Page 1

MRS19201 Rev C 2014-06-25

Molift Rail System

EN - Handbook

Page 2

2

Molift Rail System / www.molift.com

Page 3

3

Molift Rail System / www.molift.com

English Manual

Content

Molift Rail System (MRS) – Introduction..................4

General...........................................................................4

1 How to use this handbook......................................5

2 Installation criteria – Principles...............................6

2.1 Site survey – Design criterias............................6

2.2 Lifting points.......................................................6

2.3 Mounting Molift Rail system............................7

2.4 Point loads.........................................................8

3 System Overview.......................................................9

3.1 Single rail system...............................................10

3.1.1 Ceiling mounted Straight rail system......11

3.1.2 Ceiling mounted Curve rail system.........13

3.1.3 Wall mounted Straight rail system..........14

3.2 Traverse rail system...........................................15

3.2.1 Ceiling mounted traverse system............16

3.2.2 Wall mounted traverse system................18

3.3 Combination of rail systems...........................20

3.3.1 Switch systems...........................................21

3.3.2 Climbing systems......................................23

4. Component Overview...........................................26

4.1 Attachment........................................................27

4.1.1 Ceiling Mounted System..........................27

4.1.2 Wall mounted System..............................29

4.2 Rails and Curves...............................................30

4.3 End Stops and End Caps................................32

4.4 Traverse Trolleys................................................33

4.5 Lift Motor Trolleys............................................35

4.6 Switches.............................................................36

4.7 Battery Charging..............................................37

4.8 Installation tools..............................................40

5. Design Conditions..................................................42

5.1 Lifting heights and lifting area.......................42

5.2 Design conditions – Attachments.................44

5.2.1 Ceiling mounted........................................44

5.2.2 Wall mounted............................................45

5.2.3 Attachments for cur ves...........................47

5.2.4 Side Support positioning.........................48

6 Installation methods...............................................54

7 Final Installation Procedure....................................56

7.1 Load test: Straight Rail System.......................56

7.2 Load test: Traverse Rail System......................56

7.3 Identification......................................................57

7.4 Installation Certification..................................57

8. System combinations – Case studies.................58

8.1 Single Rail system.............................................59

8.2 Traverse Rail system.........................................62

9. Installation instructions.........................................67

10. Maintenance.........................................................68

Service log...................................................................69

Checklist for installation of Molift Rail System......70

Periodic inspection for Molift Rail System..............71

Important

This User Manual contains important safety

instructions and information regarding the use of

the lifter and accessories.

In this manual the user is the person being lifted.

The assistant is the person operating the lifter.

Warning!

This symbol indicates important

information related to safety.

Follow these instructions carefully.

Visit www.molift.net for download of documentation to ensure you have the latest version.

Revision table

Rev ision A . 2013-12- 0 9

First release

Revision B. 2014-02-18

Updated illustrations and miscellaneous

details. New front page.

Revision C. 2014-06-25

Removed IRC components and room-to-

room transfer Molift Air. Added boxed

traverese trolley.

Page 4

4

Molift Rail System / www.molift.com

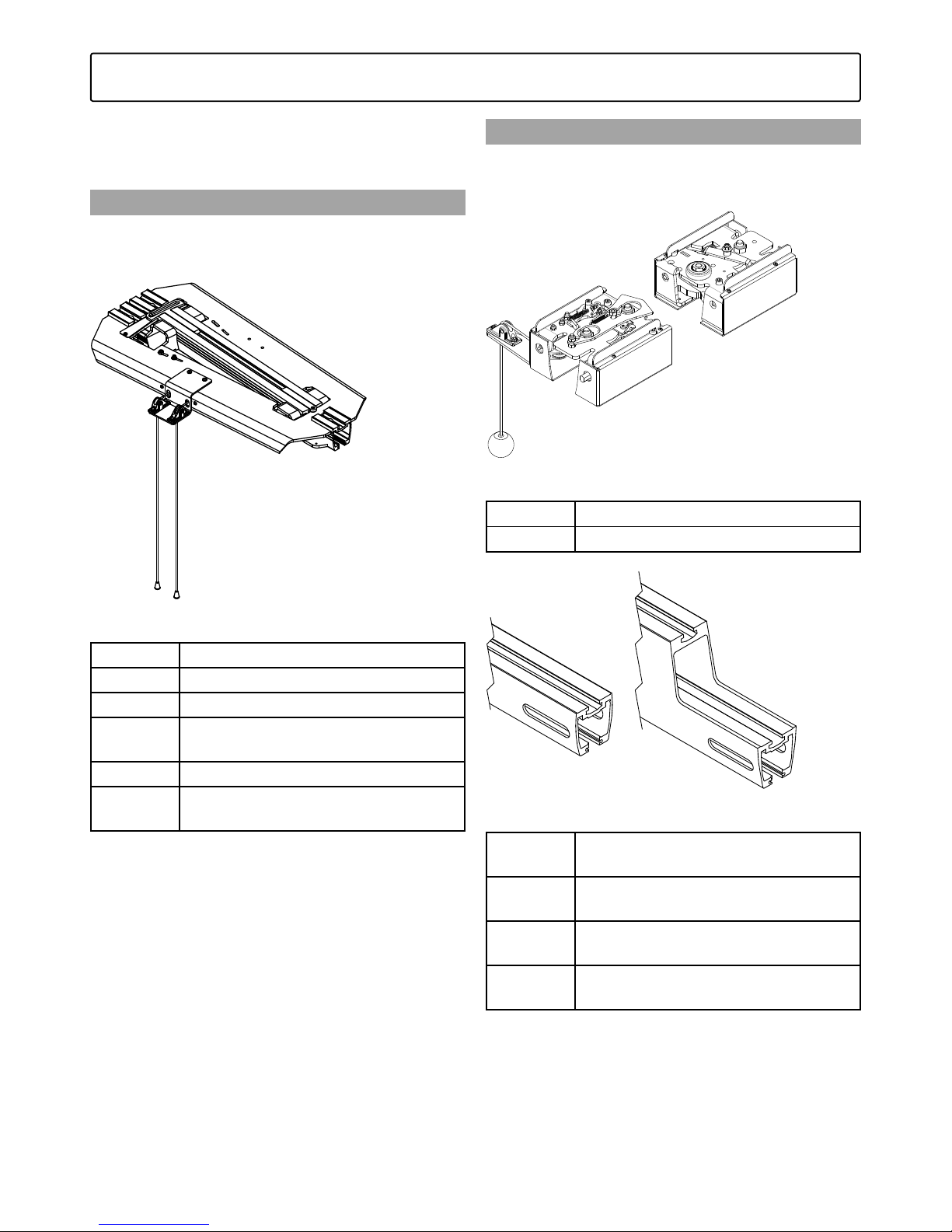

Molift Rail System (MRS)

Introduction

Molift Overhead Systems consist of a rail system,

Molift Rails System (MRS) combined with the lift

motor choices Molift AIR or Molift Nomad which

give innovative and efficient solutions when it

comes to lifting needs for disabled persons.

Molift Overhead Systems are easy and safe to use

and can solve most lifting situations. The functional and user friendly design provides greater

access to the user and increases assistant and user

safety. Molift solution gives a highly flexible, innovative, cost effective and profitable investment.

This handbook provides support and guidance to

installation performance of Molift overhead lift

systems and contains important information about

the design criteria and installation solutions. It is

important to thoroughly understand the content

of the handbook.

Conditions of Performing Installation

Lift and transfer of a person will always pose

a certain risk and only certified personnel are

allowed to install the equipment and accessories

covered by this technical manual.

Only personnel authorized by Etac

can perform installation of the

Molift overhead system and issue

the installation certificate, all in

accordance with Etac’s installation

instructions and this handbook.

The lifter is not intended to be operated by the

person being lifted. If a hoist is to be used by a

disabled person living on their own, then some

form of communication device shall be installed

in the area of use of the hoist so that in the event

of an emergency the disabled person is able to

summon assistance. This may, for example, be

the fitting of an alarm system or the supply of a

conveniently placed telephone, etc.

General

Declaration of conformity

The Molift Rail System and related accessories described in this handbook are CE marked

in accordance with EU Council Directive 93/42/EEC concerning medical devices, class 1, and

is manufactured in conformity with standards IEC 60601-1, IEC 60601-1-2 and NS-EN ISO

10535:2006.

Components made by other manufacturers

We recommend only using Etac Molift components. Etac shall not be liable for faults or accidents

that can occur when using components made by other manufacturers.

System should consist of only original MRS components. If not Decalaration of

conformity is not valid and Etac is not responisble for warranty of the system

Page 5

5

Molift Rail System / www.molift.com

In order to design a lifting solution, create a specification, order the parts and install the overhead

systems You need following documents apart

from this Handbook:

- Molift Pricelist

- Molift Product catalogue

- Site survey

- Installation instructions

The Handbook is divided into nine main chapters.

Chapter 1 – Molift Rail System (MRS)

Introduction of Molift Rail System. General terms

and a description how to use this handbook.

Chapter 2 - Installation criteria – Principles

Description of the principles for installing a Molift

Rail System, Site survey process and how to handle

different constructions material in buildings.

Chapter 3 –System Overview

Overview of possible system configuration and

combinations of MRS.

Chapter 4 – Component Overview

This chapter describes the MRS products and

which components are available for different

design solutions.

Chapter 5 - Design Conditions

This chapter describes the design conditions, limitations and possibilities how to combine the MRS

products to create a sufficient and safe Molift

Overhead System.

Chapter 6 - Installation methods

This Chapter describes work flow and tools for

survey and installation process.

Chapter 7 - Final Installation Procedure

This Chapter describes procedure for the final testing and certification of installed rail system.

Chapter 8 - System combinations – Examples

This Chapter describes a few of the most common

design solutions of Molift Rail System. Shows combination possibilities, measurements and examples

of specifications.

Chapter 9 - Installation instructions

This Chapter describe list of available Specific

Installation Instructions for the various mounting

options for MRS.

Chapter 10 - Maintenance

This Chapter describes how to perform periodic

inspection, service and repair to the rail system.

1. How to use this handbook

Page 6

6

Molift Rail System / www.molift.com

2. Installation criteria – Principles

2.1 Site survey – Design criteria

A site survey is the first project input, and it is

of great importance that this is performed and

archived in a proper way. We recommend that all

points in our Site Survey template are considered,

and that existing on-site conditions are documented preferably with photos and drawings.

Depending of the size of a ceiling lift installation

project, it is also of importance to consider how to

organize logistics for a ceiling lift installation:

• When should the installation take place (in

larger building projects)?

• What floor is the installation to be done?

• How do we get the rails there? (Crane?

Elevator? Stairs?)

• How to install efficiently? Installations teams or

single workers?

• How to handle disposals (packaging materials)?

2.2 Lifting points

One important issue in the survey is to identify

and define lifting points and optimal placement of

the rail systems.

Figure: Furniture and lifitng points

100 cm

Page 7

7

Molift Rail System / www.molift.com

2.3 Mounting Molift Rail System

The way of mounting a ceiling lift system is based

on the specific materials and structural design on

each specific site.

Ceiling materials:

- Concrete; hollow core slabs or compact

layers

- Wood structures (requires reinforcements

between rafters)

- Light materials (LECA, Siporex etc)

Wall materials:

- Concrete

- Bricks

- Wood structure

- Light walls (Gyproc/plasterboards)

Upright supports:

- Upright supports are used where the exist-

ing structure or other installations does not

allow fixing in walls or ceiling.

Reinforcements to existing structues

- Reinforcements must be installed if the

existing building structure OR the materials

are too weak for the installation

Figure: Example of reinforcement of wood wall

structure with upright reinforcement between two

studs for mounting of wall bracket or wall rail.

Figure: Example of reinforcement of wood ceiling

structure with joist hangers and reinforcement

between joists.

Figure: Example of reinforcement of wood ceiling

structure with lying joist over joists.

Page 8

8

Molift Rail System / www.molift.com

2.4 Point loads

All systems should have minimum of two

anchoring (attachment) points.

One attachment point = one or more fixings

(expander bolts, chemical anchors etc.)

All attachment points of a ceiling lift system

should, according to prevailing standard EN-ISO

10535:2006, withstand a pullout force; the working load of the system installed times a safety

factor 1,5.

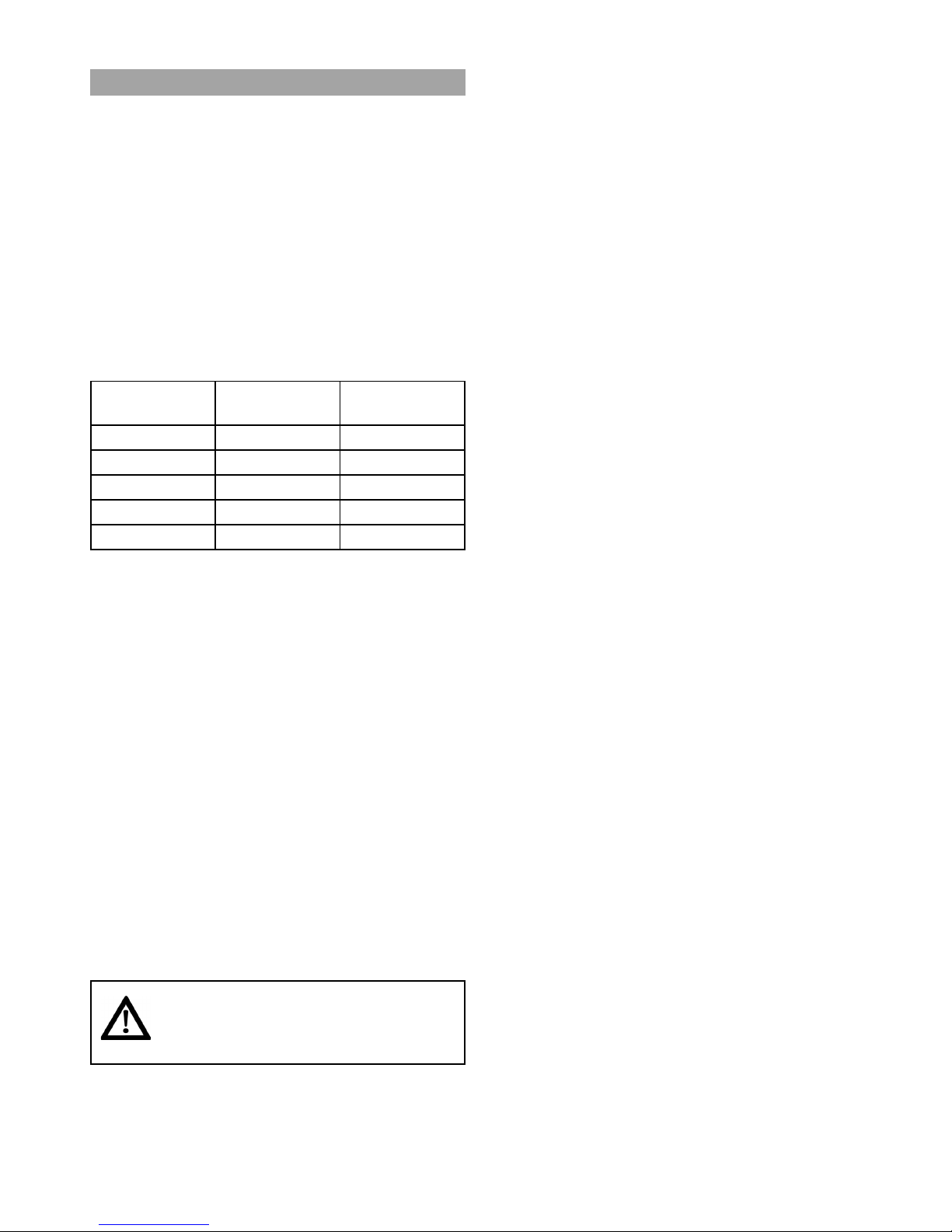

MRS attachment point Load Calculations:

• Molift Lift motors have 5 different weight

capacities within the range: 160 – 300 kg

Weight

capacity

Nomad Air

160 kg X

205 kg X X

230 kg X

255 kg X

300 kg X

• Standard ceiling lift system including any

straight rail or traverse system with 1 lift

motor.

• Estimated weight of equipment at pendant

support location for standard system =

approx. 30 kg

(includes: lift motor weight, rails, pendant,

traverse carrier, etc)

• Ultimate Point load for each support

attachment location is based upon the

maximum capacity of the lift motor +

estimated weight of the equipment at the

support attachment location times a safety

factor of 1,5

Example:

For a standard system with 200 kg motor:

200 kg = 200 kg – Safe Working Load

200 kg +30 kg = 230 kg – Working Load

230 kg x 1,5 = 345 kg – Ultimate Point

load

All fixings should always be tightened with torque specified by the

anchor/fixture manufacturer.

Page 9

9

Molift Rail System / www.molift.com

3. System Overview

Molift Rail System (MRS) is a ceiling hoist system built in three different main configurations:

1. Single rail system

2. Traverse rail system

3. Combination of single rail and traverse systems

The area below the track system is defined as the lifting area. The area below a straight rail system is

limited to the rail, while a traverse system gives lifting area below the area covered by the traversing

secondary rail.

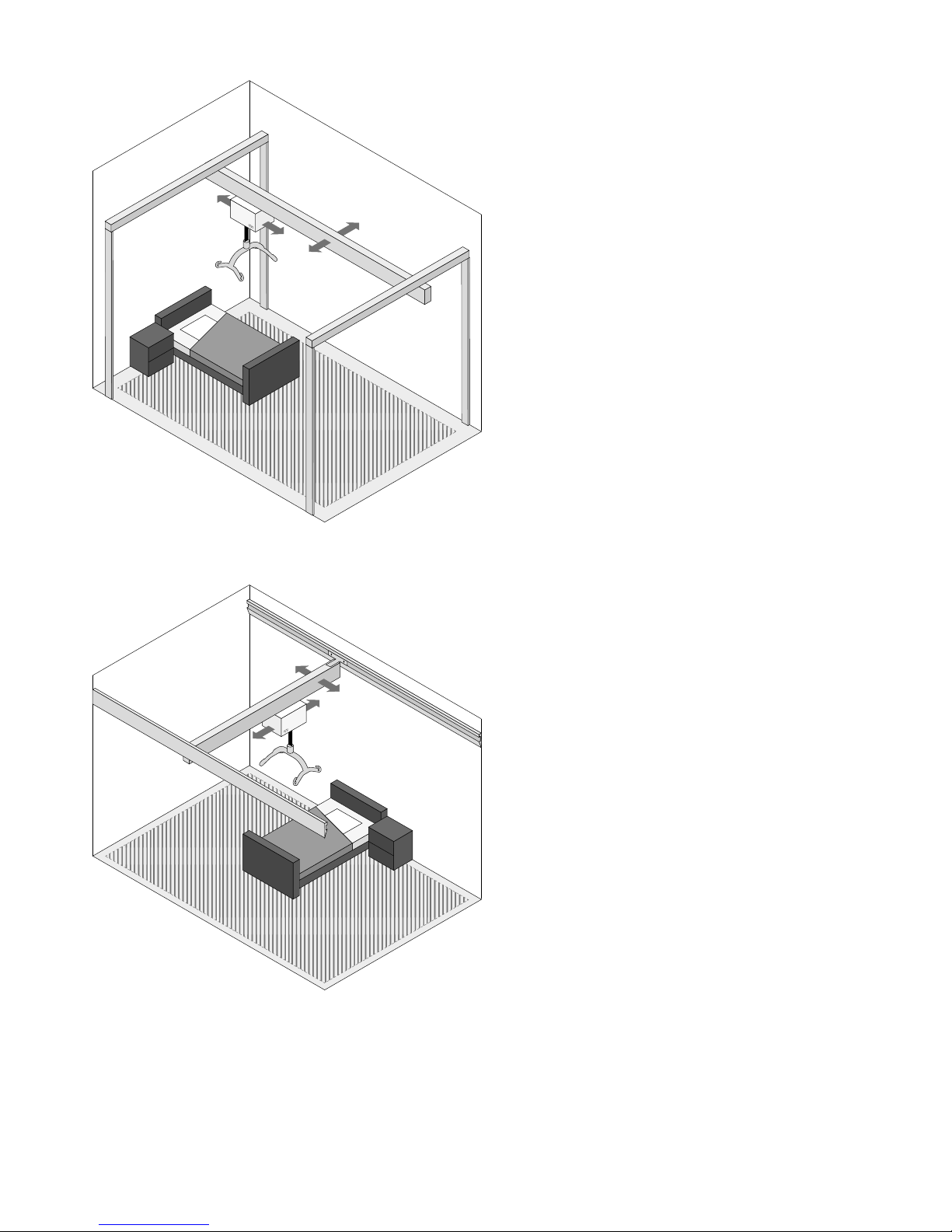

Single rail system

Traverse rail system

Page 10

10

Molift Rail System / www.molift.com

3.1 Single rail system

In a straight rail system the lift motor can be

moved horizontally along the rail path. By combining MRS curves and rails it is possible to create

single rail systems with expanded lifting area. The

curve rail system can only be mounted to ceiling

and does not allow wall mounting.

Lifting Area = Hatched area on floor under lifter.

3.1.1 Ceiling mounted Straight rail system

Can be mounted in four different ways:

1. Directly to ceiling without brackets

2. Mounted to ceiling with brackets

3. Suspended from the ceiling with telescopic

brackets

4. Suspended from the ceiling with threaded

rods

Figure: Ceiling mounted direct to ceiling without

brackets

Page 11

11

Molift Rail System / www.molift.com

Figure: Ceiling mounted with open ceiling using

40mm brackets

Figure: Ceiling mounted with telescopic brackets

Page 12

12

Molift Rail System / www.molift.com

Figure: Ceiling mounted with threaded rods

Page 13

13

Molift Rail System / www.molift.com

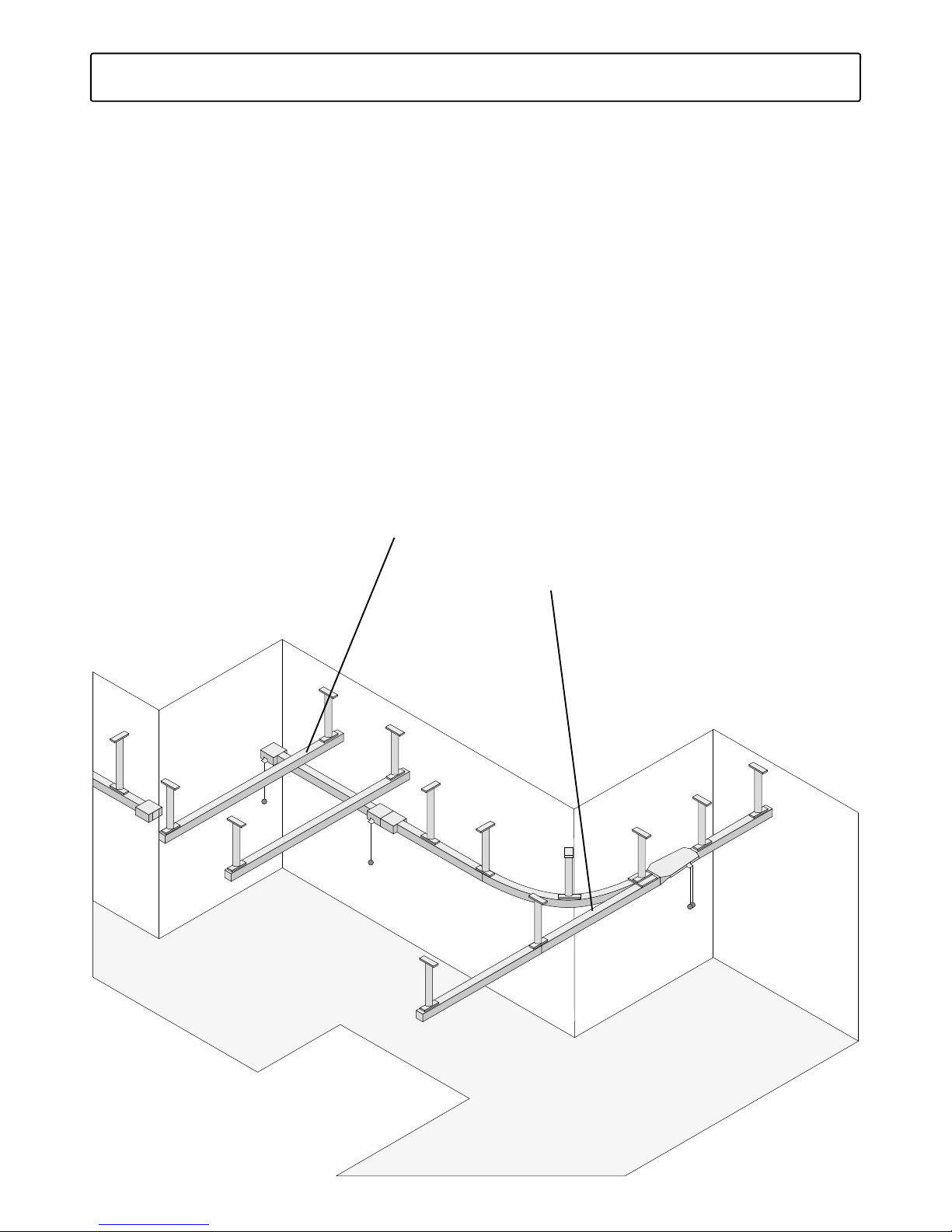

3.1.2 Ceiling mounted Curve rail system

By combining MRS curves and rails it is possible

to create single rail systems with expanded lifting

area. This solution does not allow free standing or

wall mounting. Can be mounted to ceiling only.

Figure: Ceiling mounted with telescope brackets

Figure: Ceiling mounted with open ceiling using

40 mm brackets.

Page 14

14

Molift Rail System / www.molift.com

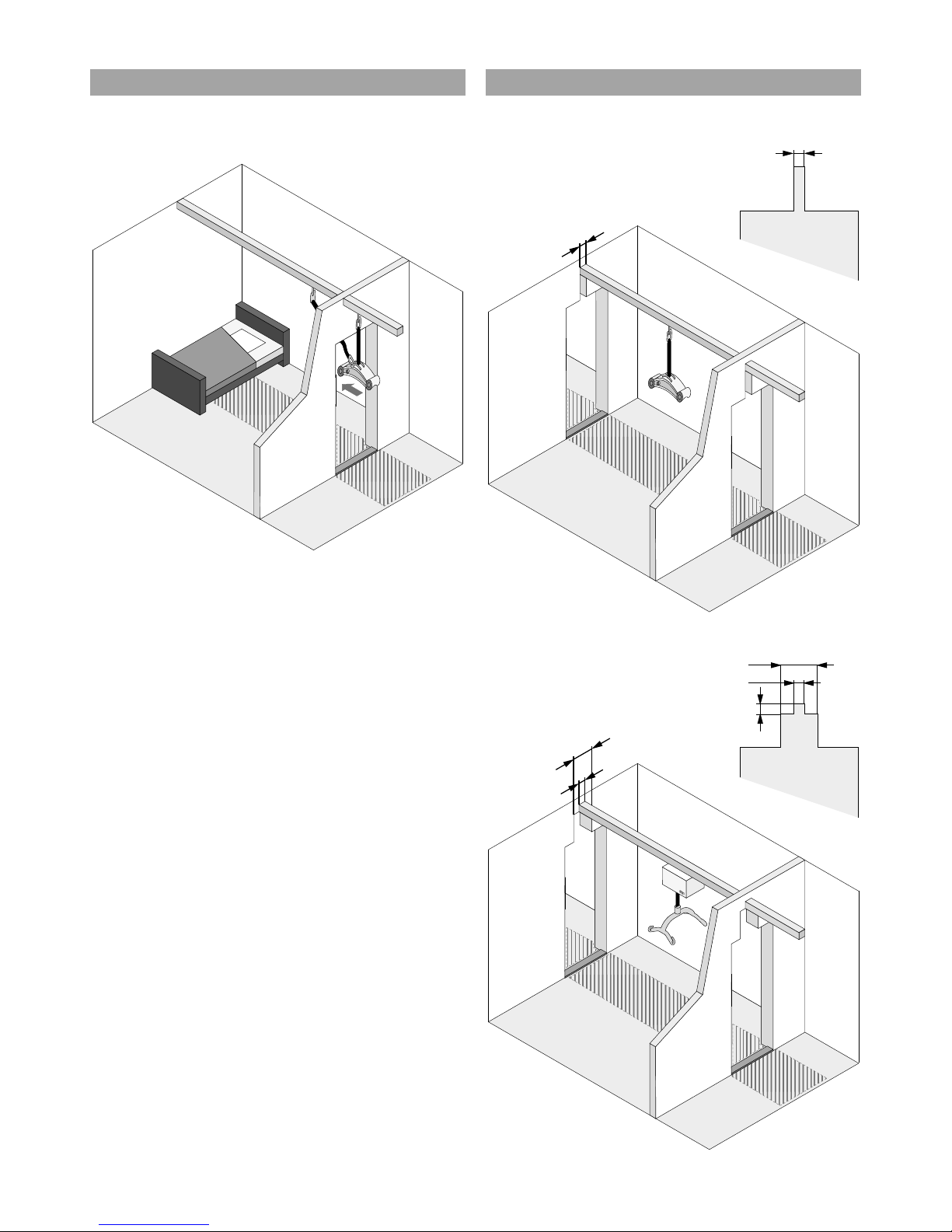

3.1.3 Wall mounted Straight rail system

A wall mounted system is mounted on separate

wall brackets or on brackets connected to uprights

supported by the wall.

Figure: Wall mounted wall bracket

Figure: Wall mounted Wall brackets supported by

upright supports

Page 15

15

Molift Rail System / www.molift.com

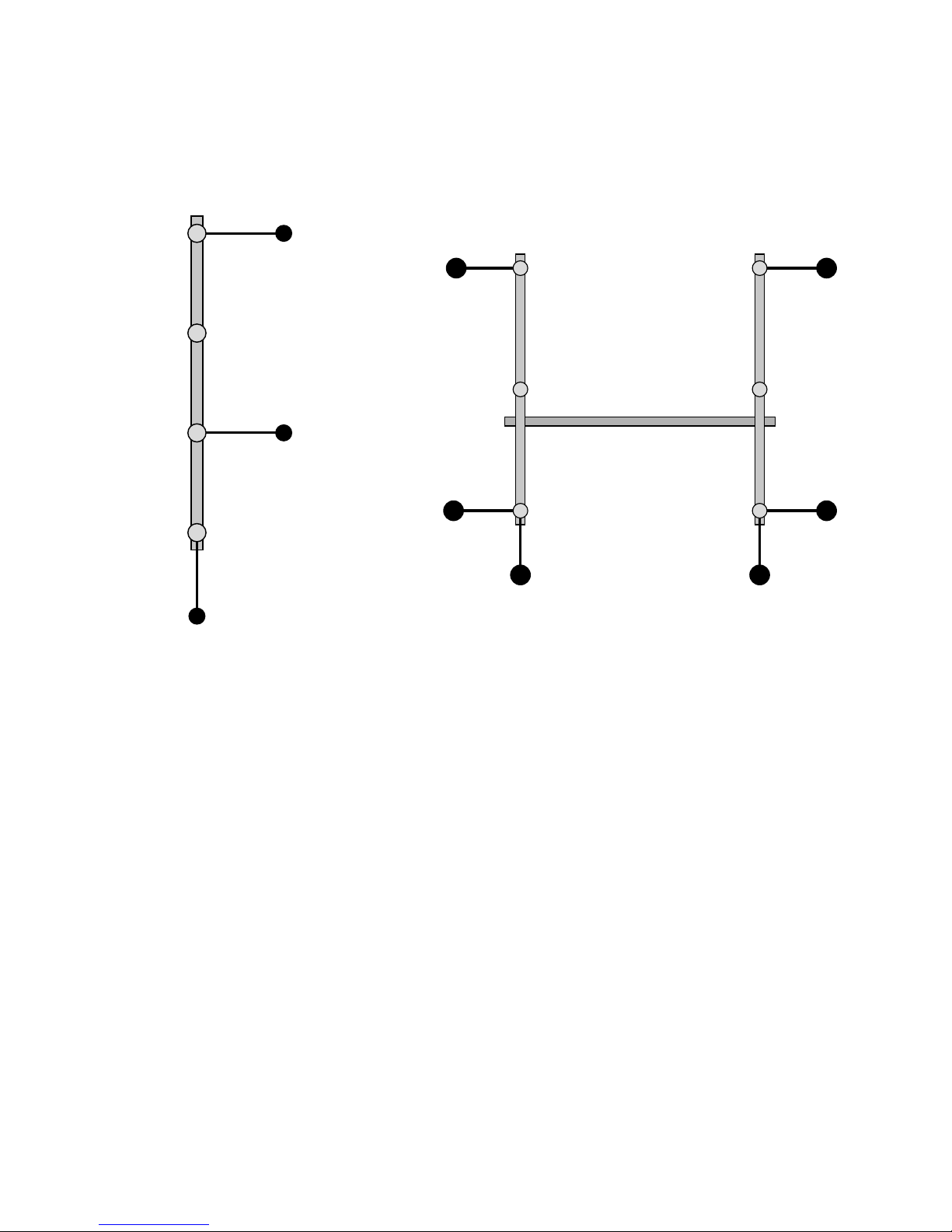

A traverse system is built up by two parallel

primary rails, a secondary rail connected to the

primary rails by a traverse trolley in each primary

rail. The lifting motor is connected in the secondary rail. This system allows full room coverage.

Primary rail

Secondary rail

3.2 Traverse System

Secondary Rail mounted

under Primary rails,

under trolley

Secondary Rail mounted

between Primary rails,

on top of trolley (Box-in)

Page 16

16

Molift Rail System / www.molift.com

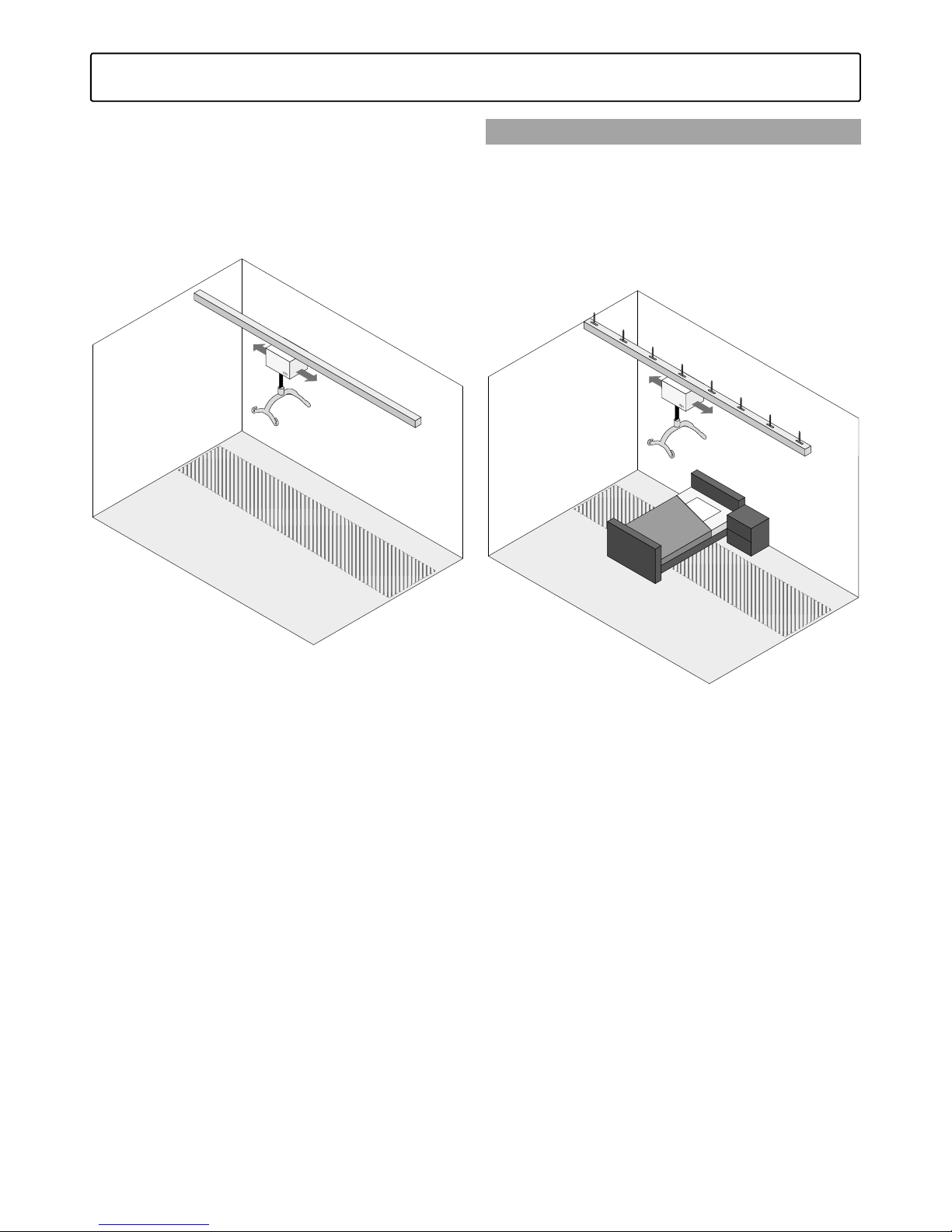

3.2.1 Ceiling mounted traverse system

Ceiling mounted traverse rail system can be

mounted in different ways:

1. Directly in ceiling without brackets

2. Directly in ceiling with brackets

3. Suspended from the ceiling with telescopic

brackets

4. Suspended from the ceiling with threaded

rods

Figure: Ceiling mounted without brackets direct

to ceiling

Figure: Ceiling mounted with brackets with open

ceiling profile

Page 17

17

Molift Rail System / www.molift.com

Figure: Ceiling mounted telescopic brackets with

open ceiling profile

Figure: Ceiling mounted threaded rods with open

ceiling profile

Page 18

18

Molift Rail System / www.molift.com

3.2.2 Wall mounted traverse system

A wall mounted system is mounted on separate

wall brackets, wall mounted rails or on brackets

connected to uprights supported by the wall and

the floor.

1. Primary rails mounted on separate wall

brackets.

2. Primary rails mounted on brackets connected

to uprights supported by the wall and the

floor.

3. Primary rails mounted on wall rails.

Figure: Wall mounted rail with wall brackets

Page 19

19

Molift Rail System / www.molift.com

Figure: Wall mounted with wall brackets and

upright supports

Figure: Wall mounted rail direct to wall with wall

rail

Page 20

20

Molift Rail System / www.molift.com

MRS allows a great variation of possibilities when

combining traverse systems and single rail system.

Transfer between different systems/rooms and

locations can be solved in several ways with MRS

The simplest way is by extending the single rail

track through doorway.

The systems can also be combined with different

switches such as Rail switch and Traverse switch.

Climbing from one system to next is also an

option both with permanently mounted lift motor

Molift AIR and portable lift motor Molift Nomad.

3.3 Combination of rail systems

Page 21

21

Molift Rail System / www.molift.com

3.3.1 Switch systems

For Single rails, switching direction from straight

rail to curve etc. Manually controlled.

Figure: Rail switch

Traverse Switch – For transfer from secondary rail

in a traverse system into a straight rail or another

secondary rail in a traverse system. Manually

controlled.

Figure: Traverse system with switch to straight rail

Page 22

22

Molift Rail System / www.molift.com

Figure: Traverse system with switch in both ends.

Figure: Double traverse system connected with

switches.

Page 23

23

Molift Rail System / www.molift.com

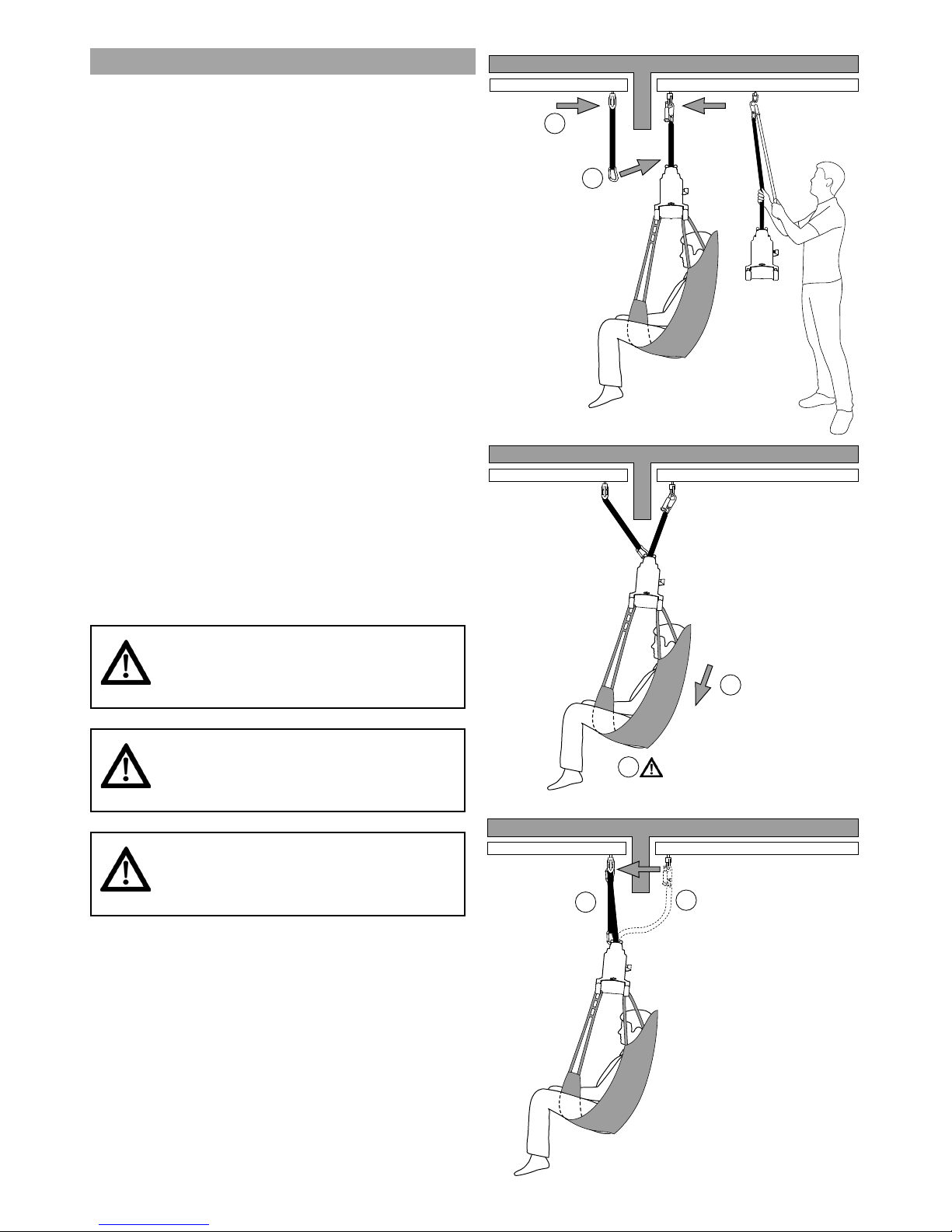

3.3.2 Climbing systems

Molift Nomad is suitable for climbing (room to

room transfer) between two rails system

Figure: Room to Room transfer with Portable

motor Molift Nomad.

3.3.3 Hatch in door opening.

With a hatch in the dooropening, hoist can move

freely from room to room.

A

A=100mm

Figure: Hatch in door opening for Molift Nomad.

A

B=100mm

A=250mm

B

C= Rail Height (62/112/142mm)

Figure: Hatch in door opening for Molift Air.

Page 24

24

Molift Rail System / www.molift.com

3

5

6

2

1

4

Room to room transfer Molift Nomad

With a climbing band (accessory) it is possible to

transfer a person from room to room through a

doorway between two rail systems that are not

connected, with a portable hoist.

1. Move the hoists and trolley with climbing band

as close as possible to doorway.

2. Lower hoist and connect the climbing band to

the hoist, make sure it is properly connected for

a safe transfer

3. Lower the hoist. The climbing band will take the

load and hoist will move through doorway.

4. Pay attention and make sure user does not

touch the floor

5. Lower the hoist until the climbing band is taking

up all the load, and the hoist lifting band can be

released.

6. Release the hoists lifting band and connect to

trolley in the other room. Run lifter up until the

climbing band can be released. The transfer is

complete.

Never lift the user higher than

necessary to carry out a lift.

Never leave a user unattended in a

lifting situation.

There is a risk of injury to user or

assistant from a swinging lifting

strap, suspension or hand control.

Page 25

25

Molift Rail System / www.molift.com

Page 26

26

Molift Rail System / www.molift.com

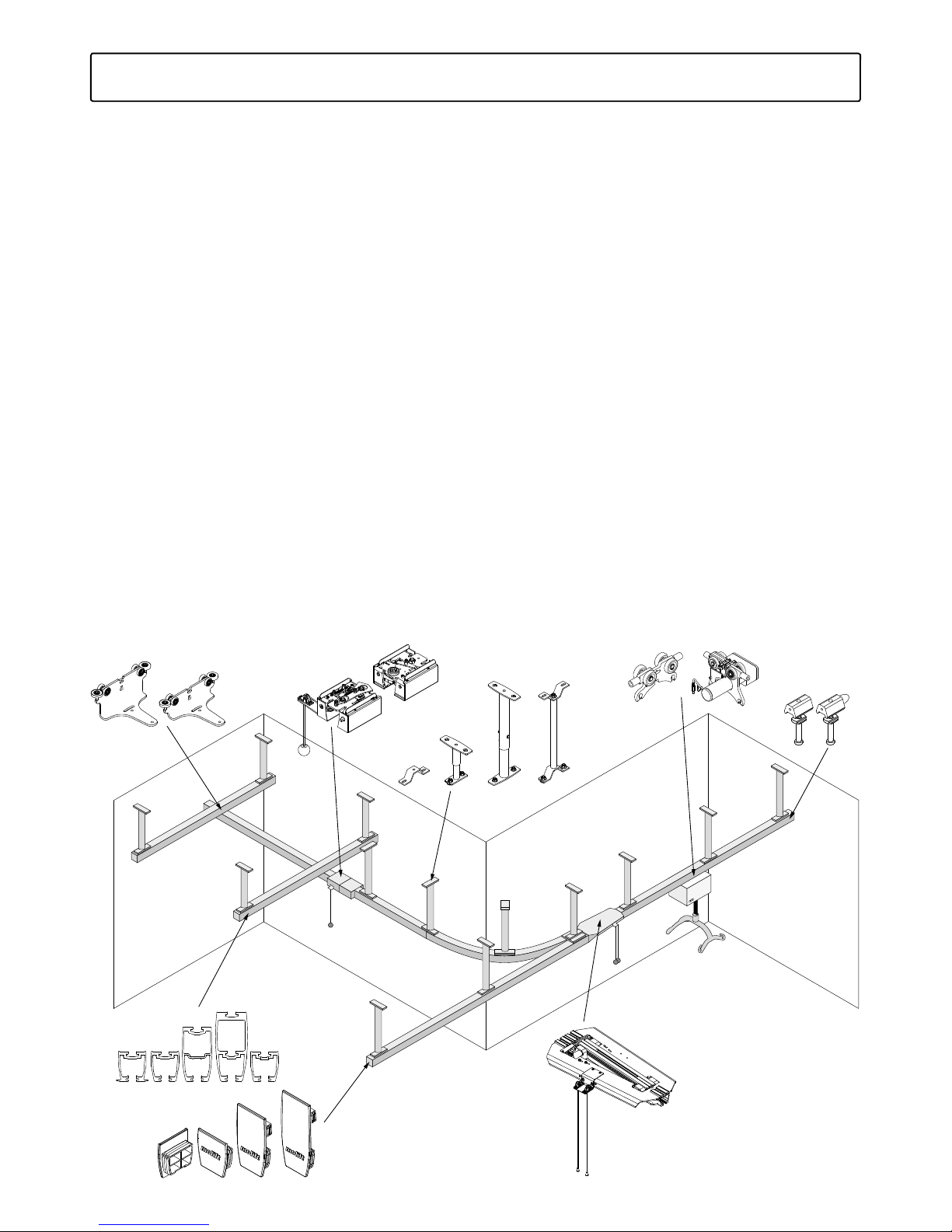

4. Component Overview

This chapter describes the MRS products and

which components are available for different

design solutions. For more details and information

of possible design, restrictions and other conditions see Chapter 5. Design conditions.

Page 27

27

Molift Rail System / www.molift.com

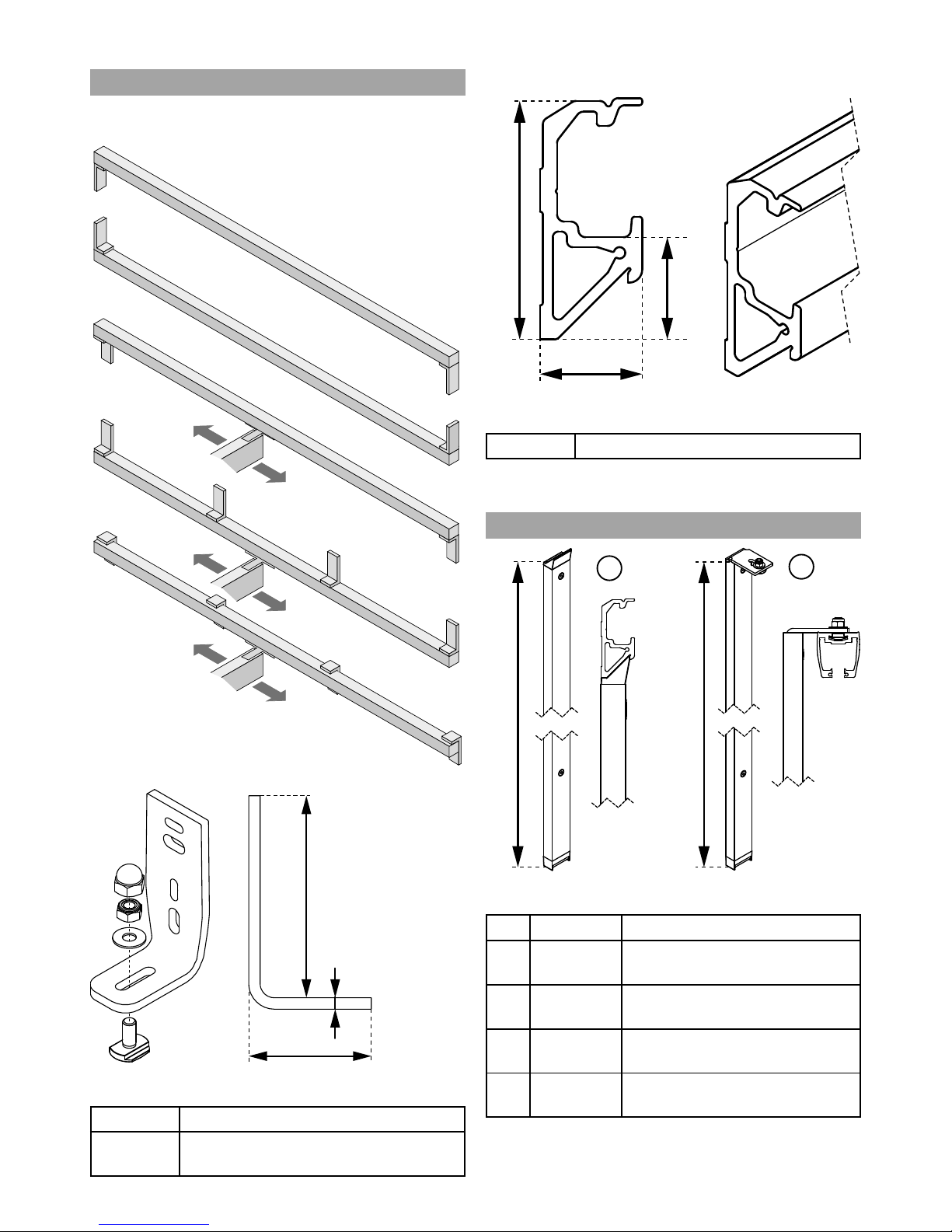

4.1 Attachment

4.1.1 Ceiling Mounted System

MRS includes 5 different attachments of ceilings

mounted systems.

1. Direct in ceiling which does not require any

attachments, just bolts directly into the ceiling

(Requires H62 DC profile).

2. Fixed Bracket. 40mm height. Two fixing points

to ceiling

3. Telescope Thread Bracket. 80-200mm. Two

fixing points to ceiling

4. Telescope Bracket. Two parts. 190-2000mm.

Two fixing points to ceiling

5. Threaded Rod. One or two fixing points to

ceiling. Comes in two lengths. Cut to length at

installation site.

Article no.

1109 6 9 5 Ceiling bracket set 40 mm

110970 0 Telescope Thread 80-125mm

1109710 Telescope Thread 120-200mm

1109715 Telescope 190-250mm

1109718 Telescope 240-350mm

1109720 Telescope 340-550mm

1109725 Telescope 540 -900mm

110973 0 Telescope 890-1300mm

1109735 Telescope 1290-2000mm

1109910 M10 Threaded Rod w/Bracket Set 1

Meter

1109 912 M10 Threaded Rod w/Bracket Set 2

Meter

3. Telescope Thread

80 -200mm

4. Telescope

190-2000mm

5. Threaded Rod

100-2000mm

2. Bracket

40mm

Page 28

28

Molift Rail System / www.molift.com

Bracing Side supports

Rails systems mounted with attachments like

Telescope brackets and Threaded rods need bracing in form of Side supports to eliminate horizontal

forces and vibrations. (Design and positioning of

Side support see chapter 5.2.4)

Support for Telescope or Threaded rod Ceiling

Bracket, for mounting in rail.

Article no.

1109 920 M10 Support Set 1 Meter

1109 92 2 M10 Support Set 2 Meter

1109 9 5 0 3/8” Support Set 36”

1109 9 5 2 3/8” Support Set 72”

Support for mounting around telescope ceiling

bracket.

Article no.

1109 815 Side Support unit for Telescope

Brackets

Page 29

29

Molift Rail System / www.molift.com

4.1.2 Wall mounted System

Wall mounting bracket is versatile and can be

mounted in different ways.

142

86

8

Article no.

1109259 Wall bracket with multibolt, white

1109269 Wall bracket with multibolt,

anodized

Wall rail

36

36

85

Article no.

1109160 Rail H85 W/A 6m-length painted

Upright Support

2500 / 3500

2500 / 3500

Article no.

Pos. Article no.

1 1109210 Wall support W-rail

L=2500mmm

1 1109215 Wall support W-rail

L=3500mmm

2 11092 2 0 Wall support OC-rail

L=2500mmm

2 1109225 Wall support OC-rail

L=3500mmm

1

2

Page 30

30

Molift Rail System / www.molift.com

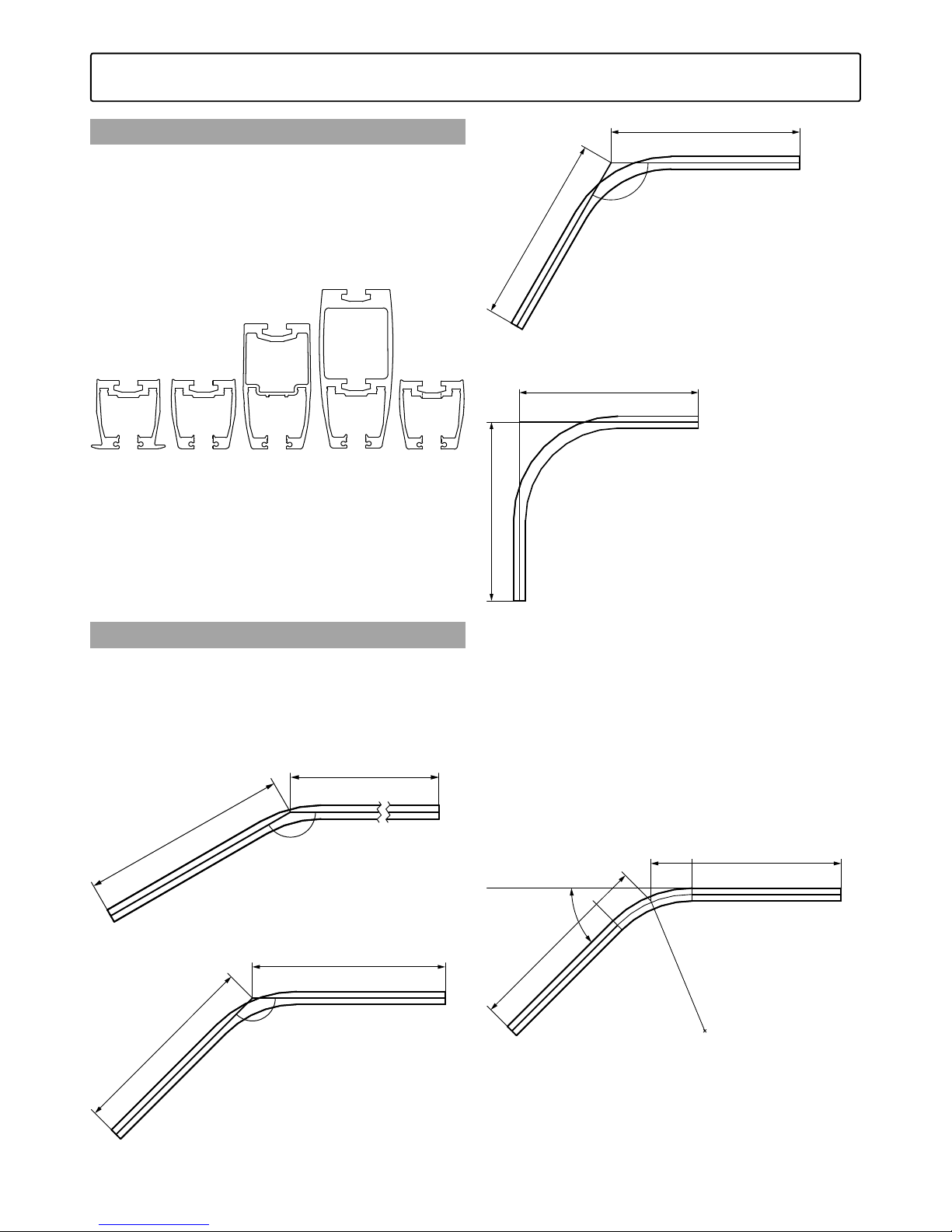

Rails

MRS rail program consists of 4 different profiles

(CC, OC, DC or W) where OC profile is available

in 3 different heights. The figures give the height

of the rail in mm. The strength of the rail relates

to the height. Higher profile gives stronger rail. All

profiles are compatible with all combinations of

the MRS products.

All rails are extruded Aluminum and comes in

two colours, anodized aluminum and white paint.

The H62 rail comes in 3 different versions, CC for

recessed rails flush to false ceiling, DC for direct

mounting in ceiling, and OC for suspended rails

from bearing ceiling.Delivered in standard lengths

or Tailor made lengths up to 7,0m.

Curves

Rail curves are available for all three H62 profiles

and come as standard in 30, 45, 60 and 90

degrees angle. Tailor made curves are possible as

well as tailor made lengths. All curves have radius

550mm. Standard length is 1000mm.

30°

1000mm

1000mm

Curve 30°

1000mm

1000mm

45°

Curve 45°

1000mm

1000mm

60°

Curve 60°

1000mm

1000mm

90°

Curve 90°

Special Curve CC/DC/OC

Tailor made curve angles can be ordered. Use part

no. 1109150 for special curves in Rail H62 profile

and specify the colour (P or A) and following

measurements when ordering:

A= 0 – 2000mm : _______

B= 0 – 2000mm : _______

C= 0-90° : _______

Dimension A

Dimension B

Dimension C 0°-90°

Top View

R 550mm, center of rail

4.2 Rails and Curves

Page 31

31

Molift Rail System / www.molift.com

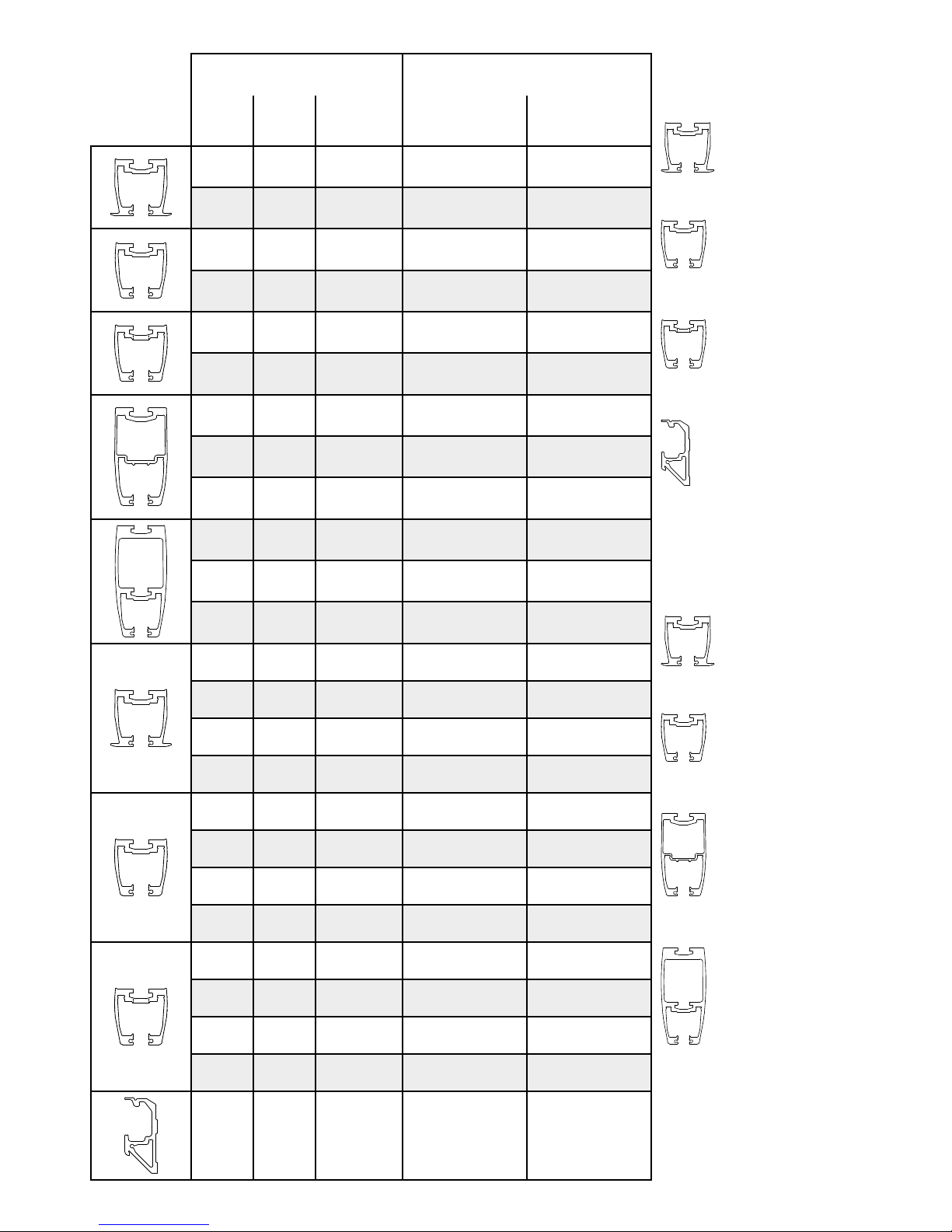

Rail profile Surface treatment

Height Profile

Length or

Curve

Anodized

(article no.)

Painted

(article no.)

H62 CC 6m 1109000-6m 1109 0 01- 6 m

H62 CC 7m 1109000-7m 110 9 0 01-7m

H62 OC 6m 110 90 02- 6m 110 9 0 03 - 6m

H62 OC 7m 1109 0 02-7m 110 9 0 03 -7m

H62 DC 6m 110 90 0 4 - 6 m 110 9 0 05 - 6m

H62 DC 7m 1109 0 0 4 -7m 1109 0 0 5 -7m

H112 OC 4m 1109 0 0 8 - 4 m 1109009-4m

H112 OC 5m 1109 0 0 8 -5m 1109009-5m

H112 OC 6m 110 9 0 0 8 - 6 m 1109009-6m

H142 OC 5m 1109010-5m 110 9011-5m

H142 OC 6m 1109010-6m 110 9 011- 6m

H142 OC 7m 1109010-7m 110 9 0 11-7m

H62 CC 30° 1109100 1109105

H62 CC 45° 1109101 1109106

H62 CC 60° 1109102 1109107

H62 CC 90° 1109103 1109108

H62 OC 30° 110913 0 1109135

H62 OC 45° 110 9131 110913 6

H62 OC 60° 110 9 132 110 9 137

H62 OC 90° 110913 3 110913 8

H62 DC 30° 110914 0 110 9 145

H62 DC 45° 110 9141 110914 6

H62 DC 60° 110 9 142 110 9 147

H62 DC 90° 110914 3 110 9148

H85 W 6m N/A 1109160

Rail profile

CC = Rail to be built into

closed ceiling

OC = Rail for open ceiling /

and mounting in rafters

DC = Rail to be mounted

directly in concrete ceiling

W = Rail for traverese

system, to be mounted

directly on wall

(H=85 W=36 mm)

Rail profile measurements:

H62 CC

H=62 W=67,3 mm

H62 OC

H=62 W=58,8 mm

H112 O C

H=112 W=61,7 mm

H142 OC = 142 mm

H=142 W=66 mm

Surface treatment

Anodized = Matte alloy

Painted = White

Page 32

32

Molift Rail System / www.molift.com

End Stops

End stop is an important safety detail for all

Overhead systems. All rail ends must have an End

stop to prevent trolleys from going out of the rail.

The end stop can also be used to limit the range

of lifting area.

45mm

Ø11

Use drill guide 1109998 to mount end stop.

Pos. Article no.

1 1109410 End stop for motor trolley

2 110 9 411 End stop for traverse trolley

Check to ensure that the end stops

are assembled into all rail ends in

the overhead system.

End caps

Plastic caps for covering rail ends. Comes in two

colours for all three different rail heights, grey and

white. (for combination with anodized or white

rails)

Article no.

1109320 End Cap Rail H62 Grey

1109321 End Cap Rail H12 Grey

1109322 End Cap Rail H142 Grey

110934 0 End Cap Rail H62 White

1109341 End Cap Rail H112 White

1109342 End Cap Rail H142 White

White plastic sleeve

To be used as cover for ceiling bracket when going

through false ceiling.

Article no.

For threaded rod system:

1120338 Sleeve LKF62/28,5/7 White

For telescope bracket (upper part):

1109 817 Sleeve RKW 1 1/2-50 White

4.3 End Stops and End Caps

1 2

Page 33

33

Molift Rail System / www.molift.com

Traverse trolleys

MRS Traverse trolleys are used in all traverse systems which uses H-profile as primary rails. Comes

in two versions, Standard and lowered 50mm.

Delivered in a complete set with two trolleys.

51

206

Primary Rail

Article no.

110955 0 Traverse trolley set (grey)

110959 0 Traverse trolley set (white)

101

206

Primary Rail

Article no.

1109570 Traverse trolley set 50mm+ (grey)

11095 8 0 Traverse trolley set 50mm+ (white)

Boxed traverse trolleys

Boxed traverse trolleys have lower building height,

and curtain pass through (CPT) version (with boggie wheels) can be used in rail systems with gap

for curtains.

224

13

Primary Rail

Article no.

1109592 Boxed traverse trolley set, white

1109593 Boxed traverse trolley set, grey

110959 6 Boxed traverse trolley CPT set, white

1109597 Boxed traverse trolley CPT set, grey

Figure: Curtain pass through.

4.4 Traverse Trolleys

Page 34

34

Molift Rail System / www.molift.com

Traverse Mounting kit

Article no.

1109345 Traverse mounting kit (under trolleys)

Article no.

1109353 Traverse mounting kit (between

primary rail)

Traverse Trolley for Wall rail

Traverse Trolley for Wall Rail (Includes end stops)

52,5

42,5 247

51,5

165

82

165

Wall,

Rail H85 W

Wall,

Rail H85 W

116

52,5

42,5 247

51,5

165

82

194

145

Article no.

110916 3 Wall mounted traverse trolley set

RH112

110916 6 Wall mounted traverse trolley set

RH142

Page 35

35

Molift Rail System / www.molift.com

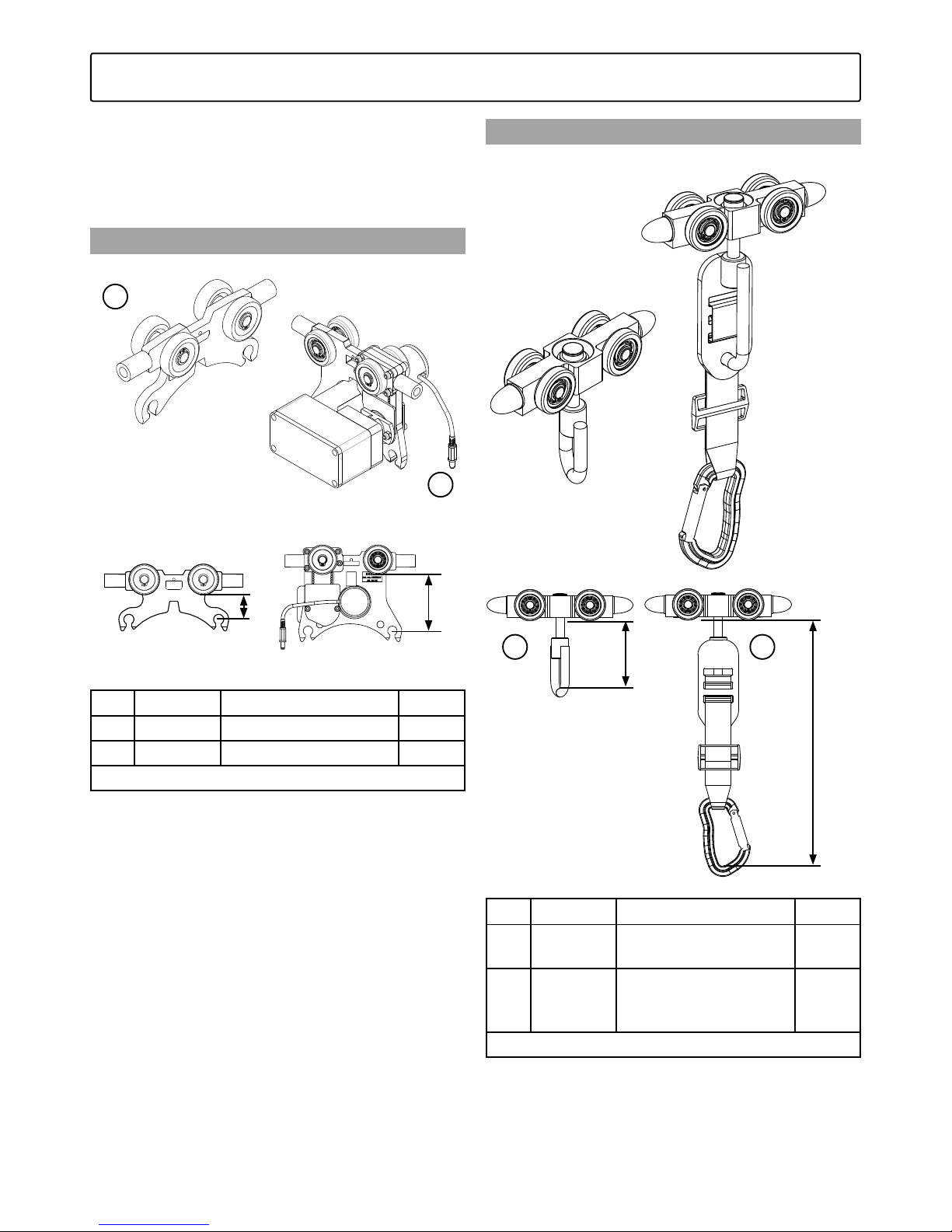

Lift motor trolleys are available in various versions

for Molift AIR and Molift Nomad. All motor

trolleys are compatible with all rail profiles and all

combinations of MRS products.

Molift AIR

Pos. Article no. L

1 2520000 Basic Trolley 29,6

2 2500103 Trolley Propulsion 72,6

All measurements in mm.

Molift Nomad

Trolley for Molift Nomad

L

L

Pos. Article no. L

1 1109109 Trolley Molift Nomad

w brake, MRS

80

2 110 9112 Trolley Molift Nomad

for climbing w brake,

MRS

295

All measurements in mm.

4.5 Lift Motor Trolleys

1

1 2

2

L

L

Page 36

36

Molift Rail System / www.molift.com

Molift Rail System has 2 different options of

switching direction within the MRS range.

Rail Switch

For Single rails, switching direction from straight

rail to curve etc. Manually controlled.

Article no.

1109 015 Switch MRS (grey)

1109066 Switch MRS (white)

1109 0 8 5 Set of covers for OC rail switch (grey)

1109 0 8 6 Set of covers for OC rail switch

(white)

1109 0 7 7 Set of covers for CC rail switch (grey)

1109 0 7 8 Set of covers for CC rail switch

(white)

Traverse Switch

For transfer from traverse system to a fixed rail.

Manually controlled.

Article no.

1109 0 2 9 Traverse Switch Unit (grey)

1109 6 5 0 Traverse Switch Unit (white)

Article no.

1109602 RH62 OC/A modified for transition

co upling (L=6m)

1109 6 5 7 RH62 OC/P modified for transition

co upling (L=6m)

1109603 RH142 OC/A modified for transition

co upling (L=6m)

1109 6 5 8 RH142 OC/P modified for transition

co upling (L=6m)

4.6 Switches

Page 37

37

Molift Rail System / www.molift.com

Charging

Molift Nomad and Molift AIR are charged with

external charger via hand control.

External charging via handcontrol

Charger mounted on wall or table connected to

motor with hand control

Article no.

124 0100 Charger for handcontrol Nomad/AIR

4.7 Battery Charging

Page 38

38

Molift Rail System / www.molift.com

Page 39

39

Molift Rail System / www.molift.com

Page 40

40

Molift Rail System / www.molift.com

Drill guide

Drill guide for Direct mounting of rail in concrete Ø

8,0mm, and Drill guide for End stops Ø 11mm

Article no.

1109999 Drill guide Ø8 mm for RH 62 DC

1109998 Drill guide Ø11 mm for endstop

Multibolt M10

Used for all connections with brackets into rail

profile.

Article no.

2520221 Multibolt kit

T-Profile washer

Used for direct mounting and for all end stops

Article no.

1109307 T-Profile washer MRS

Shims

Used for support to level brackets.

Article no.

1109312 Shims 0,5 for MRS

1109313 Shims 1,0 for MRS

1109314 Shims 2,0 for MRS

Joint set – Washer and sprints.

Used for joining rails of same profile in straight

rails or curve rail system.

Article no.

1109350 Joint set for MRS

Mounting plate for mounting of rail switch.

Article no.

1109090 Rail Mounting plate Assy Switch

MRS

4.8 Installation tools

Page 41

41

Molift Rail System / www.molift.com

Page 42

42

Molift Rail System / www.molift.com

5. Design Conditions

This chapter describes the design conditions, limitations and possibilities how to combine the MRS

products to create a sufficient and safe Molift

Overhead System.

5.1 Lifting heights and lifting areas

Recommended heights

The Overhead system working height measures

between the lower point of the rail to which the

lift motor are attached (straight rail or secondary

rail) and down to the floor of the room. Normally

the recommendation is to position the rail from

2300mm to 4000 for a Molift AIR motor depending on the ceiling heights and lifting needs. We

recommend no lower than 1800mm from the

highest position of lifting point of the suspension

down to the floor.

To be able to lift a person from the floor it is

important that the distance from floor to lifting

point of suspension does not exceed 400 mm

when the suspension is at its lowest point as picture shows. The flexibility of MRS and Molift AIR

allows walking training as well as normal patient

transfers within these heights.

Lifting Interval

2000mm

Lifting Interval

3000mm

Max 400mm

Min 1800mm 500mm

510mm

2300-3000mm

2300-4000mm

Min 1800mm

Rail

Rail

Floor

Floor

Max 400mm

Molift Nomad

Molift AIR

(4-point Medium suspension)

Page 43

43

Molift Rail System / www.molift.com

Lifting area limitations

An Overhead system covers a certain maximum

lifting area in a room. Due to the practical installation work and measurements of including parts,

a rail system cannot be mounted directly close

to the walls. There a few things to consider, the

minimum space between a rail and the wall, the

lengths of end stops, trolleys and lift motor.

Lifting Area = Hatched area

on floor under lifter.

Min. 120mm from wall

Min. 45mm

180mm

97mm

180mm

97mm

261mm

??mm

Min. 120mm

from wall

Min.

45mm

261mm

174.5mm

Page 44

44

Molift Rail System / www.molift.com

5.2 Design conditions – Attachments

Maximum distances between attachments to

fulfill maximum deflection requirements according

to ISO standard 10535 (<1mm per 200mm rail

length). Depending on Safe Working load SWL

and rail profile.

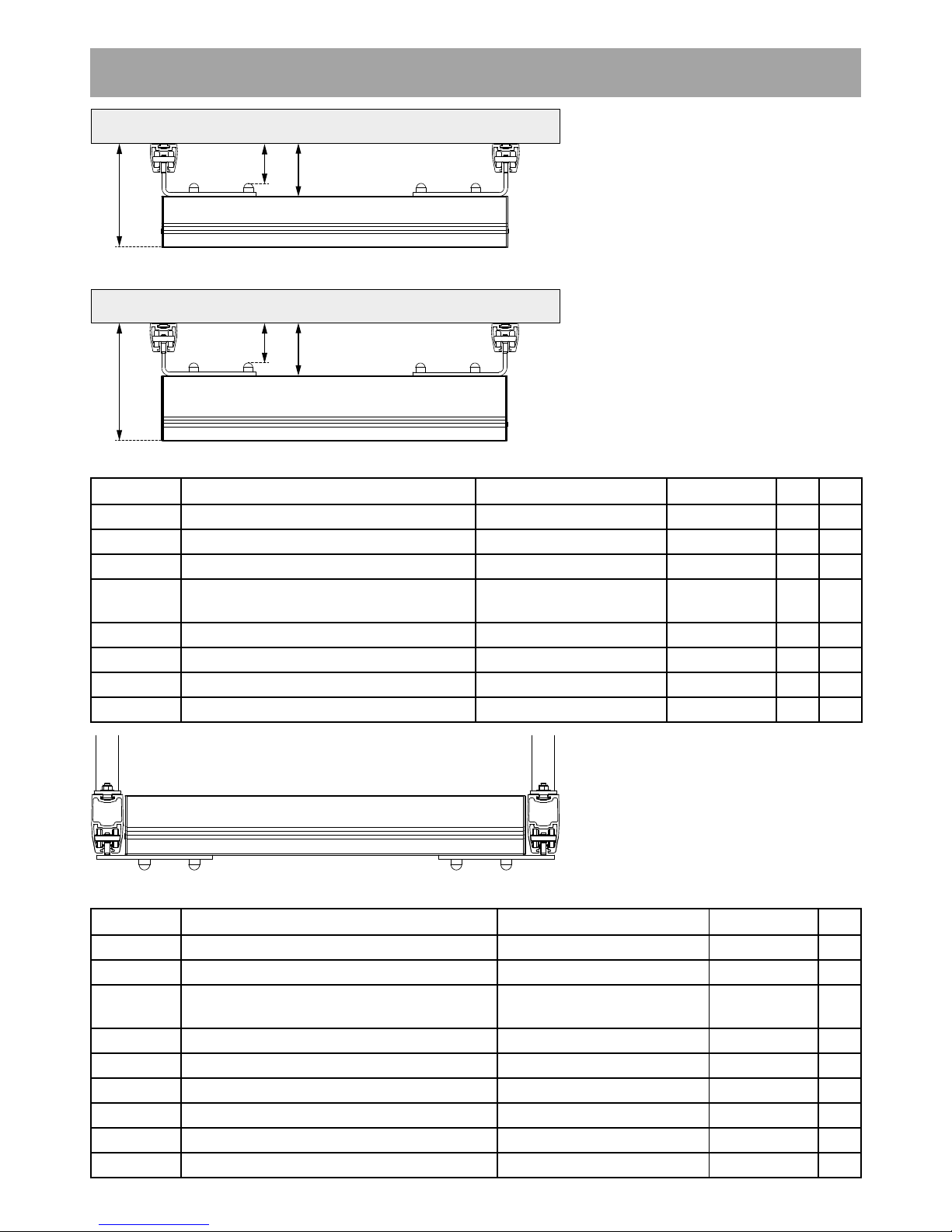

5.2.1 Ceiling mounted

A - Maximum distance between attachments

(Including distance between primary rails in

traverse systems)

B - Maximum distance from last attachment to

end of rail (Free end/Overhang)

Safe Working

Load (SWL)

Rail profile A - Max

distance

B - Max

distance

SWL 160 kg Rail H62 CC 2200 mm 400 mm

Rail H62 OC 2200 mm 400 mm

Rail H62 DC 120 0 mm 50 mm

Rail H112 OC 4800 mm 550 mm

Rail H142 OC 6000 mm 700 mm

Rail H85 W 150 0 mm 250 mm

SWL 205 kg Rail H62 CC 2000 mm 400 mm

Rail H62 OC 2000 mm 400 mm

Rail H62 DC 900 mm 50 mm

Rail H112 OC 4200 mm 500 mm

Rail H142 OC 6000 mm 650 mm

Rail H85 W 14 0 0 mm 225 mm

SWL 230 kg Rail H62 CC 1800 mm 400 mm

Rail H62 OC 1800 mm 400 mm

Rail H62 DC 600 mm 50 mm

Rail H112 OC 3900 mm 500 mm

Rail H142 OC 6000 mm 600 mm

Rail H85 W 13 0 0 mm 200 mm

SWL 255 kg Rail H62 CC 1700 mm 375 mm

Rail H62 OC 1700 mm 375 mm

Rail H62 DC 300 mm 50 mm

Rail H112 OC 3800 mm 500 mm

Rail H142 OC 5700 mm 600 mm

Rail H85 W 1250 mm 175 mm

SWL 300 kg Rail H62 CC 1600 mm 375 mm

Rail H62 OC 1600 mm 375 mm

Rail H62 DC 300 mm 50 mm

Rail H112 OC 3500 mm 450 mm

Rail H142 OC 5300 mm 550 mm

Rail H85 W 1200 mm 150 mm

B

A

A

B

B

A

A

B

B

Page 45

45

Molift Rail System / www.molift.com

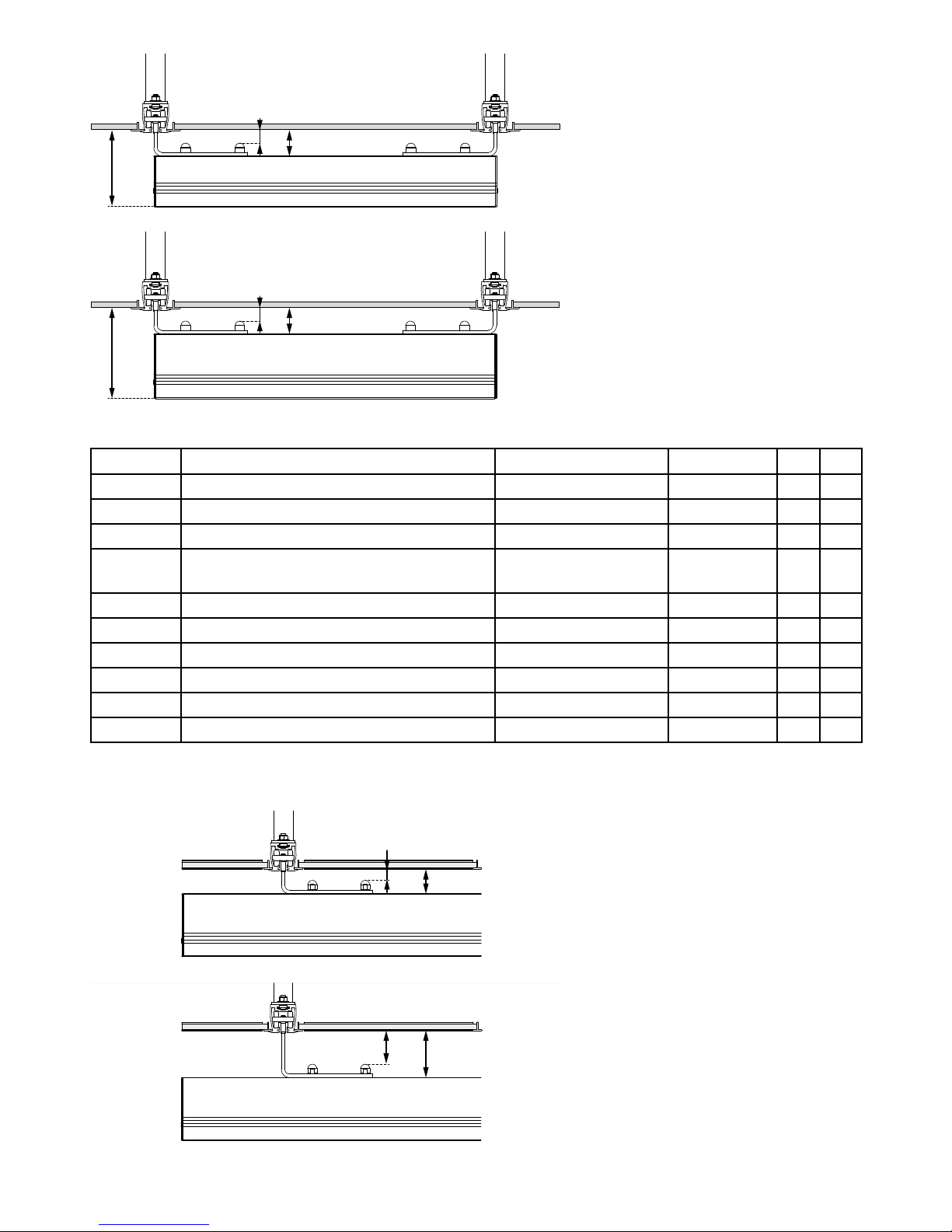

5.2.2 Wall mounted

A - Maximum distance between attachments

(Including distance between primary rails in

traverse systems)

B - Maximum distance from last attachment to

end of rail (Free end/Overhang)

Safe Working

Load (SWL)

Rail profile A - Max

distance

B - Max

distance

SWL 160 kg Rail H62 CC 2200 mm 400 mm

Rail H62 OC 2200 mm 400 mm

Rail H62 DC 1200 mm 50 mm

Rail H112 OC 4800 mm 550 mm

Rail H142 OC 6000 mm 700 mm

Rail H85 W 1500 mm 250 mm

SWL 205 kg Rail H62 CC 2000 mm 400 mm

Rail H62 OC 2000 mm 400 mm

Rail H62 DC 900 mm 50 mm

Rail H112 OC 4200 mm 500 mm

Rail H142 OC 6000 mm 650 mm

Rail H85 W 1400 mm 225 mm

SWL 230 kg Rail H62 CC 1800 mm 400 mm

Rail H62 OC 1800 mm 400 mm

Rail H62 DC 600 mm 50 mm

Rail H112 OC 3900 mm 500 mm

Rail H142 OC 6000 mm 600 mm

Rail H85 W 1300 mm 200 mm

SWL 255 kg Rail H62 CC 170 0 mm 375 mm

Rail H62 OC 170 0 mm 375 mm

Rail H62 DC 300 mm 50 mm

Rail H112 OC 3800 mm 500 mm

Rail H142 OC 5700 mm 600 mm

Rail H85 W 1250 mm 175 m m

SWL 300 kg Rail H62 CC 1600 mm 375 mm

Rail H62 OC 1600 mm 375 mm

Rail H62 DC 300 mm 50 mm

Rail H112 OC 3500 mm 450 mm

Rail H142 OC 5300 mm 550 mm

Rail H85 W 120 0 mm 150 mm

A

A

B

B

A

A

B

B

A

A

Page 46

46

Molift Rail System / www.molift.com

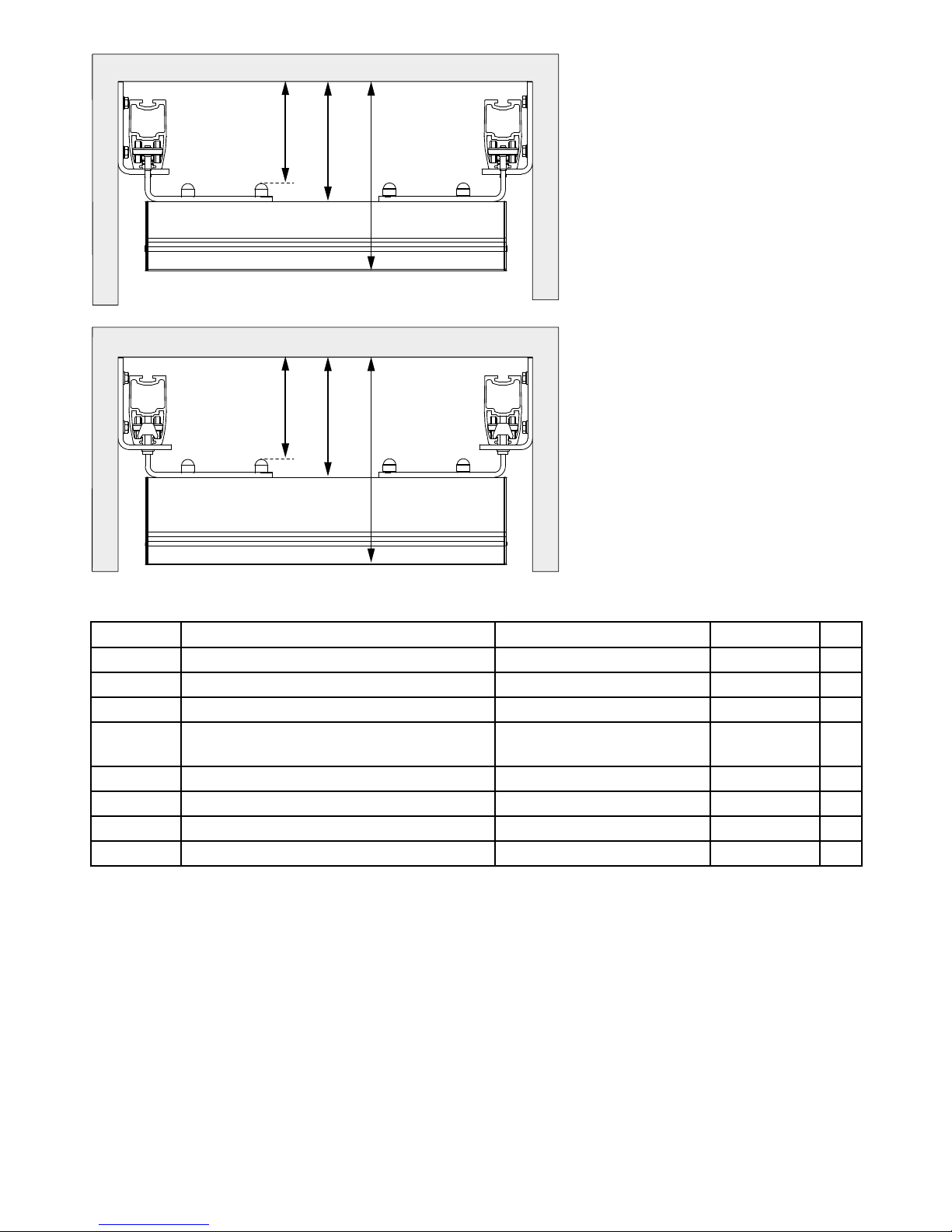

Wall mounted - Wall Rail

A - Maximum distance between wall rail attachment points or upright supports for wall rail

B - Maximum length of secondary rail

C - Maximum distance from last attachment to

end of wall rail (Free end/Overhang)

D - Minimum distance from wall in one end. This

distance is necessary for installing secondary rail

with trolley in wall rail. Minimum distance = 350

mm

Safe Working

Load (SWL)

Rail profile

A Max

distance

B Max

distance

C Max

distance

SWL 160 kg Rail H62 CC

Rail H62 OC 2200

Rail H62 DC

Rail H112 OC 4800

Rail H142 OC 6000

Rail H85 W 150 0 250

SWL 205 kg Rail H62 CC

Rail H62 OC 2000

Rail H62 DC

Rail H112 OC 4200

Rail H142 OC 6000

Rail H85 W 14 0 0 225

SWL 230 kg Rail H62 CC

Rail H62 OC 1800

Rail H62 DC

Rail H112 OC 3900

Rail H142 OC 6000

Rail H85 W 13 0 0 200

SWL 255 kg Rail H62 CC

Rail H62 OC 170 0

Rail H62 DC

Rail H112 OC 3800

Rail H142 OC 5700

Rail H85 W 1250 175

SWL 300 kg Rail H62 CC

Rail H62 OC 1600

Rail H62 DC

Rail H112 OC 3500

Rail H142 OC 5300

Rail H85 W 1200 150

All measurements in mm

A

B

C

D

C

D

A

B

Page 47

47

Molift Rail System / www.molift.com

Secondary rail length

Length of Secondary rail (B) is determined by distance between primary rails (A) in a box-in-system,

or the distance between the wall rails (C) for a wall

mounted system.

C

A

B

B

Figure: Secondary rail (B) length

Box in system: Approx 30mm shorter than (A)

Wall rail system: Approx 130mm shorter than (C)

55mm

20mm ±5

55

15mm ±515mm ±5

Figure: Distances between Secondary and Primary

rail.

5.2.3 Attachments for curves

Rail curves are only possible for ceiling mounting.

Minimum requirements:

Figure: Minimum three attachments must be

mounted. One in each joint section and one in

center of curve radius.

For joining curves with other rails of same profile a

Joint Set is used.

Figure: Joint set and bracket mounting.

Page 48

48

Molift Rail System / www.molift.com

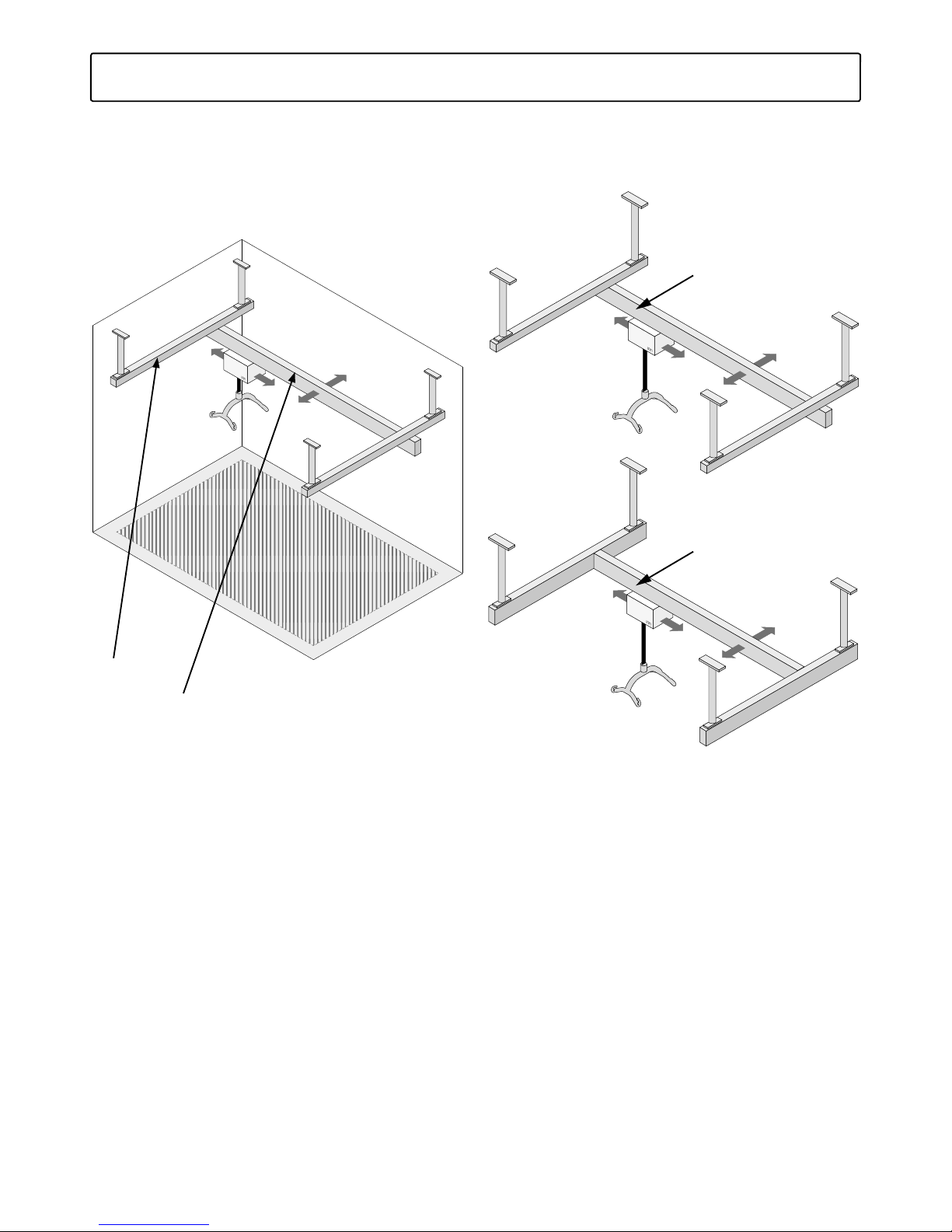

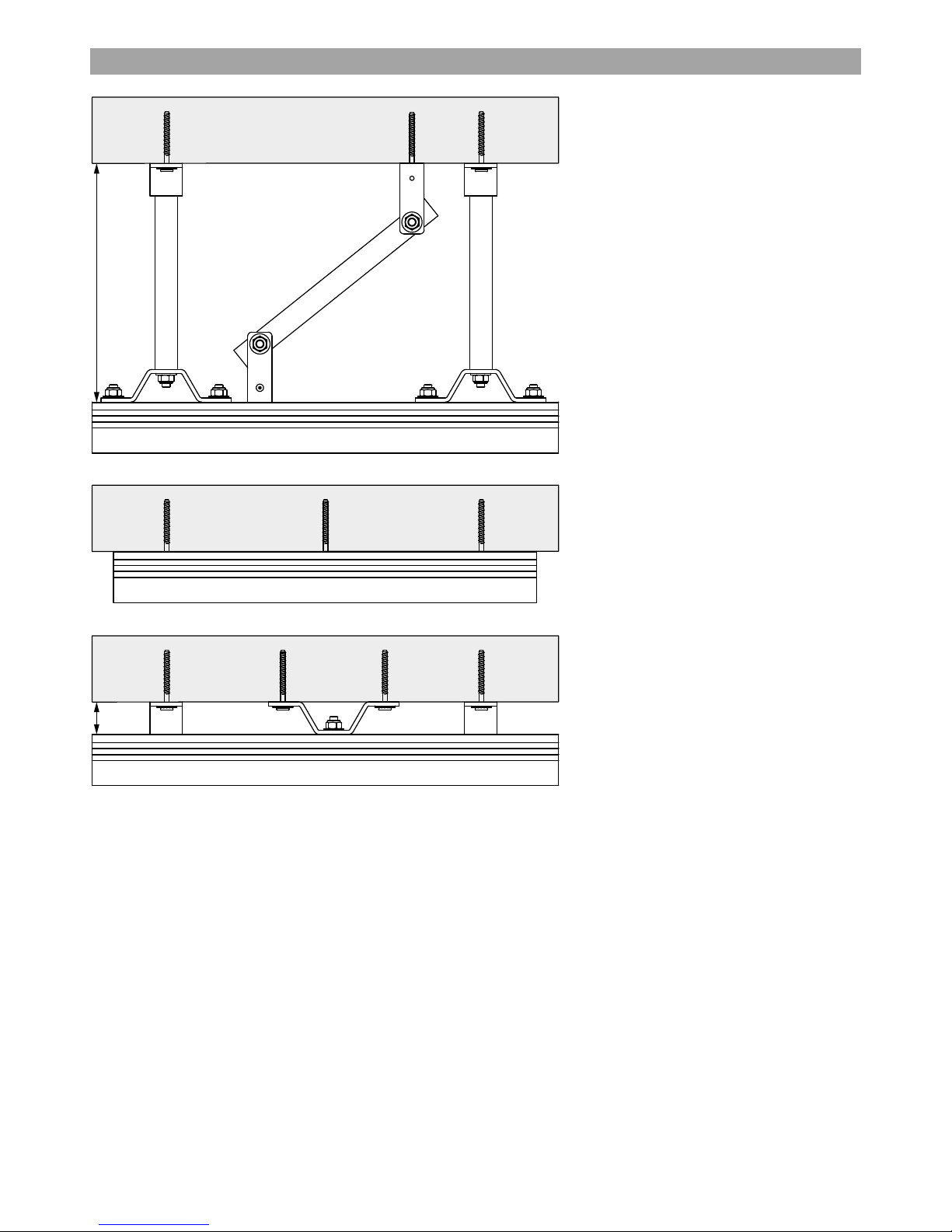

Bracing with side supports is needed to give

stability to ceiling mounted Overhead systems

depending on bracket lengths.

Straight rail and Traverse systems

Length of bracket < 800 mm, (< 32 inch.):

No need of side supports.

Length of bracket 800 > 1500 mm, (32 > 60 inch.):

Side supports should be mounted to the first and

the last bracket and in between those to every

third bracket, positioned perpendicular to the rail

in a Straight rail system and to both primary rails in

a Traverse system.

One Side support should be mounted to the first

or last pendant, positioned parallel to the rail in a

Straight rail system and to both the primary rails in

a Traverse system.

Straight Rail System Traverse System

Telescope Brackets

5.2.4 Side Support positioning

Page 49

49

Molift Rail System / www.molift.com

Length of bracket > 1500 mm ( > 60 inch.):

Side support should be mounted to all brackets

positioned perpendicular to the rail in a Straight

rail system and to both primary rails in a Traverse

system.

Side support should be mounted to the first and

last bracket positioned parallel to the rail in a

Straight rail system. Traverse Systems need one

Side support parallel to each Primary rail end.

Straight Rail System

Traverse System

Page 50

50

Molift Rail System / www.molift.com

Length of bracket < 800 mm ( < 32 inch.):

No need of side supports.

Length of bracket > 800 mm ( > 32 inch.):

One side support should be mounted to the

bracket in the middle of the curve perpendicular to

the radius.

Rules for Side support for the joining rails, see

above.

Length of bracket < 400 mm (< 16 inch.):

No need of side supports.

Length of bracket > 400 mm (> 16 inch.):

All switch functions need minimum two side supports perpendicular to each other mounted on the

closest bracket.

Traverse Switch Side rail switch

Rail Curve 90°

Rail Switches

Rail Curves – includes all angles 30°to 90°

Page 51

51

Molift Rail System / www.molift.com

Page 52

52

Molift Rail System / www.molift.com

Side support should be mounted to all rods,

positioned perpendicular to the rail in a Straight

rail system and to both primary rails in a Traverse

system.

Side support should be mounted to the first and

last rods positioned parallel to the rail in a Straight

rail system. Traverse Systems need one Side support parallel to each Primary rail end.

Straight rail and Traverse systems:

All threaded rod systems should have bracing

independent of length of rod. i.e. 100-2000mm

Straight Rail System

Traverse System

Threaded rod installation

Page 53

53

Molift Rail System / www.molift.com

Length of bracket < 800 mm ( < 32 inch.):

No need of side supports.

Length of bracket > 800 mm ( > 32 inch.)

One side support should be mounted to the rod in

the middle of the curve perpendicular to

the radius.

Rules for Side support for the joining rails, see

above.

Regardless of the lengths of Threaded rods, all

switches need minimum two side supports perpendicular to each other mounted on the closest

rod.

Traverse Switch Side rail switch

Rail Curve 90°

Rail Curves – includes all angles 30° to 90°

Rail Switches

Page 54

54

Molift Rail System / www.molift.com

6. Installation methods

The rail system can only be

installed by certified personnel in

accordance with applicable

installation instructions.

Etac is only responsible for the

system if the rail system with trolley and/or lifting motor has been

supplied by Etac and is installed by

authorised staff.

The lifter’s SWL may NEVER exceed

the SWL of the rail system.

There may never be installed more

than one lifting motor per rail

system.

The SWL of the rail system must be

clearly marked on the rail.

All rail systems must be provided

with end stops and end caps to

prevent the trolleys from running

off the system.

Etac recommends that annual

inspections of the system be carried

out according to “Check points for

periodic inspection”.

Please contact Your Service Partner

or Molift by Etac Customer Support

in case of defects to the rail system.

Tools needed for installation and surveys

Survey tools:

Digital camera

Laser range meter

Measure tape: minimum 5 meter length

Stairs

Flash light

Installation tools:

Security equipment (gloves, helmet, boots, ear

protection plugs)

Laser range meter and folding rule

Laser leveler

Working platform / stairs

Lifting equipment for profiles

Saw and table for cutting profiles

Electric drill (battery powered)

«standard» hand tooling

Lights

Fixing components for MRS

Etac Supply Gjøvik does not supply fixing components for Molift Rail System.

Fixing component examples:

- Mechanical expansion anchors

- Chemical anchors

- Concrete screws

- Wood screws

The Etac certified installer is responsible for providing correct fixing components to each project.

Building structure and material on site must be

evaluated before choosing fixing components. The

details and knowledge of this should be established during site survey. The fixing components

must meet the requirements in ISO 10535:2006

described in chapter “2.4 Point loads”.

The final installation procedure will verify the

installation before it is taken into use.

Page 55

55

Molift Rail System / www.molift.com

Principle work flow for OH installation

Recommended steps below to be performed by

installer on site:

1. Measurements – verify dimensions in drawings /

results of site survey

a. Report any mistaken dimensions or

failures early in the project

b. Place the profiles on floor according

to layout – do you have to modify

profiles?

What about the planned placement

of the charging stations? Are they

correc t?

2. Locate and mark fixing points

a. On the rails use a laser beam to

identify locations of the fixings /

holes

b. Does the planned installation make

any conflicts with other installations

/ suspended ceiling grid (are the grid

already in place?)

3. Drill holes

a. Use correct dimensions on drill bit

according to the manufacturers

specifications. (diameter / depth)

b. Remove dust and remains after

drilling

4. Mount fixings and attachments

a. Fix brackets to ceiling

b. Roughly adjust telescopes and

threaded rods (laser leveller)

5. Elevate rail system

a. Insert all multibolts necessary. Insert

from the profile end.

b. Elevate MRS rails and curves to

brackets

6. Lock profiles to brackets

a. Join rail with joint sets

b. Use correct tightening torques

according to installation instructions.

c. Loctite where necessary according

to installation instructions

7. Mount trolleys and end stops

a. Single / straight systems

b. Traver ses

c. Combined systems

8. Mount lift motor

a. Trolley

b. Charging stations

c. Start up lift motor

9. Check installations acording to Checklist for

installation of Molift Rail System

Page 56

56

Molift Rail System / www.molift.com

7. Final Installation Procedure

After finished installation a load test (according to

ISO 10535:2006) must be performed. Maximum

Safe Working Load shall be applied on all

mounted attachments. Perform at least six lifts

(lift height approx. 15 cm/6 inches) SWL at min. 6

randomly selected points along the rail.

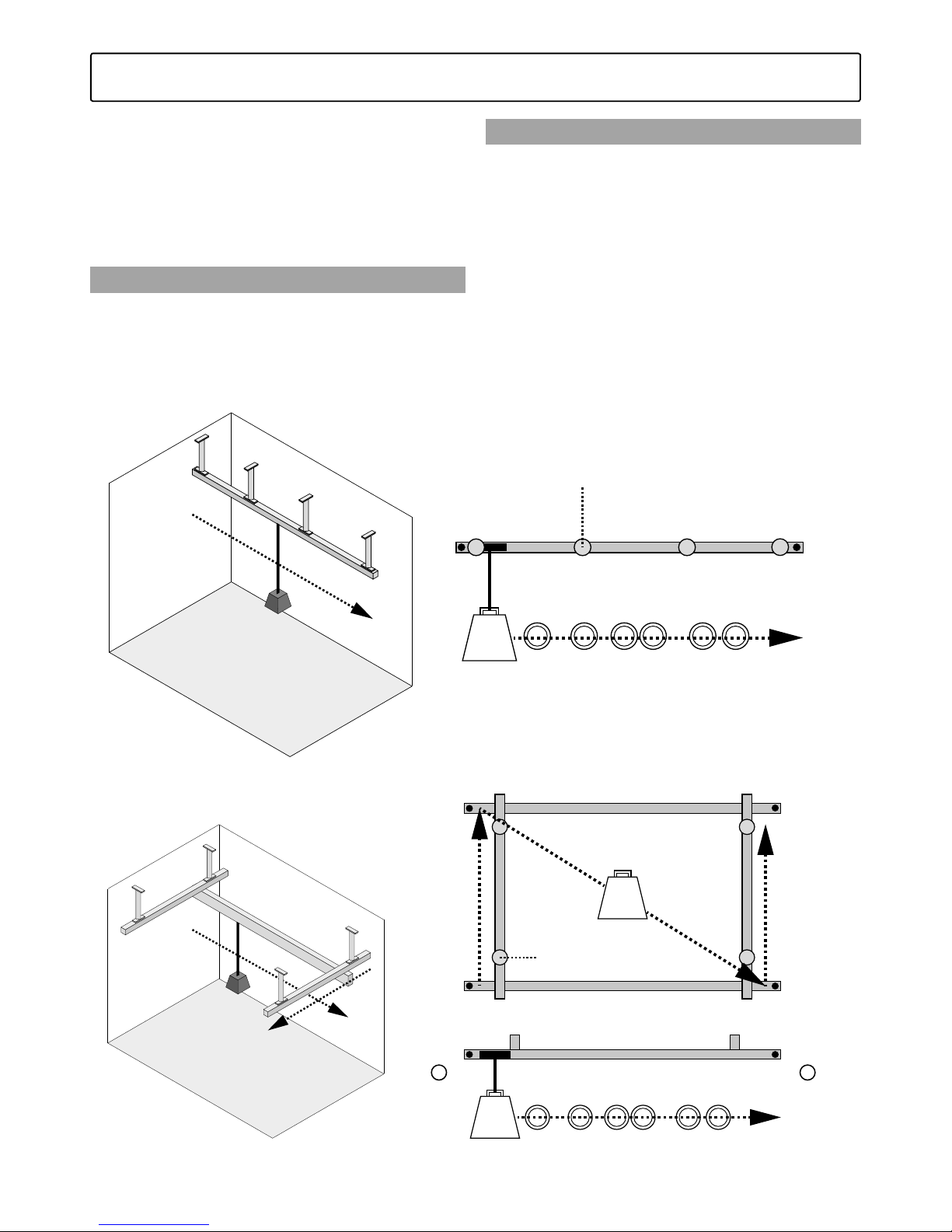

7.1 Load test: Straight Rail System

Lift the load approx. 15cm to apply the maximum

load. Travel the applied load along the rail from

one end stop to the other end stop, with a 10

second pause under each attachment point. Travel

as the dashed line shows in picture.

7.2 Load test: Traverse Rail System

Apply the maximum load for the installed

overhead rail system. Place the carriage with the

applied load at the end stop of the secondary rail

(1). Move the secondary rail, with a pause under

each attachment point, from one end stop to the

other end stop of the first primary rail. Continue

by moving the applied load diagonally through

the centre of the system over to the other side, as

the dashed line shows. Now continue by moving

the secondary rail with the applied load, from (2),

with a pause under each attachment point, from

one end stop to the other end stop of the second

primary rail.

MAX

LOAD

Pause under Attachments

Rail

End StopEnd Stop

Lift at 6 random points

Pause under

Attachments

MAX

LOAD

MAX

LOAD

Secondary Rail

End Stop

End Stop

End Stop

Primary RailPrimary Rail

Lift at 6 random points

End Stop

End Stop

End Stop

1 2

Figure: Load test: Straight Rail System

Figure: Load test: Traverse Rail System

Page 57

57

Molift Rail System / www.molift.com

7.3 Identification

After an approved test load procedure the overhead system is ready for identification marking.

This marking is made with a decal rail marking

on which the maximum load is to be stated. The

decal must be placed clearly visible on the rail in

the system to which the lift motor is attached.

When a Periodic Inspection of the system is

performed a test symbol will be placed in the

circular area on the rail decal marking. A Periodic

Inspection of the overhead system must be made

at least once a year.

Article no.

1109 014 MRS Label, SWL

SWL labels are supplied together with end stop.

7.4 Installation Certification

After approved functional and maximum load test

the installation will be finalized by the issue of

Checklist for installation of Molift Rail system as an

installation certificate. The installation certificate

has to be issued by installation personnel authorized by Etac.

Decal position for identification of SWL for Overhead

system

Molift Rail System installed by authorized personnel.

Date: Etac Molift Service ID SWL: kg

.................. (6 digits):..................... ................ lbs

Periodic

inspection

performed

www.molift.com

Page 58

58

Molift Rail System / www.molift.com

8. System configuration - Examples

This Chapter describes a few of the most common

design solutions of Molift Rail System. Shows

combination possibilities, measurements and

specifications. For each examples of configuration

there is a reference to the Installation Instructions

in chapter 9.

Page 59

59

Molift Rail System / www.molift.com

8.1 Single Rail system

Straight rail system - Ceiling mounted suspended

Straight rail system

Ceiling mounted

Suspended mounted

Telescope bracket (Threaded)

Straight rail system

Ceiling mounted

Suspended mounted

Telescope bracket

80-200

190-2000

Configuration example:

Products Description Incuding Item no Qty

Rail profile Rail H62 OC/A - 6m-length 1109 0 02- 6 m 1

Brackets Telescope Bracket Set 890-1300 mm 110973 0 3

Side Support unit for Telescope Brackets 110 9 815 3

End stops End stop for motor trolley 1109410 2

Endcaps End Cap Rail H62 Grey 1109320 2

Page 60

60

Molift Rail System / www.molift.com

Straight rail system

Ceiling mounted

Suspended mounted

Threaded rod bracket

Straight rail system

Ceiling mounted

Direct mounted

Rail H62 DC

Straight rail system

Ceiling mounted

Direct mounted

Rail H62 DC

Ceiling bracket 40mm

40

Max

2080

Straight rail system - Ceiling direct mounted

Page 61

61

Molift Rail System / www.molift.com

Straight rail system

Wall mounted

Wall bracket

H62 OC

Straight rail system

Wall mounted

Wall bracket

H62 OC

Straight rail system

Wall mounted

Wall bracket

H112 O C

Straight rail system

Wall mounted

Wall bracket

H142 OC

150

62

62

112

142

80

30

Straight rail system - Wall mounted

Configuration example:

Products Description Incuding Item no Qty

Rail profile Rail H62 OC/P - 6m-lengde 1109 0 03 - 6m 1

Brackets Wall bracket unit (White) 1109259 2

End stops End stop for motor trolley 1109410 2

Endcaps End Cap Rail H62 White 110934 0 2

Page 62

62

Molift Rail System / www.molift.com

8.2 Traverse Rail system

Traverse rail system - Ceiling mounted suspended

Traverse rail system

Ceiling mounted

Direct mounted

Primary Rail H62 DC

Secondary Rail H112 OC

Traverse rail system

Ceiling mounted

Direct mounted

Primary Rail H62 DC

Secondary Rail H142 OC

Traverse rail system (boxed in)

Ceiling mounted

Suspended mounted

Primary Rail H112 OC

Secondary Rail H112 OC

257

115

227

115

85

85

Configuration example:

Products Description Incuding Item no Qty

Rail profile Rail H62 DC/P 1109 0 0 5 4 2

Rail H112 OC/P 1109009 3 1

Trolleys Traverse trolley set (white) 2 trolleys 110959 0 1

Traverse mounting kit (under trolleys) 2 sets, Bolts, nuts and

washers

1109345 1

End stops End stop for motor trolley 1109410 2

End stop for traverse trolley 1109 411 4

Endcaps End Cap Rail H62 White 110934 0 4

End Cap Rail H112 White 1109341 2

Configuration example:

Products Description Incuding Item no Qty

Rail profile Rail H112 OC/P 1109009 3

Trolleys Boxed traverse trolley set, white 2 trolleys 1109592 1

Traverse mounting kit (under trolleys) 2 sets, Bolts, nuts and

washers

1109345 1

Brackets Telescope Bracket Set 120-200 mm 1109710 6

Side Support unit for Telescope Brackets 110 9 815 6

End stops End stop for motor trolley 1109410 2

End stop for traverse trolley 110 9 411 4

Endcaps End Cap Rail H62 White 110934 0 4

Endcaps End Cap Rail H112 White 110 9 3 41 2

Page 63

63

Molift Rail System / www.molift.com

Configuration example:

Products Description Incuding Item no Qty

Rail profile Rail H62 CC/P 1109 0 01 4 2

Rail H142 OC/P - 4m-length 1109 011- 4 m 1

Trolleys Traverse trolley set (white) 2 trolleys 110959 0 1

Traverse mounting kit (under trolleys) 2 sets, Bolts, nuts

and washers

1109345 1

Brackets Telescope Bracket Set 120-200 mm 1109710 6

Side Support unit for Telescope Brackets 110 9815 6

End stops End stop for motor trolley 1109410 2

End stop for traverse trolley 1109 411 4

Endcaps End Cap Rail H62 White 110934 0 4

End Cap Rail H142 White 11093 4 2 2

Traverse rail system

Ceiling mounted

Suspended mounted

Telescope bracket

Primary Rail H62 CC

Secondary Rail H112 OC

Traverse rail system

Ceiling mounted

Suspended mounted

Telescope bracket

Primary Rail H62 CC

Secondary Rail H142 OC

Traverse rail system

Ceiling mounted

Suspended mounted

Telescope bracket

Primary Rail H62 CC

Secondary Rail H112 OC

Traverse rail system

Ceiling mounted

Suspended mounted

Telescope bracket

Primary Rail H62 CC

Secondary Rail H112 OC

Traverse trolley +50mm

200

58

28

170

58

28

58

28

108

78

Page 64

64

Molift Rail System / www.molift.com

Traverse rail system - Wall mounted

163 51

22

193 51

22

Traverse rail system

Wall mounted

Wall rail

Primary Rail H85 W

Secondary Rail H112 OC

Traverse rail system

Wall mounted

Wall rail

Primary Rail H85 W

Secondary Rail H142 OC

Configuration example:

Products Description Incuding Item no Qty

Rail profile Rail H85 W/A 6m-length painted (4 meter) 1109160 2

Rail H142 OC/P - 4m-length 1109 011- 4 m 1

Trolleys Wall mounted traverse trolley set RH142 2 Trolleys and 4 end

stoppers

110916 6 1

End stops End stop for motor trolley 1109410 2

Endcaps End Cap Rail H142 White 1109342 2

Page 65

65

Molift Rail System / www.molift.com

163

193

335

163

193

305

Traverse rail system

Wall mounted

Wall bracket

Primary Rail H112 OC

Secondary Rail H112 OC

Traverse rail system

Wall mounted

Wall bracket

Primary Rail H112 OC

Secondary Rail H142 OC

Configuration example:

Products Description Incuding Item no Qty

Rail profile Rail H112 OC/P 4m-length 1109009-4m 2

Rail H112 OC/P 4m-length 1109009-4m 1

Trolleys Traverse trolley set (white) 2 trolleys 1109 5 9 0 1

Traverse mounting kit (under trolleys) 2 sets, Bolts, nuts and

washers

1109345 1

Brackets Wall bracket unit (White) 1109259 4

End stops End stop for motor trolley 1109410 2

End stop for traverse trolley 110 9 411 4

Endcaps End Cap Rail H112 White 110 93 41 6

Page 66

66

Molift Rail System / www.molift.com

201

185

123

201

185

73

Traverse rail system

Wall mounted

Wall bracket

Primary Rail H112 OC

Secondary Rail H112 OC

Traverse rail system

Wall mounted

Wall bracket

Primary Rail H112 OC

Secondary Rail H142 OC

Configuration example:

Products Description Incuding Item no Qty

Rail profile Rail H112 OC/P 4m-length 1109009-4m 2

Rail H112 OC/P 4m-length 1109009-4m 1

Trolleys Traverse trolley set (white) 2 trolleys 1109 5 9 0 1

Traverse mounting kit (between primary

rail)

2 sets, Bolts, nuts and

washers

1109353 1

Brackets Wall bracket unit (White) 1109259 4

End stops End stop for motor trolley 1109410 2

End stop for traverse trolley 110 9 411 4

Endcaps End Cap Rail H112 White 110 93 41 6

Page 67

67

Molift Rail System / www.molift.com

9. Installation instructions

Specific Installation Instructions for the various mounting options available upon request to

molift@etac.com. Installation instructions are supplied with the purchased article.

Documents:

Article no. Description Document

1109910, 1109912

1109 9 4 0 , 1109 9 42

MRS Threaded Rod 19-514 installation instruction.pdf

1109 920 , 1109 9 2 2

1109 9 5 0, 110 9 952

MRS Threaded Rod support 19-515 installation instruction.pdf

1109 6 9 5, 110 9 7 0 0

1109710, 1109715

1109718 , 11097 2 0

1109725, 110 9 7 30

1109735

40 mm bracket

1109700, 1109710 Threaded Telescope bracket 80-200mm 19-463 installation instruction.pdf

1109715, 110 9718

1109720, 110 9725

110973 0 , 1109735

Telescope bracket 19-2000mm 19-466 installation instruction.pdf

Box-in Traverse mounting 19-P20 installation instruction.pdf

1109 410, 1109 411 End Stop and drill guide (+ End cap) 19-185 installation instruction.pdf

1109 0 2 9, 1109 650 19-P04E Installation MRS Transition

Coupling

19-P04 installation instruction.pdf

1109 0 2 9, 1109 650 Traverse Switch 19-090 installation instruction.pdf

Page 68

68

Molift Rail System / www.molift.com

Periodic inspection of the rail system should be

undertaken at least once a year to ensure that the

device operate properly and safely.

Periodic inspection Checklist

When performing a periodic inspection, the

inspector shall fill out the inspection report for

Molift Rail System. The reports should be retained

by the person(s) responsible for servicing the hoist.

If the inspection reveals defects and damages,

the owner shall be notified and a Non-conformity

report should be sent to Etac. A new periodic

inspection must be performed after repair.

In the event of damage that jeopardizes the safety of the patient,

the rail system shall immediately

be taken out of service and marked

clearly with “out of order” and

shall not be used until the rail

system is repaired

When periodic inspection is completed the

inspector shall mark the hoist with a sticker on

the control label showing the date when periodic

inspection is performed, and this will then indicate

when next service should be performed.

Any Service or Repair should be documented in

the service log, and verified by using the Checklist

after service and repair.

Checklist after Service and Repair

Use the checklist to verify that the rail system is

properly installed safe before use. Document the

job by signing the Service Log.

Service Log

Defects and damage of importance to the safety

of the Rail system which have occurred between

inspections and have already lead to corrective

actions should be entered in the Service logbook.

A record of the date of inspection of the hoist and

inspection result should be noted in the logbook

together with a short description of the incident

and the signature of the inspector.

This will enable the owner and service partner

to see previous history for the rail system and in

that way maybe making future fault finding and

repairs easier.

10. Maintenance

Mark label

with month

and year of

inspection

Molift Rail System installed by authorized personnel.

Date: Etac Molift Service ID SWL: kg

.................. (6 digits):..................... ................ lbs

Periodic

inspection

performed

www.molift.com

Installation Checklist

Periodic inspection

checklist

Inspection

label

Service and repair

checklist

Service log

OK

FAIL

OK

Service required

every 12 months

Figure: Documentation of maintenance flow chart.

Page 69

69

Molift Rail System / www.molift.com

Checklist for installation of Molift Rail system

Installation Certificate

Customer:

........................................................................................

...

Room number / Section:

.........................................................................................

.........................................................................................

System should consist of only

original MRS components. If not

Decalaration of conformity is not

valid and Etac is not responisble for

warranty of the system

Checkpoints

N/A OK

All rail system components are fitted according to applicable installation instructions.

Check that there is no shavings after drilling or cutting or other objects in the rail

Clean after mounting

The trolley / hoist is to run smoothly and without any noise through the entire rail system

All rail ends in the system have been fitted with end stops and end covers.

All end stop screws are tightened to 40 Nm/ 30 ftlbs

Performed at least six lifts (lift height approx. 15 cm/6 inches) with load = system SWL

at randomly selected points along the rail. The trolley/lift runs smooth through the entire

system with load=SWL and:

transition coupling

switch

The hoist fitted to the system has the same or lower SWL

The hoist is checked seperately according to Hoist User manual.

The system is correctly marked with SWL label, with date and a valid signature and certifi-

cate number by the authorized installer.

All parts and components which before, during or after installation are damaged,

deformed or are otherwise defective must be replaced or repaired before the

system can be brought into use!

Performed by

Installation must be performed by a person who is certified by Etac education.

Date/Place:

...........................................................................................

Signature:

...........................................................................................

Etac Molift Service ID (6 digits):

...........................................................................................

Comments:

Page 70

70

Molift Rail System / www.molift.com

Periodic Inspection for Molift Rail System

In accordance with ISO:10535 Annex B.

Performed by

Periodic inspection should be performed by a

person who is certified by Etac education.

Date/Place:

..........................................................................................

Signature:

..........................................................................................

Etac Molift Service ID (6 digits):

..........................................................................................

Approved without faults

Approved after repair.

System is marked with “out of order” and

waiting for repair. (perform new)

System is not eligible for repair and taken

out of service.

If periodic inspection reveals any defect, wear or

other damage that jeopardizes the safety of the

user the system may not be used until the deficiency has been eliminated. Defects and damages

should be reported back to the manufacturer for

action in a non-conformity report (NCR).

The owner is notified

NCR report sent to Etac, molift@etac.com

Non conformity report can be obtained from

www.molift.com or by request, molift@etac.com.

Any Service or Repair should be documented in the service log, and verified

by using the Checklist for installation of

Molift Rail System

Installation Year:

.........................................................................................

Owner:

.........................................................................................

.........................................................................................

Situation of use:

Home

Hospital

Nursing home

Other:

.........................................................................................

Physical examination

Test FUNCTION and check for wear.

All checkpoints must be checked of to approve the rail system for further use.

OK

The entire rail system with traverse, trolleys, motors, and switches have been tested with load

and is approved without faults with no loose or missing parts.

Visual examination

Visual examination of load bearing structure to make sure there is no damage,

cracks, frays or deformation. All checkpoints must be checked of to approve the rail

system for further use.

OK N/A

The entire system has been checked for damage, wear and deformation (especially end

stops and switches).

All visible bolts have been checked. ”Loose” bolts have been fastened according to the

torque specified in applicable installation insctructions.

All ends are secured by end stops

Trolleys, including straps for climbing have been checked and has no damage or faults.

The system is clearly marked with SWL.

Systems installed in swimming facilities have been checked and has no corrosion.

Page 71

71

Molift Rail System / www.molift.com

Checklist after Service and Repair

Customer:

........................................................................................

...

Room number / Section:

.........................................................................................

.........................................................................................

Installation Year:

.........................................................................................

System should consist of only

original MRS components. If not

Decalaration of conformity is not

valid and Etac is not responisble for

warranty of the system

Checkpoints

N/A OK

Check that there is no shavings after drilling or cutting or other objects in the rail

Clean after mounting

The trolley / hoist is to run smoothly and without any noise through the entire rail system

All rail ends in the system have been fitted with end stops and end covers.

All end stop screws are tightened to 40 Nm/ 30 ftlbs

Performed at least six lifts (lift height approx. 15 cm/6 inches) with load = system SWL

at randomly selected points along the rail. The trolley/lift runs smooth through the entire

system with load=SWL and:

transition coupling

switch

The hoist fitted to the system has the same or lower SWL

The system is correctly marked with SWL label, with date and a valid signature and certifi-

cate number by the authorized installer.

All parts and components which before, during or after service and repair are damaged, deformed or are otherwise defective must be replaced or repaired before

the system can be brought into use!

Performed by

Service and Repair must be performed by a person who is certified by Etac education.

Date/Place:

...........................................................................................

Signature:

...........................................................................................

Etac Molift Service ID (6 digits):

...........................................................................................

Comments:

Page 72

Etac AS

Etac Supply Gjøvik

Hadelandsveien 2, 2816 Gjøvik, Norway

Tel +47 4000 1004

molift@etac.com www.molift.com

Find your distributor

visit www.molift.com

Loading...

Loading...