Molnar SM450 Installation Manual

SM450 FOUR POST HOIST

5 Tonne Electro-Hydraulic Four Post Hoist

Installation Manual

Updated 14/12/2018

Page 2 of 19 Molnar 4 Post Hoist SM450

Contents

Installation Instructions Page 3-16

Installer Checklist Page 17

24V Transformer Wiring Detail Page 18

Single & three Phase Wiring Diagram Page 19

Please read this manual before you get started.

You must read and understand the precautions for safety purposes and any damages that may occur to your

property.

Address: 3 Graham Street

Export Park

South Australia 5950

Ph: +61 (08) 8234 3611

Fax: +61 (08) 8234 4322

Email: sales@molnarhoists.com.au

Web: www.molnarhoists.com.au

Specifications/images subject to change without prior notice, Images and sketches are for illustration purposes only.

Before commencing

operation inspect

system components,

control, emergency

stop and safety

equipment for

condition and correct

Page 3 of 19 Molnar 4 Post Hoist SM450

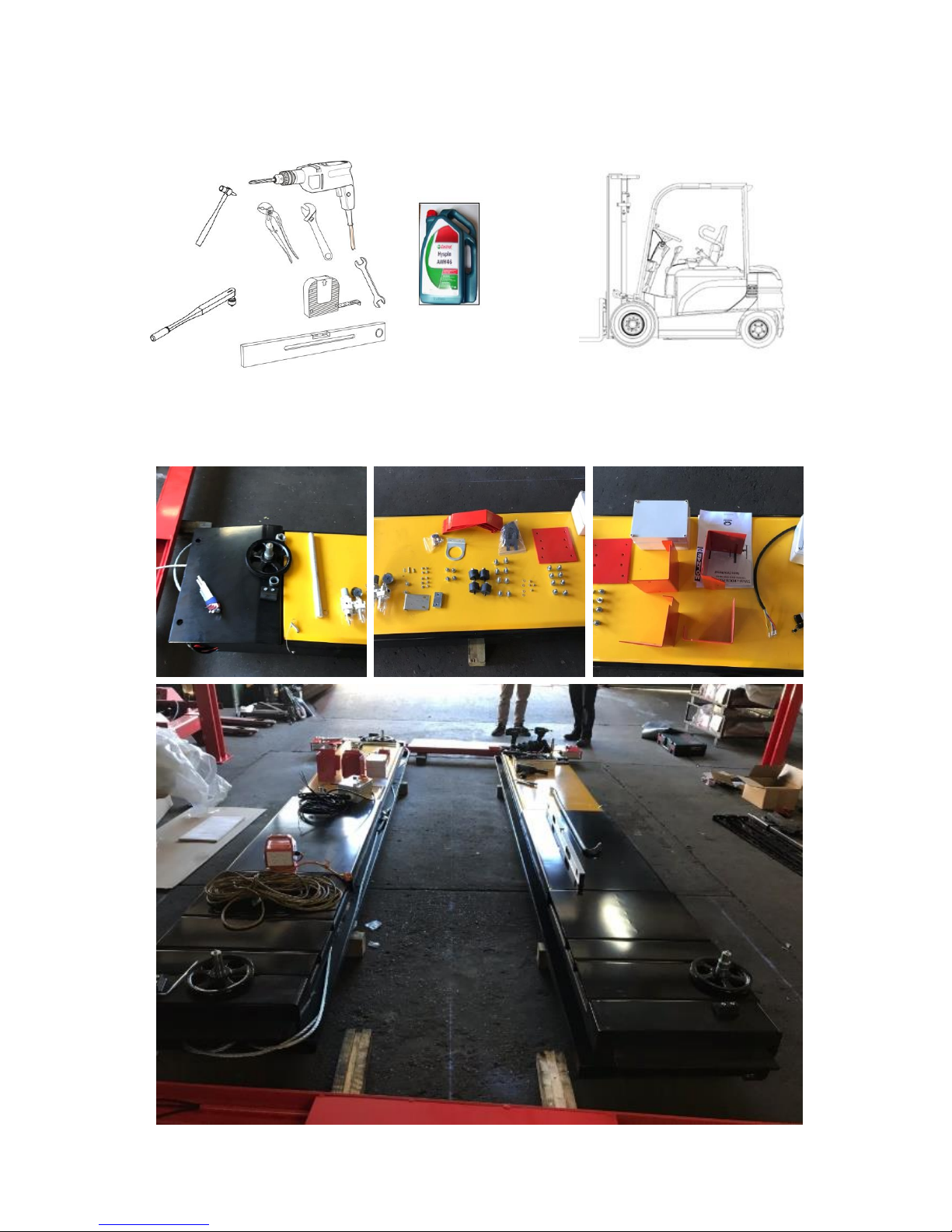

Tools Required:

Place all the components as shown to check supplied parts.

46 Weight AWH

Hydraulic Oil

10L

Page 4 of 19 Molnar 4 Post Hoist SM450

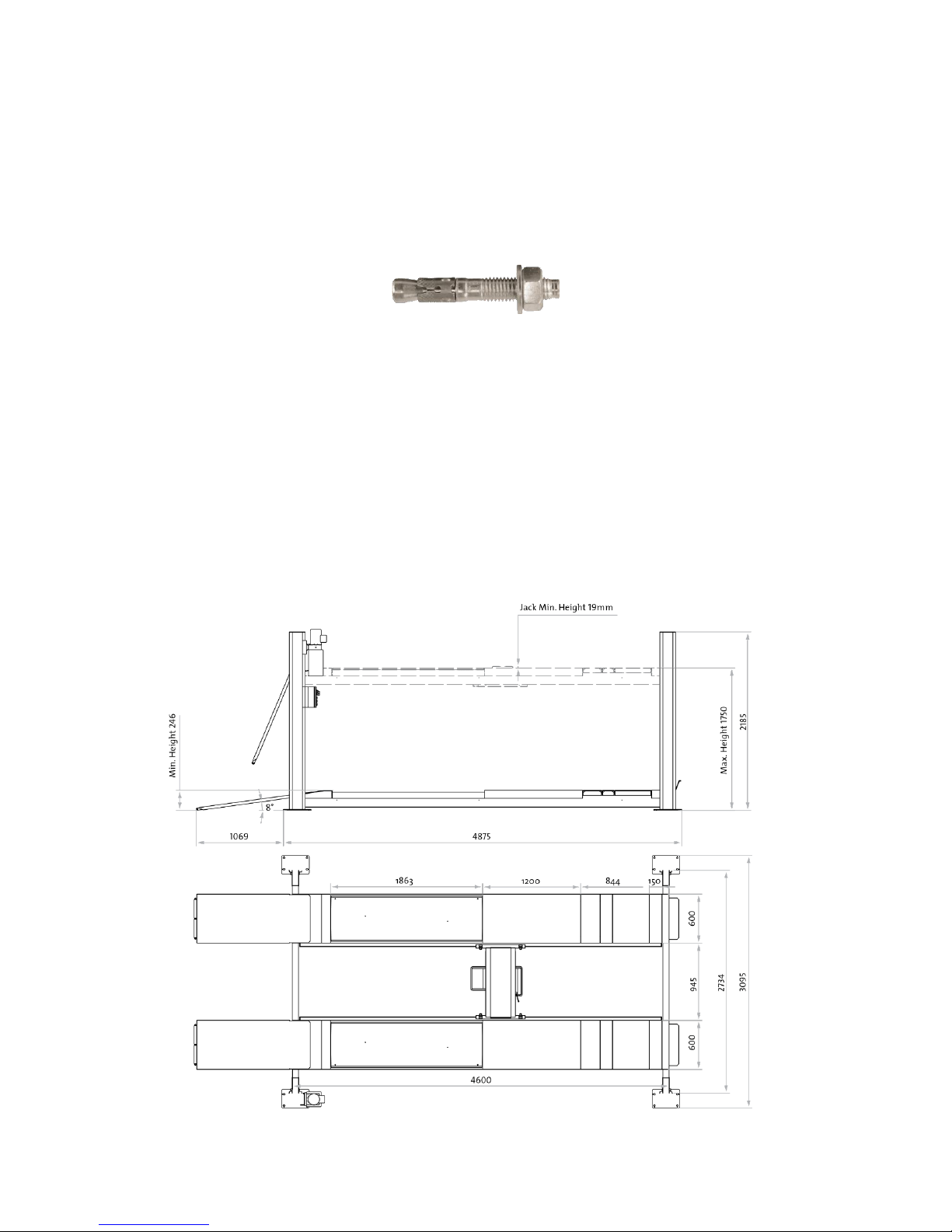

TRANSPORTATION AND INSTALLATION

Preparation for installation

The hoist shall be installed on hard and flat floor made with reinforced concrete at 32MPa grade

with the thickness of 100mm minimum. The anchor bolt shall be M16 x 140mm tru-bolt and requires

16 anchor bolts.

Iccons Part No TB16140

Generally, this machine will be installed on the following conditions:

1) Supply voltage: 0.9 - 1.1 nominal supply voltage

2) Source frequency: 0.99 - 1.01 nominal frequency

3) Ambient temperature: 50C - 400C

4) Altitude: shall be at altitudes up to 1000m above mean sea level

5) Relative humidity: not exceed 50% at 40C

6) Atmosphere: Free from excessive dust, acid fume, corrosive gases and salt.

7) Avoid exposing to direct sunlight or heat rays which can change the environmental

temperature.

8) Avoid exposing to abnormal vibration.

9) Electrical equipment shall withstand the effects of transportation and storage temperature

within a range of -25°C to 55°C and for short periods not exceeding 24 hours at up to +70°C.

Page 5 of 19 Molnar 4 Post Hoist SM450

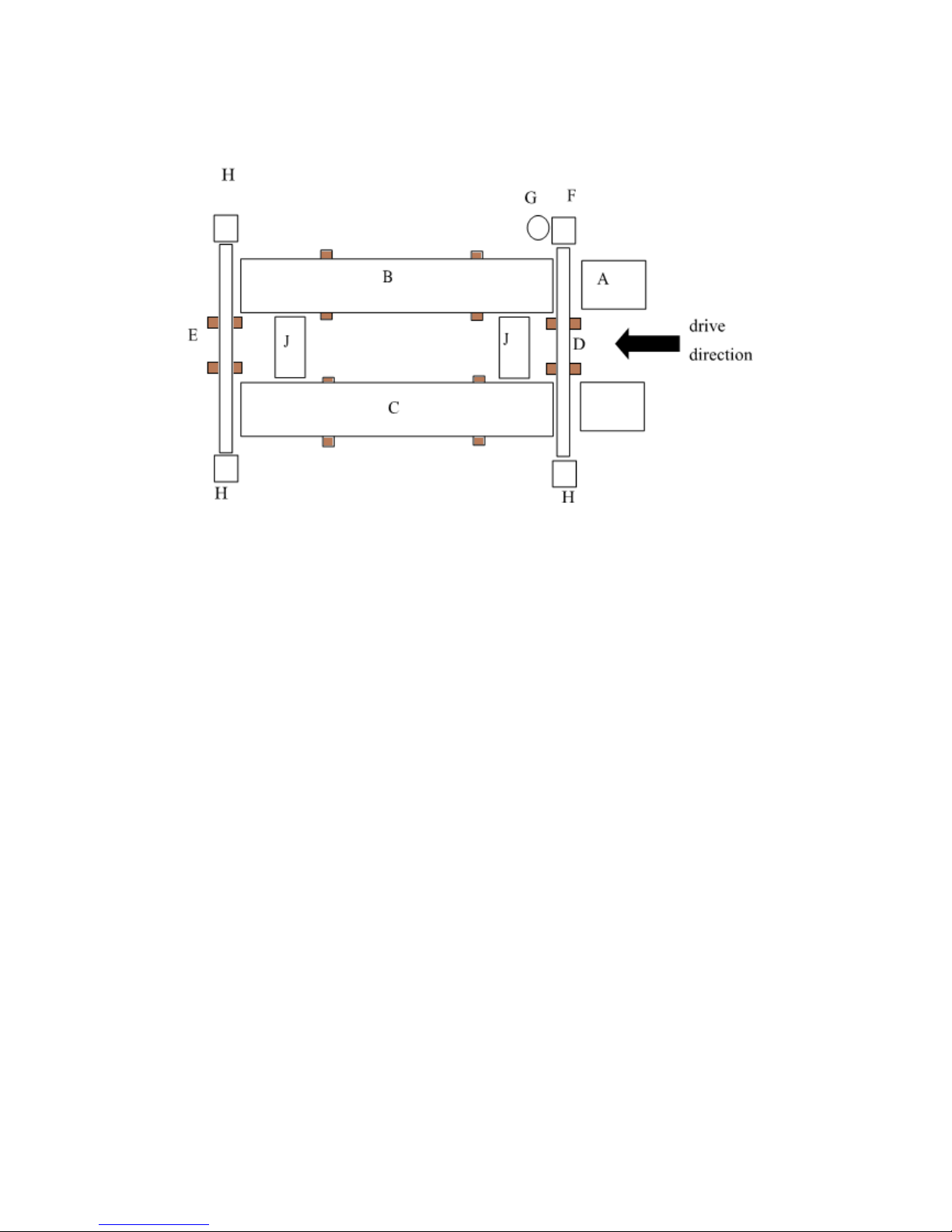

Installation Process

Layout Reference Diagram

A - Run up ramps

B - Control platform

C - Non-control platform

D - Transverse beam control end

E - Transverse beam non-control end

F - Control post

G - Power pack

H - Non-control post

J - Jacking beam

Placing hoist on the installation location using timber under the platforms and transverse beams

1) Place the main parts on the appropriate position in reference to the above layout diagram.

Page 6 of 19 Molnar 4 Post Hoist SM450

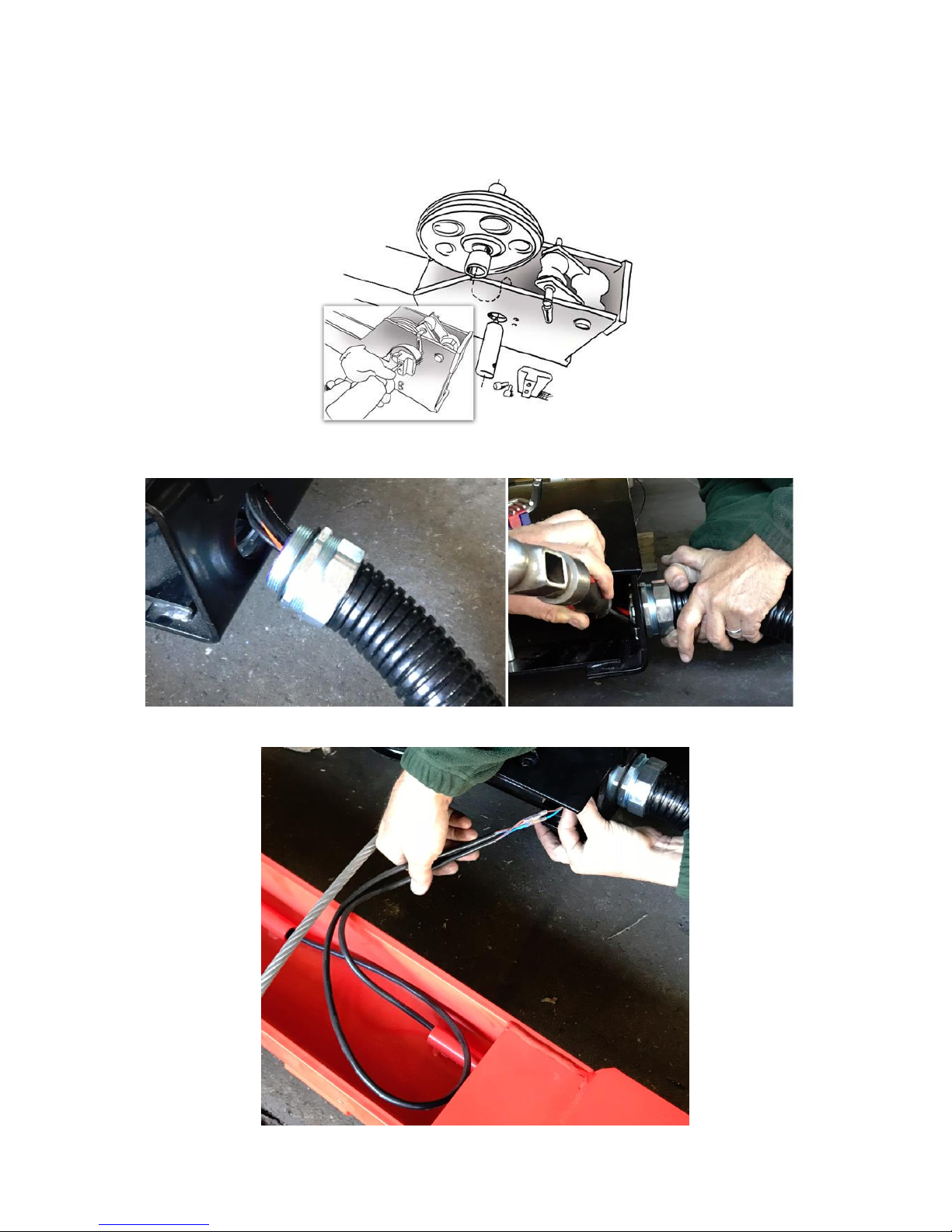

Assembling Transverse Beam for Platforms

1. Take the pins fixing guide block, pull out the pins and take out the transverse beam pulleys (4

positions)

2. Remove the wood pieces inside the platform which are holding the cables inside. Cut the cable ties

and pull out the large black conduit and tighten the nut to the side of the platform.

3. Connect the lock cables into each end of the transverse beams.

Loading...

Loading...