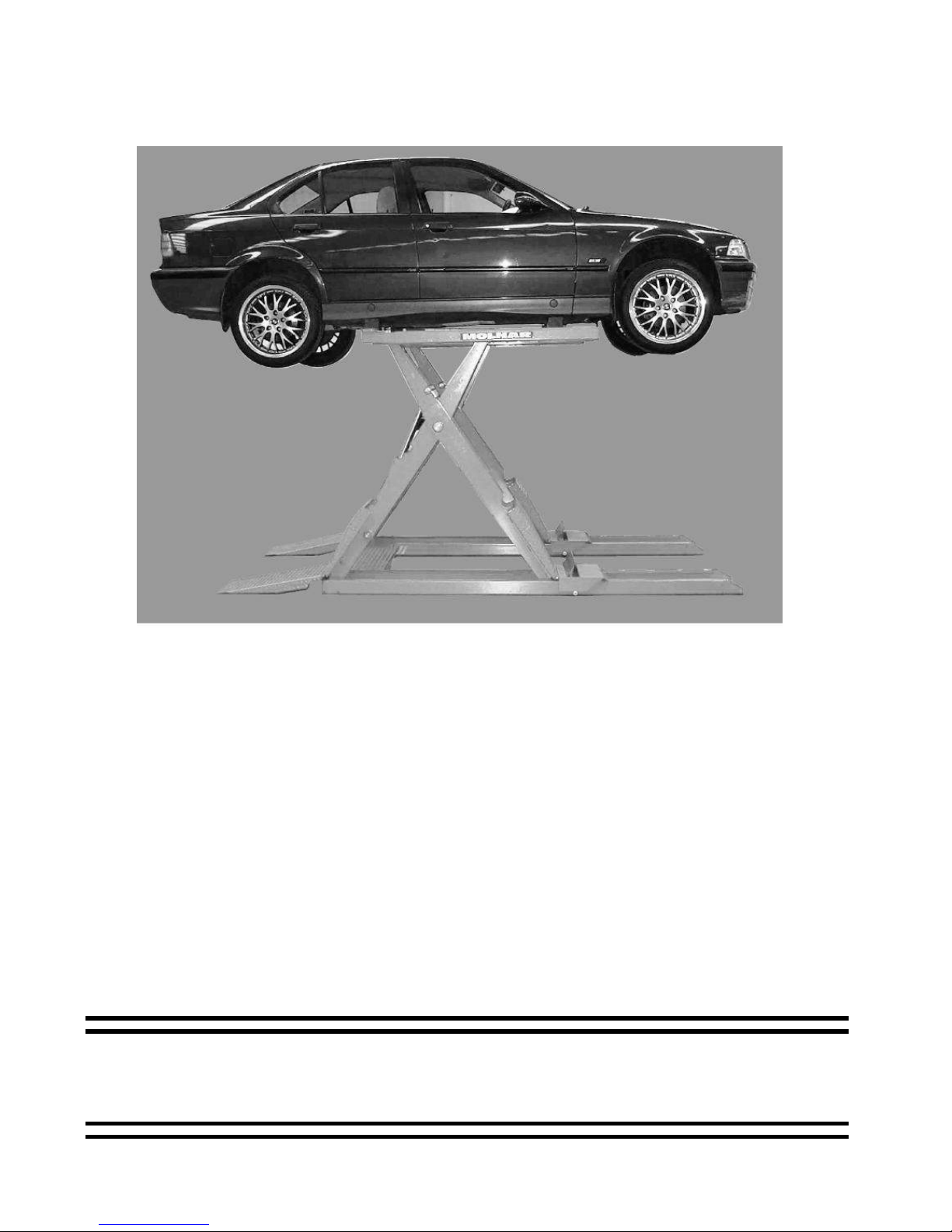

Molnar SL02 Installation Operation & Maintenance

Page 1 of 22 Rev B – Dec 2009

MOLNAR

SCISSOR LIFT HOIST

SL02

INSTALLATION, OPERATION

& MAINTENANCE MANUAL

Page 2 of 22 Rev B – Dec 2009

OPTIONAL 240 VOLT SINGLE PHASE

MINIMUM REQUIREMENTS FOR ELECTRICAL CONNECTION

OF MOLNAR HOISTS

Important: All installations should be carried out by suitably

qualified persons. Failure to comply may void warranty.

The following information is a guide only based on the

latest standards as set out in AS/NZS 3000, for installations

outside of Australia & New Zealand refer to local

standards regulations.

Circuit Breakers should be of "D" curve type (motor start,

high inrush current) - Ratings given as a maximum for

circuit & motor protection based on DOL selection guide.

Voltage operating range: -6% to + 10% of motor

nameplate Voltage.

Motor Voltage 240V Operation range 225V to 264V.

Cable sizes are given as a guide only for a maximum

cable length to 30m. Longest cable runs and in area

where supply voltage is below motor voltage,

Calculation should be made to ensure Voltage Drop will

not fall below minimum operating voltage.

When installed motors must be tested under Full Load checking

Voltage at motor terminals.

Motor 2.2kW 240V Single-phase model CWC3640F

Full Load Current 12.4 Amps

Min Cable Size 2.5mm 2 core + earth

Circuit Breaker 1 phase 32 Amp 10kA

Recommended Clipsal4CB132/10 or equivalent

Page 3 of 22 Rev B – Dec 2009

No person should be permitted to operate

the MOLNAR SCISSOR LIFT HOIST

without first studying the operating

instructions on top of page 9 and safety

precautions on page 11.

This manual should be kept in a safe

place and referred to as necessary

The installation requirements on page 19

must be completed and the certificate on

the inside back cover must be signed by

the installer. The guarantee card must be

completed and returned to MOLNAR

ENGINEERING PTY. LTD.

When installed in tropical environments it

is advisable to raise the hoist to full height

when not in use overnight or on

weekends, to minimise condensation

forming inside the cylinder which may lead

to corrosion of cylinder bore or shaft.

This vehicle hoist is not designed to be

used for steam cleaning nor be installed in

the open exposed to the elements.

Vehicle hoists installed under such

conditions are not covered by our

guarantee.

Page 4 of 22 Rev B – Dec 2009

Model SL02

Complies fully with the

Australian Standard

1418.9-1996

Page 5 of 22 Rev B – Dec 2009

Max 1890mm

CONTENTS

Introduction……………………………………………………………………6-7

Floor Requirements…………………………………………………………….8

Operating Instructions………………………………………………………….9

Maintenance…………………………………………………………………...10

Safety Precautions……………………………………………………………11

Replacement Parts List………………………………………………….……12

Parts Identification……………………………………………………….……13

Installation Instructions……………………………………………………….14

Wiring Diagram………………………………………………………………..15

Electronic Diagram……………………………………………………………16

Hydraulic Circuit Diagram…………………………………………………….17

Installation Requirements…………………………………………………….18

Certification…………………………………………………………………….19

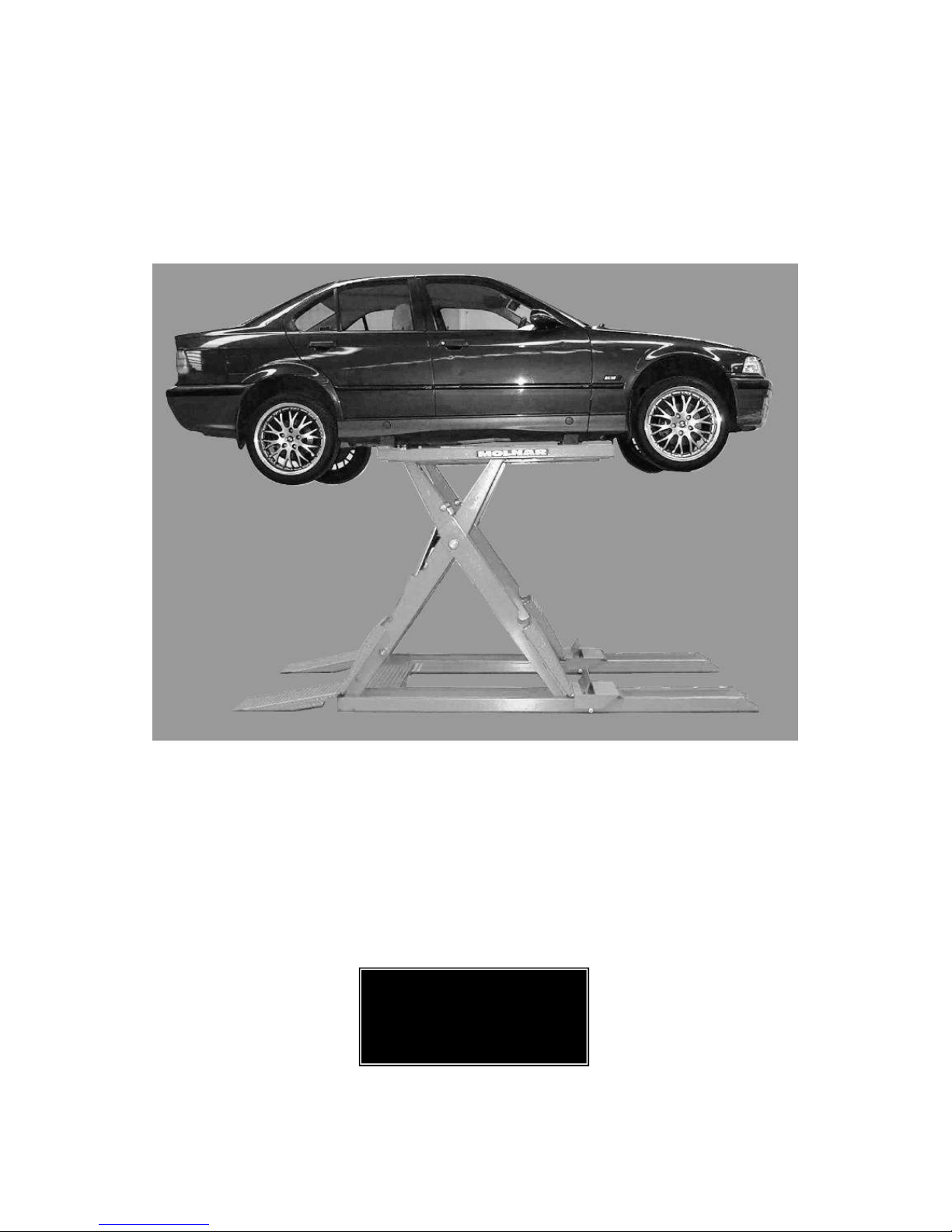

SPECIFICATIONS

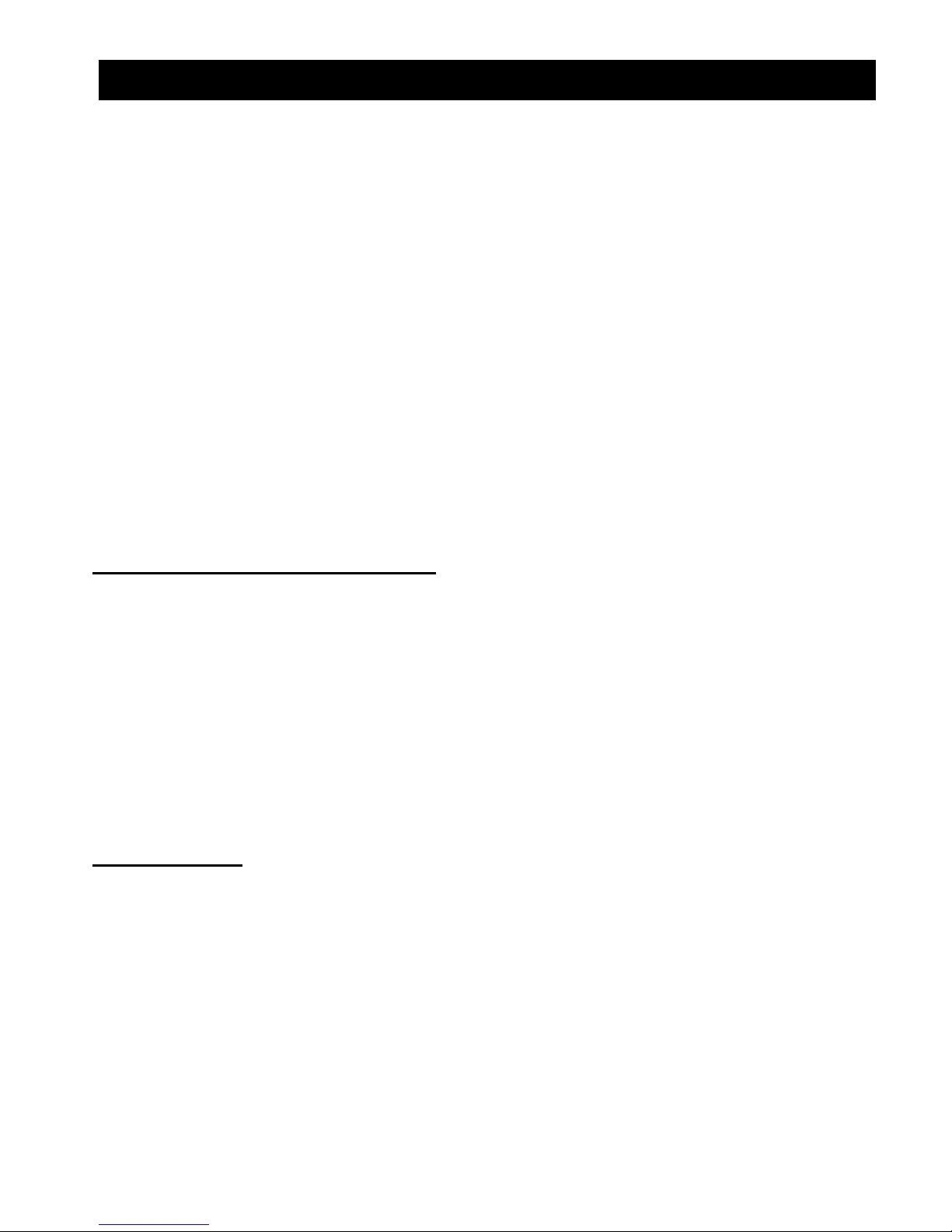

Overall width 2093mm

Overall length 3664mm

Maximum raised height 1830mm

Minimum lowered height platform 188mm

Lifting time (working height) approx. 55 secs

Lowering time (3tonnes) approx 30 secs

Electric motor - 3 phase, 2.2kw, 2700 rpm, 415 volts, 50 hertz

(Optional) - Single phase, 2.2kw, 2850 rpm, 240 volts, 50 hertz

Hoist mass - 1080 kg

Hydraulic oil - Castrol Hyspin AWH46, Shell Tellus T46,

Mobil DTE 25, BP Bartran HV46 or equivalent

SWL - 3000kg (3,0 tonnes)

Air supply - Compressed air to max 7 bar, 6mm dia min supply line.

Max Vehicle Size

Min 2200mm

The Manufacturer reserves the right to alter these features and specifications without notice

Page 6 of 22 Rev B – Dec 2009

INTRODUCTION

Here is the MOLNAR SCISSOR LIFT HOIST, a space saving wheel-free hoist and

its many advantages.

It has been purposely designed for space saving and to give versatility and

profitability to the largest garage and smallest service station. Safe, strong, simply

built to give years of trouble-free service. The MOLNAR SCISSOR LIFT HOIST

embodies many features that make it the most up-to-date equipment for quicker and

more profitable service.

SAFE AND EFFICIENT OPERATION

Due to an electro hydraulic system, which gives years of trouble free service.

Raising and lowering of vehicle is achieved through an electronic remote controller.

Sturdy safety toggles ensure against any failure with additional flow controls at the

base of each cylinder, in the event of a hydraulic line breakage.

INSTALLATION

The MOLNAR SCISSOR LIFT HOIST is fast and simple to install.

It is also ideal for upper floor level where excavation is not possible. The hoist is

surface mounted, a feature which means lower overall cost. Compared with similarpriced hoists, the MOLNAR SCISSOR LIFT HOIST can be quickly, easily and

economically re-sited.

Page 7 of 22 Rev B – Dec 2009

INTRODUCTION

FOR SPEEDIER SERVICE

With the MOLNAR SCISSOR LIFT HOIST maximum accessibility is assured. For

safe and fast efficient servicing giving the hoist unlimited advantages. With this lifting

method the suspension springs are relaxed, facilitating service and repair work.

Some other uses are wheel service, brake adjustment, spraying or sealing.

EASY TO OPERATE

The MOLNAR SCISSOR LIFT HOIST is operated with the greatest of ease. The

rubber pads are easily placed in position by one man. The operator has full

confidence due to the extensions catering for long wheelbase vehicles. The vehicle

is immediately wheel- free and stable at any height.

Loading...

Loading...