Momento DELTA SIGMA Operator's Manual

www.momento.se

OPERATORS MANUAL

DELTA SIGMA Ultrasonic instrument

Page: 1 / 32

Document No: DELTA SIGMA-USM

Version 4

Revision 3.94.2

Δσ

Index

1 Introduction…………………………………………………………………………………………………………………………………………………………………2

1.1 DS .......................................................................................................................................................................................... 3

2 Operation of the DS ......................................................................................................................................................................... 4

2.1 OVERVIEW ........................................................................................................................................................................... 4

2.2 PROJECT / BOLT DATA FILES ........................................................................................................................................... 5

2.3 SETUP SCREEN ................................................................................................................................................................... 7

2.4 MEASUREMENT PROCESS ................................................................................................................................................ 8

2.5 MEASURE BOLTS .............................................................................................................................................................. 12

2.6 MEASURE NEW BOLT ...................................................................................................................................................... 16

2.7 EXPORT EXCEL FORMAT DATA FROM THE DS TO A PC ............................................................................................. 17

2.8 EXPORT SYSTEM PROJECT DATA FROM THE DS TO A PC ........................................................................................ 20

2.9 IMPORTANT NOTES ON OPERATION OF THE DS SOFTWARE ................................................................................. 22

3 Specifications & Features: .......................................................................................................................................................... 23

Appendix A……………………………………………………………………………………………………………………………………………………………..24

Appendix B……………………………………………………………………………………………………………………………………………………………..25

Appendix C……………………………………………………………………………………………………………………………………………………………..26

Appendix D……………………………………………………………………………………………………………………………………………………………..27

Appendix E……………………………………………………………………………………………………………………………………………………………..28

Appendix F……………………………………………………………………………………………………………………………………………………………..30

Document No: DELTA SIGMA-USM

Version 4

Revision 3.94.2

Page: 2 / 32

THE RESONIC INSTRUMENTS

Delta Sigma Ultrasonic Bolt Load Measurement Instrument

1. INTRODUCTION

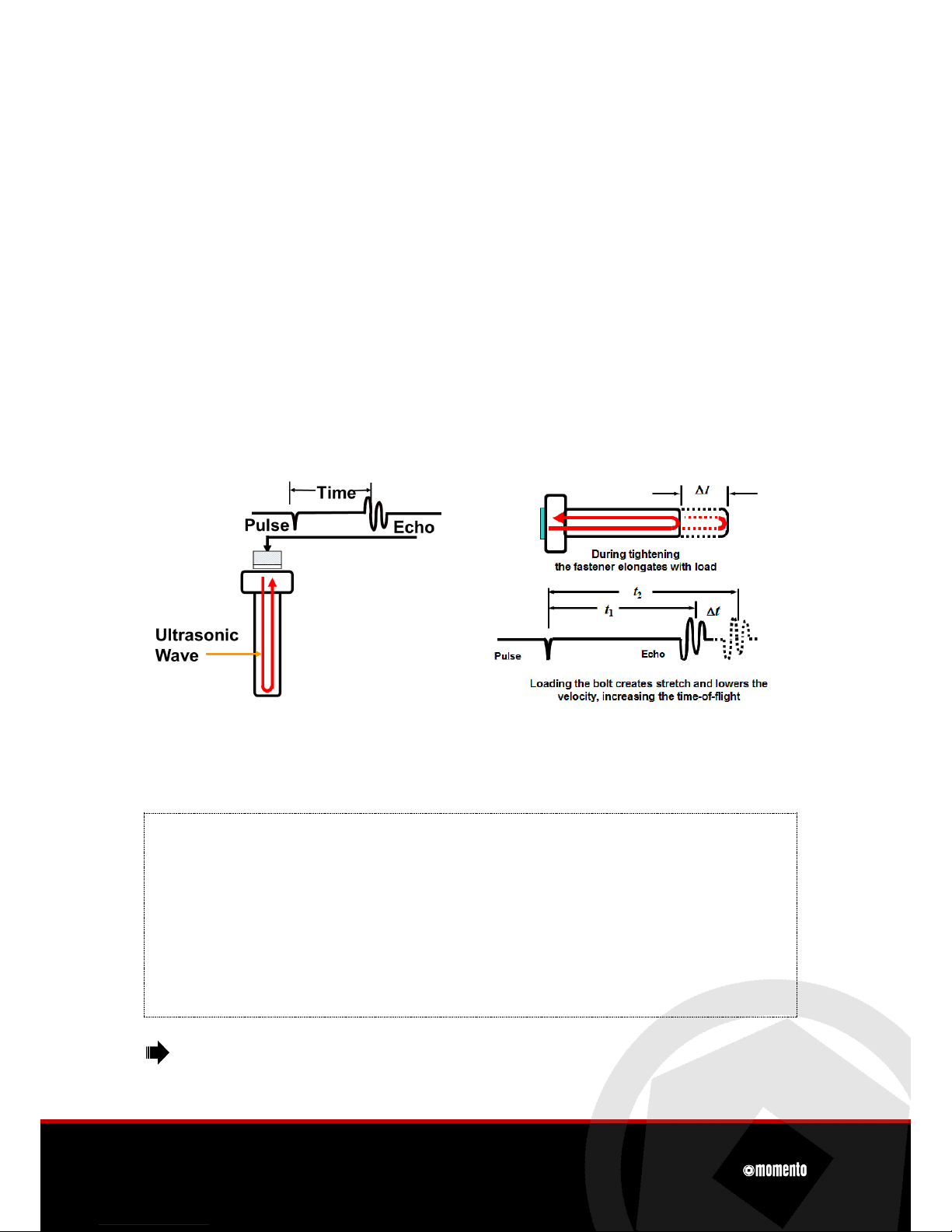

Load in a bolt is determined ultrasonically by measuring the change in the time-of-flight

(TOF) of an ultrasonic wave through a bolt as the bolt is loaded (tightened). This technology

was developed in the early ‘70s to keep cryogenic joints together in rocket engines and is still

used for that purpose by most of the world’s engine and satellite builders.

When a fastener is loaded (tightened) or unloaded (operational loss or disassembly) the

ultrasonic TOF will change due to the change in load (tension stress) in the fastener. It is this

change in TOF that we use to calculate load, by storing a “Reference” length or time and

calculate the difference between that “Reference” time and the “as found” time. This delta

time is directly proportional to the load or stretch in the fastener.

The intuitive software was created specifically for the bolting industry, the automatic echo

detection algorithm has been developed with input from the most experienced users and

electronic developers in the bolt tightening industry! Communicate to any PC with a standard

USB connection.

On receipt of your DS the batteries should be charged, plug in the included charger, turn

unit on and leave charging for 12hrs. After 5 minutes of inactivity the display will shut off

but the charger will stay on, it will shut down when fully charged. The blinking red LED

designates charging mode.

The charger/battery system is designed for long, safe battery life, the charger will not over

charge and the unit will re-set if a high current operation is call with low batteries.

We highly recommend users to watch instruction videos, visit www.momento.se

Page: 3 / 32

Document No: DELTA SIGMA-USM

Version 4

Revision 3.94.2

1.1 DS

The Δσ pulse-echo ultrasonic time-of-flight measurement device; measures, displays, stores

and transfers bolt load data. The Delta Sigma uses a sealed colour touch screen for all

operator I/O. All data is entered and presented on a 4.3” colour, resistive touch screen. Data

and digital signal traces are stored for later display and transfer. The unit has automatic

temperature compensation from an included magnetic temp probe. For data integrity, the DS

memory is divided into a secure sector (A) for all bolt data and a public sector (B) for transfer

via USB to a computer. The unit incorporates the latest smart-charge system; it will charge

through an external power supply or the waterproof micro USB connector from any standard

5V USB device, battery pack or power supply

Document No: DELTA SIGMA-USM

Version 4

Revision 3.94.2

Page: 4 / 32

2 OPERATION OF THE DS

2.1 OVERVIEW

TEMPERATURE PROBE PORT

(3 PIN LEMO)

TRANSDUCER PORT

PULSE-ECHO: P/E

(SINGLE PIN LEMO)

PITCH / CATCH PORT: P-C

(SINGLE PIN LEMO)

I/O PORT

(6 PIN LEMO)

POWER ON

LED INDICATOR

PROCESSOR WORKING

TOUCH SCREEN

MINI-USB PORT

EXTERNAL CHARGER PORT

Page: 5 / 32

Document No: DELTA SIGMA-USM

Version 4

Revision 3.94.2

2.2 PROJECT / BOLT DATA FILES

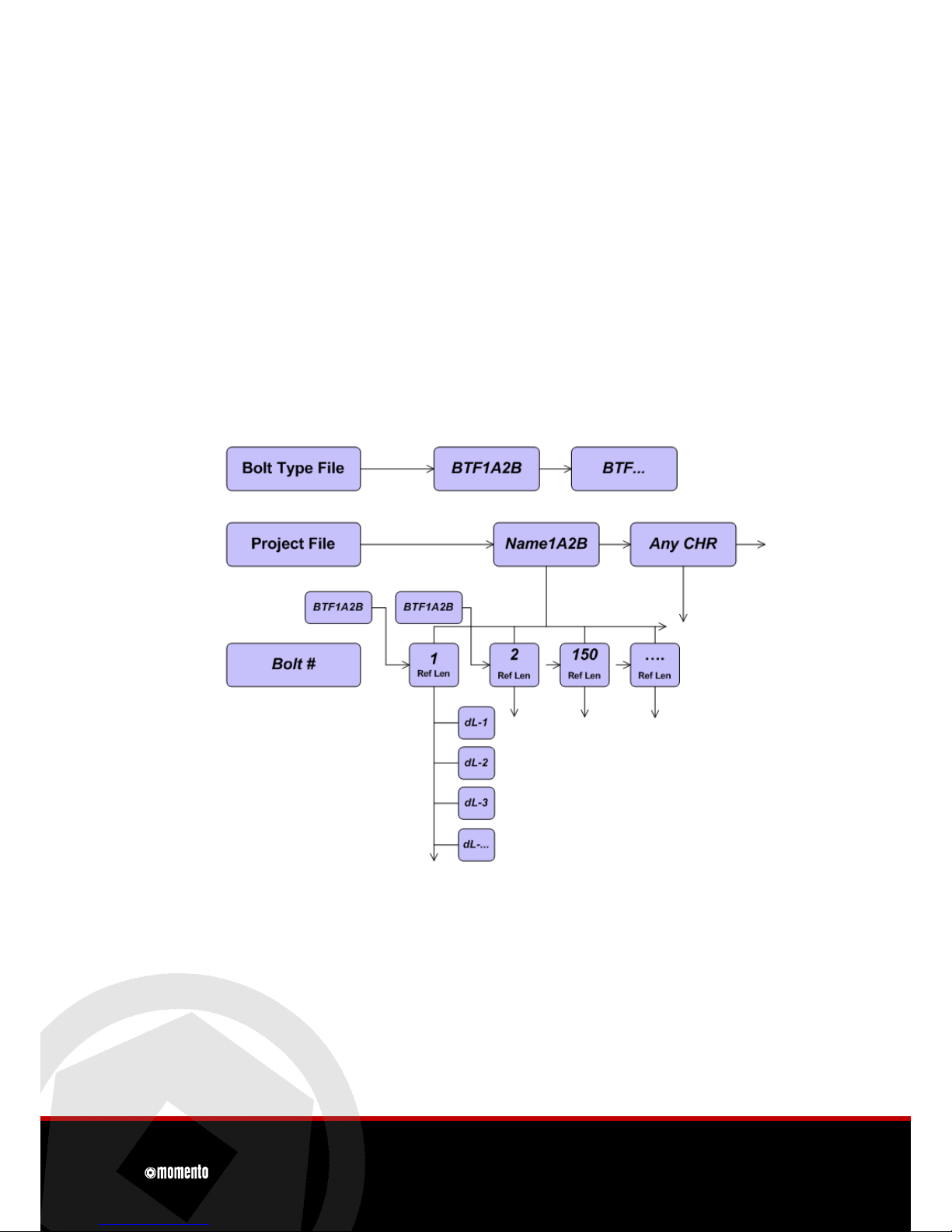

A joint is a structure that contains a collection of bolts whose purpose is to hold the structure

together through the combined clamping force of the bolts on the joint. These bolts can all be

the same size or may be of different diameters and lengths (types). The data structure used in

the DS is setup to accommodate this logical bolted joint structure. The Project file includes

the basic joint information and stores the Length, Stretch and Load data.

The DS requires geometric, ultrasonic and material information specific to a type of bolt to

determine the load ultrasonically. This information is stored in the Bolt Type File. A bolt type

must be named and entered for bolts with different geometries, grip lengths and/or loading

requirements.

Document No: DELTA SIGMA-USM

Version 4

Revision 3.94.2

Page: 6 / 32

On receipt of your DS the batteries should be charged, plug in the included charger, turn unit

on and leave charging for 12hrs. After 5 minutes of inactivity the display will shut off but the

charger will stay on, it will shut down when fully charged. The blinking red LED designates

charging mode.

Above is the DS start up screen. The time can easily be set by pressing the active Time &

Date button. Here you can easily adjust the time and date if you are in another time zone

The instrument is now ready to use.

In order to start measuring, connect the transducer and the temperature probe into the correct

port and press the MEASURE button. (See Operations Section)

To shut off the instrument, press the POWER OFF button, and then press YES in order to power

down the instrument. All data is automatically stored, so there is no risk of loosing data by

powering down the instrument.

START UP SCREEN

POWER ON

TIME & DATE

START

BOLT LOAD

MEASUREMENT

POWER OFF

SETUP AND

OPTIONS

INCLUDING

MEMORY FORMAT

BATTERY LEVEL

INDICATOR

Page: 7 / 32

Document No: DELTA SIGMA-USM

Version 4

Revision 3.94.2

2.3 SETUP SCREEN

On your first screen you have an option to press SETUP in order to configure the Delta Sigma.

• FILE BACKUP: You can backup your files. By entering this option you can select what

projects you need to backup to drive B

• ERASE FILES: If you need to delete all stored data, Choose the the data you want to delete.

If you then press YES, the data will be deleted. This operation cannot be reversed.

• MAINTENANCE: Factory settings only: password required.

• CALIBRATION: Enter this option if you want to calibrate your DS

• SECURITY: Lock-Out function for bolt-data settings. Password is: 1 2 3 4.

• OPTIONS: In this screen you can chose operational mode.

Bolt Type Mode: Chose “Expert” mode if you want to work with “Master Bolt” covered

in the “Measurement process section”.

Manual Scope Mode: You need to enable this in order to use the ADJ-function covered in

the “Measure bolt section”

The DS will not allow dual access to the Public drive memory, so The DS will not read-write to

the memory if the USB is connected to a PC.

You can also adjust the backlight brightness of the screen by pressing the plus and minus button.

Document No: DELTA SIGMA-USM

Version 4

Revision 3.94.2

Page: 8 / 32

2.4 MEASUREMENT PROCESS

The DS will automatically continue the previously run project. If there are no projects stored

in the DS, the screen will show "No projects" before going to the Project List screen as shown

on page 8.

BOLT INFORMATION SCREEN

If this is your current project, press the MEASURE button.

To select a different project or start a new project, press the Selected Project button. You now

enter the Project List Screen

PROJECT LIST SCREEN

Here all previous projects will be listed. If there are no projects stored in the DS, the page will

be empty like shown on the picture above, except for the "Operation Subsea" button. Select

the project you are working on or to start a new project by pressing the NEW button. You will

then enter the Project Data Screen as shown on the next page.

View or change

project info

View or change

Displayed Bolt Data info

View or change

Project Data

Measure Selcted Bolt

Selected Project:

Select New Project

Selected Bolt:

Select New Bolt

Selected Bolt Type:

Select New Bolt

Return to previous Screen

Scroll up through

displayed Projects

Enter new project

Scroll down

Previously stored project

Page: 9 / 32

Document No: DELTA SIGMA-USM

Version 4

Revision 3.94.2

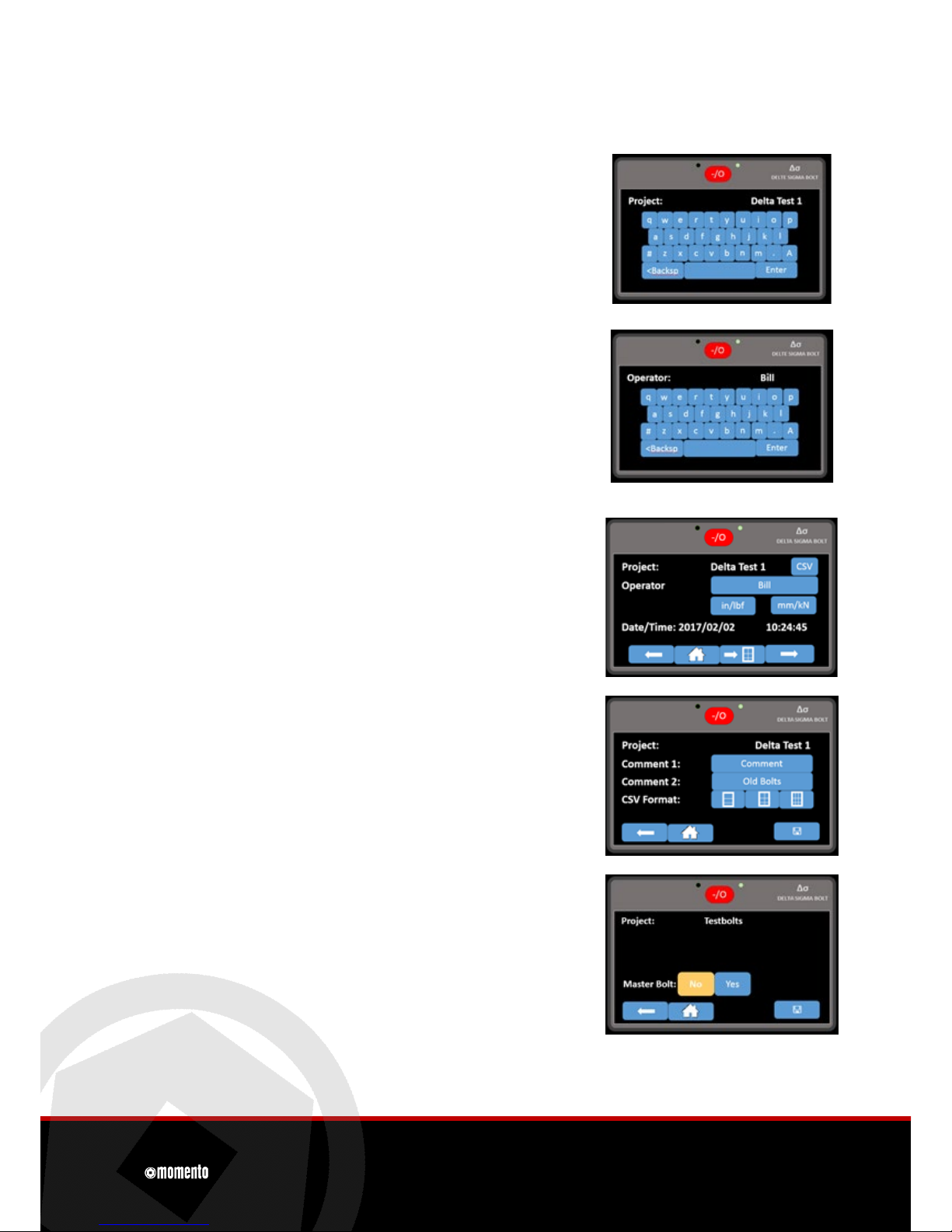

NEW PROJECT SCREEN

Enter Project Name and confirm by pressing ENTER.

You then get a question if you really want to create a new

project or not. If you do, press YES. If you do not, press NO and

you will return.

Enter Operators name and confirm by pressing ENTER.

Choose Units and press NEXT.

Enter comments, if any. Once you press SAVE button the

project is saved.

If you want a short report: Press short

If you want a long report: Press long

All data is stored in the DS so this is changeable. This can be

changed at a later stage.

If Expert mode is enabled, the “Master Bolt Option” that can

be used to speed up the initial length reading process.

By setting this to YES, if the first bolt you enter is “Bolt

000”, the unit will use this as the “Master Bolt”.

The unit will use the receiver settings for the master bolt for

all following bolts. NB: This is only to be used if the bolt

group is homogenous.

Loading...

Loading...