Page 1

Use In TM42, TM40, Base Unit Adapter

Molex Terminator

Description • Operation • Maintenance

DOC No 638500090

Release Date 99/07/01

Revision A

Revision Date 99/07/01

Page 2

WARNING

NEVER USE THIS TERMINATOR IN A PRESS WITHOUT GUARDS OR SAFETY DEVICES THAT

ARE INTENDED TO PREVENT INJURY. THE TERMINATOR IS SUPPLIED WITHOUT

GUARDS. PLEASE USE GUARDS SUPPLIED WITH THE PRESS. RUNNING THE PRESS

WITHOUT GUARDS UNDER ANY CIRCUMSTANCES CAN CAUSE SERIOUS INJURY.

NEVER INSTALL, OPERATE ADJUST, OR SERVICE THIS TERMINATOR WITHOUT PROPER IN-

STRUCTION AND WITHOUT FIRST READING AND UNDERSTANDING THE INSTRUCTIONS IN THIS MANUAL AND THE TM42 PRESS, TM40 PRESS, OR 3BF WITH BASE

UNIT ADAPTER MANUALS.

NEVER INSTALL, REMOVE OR SERVICE TERMINATOR TOOLING WHILE THE FLYWHEEL IS IN

MOTION OR POWER CONNECTED TO THE PRESS.

NEVER INSTALL, REMOVE OR SERVICE THE TERMINATOR TOOLING WITHOUT MANUALLY

CYCLING THE PRESS TO VERIFY THAT THE CLUTCH CONTROL IS IN THE LOCKED POSITION PAST TOP DEAD CENTER, BLOCK THE RAM IN THE UP POSITION IF A DEFECTIVE CLUTCH IS SUSPECTED.

CAUTION THE PRESS SHOULD ALWAYS BE HAND CYCLED WITH THE TERMINATOR INSTALLED

PRIOR TO RUNNING PRODUCTION. THIS PROCEDURE WILL PREVENT DAMAGE OR

REDUCE TOOL WEAR.

WORK SAFELY AT ALL TIMES

FOR SERVICE

CONTACT YOUR LOCAL SALES OFFICE

APPLICATION TOOLING GROUP

1150 DIEHL ROAD,

NAPERVILLE, ILLINOIS 60563

PH: (630) 969-4550

FAX: (630) 505-0049

3

Page 3

Molex Terminator

Table of Contents

Section

1. General Description

2. Installation - Setup - Operation

3. Maintenance

Appendix

A. Terminator Types & T2 Assembly Drawing

B. Crimp Definitions

C. Statistical Process Control (Summary)

5

Page 4

SECTION 1

General Description

Page

1.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Delivery Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.6 Safety & Work Area Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

7

Page 5

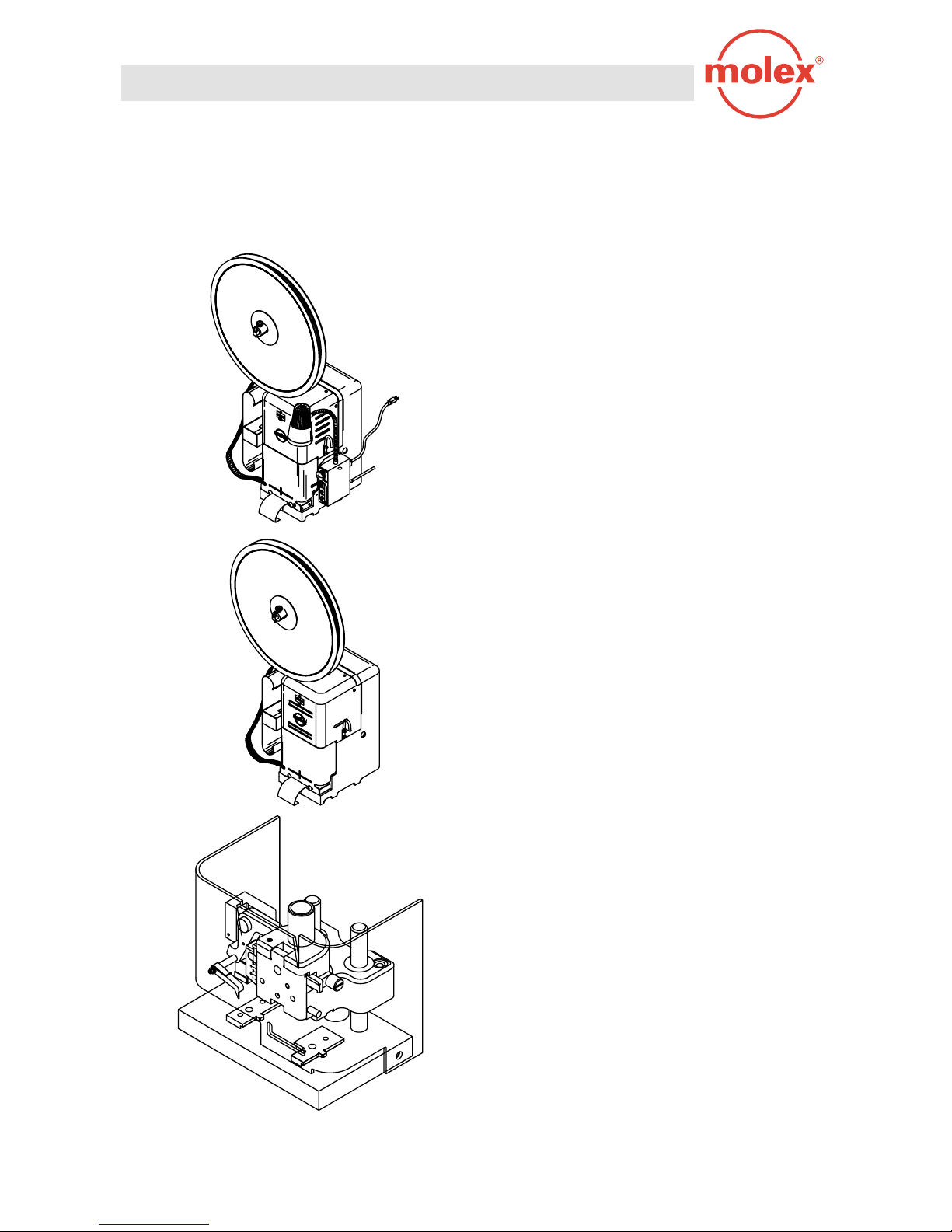

Molex Presses and Adapters

For “T” or “T2” Style Terminators

TM42 Press

ISO Metric.

■

Flexible external light.

■

Resettable counter.

■

1.5” Stroke.

■

TM40 Press

Internal Light.

■

Non resettable counter.

■

1.0” Stroke.

■

Base Unit Adapter

Allows 3BF press to run Terminator style tooling.

■

8

Page 6

General Description

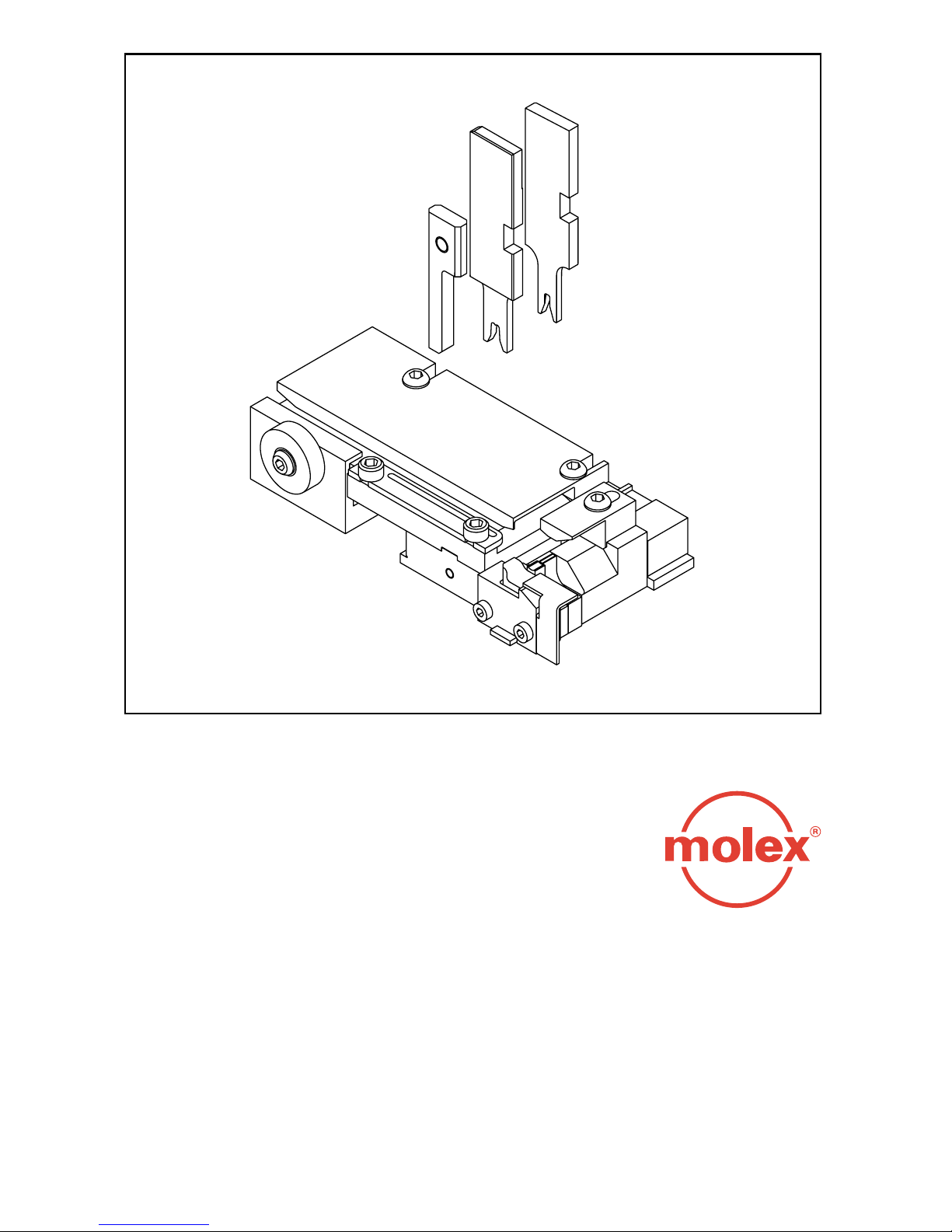

1.1 Description

The Molex Terminator is an easy to use tool for the termination of a variety of Molex crimp terminals.

Production flexibility is obtained through the use of simple interchangeable tooling. The tooling is

inexpensive, and unlike a modular applicator, all crimp height and terminal feed adjustments are located

in the press. The terminator die can be installed in the TM42, TM40 presses or Base Unit adaptor, and is

ideally suited for mid-volume bench operation.

The Molex T2 terminator is the newer version tool that allows for track adjustment. It contains the identical

perishable tooling as the Molex FineAdjust applicator. (Center carrier excluded)

1.2 Features

■

Flexible and inexpensive.

■

Enhanced crimping productivity.

■

Simple installation.

■

Quick release punches.

■

T2 terminator has standardized tooling with Molex FineAdjust Applicator.

■

Track Adjustment capabilities in the T2 terminators for improved control of the bellmouth size and cutoff

tab length.

1.3 Technical Specifications

Dimensions

Width - 127.0 mm (5.0”)

Depth - 44.0 mm (1.8”)

Height - 25.0 mm (1”)

Weight - 1.4 kg (3.0 lbs)

9

Page 7

1.4 Delivery Check

Terminator 1

Sample crimped terminals 5

Manual 1

Setup & Specification Documents 1

1.5 Tools

The following tools are recommended for setup and adjustments of the terminator tool.

1. Metric Allen Set

2. English Allen Set (for older terminator tools)

3. Large and Small Screwdriver

4. Cresent Wrench

5. Pliers (needle nose)

6. Crimp Micrometer

7. Eye Loop (10x)

8. Wire Stripper/Cutter

Qty

1.6 Safety & Work Area Check

Check that the crimping position is ergonomic for the

operator’s size. A bench height of 762 to 813 mm (30

to 32 inches) will provide operator comfort, and allow

both feet to rest on the ground. The foot pedal should

be positioned for ease of reach.

Check that the press position is located paralleled and

approximately 150 mm (6 inches) from the edge of the

table. A chair or stool, with adjustable height and

backrest should be provided for maximum comfort and

back support to the operator. Adjust press light to give

appropriate visibility to the work area.

Check that the operators and observers are wearing

approved safety goggles when the press is in operation

and/or service.

10

Page 8

SECTION 2

Setup And Operation

Page

2.1 Terminator Die Installation and Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Loading the Terminal Strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3 Manually Cycling the Press. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4 Punch and Anvil Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5 Feed Finger Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.6 Forward and Back Feed Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.7 Conductor Crimp Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.8 Insulation Crimp Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.9 Final Check and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

11

Page 9

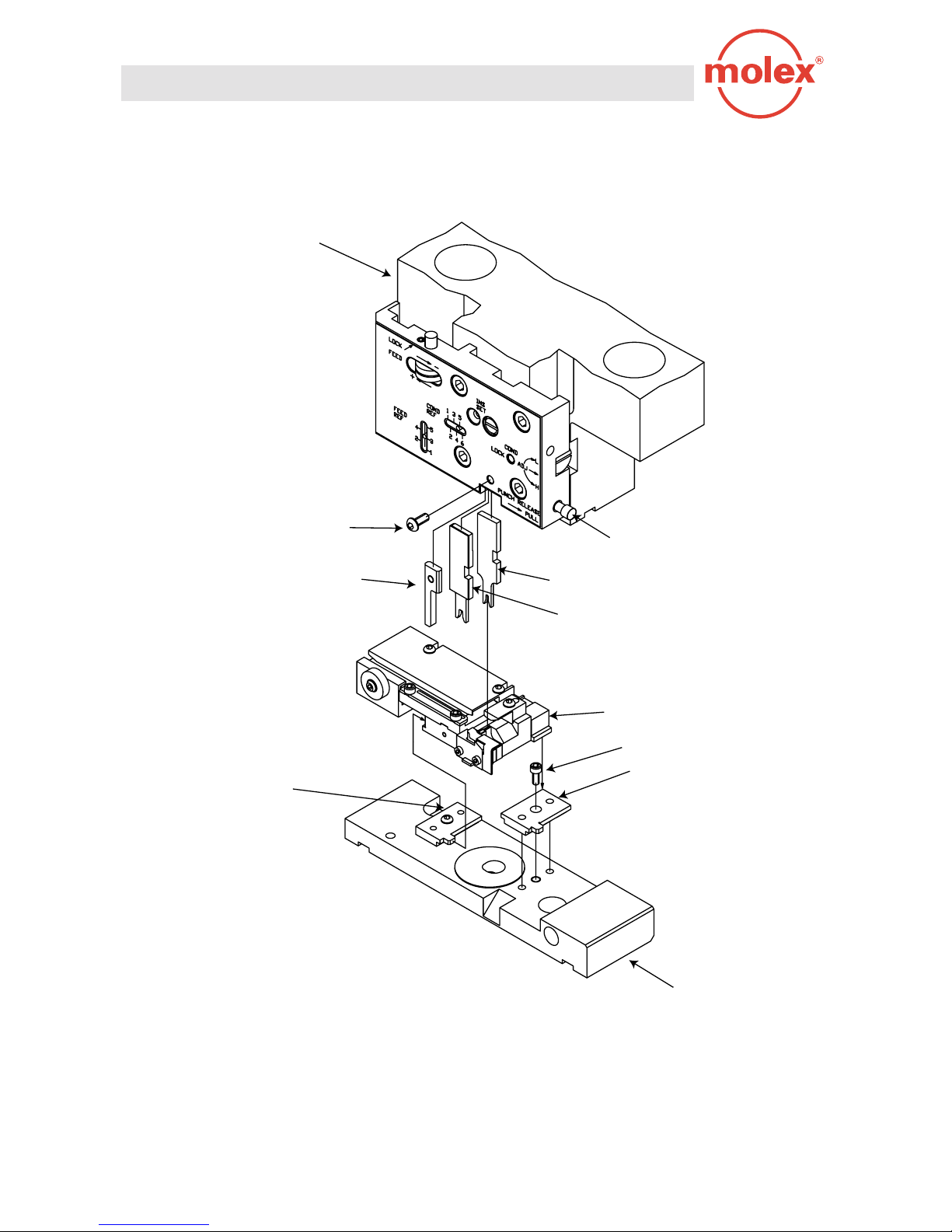

Ram

10-32 x 3/8 Lg. B.H.C.S.

Front Striker

Left Locating Plate

Punch Release Pin

Conductor Punch

Insulation Punch

T2 Terminator Base

M6 x 20 Lg. S.H.C.S.

Right Locating Plate

12

Bolster

TERMINATOR INSTALLATION

Fig. 1

Page 10

Terminator Die Installation & Removal

CAUTION

Always power down the press when installing or removing Molex tooling by pressing the emergency stop button located on

the front panel.

STEPS

(Ref. Fig. 1)

1. Remove Press guard. (Ref. Press or Base Unit manual.)

2. Confirm that the Terminator is correct for the specified product. (Ref. Specification sheets supplied with the

Terminator.)

3. Make sure all the tooling from a previous setup is removed. (See Step 11.)

4. Load all top tooling first, starting with the rear striker. (See Fig. 16.)

5. Pull on punch release pin to install punches into the punch cavity.

6. Finish with front striker (if specified). Confirm that all components follow assembly drawing sequence.

7. Clean bolster plate of scrap or chips that may interfere with the Terminator base installation.

8. Remove 6 mm S.H.C.S (TM42) and lift the right locating plate from the bolster.

9. Place the Terminator base on the bolster plate and slide to the left. The slot in the base will locate on the

left guide block

10. Replace the right locating plate and tighten 6 mm screw.

11. To remove the Terminator reverse the above steps.

13

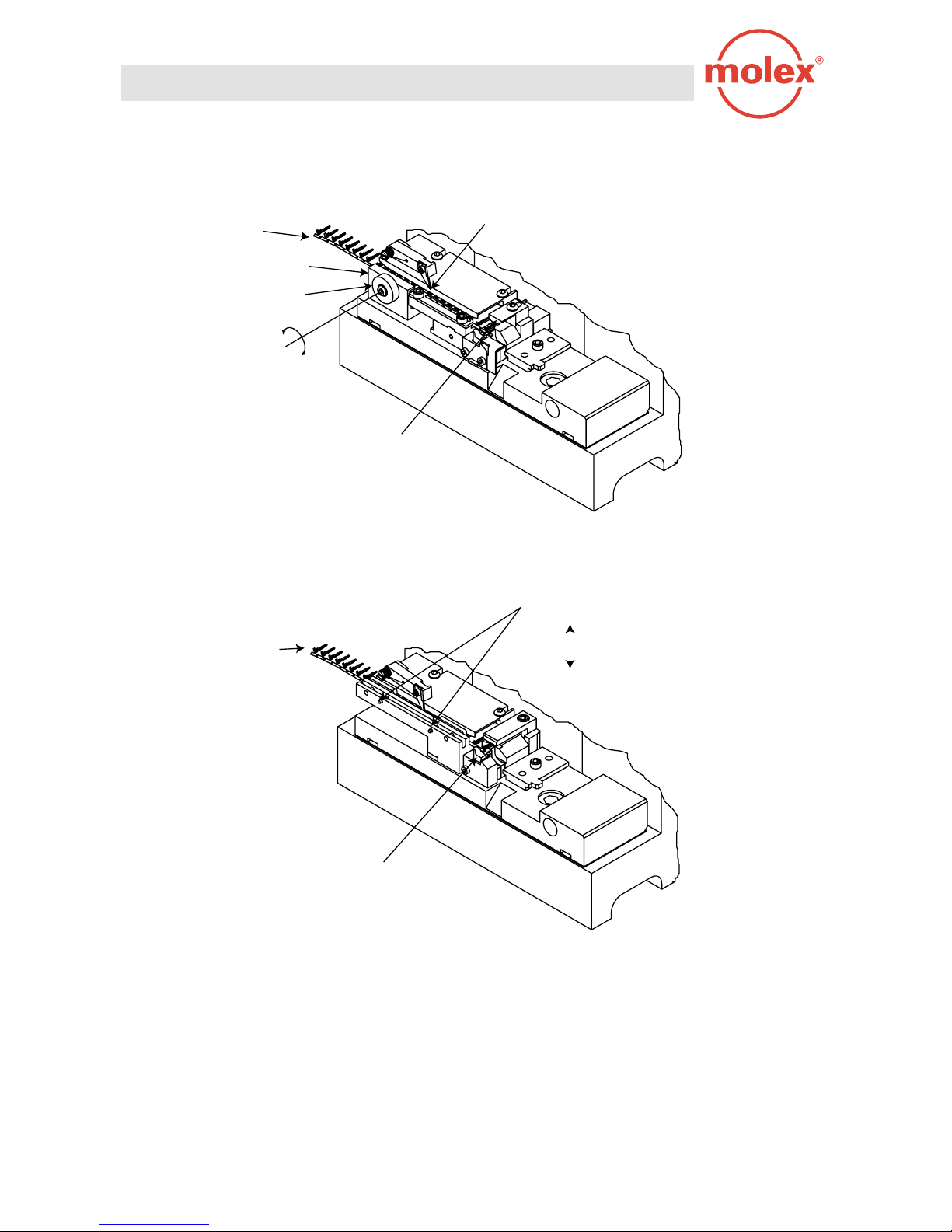

Page 11

Terminal Strip Feeding

Drag Frame

Drag Cam

Rotate Drag Cam

Either Direction

to Raise or to Lower

Drag Frame

Lift the Feed Finger Up

First Terminal

Above Anvils

"T2" Style

Drag Finger / Anti-Back Up Finger

Terminal Strip Feeding

Lift up to Feed Terminal Strip

Release to Apply Drag on Terminal Strip

First Terminal

Above Anvils

"T" Style

LOADING THE TERMINAL STRIP

Fig. 2

14

Page 12

Loading The Terminal Strip

Note

Terminator Drag mechanism may vary on product selection or Terminator type.

Steps

(Ref. Fig. 2)

1. Confirm terminal part number matches the terminator specification sheet.

2. Install the terminal reel on the press reel holder.

3. Raise the drag plate (T2) and slide the terminal strip under both the cover plate and the drag plate.

4. For other “T” style Terminators, raise the drag finger and anti backup finger.

5. Ease the terminal strip forward until the first terminal on the strip is sitting on the anvils.

6. If severe resistance is encountered or the terminal strip does not fit, you may need to make a cover plate

adjustment.

Removing The Terminal Strip

Steps

1. Raise Terminal Drag plate or “T” style drag finger and anti backup finger.

2. Lift the Feed Finger from the carrier strip

3. Gently pull on the terminal strip until it has exited the track.

15

Page 13

Manual Cycle Clutch Release

16

Manually Cycling

HAND CYCLING

Fig. 3

Page 14

Manually Cycling the Press

Note

Hand cycling is necessary to confirm correct tool alignment, terminal feed adjustment, and also to give the setup

person the ability to step through the press cycle manually.

Steps

(Ref. Fig. 3)

1. Always power down the press by pressing the emergency stop button on the front control panel.

2. Release the clutch by inserting a screwdriver through the access hole to trip the locked actuator.

3. Insert the 10 mm hex wrench supplied with the press through the hole in the center of the rear cover and

engage it in the 12 mm S.H.C.S.

4. Rotate the press flywheel to move the ram as desired.

WARNING

When the actuator is disengaged, the ram is free to drop. Due to the weight of

the ram it is possible for the ram to start a downward movement.

Care must be taken to insure that the area in front of the press is clear of fingers

and hand tools.

The guards should be in place or the ram blocked.

Never insert anything through the press guards while the flywheel is in motion.

17

Page 15

Terminal in Position

over the Anvils

Anvil Mounting Screws

Hex Wrench

M4 x 20 Lg. S.H.C.S.

M4 X 50 Lg. S.H.C.S.

Press Ram at Bottom

of Full Down Stroke

Conductor Punch

Insulation Punch

Conductor Anvil

Insulation Avil

18

PUNCH & ANVIL ALIGNMENT

Fig. 4

Page 16

Punch and Anvil Alignment

Note

Correct punch and anvil alignment will insure quality crimps and excellent tool life.

Steps

(Ref. Fig. 4)

1. Slightly loosen the anvil mounting screws.

2. Place the hand cycling wrench through the hole in the center of the rear cover.

3. Gently lower the press ram until it is in the fully down position, with a terminal sitting on the the anvils the

punch will align the bottom tooling.

4. With the ram in the fully down position tighten the anvil mounting screws.

5. Bring the ram back to top dead center insuring that the clutch collar is engaged by the actuator.

6. Repeat the hand cycling operation to confirm alignment.

19

Page 17

Feed Finger Location

Feed Finger Location

Feed Finger Location

Feed Finger Location

Dual Carrier

End Carrier

Nose Carrier

Feed Finger Location

20

Center Carrier

Center Carrier

FEED FINGER LOCATION

Fig. 5

Page 18

Feed Finger Location Adjustment

Note

Feed finger location will vary depending on product selections see the feed finger location chart. (Ref. Fig. 5)

Steps

(Ref. Fig. 5.1)

1. Select feed finger position.

2. Loosen the feed finger shaft locking screw and position the feed finger in the selected position.

3. With a small screwdriver or 6" scale rotate the feed finger shaft to increase the spring pressure on the feed

finger.

4. While maintaining the spring pressure on the feed finger, tighten the feed finger locking screw.

Hex Wrench

Feed Lever

Feed Finger Shaft

Torsion Spring

Decrease

Increase

To Shaft Locking Screw

Feed Arm

Feed Finger

FEED FINGER SPRING ADJUSTMENT

Fig. 5.1

21

Page 19

Forward Feed Adjustment Lock Screw

Forward Feed

Adjustment Lock Wheel

Adjusting Backward

+

Adjusting Forward

Forward Feed Adjustment Indicator

1

Min. Backward Feed

5

Max. Forward Feed

Backward

M6 Jam Nut and

Fine Adjust Screw

Forward

Feed Finger

22

FORWARD AND BACKFEED ADJUSTMENT

Fig. 6

Page 20

Forward and Back Feed Adjustment

Note

Because of different terminal progressions, feed adjustment may be necessary.

Steps

(Ref. Fig. 6)

1. Make sure the press ram is in the fully up position and the clutch collar is engaged by the actuator.

2. Slide the terminal carrier strip all the way forward until it is centered over the anvils.

3. See the feed finger location (Fig. 5) for feed finger position.

4. Rotate the feed finger shaft with small screwdriver or 6” scale to get desired feed finger spring pressure

and tighten shaft locking screw.

5. Loosen 6 mm feed adjustment wheel locking screw.

6. Turn the feed adjustment wheel if necessary to position the terminal over the anvils.

7. Place the 10 mm hex head Allen wrench in the 12 mm S.H.C.S. located in the back of the press and slowly

hand cycle the press to the fully down position.

8. The feed finger should start to move backward one progression, if not loosen the 6 mm jam nut and back

the set screw out enabling the feed finger to move to the next pick up point.

9. If the feed finger is moving back more than one progression rotate the 6 mm set screw clockwise until the

feed finger is in the correct pickup point.

10. Hand cycle the press ram a few times and if necessary make the appropriate adjustments.

11. Tighten M6 lock nut and 6 mm feed adjustment locking screw.

23

Page 21

Conductor Adjustment Indicator

1

Setting (Loosest)

6

Setting (Tightest)

Lower Crimp Height

Higher Crimp Height

Conductor Adjustment Lock Screw

CONDUCTOR HEIGHT ADJUSTMENT

Conductor

Adjustment

Screw

Fig. 7

24

Page 22

Conductor Height Adjustment

Note

It is desirable to adjust the conductor adjustment wheel all the way to (1) on the conductor adjustment indicator, to

avoid punch crash prior to beginning this process.

Steps

(Ref. Fig. 7)

1. Replace the press guard.

2. Prepare wire for crimping. The selected wire should meet the parameters on the specification sheet.

3. Make sure that the 10 mm hex head Allen wrench is removed from the back of the press.

4. Turn the power on.

5. Place the wire through the slot in the press guard and all the way to the Terminator wire stop.

6. Activate the foot pedal, sweeping the crimped wire to the right.

7. Measure the crimped wire and verify desired crimp height on the specification sheet.

8. If crimp height adjustments are required, power down the press and remove the press guard.

9. Loosen the 6 mm crimp height locking screw and rotate conductor adjusting screw. Rotating the conductor

adjusting screw clockwise one full turn will tighten the crimp height approximately 0.03mm (.001”).

10. Repeat steps 1 thru 9 until the correct crimp height is achieved.

11. When correct crimp height is achieved tighten 6 mm lock screw.

12. Replace the press guard.

25

Page 23

Insulation Adjustment Indicator

1

Setting (Loosest)

8

Setting (Tightest)

Lower Crimp Height

Insulation Adjustment Cam

Higher Crimp Height

26

INSULATION CRIMP ADJUSTMENT

Fig. 8

Page 24

Insulation Crimp Adjustment

Note

The insulation crimp provides strain relief for the conductor crimp. The quality of the insulation crimp will depend

on the insulation diameter and durometer. Refer to the specification sheet for insulation diameter parameters.

Steps

(Ref. Fig. 8)

1. Place a stripped wire against the wire stop, crimp it under power.

2. Inspect the sample to determine if adjustments are needed.

3. If adjustments are needed powers down the press by pressing the emergency stop the button located in the

front of the control panel.

4. Remove the press guard.

5. Rotate the insulation adjusting cam to obtain the required insulation wrap.

6. Rotate the insulation adjusting cam, counter clockwise to tighten the insulation wrap.

7. Each increment represents approximately 0.1mm (.004).

8. Beginning at # 1 (loosest) to # 8 (tightest) insulation crimp.

9. Replace the press guard.

10. Repeat the above steps until the desired insulation crimp is obtained.

27

Page 25

28

OPERATION

Fig. 9

Page 26

Operation

Note

Check that all setup procedures were followed and all locking screws have been tightened. Follow the safety and

work area instructions.

Steps

(Ref. Fig. 9)

1. Press guard should be in position.

2. Wire should be pre stripped and prepared for crimping.

3. Place pre stripped wire through the slot in the press guard.

4. Touch pre-stripped wire against the wire stop.

5. Press foot pedal down once.

6. Use sweeping motion to the right with the crimped wire.

7. Check the crimped wire and confirm that it meets the Terminator specifications and visual inspection.

29

Page 27

SECTION 3

Maintenance

Note

Terminator maintenance will increase tool life and produce a consistent, reliable quality crimp. The following

procedure should be followed at the end of each operation.

Steps

1. Power down the press.

2. Remove the press guard.

3. Make sure that the clutch collar is engaged by the clutch actuator.

4. Take a small brush and clean in and around the terminator anvils.

5. Inspect perishable tooling for wear or fracture.

Molex recommends that you maintain a spare tooling kit at your facility.

The Terminator should be free of all carrier strip tabs and plating that may have accumulated during

production.

30

Page 28

Terminator Types

Note

Molex supplies different types of Terminators depending on the vintage. The following illustrations are a generic

guide to the Tool that you may have.

1. Track Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . .Fig. 10

2. End carrier T2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fig. 11

3. Dual carrier T2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fig. 12

4. Center carrier “T”. . . . . . . . . . . . . . . . . . . . . . . . . . . .Fig. 13

5. Micro terminal “T”. . . . . . . . . . . . . . . . . . . . . . . . . . .Fig. 14

6. T2 Terminator Assembly. . . . . . . . . . . . . . . . . . . . . . .Fig. 15

7. Rear Striker Installation . . . . . . . . . . . . . . . . . . . . . . .Fig. 16

31

Page 29

T2 Terminator

Track Adjustment Front

Track Adjustment Back

T2 Terminator

Base

Terminal Track

M5 x 10 Lg. S.H.C.S.

T2 TERMINATOR

Fig. 10

Track Adjustment T2 Series

The T2 Terminator allows for adjustment of both the bellmouth and cut-off tab by loosening the 6 mm S.H.C.S and

moving the terminator track in or out to achive desired conditions on crimp.

32

Page 30

Insulation

Punch

Conductor

Punch

Rear Cover

Front

Plunger

Striker

Front Cut-Off

Plunger

Cut-Off

Plunger

Spring

Plunger

Retainer

Conductor

Anvil

Insulation

Anvil

Front Cover

Track

Base

Wire Stop

Anvil Mount

Tooling Key

Scrap Deflector

T2 END CARRIER (GENERIC)

Fig. 11

33

Page 31

Front

Plunger

Striker

Insulation

Punch

Punch

Hold Down

Spring

Hold Down

ShaftConductor

Rear

Striker

Rear Cut-Off

Plunger

Cut-Off

Plunger

Spring

Front

Cover

Rear Cover

Wire

Stop

Base

Track

Front Cut-Off

Plunger

Cut-Off

Plunger

Spring

Front

Plunger

Retainer

Cut-Off

Blade

Rear Spacer

Rear Plunger Retainer

Tooling Key

Front Spacer

Conductor Anvil

Insulation Anvil

T2 DUAL CARRIER (GENERIC)

Fig. 12

34

Page 32

Carrier Hold Down

Hold Down Spring

Hold Down Plunger

Cut-Off Punch

Conductor Punch

Stop Finger Torsion Spring

Cover Plate

Stop finger

Spiral Pin

Insulation Punch

Rear Cut-Off Die

Pivot Pin

Cover Mounting Screw

Cover Guiding Pin

Front Cover

Wire Stop

Track

Tooling Mounting Screw

Spacer

Front Cut-Off Die

& Anvil Combination

T” STYLE CENTER CARRIER (GENERIC)

Fig. 13

35

Page 33

Front Cover

Rear Cover

Conductor Punch

Insulation

Punch

Plunger

Striker

Adjusting Screw

Pin Lock

Adjusting Screw

Plunger

Retainer

Tooling

Mounting

Screw

Track

Adjustor Bar

Wire Stop

Bracket

Wire

Stop

Base

Anvil Mounting Block

Combination Anvil

Cut-Off Plunger

Cut-Off Plunger Spring

36

Spring Plate

MICRO TERMINAL (GENERIC)

Fig. 14

Page 34

2

3

1

5

6

7

8

4

T2 Terminator Bill of Materials

Item No. Order No. Description Qty.

1 638008501 T2 Terminator Base 1

2 638000108 Terminal Track 1

3 690280660 Drag Springs 2

4 638000316 Guide Pin-Drag Frame 2

5 638000312 Drag Frame 1

6 638000115 Spacer Tube 1

7 638000313 Drag Cam 1

8 M4 x 12 Lg. B.H.C.S. 1

9 M5 x 10 Lg. S.H.C.S. 1

9

T2 TERMINATOR ASSEMBLY

Fig. 15

37

Page 35

Hold Down Plunger Set Screw

Hold Down Spring

Hold Down Plunger

REAR STRIKER INSTALLATION

Rear Striker

Rear Striker Mounting Screw

Fig. 16

38

Page 36

Crimp Terminations

40

Page 37

Definitions

Anatomy Of A Crimp Termination

Bellmouth ( Flare)

The flare that is formed on the edge of the conductor crimp acts as a funnel for the wire strands. The funnel reduces

the possibility that a sharp edge on the conductor crimp will cut or nick the wire strands.

Bend Up /Bend Down /Twisting / Rolling

The terminal bending up, bending down, twisting or rolling indicates that the nose of the terminal is reacting to the

crimping process

Brush

The conductor brush is made up of wire strands that extend past the conductor crimp.

Conductor Crimp

This is the metallurgical compression of a terminal around the wire’s conductor.

Crimp Height

The conductor crimp height is measured from the top surface of the formed crimp to the bottom most radial surface.

Cut-Off Tab Length

This is the material that protrudes outside the insulation crimp after the terminal is separated from the carrier strip.

Insulation Crimp

The insulation crimp provides a strain relief for the crimped wire and support for insertion into the housing.

Strip Length

The strip length is the pre determined amount of bare wire that is exposed for crimping.

41

Page 38

Statistical Process Control (Summary)

Process Confirmation.

Molex recommends that prior to production, a 25 piece process capability study on both crimp height and pull force.

Setup/Visual Inspection

Minimum 5 piece sample should be checked for crimp height per specification sheet.

Visually check bellmouth, conductor brush, insulation position, cutoff tab length and insulation crimp to specification

sheet guidelines for optimum setup.

Production

Visual check every bundle by fanning the crimped wires.

Check crimp height every 250- 500 pieces.

Molex recommends control charting of crimp heights for long production runs.

Example Control Chart

Contol Limit for sample of 5 = Avg (Avg of 5 readings) + .577 x Avg (Ranges)

X & R Chart

Note

: For more detail information please refer to the Molex Quality Crimping Handbook, Order No. 63800-0029.

42

Page 39

Terminator Crimping Manual

Corporate Headquarters

2222 Wellington Court

Lisle, IL, 60532, U.S.A

Tel : 630-969-4550

Application Tooling Division

1150 E. Diehl Rd

Naperville, IL, 60563

Tel : 630-969-4550

European Headquarters

Munich, Germany

Tel : 49-89-413092-0

Printed in U.S.A 1999 Molex Incorporated

Order Number - 638500090

Far East North Headquarters

Kanagawa, Japan

Tel : 81-462-2324

Far East South Headquarters

Jurong Town, Singapore

Tel : 65-268-6868

Loading...

Loading...