Page 1

Industrial Crimp Quality Handbook

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 1 of 27

Revision: C Revision Date: 12-23-09

INDUSTRIAL CRIMP QUALITY

HANDBOOK

Order No. 64016-0065

Page 2

Industrial Crimp Quality Handbook

1 Introduction to Crimp Technology

2 Purpose and Scope

3 Definitions and Terms

4 Associated Materials

5 Terminal Description

5.1. Features of Solderless Terminals

5.2. Barrel Serration/Dimples

5.3. Barrel Styles

5.4. Splices

6 Procedures

6.1. Preparing the Wire

6.2. Setup and Operation of a Press

6.3. Setup and Operation of a Hand Crimp Tool

6.4. Setup and Operation of a Air Powered Crimp Tool

6.5. Crimping Dies

7 Quality Crimps

7.1. Visual Inspection of OPEN BARREL Crimps

7.2. Visual Inspection of CLOSED BARREL Crimp

8 Importance of Proper Crimping

8.1. Conditions

8.2. Testing

8.3. Final Tensile Value

8.4. Electrical Resistance

8.5. Crimp joints

9 Miscellaneous

Table of Contents

SECTION

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 2 of 27

Revision: C Revision Date: 12-23-09

Page 3

Industrial Crimp Quality Handbook

SECTION 1

INTRODUCTION TO CRIMP TECHNOLOGY

Developed to replace the need to solder terminations, crimping technology provides a high quality connection

between a terminal and a wire at a relatively low applied cost. The methods for applying crimp terminations depend

on the application, volume, and range from hand-held devices to fully automated systems.

The application methods include a basic hand tool, a press and die set, a stripper crimper, or a fully automatic wire

processing system. However, no matter what method is used, the setup of each tool is critical for achieving a

quality crimp.

Today, many OEM companies are using Statistical Process Control (SPC) to continuously improve their crimp

terminations. Crimp termination is a complex process and to ensure consistent quality it is necessary to understand

the variability and inter-relational interactions that the technology involves.

Without a thorough understanding of the crimping process, and all the factors that can affect it, the result may not

meet expectations. The three key elements in the crimping process are the terminal, the wire, and the tooling.

Terminal

For most applications, it is not economically practical for connector manufacturers to design a terminal to accept

one wire size, one wire stranding, and one insulation diameter (UL type) as well as Mil Specification. Most

terminals accommodate many wire sizes, stranding, and a range of insulation diameters, and the terminals are

designed to meet acceptable levels over this entire range.

Wire

The wire stranding and insulation type can vary widely within one wire size. For example, there is more than 18%

more material in an 18 AWG by 19-strand wire than an 18 AWG by 16-strand wire. The insulation diameter of an

18 AWG wire can range from 1.78mm (.070") to over 4.57mm (.180"). Wire strands can be copper, tinned, over

coated, or top coated. Wire insulation materials, thickness, and durometers vary from application to application.

Tooling

What type of tooling does the application require? Does the application require hand stripping of the wire or does

the volume dictate an automatic wire-stripping machine? Does the application and volume require hand tools,

press and die, or fully automatic wire process machines? Crimping with a manual hand tool, semi-automatic press

and die, or fully automatic wire processor, all involve different levels of variability. The terminal, wire, and type of

application tooling all affect the quality of the completed terminations.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 3 of 27

Revision: C Revision Date: 12-23-09

Page 4

Industrial Crimp Quality Handbook

SECTION 2

PURPOSE AND SCOPE

Purpose

This handbook provides general guidelines and procedures for understanding and achieving acceptable crimp

terminations. A glossary in Section 3 lists common terms and definitions. Section 4 lists the tools that are

necessary to take accurate measurements and evaluate the crimp's acceptability.

For open barrel only, the tooling setup is critical in determining the quality of the finished crimp. The attributes that

need to be considered include crimp height, conductor brush, bell mouth, cut-off tab and strip length and insulation

position. Variability in one or more of these attributes can reduce the measured pull force. It can be difficult to

establish acceptable variability limits because the attributes all interact with one another.

For example, a track adjustment for bell mouth also will change the cut-off tab length and the insulation wire

position while strip length and wire locations affect the conductor brush and insulation position. Adjusting the

insulation crimp height may result in a slight change to the conductor crimp height measurement. It may be

necessary for the setup person to make multiple adjustments to establishing an optimal setup.

The order in which a setup is done may help reduce the number of repetitions required for an optimum setup.

This handbook is structured so that parts, or all, of its contents can be used as a procedural guide for ISO

requirements.

Scope

This handbook is intended for Molex customers who are crimping Molex open and closed barrel crimp

terminals and are using Molex tooling.

The handbook's contents may slightly differ from other connector manufacturers' or individual company guidelines

and procedures.

This handbook provides a basic overview of what to look for in an acceptable crimp. It is not intended to replace

individual product and/or tooling specifications.

Individual terminals or applications may have special requirements. Tooling limitations also may not permit an

attribute to be adjusted to meet optimum requirements.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 4 of 27

Revision: C Revision Date: 12-23-09

Page 5

Industrial Crimp Quality Handbook

CONDUCTOR

BARREL

BRUSH

SECTION 3

DEFINITIONS AND TERMS

AWG

Acronym for American Wire Gauge. It is the most

popular of many systems for designating single,

round, solid, non-steel wire diameter in United

States of America. Stranded wires are designated

based on comparison of their total cross-sectional

area of the conductor part only (their current carrying

capacity) and cross-sectional area of a

corresponding solid wire.

Barrel

It is the back end portion of a terminal or contact. It

is crimped to the conductor, insulation, or both.

When designed to receive the conductor, it is called

the conductor barrel. When designed to support or

grip the insulation, it is called the insulation barrel.

Bell Mouth

This is the undisturbed portion of the conductor

barrel nearest the insulation crimp. It is the result

from the actual crimping, which acts as a funnel for

the wires and reduces the possibility of a sharp edge

on the barrel cutting or nicking the wires.

Bend Test

One way to test the insulation crimp is by bending

the wire several times and then evaluating the

movement of the insulation and wire strands. As a

rule, the insulation crimp should withstand the wire

being bent 60 to 90 degrees in any direction, several

times. Use care when working with small wire sizes

so the wire at the back of the insulation crimp does

not shear.

Butt Splice

It is a device to join two conductors, end-to-end,

rather than overlapping.

Chamfer

An angle on the inside edge of the barrel entrance of

a terminal that permits easier insertion of the wires

into the barrel.

Circular Mil (CM)

A unit of area used to indicate wire size. It is the

computed total cross sectional area of conductors.

One circular mil equals cross-sectional area of a

wire one mil (0.001 inches) in diameter.

CMA – acronym for Circular Mil Area

CMA

Acronym for Circular Mil Area

Contact Area

It is the area in contact between two conductors, or a

conductor and a connector permitting the flow of

electricity.

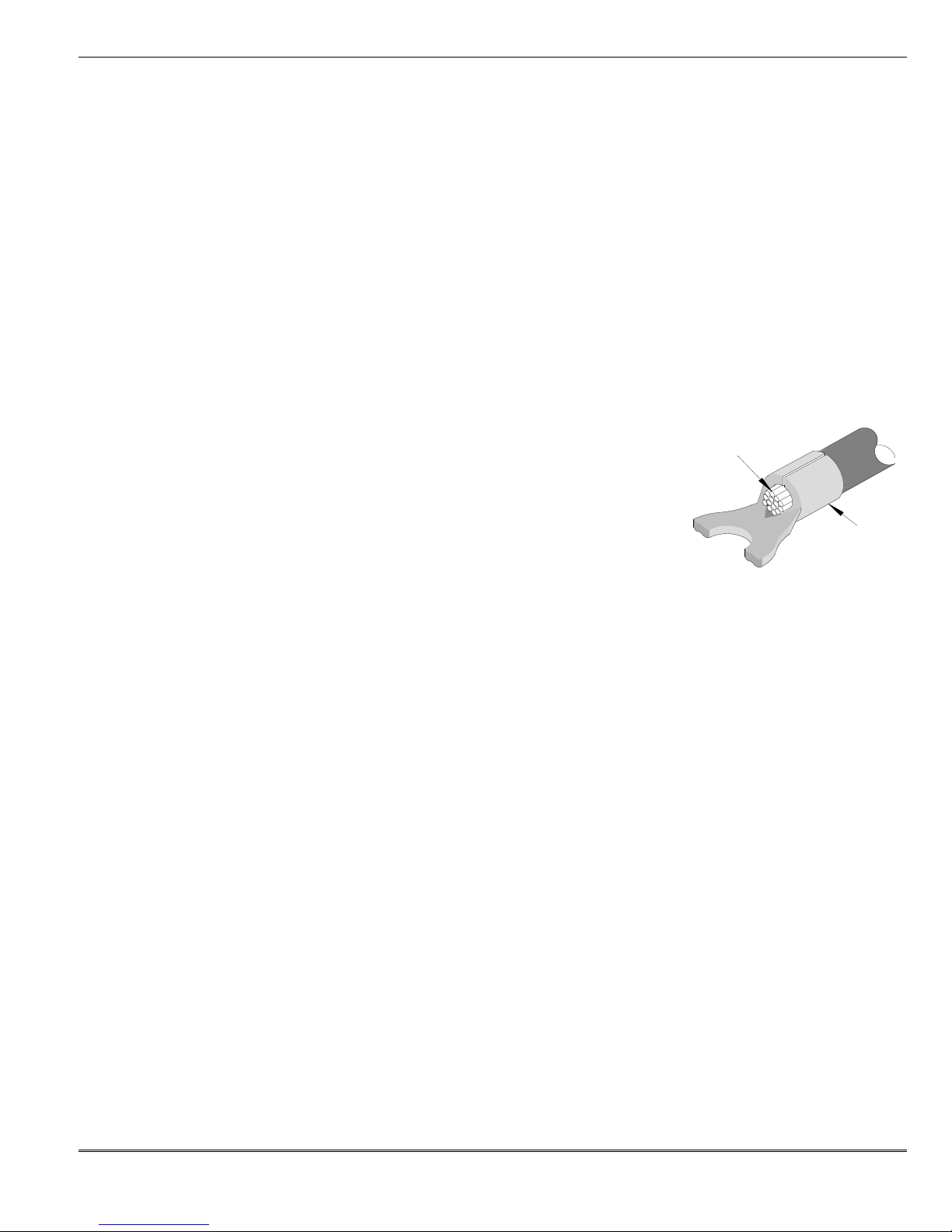

Conductor Brush

The conductor

brush is made up

of the wire strands

that extend past

the conductor

barrel on the

contact side of the terminal. This helps ensure that

mechanical compression occurs over the full length

of the conductor crimp. The conductor brush should

not extend into the contact area.

Conductor Crimp

This is the metallurgical compression of a terminal

around the wire's conductor. This connection

creates a common electrical path with low

resistance and high current carrying capabilities.

Conductor Crimp Height (Open Barrel Crimps)

The conductor crimp height is measured from the

top surface of the formed crimp to the bottom radial

surface. Do not include the extrusion points in this

measurement. Measuring crimp height is a quick,

non-destructive way to help ensure the correct

metallurgical compression of a terminal around the

wire's conductor and is an excellent attribute for

process control. The crimp height specification is

typically set as a balance between electrical and

mechanical performance over the complete range of

wire stranding and coatings, and terminal materials

and plating. Although it is possible to optimize a

crimp height to individual wire stranding and

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 5 of 27

Revision: C Revision Date: 12-23-09

Page 6

Industrial Crimp Quality Handbook

CUT-OFF TAB

LENGTH

CARRIER STRIP

terminal plating, one crimp height specification is

normally created.

*Consult individual terminal specification

requirements.

Crimp

It is the act of physically compressing (forming) a

connector or contact barrel around a cable in order

to make an electrical connection. On a crimped

terminal, a second crimp is often added to the

insulation area for added strain relief.

CSA

Canadian Standards Association is an independent

Canadian testing laboratory similar to UL

(Underwriters Laboratories Inc.).

Cut-off Tab Length

This material protrudes outside the end of the

terminal after the terminal is separated from the

carrier strip. As a rule, the cut-off tab should be

flush or .254mm (.010”) protruding outside the

housing sleeve. A cut-off tab, which is too long,

may expose a terminal outside the housing or it may

fail electrical spacing requirements. In most

situations, a tool is set-up to provide a cut-off tab

that is flush to one material thickness.

Dielectric Test

A test that uses the application of a voltage higher

than the rated voltage for a specific time for the

purpose of determining the adequacy against

breakdown of insulation materials and spacing under

normal conditions. This test is used to ensure the

crimping procedure did not puncture or destroy the

insulation material on the terminal.

Extrusions (Flash)

These small flares form on the bottom wire barrel

resulting from the clearance between the punch

and anvil tooling. If the anvil is worn or if the

terminal is over-crimped an excessive extrusion

results. An uneven extrusion may also result if the

punch and anvil being misaligned.

Ferrule

A short tube used to mate solderless connectors to

shielded or coaxial cable. It is used as an insulation

grip sleeve on solderless terminals.

Flash

It is an abnormal protrusion on the wire barrel,

(either insulation material or metal), which indicates

that the crimping tool is either misaligned or worn

and thus should not be used.

Funnel Entry

It is a crimped terminal or splice barrel, which opens

to facilitate quick and easy wire insertion.

Gas Tight Seal

A contact system that utilizes soft metals at high

contact pressures so that upon mating, metal is

upset and the resultant joint prevents contaminant

gases from entering the contact area.

Gauge

A method of measurement, often using “go” and “nogo” pins or shapes to determine if an attribute is

within tolerance.

Harness

A group of wires or cables joined to form a circuit

network for electronic or electrical equipment. A

harness is usually an assembly of cables cut to the

proper length, terminated, and tied together prior to

being assembled in a piece of equipment.

Insulation Crimp (Strain Relief)

It is a crimp encompassing both the wire and

insulation. This helps to prevent the conductor

from being exposed due to the insulation receding

and offers additional resistance to vibration.

Insulation Crimp Height

Molex does not specify insulation crimp heights

because of the wide variety of insulation thickness,

material, and hardness. Most terminals are

designed to accommodate multiple wire ranges.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 6 of 27

Revision: C Revision Date: 12-23-09

Page 7

Industrial Crimp Quality Handbook

Within the terminal’s range, an insulation grip may

not completely surround the wire or fully surround

the diameter of the wire. This condition will still

provide an acceptable insulation crimp for most

applications.

A large insulation grip should firmly grip at least

88% of the wire.

A smaller insulation grip should firmly grip at

least 50% of the wire and firmly hold the top of

the wire.

To evaluate the insulation section, cut the wire flush

with the back of the terminal. Once the optimum

setting for the application is determined, it is

important to document the insulation crimp height.

Then, as part of the setup procedure, the operator

can check the insulation crimp height.

Locator

A device for positioning terminals, splices, or

contacts in crimping dies.

MCM (or kcmil)

Unit of area, based on Circular Mil, equal to one

thousand circular mils. Usually used instead of

AWG above wire sizes greater than 4/0 AWG.

Mega (mega, M)

Prefix denoting one million, e.g., one megavolt =

one million volts.

Micro (micro, )

Prefix denoting one millionth, e.g., one microvolt =

one millionth of a volt.

Mil Spec

Military Specification. A specification used for

qualification of products for acceptability as required

for U.S. Government applications (usually for a

military branch), e.g. Mil-T-7928 covers terminals,

lugs, splices, conductors, crimp style.

Mechanical Strength

To insure how strong the connection is or how much

the wire and terminal must be squeezed to get a gas

tight seal. It’s important to crimp the wires tight

enough to keep them from slipping out of the

connector, but not so tight as to crush the wires in

the terminal, causing them to break off. The

connection is weakened if the wires are cut or

nicked.

Nest

The portion of a crimping die, which supports or

reshapes the barrel during crimping.

PSI, psi

(Pound-Force per Square Inch) Non-SI unit of

pressure. Used mainly to denote pressure of air or

other gas, e.g. 75 psi.

Pound-Force (lbf)

Unit of force, 1lbf is approximately equal to force

exerted on a mass of 1 lb by gravitational force of

Earth at its surface, or a force exerted by that mass

(stationary) on a support (i.e. if mass of 1 lb is

hanged on a wire, it exert a force of ca. 1 lbf

(directed down) on that wire).

Pull Force Testing

Pull force testing is a quick, destructive method to

evaluate the mechanical properties of a crimp

termination.

Pull force testing results out

of allowed range are good

indicators of problems in the

process. Cut or nicked

strands in the stripping

operation, lack of bell mouth

or conductor brush, or

incorrect crimp height or

tooling will reduce pull force.

Wire properties and

stranding, and terminal

design (material thickness

and serration design), also can increase, or

decrease the value of the results of a pull force test.

If results of a pull force tests are within an allowed

range, it assures that proper crimp force has been

applied during crimping. It is crucial as, when

making a crimp, enough force must be applied to

break down the layer of non-conductive oxides that

may build up on the stripped conductor and the tinplating on the inside of the terminal grip. This is

necessary to provide a good metal-to-metal contact.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 7 of 27

Revision: C Revision Date: 12-23-09

Page 8

Industrial Crimp Quality Handbook

PUNCHES

WIRE

ANVILS

TERMINAL

STRIP

LENGTH

If this does not occur, resistance can increase.

Over-crimping a crimp termination will reduce the

circular area of the conductor and increase

resistance.

Serrations

It is the saw-toothed grooves on the surface of a

terminal, which ensures firm gripping of the

conductor. Also provides additional contact area.

Solderless

This means without solder – in our case, denoting

the use of a crimping tool.

Splice

A device used to join two or more conductors

together.

Strip Length

The strip length is determined by measuring the

exposed conductor strands after the insulation is

removed. The strip length determines the

conductor brush length when the insulation position

is centered.

*Consult individual terminal specification

requirements

Tab

Flat rectangular male connection tabs on electrical

components; various sizes to fit female quick

disconnects.

Tensile Test

This is a pull test to determine the mechanical

strength of the crimped wire. They are specific

minimum values set for each wire size. See Section

8.

Terminal

A device designed to terminate a conductor that is to

be affixed to a wire or cable to establish an electrical

connection. It is a synonym for contact. There are

two main types, which include the open barrel and

the closed barrel. Parts of the terminal are:

Insulation barrel Where the wire’s insulation will be

crimped or supported so that it is

firmly gripped.

Wire barrel Where the bare wire will be

crimped.

Contact area Where the terminal will be attached

to the mating part.

Terminal Position

The terminal position is set by the alignment of the

terminal to the forming punch and anvils, and the

carrier-strip cut-off tooling. The tool set-up

determines conductor, cut-off tab length, and

terminal extrusions.

UL

Underwriters’ Laboratories, Inc., founded in 1894,

is chartered as a not-for-profit organization under

the laws of Delaware, to establish, maintain, and

operate laboratories for the investigation of

materials, devices, products, equipment,

construction methods, and systems with respect to

hazards affecting life and property.

Voltage Drop Test

A test of the voltage developed across a component

or conductor being a result of electric current flow in

the component or conductor and its non-zero

electrical resistance. It is the test of the electrical

integrity of the crimp.

Wire

They are a group of conductors that has a low

resistance to current flow, together with any

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 8 of 27

Revision: C Revision Date: 12-23-09

Page 9

Industrial Crimp Quality Handbook

WIRE STOP

WIRES

associated insulation. There are two kinds: a solid

wire, which is one single strand of material, or

stranded group of wire, which is a bundle of wires

twisted together to act as one.

Wire Size

Wires have varying sizes or gauges that carry

different amounts of electrical current with each wire

used for a separate purpose. The size (in AWG) is

called out with a number, such as 8 or 10, followed

by the letters AWG, which stand for American Wire

Gauge.

Wire Stop

It is a stop at the end of a terminal wire barrel. It

prevents wire from passing completely through the

barrel so the wire will not interfere with the function

of the contact.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 9 of 27

Revision: C Revision Date: 12-23-09

Page 10

Industrial Crimp Quality Handbook

SECTION 4

ASSOCIATED MATERIALS

Caliper

It is a gauge, consisting of two opposing blades, for

measuring linear dimensional attributes.

Eye Loupe

It is an image magnification tool,

normally 10 times power or

greater, which is used to aid

visual evaluation of a crimp

termination.

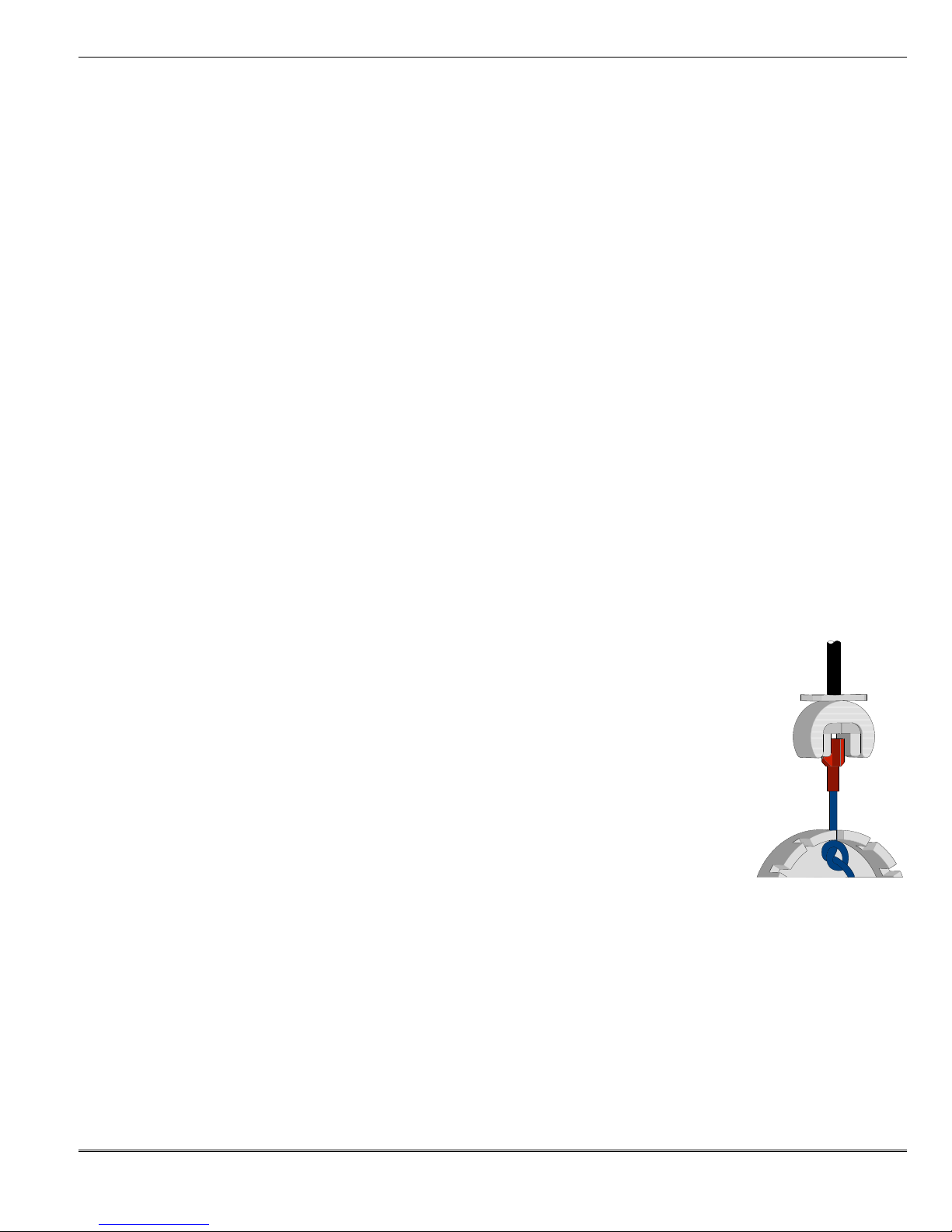

Crimp Micrometer

This is a micrometer

specifically designed to

measure crimp height. The

measurement is taken in the

center of the crimp so the

conductor bell mouth does

not influence it. It has a thin

blade that supports the top of

the crimp while a pointed

section determines the

bottom radial (curved) surface.

Ruler (Pocket Scale)

This is used to measure the length of bell mouth,

cut-off tab, conductor brush, and strip length and

estimate wire position. The recommended

minimum resolution is 0.50mm (.020”).

Pull Tester

A device used to determine

the mechanical strength of

a crimp termination. Most

pull testing is done with a

device that clamps the

wire, pulls at a set speed,

and measures force by

means of a load cell. A

pull tester also can be as

simple as hanging fixed

weights on the wire for a

minimum of one minute.

Toolmaker’s Microscope

This is used for close visual evaluation and

statistical measurement of bell mouth, cut-off tab,

conductor brush, wire position, and strip length.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 10 of 27

Revision: C Revision Date: 12-23-09

Page 11

Industrial Crimp Quality Handbook

Color Code

Wire Size (AWG)

*UL - 486 A

*UL – 486 C

*UL – 310

*Military Class 2

Yellow

26

3

N/A

N/A 7 Yellow

24

5

N/A

N/A

10

Red

22 8 8 8 15

Red

20

13

10

13

19

Red

18

20

10

20

38

Blue

16

30

15

30

50

Blue

14

50

25

50

70

Yellow

12

70

35

70

110

Yellow

10

80

40

80

150

Red 8 90

45

N/A

225

Blue 6 100

50

N/A

300

Funnel Entry

Plain Insulation

Terminal

Plastic Insulation

Sleeve

Nylon Sleeve

Tin-Plated

Brass Sleeve

Insulation with

Support Sleeve

SECTION 5

TERMINAL DESCRIPTION

5.1 Features of Solderless Terminals

The properties of the base material must be evaluated. The material (metal) is either copper or brass depending on

the product.

Molex base metals are purchased, inspected, and received to product specifications.

Most of these terminals are applied the guidelines of UL; Underwriters Laboratories is a US organization that sets

certain standards for connector testing.

Some terminals use the guidelines of Mil-T-7928, set by the United States Government.

The following charts show the UL and US Government specifications (MIL-T-7928) for wire pull-out forces of

various wire sizes. The tensile strength is shown in lbf (pound-force). It indicates the minimum acceptable force to

break or separate the terminal from the conductor.

*UL - 486 A - Terminals (Copper conductors only)

*UL - 486 C - Butt Splices, Parallel Splices, Closed End Connectors, and Wire Nuts

*UL - 310 - Quick Disconnects, Flag and Couplers

*Military Class 2- Military Approved Terminals only as listed

5.2 Barrel Serration/Dimples

1. When quality solderless terminals are stamped, the inside of the barrel is

scored with serrations or dimples.

2. When the crimp is made and the metal terminal barrel is drastically

deformed, the tin plating on the inside of the barrel is fractured at the

serrations, thus causing bare copper-to-copper contact between the wire

and the terminal barrel. This greatly enhances electrical conductivity.

3. If properly designed, the serrations, or dimples, have angled grooves that,

during the crimping operation, will bite into the wire, which will greatly

increase the mechanical integrity of the crimp.

4. A quality solderless terminal has features built into the barrel that insures a

quality crimp.

5. The non-insulated terminal will have a chamfer at the wire insertion end so

the individual strands will not bump against the end of the metal.

6. On an insulated terminal the insulation should have a funnel entry. This

acts as a guide for the wires to enter the barrel smoothly.

7. There are two styles of insulated barrels. Both have a funnel feature.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 11 of 27

Revision: C Revision Date: 12-23-09

Page 12

Industrial Crimp Quality Handbook

INSULATION

SUPPORT

CARRIER

STRIP

QUICK

DISCONNECTS

AND RING

TERMINALS

OPEN BARREL

STRIP

NYLON SLEEVE

FUNNEL

ENTRANCE

HEAVY DUTY

TERMINALS

NYLAKRIMP™

NYLON SLEEVE

TIN-PLATE

BRASS SLEEVE

AVIKRIMP™

BARREL

SEAM

TONGUE (STYLE VARIES)

TRANSITION

OR THROAT

KRIMPTITE™

BARREL

NO SEAM

TONGUE (STYLE VARIES)

TRANSITION

OR THROAT

VERSAKRIMP™

BARREL

INSULATION

SLEEVE

INSULKRIMP™

5.3 Barrel Styles

The barrel is the part of the terminal that is crimped

around the wire. Molex offers different styles listed

below.

1. The Krimptite

™

is the

basic Molex barrel style.

It is non-insulated and is

a one-piece design. This

terminal is the most

economical and has the

greatest variety of uses

where special features

are not required. It is

available in 10 to 26 AWG (0.10 to 6.60mm2).

2. The Versakrimp

™

is

the same as the

Krimptite™, except

the seam is brazed

(welded) closed.

This brazed-seam

barrel terminal will

not open under

conditions of stress

or wire pull. This

allows for crimping from any direction without the

barrel opening up, and provides greater tensile

strength. This terminal is ideal for hard to crimp

solid and stranded wires. It is available in wire

range 4/0 to 22 AWG (0.10 to 117.00mm2).

3. The Insulkrimp

™

has a

rigid insulation sleeve

made of PVC (polyvinyl

chloride), which protection

to the Krimptite barrel area

in wire sizes of 10-22

AWG or the brazed seam

of the Versakrimp barrel of 4/0 to 22 AWG. It is

available in wire range 4/0 to 22 AWG (0.10 to

117.00mm2).

4. The Avikrimp

™

has a color-coded sleeve, which

provides insulation as well as an insulation grip.

The insulation is made of Nylon, and has a

secondary tin-plated brass sleeve added. This

brass support sleeve is crimped around the wire

insulation providing a strain relief, so the wire does

not vibrate, loosen, fray, or break. It is available in

10 to 26 AWG (0.10 to 6.60mm2).

5. The Open Barrel product is used in manufacturing

operations where quantity of work is needed. The

open barrel allows the wire to be crimped faster and

easier and is the barrel style preferred when using

automated wire processing equipment.

6. The Nylakrimp

™

is specifically designed for large

wire applications. The color-coded barrel is affix

with a permanent rigid color-coded nylon insulated

sleeve. It has a funnel entrance that eliminates wire

strand fold back. It is available in wire range 4/0 to 8

AWG (8.50 to 117.00mm2).

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 12 of 27

Revision: C Revision Date: 12-23-09

Page 13

Industrial Crimp Quality Handbook

SNAP SPADES

FLAG RINGS

SPADES

FLANGED

SPADES

RINGS

HOOKS

STAR RINGS

MULTI STUDS

MALE QUICK

DISCONNECTS

FEMALE QUICK

DISCONNECTS

BARREL

LENGTH

NYLON SHRINK

TUBING

PERMA-SEAL™

FLARED BARREL

ENTRY

SEAMLESS BARREL

EYELET

7. The Perma-Seal

™is specifically

designed for water

resistant

applications. The

color-coded barrel

has a permanent

rigid color-coded nylon insulated sleeve. It has a

funnel entrance that eliminates wire strand fold back.

It is available in wire range 10 to 22 AWG (0.10 to

6.60 mm2).

8. The Eyelet can be used in place of standard

compression terminals because it is deep drawn

from CDA-110 electrolytic pitch copper and then tinplated for corrosion

resistance. It has a

seamless barrel

with a flared barrel

entry. It is available

in wire range 8 to

500 MCM.

Tongue Styles

The “tongue” is the end of the terminal that attaches

to other components (switch, stud, transformer, etc.).

These tongue configurations vary. The following are

some examples:

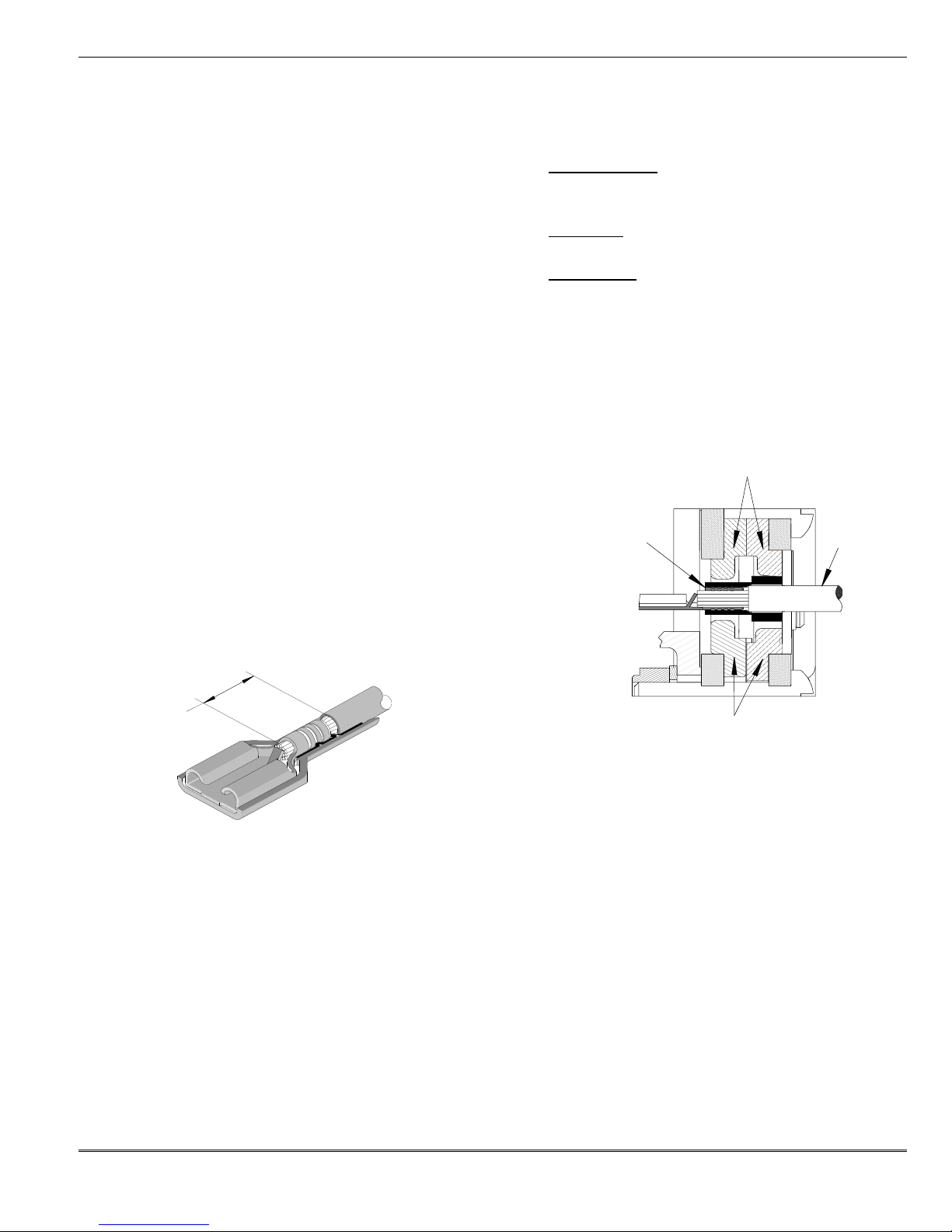

Barrel Lengths

In wire sizes 26-16 AWG, the industry has two

standard barrel lengths for the metal barrel. The

lengths are 6.35 mm (.25”) and 4.36 mm (11/64”).

The 4.36 mm barrel is the OEM (Original Equipment

Manufacturer) standard barrel length. The 6.35 mm

barrel is more

commonly used in the

maintenance and

aftermarket segments

of industry.

The purpose of the

longer barrel is simply to give the user a bigger

target area to crimp. These barrel lengths are not so

important if you use a terminal with the molded step

construction on the insulation, or if a precision

ratchet tool with terminal locator is used. OEM

tooling is usually designed for only short barrel

terminals.

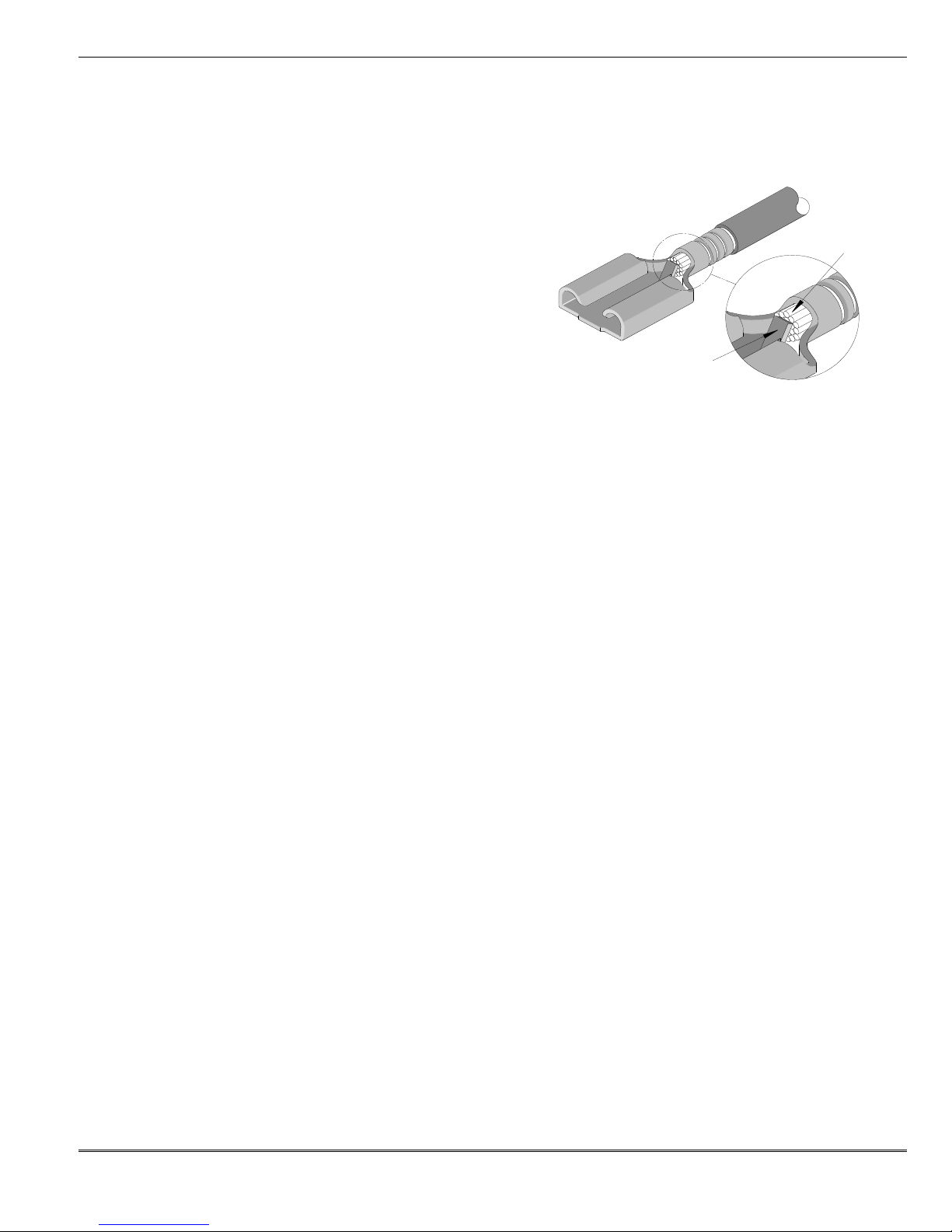

Step Construction Insulation for Tool Location

The “step” on the insulation of molded terminals is

used to position (locate) the crimping tool. The tool

should rest on the step and crimp made just above

it. This insures that the entire width of the crimping

tool is hitting on the barrel below. This step

construction is very important when using a nonratchet maintenance tool without a locator.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 13 of 27

Revision: C Revision Date: 12-23-09

Page 14

Industrial Crimp Quality Handbook

STEP

CONSTRUCTION

LOCATE

TOOL HERE

Color Code

Wire Range (AWG)

Yellow

24-26

Red

18-22

Blue

14-16

Yellow

10-12

Red

8

Blue

6

Yellow

4

Insulation Barrel Colors

The colors on the insulation barrel (red, blue, and

yellow) are used to indicate the wire range. The

colors repeat themselves and are an industry

standard color-coding. See the Chart below.

There are different kinds of barrels with different

shades of the same color, which are used for

different barrel styles. PVC and Nylon take the color

differently. In the 14-16 AWG range (blue) for

example, the PVC barrels will be dark blue. The

nylon barrels will be a lighter, translucent blue.

When using the lighter blue terminals, the secondary

sleeve will be crimped in addition to the wire barrel

crimp. The actual shade of color has nothing to do

with quality of the insulation.

5.4 Splices

Molex offers standard and special splices for nearly

every type of wiring need.

Butt Splices

On this connector, the

stripped wires are

inserted from each end

and they "butt" in the

center. Then a crimp at

each end secures the

connection.

Step Down Butt Splices

The Step Down Butt Splice is the perfect solution

when two wires need

to be inserted in one

end of a splice and a

single wire in the

other end.

Avikrimp Butt Splice

With the extra metal sleeve and nylon insulation,

these splices should be used when heavy vibration

is anticipated and a

strong strain relief is

needed.

Nylon Closed–End Connector

Used in a wide variety of

situations to “pigtail” or tie

together two or more wires.

Funnel Entry Butt Splice

In the past, the crimping of machine terminated butt

splices has been difficult and nearly impossible if

attempted on a piece of robotic equipment. Now,

with our new Funnel Entry Butt Splice, the end that

will be crimped by the crimping press is funneled to

allow quick and easy

wire insertion.

Perma-Seal Splices™

The tough sleeve of Perma-Seal splices resist

abrasion and cutting. This protective helps to

maintain the insulation and sealing properties even

in hostile

environments, not

to mention

unbeatable strain

relief.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 14 of 27

Revision: C Revision Date: 12-23-09

Page 15

Industrial Crimp Quality Handbook

Parallel Splice

This connector has stripped wires that lie side-byside in the splice. They are secured by a single

crimp in the

middle.

Window Butt Splice

This connector has military approval (Mil-T-7928/5)

to withstand the harshest environments. The

window guarantees proper wire insertion and crimp

tool alignment. They are nylon insulated and have

an insulation grip that provides superior strain relief.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 15 of 27

Revision: C Revision Date: 12-23-09

Page 16

Industrial Crimp Quality Handbook

Wire within

Outside Diameter

Exceeds

Outside Diameter

Loose Wire

Expanded Strands

ACCEPT

REJECT

Improper Stripping

“Nicked” Strands

Improper Stripping

Cut Strands

Proper Stripping

Undamaged

Strands

ACCEPT

REJECT

ACCEPT

Damage Less

Than 1/2 of

Insulation Thickness

Damage 1/2 of

Insulation Thickness

or Greater

Burred or Charred

Cut

Split

Insulation

Whiskers

REJECT

Insulation

Thickness

SECTION 6

PROCEDURES

6.1 Preparing the Wire

Check the stranded wire to see if any strands have

loosened and expanded to be larger than the wire and

the insulation together. If this has occurred, twist the

wires to the size they were before they were stripped. Be

sure that the stranded wire is within the outside diameter

of the insulation after you have twisted them.

Check the insulation to ensure that there has been

a nice clean cut. Wires with damaged insulation

should not be used.

Check to see if the stripping tool or machine has cut or

nicked any of the wires. If you see nicked wire you must

cut and re-strip the wire before crimping to be sure that

the amount of current that can be carried is not reduced.

6.2 Setup and Operation of a Press

1. Check that tooling is clean and not worn. If

necessary, clean and replace worn tooling.

2. Disconnect power to the press and remove

guarding devices.

3. Install the appropriate tooling into the press.

4. Load terminals into the tooling so that the first

terminal is located over the anvil.

5. Manually cycle the press to help ensure a complete

cycle can be made without interference. If it

cannot, remove tooling and check press shut

height. Go to procedure 3.

6. Check that the tooling is aligned. Check the

impression on the bottom of the crimp that was

made by the anvil tooling. Check that the

extrusions and crimp form are centered. If not,

align tooling and go to

procedure 5.

7. Check that the terminal

feed locates the next

terminal over the center

of the anvil tooling. If

not, adjust terminal

feed and the feed finger

and go to procedure 5.

8. Re-install all safety

devices that were removed during the set-up.

(Follow all safety requirements listed in

individual press and/or tooling manuals.)

9. Crimp sample terminals under power.

10. Evaluate cut-off tab length and conductor bell

mouth. If adjustment is necessary, disconnect

power to the press and remove guarding. Adjust

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 16 of 27

Revision: C Revision Date: 12-23-09

Page 17

Industrial Crimp Quality Handbook

WIRE

TERMINAL

Figure 2

LOCATOR

Figure 1

TERMINAL

LOCATOR

Figure 3

TERMINAL

SAFETY

SHEILD

track position. Manually cycle the press and check

the feed finger for feed location, go to procedure 7.

11. Evaluate conductor brush. If adjustment is

necessary, disconnect power to the press and

remove guarding. Adjust wire stop for bench

applications or press position on automatic wire

processing equipment. Go to procedure 8.

12. Evaluate insulation position. If necessary, adjust

strip length, crimp new samples, and go to

procedure 11.

13. Adjust insulation crimp height so the insulation

crimp is not in contact with the wire insulation.

14. Crimp sample terminals.

15. Measure conductor crimp height (if applicable) and

compare to specification. If necessary, disconnect

power and remove guarding. Adjust conductor crimp

height, install guards, connect power, and go to

procedure 14.

16. Perform a pull force test.

17. Adjust insulation crimp.

18. Crimp sample terminals.

19. Evaluate insulation crimp. If necessary,

disconnect power and remove guarding. Adjust

insulation crimp height, install guards, connect

power, and go to procedure 18.

20. Measure crimp height and compare to specification.

If necessary, disconnect power and remove guarding.

Adjust conductor crimp height, install guards, connect

power, and go to procedure 18.

21. Document measurements.

6.3 Setup and Operation of a Hand Crimp Tool

1. Insure that the hand tool is designed to crimp the

size wire and the proper terminal shown on the Hand

Crimp Tool Specification sheet.

2. Strip the wire and make sure it is clear of any nicks

or cuts. See Section “Preparing the Wire” above.

3. Place the terminal in the tool. Select the proper

color-coded crimp nest.

4. If using a locator, lift the locator and insert the

terminal in the proper nest with the barrel up and

against the locator bar. Release the locator blade to

hold the terminal in position. See Figure 1. Locator

may be raised or lowered so terminal sits flat and

straight in tool. The locator must be removed to run

splices.

5. Insert the wire. See Figure 2.

6. Squeeze the handle. All production hand tools

should have a built in full-cycle ratchet mechanism.

7. Inspect for proper crimp location. Check the Hand

Crimp Tool Specification sheet that you are using for

correct conductor crimp height.

6.4 Setup and Operation of a Air Powered Crimp

Tool

1. Insure the Air Crimp Tool is designed to crimp the

size wire and the proper terminal shown on the Air

Crimp Tool Specification Sheet.

2. Strip the wire and make sure it is clear of any nicks

or cuts. See Section “Preparing the Wire” above.

3. Place the wire into the terminal. Select the proper

color-coded crimp nest.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 17 of 27

Revision: C Revision Date: 12-23-09

Page 18

Industrial Crimp Quality Handbook

WIRE

TERMINAL

Figure 4

4. If using a locator, lift the locator and insert the

terminal with the wire in the proper nest with the

barrel up and against the locator bar. Release the

locator blade to hold the terminal in position. See

Figure 3. Locator may be raised or lowered so

terminal sits flat and straight in tool. The locator

must be removed to run splices.

5. Push on the wire to assure it is still fully seated in the

terminal. Cycle the tool. See Figure 4.

6. Inspect for proper crimp location. Check the Air

Powered Crimp Hand Tool Specification Sheet that

you are using for correct conductor crimp height

Caution:

Never operate this tool without the supplied

safety shield in place. Never place fingers in

the tool nests.

Note: Whenever crimping without the locator,

make sure the seam of the barrel is oriented up or

down in the tool as this will provide higher pull

force values.

6.5 Crimping Dies

The Molex product line includes seven types of dies

for different terminals:

Two piece INDENTOR CRIMP, VersaKrimp™

Two piece CONFINED CRIMP, Krimptite™ and

VersaKrimp™

Two piece CONFINED CRIMP, InsulKrimp™ and

AviKrimp™

Two piece F TYPE CRIMP, Krimptite™ and

VersaKrimp™

Four piece F TYPE CRIMP, VibraKrimp™

Four piece CONFINED CRIMP, InsulKrimp™ and

AviKrimp™.

Bottom INDENTOR CRIMP, 8 and 6 AWG

VersaKrimp™.

The Indentor crimp consists of a holding nest and

indentor ram to deform the barrel. The advantage of

this configuration is that while it covers a broad

range of wire sizes, it is still easy to design and

inexpensive to manufacture.

The F crimp is used to close the barrel and confine

the individual strands. The overall quality is

excellent.

The Confined crimp gives the best overall crimp. It

is in the shape of a hexagon, an enclosed “C”, or a

confined quad. The advantages of all three crimps

are uniformity and compression of individual strands

and uniform outer appearance.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 18 of 27

Revision: C Revision Date: 12-23-09

Page 19

Industrial Crimp Quality Handbook

Molex provides a complete line of fully automatic wire

processing machines, semi-automatic and manual wire

crimping tools. Each system is tailored to our customer’s

individual needs by using support equipment, and can be

adapted to wire processing equipment offered by

manufacturers

such as ARTOS, KOMAX, and others. This Manual

shows the basics of Manual and Semi-Automatic

equipment.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 19 of 27

Revision: C Revision Date: 12-23-09

Page 20

Industrial Crimp Quality Handbook

Insulation

Not Visible

REJECT

Wire Not

Visible

REJECT

Window

ACCEPT

REJECT

Insulation

Pierced or

Crushed

ACCEPT

Insulation

Slightly

Damaged

Insulation

Tab Bent

REJECT

Metal Insulation

Tabs Formed. Wire

Is Held Snugly

ACCEPT

ACCEPT

Wire Visible

REJECT

Insulation

Diameter

Exceeds

Insulation Diameter

SECTION 7

QUALITY CRIMPS

Quality is something that must be measured by some

set of criteria. Four major agencies give test criteria for

quality of solderless terminals. They are:

U.L. (Underwriters Laboratories)

CSA (Canadian Standard Association)

NEMA (National Electronic Manufacturers

Association)

Federal Government Spec - Mil-T-7928

In all of the above standards specific reference is made

to the following areas:

Copper or brass quality specifications

Tin-plating specs type and thickness

Smoothness of edges and lack of burrs

Firmness of fit between metal and insulation

Then there is a whole series of tests to be performed

on the crimp area after the crimp is made:

Tensile test

Dielectric withstand

Salt spray

Vibration

Heat rise

The most widely used field test for testing the quality of

the crimp is the pull test, or tensile test.

The two most widely used measurements are the U.L.

and Military Tensile values. See Section 8. Note that

the Military pull force is higher than the U.L.

7.1 Visual Inspection of OPEN BARREL Crimps

Insulation Not Damaged

1. Crimp the insulation just enough (may have a

slight indentation to hold the wire in place). If

the insulation has been pierced or crushed, the

wires inside may have been damaged also.

2. Be sure that the conductor insulation has not

been pierced or crushed by the crimp.

Insulation Support Crimp

1. Be sure that the insulation barrel tabs are not

bent.

2. Form the tabs properly.

3. If one of the tabs is bent, the insulation crimp

will not be strong enough to provide the

needed stress relief.

Wire Visible

1. Be sure that both the

wire and the insulation

are visible in the window.

2. If only the insulation is

visible, you may have crimp insulation in the

conductor barrel.

3. If only the bare wire is visible, you cannot assume

that the insulation has been properly crimped.

4. If there is no insulation support crimp, be sure that

the length of the wire visible behind the conductor

crimp is not greater that the diameter of the

insulation. If the length of the wire visible exceeds

the diameter of the insulation, the terminal could

cause a short circuit.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 20 of 27

Revision: C Revision Date: 12-23-09

Page 21

Industrial Crimp Quality Handbook

ACCEPT

Contact Area

Wire Stop

Contact Area

REJECT

Wire in

Contact Area

Wire in

Contact Area

No Wire Stop.

Do Not Use

REJECT

Wire

Protrudes

ACCEPT

Wire

Crimped

Wire Flush or

Greater

Up to 1/32” (1mm)

ACCEPT

REJECT

Wire

Not Flush

REJECT

ACCEPT

Contact Area

Damaged

Slight Scratch or Scrape

but No Visual Dents

REJECT

ACCEPT

Wire Stop

Wire Brush

is Visible

Wire Crimp

Wire not Visible

Insulation

Crimp

ACCEPT

Wire

Crimp

REJECT

No Bell Mouth

Slight

Bell Mouth

Good Bell Mouth Present

1. Be sure that a good bell mouth is present in the

wire barrel.

2. If no bell is present, the sharp edge of the wire

barrel may cut or nick the wires.

No Wire Strands in the Contact Area

1. Be sure that no wire strands extend into the

contact area of the lug or terminal.

2. If the wire strands are in the contact area, they

will interfere when the terminal is connected.

No Strands Sticking Out (Strand Fold Back)

1. Be sure that all of the wire strands are twisted

together, and are equal to the size they were

before being stripped.

2. If the strands are not together, or if one is left

sticking out, your wire mass is reduced and can

cause both electrical and mechanical problems.

Wire Extension

1. Be sure that the wires extend not more than

1/32” (1mm) past the end of the barrel. If the

wires are not flush or greater, you will not be

able to see if the crimp is complete and correct.

No Damage to the Contact Area

1. Be sure that the contact area is not dented or

crushed.

2. If it is dented or crushed (slight scratch or scrape

is permissible), the connection between the

terminal and another component cannot be

made properly.

7.2 Visual Inspection of CLOSED BARREL Crimp

Wire Visible

Revision: C Revision Date: 12-23-09

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 21 of 27

Page 22

Industrial Crimp Quality Handbook

Wire

Not Flush

ACCEPT

REJECT

Wire Flush or

Greater (Brush)

Not Centered.

Too Far Forward

REJECT

ACCEPT

Centered

Wire in

Contact Area

ACCEPT

REJECT

Contact Area

No Insulation Crimp

ACCEPT

ACCEPT

REJECT

METAL INSULATION

CRIMP

REJECT

PLASTIC INSULATION CRIMP

Insulation Indent Not

Formed-Wire Moves

In Insulation Crimp

REJECT

No Insulation

Crimp

No Insulation

Crimp

Insulation Deformed

Wire Can Move

In Insulation Crimp

METAL INSULATION

CRIMP

ACCEPT

Insulation Deformed.

Wire Should Not Move

In Insulation Crimp

Insulation Indent

Formed-Wire Secure

In Insulation Crimp

REJECT

No Bell Mouth

ACCEPT

REJECT

Bell Mouth

1. Be sure that the wire is visible in the inspection

window so that there is evidence of a good

crimp. See Butt Connector above.

Crimp to be Centered

1. On all crimped terminals, the conductor crimp

should be centered on the conductor barrel. This

insures even pressure on the entire length of the

barrel.

Good Bell Mouth Present

1. Be sure that a good bell mouth is present on the

wire barrel.

No Wire Strands in the Contact Area

1. Be sure that wire strands do not exceed into the

tongue area of the lug or terminal.

2. If the wire strands are in the contact area, they

will interfere when the terminal is connected.

Wire Flush or Greater

1. Be sure that the wires are either flush with the

end of the conductor barrel or extend past the

barrel.

2. This “brush” extension should be approximately

1/32” (1mm).

3. If the wires are not flush or greater, you will not

be able to see if the crimp is complete.

Wire Size (AWG) Requirements

1. To achieve a quality crimp be sure to follow the

proper insulation crimp for different wire sizes.

Wire sizes of 8 AWG and larger do not require an

insulation crimp.

Wire sizes 18 thru 10 AWG require an insulation

crimp to securely hold the wire insulation crimp.

Revision: C Revision Date: 12-23-09

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 22 of 27

Page 23

Industrial Crimp Quality Handbook

ACCEPT

Metal Sleeve

Not Snug

REJECT

Metal Sleeve Snug

Insulation Support Crimp

1. On closed barrel terminals that have a

secondary metal sleeve (AviKrimp™), the metal

sleeve should be formed snugly around the wire.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 23 of 27

Revision: C Revision Date: 12-23-09

Page 24

Industrial Crimp Quality Handbook

Tensile Strength in Pound-force

Wire Size

(AWG or MCM)

*UL-486A

*UL-486-C

*UL-310

*Military

Class 2

26

3

N/A

N/A

7

24

5

N/A

N/A

10

22 8 8 8 15

20

13

10

13

19

18

20

10

20

38

16

30

15

30

50

14

50

25

50

70

12

70

35

70

110

10

80

40

80

150 8 90

45

N/A

225

6

100

50

N/A

300 4 140

N/A

N/A

400 2 180

N/A

N/A

550

1

200

N/A

N/A

650

1/0

250

N/A

N/A

700

2/0

300

N/A

N/A

750

3/0

350

N/A

N/A

825

4/0

450

N/A

N/A

875

250 MCM

500

N/A

N/A

1000

300 MCM

550

N/A

N/A

1120

350 MCM

600

N/A

N/A

1125

SECTION 8

IMPORTANCE OF PROPER CRIMPING

Once the correct terminal is selected, proper

attachment to the wire is critical. One indication of the

importance of proper crimping is evidenced in a study

for the Space Shuttle Program that traced 28% of all

defects to improperly assembled wiring and connectors.

Mechanical as well as electrical connections are

important - The result of a properly crimped joint is a

reliable mechanical and electrical connection.

The mechanical connection is the crimping of the

terminal to the conductor. The desired result is

sufficient force on the outside of the barrel to tightly

form it around the conductor. It must be secure enough

not to vibrate loose or to be pulled off through normal

use.

The electrical characteristics are just as important. The

major concern is the amount of electrical resistance

caused by the mechanical joint. The electrical

resistance will determine the crimped joint’s ability to

conduct current

8.1 Conditions

To achieve a positive relationship between the

mechanical and electrical connection in the crimped

joint, the following conditions are required:

1. The terminal must be of sufficient cross section

size and conductive material that it is as good an

electrical conductor as the wire.

2. The surfaces of the wire and terminal that will be

pressed into contact in the crimp must be clean and

free of heavy, non-conductive films such as oxides,

sulfides, and similar substances.

Some reasons for failure of crimped joints to meet

minimum tensile requirements include nicked wires,

nicked or ruptured strands, strand turn back at crimp

joint, and ruptured wires outside of the crimped

terminal. To avoid these problems, use the correct size

wire for the barrel, prepare your wire carefully, and use

the proper crimping tool.

8.2 Testing

Mechanical

The tensile test or pull test is a means of evaluating the

mechanical properties of the crimped connection. The

chart on this page shows the UL and Military

Specifications (MIL-T-7928) for various wire sizes. The

tensile strength is shown in lbf (pound-force), it indicates

the minimum acceptable force to break or separate a

terminal from the conductor.

When the crimp is made, there must be enough pressure

applied so that the oxides that may build up on the

stripped conductor and the tin plating on the inside of the

terminal barrel are broken down and there is good metalto-metal contact. If this situation does not occur, the

resulting crimp will have unacceptably high resistance.

*UL - 486 A - Terminals (Copper conductors only)

*UL - 486 C - Butt Splices, Parallel Splices, Closed

End Connectors, and Wire Nuts

*UL - 310 - Quick Disconnects, Flag and Couplers

*Military Class 2- Military Approved Terminals only as

listed

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 24 of 27

Revision: C Revision Date: 12-23-09

Page 25

Industrial Crimp Quality Handbook

Single

Strand Wire

Terminal

Wire Barrel

Excessive

Crimp Depth

Wire is deformed

Or Compressed Beyond

Normal Yield Point

Causing Potential

Failure Mode or Future

Break or Fracture Point

Excessive

Bell Mouth

W

C

R

R

Dielectric Testing

(The term “dielectric” refers to an insulator.)

Some terminals are covered with insulation so that

electrical contact can be made only where it is

desirable. The crimp is made through (on) this

insulation, which is compressed and extruded due to

the pressure of the crimping dies. Obviously, not all

insulation materials can withstand this treatment and

even with the strongest materials, the crimp must be

correctly designed so as not to rupture the insulation.

Dielectric tests are made on insulated terminals after

crimping to determine that the crimp process is not

rupturing the insulation or thinning it out so that it will

not withstand impressed voltages. The test is made

by impressing a voltage between the wire to which the

terminal is crimped and conductive materials

contacting the terminal insulation.

The voltage is gradually increased until the

requirements are reached or until a breakdown occurs

which means the insulation breaks. Depending on the

use and the specifying agency, dielectric withstanding

requirements normally range from 1500 to 8000 volts,

resulting in a 300 to 600 volt rating of the terminal.

8.3 Final Tensile Value

The type of die affects the final tensile value in

several ways. See Crimping Dies, Section 6.5.

If the die (as in the indentor type) does not indent far

enough, a void may be created in the compression

joint permitting the individual strands to shift, thus

loosening the connection. Further, the air space

(void) acts as an electrical insulator.

If the die presses too tightly the individual strands can

be squeezed and elongated. This can cause a weak

point in the conductor, cause the wire to break at a

lower than allowable tensile strength, and/or create a

heat rise across the joint because of lower crosssection and increased resistance.

Another way to cause tensile failure is not

compressing the barrel enough to hold the conductor

securely. Molex crimp tools are designed to eliminate

these problems.

8.4 Electrical Resistance

The electrical resistance across the crimp is compared

to the resistance of an equal length of wire, and

expressed as relative resistance for a particular wire

size.

Relative resistance of the crimp to the wire is given by

the formula below:

Relative resistance

Where:

R

= Resistance over crimp

C

R

= Resistance of wire

W

Relative resistance values of less than 1.0 denote a

crimped joint with less resistance than the wire;

values more than 1.0 indicate greater resistance than

the wire. Usually it is easier to measure the voltage

drop across the crimped joint. Many specifications

state the requirements in terms of voltage drop at a

specified current. Voltage drop is the more

commonly used term in the industry. If the resistance

value is desired, it may be calculated from Ohm’s

Law:

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 25 of 27

Revision: C Revision Date: 12-23-09

Page 26

Industrial Crimp Quality Handbook

I

E

R =

Where:

R is the resistance (in milliohms)

E is the voltage drop (in millivolts)

I is the current flowing (in amperes)

Crimp voltage drop and resistance values are quite

small and are expressed in terms of milivolts (.001

volts) and miliohms (.001 ohms).

A crimp joint of poor quality could be caused by

several factors. It is indicated by increased resistance,

which cause increase in voltage drop value.

For example, the presence of air pockets or voids in

the crimped joint will cause a higher resistance

(smaller area of contact between terminal and wire).

Increased resistance results in a higher voltage drop

and a temperature rise, which in turn increases the

corrosion rate and further increases the resistance.

A crimped joint that has been over-crimped and the

conductor (wire) elongated out of shape could cut the

circular area of the conductor and cause a greater

resistance at this weakened point.

8.5 Crimp Joints

A finely stranded wire (large number of small diameter

strands) usually improves crimped joint performance.

A wire composed of a few strands of larger size will

tend to act as a solid wire in the crimp. Some

stranded wire crimp configurations are not satisfactory

for solid wire. More deformation must be imposed in

order to form wire and barrel into a solid mass. On the

other hand, finer strands will more readily fill the inside

corners of the crimp shape and more evenly distribute

the forces of the crimp.

Brazed barrel terminals usually give higher tensile test

than the non-brazed (for specific values, tensile tests

must be performed on each terminal).

Annealing

When the metal part of a solderless terminal is

stamped on a stamping press; the strip of metal

material is repeatedly hit in the stamping process.

These terminals are made on progressive dies.

This repeated hitting causes the metal (usually

copper) to become work hardened. Copper gives its

best mechanical and electrical characteristics when it

is in its original (not work hardened) state.

In order to return the work hardened copper to its

normal soft and malleable state, it must be annealed.

Annealing is accomplished by heating the metal

(copper) terminal in a furnace, and then cooling it

slowly. This process restores the copper to its

original state.

How does annealing (or lack of) affect the crimp

barrel and quality of a solderless terminal?

When a work-hardened terminal is crimped, it does

not form around the wire in a uniform fashion, thus

giving sharp angles, which allows for voids. The

annealed barrel can be easily formed, giving uniform

pressure on the wire and thus a superior crimp.

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 26 of 27

Revision: C Revision Date: 12-23-09

Page 27

Industrial Crimp Quality Handbook

Technical Wire Information

CMA — Circular Mil Area. Circular Mil is a unit of area equal to that of a circle whose

diameter is one Mil.

MIL — One mil equals .001 inches.

.001” = 1 mil

.030” = 30 mils

.125” = 125 mils

Changing Inches to Mils

1. Multiply inches by 1000 or,

2. Move decimal point 3 places to right or,

3. Change terminology, i.e. 0.032 in. = 32 thousandths or 32 mils.

Computation of CMA

Round Solid Conductor:

Change diameter from inches to mils, and then multiply the diameter “D” in mils by itself.

CMA = D mils x D mils

Stranded Conductor:

Find CMA of a single strand and multiply the result by the total number of strands.

CMA = (D x D) x Number of Strands of one Strand

AWG-CMA Table

Terminal Size /AWG

CMA Range

26-22

202-810

24-20

320-1,020

22-18

509-2,600

22-16

509-3,260

16-14

2,050-5,180

14-12

3,260-8,213

12-10

5,180-13,100

8

13,100-20,800

6

20,800-33,100

4

33,100-52,600

2

52,600-83,700

1/0

83,700-119,500

2/0

119,500-150,500

3/0

150,500-190,000

4/0

190,000-231,000

Americas Headquarters

Lisle, Illinois 60532 U.S.A.

1-800-78MOLEX

amerinfo@molex.com

Far East North Headquarters

Yamato, Kanagawa, Japan

81-462-65-2324

feninfo@molex.com

Far East South Headquarters

Jurong, Singapore

65-6-268-6868

fesinfo@molex.com

European Headquarters

Munich, Germany

49-89-413092-0

eurinfo@molex.com

Corporate Headquarters

2222 Wellington Ct.

Lisle, IL 60532 U.S.A.

630-969-4550

Fax: 630-969-1352

Visit our Web site at http://www.molex.com

SECTION 9

MISCELLANEOUS

Doc No: TM-640160065 Release Date: 00-00-02 UNCONTROLLED COPY Page 27 of 27

Revision: C Revision Date: 12-23-09

Loading...

Loading...