Page 1

MONARCH INSTRUMENT

Instruction Manual

© Monarch Instrument 2002 all rights reserved

1071-8031-410

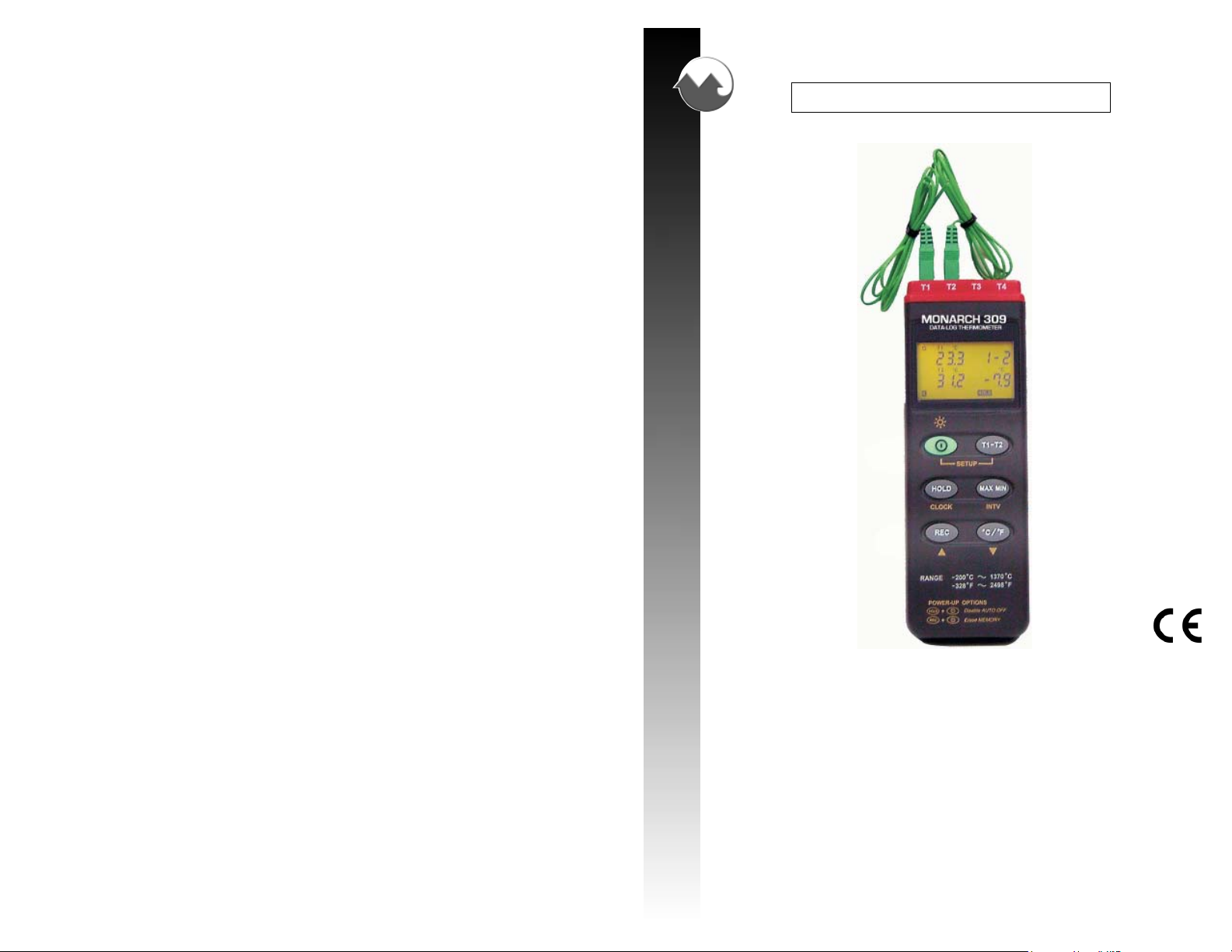

Monarch 309

Datalogging Four Channel Thermometer

15 Columbia Drive

Amherst, NH 03031-2334 USA

Phone: (603) 883-3390

Fax: (603) 886-3300

E-mail: support@monarchinstrument.com

Website: www.monarchinstrument.com

Page 2

Safeguards and Precautions

1. Read and follow all instructions in this manual

carefully, and retain this manual for future reference.

2. Do not use this instrument in any manner inconsistent

with these operating instructions or under any

conditions that exceed the environmental

specifications stated.

3. Making measurements of high or low temperature can

be dangerous. Keep the hand holding the temperature

probe well away from the object being measured.

4. This instrument is not user serviceable. For technical

assistance, contact the sales organization from which

you purchased the product or Monarch

Instrument directly.

LIMITED WARRANTY

SELLER warrants hardware products to be free from any defect in materials or workmanship

for a period of one (1) year from date of shipment to BUYER. SELLER’s entire liability and

BUYER’s sole and exclusive remedy resulting from any defect in workmanship or material

in the hardware product covered by this limited warranty shall be limited to and fully

discharged by the SELLER’s option of replacement or repair of such item without charge.

The limited warranty provided in this clause is in lieu of all other warranties, expressed or

implied, arising by law or otherwise. ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE EXCLUDED. This limited warranty

shall not be modified except by an arrangement signed by both parties specifically

referencing this clause.

SELLER warrants that any software supplied will operate in accordance with the

documentation or manual supplied therewith in all material respects when used in strict

compliance with such documentation or manual. Notwithstanding the foregoing, BUYER

acknowledges that, since software is complex and therefore may have defects, BUYER’s

sole and exclusive remedy for any such defects or breach of this warranty shall be to

require SELLER, within a reasonable period of time, to provide all reasonable programming

services to correct programming errors in the software. Except as provided above SELLER

MAKES AND BUYER RECEIVES FROM SELLER NO EXPRESS OR IMPLIED WARRANTIES

OF ANY KIND WITH RESPECT TO ALL OR ANY PORTION OF SOFTWARE AND BUYER

HEREBY AGREES AND ACKNOWLEDGES THAT IT ACCEPTS THE SOFTWARE IN ‘AS IS’

CONDITION. SELLER HEREBY EXPRESSLY EXCLUDES ANY IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO

THE SOFTWARE. BUYER agrees that any specific right or remedy granted to BUYER

hereunder with respect to any breach or default by SELLER shall be in lieu of all other

rights and remedies otherwise available to BUYER at law or in equity as the result of such

breach or default, regardless of whether based on contract, tort, strict liability, or other

theory of liability.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL,

CONSEQUENTIAL, OR PUNITIVE LOSSES OR DAMAGES (INCLUDING, BUT NOT

LIMITED TO, LOSSES OR DAMAGES FOR ANY LOST PROFITS OR LOST DATA) AS THE

RESULT OF ANY BREACH OR DEFAULT BY SELLER WITH RESPECT TO THE HARDWARE

OR SOFTWARE, EVEN IF SELLER HAS BEEN ADVISED OR MADE AWARE OF THE

POSSIBILITY OF ANY SUCH LOSSES OR DAMAGES AND REGARDLESS OF WHETHER

THE CLAIM IS BASED ON CONTRACT, TORT, STRICT LIABILITY, OR OTHER THEORY OF

LIABILITY.

This limited warranty does not extend or apply to consumables (including, but not limited

to, lamps and batteries, if applicable) or equipment, instruments or accessories which are

warranted separately by the original manufacturer of these items.

Page 3

DECLARATION OF CONFORMITY

Monarch Instrument

Division of Monarch International Inc.

15 Columbia Drive, Amherst NH 03031 USA

declares that the product:

Name: Thermometer, Four Channel, Type K

Model: Monarch 309

to which this declaration relates is in conformity with the following standards:

EMC: EN55022/1998, CISPR 22, Class B

EN50082-1/1997 / EN61000-4

and therefore conforms in accordance with 89/336/EEC-EMC Directive. The

testing of this product was performed by GesTek EMC Lab. in April of 2001.

(Ref. No. 0103105E).

MODEL 309 FOUR CHANNEL DATALOGGING THERMOMETER

Table of Contents

Section Page

1.0 Introduction

.................................................................................................................

2.0 Specifications

............................................................................................................

3.0 Symbol Definitions and Feature Locations

4.0 Operating Instructions

4.1 Preparation for Measurement .....................................................................................3

4.2 Power and Backlight....................................................................................................

4.3 Selecting the Temperature Scale ...............................................................................

4.4 Data-Hold Operation ....................................................................................................

4.5 T1-T2 Operation ...........................................................................................................3

4.6 Clock Setup ..................................................................................................................

4.7 Recording Interval Setup ............................................................................................

4.8 Recording Data ............................................................................................................

4.9 MAX/MIN Operation .....................................................................................................

4.10 Auto Power Off .............................................................................................................

4.11 Low Battery Condition.................................................................................................

4.12 Calibration ....................................................................................................................

4.13 Digital Output ...............................................................................................................

........................................................................................

Appendix: Thermocouple Probe Specifications

5.0

Setup TestLink - RS232 Interface Software

........................................

............................

......................................

1

1

2

3

3

3

3

3

3

4

4

4

4

4

4

5

5

3rd May 2001

Importer (Amherst, NH) Alan Woolfson, VP Engineering (Authorized Signature)

Page 4

MODEL 309 FOUR CHANNEL DATALOGGING THERMOMETER

1.0 Introduction:

This instrument is a four channel, recording digital thermometer for use with any Type K

thermocouple as temperature sensor. Temperature indication complies with the NIST and

IEC584 temperature/voltage tables for Type K thermocouples. Its internal memory can store

up to 16312 records per channel in any number of recording intervals. It is equipped with a

RS232 interface for bi-directional communication with a PC.

2.0 Specifications:

Measurement Range: -200°C - 1370°C -328°F - 2498°F

Accuracy: (At ambient of 23 ± 5°C)

Range Accuracy

-200°C - 200°C ±(0.2% reading + 1°C)

200°C - 400°C ±(0.5% reading + 1°C)

400°C - 1370°C ±(0.2% reading + 1°C)

-328°F - -200°F ±(0.5% reading + 2°F)

-200°F - 200°F ±(0.2% reading + 2°F)

200°F - 2498°F ±(0.3% reading + 2°F)

Note:

The basic accuracy specification does not include the error of the probe. Please refer to the probe

accuracy specification for additional details.

Resolution: -200°C - 200°C: 0.1°C; 200°C -1370°C: 1°C

-200°F - 200°F: 0.1°F; outside this range: 1°F

Number of Sensor Inputs: Four Type K Thermocouples

Input Protection at Thermocouple Input: 60V DC or 24Vrms AC

Display: Four 4 Digit Temperature Displays plus Indicators, see Section 3.0

Switchable backlight

Sample Rate: 3 seconds per period

Time Function: Real time clock, see Section 4.6

Datalogging Capacity: 16,312 records per channel

Recording Interval: User adjustable, see Section 4.7

Digital Output: Bi-directional RS232. Software and Cable included

Power requirement: 9 Volt Battery, NEDA 1604 or JIS 006P or IEC6F22

Battery Life: Approx. 100 hours with alkaline battery; Low battery indication

Operating Conditions:

x Operating Temperature and Humidity: 0°C - 50°C (32°F - 122°F); 0 - 80% RH

x Storage Temperature and Humidity: -10°C - 60°C (14°F - 140°F); 0 - 80% RH

x Altitude: Up to 2000 meters (6500 feet).

Dimensions: 184×64×30 mm (5.4×2.5×1.2 in)

Weight: Approx. 250g (8.7 oz)

Accessories: Two Type K Wire Thermocouple Probes, Battery, Carrying Case,

Instruction Manual, Software, RS232 Cable

Option: AC Adapter: 9VDC ±15%; 100mA: Plug Diameter: 3.5mm×1.35mm

Temperature Coefficient:

For ambient temperatures from 0°C - 18°C

and 28°C - 50°C, for each °C ambient

below 18°C or above 28°C, add the

following tolerance into the accuracy spec.

0.01% of reading + 0.03°C

(0.01% of reading + 0.06°F)

Notes

1

Page 5

MODEL 309 FOUR CHANNEL DATALOGGING THERMOMETER

5.0 Setup TestLink SE-309 - - RS232 Interface Software:

MODEL 309 FOUR CHANNEL DATALOGGING THERMOMETER

3.0 Symbol Definitions and Feature Locations:

The TestLink package contains:

1. One 80 mm CD

2. Custom designed RS232 cable for TestLink

System Requirements:

Windows 95, Windows 98 or Windows NT 4.0

Minimum Hardware Required:

x Pentium 90MHz PC, 32 MB RAM.

x At least 5 MB byte hard disk space available to

install TestLink

x Recommended display resolution is 800X600.

Install TestLink:

1. Close all other application before installing TestLink.

2. Insert setup CD disk in CD disk drive.

3. Choose the Start button on the Taskbar and select Run.

4. Type E:\SETUP and choose OK to copy SE309.exe (executable file) and Help file to

your hard disk (default is C:\program files\TestLink\SE309).

For other operating instructions, please refer to the online help while executing

TestLink.

: Indicates ‘Auto Power Off’ is enabled

T1 T3

: Indicates the value below is theT1, T2, T3 or T4 temperature sensor

T2 T4

°C°F : Centigrade or Fahrenheit indication

–

: Negative temperature indication

: Low battery indication. Battery voltage is not sufficient for proper operation.

: Thermocouple type indication

: Indicates that the instrument is recording. When flashing, the memory is full.

: The Maximum value is now being displayed

: The Minimum value is now being displayed

: Indicates that the display data is being held

:

Indicates the value below is T1-T2

A

M

X

4

2

V

2

1

3

T

T

1

2

3

4

HOLD

5

REC

POWER-UP OPTIONS

REC

SETUP

200

328

V

0

6

T1-T2

INTVCLOCK

C

FCF

T4T

6

7

8

F

1370RANGE

C

2498

9

L

A

C

T

U

P

T

U

O

V

9

C

D

9V BATTERY

NEDA 1604 6F22 006P

PLEASE READ

MANUAL FOR SAFETY

OPEN

Feature Locations:

1) T1 through T4 Type K temperature

sensor input connectors

2) LCD display

3) ON/OFF & Backlight button

4) Hold button

5) Record button

6) T1-T2 button

7) MAX MIN function control button

8) °C, °F control button

9) Offset calibration screw

10) Digital output connector (RS232)

11) AC power adapter connector

12) Tripod connector

13) Battery cabinet cover

5

2

Page 6

MODEL 309 FOUR CHANNEL DATALOGGING THERMOMETER

A

4.0 Operating Instructions:

4.1 Preparation for Measurement

Plug as many thermocouples as are to be monitored into the sockets marked T1 through

T4, taking care to observe the polarity of the thermocouple pins. If a differential

measurement is required, this is available only between T1 and T2, which determines

which thermocouples should be connected to these locations.

4.2 Power and Backlight

The button turns both the thermometer and the display backlight

ON or OFF. Press it once to turn the thermometer ON. Every

subsequent momentary press toggles the backlight ON or OFF.

Press and hold this button for 3 seconds to turn the power OFF.

When first powered on, the display will show how much memory

space is available for use, as shown to the right.

4.3 Selecting the Temperature Scale

When first turned on, the instrument defaults to reading in Celsius (°C). The instrument

toggles between Celsius (°C) and Fahrenheit (°F) each time the °C/°F button is pressed.

The instrument remembers the scale setting when last turned off and powers on in that

setting the next time.

4.4 Data-Hold Operation

The present reading is held on the display by pressing the HOLD button. Pressing the

HOLD button again releases the hold function and returns the instrument to

continuous reading.

In the HOLD mode, the T1-T2, MAX MIN and °C/°F buttons are disabled, as indicated by

two continuous beeps when pressed.

4.5 T1-T2 Operation

When the T1-T2 button is pressed, the display will indicate

1 – 2

indicating the instrument is in the differential mode of T1 minus T2.

The display then indicates T1 value on the top left, T2 value on the

bottom left, and the difference T1-T2 on the bottom right.

4.6 Clock Setup

To set the real time clock:

1. Press and hold the T1-T2 button and then power on the meter.

2. Press HOLD (clock).

3. Press REC (n) or °C/°F (p) to increase or decrease the

number; press HOLD to advance to the next item. The

adjusting order is: year; month; day; hour; minute. Press HOLD

again after the last setting to complete the process.

To abort during a setup process, press the button.

4.7 Recording Interval Setup

To set the recording interval:

1. Press and hold the T1-T2 button and then power on the meter.

2. Press MAX MIN (interval).

3. Press REC (n) or °C/°F (p) to increase or decrease the

number; press MAX MIN to advance to the next item. Press

MAX MIN again after the last setting to complete the process.

To abort during a setup process, press the button.

MODEL 309 FOUR CHANNEL DATALOGGING THERMOMETER

4.8 Recording Data

Each momentary press of the REC button will alternately start and

stop recording. To clear the memory, power off the meter, press

and hold the REC button followed by the button, holding both

on simultaneously for at least 5 seconds. The display will show

‘CLR’ ‘SURE 5’, and releasing all buttons then clears the memory.

4.9 MAX/MIN Operation

Press the MAX MIN button to enter the MAX/MIN mode. In this mode, both the maximum

and minimum values are simultaneously retained in memory and updated with every new

data sample. The instrument first enters the MAX mode, and the MAX symbol and value

are both displayed. Pressing MAX MIN again advances the display to the MIN symbol

and value. The next press of the MAX MIN button will cause both the MAX and MIN

symbols to flash. This indicates that the maximum and minimum values have been

updated in memory and the displayed reading is the present temperature. Each

successive press of the MAX MIN button circulates the display mode among these

options. To exit the MAX/MIN mode, press and hold the MAX MIN button for

two seconds.

In the MAX/MIN mode, the °C/°F button is disabled, as indicated by two consecutive

beeps if pressed.

4.10 Auto Power Off

By default, the instrument powers on in the ‘Auto Power Off’ mode and will automatically

shut off 30 minutes after the last key operation or RS232 communication.

To disable this feature, press and hold the HOLD button and then power on the meter.

Two successive beeps will indicate that ‘Auto Power Off’ is disabled, and the will not

be displayed.

4.11 Low Battery Condition

When the battery voltage is at or below the minimum for proper operation, the

symbol will show on the display indicating that the battery must be replaced.

4.12 Calibration

Calibration is conducted by adjusting the following potentiometers to within the

tolerances shown.

(Ambient Temperature: 23 ± 3°C)

Input Adjust VR Tolerance

0 °C VR1 ± 0.1 °C

190 °C VR2 ± 0.1 °C

1000 °C VR3 ± 1 °C

1900 °F VR4 ± 1 °F

4.13 Digital Output

simple single point calibration may be

performed by adjusting VR1 to 0 °C with

thermally stabilized ice water.

RX

TX

GND

The Digital Output is a 9600 bps N 81 serial interface.

RX is a 5V normally high input port.

TX is a 5V normally high output port.

Appendix: Thermocouple Probe Specifications

Model Range Tolerances Description

Wire probe

TP-K01

-50°C to 200°C

-58°F to 392°F

±2.2°C or ±0.75%

±3.6°F or ±0.75%

Teflon insulation. Maximum insulation

temperature: 260°C (500°F)

TP-K01:

Probe for general condition measurements, especially

for complex and hard to reach places.

3

4

Loading...

Loading...