Page 1

TM-3000 and TM-4000 Universal Press

Use with Molex FineAdjust, Mini-Mac Applicators and the Molex

Description

Operation

Maintenance

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 1 of 47

Revision: D Revision Date: 12-0-02-09

TM-3000 UNIVERSAL PRESS

TM-4000 UNIVERSAL PRESS

Tape Terminal Crimp Module

Instruction Manual

Order No.63801-7299

Page 2

TM-3000 and TM-4000 Universal Press

WARNING

NEVER USE THIS MACHINE WITHOUT THE GUARDS OR SAFETY DEVICES THAT ARE INTENDED TO

PREVENT HANDS FROM REMAINING IN THE DIE SPACE. RUNNING THIS MACHINE WITHOUT

GUARDS, UNDER ANY CIRCUMSTANCES, CAN CAUSE SERIOUS INJURY.

NEVER LIFT THIS PRESS WITHOUT THE AID OF MECHANICAL LIFTING DEVICES.

NEVER OPERATE, SERVICE, OR ADJUST THIS MACHINE OR INSTALL APPLICATOR DIES WITHOUT

PROPER INSTRUCTION AND WITHOUT FIRST READING AND UNDERSTANDING THE

INSTRUCTIONS IN THIS MANUAL.

NEVER SERVICE THIS MACHINE WHILE IT IS CONNECTED TO ANY ELECTRICAL POWER SOURCE.

DISCONNECT POWER BY UNPLUGGING THE PRESS FROM ITS POWER SOURCE AND FROM

THE COMPRESSED AIR SUPPLY.

NEVER INSTALL OR REMOVE APPLICATOR DIES WITH THE MOTOR RUNNING, OR AIR SUPPLY

CONNECTED.

CAUTION THIS PRESS IS SHIPPED FROM THE FACTORY AT A SHUT HEIGHT OF 135.80mm (5.346”).

FAILURE TO HAND CYCLE THE PRESS WHEN INSTALLING APPLICATORS CAN CAUSE

SEVERE DAMAGE TO THE TOOLING AND/OR PRESS.

CAUTION MOLEX CRIMP SPECIFICATIONS ARE VALID ONLY WHEN USED WITH MOLEX TERMINALS,

APPLICATORS AND TOOLING.

WORK SAFELY AT ALL TIMES

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 2 of 47

Revision: D Revision Date: 12-0-02-09

For Service, Contact Your

Local Molex Sales Office

Molex Application Tooling Group

2200 Wellington Court

Lisle, Illinois 60532

Tel: 630-969-4550

Fax: 630-505-0049

Page 3

TM-3000 and TM-4000 Universal Press

1 General Description

2 Installation

3 Setup - Operation

4 Maintenance and Troubleshooting

5 Parts List, Assembly Drawings, Electrical Schematics

6 EC Declaration of Conformity

A Options

1. Taped Terminal Crimp Module

Table of Contents

SECTION

APPENDIX

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 3 of 47

Revision: D Revision Date: 12-0-02-09

Page 4

TM-3000 and TM-4000 Universal Press

1.1 Description

1.2 Features

1.3 Technical Specifications

1.4 Delivery Check

1.5 Tools

Section 1

General Description

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 4 of 47

Revision: D Revision Date: 12-0-02-09

Page 5

TM-3000 and TM-4000 Universal Press

General Description

1.1 Description

The 63801-7200 (120V AC version), the 638017300 (240V AC version) TM-3000 Universal Press

and the 63801-7600 (240V AC version) TM-4000

Universal Press are economical, electricallyoperated, single-cycle and split cycle direct drive

presses. They are designed to provide an effective

method of applying a wide range of side-feed and

rear-feed terminals to a pre-stripped discrete wire or

cable. Both the TM-3000 and the TM-4000 are

suited to mid-volume semi-automatic operations.

Production flexibility is obtained using

interchangeable FineAdjust or Mini-Mac applicators

and most Industrial Standard Applicators.

These presses will complete one crimping cycle with

each depression of the foot pedal and two

depressions for split cycle. Safe operation is

provided by an interlock switch that renders the

press inoperative if the safety guard is opened or

removed.

1.2 Features

Utilizes both FineAdjust and Mini-Mac

applicators side and rear feed, and most

industry standard applicators

Press is shipped set to Industry shut height of

135.80mm (5.346”)

Ideal for mid-volume, semi-automatic

applications

Meets O.S.H.A. safety standards is ANSI-

Z535.2-2002 compliant

Totally enclosed for operator safety, including a

power interlock switch for the front guard

Resettable counter for accurate batch counting

Modular solid state controls with an easy plug in

power cord and foot switch.

“CE” Certified

1.3 Technical Specifications

Dimensions with reel mounted

Height 1210mm (47.60“)

Width 648mm (25.50“)

Depth 559mm (22.00“)

Unpacked weight 100kg (220 lb)

Power Requirements

Voltage: 63801-7200-120V AC 60 Hz

Voltage: 63801-7300-240V AC 50 – 60 Hz

Voltage: 63801-7600-240V AC 50 – 60 Hz

Note:

If 240V power is not available, then 120V power

may be used with an appropriate (1000VA

minimum) step-up transformer.

Recommended step-up transformer: Allied

Electronics #836-0181 (phone: 1-800-433-5700).

Pneumatic Requirements (Air Feed Applicators

only)

75 psi min. (366 kN/cm2) min.

1.0 SCFM (28.3 L/min)

¼” NPT inlet 12.7mm (1/2”) supply pipe minimum.

Production Rate

2400 terminations per hour maximum, depending

on operator skill and wire length.

Processing Capability

TM-3000 Press output = 4000 lbf (18kN).

Copper conductors up to 10 AWG (5.0mm²) in

solid or stranded wire.

TM-4000 Press output = 7000 lbf (31kN).

Copper conductors up to 4 AWG (21.0mm²) in

solid or stranded wire.

Sound Level

Operator will be exposed to less than 85 dBA.

1.4. Delivery Check

After removing the packaging band, the top and

sides of the box should lift off easily. The following

items are included in this package :

Quantity

Main Press Body 1

Reel Support Assembly 1

“T” wrench for manual cycling 1

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 5 of 47

Revision: D Revision Date: 12-0-02-09

Page 6

TM-3000 and TM-4000 Universal Press

Carton Contents Quantity

69018-6237 PowerCord

(for 63801-7200) 1

OR

62500-1774 Power Cord 220V 10A

(for 63801-7300 and 63801-7600) 1

63801-7271 Foot Pedal 1

TM-638007299 Instruction Manual 1

1.5 Tools

The following tools are recommended for setup

and adjustments to the applicator in this press

Metric hex wrench set

Small standard screwdriver

Adjustable wrench

Needle nose pliers

Crimp micrometer

Eye loupe (10x)

Wire stripper/cutter

English hex wrench set for some non-metric

applicators

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 6 of 47

Revision: D Revision Date: 12-0-02-09

Page 7

TM-3000 and TM-4000 Universal Press

2.1 Lifting/Mounting

2.2 Reel Support

2.3 Foot Pedal and Power Connection

2.4 Pneumatic Supply Hook-up

2.5 Terminal Feed Guide

2.6 Function Test

2.7 Safety and Work Area Check

Section 2

Installation

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 7 of 47

Revision: D Revision Date: 12-0-02-09

Page 8

TM-3000 and TM-4000 Universal Press

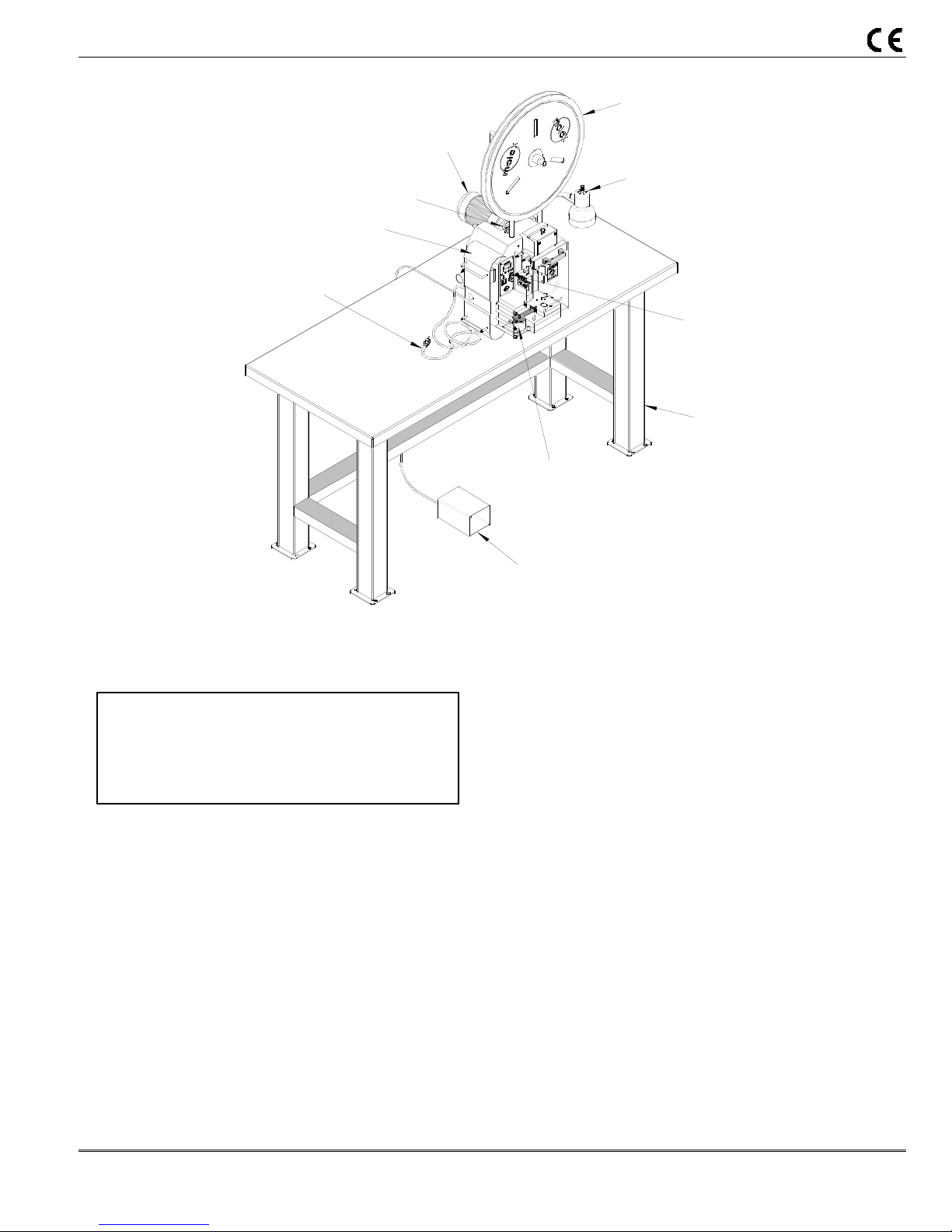

LIFT HOOK

TERMINAL GUIDE

POWER CORD

2.1 Lifting/Mounting

WARNING: This Press weighs over 100 kg (220

lb); it should not attempt to be lifted by one

individual. Mechanical lifting devices should be

used. A person lifting the press can sustain

severe back or other injuries.

A lifting hook is provided on the top of the press. A

heavy-duty chain, rope, cable, or belt can be used

with loops, links, or rings on each end that can

securely attach to the lifting hooks. An electric,

hydraulic, or mechanical crane should be used to

lift the press. Lift the press up approximately

12mm (.50”) and verify that the press is well

balanced. Upon verification, the press can be lifted

onto a sturdy workbench. Access to the back of

the machine is required for manual cycling. A

wooden bench that is a minimum of 25mm (1.00”)

thick will offer quiet vibration-free operation. For

thinner or sheet metal tops, the TM-3000 can be

MOTOR

REEL SUPPORT

ASSEMBLY

WORK LIGHT

PRESS CONTROL

ASSEMBLY

WORK BENCH

OILER ASSEMBLY

FOOT PEDAL

ASSEMBLY

Figure 2-1

attached to the table with two 12mm bolts. Bolts

are not supplied by Molex.

2.2 Reel Support

Install the reel support in the hole located on the top of

machine frame. For rear feed, rotate the reel support

as required. See Figure 2-3. Loosen the M10 set

screw that holds the reel support. Pull up from the

hole and rotate for the proper feeding orientation.

Then slide down back into the hole and tighten the

M10 set screw.

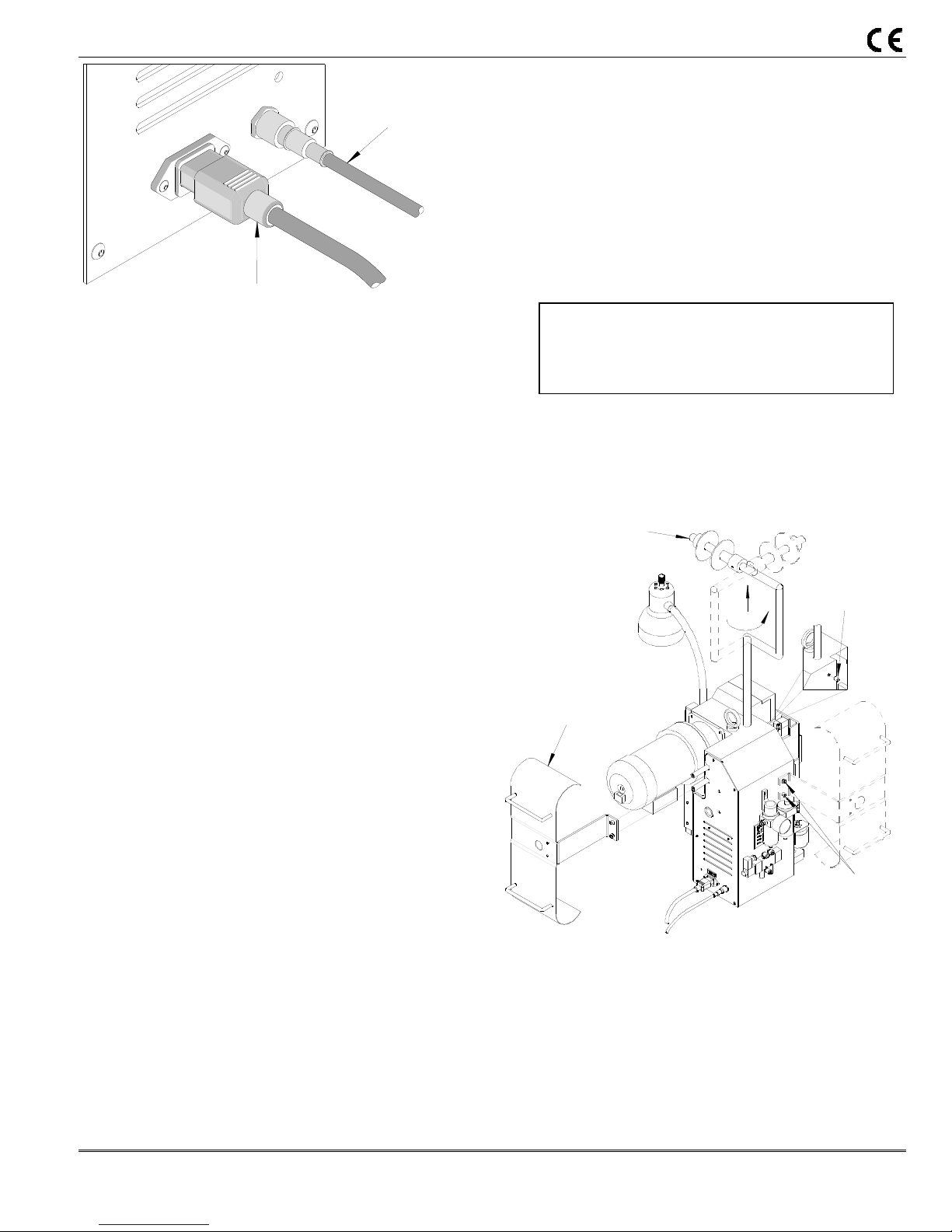

2.3 Foot Pedal and Power Connection

Connect the 3-pin plug for the foot pedal in the rear of

the press control assembly. Turn the locking ring

clockwise until tight. Connect the power cord plug to

the socket in the back of the control assembly. Use a

grounded electrical outlet as the power source. See

Figure 2-2.

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 8 of 47

Revision: D Revision Date: 12-0-02-09

Page 9

TM-3000 and TM-4000 Universal Press

FOOTSWITCH

CORD

Figure 2-2

POWER

CORD PLUG

2.4 Pneumatic Supply Hook-Up

A compressed air supply is required if air feed or other

air powered applicators will be used. The press

comes equipped with an air supply system, which

consists of filter, regulator, lubricator and a valve to

actuate the air feeds at the proper time in the press

cycle.

Due to the considerable types of air connection and

quick connect fittings available; Molex only supplies

the press with a 1/4 NPT female threaded fitting. The

customer may attach whatever type of air connections

that are commonly used in their plant to this port.

The minimum flexible tube size used to connect the

press should be 8mm or 5/16” to assure adequate flow

rate.

A filter-regulator-lubricator unit is supplied to properly

condition the incoming air. The filter will remove

particulate and moisture from the air that can damage

or reduce the life of cylinders and valves. This filter

and bowl should be serviced on a regular schedule.

(See section 4.1) The filter has an automatic drain at

the bottom of the bowl that will automatically open and

expel fluid when the bowl is getting full. It is

recommended that, a 6mm or 1/4” flexible tube, be

attached to the drain hose barb and run to a container

if the air system contains excessive moisture.

The regulator adjusts the pressure of the incoming air

to what the applicators require usually 60-80 PSI (refer

to the applicator manual for recommended pressures.)

Adjustment is accomplished by pulling up on the knob,

rotating it until the gauge indicates the desired

pressure, then pushing it down to lock the setting.

A lubricator is supplied for those applicator air feeds

that need lubrication. Molex air-feed applicators do

not require lubrication. The lubricator is shipped

without lubricant in it. To use, fill the lubricator (make

sure the main air supply is disconnected or that the

slide valve provided is in the off position before adding

lubricant) through the fill plug on the top of the unit,

with high quality SAE 10 W oil. The lubricator has a

graduated dial on top, turn the dial to the 1 or 2

setting.

Caution: Do not over lubricate. Only a very

small amount of lubricant is required to assure

smooth operation. Excess lubricant is exhausted

to the atmosphere.

If lubrication is not required set the dial to 0 to turn off

the lubricator.

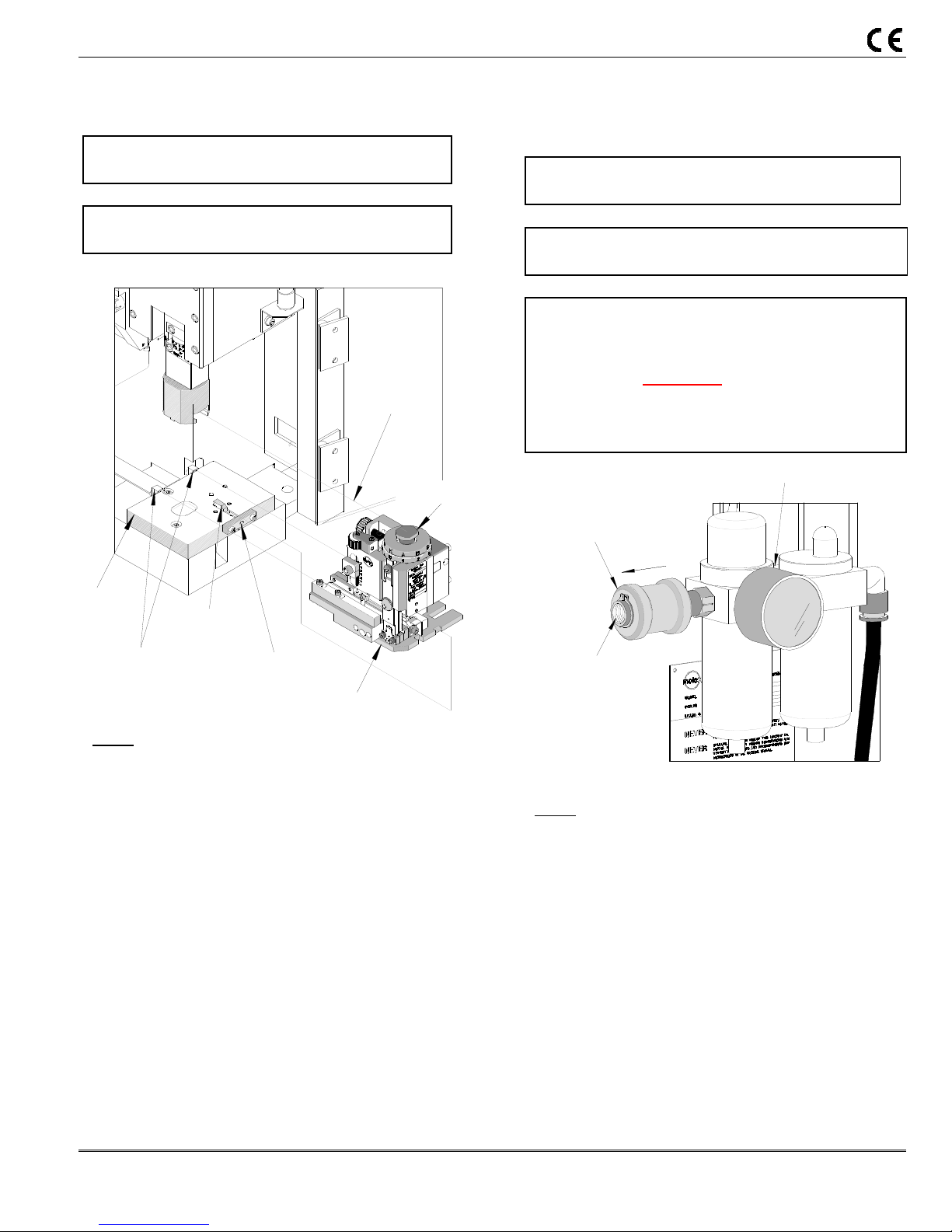

2.5 Terminal Feed Guide

PULL UP FROM

HOLE, ROTATE AND

SLIDE DOWN INTO

HOLE

REPOSITION

TERMINAL GUIDE

Figure 2-3

Depending on side or rear-feed applications, the

terminal guide plate and bracket must be repositioned.

The press is set for side-feed applicators when

shipped from the factory. When rear-feed applicators

are used, the two M6 BHCS from the terminal guidemounting bracket are to be removed. See Figure 2-3.

The guide bracket is rotated 180 degrees and the

assembly is then mounted on the two standoffs in the

LOOSEN

M10 SSS IN

FRONT OF

PRESS

REMOVE M6 BHCS

AND REMOVE

TERMINAL GUIDE

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 9 of 47

Revision: D Revision Date: 12-0-02-09

Page 10

TM-3000 and TM-4000 Universal Press

rear of the press with the two M6 SHCS. See Figure

2-3.

2.6 Function Test

When the press is shipped from the factory, it is set

to the industry shut height of 135.80 mm (5.346”) with

a calibrated load gauge. The press shut height

gauge is spring loaded to give an accurate reading

on the press shut height. See Figure 2-4. Molex

recommends hand cycling the press each time an

applicator is installed. See Section 3-3.

PRESS

SHUT HEIGHT GAUGE

CAUTION: Always manually cycle the press

before restoring power to the machine.

2.6.1 Verification of Press Shut Height

This press comes factory set at an Industry Standard

shut height of 135.80mm (5.346”). A label is

attached to the front of each press indicating the

factory settings. This press has an adjustable shut

height, see Section 3.4.3 for crimp height adjustment.

Always return the press to the factory setting on the

label before installing applicators to avoid tooling

PRESS QUICK CHANGE

MOUNTING PLATE

Figure 2-4

damage. Check the factory setting periodically with a

calibrated shut height gage.

Shut height gauges may be purchased from:

Artos Eng. 602-581-0070

Komax Corp. 847-537-6640

2.7 Safety and Work Area Check

Check that the crimping position is ergonomic

for the operator’s size. A bench height of 762.00

to 813.00mm (30.00 to 32.00”) will provide

operator comfort, and allows both feet to rest on

the floor. The foot pedal should be placed in a

comfortable position. Check that the press

position is located approximately 150mm (6“)

from the edge of the bench. A chair or stool with

adjustable height and backrest should be

provided for maximum comfort and back support

for the operator.

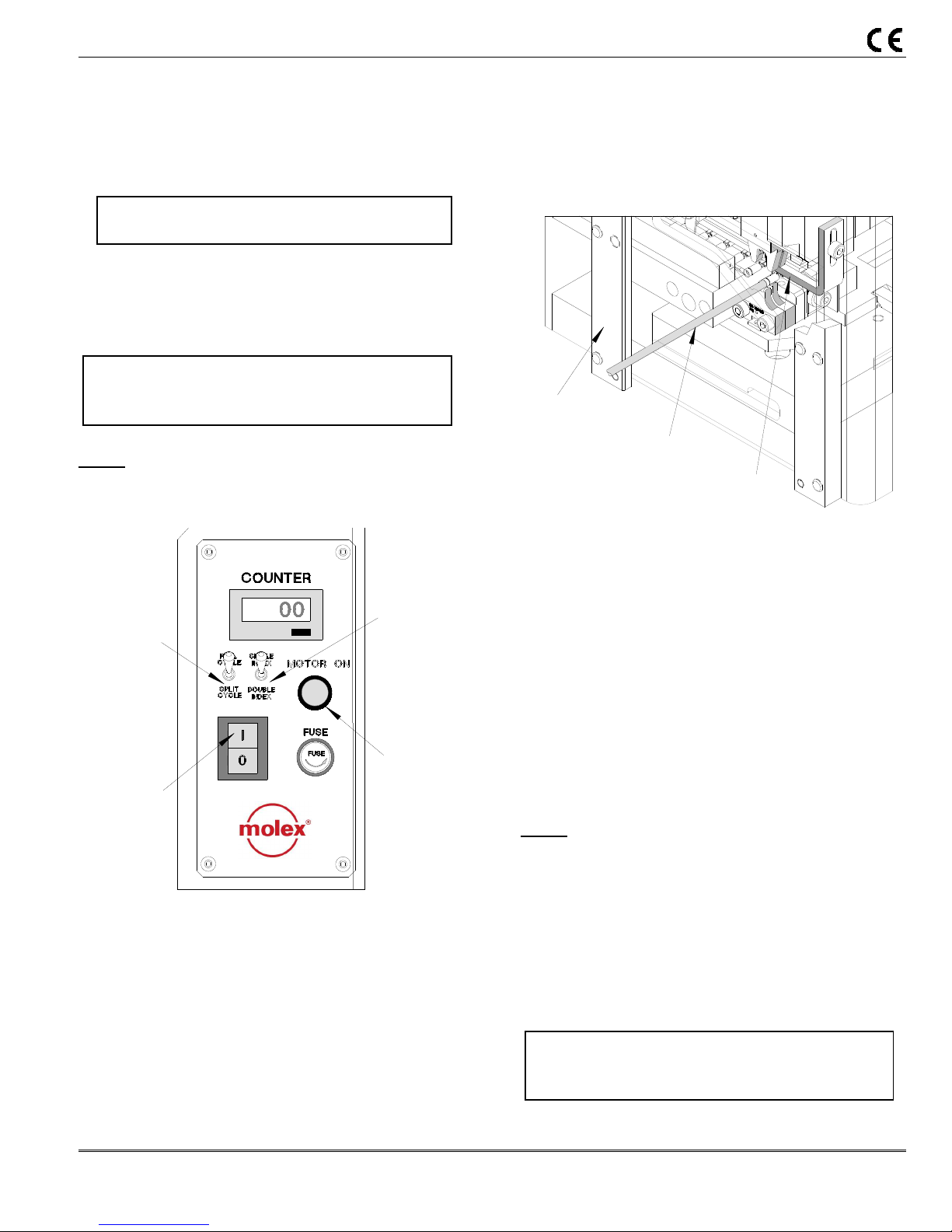

FUSE HOLDER

CAUTION: Molex recommends that the operator

and observers wear eye protection when the press

is in operation or being serviced.

The fuse is located on the control panel. To

replace the fuse (10AMP on 110 V models and

5AMP on 220V models), turn the holder in the

direction as shown. Turn clockwise to secure

holder in place when replaced. See Figure 2-5.

Figure 2-5

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 10 of 47

Revision: D Revision Date: 12-0-02-09

Page 11

TM-3000 and TM-4000 Universal Press

3.1 Applicator Installation

3.2 Air Feed Applicator Installation

3.3 Manually Cycling the Press

3.4 Operation

Section 3

Setup and Operation

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 11 of 47

Revision: D Revision Date: 12-0-02-09

Page 12

TM-3000 and TM-4000 Universal Press

3.1 Applicator Installation

Power down the press by turning off the “POWER”

switch located on the control panel.

Note: Once the press guard is open the guard

interlock switch will disconnect power to the motor.

QUICK

CHANGE

PLATE

LOCATOR

CLAMPS

LOCKING

CLAMP

HEX WRENCH

Figure 3-1

USE 4mm

BASE PLATE

Steps

1. Swing the press guard open.

2. Verify that the applicator is correctly tooled for

the terminal being used. (Reference

specification sheets supplied with the

applicator).

3. Clean the press quick change mounting plate of

scrap or chips that may interfere with the

applicator installation.

4. Using a 4mm hex wrench, turn the M5 SHCS

clockwise until the locking clamp is fully opened.

5. Locate the applicator lug bolt in the press yoke.

See Figure 3-1.

6. Align the applicator base plate slots with the

locator clamps on the press quick change plate.

7. To lock applicator, turn M5 SHCS counter

clockwise until tight.

8. Confirm that the applicator is secured properly.

ENGAGE

PRESS YOKE

LUG BOLT

3.2 Air Feed Applicator Installation

Power down the press by turning off the “POWER”

switch, located on the control panel.

Note: Once the press guard is open the guard

interlock switch will disconnect power to the motor.

Warning: When using air feed applicators, always

use the slide valve supplied to shut-off and vent air

pressure to the air feed before servicing. The guard

interlock switch DOES NOT remove air pressure. If

an air feed is jammed and air pressure is not

removed before servicing, the feed could move

unexpectedly and cause injury.

SHUT-OFF

SLEEVE

SLIDE LEFT TO

SHUT OFF

TO MAIN

AIR SUPPLY

Figure 3-2

Steps

1. Swing the press guard open.

2. Verify that the applicator is correctly tooled for the

terminal being used. (Reference specification

sheets supplied with the applicator).

3. Clean the press quick change mounting plate of

scrap or chips that may interfere with the

applicator installation.

4. Using a 4mm hex wrench, turn the M5 SHCS

clockwise until the locking clamp is fully opened.

5. Locate the applicator lug bolt in the press yoke.

See Figure 3-1.

6. Align the applicator base plate slots with the

locator clamps on the press quick change

mounting plate.

FILTER-REG-LUBRICATOR

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 12 of 47

Revision: D Revision Date: 12-0-02-09

Page 13

TM-3000 and TM-4000 Universal Press

7. To lock applicator, turn M5 SHCS counter

clockwise until tight.

8. Confirm that the applicator is secured properly.

9. Disconnect the air supply from the filter-regulatorlubricator supplied with the press, by sliding the

shutoff valve sleeve to the left, as shown in Figure

3-2. Remove the plugs from the fittings on the air

valve. Do not discard the plugs; when the air

applicator is not being used, the fittings should be

plugged.

FILTER-REG. LUBRICATOR

RETRACTS

TO MAIN

AIR SUPPLY

PORT ”A”

Figure 3-3

PORT ”B”

ADVANCES

APPLICATOR

Note: When not using an air feed applicator always

shutoff the air supply to the filter-regulator-lubricator

by sliding the shutoff valve sleeve to the left, the

opposite direction of the airflow, as shown in Figure

3-2.

Note: Some applicators feed terminals in the

retracted position, for those air tubes must be

reversed. In addition, some applicators are air

advance and spring return, on these applicators one

port will need to be plugged.

10. Insert the “A” port of the air valve with the tube

that retracts the feed mechanism of the applicator.

See Figure 3-3.

11. Insert the “B” port of the air valve with the tube

that advances the feed mechanism of the

applicator. See Figure 3-3.

Note: When using the 64016-2000 Crimp Module, set

the feed selector on the control panel to “SINGLE” or

AIR-FEED

“DOUBLE”, depending on the spacing of the taped

terminals. See Figure 3-5.

12. Connect the main air supply to the filter reglubricator. (Custumer supplied fitting)

13. Adjust the regulator to 75-80 PSI (366-390

kN/cm2).

14. Check that the tubing for the applicator is properly

connected by dry cycling the press and observing

the feed motion.

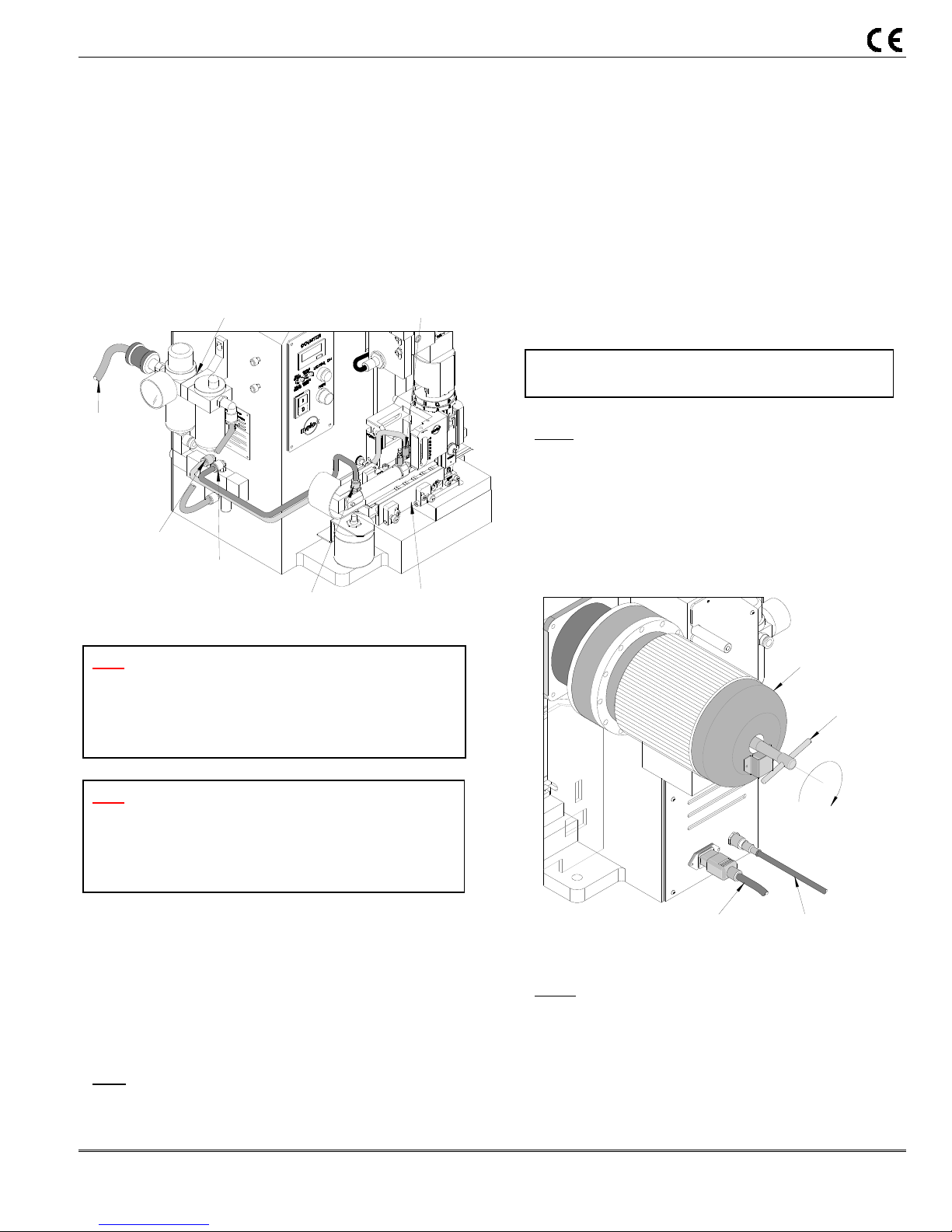

3.3. Manually Cycling the Press

Turn off the “POWER” switch which is located on

the control panel to power down the press.

Note: Once the press guard is open the guard

interlock switch will disconnect power to the motor.

Hand cycling the press is necessary to confirm

correct tool alignment and terminal feed

adjustment. It also gives the setup person the

ability to step through the press cycle manually.

Figure 3-4

POWER CORD

Steps

1. Insert the 8mm square socket T-handle wrench

through the access hole in the center of the rear

cover on the motor and locate it in the shaft motor.

See Figure 3-4.

MOTOR

T-HANDLE

WRENCH

TURN

CLOCKWISE

FOOT SWITCH

CORD

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 13 of 47

Revision: D Revision Date: 12-0-02-09

Page 14

TM-3000 and TM-4000 Universal Press

2. Rotate the wrench clockwise. This turns the motor

and moves the ram down and up.

3. Always return the press back to top dead center

insuring that the ram is in the start up position.

4. Remove the T-handle wrench.

NOTE: When the T-handle is put into the motor

shaft the motor turns off automatically.

3.4. Operation

3.4.1 Full Cycle Operation

CAUTION: Make sure the press guard is in position

and all setup procedures are followed. Follow the

safety and work area instructions.

Steps:

1. Push the toggle switch on the control panel to “Full

Cycle”. See Figure 3-5.

TOGGLE

SWITCH

TO FULL

CYCLE

POWER

ON

Figure 3-5

2. Turn the “Power “ switch on, the power indicator light

will light up.

3. Press the “Motor On” push button, the motor

indicator light will light up. After a 5 second delay

the press will be ready to cycle.

4. Place the prestripped wire through the slot in the

press guard and push until it contacts the wire stop.

See Figure 3-6.

FEED

SELECTOR

PUSH

MOTOR ON

5. Press the foot pedal down once. Use a sweeping

motion to the right with the crimped wire and

remove.

6. Check the crimped wire and confirm that it meets the

applicator specifications and visual inspection.

7. Repeat steps 4 and 5 for the next crimp.

GUARD

PRE-STRIPPED

Figure 3-6

WIRE

WIRE

STOP

3.4.2 Split Cycle Operation

Desription:

The split cycle is used mostly for closed barrel

terminals. This makes it easier to locate the terminal

before crimping the wire. The punch/ram will close

partially to assist in locating the terminal for the

termination. Then the wire can be placed into the

terminal and be terminated. To setup the machine

for split cycle push the toggle switch on the control

panel to “Split Cycle”. See Figure 3-5.

Steps:

1. Depress the foot switch once, the ram will lower

partially, positioning the terminal for termination.

2. Place the prestripped wire into the terminal.

3. Depress the foot switch a second time. The ram will

complete its downward stroke and return to the top

position to complete the cycle of terminating the

crimp.

CAUTION: Make sure the press guard is in position

and all setup procedures are followed. Follow the

safety and work area instructions.

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 14 of 47

Revision: D Revision Date: 12-0-02-09

Page 15

TM-3000 and TM-4000 Universal Press

Split Cycle Ram Adjustment

When setting up an applicator for split cycle operation it

may be necessary to adjust the ram for a partially closed

position (1st position), so the terminal will be captivated

in the punch and not terminated. For adjustment, the

prox sensor located on the left side of the ram cover,

needs to be adjusted. See the following steps:

Steps:

1. Depress the foot switch once, with the terminals in

the applicator. See where the punch is located in

the 1st position of the cycle.

2. If the punch is too high and does not center the

terminal so that the prestripped wire can be inserted

in the closed barrel or the punch is too low partially

crimping the terminal, the prox sensor needs to be

adjusted.

3. Open the press guard.

4. Loosen the two M12 jam nuts on the split cycle prox,

located on both sides of the prox bracket. Then

loosen the M4 jam nut holding the M4 X 25 SHCS.

Turn the screw clockwise to raise the prox or

counter-clockwise to lower the prox. See Figure 3-7.

Raise the prox if the punch is partially crimping the

terminal; or lower the prox if the ram is not closing

far enough and not centering the terminal punch.

M12 JAM NUT

PROX BRACKET

M4 JAM NUT

PROX SENSOR

1.52mm

(.06”)

MAX. GAP

TOGGLE SWITCH

TO SPLIT CYCLE

Figure 3-7

5. Retighten the M4 SHCS and the (2)M12 jam nuts

positioning the prox for the 1st position of the split

cycle. See Figure 3-7.

6. Close the press guard.

7. Repeat step 1 to check for the correct position of the

ram. (Be sure Ram is at Top-Dead-Center first.)

Note: The gap between the prox and the ram

should be 1.52mm (.06”) Max. See Figure 3-7.

CAUTION: Always return the ram to the top dead

center position or start position of the cycle before

recycling the press. This is done by manually

cycling the press. See section 3.3.

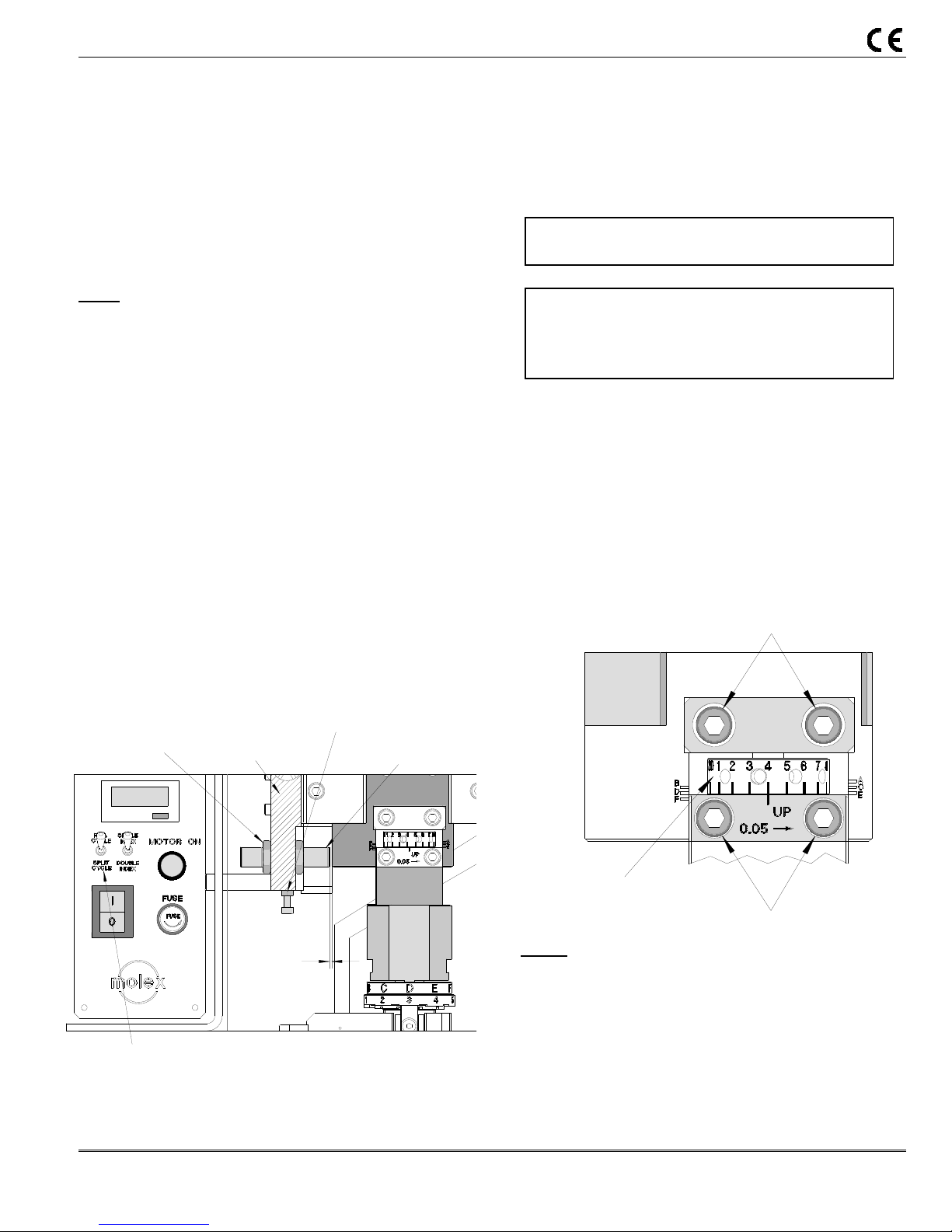

3.4.3 Crimp Adjustment

See Section 2.6.1 for Industry standard shut height.

Crimp Adjustment Full and Split Cycle

If crimp adjustment is required and cannot be made by

the cam adjustment on the applicator, the fine

adjustment dial on the press ram can be adjusted by

following the steps below.

LOOSEN M6 SHCS

ADJUSTABLE DIAL

Figure 3-8

LOOSEN M6 SHCS

Steps:

1. Open the press guard.

2. Loosen the four M6 SHCSs on the front of the press.

3. Rotate the adjustment dial to the right to raise crimp

height or to the left to decrease. Dial indicator lines

represent increments of .05mm (.002”). See Figure

3-8.

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 15 of 47

Revision: D Revision Date: 12-0-02-09

Page 16

TM-3000 and TM-4000 Universal Press

4. When adjustment is complete, retighten the four M6

SHCSs.

5. Close the guard.

6. Place a prestripped wire into the terminal and

terminate under power. Examine the quality of the

crimp.

7. Repeat steps 1 thru 6 if the desired crimp is not

achieved.

Use caution adjusting the ram downward. Over

adjustment in this direction may cause tooling

damage or breakage.

Always return the adjustment to the factory setting

before installing another applicator, or recalibrating

shut height. See Section 2.6.1.

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 16 of 47

Revision: D Revision Date: 12-0-02-09

Page 17

Molex Taped Terminal Crimp Module

4.1 Maintenance

4.2 Oiler

4.3 Troubleshooting

Section 4

Order No: ATS-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 17 of 47

Revision: B Revision Date: 10-06-08

Page 18

TM-3000 and TM-4000 Universal Press

4.1 Maintenance

Power down the press by pressing the power button to off “O” located on the control panel.

For efficient operation the press should be cleaned daily with a soft

bristle brush to remove any carrier strip debris and terminal plating dust

from the tooling area.

Maintenance Schedule

The following is offered as a general guideline for maintenance. Tool

life can be increased with good maintenance practices or decrease with

lack of maintenance.

Item

Air Filter 100,000 Weekly

Air

Lubricator

Ram 25,000 Daily

Main Bearing 25,000 Daily

Cleaning 25,000 Daily

Frequency

Cycles

100,000 Weekly

Frequency

Time

Materials

Clean bowl and sintered

filter with denatured alcohol

SAE 10W oil. Check and

refill if used

SAE 10W oil

Oil Cup (Top of ram)

Grease fitting right side of

Press bearing lube

Use soft bristle brush on

Applicator mounting plate

4.2. Oiler

LID

Description

The wick action oiler is included with the press. The oiler

applies a thin coat of lubricant to the terminals, which

TUBE

helps with feeding and better release from termination

punches. The oiler is primarily used for terminals with

gold plating. To avoid contamination when shipped and

WICK

(PKG OF 25

#638900727)

during setup, the oiler is shipped from the factory with no

lubricant oil. The oiler should only be used on

applicators that require lubrication for smooth troublefree operation.

Oiler Position

Adjust the position of the oiler unit using the mounting screw that attaches the oiler to the quick change mounting

plate. Simply loosen the screw, slide the unit to the desired position, and tighten the screw. The unit can be removed

and placed on the rear side of the quick change mounting plate for rear-feed applications.

OIL CUP

Figure 4-8

Figure 4-9 OILER ASSEMBLY

GREASE FITTING

(OIL RESERVOIR)

MOUNTING

BRACKET

JAR

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 18 of 47

Revision: D Revision Date: 12-0-02-09

Page 19

TM-3000 and TM-4000 Universal Press

Oiler Wick

Adjust the height of the oiler wick by pulling up or pushing down on the wick to the appropriate height. The wick can

be moved using pliers or simply grab it with your fingers.

Filling the Reservoir

While firmly holding the lid, screw the jar (oil reservoir) counter clockwise until it is removed. Fill the jar with the

desired lubricant oil and replace the lid.

Replacing the Wick

While firmly holding the lid, screw the jar oil reservoir) counter clockwise until it is removed. Feed a new wick up into

the tube until it protrudes from the top end of the tube and replace the lid.

Package of 25 Wicks:

Molex Order No: 63890-0727

Lubricant Oil

Recommended oil: Transdraw B-19

Vendor: Sure Lubricants Inc.

356 South Lively Boulevard

Elk Grove Village, IL 60007-2010

Phone: 888-787-3582

Fax: 847-956-6655

E-mail: surelub@aol.com

4.3 Troubleshooting

Symptom Cause Solution

Power/Power cord failure Check supply

Loose connection Refer to control schematic

Guard interlock switch disengaged Re-Install guard

Fuse blown Replace

Motor will not run

Press will not cycle

Press partially cycles Toggle switch set to split cycle Reset the toggle switch to full cycle

On/Off switch failure Replace

Motor failure Replace

T-wrench not removed from motor Removed T-wrench from motor

Control PCB not working Replace

Solid state relay not working Replace

Control board for motor Repair or replace

Guard interlock switch disengaged Re-Install guard

Faulty footswitch Check Connection. Repair or replace

Control PCB not working Replace

Fuse blown Replace

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 19 of 47

Revision: D Revision Date: 12-0-02-09

Page 20

TM-3000 and TM-4000 Universal Press

5.1 Parts List

5.2 Assembly Drawings

5.3 Electrical and Pnuematic Schematics

Section 5

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 20 of 47

Revision: D Revision Date: 12-0-02-09

Page 21

TM-3000 and TM-4000 Universal Press

5.1. Parts List

Item No. Order No. Ref. No. Description Quantity

1 63801-7200 FE-2TC (110VAC)

2 63801-7300 FE-2TC (220VAC)

3 63801-7201

4 63801-7202

5 63801-7203

6 63801-7204

7 63801-7205

8 63801-7206

9 63801-7207

10 63801-7208

11 63801-7209

12 63801-7210

13 63801-7211

14 63801-7212

15 63801-7213

16 63801-7214

17 63801-7215

18 63801-7216

19 63801-7217

20 63801-7218

21 63801-7219 A007-NA6911 Front Bearing 1

22 64016-2501

23 64016-2502

24 64016-2503

25 63801-7281

26 63801-7222

27 63801-7283

28 63801-7224

29 63801-7284

30 63801-7285

31 63801-7286

32 63801-7287

33 63801-7288

34 63801-7631

35 63801-7232

36 63801-7233

37 63801-7234

38 63801-7235

39 63801-7236

40 63700-3845

41 63801-7237

42 63801-7238

43 63801-7239

44 63801-7240

45 63801-7241

46 63801-7242

47 63801-7243

48 63801-7244

49 63801-7245

A021-R80 Shaft E-Ring 1

TM-3000 Main Assembly (Figure 5-1 and 5-2)

Universal Press (110VAC) See Notes Below

Universal Press (220VAC) See Notes Below

A01 Press Frame 1

A02 Ram 1

A03 Follower 1

A04 Front Cap 1

A05 Press Face Plate 1

A06 Switch-TDC 1

F05 Flag Pickup 1

A08 Access Cover 1

F17 Oil Fill Cap 1

A10 Flag-Position 1

(M) B01 Split Cycle Prox 1

(M) B03 Guard Handle 1

B02 Yoke Adapter 1

B03 Mounting Block Cover 1

B04 Mounting Block 1

(M) A01 Press Yoke 1

B01 Press Shaft 1

--- Guard Slide 2

--- Guard Front 1

--- Front Guard Insert 1

(M) Rear Guard 1

(M) A02 Quick Change Plate 1

(M) Side Guard 1

(M) Name Plate (Universal Press) 1

(M) Hinge Mounting Bracket 1

(M) Guard Hinge 2

(M) A06 Guard Sensor Bracket 1

(M) Guard Bracket 1

(M) Stand-off, Guard Side 3

--- Control Panel 1

F12 Eye Bolt 1

C04 Stand off 2

C01 Terminal Guide 1

C03 Guide 2

C02 Terminal Guide Bracket 1

(M) Rotor Magnet 1

F06 Press Lamp 1

E05 Lamp Mounting Bracket 1

(M) B02 Guard Switch Prox 1

(M) Oiler Assembly (Figure 5-3) 1

F07A

F07B

(M) A03 Alignment Block 2

(M) A04 Locking Clamp 1

(M) A05 Clamp Retainer 1

∗∗∗∗Bulb-110 VAC

∗∗∗∗∗∗∗∗Bulb-220 VAC

1

1

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 21 of 47

Revision: D Revision Date: 12-0-02-09

Page 22

TM-3000 and TM-4000 Universal Press

Item No. Order No. Ref. No. Description Quantity

50 63801-7246

51 63801-7247 A007-A6909ZZ Rear Bearing 2

52

53 63801-7249

54 63801-7250

55 63801-7251

56 63801-7252

57 63801-7253

58 63801-7254

59 63801-7256

60 63801-7257

61 63801-7258

62 63801-7259

63 63801-7260

64 63801-7261

65 63801-7262

66 63801-7263

67 63801-7269

68 63801-7270

69 63801-7271

70 69018-6237

71 62500-1774

72 63801-7272

73 63801-7273

74 63801-7274

75 63801-7275

76 63801-7276

77 63801-7277

78 63801-7278

79 63801-7279

80 63801-7600

63801-7248

63801-7648

A021-R68 E-Ring 2

A021-S45 Small E-Ring 1

Note:

1. For TM-3000 Press 220VAC use assembly no. 63801-7300.

2. For TM-4000 Press (220VAC only) use assembly no. 63801-7600.

3. All parts for both 63801-7200 and 63801-7300 Presses unless otherwise specified.

4. ∗∗∗∗ Indicates parts for 63801-7200 (110VAC) Press only.

5. ∗∗∗∗ ∗∗∗∗ Indicates parts for 63801-7300 (220VAC) Press only.

6. ∗∗∗∗ ∗∗∗∗∗∗∗∗ Indicates parts for 63801-7600 (220VAC) Press only.

TM-3000 Main Assembly (Figure 5-1 and 5-2)

(M) F01 Motor with Gear Reducer 1

(M) F01

F02

F02A

F03 Relay - Motor On 1

F04 Transformer (18V) 1

(M) E04 PCB-Machine 1

E03 Sensor Flag -Motor 1

F08 Motor Shutoff Prox 1

E02 Prox Motor Shutoff Bracket 1

A09 Rear Cover 1

D01 Reel Support 1

D02 Reel Boss 2

D03 Reel Disc 2

D04 Reel-Spring 1

(M) Filter-Regulator-Lubricator 1

(M) Air Valve-3 Way 1

(M) Foot switch with cord 1

---

--(M) Slide Valve 1

(M) Label (Lightning Bolt) 1-1/2” Triangle 1

(M) Label (Eye-Glasses) 1

(M) Label (Caution) 2

(M) Plug (1/4” Tube) 2

(M) Elbow Male (1/4” Tube) for Filter-Reg.-Lubricator

(M) Elbow Male (1/4” Tube) for 3-Way Valve 3

(M) Terminal Guide Standoff 4

--- Universal Press (220VAC) See Notes Below

∗∗∗∗∗∗∗∗∗∗∗∗ Motor with Gear Reducer

∗∗∗∗ Motor Controller 110VAC

∗∗∗∗∗∗∗∗ Motor Controller 220 VAC

∗∗∗∗ Power Cord (110VAC) 20 AMP

∗∗∗∗∗∗∗∗ Power Cord (220VAC) 10 AMP

1

1

1

1

1

1

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 22 of 47

Revision: D Revision Date: 12-0-02-09

Page 23

TM-3000 and TM-4000 Universal Press

27

5.2. Assembly

35

(3)

43

(2)

72

67

44

68

77

28

76

78

75

33

(3)

13

25

34

31

M12

JAM NUT (2)

(REF)

29

26

40

79

Figure 5-1

(4)

32

24

30

(2)

22

23

74

14

(2)

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 23 of 47

Revision: D Revision Date: 12-0-02-09

Page 24

TM-3000 and TM-4000 Universal Press

5.2 Assembly (Continued)

(2)

4

5

47

56

110V

220V

110V

220V

11

7

6

16

26

48

15

17

18

49

41

45

46

42

29

REF

54

55

64

20

12

(2)

10

58

(2)

19

8

57

65

21

Figure 5-2

66

73

63

70

71

37

110V

220V

53

59

38

(2)

52

60

61

69

36

(2)

39

3

51

9

(2)

(2)

50

62

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 24 of 47

Revision: D Revision Date: 12-0-02-09

Page 25

TM-3000 and TM-4000 Universal Press

Assembly (continued)

Item No. Description Quantity

3

6

5

3

2

1

4

Figure 5-3

Oiler Assembly

Item No. 43 (63801-7240)

1 Oiler Wick 1

2 Oiler Lamp Tube 1

3 Oiler Lamp Tube Nut 2

4 Wide Mouth Glass Jar 1

5 Oiler Glass Jar Lid 1

6 Oiler Bracket 1

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 25 of 47

Revision: D Revision Date: 12-0-02-09

Page 26

TM-3000 and TM-4000 Universal Press

5.3. Electrical Schematic

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 26 of 47

Revision: D Revision Date: 12-0-02-09

Page 27

TM-3000 and TM-4000 Universal Press

5.3. Pnuematic Schematic

Americas Headquarters

Lisle, Illinois 60532 U.S.A.

1-800-78MOLEX

amerinfo@molex.com

Far East North Headquarters

Yamato, Kanagawa, Japan

81-462-65-2324

feninfo@molex.com

Figure 5-5

Far East South Headquarters

Jurong, Singapore

65-6-268-6868

fesinfo@molex.com

Visit our Web site at http://www.molex.com

European Headquarters

Munich, Germany

49-89-413092-0

eurinfo@molex.com

Corporate Headquarters

2222 Wellington Ct.

Lisle, IL 60532 U.S.A.

630-969-4550

Fax: 630-969-1352

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 27 of 47

Revision: D Revision Date: 12-0-02-09

Page 28

TM-3000 and TM-4000 Universal Press

6.1 EC Declaration of Conformity

Section 6

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 28 of 47

Revision: D Revision Date: 12-0-02-09

Page 29

TM-3000 and TM-4000 Universal Press

6.1 EC Declaration of Conformity

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 29 of 47

Revision: D Revision Date: 12-0-02-09

Page 30

TM-3000 and TM-4000 Universal Press

For more information use the Quality Crimping Handbook

And Industrial Crimping Handbook

There is no charge for these books, they can be found on the Molex Website (www.molex.com) or contact you

local Molex sales engineer

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 30 of 47

Revision: D Revision Date: 12-0-02-09

Page 31

TM-3000 and TM-4000 Universal Press

1. Taped Terminal Crimp Module

APPENDIX A

OPTIONS

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 31 of 47

Revision: D Revision Date: 12-0-02-09

Page 32

TM-3000 and TM-4000 Universal Press

TAPED TERMINAL CRIMP MODULE

Description

Operation

Maintenance

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 32 of 47

Revision: D Revision Date: 12-0-02-09

Order Number 64016-2000

Instruction Manual

Page 33

TM-3000 and TM-4000 Universal Press

WARNING

NEVER USE THIS CRIMP MODULE IN A PRESS WITHOUT GUARDS OR SAFETY DEVICES THAT ARE

INTENDED TO PREVENT HANDS FROM REMAINING IN THE DIE SPACE.

NEVER OPERATE, SERVICE, INSTALL, OR ADJUST THIS CRIMP MODULE WITHOUT PROPER

INSTRUCTION AND WITHOUT FIRST READING AND UNDERSTANDING THE INSTRUCTIONS IN

THIS MANUAL AND ALL APPLICABLE PRESS MANUALS.

NEVER INSTALL OR SERVICE THIS CRIMP MODULE WHILE CONNECTED TO ANY ELECTRICAL

POWER SOURCE. DISCONNECT POWER BY UNPLUGGING THE PRESS FROM ITS POWER

SOURCE.

CAUTION THE MOLEX CRIMP MODULE IS DESIGNED TO OPERATE ONLY IN THE MOLEX TM-3000 OR

TM-4000 PRESSES. INSTALLATION IN OTHER CRIMP PRESSES CAN CAUSE SEVERE TOOL

DAMAGE. IT IS ADVISABLE THAT BEFORE INSTALLATION, A CHECK OF THE PRESS SHUT

HEIGHT BE PERFORMED. MOLEX WILL NOT BE LIABLE FOR ANY DAMAGES AS A RESULT

OF INSTALLATION IN A PRESS WITH AN IMPROPERLY SET SHUT HEIGHT.

CAUTION MOLEX CRIMP SPECIFICATIONS ARE VALID ONLY WHEN USED WITH MOLEX TERMINALS

AND MOLEX APPLICATION TOOLING.

WORK SAFELY AT ALL TIMES

For Service, Contact Your

Local Molex Sales Office

Molex Application Tooling Group

2200 Wellington Court

Lisle, IL 60532

Tel: (630) 969-4550

Fax: (630) 505-0049

Visit our Web site at http://www.molex.com

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 33 of 47

Revision: D Revision Date: 12-0-02-09

Page 34

TM-3000 and TM-4000 Universal Press

Table of Contents

SECTION

1 General Description

2 Setup, Adjustments, and Operation

3 Maintenance

4 Parts List, Assembly Drawings, Troubleshooting, and Guard upgrade

APPENDIX

A Pull Force Testing

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 34 of 47

Revision: D Revision Date: 12-0-02-09

Page 35

TM-3000 and TM-4000 Universal Press

1.1 Description

1.2 Features

1.3 Technical Specifications

1.4 Delivery Check

1.5 Tools

1.6 Specification Sheets

Section 1

General Description

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 35 of 47

Revision: D Revision Date: 12-0-02-09

Page 36

TM-3000 and TM-4000 Universal Press

AND P

RESS YOKE

Principal Mechanical Parts of the Taped Terminal Crimp Module

PRESS YOKE

PUNCH HOLDER

ATP-301

CARRYING

HANDLE

TAPE GUIDE

COVER

Figure 1-1

RAM

WIRE STOP/

STRIPPER UNIT

ANVIL MOUNT

STORAGE FOR

PUNCH HOLDER

FEED

CYLINDER

STORAGE

FOR

WIRE STOP/

STRIPPER

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 36 of 47

Revision: D Revision Date: 12-0-02-09

Page 37

TM-3000 and TM-4000 Universal Press

General Description

Description

The taped terminal crimp module provides an

effective method of applying a wide range of

side feed tape-mounted terminals to prestripped discrete wire(s) from 4 to 30 AWG.

The crimp module and press combination

replaces the Molex ATP-301 Press (19228-

0030) and the Molex ATP-201 Press (19047-

0001).

This crimp module operates only in the Molex

TM-3000 and TM-4000 Universal Presses. The

crimp module uses quick-change modular

tooling, requires little or no adjustments, and is

intended for mid-volume to high-volume, semiautomatic operations.

Molex offers the following crimp presses for

operating the crimp module:

TM-3000 Universal Press 120V 50-60 Hz.

63801-7200

TM-3000 Universal Press 240V 50-60 Hz.

63801-7300

The TM-3000 should be used for 10-30

AWG terminals.

TM-4000 Universal Press 240V 50-60 Hz.

63801-7600

The TM-4000 should be used for 4-30 AWG

terminals.

General Features

Independent adjustment of insulation crimp height.

Tooling is accessed from the front of the module,

simplifying change over.

No track adjustment is required.

Compatible with the Molex TM-3000 and TM-4000

Universal Presses only. It does NOT fit into

Molex TM-40, TM-42, or TM-2000 presses.

No terminal feed adjustment is required.

Uses crimp tooling from existing Molex ATP-201 and

ATP-301 crimp presses.

Technical Specification

Dimensions

Crimp Module Only

Width: 140mm (5.5")

Depth: 136mm (5.3")

Height: 175mm (6.9")

(ram down)

Weight 4.1kg (9lb)

Guarding

The crimp module is intended to be used with

the guards supplied on the TM-3000 or TM4000 Universal Press.

A special retrofit guard kit is available when the

crimp module is installed on earlier TM-3000

press models. See Section 4.3.

Caution: DO NOT operate the crimp

module without press guards in place.

Delivery Check

Carefully remove the crimp module from its

shipping container and determine that the

following items are included in the package.

Crimp Module 1

Air line Kit 1

Press Guard Kit (if required) 1

Instruction Manual 1

NOTE: Terminal crimp tooling is not included with

the crimp module and must be ordered separately.

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 37 of 47

Revision: D Revision Date: 12-0-02-09

Page 38

TM-3000 and TM-4000 Universal Press

Tools

The following tools are recommended for setup

and adjustments to the crimp module:

1. Metric standard hex wrench set

2. Inch standard hex wrench set

3. Wire stripper / cutter

4. Crimp Micrometer or caliper

Specification Sheets

Specification sheets are available for all crimp

tooling. The specification sheet contains the

following:

Applicable terminal numbers

Wire AWG ranges

Insulation diameter ranges

Pull Force specification

Strip lengths

Slug height specification

Tooling parts lists and assembly drawings

The specification sheet is available on the Molex

website (www.molex.com).

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 38 of 47

Revision: D Revision Date: 12-0-02-09

Page 39

TM-3000 and TM-4000 Universal Press

Set-Up and Operation

2.1 Shut Height

2.2 Setup

2.3 Crimp Height Adjustments

2.4 Crimp Tooling Installation and Removal

2.5 Specific Crimp Module Adjustments

2.6 Operation

Section 2

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 39 of 47

Revision: D Revision Date: 12-0-02-09

Page 40

TM-3000 and TM-4000 Universal Press

Figure 2

-2

Read the following instructions before

attempting to operate the crimp module.

2.1. Shut Height

The Molex Taped Terminal Crimp Module operates only in

the TM-3000 and TM-4000 presses with standard shut

height of 135.80mm (5.346"). Installation in crimp presses

with other than standard shut heights can cause severe

tool damage. Before installing the crimp module, the

press shut height must be verified. The correct shut

height is required for proper crimping without causing tool

damage.

The shut height of the TM-3000 and the TM-4000 presses

are preset at the factory and labeled on the front of the

press. Over time, however, the press may wear causing a

change in the shut height.

The shut height of the press can be checked with a shut

height gauge, which is calibrated under load to achieve

the 135.80mm (5.346") measurement. It is recommended

that the shut height be checked monthly. A shut height

gauge is available from most press manufacturers.

PRESS

SHUT HEIGHT GAUGE

Measuring Press Shut Height

1. Disconnect the power supply from the press. Remove

the machine guards if necessary.

PRESS QUICK CHANGE

MOUNTING PLATE

Figure 2-1

2. Remove the applicator from the press. Make sure

that the bottom of the press ram and quick change

mounting plate are free of foreign material.

3. Place the shut height gauge into the press on the

press quick change mounting plate. See Figure 2-

1.

4. Manually cycle the press to the full down stroke

position. (See the TM-3000 press instructions on

manually cycling the press.)

5. Read the shut height measurement from the front

of the gauge. Follow gauge manufacturer’s

instructions; usually the gauge reads “0” at the

correct shut height.

6. If shut height adjustment is necessary:

LOOSEN M6 SHCS

ADJUSTABLE DIAL

LOOSEN M6 SHCS

a. Loosen the four M6 SHCS on the front of the

press.

b. Rotate the adjustment dial to the right to raise

shut height or to the left to decrease. Dial

indicator lines represent increments of .05mm

(.002”). See Figure 2-2.

c. When adjustment is complete, retighten the four

M6 SHCS.

7. Repeat the above steps until the correct shut height

is obtained.

8. Shut height gauges must be calibrated on a regular

basis.

2.2. Set-Up

The principal mechanical parts of the crimp module are

illustrated in the assembly drawings (Section 4-1).

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 40 of 47

Revision: D Revision Date: 12-0-02-09

Page 41

TM-3000 and TM-4000 Universal Press

Crimp Module Installation and Removal

1. Turn off the press and disconnect the power. Open

the press guard.

2. Clean the quick-change mounting plate of scrap or

chips that may interfere with the crimp module

installation.

3. Using a 3mm hex wrench, loosen the set screw

holding the press yoke. Pull the press yoke straight

down and remove it from the press. (Note: a storage

hole is provided on right side of the crimp module

frame to keep the press yoke)

4. Install the press yoke furnished with the crimp module

in the press ram. Tighten the set screw securely.

5. Using a 4mm hex wrench, turn the M5 SHCS

clockwise until the locking clamp is fully opened.

6. Visually align the crimp module’s base plate slots with

the location clamps on the press quick-change

mounting plate.

PRESS YOKE

LOCATOR

CLAMPS

RAM

ADAPTER

QUICK

CHANGE

PLATE

LOCKING

CLAMP

Figure 2-2

M5

SHCS

BASE PLATE

7. Slide the crimp module onto the quick-change

mounting plate until the two notches on the left side

engage against the stops, and at the same time,

guide the ram adapter into the press yoke. See

Figure 2-2.

8. To lock the crimp module, turn the M5 SHCS

counterclockwise until tight.

9. Connect the air lines from the feed cylinder to the

press air valve. The cylinder port closest to the

module frame must be connected to the “normally

open” valve port. The other cylinder port (with the

flow control valve) must be connected to the

“normally closed” valve port.

10. Close the press guard.

11. Remove the crimp module by reversing the previous

steps. When storing the crimp module, always

leave a strip of terminals in the module on the anvils

to prevent damage to the tooling. See Section 3.5

Storage.

Punch and Anvil Alignments

Note: Always clean mounting surfaces of crimp tooling

and tooling holders prior to alignment.

1. Disconnect power from the press and open the

machine guard.

2. Using a 5/32” hex wrench, slightly loosen the anvil

mounting screw. See Figure 2-3.

3. Slowly hand-cycle the ram of the press to bottom of

its stroke. With the punches engaging the anvils,

securely tighten the anvil mounting screw to ensure

alignment of punches and anvils.

4. Hand cycle the press ram to its up position.

5. Close the machine guard and restore power to the

press.

ANVIL

LOOSEN THE

#10 SHCS

Figure 2-3

2.3. Crimp Height Adjustments

Conductor Crimp Height Adjustment

1. Obtain a piece of solder, approximately 40mm (1.5”)

long and approximately 0.5mm (.02”) larger in

diameter than the crimped slug height. If the solder

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 41 of 47

Revision: D Revision Date: 12-0-02-09

Page 42

TM-3000 and TM-4000 Universal Press

diameter is too large the crimped slug will have large

extrusions, making it difficult to measure the overall

slug height.

2. With no terminals in the applicator, lay the solder

across the anvils and cycle the press (by hand or

under power).

3. Using a crimp micrometer or dial caliper, measure the

solder slug height and compare to specification.

4. If adjustments are necessary, turn off the press and

open the machine guard.

5. The conductor crimp height is based on the conductor

punch contacting the conductor anvil. If the press shut

height was correctly set prior to crimp module

installation (see section 2.1) there should be no need

to adjust conductor crimp height. However, some of

the larger terminal crimps may cause minor press

frame deflection which can be compensated by

adjusting the press shut height. See section 2.1 for

shut height adjustment.

NOTE: Crimp height adjustments for closed-barrel

industrial terminals are always based on solder slug

heights, not terminal crimp heights.

1. Load the terminals, close the machine guard, and

crimp several wires under power.

2. Perform a pull test on the conductor crimp to verify

the mechanical integrity of the crimp. See Appendix

A-Pull Force Test.

Insulation Crimp Height

1. Place a stripped length of the appropriate wire into the

terminal and crimp under power.

2. Observe quality of insulation crimp.

3. If adjustments are necessary, turn off the press.

Open the machine guard.

4. Using a 5/32” hex wrench, loosen the #10 SHCS

holding the punches.

5. Rotate the insulation adjusting cam to achieve the

desired insulation height. There are three cam

positions (marked L, M, and S) for large, medium, and

small diameter wires. The cam must be in one of the

three positions; do not adjust it between positions.

See Figure 2-4.

6. While holding the punches up against the punch

holder, securely tighten the #10 SHCS.

7. Close the machine guards, restore power, and crimp

a wire under power. Inspect the insulation crimp and

make further adjustments if needed.

INSULATION CAM

LOOSEN THE

#10 SHCS

PUNCHES

Figure 2-4

Note: Due to the large variety of insulation wall

thickness, materials, and durometers, Molex does not

specify insulation crimp height.

2.4. Crimp Tooling Removal and Installation

Caution: Always disconnect power before installing or

removing tooling.

Removal and Installation of ATP-301 Style Punches

NOTE: Always clean mounting surfaces of crimp tooling

and tooling holders prior to installation.

PUNCH HOLDER

O-RING

PUNCHES

#10 SHCS

Figure 2-5

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 42 of 47

Revision: D Revision Date: 12-0-02-09

Page 43

TM-3000 and TM-4000 Universal Press

1. Disconnect power from the press. Open the machine

guard.

2. If the ram is down, move it manually to the full up

position.

3. To remove the punches, use a 5/32” hex wrench to

remove the #10 SHCS holding the punches to the

punch holder. See Figure 2-5.

4. Remove the screw, punches, and O-ring together.

Some tool kits may include a spacer plate (behind the

conductor punch).

5. To install, place the punches with the spacer (if used)

and O-ring against the punch holder and securely

tighten the #10 SHCS. The conductor punch (“E2”)

goes against the punch holder and the insulation

punch (“I2”) is stacked on the conductor punch. Make

sure the etched “E2” or “I2” on each punch faces

outward.

Note: The press should be hand-cycled after

installing punches to insure a free fit between punch

and anvil. If excessive resistance is felt, check for an

incorrectly installed punch and/or anvil misalignment.

Removal and Installation of ATP-301 Style Anvils

ANVIL MOUNT

O-RING

ANVILS

NOTE THE SIDE

PLATE POSITION

Figure 2-6

#10 SHCS

NOTE: Always clean mounting surfaces of crimp tooling

and tooling holders prior to installation.

1. Disconnect power from the press. Open the machine

guard.

2. If the ram is down, move it manually to the full up

position.

3. To remove the anvils, use a 5/32” hex wrench to

remove the #10 SHCS holding the anvils to the anvil

mount. See Figure 2-6.

4. Remove the screw, anvils, and O-ring together.

Some tool kits may include a spacer plate (behind

the conductor anvil).

5. To install, place the anvils with the spacer (if used)

and O-ring against the anvil mount, leaving the

mounting screw slightly loose. The conductor anvil

(“E1”) is installed first and the insulation anvil (“I1”)

is stacked onto it. Make sure the etched “E1” or

“I1”on each anvil face outward.

WARNING: Use the mounting screws that are

furnished with the ATP tool kit. The feed

mechanism may become damage when using

screws that are too long.

6. The side plates must be a close fit to the width of

the anvils. For the ATP-301 style anvils, the step on

the side plates must be toward the outside. If it is

not, loosen the M4 SHCS and reverse the side

plate.

7. The anvils must be aligned to the punches before

tightening the screws. See section 2.2 (Set Up;

Punch and Anvil Alignments).

Removal and Installation of ATP-201 Style Punches

RAM

SET SCREW

VISIBLE IN

THE HOLE

RAM IN THE

FULL UP

POSITION

ATP-201

PUNCH

Figure 2-7

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 43 of 47

Revision: D Revision Date: 12-0-02-09

Page 44

TM-3000 and TM-4000 Universal Press

1. Disconnect power from the press. Open the

machine guard.

2. If the ram is down, move it manually to the full up

position.

3. To remove the punch assembly, use a 3mm hex

wrench to loosen the set screw on the front of the

ram. This screw is accessible through the

module’s front cover. See Figure 2-7.

4. With the set screw loosened, pull the punch

assembly straight down.

5. To install the punch assembly, orient the

assembly so the flat on the round stub faces

forward. Put the stub into the hole in the bottom

of the ram and push the punch assembly up

against the bottom of the ram. See Figure 2-8.

RAM

FLAT FACE

OF THE ATP-201

PUNCH FACING

FORWARD

Figure 2-8

6. With the punch assembly in the ram, tighten the

set screw securely.

Note: The press should be hand-cycled after

installing the punch assembly to insure a free fit

between punch and anvil. If excessive resistance is

felt, check for an incorrectly installed punch and/or

anvil misalignment.

Removal and Installation of ATP-201 Style Anvils

NOTE: Always clean mounting surfaces of crimp tooling

and tooling holders prior to installation.

1. Disconnect power from the press. Open the

machine guard.

2. If the ram is down, move it manually to the full up

position.

3. To remove the anvils, use a 5/32” hex wrench to

remove the #10 SHCS holding the anvils to the anvil

mount. See Figure 2-9.

ANVIL MOUNT

O-RING

ANVIL

NOTE THE SIDE

PLATE POSITION

Figure 2-9

#10 SHCS

4. Remove the screw, anvil(s), and O-ring together.

5. To install, place the anvil(s) and O-ring against the

anvil mount, leaving the mounting screw slightly

loose. The conductor anvil (“E1”) is installed first

and the insulation anvil (“I1”) is stacked onto it.

Make sure the etched “E1” or “I1”on each anvil face

outward.

WARNING: Use the mounting screws that are

furnished with the ATP tool kit. Screws that are to

long may damage the feed mechanism.

6. The side plates must be a close fit to the width of

the anvils. For the ATP-201 style anvils, the step on

the side plates must be toward the inside. If it is

not, loosen the M4 SHCS and reverse the side

plate.

7. The anvils must be aligned to the punches before

tightening the screws. See section 2.2 (Set Up;

Punch and Anvil Alignments).

2.5. Crimp Module Adjustments

Terminal Feed Adjustments

The tape feed mechanism is a ratcheting wheel and has

no adjustable features.

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 44 of 47

Revision: D Revision Date: 12-0-02-09

Page 45

TM-3000 and TM-4000 Universal Press

Feed Speed Adjustments

Terminal feed speed is controlled by the flow control

valve on the feed cylinder. Loosen the locking ring, then

turn the adjustment knob clockwise (CW) to reduce the

feed speed or counterclockwise (CCW) to increase the

feed speed. See Figure 2-10.

Adjustments to the feed speed should be made

gradually.

When adjustment is complete, turn the locking ring until it

is finger-tight.

KNOB

LOCKING

RING

Figure 2-10

FEED

CYLINDER

Terminal Stripper Adjustment

ADJUST

M5 SHCS

M5 SHCS

Figure 2-11

ADJUST

Some terminals have a tendency to stick in the

conductor punch after being crimped. The terminal

stripper is used to shed the terminal away from the

retracting punches.

1. Disconnect power from the press. Open the

machine guard.

2. If the ram is down, move it manually to the full up

position.

3. To adjust the stripper in and out, use a 4mm hex

wrench to loosen the M5 SHCS on the side of the

stripper. Move the stripper toward the punches, but

not too close or it could interfere with the ram

stroke. See Figure 2-11. Tighten the M5 SHCS

when adjustment is complete.

4. To adjust the stripper up and down, use a 4mm hex

wrench to loosen the M5 SHCS on the front of the

stripper. Move the stripper down until it is just

above the taped terminal on the anvils. See Figure

2-11. Tighten the M5 SHCS when adjustment is

complete.

NOTE: If the stripper is adjusted down too far it may

interfere with the terminal feed motion.

Wire Stop Adjustment

The wire stop is used when the terminal being crimped

does not have an internal wire stop tab. Some larger

ring terminals fall into this category.

M5 SHCS

ADJUST

WIRE STOP

TERMINAL

Figure 2-12

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 45 of 47

Revision: D Revision Date: 12-0-02-09

Page 46

TM-3000 and TM-4000 Universal Press

ON ANVIL

1. Disconnect power from the press. Open the machine

guard.

2. If the ram is down, move it manually to the full up

position.

3. To adjust the wire stop, loosen the M5 SHCS on the

side of the stripper. Move the wire stop in or out until it

is near the end of the terminal barrel. See Figure 2-12.

Tighten the M5 SHCS when adjustment is complete.

NOTE: Since they are mounted to the same block,

adjustments to the wire stop will also influence the

terminal stripper. To achieve full adjustment of the wire

stop, the stripping tool may need to be removed from the

block.

2.6 Operation

Loading and Unloading Tape

1. Applicable terminals are listed on the Crimp Tooling

Specification Sheet. Do not crimp terminals that are

not listed on the Specification Sheet.

2. Disconnect power from the press. Open the machine

guard.

3. The tape will be easier to “start” in the track if the

corner of the tape is trimmed as shown in Figure 2-13.

4. Open the tape track cover by pulling out the spring-

loaded knob and lifting the cover up. A hole is

provided in the module frame for the knob’s pin to

enter to hold the track cover open. See Figure 2-14.

5. Load the taped terminal strip from the front of the

module, engaging the slots in the tape with the teeth

on the feed wheel. Make sure the terminal is also

centered above the crimp anvils. See Figure 2-15.

TRIM THE CORNER

OF THE TAPE

Figure 2-13

HOLE

TRACK COVER

LIFT KNOB UP

TRACK

COVER CLOSED

PULL KNOB OUT

Figure 2-14

6. Pull out the spring-loaded knob and lower the track

cover, allowing the pin to engage the lower hole.

7. Unloading the tape is the reverse process.

TAPE SLOT

TERMINAL

Figure 2-15

Tape De-Reeling Information

The tape reel should be mounted on the reel arm of

the press, with the printed side of the reel facing the

operator. The tape de-reels counterclockwise

(CCW).

To prevent tape feed jams, the tape should enter the

press guard below the bottom horizontal bar. If the

tape is threaded between the bars, a terminal may

become snagged on the bar during feeding. See

Figure 2-16.

TERMINAL

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 46 of 47

Revision: D Revision Date: 12-0-02-09

Page 47

TM-3000 and TM-4000 Universal Press

While operating the crimp module, the tape entering the press should not become taut. The operator should

occasionally turn the terminal reel to maintain a slack loop.

The scrap tape exits below the press guard.

Removal of Crimped Terminals from Tape

After being crimped, the tape feed will advance the terminal one position to the right. It is the operator’s

responsibility to remove the crimped terminal from the tape.

If crimped wires are allowed to accumulate on the tape they will eventually cause a tape feed jam.

To prevent tape damage, the terminal should be pulled off the tape towards the operator’s right. This sideways

action makes it easier for the terminal to break free from the adhesive holding it to the tape.

TAPE REEL

TAPE ENTERS

BELOW GUARD

TAPE EXIT

Figure 2-16

Order No: TM-638017299 Release Date: 06-06-05 UNCONTROLLED COPY Page 47 of 47

Revision: D Revision Date: 12-0-02-09

Loading...

Loading...