression and historic data browsing. The recorder is programmed via a touch screen keypad on

the display .

The recorder will measure and process up to six direct inputs, calculated, conditional, or external points for logging,

trending, or data manipulation.

If direct inputs are not desired, the Data Recorder will accept up to fifteen points from a combination of calculated,

conditional, or external point types.

1.1.1 Inputs

Direct input sources may come from voltage, current, dry contacts, thermocouple, or RTD sources. The

voltage and current ranges accepted by the instrument include: ±150 mV , ±1.25 V , ±2.5 V , ±12.5 V, and ±25 V ;

4 to 20 mA, 0 to 20 mA and 10 to 50 mA current. Thermocouple inputs include T ype J,K,T,E,R,S,B,C and N.

RTD inputs accepted include 10 ohm Cu, 100 ohm Platinum, 200 ohm Platinum, 120 ohm Nickel and 1000

ohm Nickel.

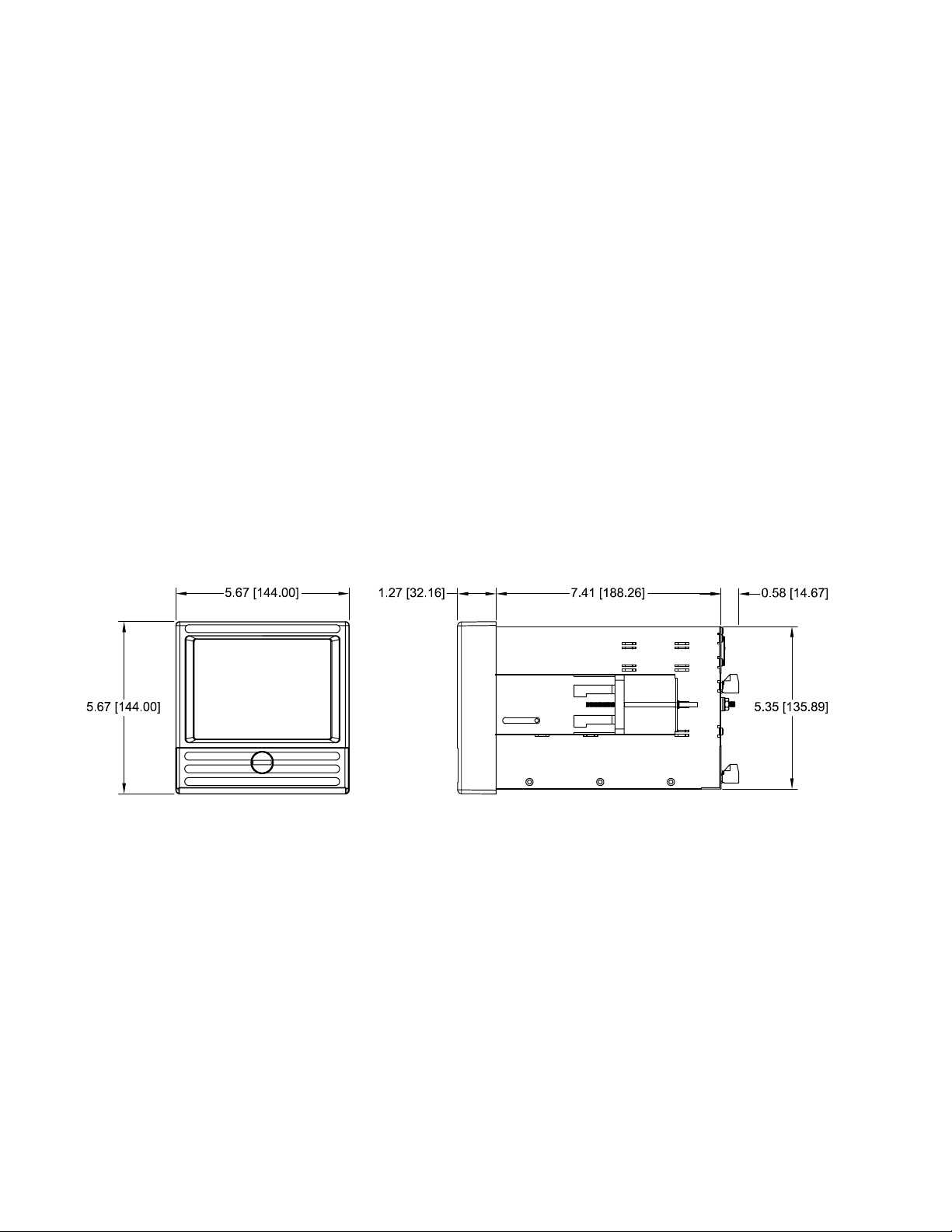

1.1.2 Instrument Size

The instrument is sized to fit in a DIN standard panel cutout of 5.43 inches x 5.43 inches [138 mm x 138 mm]

and requires 7.41 inches [188.2 mm] behind panel depth, not including power and input source cable space

needed. Actual dimensions of the instrument are shown in Figure 2-1 Recorder Dimensions in Chapter 2 of this

manual.

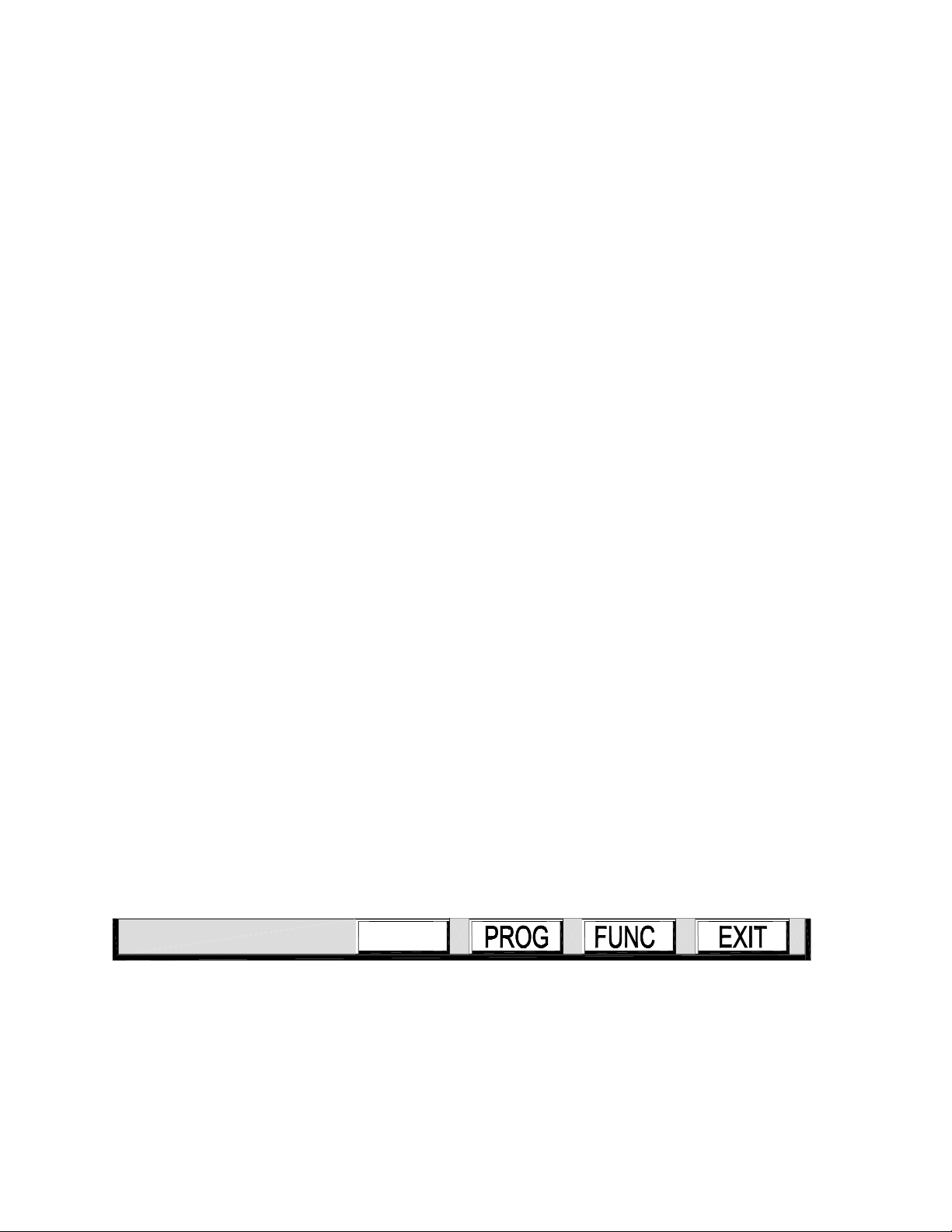

1.1.3 Menus

The instrument’s features are accessed through a series of menus. Press the MENU button displayed in the

bottom right hand corner of the LCD screen. The ST A TUS bar along the top of the screen displays the various

recorder parameters. (Refer to Section 3.1). The Command Button Bar contains three user programming option

buttons - DISPLay , PROGram, and FUNCtion (see Figure 1-2 below). Each menu level features easy-to-follow

prompts that simplify operation.

DISPL

Figure 1-2 The Command Button Bar

Page 1-2

Page 11

Chapter 1 General Description

1.1.3.1 Display Menu

The Display Menu is accessed by pressing the Display button (DISPL) on the Command Button Bar. This

menu allows you to display any programmed point or series of points, or any current alarm or series of

alarms on the STATUS line along the top of the display. The version of operating software can also be

shown in a pop up window.

1.1.3.2 Program Menu

The Program Menu is accessed by pressing the Program button (PROG) on the Command Button Bar.

This Menu item may be passcode protected. The Program Menu allows you to define the system operating

parameters. Menu driven prompts, answered by yes, no or by entering the desired value, enable you to

customize the instrument to meet your application requirements. Refer to Chapter 5 for detailed instructions

on programming.

1.1.3.3 Function Menu

The Function Menu is accessed by pressing the Function button (FUNC) on the Command Button Bar .

This Menu item may be passcode protected. The Function Menu allows you to Activate, Bypass, and/or

Reset a point. This menu also allows you to change between high and low display chart speed or record

speed, turn Alarm Check on or off, and choose Scale Set 1 or 2.

1.1.3.4 Hidden Menu

The Hidden Menu can only be accessed by pressing a certain combination of buttons and may be passcode

protected. This menu allows you to Initialize the recorder, set Passcodes, perform Calibrations and

perform Diagnostics on the recorder. Refer to Chapter 4 for det ailed information.

1.1.4 Memory

All the Random Access Memory (RAM) in the Recorder is battery backed. This enables the unit to recover in

the event of a mains failure with minor data loss. Any programming will be protected in the event of power

removal and past browse data is maintained in the off state. The battery is a Non-rechargeable lithium and will

keep memory intact for at least 12 months.

1.1.5 Clock

A real time clock monitors the time and date in the event of a power loss. It uses the same battery as the

Random Access Memory.

1.1.6 Recorder Construction

The Data Recorder features modular construction. Power Supply and Analog conditioning modules are

conveniently accessible for fast and simple troubleshooting and/or removal. The floppy disk, PCMCIA or Z ip

drive can be accessed through the front of the unit.

Page 1-3

Page 12

Chapter 1 General Description

1.2 Recording Options

The Recorder can be ordered with one of three storage mediums: a standard PC compatible floppy disk drive,

an industry-standard PCMCIA memory card drive, or a Zip drive. The optional Companion Software supports al l

three media types.

1.2.1 Floppy Disk Drive

The Floppy disk drive uses PC compatible 3½ inch (89mm) floppy disks. These disks store 1.44 Megabytes

of data which translates to approximately 700,000 data samples (each sample is 16 bits). The disks are

magnetic media and the drives are mechanical. This limits their use in harsh environments where vibration or

temperature is a problem, but they are convenient as they are very inexpensive and can simply be plugged into

any IBM compatible PC.

1.2.2 PCMCIA Memory Card

The PCMCIA card (Personal Computer Memory Card Interface Association) is a small solid state card

containing Flash memory . The PCMCIA drive supports memory cards up to 200 Megabytes in size which is

approximately 100,000,000 data samples. The cards do require a special drive in your PC which is readily

available, inexpensive and already standard on many laptops and desktop machines. Contact your dealer

for details.

NOTE: It is recommended that a Sandisk 4-200 Meg Flash card be used.

1.2.3 Zip Drive

The Zip Drive stores 100 Megabytes of information which is approximately 50,000,000 samples for a 100

Megabyte Disk. This Recorder does not support 250 Megabyte Zip drives.

1.3 Recorder Options

Additional functions and capabilities can be added to the Recorder and are described in the following paragraphs.

1.3.1 Digital Input and Output

This option provides three or six mechanical form C (Normally Open, Common, Normally Closed contacts)

relay outputs capable of switching 250 V ac as well as three isolated digital control input s, or three or six solid

state open collector type contacts able to switch 30 Vdc at 0.5 Amps. The relay outputs can be programmed

to respond to alarm events while the digital inputs can be used to trigger events such as changing recording

speeds or stopping and starting recording.

1.3.2 Communications Interface

There are two communications options available:

1. An isolated RS232/RS485 interface using the Modbus protocol with the recorder acting as a slave device

in a Modbus RTU or Modbus ASCII environment.

2. An 802.3 compatible Ethernet option with RJ45 four wire connection.

Page 1-4

Page 13

Chapter 1 General Description

1.4 Specifications

OPERATING

Input Signals DC Voltage: Linear, Industrial square root, Logarithmic

Thermocouple: Resolution 0.1°C

RTD: Base accuracy 0.2% or 0.5 °C (1 °F). Resolution 0.1 °C.

Full scale ranges: +150 mV, +1.25 V, +2.5 V Accuracy ±0.06%

±12.5 V, and ±25 V Accuracy ±0.1%

DC Current: 4 to 20 mA, 0 to 20 mA and 10 to 50 mA

Accuracy ±0.15% using external 50 ohm 0.1% shunt

Type Range (°C) Accuracy (°C) Range (°F) Accuracy (°F)

J -210 to -100 °C ±2.5 °C -340 to -150 °F ±5 °F

-100 to 1200 °C ±1.5 °C -150 to 2190 °F ±3 °F

K -270 to -100 °C ±2.5 °C -450 to -150 °F ±5 °F

-100 to 1372 °C ±1.5 °C -150 to 250 °F ±3 °F

T -270 to -100 °C ±2.5 °C -450 to -150 °F ±5 °F

-100 to 400 °C ±1.5 °C -150 to 750 °F ±3 °F

E -270 to -100 °C ±2.5 °C -450 to -150 °F ±5 °F

-100 to 1000 °C ±1.5 °C -150 to 1832 °F ±3 °F

N -270 to -100 °C ±2.5 °C -450 to -150 °F ±5 °F

-100 to 1300 °C ±1.5 °C -150 to 2372 °F ±3 °F

R -50 to 1768 °C ±3 °C -58 to 3200 °F ±6 °F

S -50 to 1768 °C ±3 °C -58 to 3200 °F ±6 °F

B 0 to 1820 °C ±4 °C 32 to 3300 °F ±7 °F

C 0 to 2400 °C ±3 °C 32 to 4350 °F ±6 °F

Reference junction compensation accuracy ±0.5 °C (0 °C to 50 °C)

Thermocouple burnout detection - internal

2, 3 or 4 wire connection. Cable compensation to +50 Ohm

Open and short circuit detection.

10 ohm Cu -70 to 170 °C -94 to 338 °F

100 ohm Pt 385 -220 to 850 °C -364 to 1560 °F

100 ohm Pt 392 -180 to 820 °C -292 to 1500 °F

200 ohm Pt 385 -220 to 400 °C -364 to 750 °F

200 ohm Pt 392 -180 to 400 °C -292 to 750 °F

120 ohm Ni -70 to 300 °C -94 to 570 °F

1000 ohm Ni -60 to 209 °C -76 to 408 °F

Input Resolution 0.0015% of full scale, 16 bit unless otherwise stated

Input Impedance >10 megohms on 150 mV, 1.25 V and 2.5 V Ranges, >100 K on 12.5 V, and 25 V ranges

Input Channels 2, 4, or 6 direct

Maximum Input 50 Vdc

Common Mode Noise Rejection >100 dB, 50/60 Hz

Measurement Rate 8 times per second on all direct input channels

Normal Mode Noise Rejection >50 dB at 50/60 Hz

RECORDING

Recording Rates User programmable from 8 samples per second to 1 sample every 600 seconds (10 Minutes).

Data Storage Capacity Data stored in non-volatile RAM and recorded automatically to on board removable media

Removable Media Types 3½ inch (89mm) floppy disk - approximately 700,000 samples for a 1.44 Megabyte Disk

Isolation 250 Vdc or peak AC channel to channel, 300 Vdc or peak AC to Chassis

Math Functions +, -, x, /, logarithms, totalization, powers, averages, and timers

Channels independently programmed.

Data Format Proprietary binary format. User File naming.

PCMCIA Flash cards - approximately 100,000,000 samples for a 200 Megabyte Card

Zip Disk - approximately 50,000,000 samples for a 100 Megabyte Disk

Internal Media One Megabyte RAM (Non-Volatile)

Two Megabyte RAM (Non-Volatile) - optional

File types Data files, Alarm and Event files, Configuration files, Language Files. Multiple files

of different names on a single disk.

Page 1-5

Page 14

Chapter 1 General Description

DISPLA Y

OTHER

Display Type Mono CCFL backlit STN Liquid Crystal Display (5.0 inch) with touchscreen control.

Resolution Mono 240 (H) X 128 (V) pixels.

Display Type Color CCFL backlit Active Matrix TFT Liquid Crystal Display (5.6 inch) with touchscreen control.

Resolution Color 320 (H) X 240 (V) pixels.

Display Modes Graphics (Trending vertical or horizontal), Bar Graphs (vertical or horizontal), Digital Meter,

Alphanumeric Alarm and Event data or combinations on a split screen. Review trended data.

Virtual Chart Speed Programmable: 0.5 in/hr to 600 in/hr (10 mm/hr to 15,000 mm/hr)

Virtual Chart Scales 2 sets of 8 scales

Display Windows Time/Date, Graphics (Bars, Large Digital, Trends), Disk Status, System Status, Menu Button Bar,

Unit Identification, Alarms/Events.

Power Requirements 100 to 240 Vac, 50/60 Hz. 35 VA max. Optional 24 Vdc + 15%

Power Fail Protection Programmed parameters stored in non-volatile memory. Clock battery backed. Data retention

time without power > 12 months.

Operating Range -10°C to 50°C, 10% to 80% RH (5°C to 40°C for floppy media)

Safety Meets the requirements of UL-3111-1 and EN61010- 1 when installed in accordance with the

instruction in this manual.

UL and cUL approved - File No. E175096

EMC Meets the requirements of EN61326:1998 and CE directive 89/336/EEC

Input Voltage 100 to 240 Vac, 50/60 Hz or 125 Vdc @ 35VA max.

Weight Approx. 7 lbs (3.2 kg) - weight will vary depending on options installed

Page 1-6

Page 15

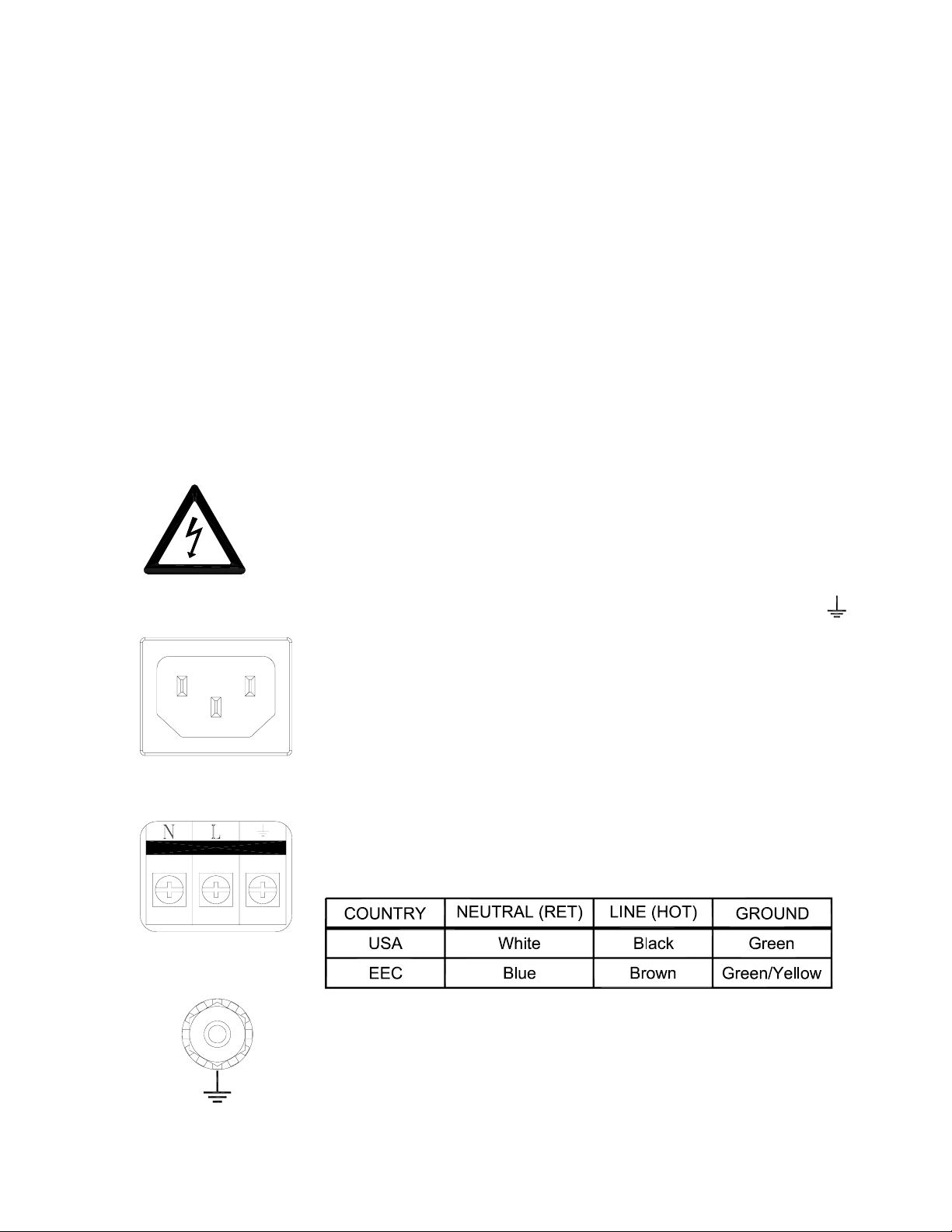

SAFETY NOTICE

This Safety Notice has been included to emphasize the danger of hazardous voltages on the REAR

TERMINAL PANEL of your instrument. USE EXTREME CAUTION WHEN INSTALLING OR

SERVICING your instrument. Please read the entire contents of the Installation and Wiring Chapter

before attempting to install or service your instrument.

ELECTRIC SHOCK HAZARD

WARNING

MAY CAUSE INJURY OR DEATH.

USE EXTREME CAUTION

WHEN INSTALLING OR SERVICING

POWER INPUTS WARNING

When connecting power to the Rear Terminal Panel of your instrument, it is important to ensure that the

AC mains cable has an effective ground and provide a low impedance earth ground connection (Safety

Ground) to the screw terminal on the rear panel labeled “

electrical shock. Power may be exposed on the Rear Terminal Panel and is exposed inside the

instrument case. When wiring, use the supplied AC mains cable or recommended plug, make sure the

HOT wire, or Line 1 is connected to L/H. Make sure the NEUTRAL wire, or Line 2, is connected to N, and

make sure a low impedance SAFETY GROUND wire is connected to “

SIGNAL INPUTS WARNING

Use extreme caution when wiring signal input connections. Hazardous potentials may exist on signal

input terminals, which are floating, with respect to instrument ground. These hazardous potentials may

be exposed inside the instrument case and on the Rear Terminal Panel of your instrument. Any voltage

potential at the signal source will exist on the instrument’s respective signal input terminal: e.g. power

generator stator winding temperature-monitoring thermocouples.

CONTACT OUTPUT TERMINALS WARNING

Use extreme caution when wiring contact output connections. Hazardous potentials may exist on contact

output terminals, which are floating, with respect to instrument ground. These hazardous potentials may

be exposed inside the instrument case and on the Rear Terminal Panel of your instrument. Any voltage

potentials at the contact circuit will exist on the instrument’s respective contact output terminals: e.g. linepowered circuits.

REAR TERMINAL PANEL.

FOLLOW INSTRUCTIONS BELOW.

“ or “GND” to prevent the possibility of

“ or “GND”.

Page 16

Page 17

Chapter 2 Installation/Wiring

2.1 Equipment Handling .................................................................................................................................2-1

2.1.1 Initial Inspection ............................................................................................................................. 2-1

2.1.2 Unpacking Procedure ..................................................................................................................... 2-1

2.1.3 Detected Damage ..........................................................................................................................2-1

2.1.4 Equipment Return ..........................................................................................................................2-1

2.1.5 Storage ..........................................................................................................................................2-1

2.2 Installation ................................................................................................................................................2-2

2.2.1 Panel Mounting ...............................................................................................................................2-3

2.3 Wiring Specifications and Procedures .....................................................................................................2-5

2.3.1 Power Requirements ...................................................................................................................... 2-5

2.3.2 Power Connections ........................................................................................................................ 2-5

2.3.3 Signal Input Wiring .........................................................................................................................2-6

2.3.4 Relay Output, Contact Input ........................................................................................................... 2-8

2.3.4.1 Mechanical Relay Option ...................................................................................................... 2-8

2.3.4.2 Solid State Relay Option .......................................................................................................2-8

2.3.4.3 Opto-isolated Inputs/Outputs ................................................................................................2-8

2.4 Serial Interface Option .............................................................................................................................. 2-9

2.5 Ethernet Option ......................................................................................................................................2-10

2.6 Cleaning .................................................................................................................................................2-10

2.7 Contrast Adjust (Monochrome Only) ....................................................................................................... 2-10

Page 18

Page 19

Chapter 2 Installation and Wiring

CHAPTER 2

This chapter provides information and procedures on installing and wiring the Recorder. Included are handling

procedures, installation and wiring specifications, and instructions for both standard and optional equipment.

2.1 Equipment Handling

2.1.1 Initial Inspection

Exercise care when unpacking the instrument from the shipping carton. The instrument is packed in a

shock-proof foam retainer to prevent damage during normal transit. If damage to the shipping carton is evident,

ask the carrier’s representative to be present when the instrument is unpacked.

2.1.2 Unpacking Procedure

To unpack your Recorder, first remove the foam retainer and instrument from the shipping carton. Then,

carefully remove the instrument from the foam retainer.

2.1.3 Detected Damage

If damage is detected after unpacking the instrument, re-pack the instrument and return it to the factory as

described in the following section.

2.1.4 Equipment Return

Before returning a damaged or malfunctioning instrument to the factory for repairs, contact the sales organization from which you purchased the instrument. A Return Merchandise Authorization number must be obtained

from the factory before returning an instrument for any reason.

2.1.5 Storage

For prolonged storage before installation, re-pack the Recorder in the shipping container. Cushion the

Recorder with foam molding or an equivalent and store in a cool, dry area. We do not recommend storage of

the Recorder for more than one year. If longer storage time is required, contact the factory for additional

storage information.

Page 2-1

Page 20

Chapter 2 Installation and Wiring

2.2 Installation

The instrument is intended to operate in the following environment:

Indoor Use Only

Installation Category II per IEC 664

Pollution Degree Level II per UL3111-1/IEC1010-1

Temperature 5° C to 40° C per UL3111-1/IEC1010-1 with disk drive

-10° C to 50° C with PCMCIA drive or Zip drive

Humidity 10% to 80% RH per UL3111-1/IEC1010-1

AC Mains Supply 100 - 240 Vac ~ 50/60 Hz 35 Vac

NOTE: The recorder is designed to be panel mounted and as such should be considered as permanently

connected. Disconnection from the supply must be possible via a customer supplied switch or circuit

breaker. This disconnection device must be included in the panel installation and should be clearly

marked, in close proximity to the Recorder and easily accessible to the operator.

The Recorder is sized to fit in a standard DIN panel cutout of 5.43” x 5.43” [138 mm x 138 mm] and requires 7.41”

[188.2 mm] behind panel depth not including power and input source cable space needed. Actual dimensions are

shown in Figure 2-1.

Figure 2-1 Recorder Dimensions in Inches [mm]

WARNING: Do not use this instrument in any manner inconsistent with these operating

instructions or under any conditions that exceed the environmental

specifications stated.

Page 2-2

Page 21

Chapter 2 Installation and Wiring

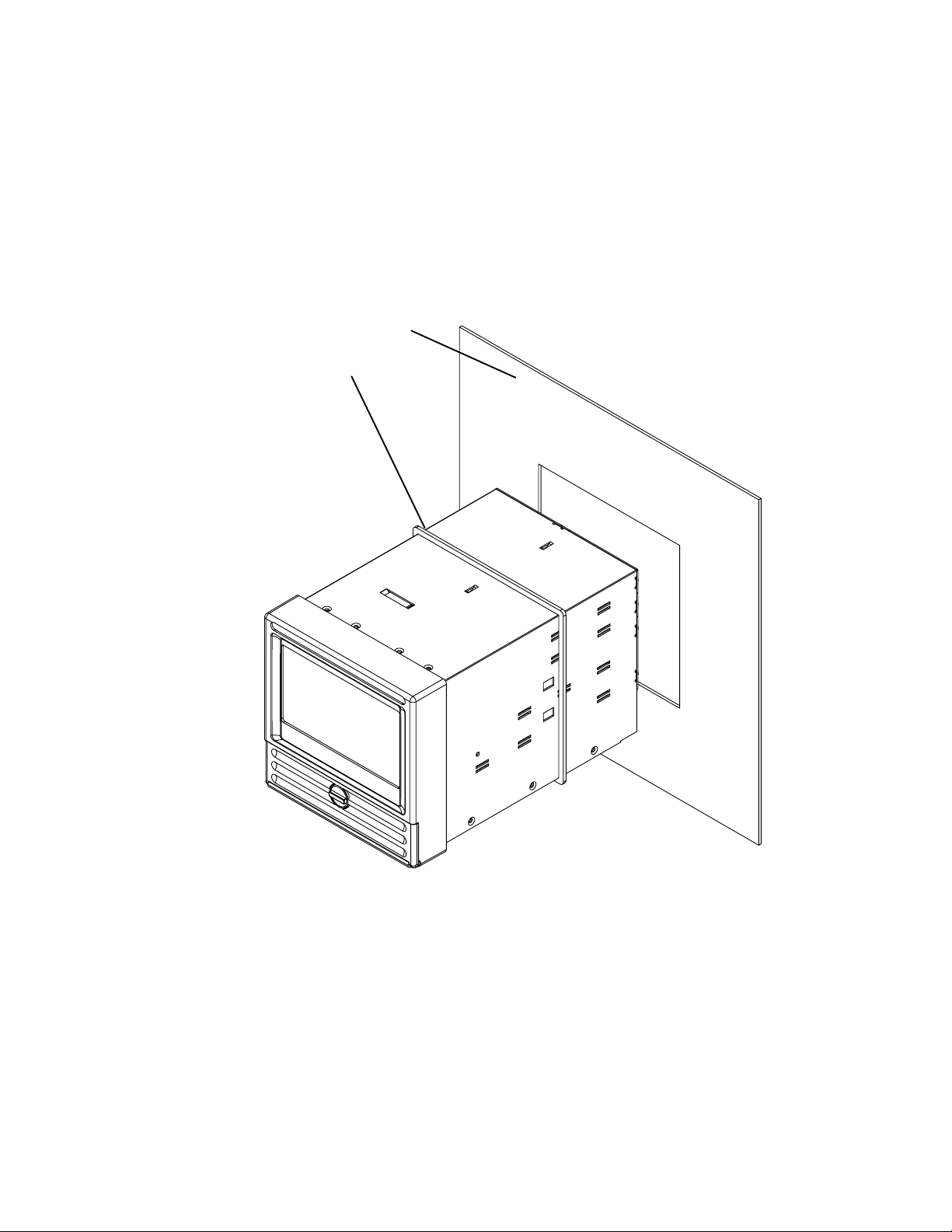

2.2.1 Panel Mounting

The Recorder should be mounted in a vertical panel to ensure proper operation. Ensure you have the proper

clearances and proceed as follows:

2.2.1.1 Cut a panel opening 5.43” x 5.43” [138 mm x 138 mm].

2.2.1.2 Remove any packaging material from the Recorder. Always handle the unit carefully to avoid

damaging the LCD display or scratching the display surface.

Front Panel

Gasket

Figure 2-2 Front Panel Insertion

2.2.1.3 Remove the locking bars from the Recorder enclosure and ensure the gasket is not twisted on the

enclosure.

2.2.1.4 Insert the Recorder rear end first, into the panel opening from the front of the panel. Ensure the

gasket is between the front bezel of the Recorder and the front panel.

Page 2-3

Page 22

Chapter 2 Installation and Wiring

2.2.1.5 With the Recorder held firmly in place against the panel, install one of the locking bar assemblies

by sliding the locking bar notch into the slot on the side of the Data Chart enclosure.

Rear of Panel

Locking Bar Assembly

Screw

Figure 2-3 Rear View Panel Installation

2.2.1.6 Using a slotted screwdriver, tighten the screw until the locking bar is just pressing against the

panel.

2.2.1.7 Install the other locking bar assembly into the slot on the opposite side of the Recorder enclosure

and tighten as before.

2.2.1.8 Using the screwdriver, tighten both screws so that the Recorder is held firmly in place. Do not over

tighten.

Page 2-4

Page 23

Chapter 2 Installation and Wiring

2.3 Wiring Specifications and Procedures

2.3.1 Power Requirements

The Recorder operates on any voltage from 100 to 240 Vac +10%, 50/60 Hz enabling it to be used in most

countries. The maximum apparent power required by the unit is 35 VA.

2.3.2 Power Connections

NOTE: The recorder is designed to be panel mounted and as such should be considered as

permanently connected. Disconnection from the supply must be possible via a customer supplied switch

or circuit breaker. This disconnection device must be included in the panel installation and should be

clearly marked, in close proximity to the Recorder and easily accessible to the operator.

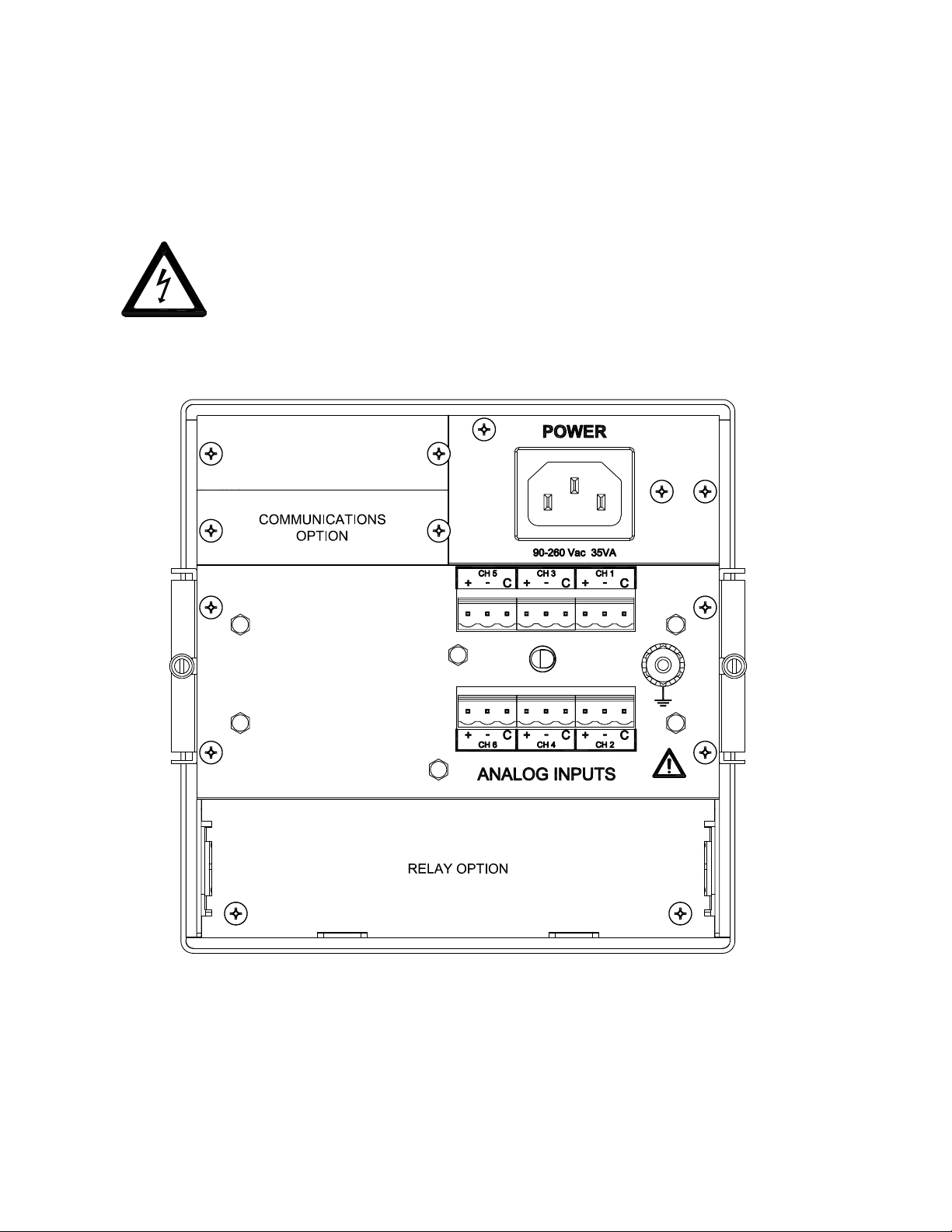

All connections to the Recorder are made to the Rear Terminal Panel. Any wiring carrying hazardous voltages

must conform to all applicable local and national safety codes. AC Mains connection is via an internationally

accepted IEC 320 AC mains connector or screw terminal (Figure 2-4 and Figure 2-5).

WARNING

Ensure all mains power is turned off before proceeding with installation. This unit

is provided with a mating connector for the ac power socket or with a compatible

three wire grounded cable which may be terminated with a plug. Always ensure

the ground wire (green or green and yellow) or ground pin of the plug, is connected

to a low impedance safety ground (earth) within the ac power distribution system

you are using. Always use the recommended mating connector and an approved

three wire cable to connect this unit to the ac mains. Always provide a low

impedance safety ground wire to the ground lug on the rear panel marked .

Figure 2-4

AC Connector

Figure 2-5

Screw Terminal

Figure 2-4 shows the IEC 320 AC mains connector on the rear of the Recorder. The

center pin is the ground termination. If a mating plug is provided, it will be marked

with the Ground, LINE (L) or hot, and NEUTRAL (N) or return. In the United

States, an approved cable with integral plug (NEMA 5-15 P) is provided. In some

instances, a cable with no plug may be provided. In this instance, the user must

connect an approved plug to the cable prior to connecting to the AC source.

Figure 2-5 shows the screw terminal power connections on the rear of the Recorder.

The right terminal is ground, the center terminal is LINE (L) or hot and the left terminal

is NEUTRAL (N) or return. The wire color codes are as follows:

Figure 2-5a shows the ground lug on the rear panel. This screw terminal must be

connected to an earth wire which in turn is connected to the ground or earth of the

AC power distrubution system.

Figure 2-5a

Ground Lug

Page 2-5

Page 24

Chapter 2 Installation and Wiring

This unit is equipped with an AC mains fuse internally. If this fuse should blow, it generally indicates a serious

problem with the Recorder. THE FUSE SHOULD NOT BE REPLACED BY AN OPERATOR. The fuse is a

quick acting 5 x 20mm type rated at 2.0 Amps 250 VAC (~).

An optional AC mains plug retention clip is available - contact the factory.

2.3.3 Signal Input Wiring

Signal input connections. Hazardous potentials may exist on signal input terminals

which are floating with respect to case ground. These hazardous potentials may be

on the rear terminal panel of your instrument. Any voltage potential at the signal

source will exist on the instrument’s respective signal input terminal (i.e. power

generator stator winding).

Figure 2-6 DC2000 Rear Panel Connections

Page 2-6

Page 25

Chapter 2 Installation and Wiring

The Recorder accepts up to six direct inputs. Input connection is via plug in screw terminal connectors on the

rear panel. Inputs can be mixed in any combination of thermocouple, RTD, milliamps, millivolts, volts or contact

inputs. There is a common ground lug marked with a

Read the following procedures prior to connecting inputs to the terminals.

WARNING: Ensure the power is off before connecting signal inputs to the unit.

The plug in screw terminal connectors are of the clamping screw variety, putting even pressure on the signal

wire. It is therefore not necessary to terminate the wires with lugs, however you may do so if you wish. The

maximum gauge wire that can be accommodated is 14 AWG or 2.5 mm². You will need a small screwdriver and

a pair of wire cutters and strippers. The use of shielded twisted lead wire is recommended to minimize electromagnetically induced noise.

WARNING: All unused inputs must have all contacts commoned togther.

CAUTION: Never run signal and power or control wiring together in the same conduit. This is to

prevent possible recording error due to induced signals between lines. Route signal

wires away from power wires at the rear panel.

NOTE: Ground cable shields at one end only to eliminate the possibility of interference due to

ground loop currents. When grounded transducers are used, the shield should be grounded

at the sensor end only.

for connection of signal cable shields or screens.

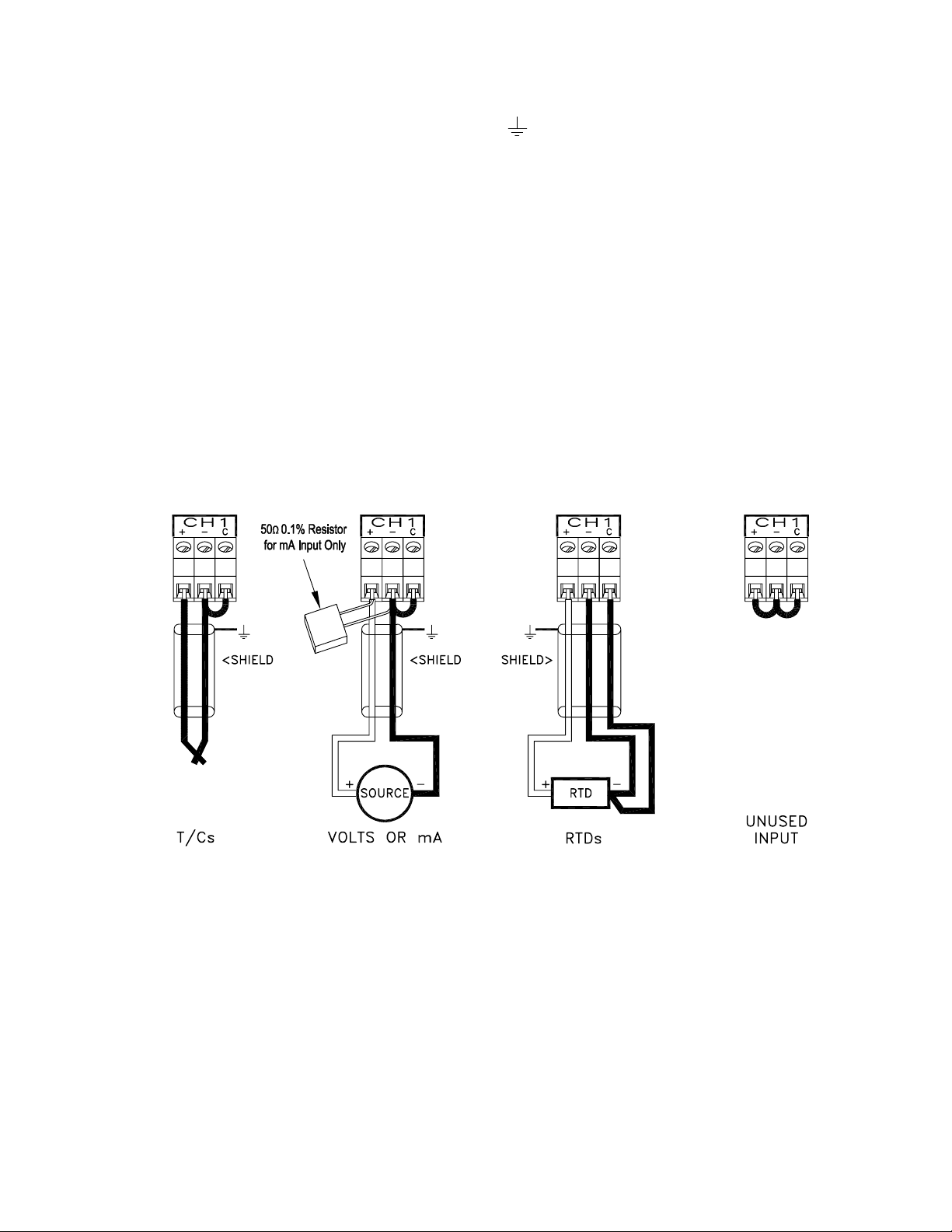

Figure 2-7 Thermocouple, RTD and Linear Inputs

2.3.3.1 Thermocouple Inputs

Thermocouple input connections are made as shown in Figure 2-7 T/Cs. Note that a link must be installed

between the “-” terminal and “C” terminal.

2.3.3.2 Resistance Temperature Detector (RTD) Inputs

Two, three or four wire RTDs may be used for connection with cable compensation of ±50 ohms. Refer to

Figure 2-7 and manufacturing specifications.

2.3.3.3 Linear Inputs

Current inputs: 4-20 milliamps, 0-20 milliamps and 10-50 milliamps, using an external 50 ohm shunt.

Voltage inputs: ±150 millivolts, ±1.25 volts, ±2.5 volts, ±12.5 volts, ±25 volts and normally open/closed

contact inputs. Note that a link must be installed between the “-” terminal and “C” terminal. Refer to Figure

2-7 for details.

Page 2-7

Page 26

Chapter 2 Installation and Wiring

2.3.4 Relay Output, Contact Input

WARNING

To prevent the possibiltiy of electrical shock, use extreme caution when wiring

contact output connections. Hazardous potentials may exist on contact output

terminals which are floating with respect to instrument ground. These hazardous

potentials may be exposed on the rear terminal panel of your instrument. Any

voltage potentials at the contact circuit will exist on the instrument’s respective

contact output terminals (i.e. line-powered circuits).

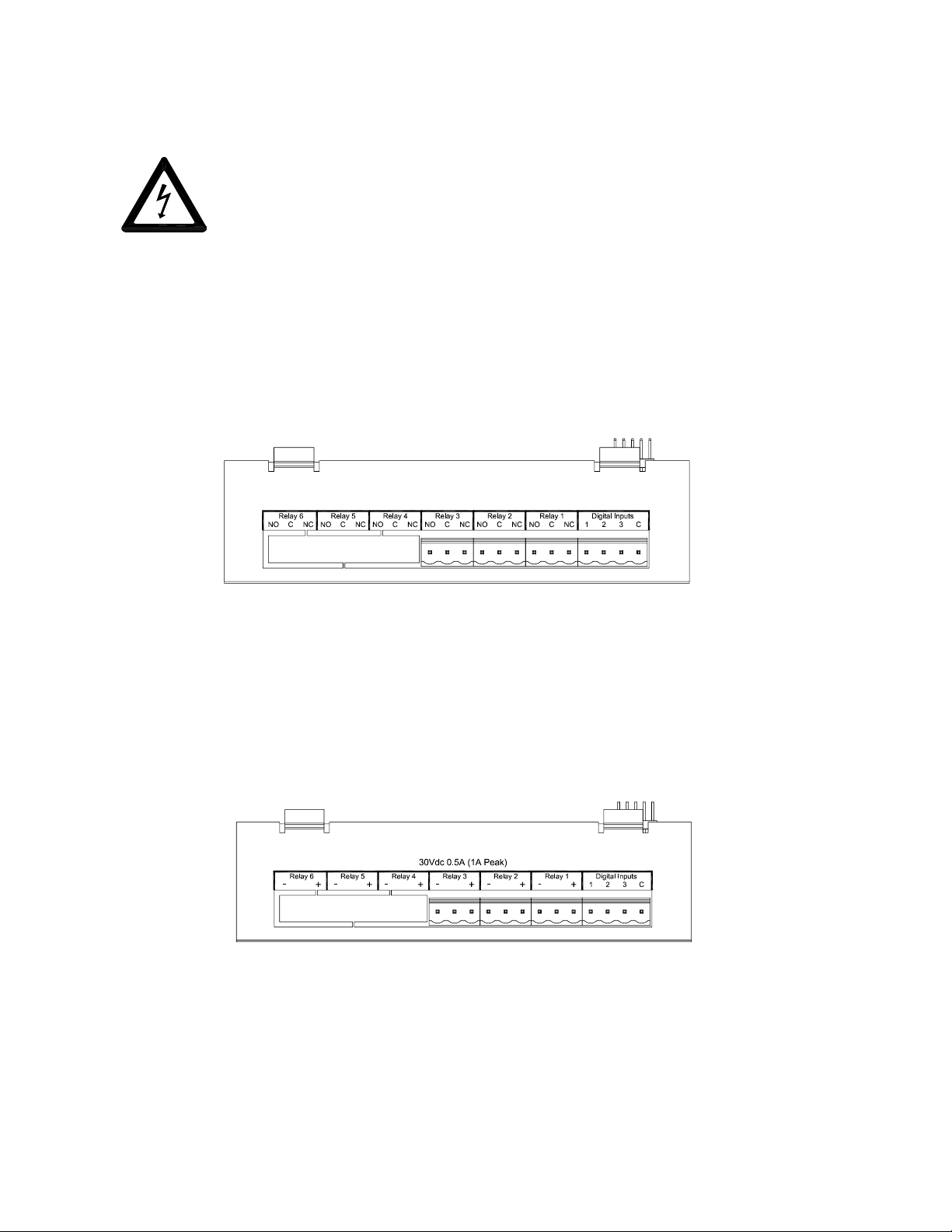

2.3.4.1 Mechanical Relay Option

The Recorder may be equipped with an optional Digital Input Output Board which has three or six potential

free Form C relay contacts and three opto-isolated digital inputs. A terminal block as shown in Figure 2-8

below, is provided for the three alarm output Potential Free Form C connections: Normally Open (NO),

Common (C), and Normally Closed (NC), and the three digital inputs which share a common. The relay

contacts are capable of switching 125 Vac ~ at 0.5 Amp or 30 Vdc at 2 Amps. The potential free relay

contacts are protected internally with 300 volt Metal Oxide Varistors (MOVs) to prevent contact arcing.

Figure 2-8 Mechanical Relay Connections (3 Channel Shown)

2.3.4.2 Solid State Relay Option

The Recorder may be equipped with an optional Digital Input Output Board which has three or six solid

state open collector outputs and three opto-isolated digital inputs. A terminal block as shown in Figure

2-9 below, is provided for the alarm output connections. The output connections are polarized and are

intended for DC operation only. Reverse polarity protection is provided and each output is fused at 1 Amp.

The fuse is solid state and will reverse once the load is removed. The outputs are rated at 30 VDC at 0.5

Amp and are optically isolated from the recorder.

Figure 2-9 Solid State Relay Connections (3 Channel Shown)

2.3.4.3 Opto-isolated Inputs/Outputs

The opto-isolated inputs require an external potential of 5 to 12 volts DC @ 10 milliAmps. The three inputs

are isolated from the unit, but not from each other as they share a common. The positive voltage connects

to the terminals marked 1, 2 or 3 and the common connects to the terminal marked C. It is possible to use

potential free contacts to operate the digital inputs. This requires opening the unit and setting jumpers on

the relay board. Refer to Appendix A for details.

Page 2-8

Page 27

Chapter 2 Installation and Wiring

2.4 Serial Interface Option

Data can be accessed to download Configuration files or Data files using the RS232C option and a modem. The

RS485 option allows the Recorder to be installed into an existing Modbus network or it can be used to connect up

to thirty-one recorders in series. A standard DB9 Female connector is required for the RS232 to connect to an IBM

PC compatible computer using a null modem cable and the RS232 can support cable runs up to 50 feet [16 m]. The

RS485 connection is via two wire (twisted pair) cable (a DB9 Female connector is required) and can support cable

runs up to 4000 feet [1300 m].

The Serial Interface contains an isolated switching unit for RS232 and RS485 access with a standard DB9 Female

connector. When switch 2 is in the ON position, RS485 is enabled. When switch 2 is in the OFF position, RS232

is enabled.

When more than one recorder are connected in a series, it is necessary to apply a termination resistor on the last

recorder. Switch 1 in the ON position applies this necessary termination resistor and should be switched to the ON

position only on the last recorder in series.

SW1

On=485 Term.

12

ON

SW2

On=RS485

Off=RS232

Figure 2-10 RS232/RS485 Modbus

All Serial Interface connections are made through the DB9 female connector.

The RS232 Connection to the DB9 female connector are as follows:

DB9 PIN CONNECTION DIRECTION

2 RxD Receive Data In

3 TxD Transmit Data Out

4 DTR Data Terminal Ready Out

5 Common N/A

7 RTS Request To Send Out

8 CTS Clear to Send In

The RS485 (Half Duplex Mode) Connection to the DB9 female connector are as follows:

DB9 PIN CONNECTION DIRECTION

6 A- Negative Input/Output

9 B+ Positive Input/Output

Page 2-9

Page 28

Chapter 2 Installation and Wiring

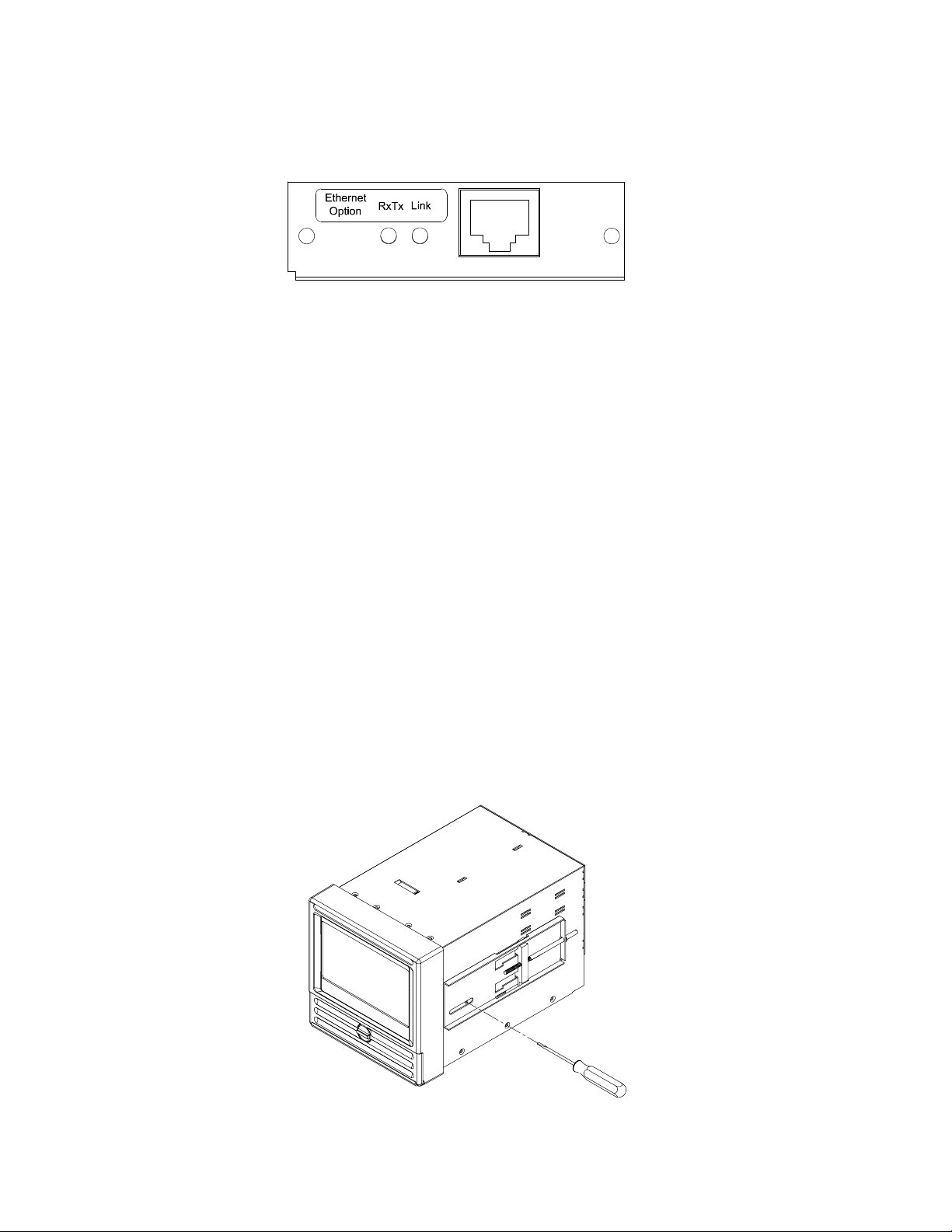

2.5 Ethernet Option

The 10BaseT Ethernet option allows direct connection to a LAN or WAN and the standard TCP/IP protocol enables

the transfer of data over the Internet.

Figure 2-11 Ethernet Option

The RJ45 Connection for the Ethernet are as follows:

Receive Differential Pair

3 RX6 RX+

Transmit Differential Pair

7 TX8 TX+

Two LEDs on the rear panel show Ethernet activity. The Link LED indicates a good connection and the RxTx LED

indicates communication activity.

2.6 Cleaning

The unit may be cleaned by wiping with a soft cloth. The front panel and display / keypad may be wiped with a

slightly damp soft cloth containing soapy solution or a mild detergent. Do not use any lemon based (citric acid)

product to clean the display / keypad.

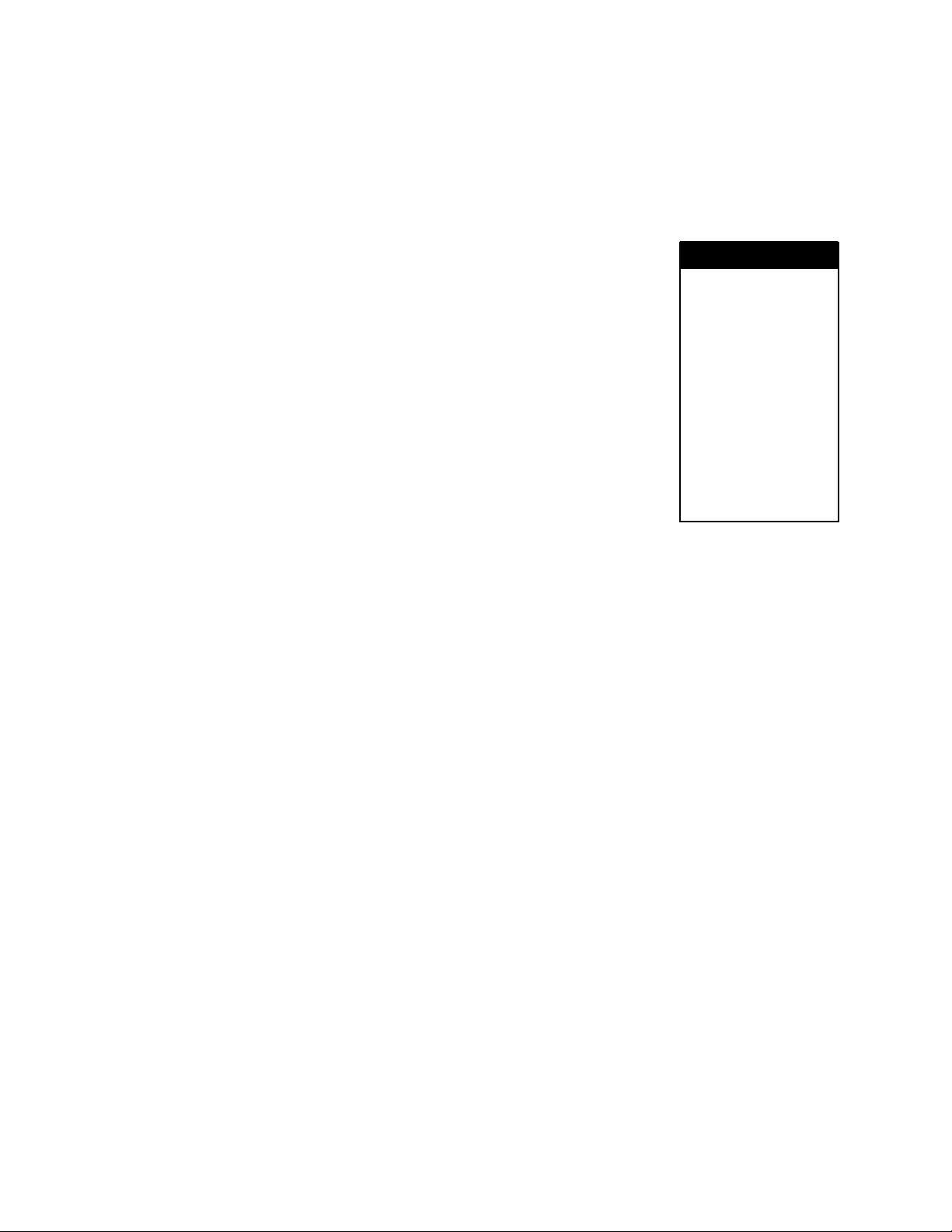

2.7 Contrast Adjust (Monochrome Only)

The contrast or viewing angle of the monochrome LCD display can be adjusted from the side panel. If not

adjusted correctly, the display may look dim, dirty, completely black, washed out or blank. Insert a small star or

Phillip type screwdriver into the hole in the side panel as shown in Figure 2-12 and turn to adjust the display

contrast. The adjustment potentiometer has a 270° rotation. Do not apply excess pressure or attempt to

turn it beyond the end stops.

Figure 2-12 Contrast Adjust

Page 2-10

Page 29

Chapter 3 Getting Started

3.1 Moving About the Screen .........................................................................................................................3-1

3.2 What the Screens Mean ........................................................................................................................... 3-3

3.2.1 Status Line ...................................................................................................................................... 3-3

3.2.2 Disk Status ......................................................................................................................................3-3

3.2.3 Button Bar ....................................................................................................................................... 3-4

3.2.4 Date/Time Window .......................................................................................................................... 3-4

3.2.5 Graphics Window ............................................................................................................................ 3-4

3.2.5.1 Bar Charts.............................................................................................................................. 3-4

3.2.5.2 Digital Windows .....................................................................................................................3-5

3.2.5.3 Alarm/Events Data Window ...................................................................................................3-5

3.2.5.4 Trend Window ........................................................................................................................3-6

3.2.5.5 Transient Windows ................................................................................................................3-7

3.3 Browsing, Compressing and Searching Data ........................................................................................... 3-7

3.3.1 Compressing Data ..........................................................................................................................3-7

3.3.2 Searching Data By Time ................................................................................................................. 3-8

3.3.3 Searching Data By Value ................................................................................................................3-8

3.3.4 Interactive Browse ........................................................................................................................... 3-9

3.3.5 File Browsing ................................................................................................................................... 3-9

3.4 Getting to the Points ............................................................................................................................... 3-11

3.5 Using Chart Scales .................................................................................................................................3-12

3.6 Programming .......................................................................................................................................... 3-13

3.7 Programming Time and Date .................................................................................................................. 3-13

3.8 Programming Points ............................................................................................................................... 3-14

3.8.1 Point tag .......................................................................................................................................3-14

3.8.2 Input Scale ................................................................................................................................... 3-14

3.8.3 Output Scale ................................................................................................................................3-15

3.8.4 Engineering Units .........................................................................................................................3-15

3.8.5 Chart Scale ..................................................................................................................................3-15

3.8.6 Alarms .......................................................................................................................................... 3-15

3.9 Programming Point Scales .....................................................................................................................3-15

3.9.1 Programming Scales ....................................................................................................................3-15

3.9.1.1 Scale Ends .......................................................................................................................... 3-16

3.9.1.2 Scale Units .......................................................................................................................... 3-16

3.10 Recording Data .................................................................................................................................... 3-16

3.10.1 Using the Recorder to format a floppy/zip disk or PCMCIA card ................................................3-17

3.10.2 Selecting the Record Mode ........................................................................................................ 3-17

3.10.2.1 Fill to End ..........................................................................................................................3-17

3.10.2.2 Cyclic ................................................................................................................................3-17

3.10.2.3 Average or Instantaneous Recording ................................................................................3-17

Page 30

3.10.3 Programming the unit for recording ............................................................................................ 3-18

3.10.3.1 Set the record mode ......................................................................................................... 3-18

3.10.3.2 Points ............................................................................................................................... 3-18

3.10.3.3 Record Rate ...................................................................................................................... 3-18

3.11 Hot-Swap ............................................................................................................................................. 3-19

3.12 Changing File Names ..........................................................................................................................3-19

3.13 Setting the Disk Full Alarm ................................................................................................................... 3-19

3.14 Loading and Saving Configuration Files ............................................................................................... 3-20

Page 31

Chapter 3 Getting Started

The Instrument is an extremely versatile solid state data recorder . It has a liquid crystal display capable of complex

graphical representation and either a floppy disk drive, Zip drive or PCMCIA Memory Card for data storage. The unit

is easily programmable and the average user will probably never need to use most of the features or functions

available in the recorder . This chapter will give the user a brief system overview and guide the first-time user

into a simplified setup which will enable you to begin recording with the least amount of effort.

3.1 Moving About the Screen

The Recorder has an LCD Graphics Screen that also acts as a touch keypad. Areas of the screen are active as

push buttons, the exact areas which are sensitive depends on what is currently displayed. The user has only to

lightly touch the screen area depicting the button to activate the function. If the buzzer is turned on, the unit will

provide audible feedback, as a short beep, each time a “button” press is registered. The default display is shown in

Figure 3-1 below.

STATUS LINE

GRAPHICS AREA

4/17/01 15:52:35

Figure 3-1 Recorder Screen

The screen is divided into three distinct areas, the BUTTON BAR, along the bottom of the screen (containing the

time / date stamp), the ST A TUS LINE, across the top of the screen, and the GRAPHICS AREA between the them.

Under normal operating modes, when not in a menu, the BUTTON BAR area is active for “Button” pressing. The

MENU button on the bottom right of the screen, will bring up the command menu button bar, see below, which

allows the user to do a number of functions and select the option of programming the unit. Refer to Chapters 4 and

5 for details.

DISPL

Figure 3-2 The Command Menu Button Bar

Page 3-1

Page 32

Chapter 3 Getting Started

The VIEW button is on the lower left side of the screen, and it enables the user to scroll through the selectable

display options in the graphics area of the screen. These views might be charts, bar graphs, digital or alarm

information. Each time the “button” is pressed, the next view is presented. The Graphics display can be either a full

screen of information, or the screen can be split, allowing combinations of the primary screens to be displayed. The

user can also choose whether the screen is horizontally or vertically oriented.

The area along the top of the display is the Status Bar or Status Line, and it is used to display a number of user

programmed functions such as the unit tag (identification) or the digital values of the various channels or alarm

status. On the right hand side of the Status Line is the disk status information (disk info). This displays the

current condition of the disk that is currently being used to save data. When the unit is not recording, this area

shows REC OFF. When Recording it displays REC

the slow rate, as well as XX% used, where XX is the amount of disk space already recorded. The default display

is set using the DISPL option on the Command Menu button bar. The JOG button is used to switch between

channel data.

To the left of the St atus Line is the position of the ACK button (not shown). This is the Alarm ACKnowledge and

is only present when there is an alarm condition, at which time it blinks until the user presses it to acknowledge

the alarm condition. Pressing the Acknowledge button will also reset any output relays if this option is installed and

programmed. Note that the ACK button will always be the top most button, always rising to the surface when

covered by other items such as menus. The user can thus acknowledge an alarm at any time, even while in the

programming mode.

↑↑

↑ when recording at the fast rate or REC

↑↑

↓↓

↓ when recording at

↓↓

As the user moves through the menu options, more or fewer buttons will be shown. The key buttons are always

displayed on the button bar along the bottom of the display . ENTER and EXIT buttons are always in the same place

on the button bar allowing rapid movement through menus.

The BROWSe button is only displayed on screen views that can actually be browsed. These are the full Chart

Screen and the full Alarm Status Screen. The user can choose to browse RAM (Random Access Memory) which

is the screen trace data, or File, in which case a file menu will be presented so that the user can choose a file from

the disk. The BROWS button also allows the user to SEARCH historic data either by TIME or V ALUE, as well as

COMPRESS data in time.

Pressing the BROWS button puts a freeze on real time display and allows the user to scroll back in time to

browse through historical data that has passed off the screen or has been recorded previously, even on another

machine. The actual Chart Screen browse buffer is dependent on the memory options installed, the number of

traces being displayed and the effective chart speed. With the standard buffer, a chart speed of one inch per

hour with four traces active, it is possible to browse back around 140 hours (5½ days). The user may choose to

browse files on the disk rather than the current memory buffer even though the unit is currently recording. The

user can then browse files that had been recorded earlier, or may even browse the file that is currently being

recorded. Once the data has been recorded to disk, it is possible to use the file browser or the PC and the

companion software to view data as far back as the start of recording, irrespective of how long that may be,

within the constraints of disk capacity.

Page 3-2

Page 33

Chapter 3 Getting Started

3.2 What the Screens Mean

The basic screen layout is shown in Figure 3-3 below. Each area is used to present different information to the user .

3.2.1 Status Line

STATUS LINE

GRAPHICS AREA

4/17/01 15:52:35

Figure 3-3 Basic Screen Layout

The Point information is displayed on the Status line as “ Point No. Value Units” as shown:

The Alarm information is shown on the S t atus line as “Point No. V alue Alarm T ype/Number” where H1 is High Alarm #1. There are 5 possible alarms per channel, H = High, L= Low R = Rate.

If more than one alarm is active they will cycle on the Status Line.

If there are no alarms active the Status Line will show -

The St atus Line is used to show the Unit Tag, Point information, rear terminal Junction Temperature or Alarm information.

The choice as to what is transiently displayed is set in the

DISPL menu (Chapter 4.2.1) or the user can set the default

display for this line in the “PROGram - Display - Powerup disp”

menu (Chapter 5.4.3). At any time the user can press the JOG

button to display point data on the Status line. Each time JOG

is pressed the next point data will be shown. The data can be

set to auto jog from the “PROGram - Display - Powerup disp

- Autojog” menu (Chapter 5.4.3.2).

1 0.496 VOLTS

NO ALARMS

1 0.496 HI

The Unit T ag is shown on the S tatus Line and may be up to 20 characters long. It is entered from the “PROGram Display - Powerup disp - Unit T ag” menu (Chapter 5.4.3.1) and displays as entered -

This is a UNIT T AG

3.2.2 Disk Status

The area in the top right corner marked DISK ST A TUS is used to show Disk S t atus. The following messages

may appear in this area:

OFF 15% Unit is not recording to disk. Record Mode is OFF - Disk is 15% full.

↑↑

REC

↑ 15% Unit is recording to Disk in HIGH speed mode - Disk is 15% full.

↑↑

↓↓

REC

↓ 75% Unit is recording to Disk in LOW speed mode - Disk is 75% full

↓↓

FORMAT Disk is being Formatted

SAVE CFG Saving Configuration to Disk

LOAD CFG Loading Configuration from Disk

TRIG 75% Unit is waiting for an Event or Alarm to turn the Record Mode on - Disk is

75% full.

Page 3-3

Page 34

Chapter 3 Getting Started

3.2.3 Button Bar

The Button Bar is the area across the bottom of the screen where the main menu buttons appear. The function

of these buttons varies according to which mode is selected for the unit. Figure 3-3 shows the Normal mode

button layout.

3.2.4 Date/Time Window

The Date /Time window sits at the bottom of the screen in the Button Bar and continuously shows the current

date and time. Date is shown numerically in either American Month/Day/Year or European Day/Month/Year

format. The format is selected in the “PROGram - Display - Time format” menu (Chapter 5.4.2)

3.2.5 Graphics Window

The graphics window is used to display various information in different formats. The VIEW button is used

to switch between the various graphic displays which can be Trend Charts, Bar Graphs, Digital Windows

or Alarm/Event data, or combinations of these. Furthermore the graphics can be horizontally or vertically

oriented. The orientation is selected in the “PROGram - Chart/Pens - Direction” menu (Chapter 5.5.4)

3.2.5.1 Bar Charts

Bar graphs can be displayed on their own or as part of a split screen. Up to

twelve can be displayed at a time. The user can select to display bar graphs

either horizontally or vertically . The assignment s of points to bar graphs is made

in the “PROGram - Display - Bar assign” menu (Chapter 5.4.4). The format of

the vertical bar graph is shown opposite in Figure 3-4. The very top of the bar

has the actual/real time digital value of the point, in this case 0.385. Immediately

below this is the Engineering Units shown as ENG UNITS. There can be a

maximum of five characters. At the very bottom of the bar graph is the POINT

T AG. This is a ten character description of the point.

Figure 3-4 Bar Chart

NOTE: Not all characters can be displayed on the bar graph.

Between the ENG UNITS and POINT TAG is a bar that represents the actual

value as a function of the full scale value. To the right of the bar are scale values.

The alarm setpoints, if any are set, are indicated on the bar by a “ W “ in the text

area. If any alarm is active, the bar will be blinking. The Engineering Units, Point

Tag, alarm setpoints and scaling of the bar is done in the “PROGram - Points”

menu (Chapter 5.6)

Page 3-4

Page 35

Chapter 3 Getting Started

3.2.5.2 Digital Windows

Figure 3-5 Digital Window

3.2.5.3 Alarm/Events Data Window

Digital Windows can be displayed on their own or as part of

a split screen. Up to twelve can be displayed at a time. The

assignment of points to digital windows is made in the

“PROGram - Display - Digital assign” menu (Chapter 5.4.5).

The format of the digital window is shown opposite in Figure 3-5. The large numbers in the center of the window are

the real time point value. Above this point value is the Point

T ag shown as POINT TAG. This is a ten character description of the point. Below the point value is the Engineering

Units shown as ENG UNITS. There can be a maximum of

five characters. The Engineering Units, Point Tag, and scaling of the digital value is done in the “PROGram - Points”

menu (Section 5.6).

Alarms/Events Data Log

Alarm Checks On

Date Time Point Status Value

07/20 13:10:37 POWER UP

07/28 14:58:56 Pt 1 HIGH1 0.504

07/28 14:52:09 Pt 1 * 0.492

07/28 14:51:33 Pt 5 FALSE 0.000

07/28 14:45:00 Pt 6 HI Reset 17.427

07/28 14:35:27 Pt 6 Hi Peak 23.568

07/28 14:40:15 Pt 1 HIGH1 0.504

07/28 14:22:56 Sw 1 CLOSE

07/29 07:34:28 POWER DOWN

Figure 3-6 Alarm/Event Window

The format for any entry in the Alarm/Event file is - Date T ime Point S tatus V alue. The Point value is

shown as Pt X, where X is the point number. The Value shown is dependent on the Event. The Event can be

an Alarm, an input cont act closure (event) or a reset, either automatic or manual.

For linear inputs, the alarm event description is HIGH1 or LOW2, where the number is the alarm count up

to a maximum of 5. For conditional inputs, the alarm event descriptions are OPEN, CLOSE, TRUE or

FALSE. The value is the actual value at the time the alarm was registered. An event message of “*” is an

alarm return to normal condition, the time the point came out of alarm.

The alarm/event window is used to display

alarms, events, reset, power up and power

down information. This data may also be

recorded to disk by enabling Alarm data

in the “PROGram - Disk functions - Alarm

on/off” menu. (Chapter 5.7.2).

The second line of the display indicates the

status of the alarm checking. If alarm checking is enabled this will indicate ‘Alarm Check

On’ or it will indicate ‘Alarm Check Off’ in

which case no alarms will occur.

The state of alarm checking is changed in

the “FUNCtion - Alarm Check” menu (Chapter 4.2.3.7).

Resettable points, such as totalizers, will show the event as RESET, with the actual value at the time of

reset. Some Resettable point types, such as HI PEAK will have two entries (Pt 6 above). The first entry is

the date and time that the high peak occurred, with the peak value, the second entry , above it, is the actual

time the reset occurred, with the value at that time. Note: Resettable points will not print unless the Reset

Print option is turned on in the “PROGram - Points” menu (Section 5.6)

For external events via the digital inputs, the user can define separate messages for each of the three

inputs, one for input activated (Close) and one for input deactivated (Open). These event messages

can be entered, up to a maximum of ten characters, in the “PROGram - Digital I/O - Event msgs” menu

(Chapter 5.9.3). This message will appear in the log as - date - time - Switch number (Sw X) - Event

message. Default event messages are CLOSE and OPEN as seen in the data log example above.

Page 3-5

Page 36

Chapter 3 Getting Started

3.2.5.4 Trend Window

The trend window is the one that looks like a “paper” recorder. It has traces or pens and emulates the p aper

chart, moving the “paper” across the screen, and is shown in the vertical mode in Figure 3-7 below. The

direction of the trending can be vertical, from top to bottom, or horizontal, from right to left. The direction

can be changed in the “PROGram - Chart/Pens - Direction” menu (Chapter 5.5.4). There may be as many

as twelve pens on the chart at a given time. Pens are assigned to the chart in the “PROGram - Chart/Pens

- Pens” menu (Chapter 5.5.3).

Consider the vertical chart below, the same features are found on the horizont al chart. Along the top of the

chart are the pen pointers, one for each pen that is on. These track the real time value of the points and

identify the origin of the trace.

S S

Figure 3-7 Vertical Trend Window

There are grids on the screen, both horizontal and vertical. In the above example, the vertical grid spacing is a

function of the divisions on the chart scales. The horizontal grid lines indicate the scales for the chart, and if

there is more than one scale set, they alternate. On the full screen trend view, the scales can be toggled through

by pressing the middle of the scale (top center of the display). Each scale has its end points marked along the

top of the chart with the scale value, the 0.00 and 1.00 indicating that the trace has a value of zero when it is

hard to the left, and 1.00 when it is hard to the right. There is a marker on top of the pen pointers to indicate

which pens reference the current scale. Thus when interpreting the data for pens 1 and 2 use a value of 0 to

1.00 full scale. When the scale changes, so will the markers on the pen pointers to indicate the pens for the

next scale. Also along the top of the chart are the scale UNITS.

Page 3-6

Page 37

Chapter 3 Getting Started

3.2.5.5 Transient W indows

Transient windows are those that appear momentarily . They pop

up over any existing window to inform the user of a problem

or of a background task being completed. They require a user

response, normally pressing the “OK?” button, to acknowledge

the message.

Figure 3-8 Transient Window

3.3 Browsing, Compressing and Searching Data

Once at the full trend screen (using the VIEW button), the user can choose to browse, search or compress either

data from the disk, including the file currently being recorded to disk, or immediate past data which is buffered to

memory (RAM). The operation of browsing is the same whether the user is browsing memory or file data. When

BROWS is pressed a new button bar is presented with three buttons, FILE , RAM and EXIT as shown in Figure 39 below.

4/17/01 15:52:35

Figure 3-9 The Browse Source Button Bar

Select FILE to browse prerecorded files on the disk, RAM to browse Trend data from memory , or EXIT to return to

the real time view.

Browsing allows the user to view historic data of the pens currently trending on the display or saved on the disk,

without affecting any real time data acquisition. Alarm data can also be browsed from memory by selecting BROWS

on the full view Alarm window . See section 3.3.5 for the added step required to browse from disk.

On the Trend screen, pressing BROWS brings up the Browse Source button bar . Press RAM to browse memory or

FILE to browse from disk. This brings up the Browse Mode Button Bar shown below (Figure 3-10).

Figure 3-10 The Browse Mode Button Bar

The FINDV and the FINDT buttons initiate the SEARCH functions. FINDV is FIND by

Time. The “ÎÍ“ and “ÍΔ are to COMPRESS and EXPAND data respectively. BROWS enters the interac-

tive Browse Screen and EXIT returns to the prior screen.

V alue, FINDT is to FIND by

3.3.1 Compressing Data

The data on the screen may be compressed up to 32 times the normal view , this enables long term trends to

be seen on a single screen. Each time the “ÎÍ“ (Compress) button is pressed the data is compressed by a

factor of 2, and it may require a short time for the recorder to process the data. Five presses give the maximum

32 times compression. The data may be expanded back by pressing the “ÍΔ (Expand) button. The user can

enter the interactive browse mode with any level of compression by simply pressing the BROWS button.

Page 3-7

Page 38

Chapter 3 Getting Started

3.3.2 Searching Data By Time

The historic data can be searched by time, by pressing the FINDT (FIND Time) button. This will bring up a

transient window showing the time to be searched. If the displayed time is correct press ENTER, if not press

NO. This will bring up a series of windows to allow the required time to be entered. The Date will then be

displayed. Press NO to change or ENTER to accept. The data will be searched and the sample corresponding to the required time and date will be placed under the cursor near the center of the screen. The search

may take some time, especially if searching a large disk file. If no point is found the unit will display “No

Point Found”. The user can then enter the interactive browse mode by pressing the BROWS button.

3.3.3 Searching Data By Value

The historic data can be searched by value, by pressing the FINDV (FIND Value) button. This will bring up

the Search V alue button bar shown in Figure 3-1 1 below.

Figure 3-11 The Search Value Button Bar

T o set up the actual Value to search for, press the VALUE button. Use the numeric keypad to enter the value

to search for. Note that you cannot search for an exact match, you will be looking for a value immediately

greater than or less than the value you enter. Once you have entered the value you want, press the ENTER

button.

Before you begin a search, you have to decide which PEN or point to use as the search reference, and which

direction to search in.

Use the PEN button to select the pen trace to search. Each time this button is pressed, the next pen is

selected. The current pen is shown in the status line at the top of the screen, together with the value of the

trace under the cursor and its actual time and date stamp.

The search direction is determined by the button to the left of the PEN button. This button toggles between

BACK and FWD. BACK will search BACKWARDS in time from the current cursor position (into older data),

while FWD will search FORWARDS in time from the current cursor position (into newer data).

To initiate a search press either the FIND> button to find the first point GREA TER than the search value, or

FIND< to find the first point LESS than the current search value. Each time either of these buttons is

pressed, the next point that meets the search criteria is found. Note that once a point is found, the next point

to be found will be the one that is after the first point that does not meet the criteria. The search “hops”

across all other values so that you are not bogged down finding useless information. Therefore if you are

searching for a point on a sine wave, for example, you will find the same point on the same phase of the

wave (360° apart). Otherwise you would find every point less than or greater than the search point which

could be every point in the trend.

The point that meets the search criteria will be placed under the cursor near the center of the screen. The

search may take some time, especially if searching a large disk file. If no point is found the unit will display

“No Point Found”. The user can continue to search for other points in the same direction or change direction

and search again. Once an acceptable point is found, the user can enter the interactive browse mode by

first pressing the EXIT button to return to the Browse mode button bar and then pressing the BROWS button.

Page 3-8

Page 39

Chapter 3 Getting Started

3.3.4 Interactive Browse

The interactive browse mode enables the user to uniquely identify points on the screen by time, date and value,

and move around in time. Once the Browse source has been selected, FILE or RAM, pressing the BROWS

button again, immediately or after a search or compress operation, will enter the Interactive Browse mode, and

the Browse Button Bar shown in Figure 3-12 below will appear.

Figure 3-12 The Browse Button Bar

The cursor appears near the center of the screen. It can be moved with the UP Arrow and the Down Arrow keys

in the Vertical mode, or with the Lef t Arrow and the Right Arrow keys in the Horizont al mode. Pressing these

keys a single time, moves the cursor one sample at a time, holding these keys will cause the cursor to move

in 10 sample increments. As the cursor moves, the time and date information is updated in the status window

at the top of the screen. T o move about more speedily , the PAGE- and PAGE+ buttons move the data forward

or backward an entire screen at a time.

When browsing graphics, the Status Bar at the top of the screen shows the Date and Time stamp and actual

value for the trace data directly under the cursor . Note that if you are browsing Memory there will be an “M” in

07/27/96 17:03:06 point 1: 0.318 Volt s F

the right hand corner of this line or if browsing Files, there will be an “F” as follows:

T o see the actual pen data value press the PEN button to toggle the dat a through each trace if more than one

trace is displayed. As the data is toggled, the traces for all pens but the selected one, disappear. Press EXIT

to return to real time viewing from the RAM browser or to the directory from the FILE browser.

3.3.5 File Browsing

File Browsing can be done at any time, note however that if you are browsing from disk while recording,

there may be delays in retrieving data from the disk as writing to disk has priority over reading from disk.

Press BROWS to bring up the Browse Select Button Bar and choose FILE, to browse files from the disk.

Note: Ensure that a disk is present and that it has suitable files or you will get an error message.

Once FILE has been pressed the unit will check the disk then bring up a directory . If there is more than one

file per point, the files for that point will be displayed one under the other with an “<” indicating the current

file selected as shown below. The list will scroll if it is longer than what will fit on the screen.

Page 3-9

Page 40

Chapter 3 Getting Started

File Directory

Point: 1

BATCH1 .DT1<

BATCH2 .DT1

BA TCH3 .DT1

If only one file is available per point, the directory selection will default to that file, if no files are available for that

point, the directory will indicate “No Files Found”. Use the POINT button to select the point you want.

Once you have the directory listing of files for the specific point, use the

keys to select the file you wish to browse, indicated by the “<” mark. Press the ENTER button to browse the

selected file. Once the file is loaded, it is browsed, compressed or searched in the same manner as the

memory browser described above. Press EXIT to select a different file or EXIT again to return to real time

viewing.

This space intentionally left blank.

ÏÏ

Ï (UP Arrow) and

ÏÏ

ÐÐ

Ð (Down Arrow)

ÐÐ

Page 3-10

Page 41

Chapter 3 Getting Started

3.4 Getting to the Points

The Instrument is a 15 point recorder of which up to 6 channels may be direct or real world inputs. These are

typically voltages or currents. Any channel not being used to record or display live inputs may be used as a

computational channel. Inputs can be conditioned or scaled to display any range of engineering units. Refer to

Figure 3-13 below.

Figure 3-13 Data Flow

There are four distinct levels of data handling, namely conversion, conditioning, scaling and display/record. Conversion applies only to live inputs and is the process of converting real world analog signals into a 16-bit digital value

that can be used by the Recorder. There are five full-scale ranges for all conversions, 150 milliVolt s, 1.25 V , 2.5 V ,

12.5 V , 25V , and DC. The converted values p ass to a conditioning block which converts the binary value which is

effectively a percentage of full scale, into a value useful to the user. Conditioning includes converting the binary

value into a representative voltage, conditioning and linearizing this voltage to represent for example, a real world

temperature as might be input by a thermocouple or RTD, and applying any other computation as required. The

conditioning block handles 15 channels. The outputs from the conditioning block are referred to as base points

and may be fed back to the inputs of the conditioning block to form the basis (base point) for other base point

computations. This includes tracking peak or valley values, doing moving averages, timed averages, difference,

totalization or any other user-entered equation.

Page 3-11

Page 42

Chapter 3 Getting Started

The input to any channel in the conditioning block can be any one of the base points, or it can be the live inputs.

Live inputs can have input and output scaling applied in the conditioning block unless this is predefined by the

nature of the input, i.e., thermocouples. An example of input/output scaling is given in section 3.5.

The outputs of the conditioning block are also the values represented in the Digital Windows and are real-world

engineering values. The outputs of the conditioning block are also fed through to a scale block where a chart

scale is applied to each point. The chart scales determine what part of the full scale range will be used by the

display/record block. There are two sets of 8 scales available to the user . The second set is an alternate set which

can be applied to the base points in place of the normal set when triggered by an external event. Each chart scale

may be applied to any one or more of the base points to provide an output scaled point. These scale points are

then applied to the display/record block which consists of the visual information or recorded information that the

user requires. Up to twelve scaled points are applied to the bar graph display . Up to twelve may be displayed on the

chart and up to fifteen may be recorded to disk. Note that points recorded to disk need not be the same as points

displayed on the bar graph or the chart, however, in the case of the chart, any point which is not recorded to disk will

have limited browse capability . The user should also be aware that applying scaling other than full scale output to

recorded data, limits the data to the range between scale endpoints. It is possible to store the base point with

different scaling than is used to display it on the chart using one of the computational channels.

3.5 Using Chart Scales

T o better understand the use of input and output scaling, and how scaling base points af fects the data, consider the

following example, highlighted by Figure 3-14.

Figure 3-14 Scaling Example

Assume the user wants to record the output from a pressure transducer which gives a 0 to 5 volt DC output signal.

This coincides to a pressure of 0 to 3000 pounds per square inch (PSI). The process being monitored typically runs

at 2200 PSI ±10%, this is the area of interest. The output of the transducer which peaks at 5 volts is connected to