C-99A / C-100A

FIRE

ALARM CONTROL PANELS

INSTALLATION

OPERATION

MAINTENANCE

MANUAL

.

LIST

OF

EFFECTIVE

ADDENDUMS

November.

1994

The

C-99A/C-100A

Fire

Alarm

Control

Panels

I-O-M

Manual,

P/N

001-097-00,

includes

the

following addendum:

A

o

MONACO

ENTERPRISES,

INC

1994

DOCUMENT

NO.

001 -097-00

PAGE

Monaco Ente~p~ises

INC.

SPOKANE, WASHINGTON

99214

C-GQA/ C-

100A

CONTROL PANELS

INSTALLATION-OPERATION-MAINTENANCE

MANUAL

ADDENDUM

A

The

attached INTERCONNECTION

DRAWING:

?YPICAL

FIRE

AIARM

EQUIPMENT

replaces the drawing on pages C4 -C5

in

the

Appendix of

this

Manual.

MONACO

ENTERPRISES.

INC

1994

DOCUMENT

NO.

001-097-00, ADD. A

PAGE

1

of

2

Monaco Ente~p~ises

INC.

941214

CPnKANF WACUlNCTnN

P991A

C-99A/C-100A

CONTROL

PANELS

INSTALLATION

-

OPERATION - MAINTENANCE

MANUAL

Copyright, 1983

All

Rights Reserved by Monaco Enterprises, Inc., Spokane,

WA

This manual is for exclusive use by Monaco Customers and contains propri-

etary information. The manual may be loaned to subcontractors to assist in

performance of duties. Further disclosure or reproduction is expressly

prohibited unless authorized in writing by Monaco Enterprises, Inc.

These instructions are not intended to cover all details or variations in

equipment nor to provide for every possible contingency to be met in

connection with installation, operation, or maintenance. Should further

information be desired or should particular problems arise which are not

covered sufficiently for the

Customersf purposes, the matter should be

referred to Monaco Enterprises, Inc.

001-097-00

Revision

C

November, 1985

TABLE OF CONTENTS

(Continued)

SECTION

FOUR.. MAINTENANCE

4.1 SCHEDULED PREVENTIVE MAINTENANCE

..............

4.2

DISASSEMBLYANDREASSEMBLY

.................

4.2.1 ControlPanel

....................

4.2.2 Transformer Assembly (C-99A-24 version only)

....

4.2.3 Lamps

........................

4.2.4 Meter

........................

4.3 TROUBLESHOOTING

......................

PAGE

4-1

4-1

4-1

4-2

4-3

4-3

4-4

SECTION FIVE.. REPLACEMENT PARTS

.................

5-1

SECTION SIX.. APPENDIX

A..WARRCWTY

..........................

A1

B

.

SCHEMATIC DIAGRAMS

C-99A-12 Control Panel PCB Assembly

............

B1

C-99A-24 Control Panel PCB Assembly

............

B2

C-99A-24 Transformer Assembly

...............

B3

C-100A-24 Control Panel PCB Assembly

............

B4

C

.

WIRING DIAGRAMS

C-99A-12 Control Panel

...................

C1

C-99A-24 Control Panel

...................

C2

C-100A-24 Control Panel

..................

C3

Typical Fire Alarm 24V Installation

............

C4

D

.

ADDITIONAL EQUIPMENT FOR CUSTOM CONFIGURATION

.......

Dl

E

.

INSTALLATION OF ADDITIONAL EQUIPMENT

AND

ACCESSORIES

....

El

F

.

BATTERY CAPACITY CALCULATION

................

F1

G

.

CONDENSED OPERATING INSTRUCTIONS

..............

G1

LIST OF ILLUSTRATIONS

F

I

GURE

1-1

1-2

DESCRIPTION PAGE

.

Low Voltage Fire Alarm Control Panel

.........

4

Simplified Control Panel Schematic in

.............

Normal Operating Condition 1-4

Wiring for Supervising Smoke Detector Power Leads

...

2-6

.................

C-99A-12 PCB Assembly 3-1

.........

C-99A-24 Transformer and PCB Assembly

3-3

................

C-100A-24 PCB Assembly 3-4

............

End-of-Line Diode Configuration E2

LIST OF TABLES

TABLE DESCRIPTION

.

PAGE

................

1-1

Control Panel Versions

1-1

2-

1

Standard Control Panel Configurations

.........

2-4

3-1

Control Panel Initial Voltages

............

3-5

...................

4-

1

Trouble Condition 4-4

4-

2

Continuous Alarmcondition

..............

4-5

...................

4-3 No Battery Power 4-5

001-097-00

PAGE

3

555

LDOCUMENT

NO

.

Monaco

Ente~p~ises

rc

.

SPOKANE . WASHINGTON

99214

Figure

1-1:

Low

Voltage

Fire

Alarm

Control

Panel

555

LDOCUMENT

NO.

001-097-00

PAGE

4

Monaco

Ente~p~ises

INC.

SPOKANE WASHINGTON

99214

SECTION ONE

GENERAL INFORMATION

1.1 OVERVIEW

These low voltage automatic fire alarm Control Panels are local or

auxiliary units which sound local alarms and, if desired, transmit signals

to the fire headquarters through municipal Alarm boxes, McCulloh Alarm and

Trouble transmitters, polarity reversing transmitters, or Radio Alarm

System transceivers.

Table 1-1 shows the available versions.

TABLE 1- 1

CONTROL PANEL VERSIONS

MODEL VOLTAGE

(Volts) (Amperes)

C-99A-12

C-99A-24

......................................

NOTE

The 12 Vdc

3

Amp version of the C-100A is covered in separate manual. See

document Part Number 001-045-00 (C-100A-12 Fire Alarm Control Panel Installation, Operation, and Maintenance Manual) for complete information

regarding this Control Panel.

555

M

DOCUMENT

NO.

001-097-00

PAGE

Monaco

Entepp~ises

ING.

SPOKANE WASHINGTON

99214

The primary power input to the Control Panels is 120 VAC obtained from the

input side of the building main supply through an independent fused disconnect switch. The primary voltage is reduced and rectified to the proper

operating voltage. Terminals are also provided for connection of an emergency battery supply which is automatically connected to operate the system

in the event of a failure of the primary power.

These Control Panels are either stand-alone units or custom configured to

meet a specific application.

This manual describes the Installation, Operation, and Maintenance of the

C-99A-12, C-99A-24, and C-100A-24 low voltage automatic fire alarm Control

Panels.

1.2 FUNCTIONAL DESCRIPTION

I

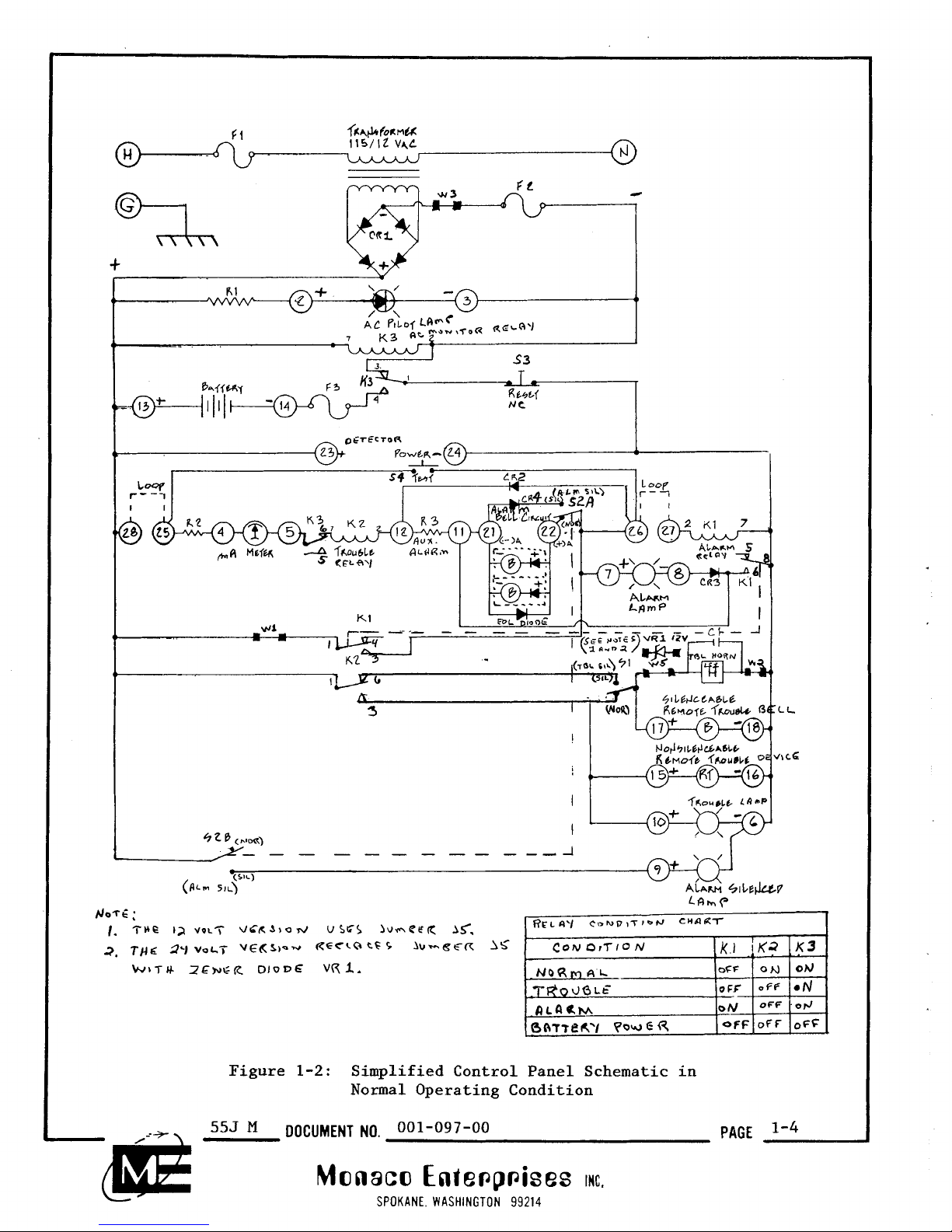

All the Control Panels operate identically except for the voltage and

I

current outputs. Figure 1-2 is a simplified version of the Control Panel

models.

1.2.1 Operating Principle

Three relays operate the Control Panel circuitry. The AC monitor relay and

the Alarm relay are voltage sensitive. This means they require the full DC

voltage applied across the coil before changing their state. The Trouble

relay is current sensitive. This relay is normally energized and is

de-energized whenever supervisory current is interrupted.

555

M

DOCUMENT

NO.

001-097-00

PAGE

I'2!

Monaco Enfe~p~ises

MC.

SPOKANE. WASHINGTON

99214

NOTES

1.2.2 Normal Condition

The circuitry in Figure 1-2 shows the positive DC voltage on the left side

and the DC return on the right side. A closer study reveals several

parallel paths for potential current flow.

In the Normal condition, full potential is applied causing:

o AC pilot lamp to go ON (between terminals 2 and

3)

o AC monitor relay (K3) to energize

o Relay K3 contacts 1 and 3 to close applying normal power

to the rest of the circuit.

Detector power is applied to teminals 23 and 24. Supervisory current is

applied through to the following supervised series circuit:

o High detector loop (between terminals 28 and 25)

o Resistor R2

o Milliamp meter (between terminals

4

and

5)

o

AC

monitor relay (K3) contacts 8 and

6

o Trouble relay (K2) coil (pins 7 and 2)

o Resistor R3 (between terminals 12 and 11)

o Circuit trace (between terminals 11 and 21)

o Bell circuit end-of-line (EOL) diode

(between terminals 21 and 22)

o Alarm Silence switch (S2) contacts

A

(between terminals 22 and 26)

o Low detector loop (between terminals 26 and 27)

o Alarm relay (Kl) coil (pins 2 and 7).

The momentary Test switch S4 (between terminals 25 and 26) is used to Alarm

test the system. The momentary Reset switch S3 is used to reset the system

to Normal condition.

The standby battery is connected to terminals 13 and

14.

Fuse F3 protects

the circuitry when battery power is used.

555

M

DOCUMENT

NO.

001-097-00

PAGE

Monaco

Ente~p~ises

INC.

SPOKANE. WASHINGTON

99214

1.2.3 Trouble Condition

The series circuit containing the Trouble relay (K2) coil is the system's

supervised circuit. In the Normal condition, supervisory current is

observed by the Milliamp meter reading. The Trouble relay activates,

closing contacts

1

and 6.

An open in any portion of the series circuit causes a Trouble condition.

The following events take place:

o Supervisory Current is interrupted

o Milliamp meter reading goes to zero

o Trouble relay

(K2) de-energizes

o Trouble relay (K2) contacts 1 and

3

close

o Trouble lamp goes ON (terminals 10 and

6)

o Silenceable Trouble horn (LS1) goes ON

o Silenceable remote Trouble bell goes ON

(terminals 17 and 18)

o Nonsilenceable remote Trouble device goes ON

(terminals 15 and 16)

The silenceable Trouble horn and remote Trouble bell can be turned

OFF

by

placing the Trouble Silence switch (Sl) in the Silence position.

Correcting the Trouble condition automatically places the system in Normal

condition with one exception. The silenceable Trouble horn and remote bell

goes ON (ring back feature) indicating the Trouble Silence switch

(Sl) must

be placed in the Normal position.

1.2.4 Alarm Condition

The Control Panel goes into Alarm with the activation of any one of the

following:

o Test switch (S4)

o Heat detector

o Smoke detector

o Manual pull station.

L-

Monaco

Enie~p~ises

rc.

SPOKANE. WASHINGTON

99214

A

properly wired detector or manual pull station has its Alarm contacts (or

equivalent) closed across terminals 25 and 26 of the Control Panel.

An Alarm condition causes the following sequence of events to occur:

o Control Panel terminals 25 and 26 have a closed circuit path

o Control Panel goes into Trouble condition (see paragraph 1.2.3)

o Alarm relay

(Kl) energizes

o

Alarm relay (Kl) contacts 1 and 3 close

o Alarm relay (Kl) contacts

6

and 8 close

o Alarm lamp goes ON (between terminals 7.and

8)

o Diode CR2 conducts (between terminals 26 and 12)

o Resistor R3 or external device (auxiliary alarm) has

supply voltage applied (between terminals 12 and 11)

o Alarm bells turn ON (between terminals 22 and 21)

o Circuit conducts between terminals 21 and 11.

Silencing the Alarm bell circuit is done by placing the Alarm Silence

switch (S2) in the Silence position. The Alarm Silence lamp now goes ON

(between terminals

9

and 6). Note the auxiliary Alarm, terminals 12 and

11, cannot be silenced.

The Alarm relay (Kl) is locked ON as a result of its contacts

1

and 3

closing (terminals 26 and 27 are always shorted). This relay (Kl) coil

now has the full DC voltage applied across it.

Resetting the Control Panel can only be done by momentarily placing the

Reset switch (S3) in the Reset condition.

Be sure the alarmed detector or manual pull station is in the Normal condition or removed from the detection loop before resetting the Control Panel.

......................................

-dl@

555

M

DOCUMENT

NO.

001-097-00

PAGE

1-7

M~naco

~nie~~~ises

int.

SPOKANE. WASHINGTON

99214

The Alarm Silence lamp

will

remain

ON

indicating the Alarm Silence switch

must be placed back in the Normal condition.

1.2.5 Battery Power Condition

In the event of an

AC

power failure, the Control Panel can operate with

battery power.

A

power failure causes the following sequence of events to

occur:

o

AC

pilot lamp goes

OFF

o

AC

monitor relay (K3) de-energizes

o

AC

monitor relay (K3) contacts 1 and 4 close

o

AC

monitor relay (K3) contacts 6 and 8 open

o Battery power is applied to Control Panel

o Trouble condition occurs (see Paragraph 1.2.3)

When

AC

power is restored the Control Panel automatically restores except

for the ring back feature (due to the Trouble Silence switch (Sl) in the

Silence position). Placing this switch in Normal position turns the

audible Trouble signal

OFF.

Appendix

C

contains information on how to

calculate required battery capacity.

555

M

DOCUMENT

NO.

001-097-00

PAGE

Monaco Ente~p~ises

ac,

SPOKANE. WASHINGTON

99214

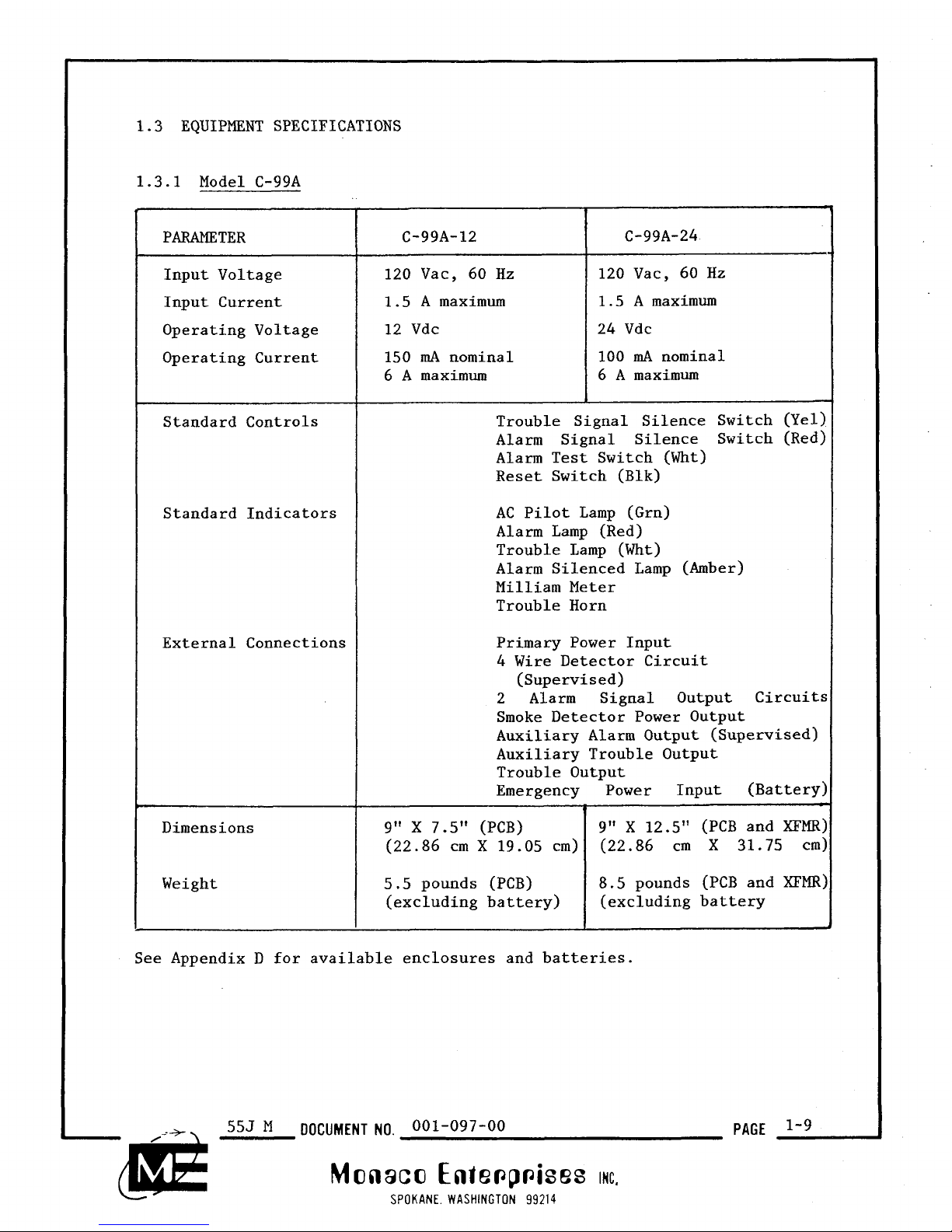

PARAMETER

Input Voltage

Input Current

Operating Voltage

Operating Current

Standard Controls

Standard Indicators

External Connections

Dimensions

Weight

C-99A-12 C-99A-24

120 Vac, 60 Hz 120 Vac, 60 Hz

1.5

A

maximum 1.5 A maximum

12 Vdc

24 Vdc

150

mA

nominal 100

mA

nominal

6

A

maximum 6 A maximum

1.3 EQUIPMENT SPECIFICATIONS

1.3.1 Model C-99A

C

-

-

C

-

See Appendix D for available enclosures and batteries.

555

M

DOCUMENT NO.

001-097-00

Monaco Ente~p~ises

rc.

SPOKANE WASHINGTON

99214

Trouble Signal Silence Switch (Yel)

Alarm Signal Silence Switch (Red)

Alarm Test Switch (Wht)

Reset Switch (Blk)

AC

Pilot Lamp (Grn)

Alarm Lamp (Red)

Trouble Lamp (Wht)

Alarm Silenced Lamp

(Amber)

Milliam Meter

Trouble Horn

Primary Power Input

4 Wire Detector Circuit

(Supervised)

2 Alarm Signal Output Circuits

Smoke Detector Power Output

Auxiliary Alarm Output (Supervised)

Auxiliary Trouble Output

Trouble Output

Emergency Power Input (Battery)

9"

X

7.5" (PCB) 9" X 12.5" (PCB and XFMR)

(22.86 cm

X

19 .05 cm) (22.86 cm

X

31.75 cm)

5.5 pounds (PCB) 8.5 pounds (PCB and XFMR)

(excluding battery)

(excluding battery

PAGE

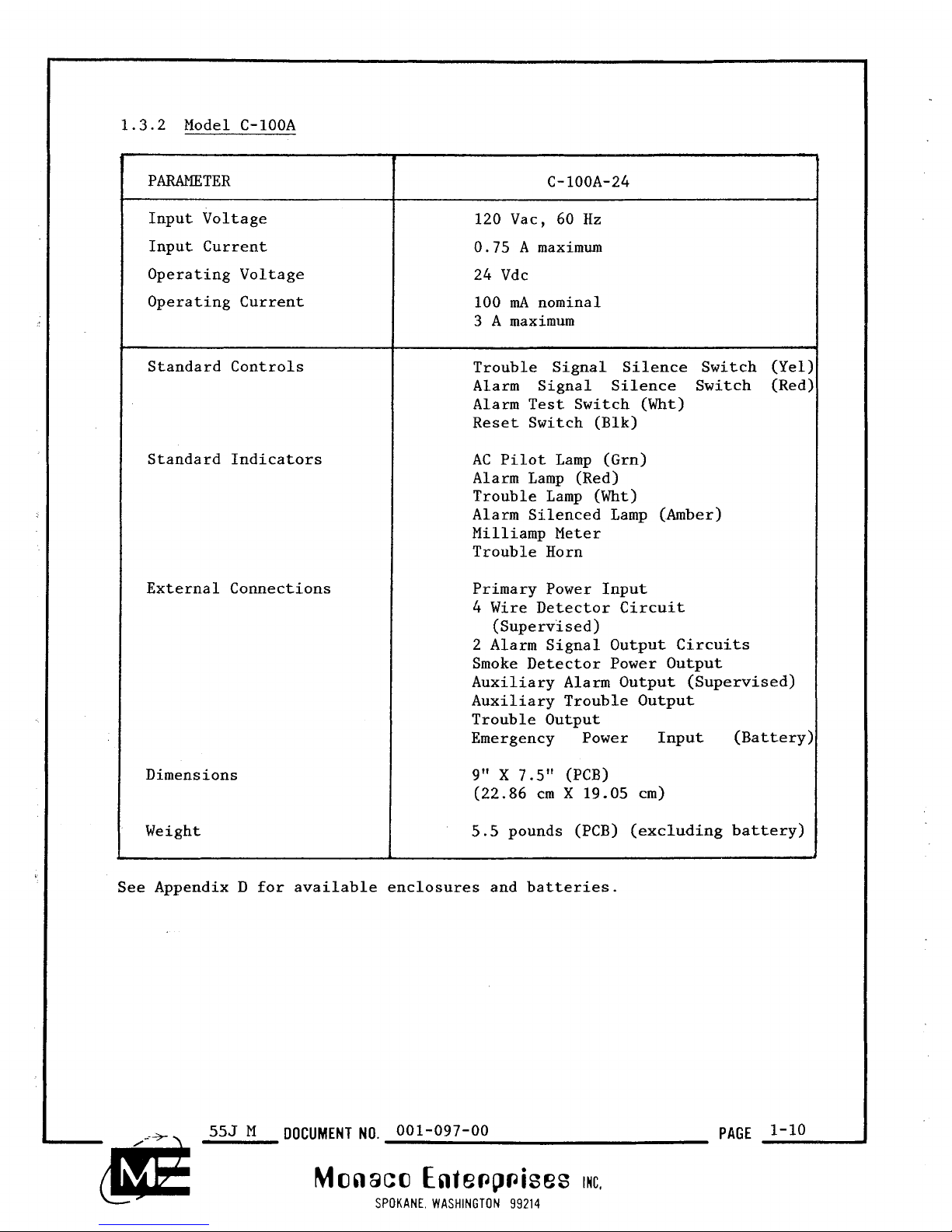

PARAMETER

Input Voltage

Input Current

Operating Voltage

Operating Current

Standard Controls

Standard Indicators

External Connections

Dimensions

Weight

120

Vac, 60 Hz

0.75

A

maximum

24 Vdc

100

mA

nominal

3

A

maximum

1.3.2 Model C-100A

f

-

-

L

See Appendix D for available enclosures and batteries.

555

M

DOCUMENT NO.

001-097-00

Monaco Ente~p~ises

IMC.

SPOKANE WASHINGTON

99214

Trouble Signal Silence Switch (Yel:

Alarm Signal Silence Switch (Red:

Alarm Test Switch (Wht)

Reset Switch (Blk)

AC

Pilot Lamp (Grn)

Alarm Lamp (Red)

Trouble Lamp (Wht)

Alarm Silenced Lamp (Amber)

Milliamp Meter

Trouble Horn

Primary Power Input

4 Wire Detector Circuit

(Supervised)

2 Alarm Signal Output Circuits

Smoke Detector Power Output

Auxiliary Alarm Output (Supervised)

Auxiliary Trouble Output

Trouble Output

Emergency Power Input (Battery:

9"

X

7.5" (PCB)

(22.86 cm

X

19.05 cm)

5.5

pounds (PCB) (excluding battery)

PAGE

SECTION TWO

INSTALLATION

2.1

UNPACKING

AND

INSPECTION

Your Control Panel was carefully checked and packaged at the factory and

should be ready for installation and operation when it is unpacked. If the

shipping carton shows evidence of rough handling, inspect the contents

carefully for shipping damage. If damage is found notify the carrier

immediately. Verify that all parts ordered have been received. Check the

parts against the packing list and your Purchase Order. Part lists are

provided in Section

5.

2.2

WARNINGS

2.2.1

Personnel Safeguards

The following general

safety precautions must be observed during all phases

of operation, service, and repair of this equipment. Failure to comply

with these precautions or with specific warnings elsewhere in this manual

violates safety standards of design, manufacture, and intended use of the

equipment. Monaco assumes no liability for the Customers' failure to

comply with these requirements.

A.

Proper Ground

The equipment must be connected to an electrical ground to minimize the

shock hazard.

B.

Explosive Atmosphere

Do not operate the equipment in the presence of flammable gases, fumes or

dust

.

555

N

DOCUMENT NO.

001-097-00

PAGE

2-1

Monaco Ente~p~ises

IMG.

SPOKANE WASHINGTON

99214

C. Live Circuits

Component replacement and internal adjustments must be made only by

qualified Maintenance Personnel. Do not replace components with power

connected. Under certain conditions, dangerous voltages may exist even

with the power removed. To avoid injuries, always disconnect power and

discharge circuits before touching them.

D.

Two Service Persons Required

It is recommended that another person be present when internal service or

adjustments are attempted in order to render assistance if necessary.

E.

Substitutions or Modifications

Do not install substitute parts or perform any unauthorized modifications

to the equipment before consulting with Monaco to ensure that safety

features are maintained.

2.2.2

Equipment Protection

The following general requirements must be observed during all phases of

operation, service, and repair of this equipment. Failure to comply with

these precautions or with specific warnings elsewhere in this manual may

cause considerable damage to the equipment. Monaco assumes no liability

for the Customers' failure to comply with these requirements.

A.

Power Removal

Removal of individual assemblies or their subcomponents must be done only

after power is removed from the particular equipment. This includes both

line power and battery power.

555

N

DOCUMENT

NO.

001-097-00

PAGE

2-2

Monaco Ente~p~ises

INC.

SPOKANE WASHINGTON

99214

B.

Stay within Specifications

The equipment is designed to operate within specified design parameters

such as input voltage, temperature, etc. Do not exceed the parameters

listed in the Specifications.

(See Paragraph

1.3.)

C. Authorized Personnel

Only authorized personnel are allowed to disassemble the equipment for

repair.

2.3 STANDARD CONFIGURATION

Each version of the Control Panel comes in several standard configurations.

Table 2-1 gives a detail breakdown of each configuration.

Identify the configuration purchased. An Installation, Operation, and

Maintenance Manual is included for each option in the configuration.

Contact Monaco Enterprises, Inc. to purchase additional copies of these

manua 1 s

.

Every configuration is available with the options pre-wired in an enclo-

sure. External wiring is required to complete the system, i.e. input

power, detector hook-up, and to other optional equipment.

2.4 FIELD REPLACEMENT

The low voltage automatic fire alarm Control Panels are designed to

simplify field replacement. Replaceable plug-in items are as follows:

o AC line fuse (Fl)

o DC line fuse

(F2)

o Battery power fuse

(F3)

o Alarm relay

(Kl)

o Trouble relay (K2)

o

AC monitor relay (K3).

Control Panel replacement involves removal of the electrical connections,

fasteners, and the component. See Maintenance Section for complete

details.

553

N

DOCUMENT

NO.

001-097-00

PAGE

2-3

Monaco Ente~p~ises

ac.

SPOKANE WASHINGTON

99214

TABLE

2-

1

STANDARD CONTROL

PANEL

CONFIGURATIONS

(one for

l2VDC

McCulloh-Type

Annunciator

Part Number two for

24VDC)

555

N

DOCUMENT

NO.

001-097-00

PAGE

2-4

Monaco

Ente~pises

INC.

SPOKANE WASHINGTON

99214

2.5

ENCLOSURE MOUNTING

The Control Panel and any optional accessory enclosures should be mounted

closely to each other. They may be placed at any convenient location but

preferably as close to the main building as possible. Annunciators should

be placed where the indicator lamps may be readily seen.

Before beginning any installation procedure, the PCB

Assembly(s)

MUST

BE

REMOVED

FROM

THE

ENCLOSURE.

A.

Determine where the enclosure is to be located. Use the appropriate

wall anchors, toggle bolts, lag bolts, etc., to adequately support the

weight of the enclosure. Mounting holes are provided in the back

of

the enclosure. Install any conduit necessary.

B.

After all mounting, drilling, and mechanical fitting is complete, the

enclosure must be thoroughly cleaned of all shavings and debris.

C.

Reinstall the

PCB

Assembly(s) in the enclosure using the original

hardware.

Do not use plastic anchors because they do not adequately support the

weight of the Enclosure.

See Appendix

E

for installation information on additional equipment and

accessories.

555

N

DOCUMENT

NO.

001-097-00

PAGE

2-51

Monaco

Ente~p~ises

INC.

SPOKANE WASHINGTON

99214

2.6 CUSTOM CONFIGURATION

Building monitoring requirements may change from time to time requiring

additional equipment to an existing Control Panel configuration. These new

requirements are accommodated by adding to the existing system new options.

Consult either Monaco Field Service or Customer Service for all necessary

information.

2.7 ADDITIONAL EQUIPMENT

Supervising smoke detector power leads may be done with the aid of an

end-of-line power supervision relay module. Figure 2-1 shows the supervisory scheme. The miscellaneous part Tables in Section

5

contain ordering

information for this module.

L

Single Loop Panel Functional Diagram

I

Double Loop Panel Functional Diagram

Figure 2-1: Wiring for Supervising Smoke Detector Power Leads

Refer to Appendix

D

for additional equipment which may be used in conjunc-

tion with the low voltage alarm Control Panel. See Appendix C for the

wiring diagram of a typical 24 volt installation.

555

N

DOCUMENT NO.

001-097-00

PAGE

2-6

Monaco Ente~p~ises

INC,

LT

SPOKANE. WASHINGTON

99214

SECTION TmEE

OPEMTION

This Section describes the three operating conditions (Normal, Trouble, and

Alarm). Also included are the Battery Powered Condition and Initial

Testing. Appendix

G

contains a condensed Control Operation Instruction

label included with each Control Panel.

3.1

NORMAL CONDITION

In

a

Normal condition the:

o AC pilot lamp is ON (front of enclosure)

o Milliamp meter is reading supervisory current,

8mA

nominal (front of enclosure)

o Four switches are in the "normal" (up) position

(Control Panel PCB).

Figure

3-1:

C-99A-12 PCB Assembly

3.2 TROUBLE CONDITION

In a Trouble condition the:

o Milliamp meter reading goes

to zero (front of enclosure)

o Trouble lamp goes ON (front of enclosure)

o

Silenceable Trouble horn

o Silenceable remote Trouble bell terminals 17 and

(LS1)

goes ON (Control Panel PCB)

18

have power

causing bells to ring (Control Panel PCB)

o Nonsilenceable remote Trouble device terminals 15 and 16 have

power causing device to activate (Control Panel PCB).

The Trouble horn can be turned OFF by placing the Trouble Silence switch

(Sl) in the "Silence" (down) position. Refer to Troubleshooting Section

for corrective action. Correcting the Trouble condition automatically

restores the system to normal with one exception. The ring back feature

causes the Trouble horn to sound again. This alerts the Operator to

restore the Trouble Silence switch

(Sl) to the "normal" (up) position and

silence the Trouble horn.

3.3 ALARM CONDITION

In an Alarm condition the:

o Control Panel goes into Trouble condition (see paragraph 3.2)

o Alarm lamp goes ON (front of enclosure)

o Auxiliary Alarm terminals 12 and 11 have power causing device to

activate (Control Panel PCB)

o Alarm bell terminals 22 and 21 have power causing bells to ring

(Control Panel PCB).

The Operator can silence the Alarm bells by placing the Alarm Silence

switch (SZ), located on the Control Panel PCB, in the "Silence" (down)

position. The Alarm Silence lamp now goes ON.

555

0

DOCUMENT NO.

001-097-00

PAGE

3-2

Monaco Ente~p~ises

SPOKANE. WASHINGTON

99214

INC.

The alarmed device must now he either reset to the Normal condition or

removed from the detection loop.

The Control Panel is now reset to the Normal. condition with the following

!

switches located on the

PCB.

o Momentarily place the Reset switch

(S2)

in

the "reset"

(down) position.

o Place Trouble Silence switch

(Sl)

in the "normal"

(up) position.

o Place Alarm Silence switch

(52)

in the "normal"

(up) position.

Figure

3-2:

C-99A-24 Transformer and

PCB

Assembly

555

0

DOCUMENT NO.

001-097-00

PAGE

3'3

Monaco

Ente~p~ises

IMC.

SPOKANE. WASHINGTON

99214

3.4

BATTERY

POWERED

CONDITION

Loss of primary AC power causes the Control Panel with standby batteries to

automatically go into the battery powered condition. The system's Alarm

operation is maintained. In a battery powered condition the:

o AC pilot lamp goes OFF

o Trouble condition occurs (see Paragraph 1.2.3).

Restoration of primary AC power automatically places the Control Panel in

Normal condition. The Trouble ring back feature alerts the Operator to the

changed condition.

3.5

INITIAL TEST

After the Alarm system installation is completed, wiring should be

rechecked both visually and with an ohmmeter.

Apply AC power to the system and note the AC pilot lamp on the enclosure

goes ON. Make initial voltage measurements according to Table 3-1 to

verify proper working voltages.

Figure 3-3:

C-100A-24 PCB Assembly

-

,

555

0

DOCUMENT

NO.

001-097-00

PAGE

3-4

Monaco

Ente~p~ises

m.

SPOKANE.

WASHINGTON

99214

TABLE

3-

1

CONTROL PANEL INITIAL VOLTAGES

Control Panel Nominal DC Voltages.

Terminal Block

1

C-99A-12

I

C-99A-24

I

C-

100A-24

I

Normal Condition

(+)I2

to

11

0.5 5

4

(+)21

to

22

0.5 0.5 0.5

(+)23

to

24 12 24 2 4

(+)25

to

26

10.5 22.5 22.5

(+)28

to

27

11

2 3 2 3

Trouble Condition

(+)I2

to

11

0 0 0

(+)21

to

22

0

0 0

(+)23

to

24 12 2 4 24

-L

(+)25

to

26

J-

(+)28

to

27 12 24 2 4

Alarm Condition

(+)I2

to

11

11.5 23.5

21

to

(+)22 12 2 4

(+)23

to

24

12 2 4

(+)25

to

26 0 0

(+)28

to

27

0

0

I

Battery Power Condition

(+)I2

to

11

0 0 0

(+)21

to

22

0 0 0

(+)23

to

24 12 24

2

4

(+)25

to

26 12 2 4 24

(+)28

to

27 12 2 4 24

*

Trouble condition voltage at Terminals

25

and

26

depends on where the open occurs

(0

or operating

voltage).

555

0

DOCUMENT

NO,

001-097-00

PAGE

3-5

Monaco

Ente~p~ises

ra.

SPOKANE. WASHINGTON

99214

WARNING

If this Control Panel is being connected to any central alarm system,

the authority having jurisdiction shall be notified.

No tests shall be

made without proper notification.

......................................

NOTE

Terminals 19 and 20 on all Control Panel terminal blocks are not used.

......................................

555

0

DOCUMENT

NO,

001-097-00

PAGE

3-6

Monaco

Ente~p~ises

ING,

SPOKANE WASHINGTON

99214

SECTION

FOUR

MAINTENANCE

4.1

SCHEDULED PREVENTIVE MAINTENANCE

To guarantee the entire fire alarm system is operating properly, it is

recommended a test (Alarm and Trouble condition) be performed once each

month. Tests shall be made under direct supervision of the owner or a

qualified person representing the owner and the municiple authorities

having jurisdiction.

A complete record shall be kept of all tests and operation of the system

(inspection of all equipment condition, both visual and functional,

including all batteries). After each test, the system shall be restored to

the Normal condition.

Occupants of the building shall be notified in advance as to time of

testing of sounding devices. Such tests should be held during daytime

hours.

4.2 DISASSEMBLY

AND

REASSEMBLY

Remove all

AC

input power and battery backup power from the Control Panel

enclosure before attempting to replace any components. Refer to wiring

diagrams and schematics in the Appendix for actual wiring configuration.

4.2.1

Control Panel

The Control Panel is located in the upper portion of the enclosure. Dis-

assembly requires the following:

o Remove the AC protective shield located on the top left corner of

the assembly.

o

Remove the three AC input wires

attached to terminal block (TB1).

555

P

DOCUMENT

NO.

001-097-00

PAGE

4-1

Monaco Ente~p~ises

rc,

SPOKANE WASHINGTON

99214

Only the C-99A-24 Control Panel requires these two additional steps.

o Remove the AC protective shield located on the top center of the

assembly.

o Remove the two black wires (high AC voltage) and the two green

wires (low AC voltage) attached to terminal block

(TB4).

......................................

o Carefully label and remove all internal wiring attached to

terminal blocks (TB2) and (TB3).

o Carefully label and remove all additional wiring attached to

terminal block (TB3).

o Remove the four hold down screws located near each corner of the

Control Panel.

o Carefully remove the Control Panel from the enclosure.

Assembly of a new Control Panel into the enclosure is the reversal of the

above procedure.

I

4.2.2

Transformer Assembly (C-99A-24 version only)

The transformer assembly is located at the top of the enclosure. Disas-

sembly requires the following:

o Remove the AC protective shield located on the left of the trans-

former.

o Remove the two black wires (high AC voltage) and the two green

wires (low AC voltage) attached to terminal block

(TB5).

o Remove the four hold down screws located near each corner of the

transformer assembly.

o Carefully remove the transformer assembly from the enclosure.

Assembly of a new transformer assembly into the enclosure is the reversal

of the above procedure.

555 P

DOCUMENT NO.

001-097-00

PAGE

4'2

Monaco

Enteop~ises

ac.

SPOKANE.

WASHINGTON

99214

4.2.3

Lamps

The four indicator lamps are located on the door of the enclosure. Disassembly requires the following:

o Carefully label and remove the two wires attached to the defec-

t

ive lamp.

o Using adjustable pliers crush the back of the indicator lamp.

o Carefully remove the speednut from the back of the defective

lamp.

o Carefully remove the defective lamp through front of enclosure

door.

Assembly of a new indicator lamp into the enclosure door

is

the reversal of

the above procedure with one exception. Do not crush the back of the new

indicator lamp.

[

CAUTION

I

The

AC

pilot lamp

is

a

light emitting diode (LED). Polarity must be

observed when installing or

it

will

not properly function.

4.2.4

Meter

The Milliamp meter

is

located on the door of the enclosure. Disassembly

requires the following:

o Carefully label and remove the two wires attached to the meter.

o Remove meter clamp nuts on either side of the meter clamp.

o Remove meter clamp.

o Carefully remove meter through front of enclosure door.

Assembly of a new meter into the enclosure door

is

the reversal of the

above procedure.

Monaco

Ente~p~ises

IMC.

L

fl

~-

SPOKANE. WASHINGTON

99214

4.3 TROUBLESHOOTING

Troubleshooting is presented in Tables 4-1 through 4-3. Each Table

contains one symptom with the Probable Causes and the Corrective Actions.

Determine which symptom applies to the Control Panel. Proceed to the

Appropriate Table and perform the Probable Cause and Correction Steps in

the order given.

Replace all defective parts.

Monaco provides a complete repair service program. Contact Field Service

for additional information.

TABLE 4-1

TROUBLE CONDITION

PROBABLE CAUSE

AC

Line Fuse (Fl) Open

DC

Line Fuse (F2) Open

No Supervisory Current

CORRECTIVE ACTION

Check if

CR1

diode bridge defective

Check if T1 power transformer

defective

Check for correct system wiring

Check if EOL diode is backward

Check for defective detector

Check for defective bell

Reduce peripherals

Short across the following Control

Panel terminals to check continuity (system

will

not Alarm):

o 26 to 27 (Detector Loop)

o 25 to 28 (Detector Loop)

o

4

to 5 (Meter)

o

11

to 12 (Aux. A1arm)ik

o

11

to 21 (Circuit Trace)

o 21 to 22 (Alarm Bells)*

o 22 to 26 (Alarm Sil Sw "S2"

Contacts "A")

Check if R2 (Terminals 25 and 4)

ope

nihk

Check if Alarm relay (Kl) coil open

Check if Trouble relay (K2) coil

open

Check if

AC

monitor relay (K3) coil

and contacts defective

Check if EOL diode defective

*

Do not short while panel is in Alarm condition.

J^t.

n4b

DO

not short or damage to Meter may occur.

555

P

DOCUMENT

NO.

001-097-00

PAGE

4'4

Monaco Ente~p~ises

rc.

SPOKANE WASHINGTON

99214

TABLE 4-2

CONTINUOUS

ALARM

CONDITION

I

PROBABLE CAUSE CORRECTIVE ACTION

I

Detector Loops Shorted

(Terminals 25 to 26)

Check if momentary Test switch

shorted

Check for defective loop wiring

Check for defective detectors

Check for defective manual pull

I

station

\

......................................

NOTE

The

AC

monitor relay (K3) and the Alarm relay (Kl) are the same and

can

be

interchanged if either

is

suspected of causing a problem.

......................................

Detector Loops Not Shorted

(Terminals 25 to 26)

TABLE 4-3

NO

BATTERY POWER

Replace Alarm relay (Kl)

b

PROBABLE CAUSE

1

CORRECTIVE ACTION

Battery Power Fuse (F3) open

Low Battery Voltage

Replace if battery power fuse

(F3)

open

Replace battery

(shoited)

Check battery wiring

Check if battery charger defective

Replace battery

a

%J

P

DOCUMENT

NO.

001-097-00

PAGE

4-5

1

Monaco

Ente~p~ises

INC.

SPOKANE WASHINGTON

99214

SECTION FIVE

REPLACEMENT PARTS

It is recommended that

you

have

the following spare parts on-hand to minimize

down time.

Part

numbers are

as

follows.

Part

Number

452-200-00

455-000-00

500-026-00

500-041-00

360-220-00

360-230-00

363-011-00

360-290-00

421-000-02

477-001-00

561-001-00

585-000-00

426-000-00

Description

RELAY:DPDT,12VDC,lOA CONT

RELAY:SPDT,I OPERATED,2A CONT

FUSE:FAST BLOW,1.5AMP/250V

FUSE:FAST BLOW,8AMP/32V

LAMP:INCAND,RED,l4V,lOOMA,QC

LAMP:INCAND,AMB,14V,lOOMA,QC

LED:GRN,12VDC,20MA,QC

LAMP: INCAND,WHT, I~V, 100MA,~c

ASSY,DIODE:EOL,6"LEADS

RESISTOR,P?dR:WW,50 OHM,5W,5%

XE'MR:PWR,115/230V:29V/3A,50/60

HORN:MIDI,12VDC/O.O7A,SCR

MT

BRDG RECT:VHl48,6AMP/lOOV

555

Q

DOCUMENT

NO.

001-097-00

PAGE

5'1

Monaco Ente~p~ises

at.

SPOKANE. WASHINGTON

99214

C-99A-24

(PIN 175-014-03)

PartNumber Description

452-300-00 RELAY:DPDT,24VDC,lOA CONT

455-000-00 RELAY:SPDT,I OPERATED,2A CONT

500-033-00 FUSE:FAST BLOW,3 AMP/250V

500-041-00 FUSE:FAST BLOW,8 AMP/32V

360-320-00

LAMP:INCAND,RED,28V,40MA,QC

360-330-00

LAMP:INCAND,AMB,28V,40MA,QC

363-012-00 LED:GRN,24VDC,20MA,QC

360-390-00

LAMP:INCAND,WHT,28V,40MA,QC

421-000-02 ASSY,DIODE:EOL,G" LEADS

477-016-00 RESISTOR,PWR:WW,500 OHM,5W,

426-000-00 BRDG RECT:VHl48,6AMP/lOOV

585-000-00

HORN:MIDI,12VDC/O.O5A,SCR

MT

C-100A-24

(PIN 175-014-01)

Part Number Description

452-300-00 RELAY:DPDT,24VDC,lOA CONT

455-000-00 RELAY:SPDT,I OPERATED,ZA CONT

500-123-00 FUSE:SLO BLOW,l AMP/250V

500-035-00 FUSE:FAST BLOW,4 AMP/32V

360-320-00

LAMP:INCAND,RED,28V,40MA,QC

360-330-00

LAMP:INCAND,AMB,28V,40MA,QC

363-012-00 LED:GRN,24VDC,20MA,QC

360-390-00

LAMP:1NCAND,WHT,28V,40MA9QC

421-000-02

ASSY ,DIODE

:

EOL

,6"

LEADS

477-005-00 RESISTOR,PWR:WW,400 OHM,5W,

561-001-00

XFMR:PWR,115/230V:29V/3A,50/60

585-000-00

HORN:MID1,12VDC/O.O5A,SCR

MT

426-000-00 BRDG RECT:VH148,6AMP/lOOV

-

.-+-

\

555

Q

DOCUMENT

NO.

001-097-00

PAGE

5-2

Monaco Ente~pises

rc.

SPOKANE. WASHINGTON

99214

SECTION SIX

APPENDIX

The Appendix contains the following helpful documents

.

DESCRIPTION PAGE

......................

Warranty

Schematics

C-99A-12 Control Panel PCB Assembly

......

C-99A-24 Control Panel PCB Assembly

......

C-99A-24 Transformer Assembly

.........

C-100A-24 Control Panel PCB Assembly

.....

Wiring Diagrams

............

C-99A-12 Control Panel

............

C-99A-24 Control Panel

C-100A-24 Control Panel

............

Typical Fire Alarm 24V Installation

......

Additional Equipment for Custom Configurations

...

Installation of Additional Equipment and Accessories

Battery Capacity Calculation

............

Condensed Operating Instructions

..........

55J

R

DOCUMENT

NO . 001-097-00

PAGE

6-1

Monaco

Ente~p~ises

inc

.

SPOKANE . WASHINGTON

99214

Monaco

Enteepoises

ac.

SPOKANE,

WASHINGTON

99214

LIMITED PRODUCT WARRANTY AND LIMITATION

OF

LIABILITY

Products sold by Monaco Enterprises, Inc. (hereinafter called "the Company

")

are warranted only as stated below:

Subject to the exceptions and upon the conditions specified below, the Company agrees to correct, either by repair, or

at its election by replacement, free of charge, F.O.B. Spokane, Washington, any defect of material or workmanship which

develops within

12

months from the date of delivery to the customer but in no event more than fourteen

(14)

months

after date of shipment, whichever is earlier. The buyer must notify the Company of any defect immediately after discovery, and must give satisfactory proof of defect or, upon request, return the defective item to the Company in

Spokane, Washington, at his expense for examination.

In addition to such notification and proof the following are additional exceptions and conditions:

If any expendable component or accessory incorporated in or used in connection with products manufactured by the

Company, such as batteries, visual indicators and fusing devices, or any other expendable material fails to give reasonable

service for a reasonable period of time, the Company will, at its election, replace or repair such component or accessory.

What constitutes a reasonable period of time shall be determined solely by the Company in its absolute discretion after

the Company is in possession of all the facts concerning operating conditions and other pertinent factors and after

such

component or accessory has been returned to the Company, transportation prepaid.

The Company makes no warranty concerning components or accessories not manufactured by it. However, in the event

of the failure of any component or accessory not manufactured by the Company, the Company will give reasonable assistance to the buyer in seeking an adjustment from the manufacturer of the item in question based on the manufacturer's

own warranty, if any.

The Company shall be released

From all obligations under its warranty in the event its products or parts have been subject

to accident, alteration, abuse or misuse, or which have not been operated and maintained in a normal manner.

Except as stated above, the Company makes no warranty, expressed or implied (either in fact or by operation of law),

statutory or otherwise;

all

warranties not expressly stated herein being expressly waived by the buyer.

The Company expressly disclaims any liability to its customers, dealers, distributors and representatives, and to users of

its products and to any other person or persons for special or consequential damages of any kind and from any cause

whatsoever arising out of or in any way connected with the manufacture, sale, handling, repair, maintenance or replacement of or arising out of or in any way connected with the use of said products.

Representations and warranties made by any person, including dealers, distributors and representatives of the Company,

which are inconsistent or in conflict with the terms of this warranty (including but not limited to the limitations of the

liability of the Company as set forth above), shall not be binding upon the Company unless reduced to writing and

approved by an officer of the Company.

This warranty shall be construed in accordance with and governed by the laws of the State of Washington.

This warranty gives you specific legal rights and you may also have other rights which may vary from state to state.

555

R

DOCUMENT NO.

001-097-00

PAGE

A1

Monaco

Ente~p~ises

INC.

SPOKANE WASHINGTON

99214

LOOP

AMP

I

METER

BATTERY

F3

LAST

DESIGN

CHART

RELAY

CONDITION

CHART

E=

ErJCRGlZtP

NE

=

NOT

ENIICLGIZEP

NIT

I

I

AC

PILOT

I'

I

LOOP

E=

EhlELZGIZED

N

E

:

NOT

ENEffiIZED

GRN

GRN

I

I

I

C-99A-24 Transformer Assembly Schematic

555

R

DOCUMENT

NO.

001-097-00

PAGE

B3

Monaco Ente~p~ises

rc.

SPOKANE WASHINGTON

99214

4

3

2

I

1

PROPRIETARY NOTICE

R4VlslONS

OESCRlPTlON

OATE

AP

F~RMAL

RELEASE

---

I

----

QL<

RE8

AMP

I

METEF

'Nl-C+5

0THECWtSE

TBL LAMP

0

5P%lFlED

NOTIIS"

ALM

SIL

LAMP

I,

L,NIT

5UOWN

IN

OFF

tOhlDl

TlOhr.

2

4HLDED

TCF~MINALS

ALF

IN

9IPEEVISOLY

LCOP

COMMON

3

LLL

RESISTOK5

MEASUPED

IN

OHMS.

4

ALL

CAPALITORS

FIEASVEED

I

lu

MILS2DFAfZADS.

ALM LAM

5

POLARITY

SHOWhl

OU

TERMlhl4LS

21

<

22

+.RE

FOR

AARU

MODE.

NORMAL

SLJPEKVIS

IOU

P-RITY 15

oPPOll~E

THE

ALAW NODE

POW&I~.

I

LOOP

RELAY

CONDITION

CHART

LAST

DESIGN

CHART

L-------

E=

Et4ERGIZED

NE

=

NOT

ENEtCGlZED

SUPERVISORY

NRREM

MILLInIIIIETER

0.10

MA.

IRED) ALLW

(AMBER)

ALAN

SILENCED

INSTALLATION

WIRING

DIAGRAM

CMMET

DOOR

I

M

OHM

5

WAIT

AUX.

ALARM

12

vD€

25 AMAX.

(SUPERVISED)

MODEL

C-99A-12

FIRE

ALARM

CONTROL

IRED1

ALARM SILENCE

NORMAL

SILENCE

(YELLOW)

TROUBLE

SILENCE

NORMAL

SILENCE

NORMAL

RESET

NORMAL

TEST

-

+

ALARMMODE

POLAR!TV

4-

-

SUPERVISORY

MODE

POLARITY

PAGE

C1

Monaco Ente~p~ises

MC,

SPOKANE WASHINGTON

99214

10

(SUPERVISED)

NOTE

4

NOTES:

(SUPERVISED

LBIITED

ENERGY

CIRCUIT)

Wire in accordance with NFPA Installation Standards 72A and 72B, and all applicable national, state, and local electrical codes.

Indicated circuit capacities may be exceeded provided total external current drain does not exceed 5.55 amps.

Remove resistor from terminals 11 and 12 when connecting an external device or municipal box circuit. Connect any 43 ohm 250 ma

trip coil direct. Maximum recommended supervisory current is 10 ma.

If shunt connection is used, the shunt connection is recog-

nized

as

a supplementary signaling unit

as

part of local control unit only. This type connection is not recommended as an auxiliary

control unit connection per NFPA Number 72B.

Automatic detectors, manual alarm stations and smoke detectors may be used with the C-99A but must be

U.

L. listed. The C-99A

is

also suitable for connection of waterflow alarm devices when an audible device is connected to terminals 11 and 12.

Only circuits connected to terminals 25 through 28 are limited energy arcuits.

The system

is

actuated manually or automatically through the C-99A control to sounding devices and auxiliary circuits.

The

signal

circuit is supervised noncoded type.

The C-99A may be used for local and/or auxiliary systems. When used for auxiliary systems, only rechargeable standby power system

with 60 hours capacity (NFPA 728) may be used.

U.

L. listed polarized alarm bells must be used to block the bell circuit supervisory current.

Use

IN4003 (200 volt, 1 amp) diode as end of line device on supervised alarm bell circuit.

12 VDC smoke detectors must have a minimum voltage rating of 14 VDC. End of loop detectors not having internal power supervision

must have external power supervisory module connected to the loop.

Use

Eveready 1463 battery or equal. Test battery by disconnecting AC power and placing control in alarm. Battery voltage below

10 V measured during the test indicates battery should be replaced.

For control operation instruction, refer to label

243-043-00.

Supervised power supply connections when using smoke detectors are included in I-O-M Manual, Section

11.

The

C-99A-12 is intended for the following type and senrice:

TYPE: SERVICE:

(L): Local system type. (A): Automatic fire alarm: Thermostats, smoke detectors, etc.

(A): Auxiliary system type

(M):

Manual fire alarm: ~huall~ operated boxes.

LABEL

PIN

243041.00

FBDl

REV

CMONACO

ENTERPRISES,

INC. SPOKANE.

WA

99214

INSTALLATION WIRING DIAGRAM

lW

VAC

60

HZ

3A

MAX.

(SUPERVISED)

Ill

(GREEN)

AC

PILOT

SUPERVISORY

CURRENT

MILLIMIMETER

0.10 MA.

(RED)

ALAN

(AMBER)

ALARM

SUXNCED

OXHll'E)

TROUBLE

0

AC

PRI

MODEL

C-99A-24

FIRE ALARM CONTROL

. .

(YELLOW)

TROUBLE

SILENCE

'",%?

(WHITE)

TEST

fi

&

NORMAL

&

NOPMAL

&

NORM-

4

4

SILENCE

RESET

TEST

-

+

ALARM

MODE POLARITY

CABINET

WOR

-I-

-

SUPERVISORY

MODE

POLARITY

I

SILENCE)

I,~&",L~,"X,

I$EM%zN

MAX.

CURRENT

I00

MA.

(500

NO. I4

AWG)

SUITABLE

FOR

AT

24

VDC CONNECIION

TO

REFER

10

TO

NOTE

DEVICE

INDICATED

IN

NOTE

4

NOTES:

(SUPERVISED)

(SUPERVISED

LIMITED

ENERGY

CIRCUIT1

Wire in accordance with NFPA Installation Standards 72A and 728, and all applicable national, state, and local electrical codes.

Indicated circuit capacities may be exceeded provided total external current drain does not exceed

5.55

amps.

Remove resistor from terminals

11

and 12 when connecting an external device or municipal box circuit. Connect any 43 ohm

250 ma trip coil in series with 43 ohm,

5

watt resistor and connect direct. Maximum recommended supervisory current is 10 ma.

If shunt connection is used, the shunt connection is recognized as a supplementary signalling unit as a part of local control unit

only. This type connection is not recommended as an auxiliary control unit connection per NFPA Number 72B.

Automatic detectors, manual alarm stations and smoke detectors may be used with the C-99A but must be U.L. listed. The C-99A

is also suitable for connection of waterflow alarm devices when an audible device is connected to terminals

11

and 12.

Only circuits connected to terminals 25 through 28 are limited energy circuits.

The system is actuated manually or automatically through the C-99A control to sounding devices and auxiliary circuits.

The signal circuit is supervised non-coded type.

The C-99A may be used for local

and/or auxiliary systems. When used for auxiliary systems, only rechargeable standby power

system with 60 hours capacity (NFPA 72B) may be used.

U.L. listed polarized alarm bells must be used to block the bell circuit supervisory current.

Use IN4003 (200 volt,

1

amp) diode

as

end of line device on supervised alarm bell circuit.

24 VDC smoke detectors must have a minimum voltage rating of 28 VDC. End of loop detectors not having internal power super-

vision must have external power supervisory module connected to the loop.

Use two Eveready 1463 batteries or equal connected in series. Test batteries by disconnecting AC power and placing control in

alarm. Battery voltage below 20 V measured during the test indicates batteries should be replaced.

For control operation instructions, refer to label 243-043-00.

Supervised power supply connections when using smoke detectors are included in I-0-M Manual, Section 11.

The C-99A-24 is intended for the following type and service:

TYPE: SERVICE:

(L):

Local system type. (A): Automatic fire alarm: Thermostats, smoke detectors, etc.

(A): Auxiliary system type. (M): Manual fire alarm: Manually operated boxes.

LABEL PIN 243.04240 F801 REV C MONACO ENTERPRISES INC. SPOKANE. WA 99214

555

R

DOCUMENT

NO.

001-097-00

PAGE

C2

Monaco

Ente~pises

Inc.

CPnKANF WACUINCTflhl

99714

INSTALLATION WIRING

DIAGRAM

I20

VAC

60

HZ

I A MAX

(SUPERVISED)

PRINTLO

CIRCUIT

BOAR~

TB1

I

(GREEN)

AC PILOT

SUPERVISORY

(RED)

ALARM

(WHITE)

TROUBLE

CABINET

WOR

1

MODEL

C-100A-24

FIRE

ALARM CONTROL

::

::

I

(RED1

(YELWW)

TROUBLE

HmwL

8NoMAL

Noma

%p

I

I

I

SILENCE

SILENCE

RESET

TEST

I

I

-

+

nLARM

MODE

POLARITY

I

-b

-

SUPERvlSORV

MCDE

POLARITY

I

+OOOI~MS

BATIZRY

REMOTE

TROUBLE

wA"

24V

TROUBLE

BELL

nux

3-IS AMPS

24

VDC 24VDC

ALARM

pdR

.2S(;,"TAX.

25

AMAX.

(HOT

WEN

z:42i&

TONOTE

SWERVISEDI SUPERVISED)

(SUPERVISED)

l2

(DOES

IS

USE0

.3

A

MU.

CIRCUIT

&%rq

12

SOHMS

l

2 R MAX.

ON

CONDumRS

FOR

SMOKE

I.E.

zs

m

28 & 26

m 27

(S00'NO.

IIAWCI

SUITABLE

FOR

AT

24

VDC

CONNECTION

7'0

REFER

TO

NOTE

DEVICE INDICATED

IN

10

NOTE

I

NOTES:

(SUPERVISED) (SUPERVISED

LIMITED

ENERGY

CIRCUIT)

Wire

in

accordance with NFPA Installation Standards 72A and 728, and all applicable national, state, and local electricai codes.

Indicated circuit capacities may be exceeded provided total external current drain does not exceed 2.85 amps.

Remove resistor from terminals

11

and 12 when connecting an external device or municipal box circuit. Connect any 43 ohm 250

ma trip coil in series with 43 ohm

5

watt resistor and connect direct. Maximum recommended supe~sory current is 10 ma. If shunt

connection

is

used, the shunt connection is recognized as a supplementary signaling unit as part of local control unit only. This type

connection is not recommended as an auxiliary control unit connection per NFPA Number 72B.

Automatic detectors, manual alarm stations and smoke detectors may be used with the C-100A but must be U.

L.

listed. The C-100A

is

also suitable for connection of waterflow alarm devices when an audible device is connected to terminals 11 and 12.

Only circuits co~ected to terminals 25 through 28 are limited energy circuits.

The system

is

actuated manually or automatically through the C-100A control to sounding devices and auxiliary circuits.

The signal circuit is supervised noncoded type.

?he C-100A may

be

used for local andlor auxiliary systems. When used for auxiliary systems, only rechargeable standby power system

with 60 hours capacity (NFPA 72B) may be used.

U. L. listed polarized alarm bells must be used to block the bell circuit supervisory current.

Use

IN4003 (200 volt, 1 amp) diode as end of tine device on supenriled alarm bell circuit.

24 VDC smoke detectors must have

a

minimum voltage rating of 28 VDC. End of loop detectors not having internal power super-

vision must have external power supervisory module connected to the loop.

Use two Eveready 1463 batteries or equal connected in series. Test batteries by disconnecting AC power and placing control in alarm.

Battery voltage below 20 V measured during the test indicates batteries should be replaced.

For control operation instructions. refer to label

243-045-00.

Supe~sed power supply connections when using smoke detectors are included in I-O-M Manual, Section 11.

The C-100A-24 is intended for the following type and sewice:

TYPE:

SERVICE:

(L): Local system type.

(A):

Automatic fie alarm: Thermostats, smoke detectors, etc.

(A): Auxiliary system type. (M): Manual fire alarm: Nhnually operated boxes.

LABEL

PIN

243-040-00

F7935

REV

D

MONACO

ENTERPRISES.

INC.

SPOKANE.

WA

99214

120 VAC POWER THROUGH IP 20A FUSIBLE DISCONNECT

CONNECT LINE SIDE OF DISCONNECT TO MAIN BREAKER.

I

I

CS-579-BC

I

BATTERY CHARGER

??

BATTERY CHARGER

P/N:

401

-001

-00

TO FRONT PANEL

CA42-4

ANNUNCIATOR

P/N:

710-001-00

SEE

NOT

ZONE

2

ZONE

4

(FOR GFA OR EOL ANNUNCIATDRS.

SEE RESPECnVE MANUALS)

F??f

4222

o

123456

I

I

I

TlPl

AW

I

SEE NOTE

6

I

r--'-l

AM

000000

KEMUL'

~1

u

PI PZ

n

n

NI

II~

P

*

A

I C D

lRlNC

DI

.

RT-100

SUPERMSION INTERFACE

P/N:

750-300-00

r

PNAICD

000000

12 3

4

5

6

7 8 9 10

TWPER

EOL FROM

INPUT

CONTROL PANEL

ALARM OUTPUT

K-110

ET-1 TRANSMITTER

7

2

AUXIUARY RELAY

P/N: 710-048-00

YP

P/N:

458-000-02

0

7.2

"ZZ

1234 143

8

5

1

TO AUXIUARY

CONTROL FUNCTIONS

SHUNT

C-99A/C-100A TERMINALS

I I

I

0

TB1

TB2

b b

SEE NOTE 7\ 1

2

1234

7

TM TRANSMITTER MODULE

P/N: 176-099-00

I

Lwm FOR voLrAcx

REKRSAL OR EOL RECEIVER

#

Mi-

'

/

-J

'

II

[I1

--..=..-..-

I

REVISIONS

SEE NOTE

4-

WEN AANSYlTlED ZONES ARE INOIL

MOUALLY. A

K-110

RELAY MUST

BE

USED TO PREKNT

A

TROUBLE

SCUM

Rl?l

ALL ZONE

ALARMS. ZOClE 1

lRANSYlrS ZONE

ALARM AND

PAmL

TRWBLE. ZOmS

2.

3,

&

4

TRANSWT

ALARMS ONLY.

*PPPOYED

3X.

RELAY

24

MC

a

-

I K I

(MADE NEW OWC. AOOEO

TM.

SACM. BT2-4

[

10/7/BB

]

f

&nu

DATE

ECO

;,"

:

1

2

3

4

5

CLZLI

00 00 00 00 00

lo

120 "Ac

(-

JAL CA42 ANNiJNCIATORS

REV

ZONE RT-100

w

UNUSED ZONES 00 NOT REQUIRE

TERMINATIOEI

ZONE

C

ZONE TERMINATIONS AND CONNECTIONS

ARE SAME AS ON BT2-4. EXCEPT UNUSED

ZONES MUST BE TERMINATED

WlTH 15K

OHM RESISTOR.

DESCRIPTION

ADDITIONAL BT2-

4

ZONE

CONNECTION ALTERNATE

5.)

FOR ADDITIONAL INFORMATION ON ANY PRODUCT,

CONSULT

ITS

RESPECTIVE MANUAL.

1.)

DOTTED LINES INDICATE

FOUIPMEN T.

2.)

MAY BE USEO FOR SMOKE DETECTOR POWER

PROMOED THAT TOTAL CURRENT DRAW ON

ALL ZONES

DOES NOT EXCEED THAT LISTEO

ON THE C-100A OR C-99A DATA SHEET FOR

TERMINALS 23

&

24.

THESE TERMI'IALS MAY

ALSO BE USEO FOR REMOTE ZONE ALARM MEN

6.)

TERMINALS PROWOE EASY THROUGH CONNECTIONS

FOll

F.A.C.P. DETECTION LOOP EXFANSION AND ARE ISOUTED

FROM THE RT-100 PANEL INTERFACE FVNCTION. NO

CONNECTIONS TO TERMINALS ARE REWIRED

FM INTER-

FACE OPERATION.

(79-000-00 RESISTOR ASSY.

W/tEADS. NORMALLY OPEN

COIITACTS (1.6. WATER FLOW

SHITCH,

atc.)

7.)

JUMPERS

ON

mE

M

MODULE MUST

BE

CUT

TO

SELECT

THE

DESIRED

INPUT/OUTPUT

wnom

IF

EOL

WTWT

IS USEO. AN EN0 OF LINE OEMCE WICH MATCMS

ME

SPECIFIED ON ORDER.

3.)

SUPERMSEO AUDIBLE CIRCUIT MODULES MAY BE

USEO TO EXPAND BELL CIRCUIT CAPACITY THE

INSFUCTIONS FOR DETAILS.

CONTROL PANEL

I.)

CA42/4 PCB AUXILIARY POWER/AUXILIARY ALARM

OPTION MUST BE STRAPPED FOR AUXILIARY ALARM.

mus.

SMOKE

DETECTOR

POWER

MUST BE

OBTAINED

FROM C-10OA/C-IOOA. TERMINALS 23

&

24

OR

C.4 42, TERMINALS 1

&

2.

UNLESS OTHEWlS WClFlED JOB NO.

DIMENSIONSARF IN INCHES

TOLERANCESARE: STANDARD

MONACO

ENTERBRISLS,

#1C.

FRACTIONS DECIhULS ANGLES

SPOKANE. WASHINGTON

99214

-

fl1M

.U

*

-1.

APPP~YAI~

I

~&TF

TITLE:

XXX

f

. . . . .

.-

.

. .-

-

WTERIAI

DRAWN

lO/S/as

INTERCONNECTlON DRAWING:

CHECKED

6

>&

?\

jz

ae

TYPICAL FIRE ALARM

A~MD~.F~lch III~IRR EQUIPMENT:

24

VOLT SYSTEM

I

-

L

NOTICE

1

I

FINISH OUTSTANDlNGECOlSl SIZE DRAWNGNO

REV

X-700-011-DO-D

D

.PIN

700

roll

00

K

DO NOT SCALE DRAWNG SCALE NONE

1

I

SHLtT

1

OF 1

ADDITIONAL EQUIPMENT FOR CUSTOM CONFIGURATION

Control Panels

700-010-XX C-100A Fire Alarm Control Panel, 3 AMP Capacity, 12 VDC

700-01 1-XX C-100A Fire Alarm Control Panel, 3 AMP Capacity, 24 VDC

700-01 2-XX C-99A Fire Alarm Control Panel, 6 AMP Capacity, 12 VDC

700-01 3-XX

C-99A Flre Alarm Control Panel. 6 AMP Capacity, 24 VDC

Battery Chargers

175-026-02

175-026-03

401-000-00

401.001-00

175-01 9-06

401 -002-00

401-003-00

Annunciation

7

1 0-000-00

710-001-00

7

10-002-00

7 10-003-00

7 10-004-00

7 10-040-00

7 10-046-00

Batteries

400-700-00

400-701-00

400-704-00

400-300-00

BC-112 Battery Charger, 12 VDC

BC-124 Battery Charger, 24 VDC

CU-4 Battery Charger, 12 VDC

CU.4 Battery Charger, 24

VDC

NC-579-BC-29 Nicad Battery Charger 24 VDC

CS-579 Power SupplyIBattery Charger, 12 VDC

CS-579 Power SupplyIBattery Charger, 24 VDC

CA4214-12 Four Zone Alarm and Troubie Annunciator, 12 VDC

CA4214-24 Four Zone Alarm and Trouble Annunciator, 24 VDC

CA4212-12 Two Zone Alarm and Trouble Annunciator, 12 VDC

CA4212-24 Two Zone Alarm and Trouble Annunciator, 24 VDC

CA42Rl4-24 Four Zone End of Line Resistor Annunciator, 24 VDC

CA42Rl2-24 Two Zone End of Line Resistor Annunciator, 24 VDC

GFA24 Two Zone, Class AIB Annunciator, 24 VDC

Sealed Gel-Type Battery, 12Vl5AH (See Note 1)

Sealed Gel-Type Battery,

12Vl20AH (See Note 2)

Sealed Gel-Type Battery, 12V16.5AH (See Note 1)

Nicad Battery,

24Vl7AH (7"L x 5.8" x 3.9"H)*

Transmitters and Supervisory Interface Panels

176-092-00 ET-1 McCulloh Circuit Transmitter, 12 to 24 VDCIVAC

750-200-00

RT-100 Remote Transmitter Interface Panel, Radio System, 12 VDC

750-300-00 RT-100 Remote Transmitter Interface Panel, Radio System, 24 VDC

176-099-00 TM Transmitter Module: NO, NC or Voltage Reversal Alarm and Trouble

Inputs; EOL or Voltage Reversal Output; 12 to 24

VDCIVAC

Relays

458-000-0 1 K-110-12 Auxiliary Relay, DPDT, 12 VDC

458-000-02 K-110-24 Auxiliary Relay, DPDT, 24 VDC

Accessories

Booster Panel, ACIDC, 6 AMP112 VDC

Booster Panel, ACIDC, 3 AMP112 VDC

Booster Panel, ACIDC, 3

AMP124 VDC

Supervised Audible Circuit Module, 3 AMP112 VDC*

Supervised Audible Circuit Module,

3

AMP124 VDC*

Transmitter Disconnect Switch Assembly

Lamp Test Switch Assembly, 12 volt (8 lamps per assembly)

Lamp Test Switch

~ssembly, 24 volt (8 lamps per assembly)

Pre-Signal Alarm Assembly

Height

7.75"

7.75"

7.75"

11.75"

2.5"

2.5"

8.5"

8.5"

10.5"'

6"

6

"

8.5"

8.5"

5"

5"

8.5"

5"

5"

*Items must be in a separate enclosure from the Control Panel.

-

,--+

\

55JR

DOCUMENTNO.

001-097-00

PAGE

Ill

Monaco

Ente~p~ises

INC.

SPOKANE.

WASHINGTON

99214

STEPS:

1.

Determine what components will be required for a

complete operational system.

2. Obtain height measurements for each component.

3.

To determine the size of the control panel enclosure

needed, follow the guidelines listed below:

a. Leave space at the topof the panel, 1 inch required.

b. List height of first component.

c. Space each component 0.5" apart.

d. Add 0.5 after last component listed for space

at bottom of panel.

e. Add up all component spacing required.

1

'

C-100A Fire Alarm

Control Panel

7.75"

.5'

CA42 Four Zone

Alarm

&

Trouble

Annunciator

8.5

n

2.5"

Total

.

.

.

. .

21.25"

4. Compare total with standard enclosure sizes listed below. There are five standard size control panel enclosures.

After you have determined how large your custom enclosure needs to be, select the standard enclosure size that

is closest to (larger) your requirements. When ordering a control panel, the last two digits (denoted by

XX

in custom

order list) indicate what size the enclosure will be.

-00 18" Enclosure

-01 24" Enclosure

-02 12" Enclosure

-03 36 Enclosure

-04

42"

Enclosure

If your component and space measurements total 25". the correct control panel enclosure would be 36" and the

part number would have a -03 as the last two digits (i.e., 700-010-03).

Note

1:

The 5 and 6.5 amplhour batteries are 5.9" wide, 3.7" tall, and 2.6" deep. If your system is 12 VDC you

will need one battery; if your system is 24 VDC you will need two batteries. When computing the space

required for this battery, follow the guidelines below:

Rail

Batter,

-

5.9"

-

Charwr

B

1-

12"

-

6"

4

Front View

Side View

Two batteries can fit side by side-

The battery(s) can fit in front of the charger

Note 2: The 20 amplhour battery is 6.5" wide, 6.75" tall, and 5" deep. If your system is

12

VDC you will need one

battery; if your system is 24 VDC you will need two batteries. When computing the space required for this

battery, follow the guidelines below:

Battery

Rail

Chargel

Front View

+

6--i

Side View

Batteries will

NOT

fit side-by-side.

Batteries are stacked on top

of each other under the charging

unit.

001-097-00

D2

-

/

-.+-

\

55J

DOCUMENT

NO.

PAGE

Monaco

Ente~p~ises

INC.

SPOKANE. WASHINGTON

99214

INSTALLATION OF ADDITIONAL EQUIPMENT

AND

ACCESSORIES

The information in this Appendix should be carefully read before installing

these items. This information helps insure a properly installed system.

BATTERIES: When optional wet cell batteries are used, follow instructions

packed with the batteries. A battery charger must be used when wet cell

batteries are used for emergency power. If dry cell batteries are used,

ensure that the battery cases do not come in direct contact with the

enclosure surface. The bottom of the battery enclosure or Control Panel

enclosure should be covered with rubber matting.

WIRING: All wiring shall be installed in accordance with the latest edition of the National Electric Code, the applicable National Fire Protection Association Installation standards, and local authorities having

jurisdiction.

DETECTOR CIRCUITS: Any number of automatic detectors or manual fire alarm

stations may be intalled on the detector circuits provided that the stated

wire resistance on the Installation Wiring Diagram is not exceeded. Smoke

detectors may be installed on the detector circuit only to the extent that

their total current draw does not exceed the capacity stated on the

diagram. Refer to the connection diagrams supplied with the smoke

detectors used for installation and current requirements of the detectors.

Continuity of the detector loops must be maintained when connecting

detectors. Refer to Installation Wiring Diagram for proper connection of

detector loops.

BELLS: One supervised bell circuit is provided. Total current draw of the

bells may not exceed that shown on the Installation Wiring Diagram. Wire

smaller than 1/14 AWG should not be used on bell circuits.

All bells must be Polarized to block bell circuit supervisory current. A

polarized bell has an internal diode. See Figure 6-1. This diode allows

the bell current to flow only in one direction. The usual bell wire lead

555

R

DOCUMENT

NO.

001-097-00

PAGE

El

Monaco Ente~p~ises

Inc.

SPOKANE WASHINGTON

99214

colors are Red and Black (for Positive and Negative during the Alarm mode).

Wire polarized bells so that the Alarm current (electron flow) enters the

Black lead and leaves the Red lead. Some non-standard bells may have

reversed lead colors (representing Supervisory polarity rather than Alarm

polarity).

The Control Panel reverses the voltage polarity at Terminals

21

and

22

when

an Alarm is activated, changing from the Normal supervisory mode to the

Alarm mode. In the Normal mode, the internal bell diodes block the Control

Panel bell loop supervisory current and prevent the ringing of the Alarm

bells. When the polarity of the voltage is reversed (Alarm mode), the

internal bell diodes become conducting paths allowing the Alarm bells to

ring. Figure

6-1

shows two sets of polarity markings above Terminals

21

and

22

(the bell terminals). One set represents the terminal polarity

during the Normal supervisory mode; the other represents the Alarm mode

polarity. These polarities must be observed when connecting polarized

bells.

TB3 TB3

TERMINAL

21

TERMINAL

22

-

ALARM MODE POLARITY

+

SUPERVISORY MODE POLARITY

+

-

Figure

6-1:

End-of-Line Diode Configuration

0

0

555

R

DOCUMENT

NO.

001-097-00

PAGE

E2

Monaco

Ente~p~ises

INC.

SPOKANE WASHINGTON

99214

ALARM

POLARIZED BELL

MODE

r-------

CURRENT

I

1

PATH

I

I

I

I

I

BLACK LEAD RED LEAD

I

INTERNAL

BELL DIODE

I

L

1

(TYPICAL FOR ALL BELLS)

BLACK LEAD ANODE CATHODE RED LEAD

(1

EOL DIODE

CR5

+J

SUPERVISORY MODE CURRENT PATH

(ELECTRON FLOW)

END-OF-LINE DIODE: The EOL diode is connected to allow supervisory current

to flow and to block Alarm current. The Controls Panels come with a

removeable end-of-line (EOL) diode connected to terminals 21 and 22 (see

Figure 6-1). When no external bells are connected, this diode must be

secured to these terminals to prevent a constant Trouble condition. When

external bells are connected, this diode must be removed from terminals 21

and 22. Then it must be placed at the end of the bell

loop as shown in the

Installation Wiring Diagram. The diode should be connected in parallel

with the last bell.

The polarity of the diode must be observed. The diode has a red lead and a

black lead. While connected to the Control Panel, the Black lead (anode)

is connected to Terminal 21. The Red lead (cathode) is connected to

Terminal

22. When used in the last bell box, make sure the diode's Black

wire connects to the bell loop wiring that originates at Terminal 21

(+).

Likewies, make sure the diode's Red wire connects to the bell loop wiring

that originates at Terminal 22

(-).

TROUBLE BELL: Terminals are provided for a remote Trouble bell if

required. The Trouble bell should be placed where it can be readily heard

if Trouble occurs.

AUXILIARY CIRCUIT:

If

the system is for local operation only and is not to

be connected to a municipal auxiliary box, a

5

watt,

5%

resistor shall be

connected across Terminals 11 and 12 of the Control Panel. The resistor's

value is determined by the Control Panel as follows:

0

50 ohms for the C-99A-12

4.00

ohms for the C-100A-24

500 ohms for the C-99A-24

This will maintain supervision of the auxiliary circuit.

Monaco

Ente~p~ises

at.

SPOKANE

WASHINGTON

49714