Page 1

© Monarch Instrument 2002 all rights reserved

1071-8011-210

True RMS Multimeter

Monarch 120

15 Columbia Drive

Amherst, NH 03031-2334 USA

Phone: (603) 883-3390

Fax: (603) 886-3300

E-mail: support@monarchinstrument.com

Website: www.monarchinstrument.com

MONARCH INSTRUMENT

Instruction Manual

Page 2

14. With the exception of replacing the battery or fuses, this

13. To avoid false readings, replace the battery immediately

12. Keep fingers behind the finger guards on the test leads

11. Exercise extreme caution when working with voltages

10. Do not connect the test leads to a voltage source when

9. Discharge all capacitors in a circuit before measuring

8. Do not measure resistance or continuity in a circuit or test

7. Do not exceed the rated voltage between any input jack

6. Do not, under any circumstances, exceed the maximum

5. Ensure the Function Selector switch is in the proper

4. Ensure the test leads are installed in the proper connectors

3. Ensure that the instrument and test leads are in good

2. Do not use this instrument in any manner inconsistent with

1. Read and follow all instructions in this manual carefully,

instrument is not user serviceable. For technical

assistance, contact the sales organization from which you

purchased the product or Monarch Instrument directly.

when the low battery indication appears.

when making measurements.

above 60Vdc or 30Vac. Such voltages pose a shock hazard.

the test leads are connected to the µA /mA or 10A input jacks.

capacitance.

diodes while power is applied to that circuit.

and ground.

ratings of this instrument.

position for the measurement to be made.

for the measurement to be made.

condition with no visible signs of damage before use.

these operating instructions or under any conditions that

exceed the environmental specifications stated.

and retain this manual for future reference.

Safeguards and Precautions

referencing this clause.

SELLER warrants that any software supplied will operate in accordance with the

documentation or manual supplied therewith in all material respects when used in strict

compliance with such documentation or manual. Notwithstanding the foregoing, BUYER

acknowledges that, since software is complex and therefore may have defects, BUYER’s

sole and exclusive remedy for any such defects or breach of this warranty shall be to

require SELLER, within a reasonable period of time, to provide all reasonable programming

services to correct programming errors in the software. Except as provided above SELLER

MAKES AND BUYER RECEIVES FROM SELLER NO EXPRESS OR IMPLIED WARRANTIES

OF ANY KIND WITH RESPECT TO ALL OR ANY PORTION OF SOFTWARE AND BUYER

HEREBY AGREES AND ACKNOWLEDGES THAT IT ACCEPTS THE SOFTWARE IN ‘AS IS’

CONDITION. SELLER HEREBY EXPRESSLY EXCLUDES ANY IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO

THE SOFTWARE. BUYER agrees that any specific right or remedy granted to BUYER

hereunder with respect to any breach or default by SELLER shall be in lieu of all other

rights and remedies otherwise available to BUYER at law or in equity as the result of such

breach or default, regardless of whether based on contract, tort, strict liability, or other

theory of liability.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL,

CONSEQUENTIAL, OR PUNITIVE LOSSES OR DAMAGES (INCLUDING, BUT NOT

LIMITED TO, LOSSES OR DAMAGES FOR ANY LOST PROFITS OR LOST DATA) AS THE

RESULT OF ANY BREACH OR DEFAULT BY SELLER WITH RESPECT TO THE HARDWARE

OR SOFTWARE, EVEN IF SELLER HAS BEEN ADVISED OR MADE AWARE OF THE

POSSIBILITY OF ANY SUCH LOSSES OR DAMAGES AND REGARDLESS OF WHETHER

THE CLAIM IS BASED ON CONTRACT, TORT, STRICT LIABILITY, OR OTHER THEORY OF

LIABILITY.

This limited warranty does not extend or apply to consumables (including, but not limited

to, lamps and batteries, if applicable) or equipment, instruments or accessories which are

warranted separately by the original manufacturer of these items.

SELLER warrants hardware products to be free from any defect in materials or workmanship

for a period of one (1) year from date of shipment to BUYER. SELLER’s entire liability and

BUYER’s sole and exclusive remedy resulting from any defect in workmanship or material

in the hardware product covered by this limited warranty shall be limited to and fully

discharged by the SELLER’s option of replacement or repair of such item without charge.

The limited warranty provided in this clause is in lieu of all other warranties, expressed or

implied, arising by law or otherwise. ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE EXCLUDED. This limited warranty

shall not be modified except by an arrangement signed by both parties specifically

LIMITED WARRANTY

Page 3

19

Importer (Amherst, NH) Alan Woolfson, VP Engineering (Authorized Signature)

th

July 2000

and therefore conforms in accordance with 89/336/EEC-EMC Directive. The

testing of this product was performed by GesTek EMC Lab. in July of 2000.

(Ref. No. 0007018E).

EMC: EN55022/1998, CISPR 22, Class B

to which this declaration relates is in conformity with the following standards:

Name: True RMS Multimeter

Model: Monarch 120

DECLARATION OF CONFORMITY

EN50082-1/1997 / EN61000-4 Series

Division of Monarch International Inc.

declares that the product:

15 Columbia Drive, Amherst NH 03031 USA

Monarch Instrument

6.0 Battery and Fuse Replacement

6.1 Opening the Instrument Case .....................................................................................9

6.3 Fuse Replacement .......................................................................................................9

6.2 Battery Replacement ...................................................................................................

6.4 Closing the Instrument Case ......................................................................................

5.9 Capacitance Measurements........................................................................................8

...................................................................9

5.6 Diode Tests...................................................................................................................7

5.7 Frequency and RPM Measurements ..........................................................................

5.8 Temperature Measurements .......................................................................................

5.3 AC/DC Current Measurements ...................................................................................6

5.4 Resistance Measurements..........................................................................................

5.5 Continuity Measurements ...........................................................................................

5.0 Operating Instructions........................................................................................6

5.1 AC Voltage Measurements ..........................................................................................6

5.2 DC Voltage Measurements..........................................................................................

4.15 Digital Output

............................................................................................................................

3.0 Symbol Definitions and Feature Locations

4.0 Control Functions

4.1 Function Selector Rotary Switch................................................................................4

4.14 V, Hz, , RPM, , ȍ, TEMP Measuring Connector

4.12 µA/mA Measuring Connector......................................................................................

4.13 COM Measuring Connector.........................................................................................

..................................................

4.9 Second Function Button .............................................................................................

4.10 Auto Power Off .............................................................................................................

4.11 20A Measuring Connector ..........................................................................................

4.6 Relative Operation .......................................................................................................

4.7 Voltage or Current to Frequency Function................................................................

4.8 Backlight Button ..........................................................................................................

4.3 MAX/MIN Button...........................................................................................................4

4.2 Range Button ...............................................................................................................

4.4 Data Hold Function ......................................................................................................

4.5 Peak Hold Function .....................................................................................................

...................................................................................................4

........................................3

Section Page

1.0 Introduction

2.0 Specifications

.................................................................................................................1

............................................................................................................1

MODEL 120 TRUE RMS MULTIMETER

Table of Contents

9

9

8

6

7

7

8

5

5

5

4

4

4

5

5

5

5

5

5

5

Page 4

1

Under 40

ȍ

<1.5V 600Vrms

Continuity Beeper:

40M

ȍ

Range

10K

ȍ

1%+3 <1.5VDC 600Vrms

Active Range

Test Voltage

Overload protection

400K

4M

ȍ

ȍ

1K

100

ȍ

ȍ

0.6%+2

0.6%+2

<1.5VDC 600Vrms

<1.5VDC 600Vrms

Range

40K

400

4K

ȍ

ȍ

ȍ

1

0.1

10

Resolution

ȍ

ȍ

ȍ

0.6%+2

0.6%+2

0.6%+2 <1.5VDC 600Vrms

Accuracy

Test Voltage

<1.5VDC 600Vrms

<1.5VDC 600Vrms

Overload Protection

Resistance (Autoranging):

400mA 100uA

20A 10mA 1%+2 <1V 15A / 600V Fast Blow Fuse

0.8%+2

<1.5V

0.5A / 600V Fast Blow Fuse

4000uA 1uA

Range

400uA 0.1uA 0.8%+2 <0.25V 0.5A / 600V Fast Blow Fuse

40mA 10uA

Resolution

0.8%+2

<1V

0.5A / 600V Fast Blow Fuse

Accuracy

Burden Voltage

Overload Protection

0.8%+2

<0.25V

0.5A / 600V Fast Blow Fuse

DC Current (uA and mA - Autoranging):

1000V 1V 0.5%+2

10M

ȍ

1200Vpeak

400V 100mV

0.3%+2

10M

ȍ

1200Vpeak

400mV 0.1mV 0.3%+2 100M

40V 10mV

4V 1mV

0.3%+2

0.3%+2

10M

10M

ȍ

ȍ

ȍ

1200Vpeak

1200Vpeak

1200Vpeak

DC Voltage (Autoranging):

Range

20A 10mA

Resolution

1.5%+5 1.8%+5

Accuracy

Input Impedance

<1Vrms 15A / 600V Fast Blow Fuse

Overload Protection

4000uA 1uA

400mA 100uA

40mA 10uA

1.3%+5

1.3%+5

1.3%+5

1.6%+5

1.6%+5

1.6%+5

<0.25Vrms

<1.5Vrms

<1Vrms

0.5A / 600V Fast Blow Fuse

0.5A / 600V Fast Blow Fuse

0.5A / 600V Fast Blow Fuse

Range Resolution

400uA 0.1uA

45Hz~500Hz 500Hz~1KHz

1.3%+5 1.6%+5

Accuracy

<0.25Vrms 0.5A / 600V Fast Blow Fuse

Voltage

Burden

Overload Protection

MODEL 120 TRUE RMS MULTIMETER

2.0 Specifications:

capacitance. It is also equipped with a diode testing feature. The instrument complies with

IEC 1010-1 1000V CAT III.

AC Current (uA and mA - Autoranging):

400V 100mV 0.5%+5

750V 1V 0.8%+5

400mV 0.1mV 100M

40V 10mV 0.5%+5

4V 1mV 0.5%+5 1%+5

AC Voltage (Autoranging):

Range

Resolution

1.0 Introduction:

This instrument is a true RMS autoranging digital multimeter capable of measuring AC voltage

and current, DC voltage and current, resistance, continuity, frequency, RPM, temperature and

45Hz~500Hz 500Hz~1KHz

1.2%+5

10M

ȍ

1200V peak

1%+5

10M

ȍ

1200V peak

1%+5

10M

ȍ

1200V peak

10M

ȍ

1200V peak

Accuracy

Impedance

Input

ȍ

1200V peak

Overload Protection

NOTES

Page 5

9

6.4 Closing the Instrument Case

Ensure the Function Selector switch has not been rotated from the position when it was

removed. Check to be certain that the battery leads are safely routed through the slot

provided for this purpose. Replace the top half of the instrument case, turn the

instrument over, and replace the five screws in the back.

Note: Do not over tighten screws. Excessive tightening could strip the threads in the

plastic case.

Remove and replace the defective fuse with an exact replacement.

Fuse ratings are as follows:

Fuse 2:F15A/600V

Fuse 1: F0.5A/600V 10

10

³

³

× 38mm Fast Blow

× 38mm Fast Blow

To avoid damage to the instrument or potential electrical hazard or shock, replace fuses with exact

replacements. Do not use higher rated fuses in either location.

installing a new battery, be careful to route the battery leads through the slot in the

battery enclosure. Failure to do so could result in damage to the leads upon replacement

6.2 Battery Replacement

This instrument uses a single 9V, NEDA 1604 or IEC6F22 or JIS006P battery. When

15A fuse

Battery

Fuse 2

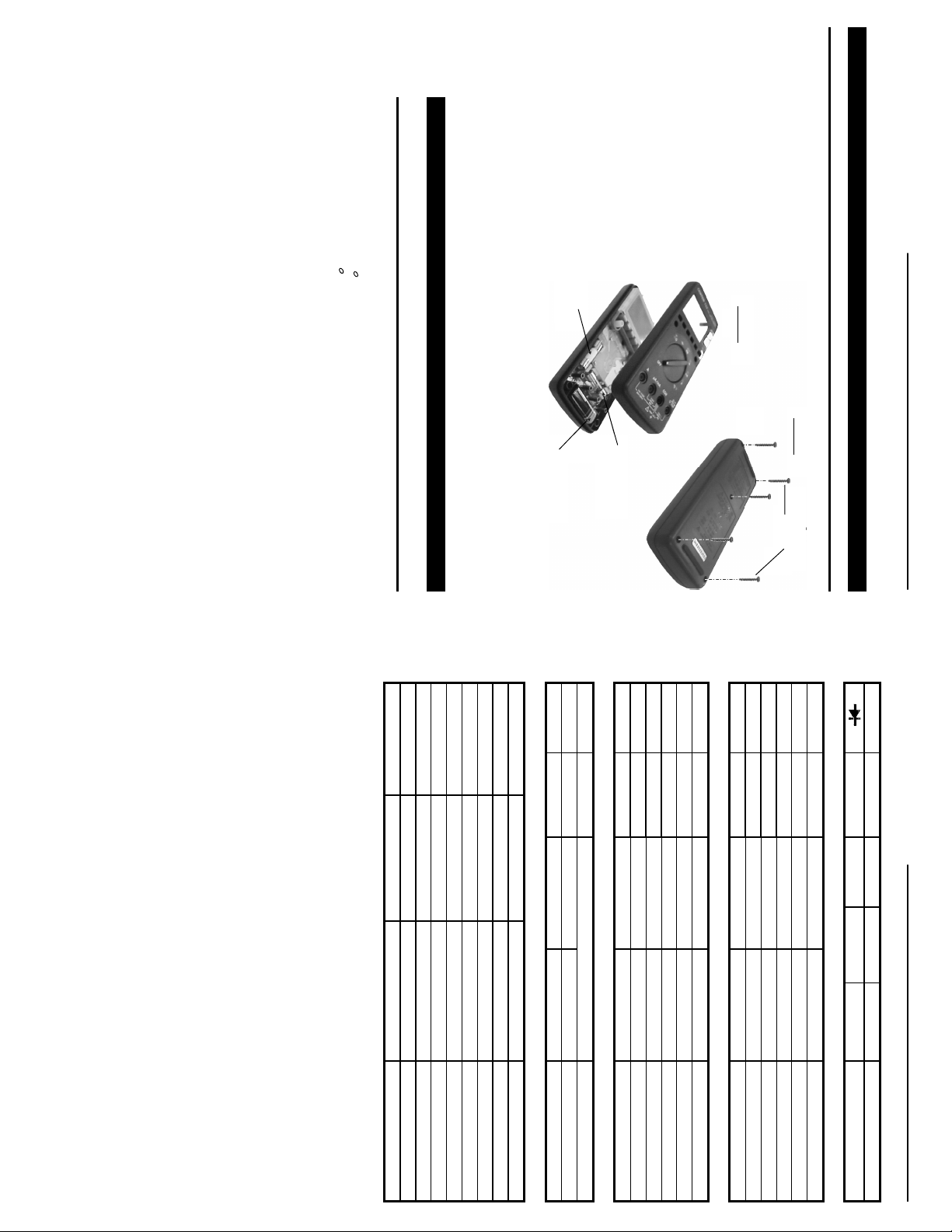

switch to the OFF position.

Turn the unit over and remove

the five screws from the back

as shown in Figure 1.

Turn the unit face up and

carefully separate the case

halves as shown in Figure 2.

Fuse 1

0.5A fuse

shows in the display or when a

fuse blows due to an overload

condition, the case must be

opened to replace the battery

or fuse(s).

Set the Function Selector

Figure 2

6.3 Fuse Replacement

of the top half of the instrument case.

WARNING

To prevent electrical hazard or shock, turn multimeter off and disconnect test leads before removing back cover.

6.1 Opening the Instrument Case

When the low battery indicator

Figure 1

WARNING

MODEL 120 TRUE RMS MULTIMETER

6.0 Battery and Fuse Replacement:

Screws

MODEL 120 TRUE RMS MULTIMETER

Temperature (°C/°F)

400M RPM 100K RPM 0.05%+1

400K RPM 0.1K RPM 0.05%+1

40M RPM 10K RPM 0.05%+1

Range

°C

1

Resolution

°

-50 to 0°C: 1%+4

Accuracy

0 to 1000

4M RPM 1K RPM 0.05%+1

Range

4nF 1PF 1.9%+20 600Vrms

Resolution

Capacitance (Autoranging)

°F

1

°

-58 to 32

°F: 1%+8

32 to 1832

Accuracy specification: ± ([…% of reading] + [… number of least significant digits]) at

True RMS accuracy for ACV and ACA are specified from 5% to

Electromagnetic compatibility:

Vac and Aac only: RF field = 3V/m

Total accuracy: Specified accuracy + 2% of range

Digital display: 4000 counts

Sampling rate: Twice per second

Analog display: 41 segments

Sampling rate: 20 times per second

Overrange indication: Displays ‘OL’ when value exceeds range selected

Digital Output: Bi-directional RS232. (Cable and software optional.)

Power requirement: 9 Volt battery, NEDA 1604 or JIS 006P or IEC 6F22

Battery life: 100 hours typical. Low battery indication.

Safety: 1000V CAT III, Regulation EN61010: Part 1:1993

Dimensions: Meter only: 198×86×38mm (7.8×3.4×1.5 in)

With holster: 209×94×48mm (8.2×3.7×1.9 in)

Weight: Meter only: Approx. 430g (15.2 oz)

With holster: Approx. 600g (21.3 oz)

400nF 100PF 1.5%+10 600Vrms

400uF 100nF 1.9%+10

40mF 10uF 3%+10 600Vrms

4mF 1uF 1.9%+10

18°C to 28°C (64°F to 82°F) at less than 80% RH

100% of range. Add 1% of reading for crest factor between 1.4

and 3 at full scale, or less than 6 at half scale.

40nF 10PF 1.5%+10 600Vrms

40uF 10nF 1.9%+10 600Vrms

4uF 1nF 1.5%+10 600Vrms

40K RPM 0.01K RPM 0.05%+1 <1Vrms 600Vrms

Range

Resolution

Accuracy

RPM (Autoranging):

400KHz 100Hz 0.05%+1

40MHZ 10KHz 0.05%+1

40KHz 10Hz 0.05%+1

4MHz 1KHz 0.05%+1

Frequency (Autoranging):

Range

4KHz 1Hz 0.05%+1 <1Vrms 600Vrms

Resolution

Accuracy

Diode Tester:

Range

Resolution

1mV 1% +2 <1mA <3.5V 600Vrms

Accuracy

Test Current

Accuracy

600Vrms

600Vrms

2

Overload protection

°C: 1%+3

°F: 1%+6

600Vrms

600Vrms

Overload protection

<10Vrms

600Vrms

<3Vrms

600Vrms

<1Vrms

600Vrms

<1Vrms

600Vrms

Sensitivity

<10Vrms

Overload Protection

600Vrms

<3Vrms

600Vrms

<1Vrms

600Vrms

<1Vrms

600Vrms

Sensitivity

Overload Protection

Test Voltage

Overload protection

Page 6

3

3.0 Symbol Definitions and Button Locations:

MODEL 120 TRUE RMS MULTIMETER

3) MAX/MIN Button 12) ‘Amp’ Terminal

4) Range Button 13) ‘COM’ Terminal

5) Backlight Button 14) ‘Volts, Ohms, Frequency, RPM, Capacitance,

6) Peak Hold Button Temperature, Diode Test Terminal’

7) Relative Button 15) RS232 Interface Connector

8) Voltage/Current/Frequency Button 16) Holster

9) Second Function Button 17) Tilt Stand

1) LCD Display 10) Function Select Dial

2) Hold Button 11)

Accessories: Test Leads, Battery, Holster, Instruction Manual

Options: Temperature Converter, Type K Wire Temperature Probe, RS232 Cable,

x Indoor use only

x Altitude up to 2000 meters (6500 feet)

x Pollution Degree 2

Below 70% RH Non-condensing

x Installation category III

Operating conditions:

x Operating Temperature and Humidity: 0°C - 40°C (32°F - 104°F)

Below 80% RH Non-condensing

x Storage Temperature and Humidity: -10°C - 60°C (14°F - 140°F)

Software

‘

µ

A/mA’ Terminal

MODEL 120 TRUE RMS MULTIMETER

5.9 Capacitance Measurements

5.8 Temperature Measurements

5.7 Frequency and RPM Measurements

Notes: 1. The bar graph is disabled in the Capacitance measuring mode. However, in

2. To obtain an accurate reading, the capacitor under test must be fully

the 4mF and 40mF ranges, the bargraph indicates the time required to

accomplish this measurement.

discharged. This instrument will automatically discharge the capacitor, if

necessary, but requires considerable time to do so. Because of this time

factor, it is preferable to discharge the capacitor by external means. If the

instrument is discharging a capacitor prior to measurement,

on the display.

4. Read the Capacitance on the instrument display.

2. Set the Function Selector switch to the function.

3. Ensure there is no power applied to the circuit, and then

1. Connect the red test lead to the ‘ ’ jack and the black test

connect the test leads to the leads of the capacitor being

tested, observing proper polarity on polarized capacitors.

lead to the

capacitors before measuring capacitance. Use the DC voltage function to

confirm that all capacitors are fully discharged.

To avoid damage to the instrument, disconnect circuit power and discharge all

measured and allow sufficient time for the probe

temperature to stabilize.

2. Set the Function Selector switch to the °C °F function.

3. Press the blue button, if necessary, to select °C or °F.

4. Locate the thermocouple probe in the environment to be

5. Read the Temperature on the instrument display.

‘COM’

jack.

1. Plug the optional temperature converter module into the

‘TEMP’

polarities. Plug a Type K thermocouple into the converter,

again ensuring proper polarity.

and

‘COM’

jacks, taking care to observe the proper

1. Connect the red test lead to the

2. Set the Function Selector switch to the Hz RPM function.

3. Connect the test leads in parallel with the circuit being

4. Read the Frequency or RPM on the instrument display.

For RPM measurements, press the blue button to select the

RPM function.

measured.

lead to the ‘

COM

’ jack.

WARNING

‘Hz’

jack and the black test

disc

will appear

8

Page 7

7

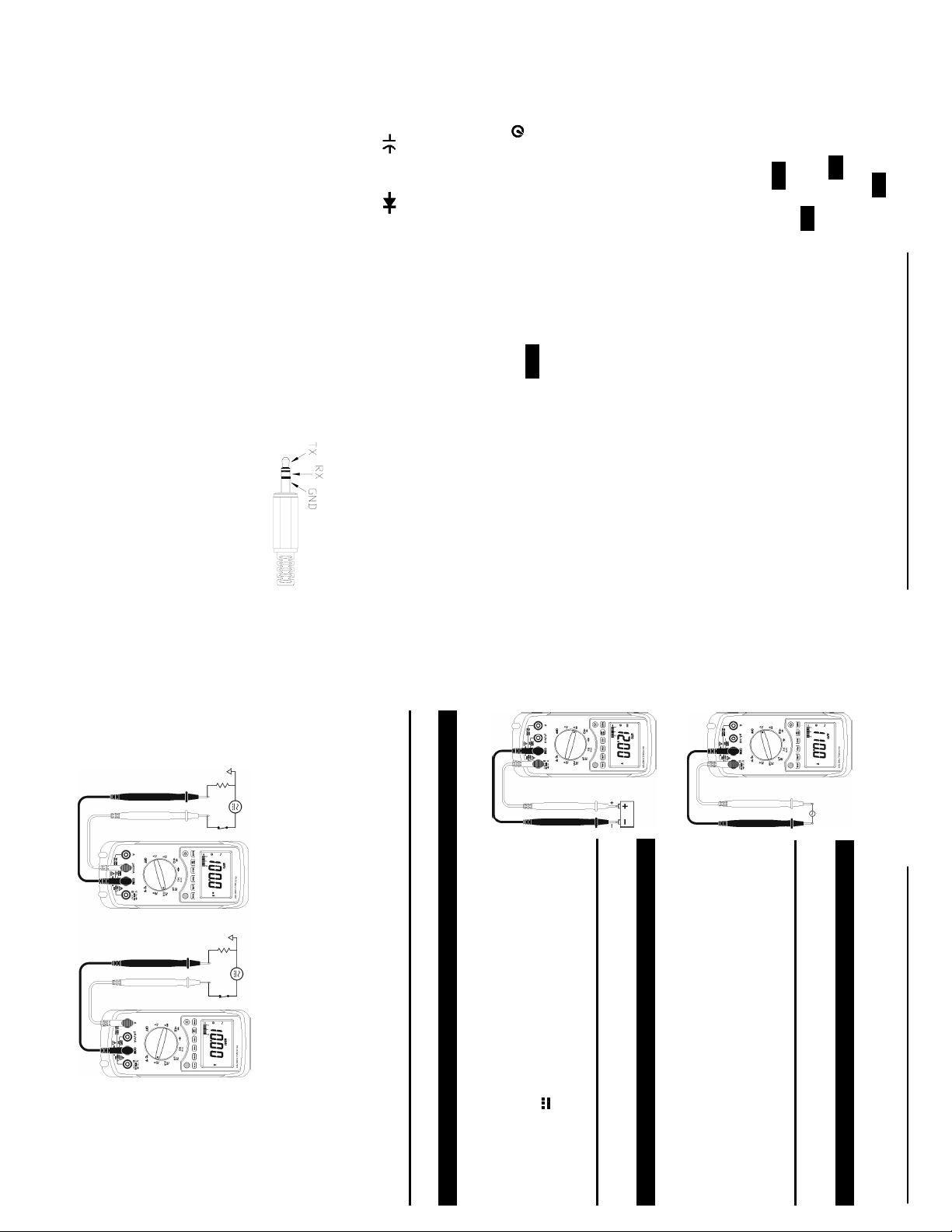

Open Circuit Short Circuit

MODEL 120 TRUE RMS MULTIMETER

used to determine the anode and cathode terminals of a diode.

Note: If the polarity of the test leads is reversed, the display will read ‘OL’. This can be

5. Read the Forward Voltage (V

test lead to the cathode side of the diode being tested.

f

) on the instrument display.

4. Ensure there is no power applied to the circuit, and then

function.

connect the red test lead to the anode side and the black

3. Press the blue Second Function button twice to select the

2. Set the Function Selector switch to the

:

ҏҏҏҏҏfunction.

Before making any in-circuit measurements, remove power from the circuit

being tested and discharge all capacitors in the circuit.

1. Connect the red test lead to the ‘ ’ jack and the black

test lead to the ‘

COM

’ jack.

WARNING

5.6 Diode Tests

4. Ensure there is no power applied to the circuit, and then connect the test leads in

5. When the impedance between the test leads is less than 40:a continuous beeper

parallel with the circuit being tested.

will activate.

5.5 Continuity Measurements

2. Set the Function Selector switch to the

3. Press the blue Second Function button once to select the

Before making any in-circuit measurements, remove power from the circuit being tested and discharge all

capacitors in the circuit.

1. Connect the red test lead to the

‘

:

’

jack and the black test lead to the

WARNING

:

function.

function.

‘COM’

3. Ensure there is no power applied to the circuit, and then

2. Set the Function Selector switch to the

connect the test leads in parallel with the circuit being

tested and read the measured resistance on the instrument

display.

lead to the

‘COM’

jack.

:

function.

5.4 Resistance Measurements

Before making any in-circuit measurements, remove power from the circuit

being tested and discharge all capacitors in the circuit.

1. Connect the red test lead to the

WARNING

‘

:

’

jack and the black test

jack.

Relative indication Revolutions per minute

Auto range indication Minimum indication

Data hold indication Peak max/min indication

Low battery indication Diode indication

RS-232 indication Continuity with beeper

AC source Temperature indication

DC source Capacitance indication

Negative polarity indication Voltage/current indication

Auto power off indication Frequency indication

Digital value indication Resistance indication

indicator in the display. Press it once more to display the ‘P

capture Peak values.

Note: The instrument must be calibrated in accordance with the above procedure

Press and hold the

seconds until

To invoke the calibration operation, press and hold the

Press the

high speed Peak value.

whenever the function range is changed.

PEAK

‘CAL’

button again to display the Maximum Peak, as indicated by the ‘P

PEAK

appears in the display. The instrument is now calibrated to properly

button for 2 seconds to exit the Peak mode.

measurement range selected. The instrument must then conduct an internal self-

calibration, which calculates and stores the offset voltage in preparation for capturing a

and DCV ranges. The Peak values are the highest and lowest transient values captured

by the instrument, regardless of whether or not they might be displayed in the normal

measuring mode. To display Peak values, first ensure the value will not exceed the

4.4 Data Hold Function

4.5 Peak Hold Function

the display. Press it again to display the ‘

to release the held data and return to continuous reading.

This instrument is equipped with a 1ms Peak capture capability in the ACA, ACV, DCA

display the current value. In this selection, the

MAX/MIN mode, press and hold the

To hold the current measured value, press the

MAX/MIN

button once to display the Maximum value, as indicated by the ‘

Analog bar indication

4.0 Control Functions:

4.3 MAX/MIN Button

The Maximum and Minimum values are the highest and lowest values displayed during

the time the instrument is in the MAX/MIN mode. To display Maximum and Minimum

values, first ensure the value will not exceed the measurement range selected. Press the

or wraps from the highest back to the lowest range. To exit the Manual Range mode and

return to Auto Range, press and hold the

subsequent press of the

RANGE

4.2 Range Button

meter in its’ present range and bring on the

Button, are printed in blue.

The instrument powers on in the Auto Range mode, as indicated by the

in the display. To select a Manual Range, press the

measured. The primary functions available are printed in red and white on the instrument

scale. Alternate functions, accessed in conjunction with the blue Second Function

4.1 Function Selector Rotary Switch

The rotary switch turns power on to the instrument and selects the function to be

MODEL 120 TRUE RMS MULTIMETER

Manual range indication Maximum indication

button circulates the instrument to the next higher range

PEAK

MIN’

button for approximately 2

MAX/MIN

MIN’

button for one second.

HOLD

value and indicator. Press it once more to

‘MAX/MIN’

button. Press the

indicator will flash. To exit the

RANGE

button for one second.

MANU’

indicator in the display. Each

RANGE

button which will lock the

value and indicator.

HOLD

button again

MAX’

indicator in

‘AUTO’

indicator

MAX’

4

Page 8

MODEL 120 TRUE RMS MULTIMETER

5

4.10 Auto Power Off

By default, the instrument powers on in the ‘Auto Power Off’ mode and will automatically

shut off 30 minutes after the last key operation or optional RS232 communication.

x In the Temperature function, the blue button toggles between °C and °F.

x In the Frequency position, the blue button selects the RPM mode.

To disable this feature, press and hold the

x In any of the Current measuring modes, the blue button toggles between AC and DC.

around the rotary function selector.

The secondary functions available with this button are:

x In the Resistance position, the first press of the blue button selects the Continuity with

Pressing the

a reference for subsequent measurements. The display now shows the difference

between the stored value and the new reading.

4.6 Relative Operation

4.8 Backlight Button

4.9 Second Function Button

The round yellow button with a ‘Sun’ logo turns the display backlight ON and OFF. The

backlight automatically shuts off after 30 seconds to conserve battery power.

The solid blue button selects the second functions printed in blue on the instrument scale

4.7 Voltage or Current to Frequency Function

Frequency Counter mode with automatic range selection.

Press the

Press the

Press and hold the

will flash in the Relative Hold mode.

TX is a 5V normally high output port.

RX is a 5V normally high input port.

4.14

4.15 Digital Output

measurements, connect the positive (red) test lead to this connector.

The RS232 Digital Output is a 9600 bps N 81 serial interface.

4.13 COM Measuring Connector

4.12 µA/mA Measuring Connector

This connector is the negative (black) lead connection for all measurements.

For all voltage, frequency, capacitance, RPM, diode test, resistance or temperature

connection is internally fused at 400mA for protection of the instrument.

V, Hz, , RPM, , ȍ, TEMP Measuring Connector

This instrument is capable of measuring up to 10 amps continuously, or up to 20 amps

for no more than 30 seconds. Connect the positive (red) test lead to this connector.

Current measurements up to 400mA are best measured via this connector. This

4.11 20A Measuring Connector

The will not be displayed, indicating that ‘Auto Power Off’ is disabled.

beeper function. The second push of this button selects the Diode Test function.

'REL

'REL

'REL

button again to hold the Relative reading. The

button zeroes the display and internally stores the present reading as

VA-Hz

button in any Voltage or Current measurement mode to enter the

for 1 second to exit the Relative mode.

RANGE

button and then power on the meter.

‘'REL’

symbol in the display

µA/mA Measurement Amp Measurement

MODEL 120 TRUE RMS MULTIMETER

5.0 Operating Instructions:

Maximum Input Voltage is 1000VDC. To avoid electrical shock hazard and/or

damage to this instrument, do not attempt to make any voltage measurement

5.2 DC Voltage Measurements

4. Read the measured voltage on the instrument display.

2. Set the Function Selector switch to the V~ range

3. Connect the test leads in parallel with the circuit being

measured.

that may exceed this limit.

1. Connect the red test lead to the

lead to the

‘COM’

jack.

5.3 AC/DC Current Measurements

To avoid injury, do not attempt a current measurement if the open circuit voltage exceeds the rated voltage of

this instrument.

1. If the current to be measured is unknown, connect the red lead to the

2. Set the Function Selector switch to the current range corresponding to the jack

3. Remove power from the circuit to be measured and connect the instrument in

4. Apply power to the circuit and read the measured current on the instrument display.

being used and press the blue button to select AC or DC.

series with this circuit. Connect the black lead to the negative (-) side and the red

lead to the positive (+) side being measured.

known or has been determined that the current is 400mA or less, connect the red

lead to the

‘µA/mA’

jack. Connect the black lead to the

WARNING

1. Connect the red test lead to the

2. Set the Function Selector switch to the V range

3. Connect the test leads in parallel with the circuit being

4. Read the measured voltage on the instrument display.

measured.

lead to the

‘COM’

that may exceed this limit.

jack.

WARNING

‘COM’

jack.

‘V’

jack and the black test

‘V’

jack and the black test

damage to this instrument, do not attempt to make any voltage measurement

5.1 AC Voltage Measurements

Maximum Input Voltage is 750VAC. To avoid electrical shock hazard and/or

WARNING

‘A’

jack. If it is

.

.

6

Loading...

Loading...