Monaco VMOTO Owner's Manual

VMOTO MONACO

OWNER

HANDBOOK

1 VMOTO MONACO V1 ............................................................................................. 4

2 GENERAL INFORMATION..................................................................................... 5

2.1 Description.......................................................................................................... 5

2.2 Specifications...................................................................................................... 6

2.3 Inspection Tips.................................................................................................... 7

2.4 Safety Precautions............................................................................................... 7

2.5 Torque Settings ................................................................................................... 8

2.6 Lubrication Points............................................................................................. 10

2.7 Trouble Shooting .............................................................................................. 12

2.7.1 Engine Fails to Start:................................................................................. 12

2.7.2 Poor spark ................................................................................................. 12

2.7.3 Poor idle .................................................................................................... 13

2.7.4 Poor acceleration and loss of power ......................................................... 13

3 INSPECTION AND ADJUSTMENT ...................................................................... 14

3.1 Regular Maintenance Schedule......................................................................... 14

3.2 Checking and Changing Engine Oil ................................................................. 14

3.3 Final Drive Gear Oil ......................................................................................... 16

3.4 Brake System .................................................................................................... 17

3.4.1 Front Brake Lever Free Play..................................................................... 17

3.4.2 Brake Fluid................................................................................................ 17

3.4.3 Refill Brake Fluid ..................................................................................... 17

3.4.4 Bleed Brake Line ...................................................................................... 18

3.4.5 Front Brake Disk....................................................................................... 18

3.4.6 Rear Brake Adjustment............................................................................. 18

3.4.7 Inspection of Brake Lining and Wheel ..................................................... 19

3.5 Tyre and Tyre Pressure ..................................................................................... 20

3.6 Air Filter............................................................................................................ 21

3.7 Battery............................................................................................................... 22

3.8 Spark Plug......................................................................................................... 22

3.9 Fuel Filter.......................................................................................................... 23

3.10 Carburettor Idle Speed ...................................................................................... 23

3.11 Throttle Valve ................................................................................................... 24

3.11.1 Throttle Lever Play Adjustment................................................................ 24

3.11.2 Carburettor Throttle Cable Play................................................................ 25

3.12 V Belt ................................................................................................................ 25

3.13 Lubrication........................................................................................................ 27

3.13.1 Engine oil level ......................................................................................... 27

3.13.2 Oil renewal................................................................................................ 27

4 CHASSIS .................................................................................................................. 29

4.1 Removal of Cover ............................................................................................. 29

5 TROUBLESHOOTING CHASSIS PROBLEMS .................................................... 30

5.1 Steering/ Suspension/ Front Wheels/ Front Brakes .......................................... 30

5.1.1 Troubleshooting ........................................................................................ 31

5.2 Front Wheel ...................................................................................................... 32

5.2.1 Inspection of Wheel Rim .......................................................................... 33

5.3 Rear Wheel........................................................................................................ 34

5.3.1 Brake lining assembly (brake shoe, brake shoe spring)............................ 35

5.4 Rear Shock Absorber ........................................................................................ 35

6 ELECTRICAL SYSTEM ......................................................................................... 36

6.1 Maintenance & troubleshooting........................................................................ 36

6.1.1 Starter System ........................................................................................... 38

6.2 Battery............................................................................................................... 38

6.2.1 Charging the battery.................................................................................. 39

6.2.2 Rectifier..................................................................................................... 39

6.2.3 Starter Relay.............................................................................................. 40

6.2.4 Operation of starter relay. ......................................................................... 40

1 VMOTO MONACO V1

This Owner Handbook was compiled by Gledhill & Associates and remains the property

of Gledhill & Associates. This document may not be copied or distributed without the

expressed permission of Gledhill & Associates.

While all care has been taken in the compilation of this document, variation in

manufacturer’s specification and production values may lead to some differences from

your model of the scooter. Therefore care should be taken when undertaking

maintenance or adjustments to check for compliance between the details in this manual

and your scooter.

2 GENERAL INFORMATION

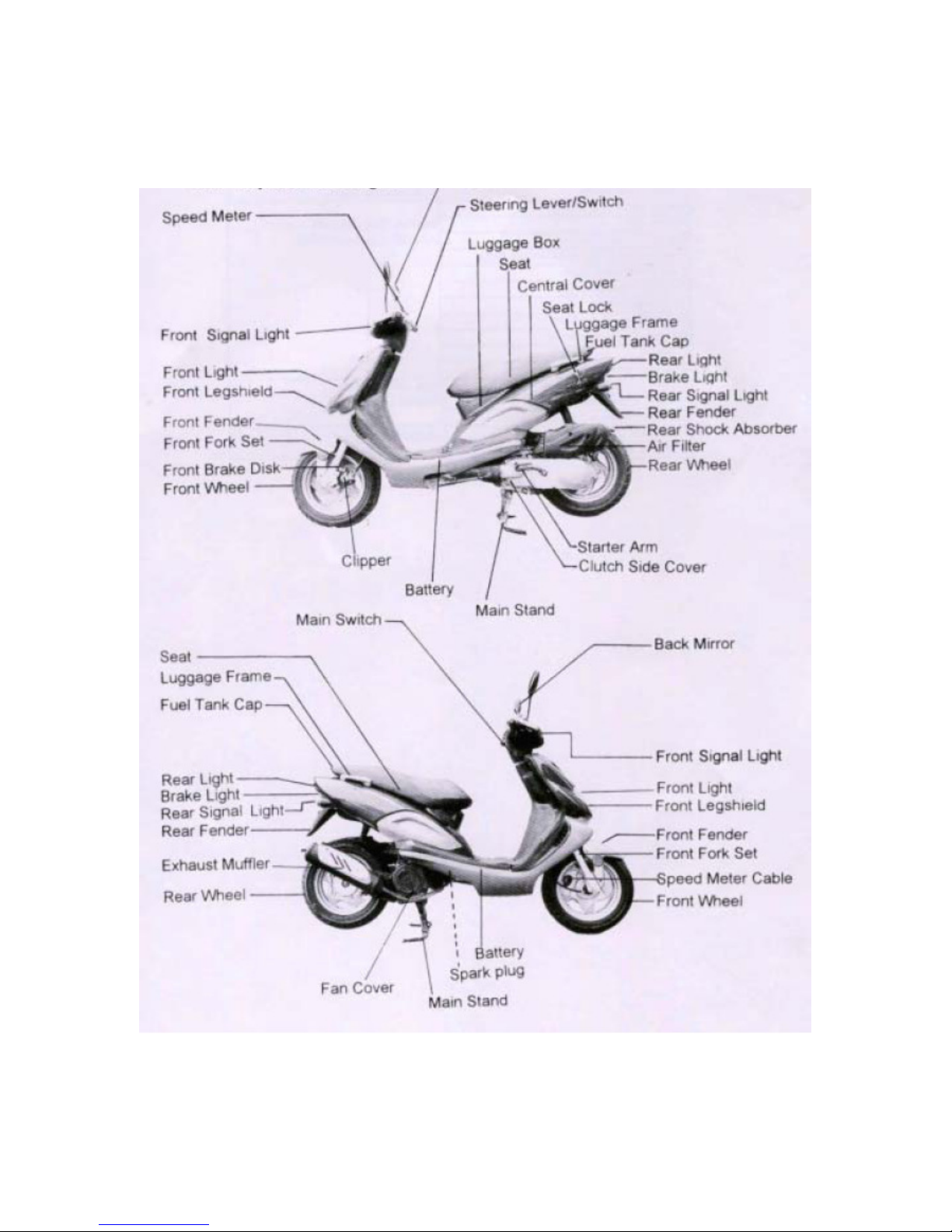

2.1 Description

2.2 Specifications

Total Length 1920 mm

Total Width 705 mm

Total Height 1165 mm

Wheel Base 1265 mm

Ground Clearance 120 mm

Weight (dry) 100 Kg

Engine Style Single cylinder, 4 stroke, air cooled.

Engine Type 153QMI-3

Bore & Stroke 52.4 mm x 57.8 mm

Intake Valve Gap (mm) 0.08 – 0.10

Exhaust Valve Gap (mm) 0.08 – 0.10

Lubrication Pump and splash

Fuel Type 92/95 unleaded

Fuel Capacity 6.8 litre

Displacement 124.6 cc

Nominal Engine Capacity 125 cc

Maximum Power 6,2 KW @ 8000 rpm

Standard Power 5.5 KW @ 7500 rpm

Idle Speed 1800 +/- 100

Ignition Type CDI

Starting Method Electric starter or kickstart

Clutch Dry Shoe, Acentric

Drive V-belt CVT

Front Brake Hydraulic disc

Rear Brake Cable drum

Front Tyre Specification 120/70 – 12/4PR 25 psi

Rear Tyre Specification 130/70 – 12/4PR 30 psi

Max Load Weight 150 Kg

Fuel Consumption (economy running) 2.8 litre/100 Km

Max Speed 83 Km/Hr

Engine Oil Type SAE 20W-40

Engine Oil Quantity 900 cc

Gear Oil Type SAE 90#

Gear Oil Quantity 120 cc

Air Cleaner Type Paper filter

Carburettor Type CVK

Throttle Valve Diameter 24 mm

Venturi Diameter 22.1 mm

Throttle Valve Type Butterfly

Ignition Type CDI

Spark Advance BTDC 13deg/2950 rpm

Spark Plug NGK CR7HSA

Spark Plug Gap 0.6 - 0.7 mm

Battery 12V 7AH

Head Lamp (H/L) 12V 35W/35W x1

Rear Lamp 12V 5W x1

Brake Lamp 12V 21W x1

Turn Lamp 12V 10W x4

Suspension Front Telescopic

Suspension Rear Rocker Arm

Frame Steel Tube

2.3 Inspection Tips

1. Bolts and bolt heads use the International Standard (Metric) measurement system.

Use of tools other than those complying with the Metric system may cause

damage to the parts.

2. Clean parts of any outside dirt or deposits before maintenance to prevent the

chance of contaminants dropping into the engine and causing damage.

3. Use kerosene to clean-up disassembled parts. Check and measure parts after

clean-up. Apply engine oil for lubrication to any contact and sliding surfaces of

parts.

4. The packing, metal gasket, O-ring, seal, clamp, and clipper should be replaced

with new ones after disassembly.

5. Pay attention to the orientation and relative positions of the major components.

Arrange the parts in order during disassembly. Make marks if necessary to avoid

mistakes in re-assembly.

6. Removing parts should start from small to big, from outside to inside. Assembly

is in reverse order of disassembly.

7. The oil seals should be replaced with new ones after disassembly. The contact

surface should be cleaned-up. Check shafts for scratches or burrs. Use special

tools for assembly to avoid damaging the seal lip area. The manufacturer logo

should face outward on seals and bearings. Apply grease at seal lip area.

8. Disconnect the battery negative (-) terminal before maintenance. Connect the

positive (+) terminal first in assembly. Apply a thin layer of grease on terminals,

and cover with terminal caps.

2.4 Safety Precautions

Warning: Engine Exhaust

Keep the area well ventilated during engine operation. Do not operate engine in an

enclosed area. Carbon monoxide (CO) in exhaust fumes may lead to loss of

consciousness and even death.

Warning: Petrol

Petrol is highly flammable. Avoid any naked flame during inspection of the petrol tank or

of a petrol leak.

Warning: Battery Gasses and Battery Liquid

1. The battery liquid is highly corrosive. Avoid contact of the liquid with skin or eye.

If any contact occurs, wash with large quantities of clean water and in the case of

eye contact, consult a doctor.

2. The hydrogen released from battery during charging is explosive. Keep the area

well ventilated during battery charging and avoid naked flame.

Warning: Brake Fluid

Brake fluid can damage the paint and some plastics. Cover the parts that can be damaged

with cloth during maintenance of hydraulic brakes. If the brake fluid is spilt on plastic or

a painted component, remove the fluid and wash the surface with water immediately.

Warning: High Temperature of Engine

The engine cover, cylinder, and exhaust pipe can be at a high temperature after the engine

has been running. Wait for the engine to cool before working on it or use protective

gloves.

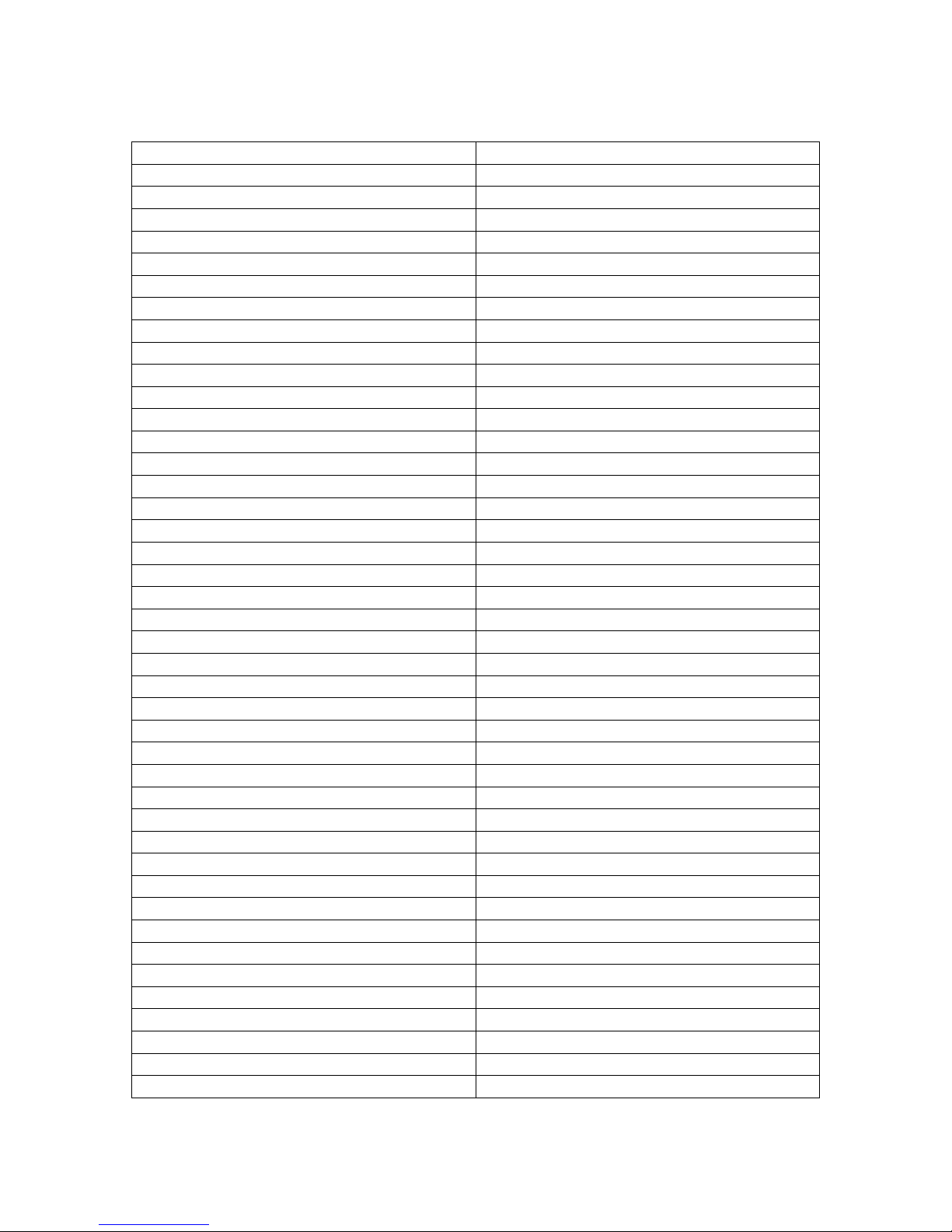

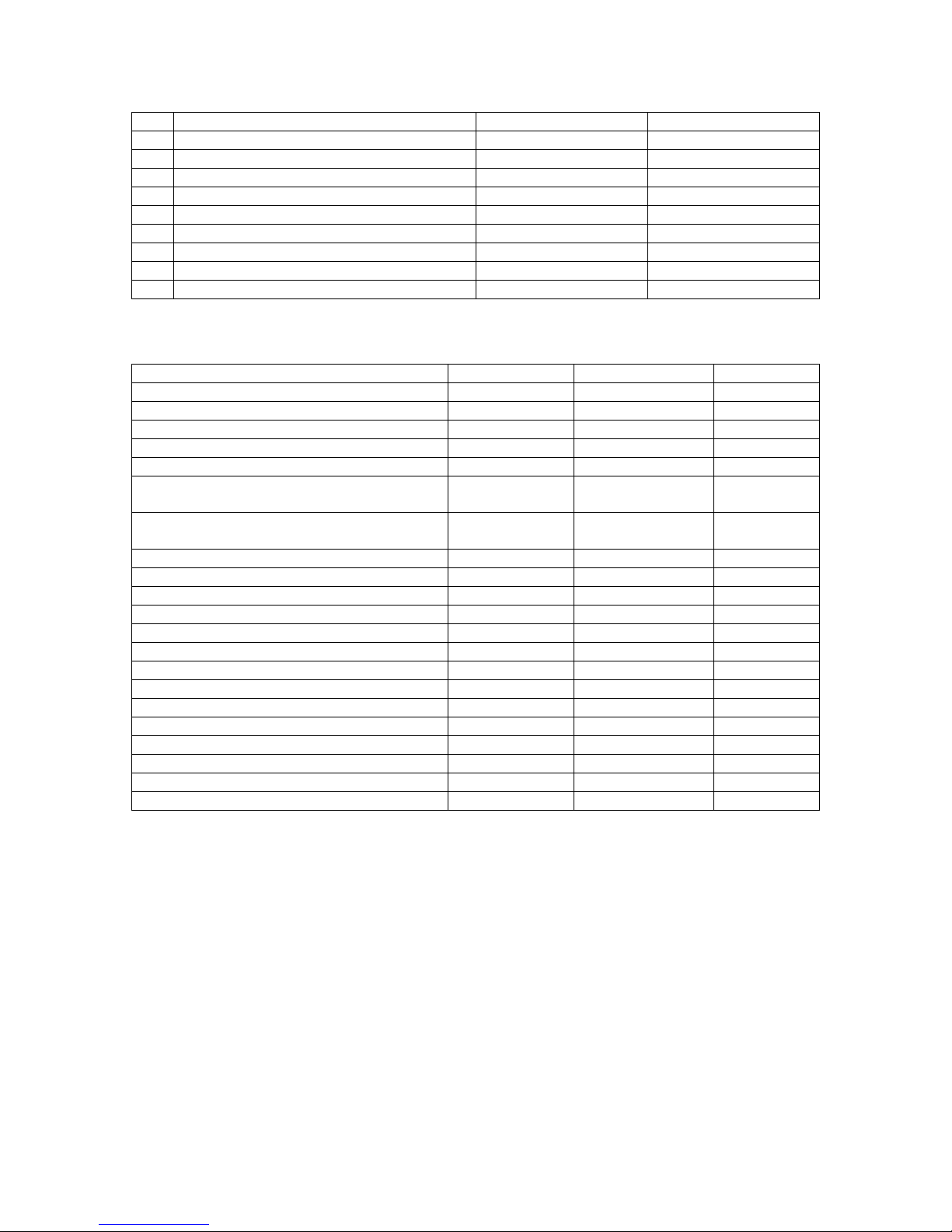

2.5 Torque Settings

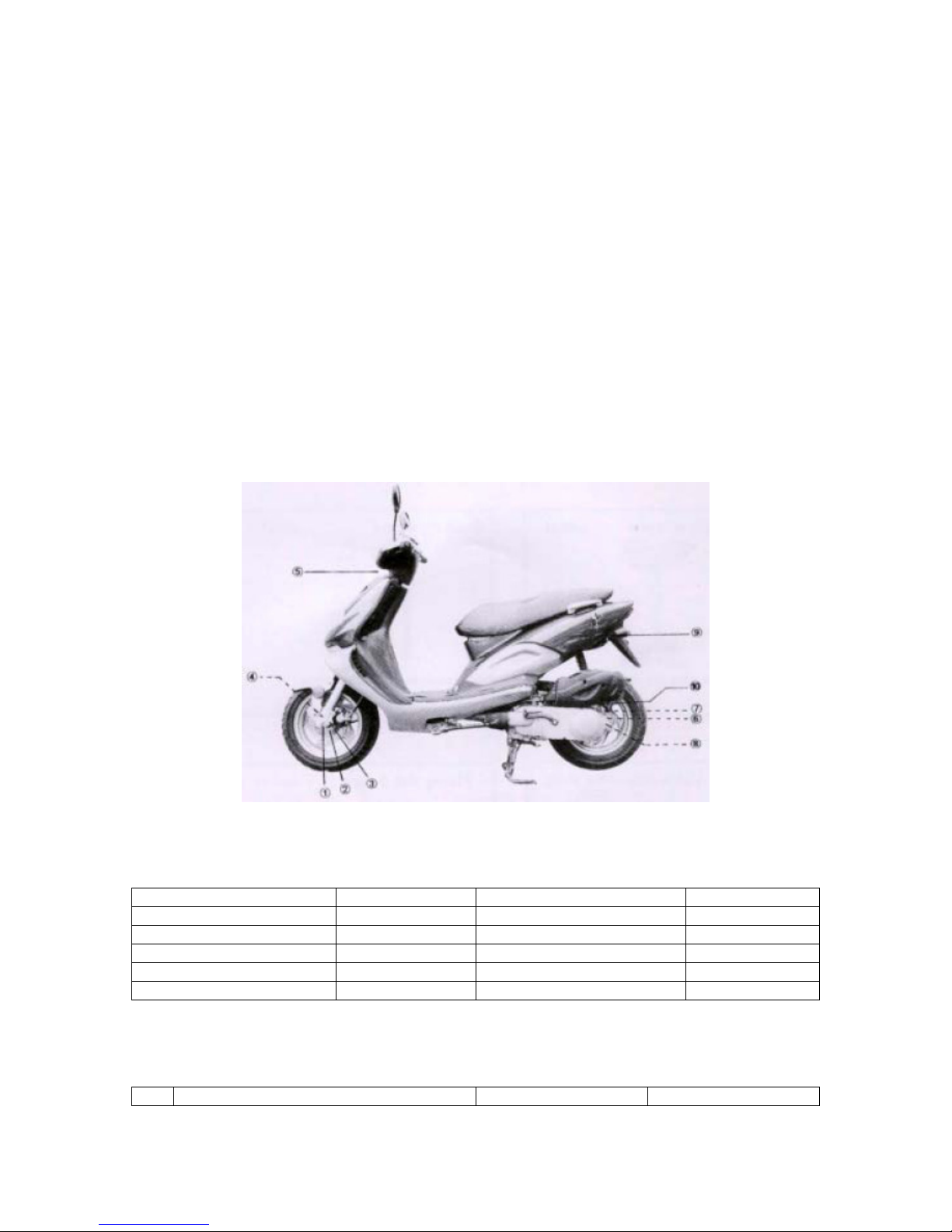

(Monaco representative figure)

Standard Torque Values of Bolts and Nuts

Specification

5 mm Bolt and Nut 40 8 mm Bolt and Nut 220

5 mm Flange Bolt and Nut 50 8 mm Flange Bolt and Nut 270

6 mm Bolt and Nut 100 10 mm Bolt and Nut 350

6 mm Flange Bolt and Nut 120 10 mm Flange Bolt and Nut 400

6 mm SH Bolt and Nut 90 12 mm Bolt and Nut 550

Torque Values of Chassis Components

No. Tightening Location Specification Torque (kg-cm)

Torque (kg-cm) Specification Torque (kg-cm)

1 Front Wheel Axle Self-lock Nut M12 500~600

2 Brake Disk Hex Bolt M5 180~280

3 Brake Clipper Tightening Bolt M8x35 210~250

4 Speed Meter Cable Nut X 60

5 Front Fork Bearing Tightening Nut M25x1.0 600~650

6 Rear Wheel Axle Self-lock Nut M16x10 600~900

7 Rear Brake Connecting Rod Bolt M16x32 50~80

8 Rear Brake Pin Self-lock Nut M8 250~270

9 Rear Upper Cushion Tightening Bolt M10×46 200~300

10 Rear Lower Cushion Tightening Bolt M8×35 200~300

Torque Values of Engine Components

Tightening Location Specification Torque (kg-cm) Quantities

Cylinder Head Bolt M6 80~100 4

Cylinder Stud Bolt M8x182.5 500~800 2

M8x195.5 2

Cylinder Intake Pipe Stud Bolt M6x50 500~800 2

Muffler and Exhaust Pipe Tightening Screw M6 100~120 2

Muffler & Right Crankcase Upper Tightening

Screw

Muffler & Right Crankcase Lower Tightening

Screw

Spark Plug M10 100~120 1

Valve Gap Adjust Lock Bolt M5 50~90 2

Fuel Filter Nut Cap M30 150~200 1

Cooler Fan Lock CR M6x18 500~800 4

Wire Assembly Lock Screw M6x20 800~1000 2

Start Clutch Gear Tightening Nut M22 (R.T.) 800~1000 1

Driven Belt Pulley Assembly M12 400~600 1

Gearbox Cover Tightening Bolt M6x28 100~1200 3

M6x35 3

Gearbox Oil Fill Cover Screw M8 90~150 1

Gearbox Oil Drain Cover Screw M8x12 90~150 1

Clutch Side Cover Screw M6x40 50~80 6

M6x65 2

Starter Arm Tightening Screw M6x22 100~120 1

M8x42 300~400 1

M8x38 300~400 1

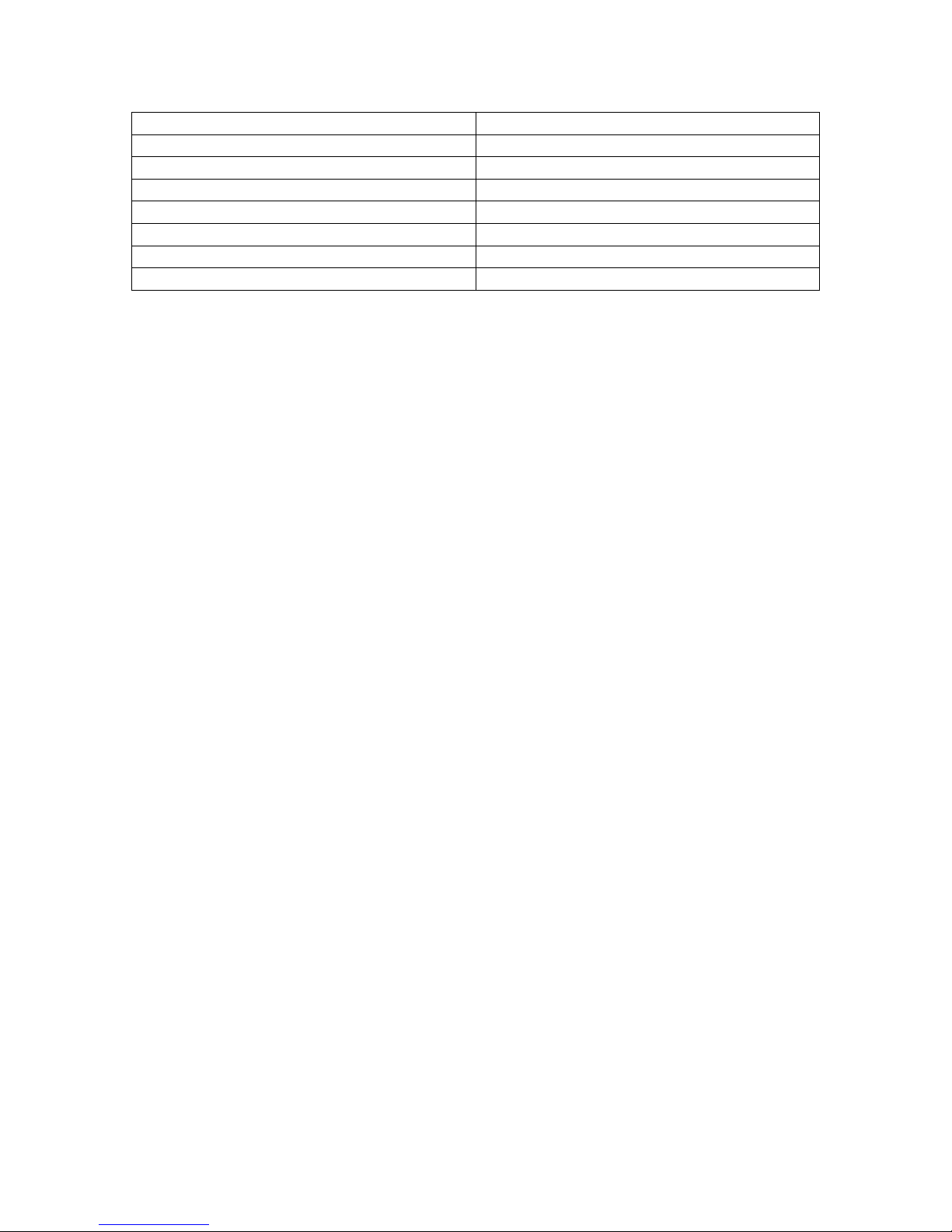

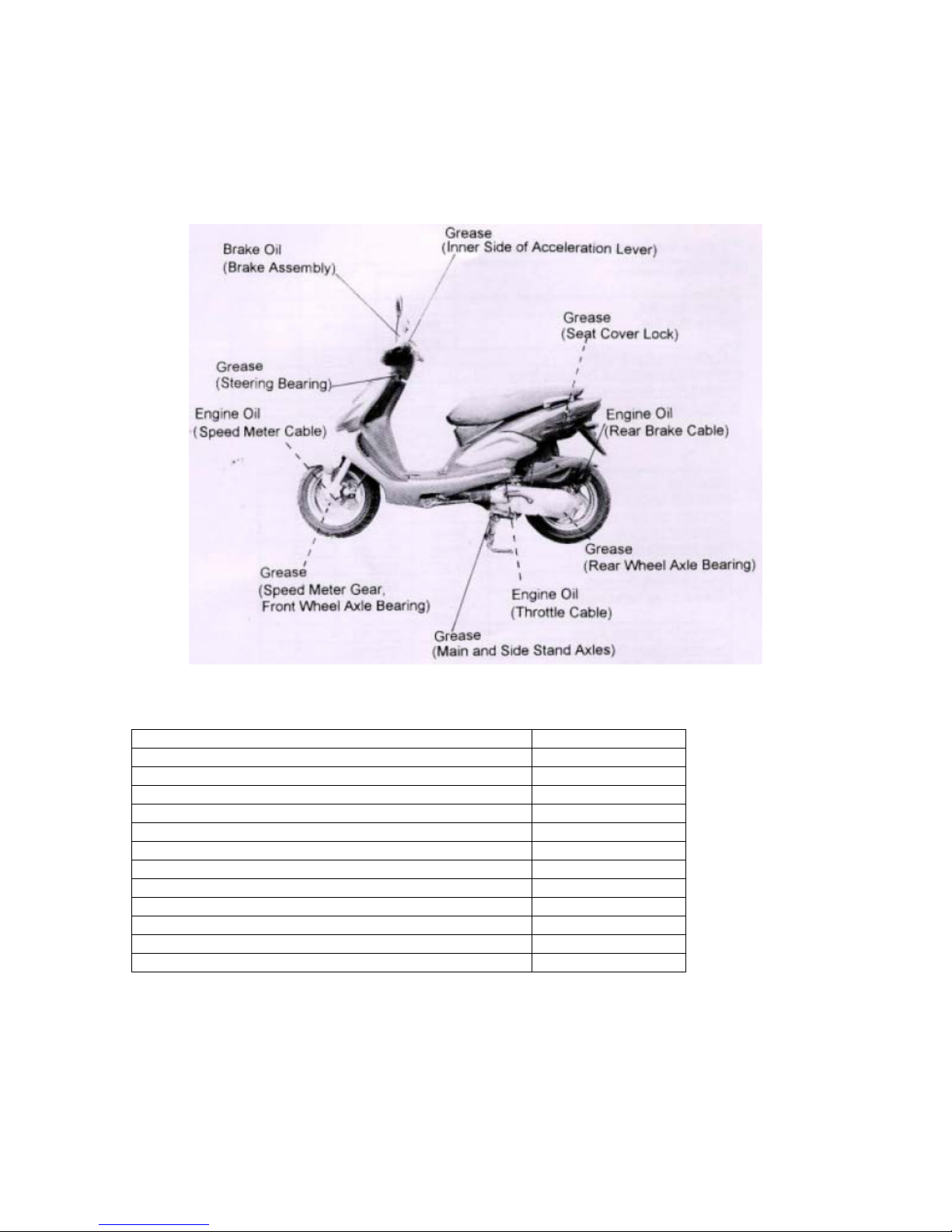

2.6 Lubrication Points

(Monaco representative figure)

Chassis

Lubrication Area Lubrication Type

Inner Side of Acceleration Lever Grease

Steering Bearing Grease

Speed Meter Gear Grease

Front Wheel Axle Bearing Grease

Front Wheel Axle Grease

Main and Side Stand Axles Grease

Rear Wheel Bearing Grease

Seat Cover Lock Grease

Speed Meter Cable Grease

Throttle Wire Grease

Rear Brake Cable Grease

Brake Assembly Brake Fluid

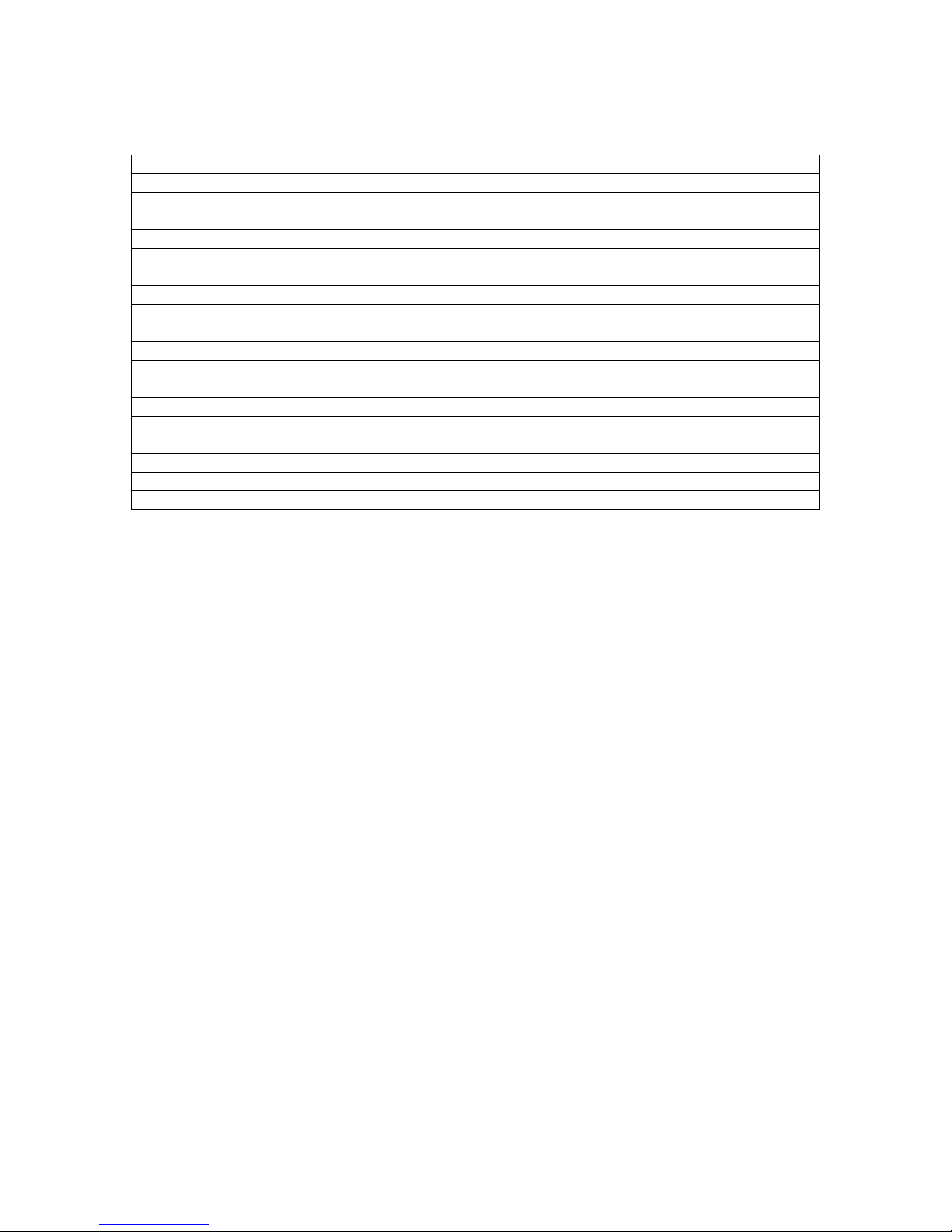

Engine

Lubrication Area Lubrication Type

Piston and Piston Rings SAE 10W-40 and API SE,SG Engine Oil

Piston Pin

Big End of Connecting Rod

Rocker Arm Frictional Contact Area

Cam Shaft and Chain

Cylinder Frictional Area

Oil Pump Chain

Gears Contact Surface

Bearing Operation Area

O Rings

Seal Lip Area

Starter Frictional Surface High Temperature Durable Grease

Starting Cam Gear

Spring Operation Frictional Area

Generator Connector Adhesives

Gearbox Ventilation Tube

2.7 Trouble Shooting

2.7.1 Engine Fails to Start:

Check the following possible causes -

No fuel

Dirty fuel filter

Obstructed fuel pipe

Obstructed ventilation tube on the fuel tank

Damaged carburettor float needle valve

Carburettor float chamber dirty

Faulty carburettor float

No spark from spark plugs

Poor spark from spark plugs

Dirty spark plugs

Incorrect spark plug gap

Wet spark plugs

Loose adjustment screws in the carburettor

Carburettor choke not operating

Blocked carburettor idle nozzle

Dirty air filter

Engine flooded with fuel

Loose spark plug

Dead battery

Poor contact of battery terminals

Ignition or starter switch faulty

Starter relay faulty

Loose contacts or wiring

Starter gear and clutch gear seriously worn

Starter gear and clutch gear not engaging

Faulty starter motor

2.7.2 Poor spark

Loose spark plugs

Worn spark plugs

Damaged high-voltage wiring

Faulty distributor coils

Ignition switch high resistance

Relays faulty

Loose spark plug connector

Faulty C.D.I.

Faulty distributor high-voltage wiring

Loading...

Loading...