Molicel FSSF00058AK User Manual

White Paper

Improving Data Integrity

with Auto Sync

White Paper

Improving Data Integrity with Auto Sync

“Less than 50 percent of companies claim to be very

confident in the quality of their data.”

Marsh, Drowning in dirty data?, 2005

Organizations rely heavily on the records they keep in their asset management

databases. In many plants, systems like AMS Device Manager are online all the time,

allowing maintenance and operations personnel a constant, critical window into the

health of intelligent eld devices.

However, even with the ever-expanding reach of the Industrial Internet of Things (IIoT),

there are still stranded devices, due to their age, location, or criticality rating. Moreover,

even for critical, connected devices, there will always be situations where a technician

needs to make repairs or run a diagnostic at the device, even in fully connected systems.

For many organizations, this collection of data at the device means a buildup of critical

information that never makes it into the asset database. Because current handhelds have

no method of enforcing authorization requirements—any technician with the handheld

can make necessary changes to a eld device—there is no guarantee that changes made

in the eld are reected in the master information store. The only way to be sure this

data is kept up-to-date is to perform a manual synchronization after every use. Yet, in the

busy plant environment, it is easy for this synchronization to be overlooked indenitely.

Over time, this failure to keep the master database updated leads to conguration

drift, in which the congurations of an organization’s assets become more and more

divergent due to manual, ad-hoc changes and updates made by technicians operating

on devices in the eld.

2

Improving Data Integrity with Auto Sync

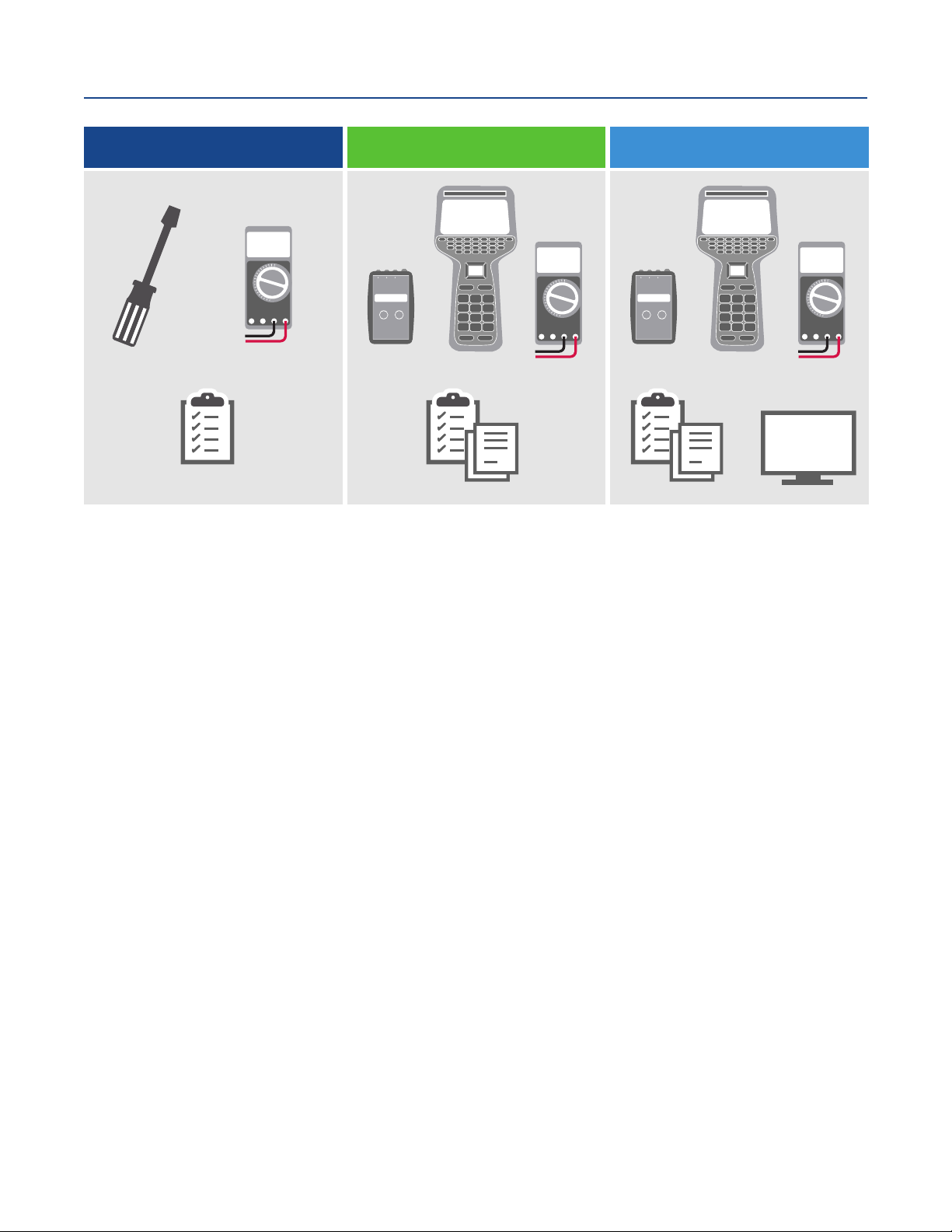

Pre-Digital Smart Devices Asset Management

As device maintenance grew more sophisticated, data became more and more disconnected.

White Paper

The Problem with Missing Data

Operators and technicians rely on critical device status data to perform their jobs. As

more and more device health and conguration data fails to make its way back to the

asset database, it becomes difcult to take full advantage of the system. A technician

heading into the eld to work on a device cannot be sure that the records in the

database accurately reect what will be seen at the device. On the other hand, operators

who don’t know the accurate status of plant devices cannot properly manage the

processes they are responsible for. Further complicating plant operations, when asset

management database information is unreliable, records required for compliance or

internal troubleshooting take longer to nd and compile, potentially resulting in nes or

production outages.

3

Loading...

Loading...