molex TCDEC-8B4P-DYU-G8, TCDEC-8B4P-D1U-G8, TCDEC-8B4B-D1U-G8, TCDEC-8B4B-D1U-GW, TCDEC-8B4P-D1U-GW Original Instructions Manual

...Page 1

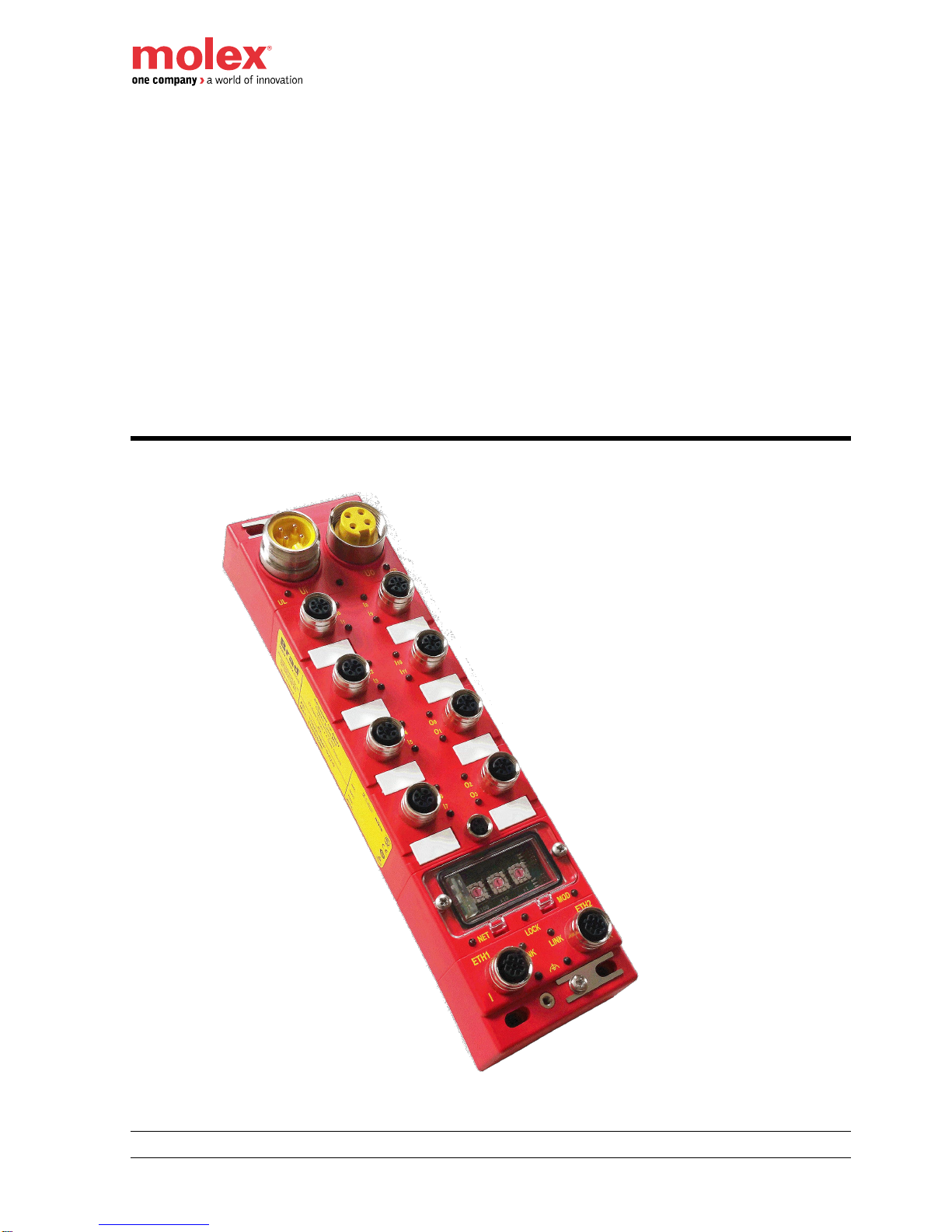

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

1 IP67 Safety Digital I/O Modules

User’s Safety Manual

‘ORIGINAL INSTRUCTIONS’

EtherNet/IP™ CIP Safety™ HarshIO

IP67 Digital I/O Modules

Brad™ from Molex

Version 1.2

June 06th, 2017

Page 2

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

2 IP67 Safety Digital I/O Modules

Revision History

Date

Author

Changes

Revision

February 04, 2016

E. Gory

Release version

1.0

May 19, 2016

E. Gory

Page 34 – Output sourcing - Update wiring schematic with

24 VDC on Pin1

Page 42 – Add 5-pole product references

Page 84 – Add product code in decimal

New “Safety I/O connections” chapter

Update template of “Declaration of Conformity” (DoC)

1.1

June 06, 2017

E. Gory

Page 27 – Update concerning the safety classes

Page 42 – Add important note when UB is in overvoltage

Page 61 – Correction of 5-pole power connector wiring

Page 80 – Correction of the default Gateway address

when using the static IP method

Page 136 – Update of the Safety Reset procedure

1.2

Although every effort has been made to ensure the accuracy of this document, all information is subject to

change without notice. Molex takes no liability for any errors in this document or for direct, indirect, or

consequential damage resulting from the use of this manual.

Page 3

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

3 IP67 Safety Digital I/O Modules

STATEMENT OF LIMITED WARRANTY

Brad™ from Molex, manufacturer of HarshIO products, warrants to the Buyer that products, except software,

manufactured by Brad™ will be free from defects in material and workmanship. Brad™ obligation under this

warranty will be limited to replacing the defective parts within one year of the date of installation. Products may

be returned by Buyer only after permission has been obtained from Molex. Buyer will prepay all freight charges

to return any products to the facility designated by Brad™.

Brad™ further warrants that any software supplied as part of a product sale, except obsolete products, will be

free from non-conformances with Brad™ published specifications for a period of 90 days from the time of

delivery. While Brad™ endeavors to improve the features and performance of software associated with its

products, no effort on the part of Brad™ to investigate, improve or modify HarshIO modules firmware at the

request of a customer will obligate Brad™ in any way.

For the convenience of existing customers, Brad™ continues to supply certain products that are classified as

obsolete. No warranty on the software features of these products is stated or implied and Brad™ specifically is

not obligated to improve the design of these products in any way. Information about the status of any product

is available upon request and customers are advised to inquire about the status of older products prior to

making a purchase.

This limited warranty does not cover losses or damages which occur in shipment to or from the Buyer or due to

improper installation, maintenance, misuse, neglect or any cause other than ordinary commercial or industrial

applications. All such warranties are hereby expressly disclaimed. No oral or written information or advice

given by Brad™ or Brad’s representative shall create a warranty or in any way increase the scope of this

warranty. This limited warranty is in lieu of all other warranties whether oral or written, expressed or implied.

Brad’s liability shall not exceed the price of the individual units, which are the basis of the claim. In no event

shall Brad™ be liable for any loss of profits, loss of use of facilities or equipment, or other indirect, incidental or

consequential damages.

Although every effort has been made to ensure the accuracy of this document, all information is subject to

change without any notice. Brad™ takes no liability for any errors in this document or for direct, indirect, or

consequential damage resulting from the use of this manual.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Brad™ cannot assume responsibility or

liability for actual use based on the examples and diagrams.

COPYRIGHTS and TRADEMARKS

Reproduction of the contents of this manual, in whole or in part, without written permission of Molex is

prohibited.

Mini-Change®, Ultra-Lock™, Brad™ are all registered trademarks of Molex, Inc.

All other products or trademarks are the property of their respective owners.

Page 4

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

4 IP67 Safety Digital I/O Modules

This page intentionally left blank.

Page 5

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

5 IP67 Safety Digital I/O Modules

Table of contents

1. About This Manual ............................................................................... 8

About this manual .................................................................................................... 8

2. General Safety Instructions .............................................................. 11

Intended use .......................................................................................................... 11

Responsibility of the user ...................................................................................... 11

Documentation ...................................................................................................... 12

Maintenance .......................................................................................................... 12

Spare parts ............................................................................................................ 12

Shipping ................................................................................................................ 12

Disposal ................................................................................................................. 13

Education of the personnel ................................................................................... 13

Personal protective equipment .............................................................................. 13

Special hazards ..................................................................................................... 14

Sign-posting .......................................................................................................... 15

3. Product Overview .............................................................................. 16

Introduction ............................................................................................................ 16

Functional safety - safety relevant parameters ..................................................... 18

Product environmental and safety instructions ..................................................... 19

Product features .................................................................................................... 21

Ultra-Lock M12 connectivity .................................................................................. 21

Ordering information.............................................................................................. 22

Ethernet topologies ............................................................................................... 23

4. Functional Safety Functions ............................................................. 27

Safety States ......................................................................................................... 27

Safety Inputs ......................................................................................................... 28

Safety Sourcing Outputs (TCDEC-8B4P-D1U-Gx and TCDEC-8B4P-DYU-Gx) .. 33

Bipolar Safety Outputs (TCDEC-8B4B-D1U-Gx and TCDEC-8B4B-DYU-Gx) ..... 37

I/O Status .............................................................................................................. 39

Behavior in case of fault ........................................................................................ 39

Response Time ..................................................................................................... 41

5. Product Characteristics .................................................................... 42

Hardware characteristics ....................................................................................... 42

Mechanical characteristics .................................................................................... 47

Physical I/O mapping ............................................................................................ 48

Safety I/O assemblies ........................................................................................... 49

Safety I/O connections .......................................................................................... 50

Safety I/O data mapping ....................................................................................... 52

Pin assignment ...................................................................................................... 60

LED assignment .................................................................................................... 62

6. Product installation and wiring ........................................................ 66

Page 6

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

6 IP67 Safety Digital I/O Modules

Power supply ......................................................................................................... 66

Ethernet connection .............................................................................................. 67

Module grounding .................................................................................................. 70

I/O wiring ............................................................................................................... 71

7. Product Deployment .......................................................................... 78

Getting Started ...................................................................................................... 78

IP address setting .................................................................................................. 78

EDS files ................................................................................................................ 85

Import HarshIO Safety EDS into Rockwell hardware description library .............. 89

Configure HarshIO Safety module into Rockwell RSLogix 5000 project .............. 97

Safety I/O assemblies ......................................................................................... 100

Configure HarshIO Safety module in Molex SNCT ............................................. 103

Connection and testing of HarshIO Safety module in RSLogix 5000 ................. 119

8. EtherNet/IP Behavior ....................................................................... 122

I/O behavior ......................................................................................................... 122

IDLE behavior ...................................................................................................... 122

Duplicate IP address ........................................................................................... 122

EtherNet/IP Object Classes ................................................................................ 123

9. Product Replacement ...................................................................... 131

Before to start ...................................................................................................... 131

Replacement procedure ...................................................................................... 132

Verification ........................................................................................................... 133

10. SNCT Configuration Software ........................................................ 134

Overview ............................................................................................................. 134

Safety Reset ........................................................................................................ 136

Lock / Unlock Configuration ................................................................................ 142

Stored IP Address using DHCP Server............................................................... 149

IP Address Conflict .............................................................................................. 155

Ethernet Port Diagnostics ................................................................................... 156

Module Information .............................................................................................. 157

Set/Reset password ............................................................................................ 159

Additional Information.......................................................................................... 162

Download Firmware ............................................................................................ 164

Print module configuration .................................................................................. 169

Log (Emergency Mode) ....................................................................................... 172

11. Product Package .............................................................................. 173

Product package ................................................................................................. 173

USB Stick ............................................................................................................ 173

Memory Key ........................................................................................................ 174

12. Web Server Interface ....................................................................... 176

How to connect the web server ........................................................................... 176

General information ............................................................................................. 177

Page 7

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

7 IP67 Safety Digital I/O Modules

Diagnostic information ......................................................................................... 178

13. Selection of Cables and Cordsets .................................................. 180

Overview ............................................................................................................. 180

14. Certifications .................................................................................... 181

TUV Certificate .................................................................................................... 182

EU Declarations of Conformity ............................................................................ 183

15. Product Support .............................................................................. 185

Warranty conditions ............................................................................................. 185

Product Information ............................................................................................. 185

Technical Support ............................................................................................... 186

Page 8

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

8 IP67 Safety Digital I/O Modules

1. About This Manual

This Safety Manual describes the IP67 digital safety I/O modules (also called HarshIO) from Molex.

About this manual

Chapter 1: About This Manual

This is this present chapter.

Chapter 2: General Safety Instructions

This chapter gives an overview of all important safety aspects for optimum protection of the personnel, as well

as for the safe and fault-free operation.

Chapter 3: Product Overview

This chapter gives an overview of the product usage and main features.

Chapter 4: Safety Functions

This chapter gives a presentation of the characteristics of the Safety Inputs and Safety Outputs of the module.

Chapter 5: Product Characteristics

This chapter gives an overview of characteristics and technical data of the HarshIO safety modules.

Chapter 6: Product Installation and Wiring

This chapter details the wiring possibilities and associated safety categories.

Chapter 7: Product Deployment

This chapter presents an example of how to proceed with the commissioning of the HarshIO Safety modules

based on the Rockwell Automation RSLogix™ 5000 software version 20.

Chapter 8: Product Behavior

This chapter gives a presentation of HarshIO safety modules behaviors related to EtherNet/IP communication.

Chapter 9: Product Replacement

This chapter describes the strategy in case of replacement of commissioned HarshIO Safety modules.

Chapter 10: SNCT Configuration software

This chapter presents the important features that are available in the SNCT software used for the HarshIO

module commissioning.

Chapter 11: Product Package

This chapter details the contents of the product package.

Chapter 12: Web Server Interface

This chapter presents the HarshIO information available by connecting the module web server.

Page 9

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

9 IP67 Safety Digital I/O Modules

Chapter 13: Selection of cables and cordsets

This chapter presents how to access to a selection of connectivity products and associated part numbers to

help designing the system infrastructure.

Chapter 14: Certifications

This chapter describes how to identify the product and contact information the technical support.

Chapter 15: Product Support

This chapter describes how to identify the product and contact information the technical support.

Target audience

The manual is targeted at users who have a background in automation and networking technology, including

safety application, EtherNet/IP™ and CIP Safety™.

Structure of the manual

The manual consists of chapters. Every chapter provides a self-contained description of a specific topic.

Availability

The manual is available in electronic form as PDF-file (Adobe Acrobat Reader) in English language. It is

important to warrant that the product will be implemented by a body having the right skill to understand

English. In case of concern, this document could be on request translated to a different language.

Nevertheless the English version will remain the reference in case on hazardous translation.

Icon headings

Important passages in the text are highlighted by following icons and headings:

Danger!

Immediate danger to life and limb of personnel and others. Non-compliance will

cause death or serious injury.

Warning!

Hazardous situation to life and limb of personnel and others. Non-compliance may

cause death or serious injury.

Attention!

Designates a possibly harmful situation. Non-compliance can damage the product

or something in its environment.

Note!

Supplementary information and useful tips.

Page 10

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

10 IP67 Safety Digital I/O Modules

Liability Limitation

All data and notes in these instructions were prepared with consideration to the statutory standards and

regulations, the present state of technology, as well as our many years of knowledge and experience.

The manufacturer accepts no liability for damage caused because:

Non-compliance with the instructions

Non-specified use

Use of untrained personnel

The actual scope of delivery can, by special designs, deviate from the explanations and presentations given

here, because of the utilization of additional order options, or because of the most recent technical changes.

The user is responsible for the execution of service and commissioning according to the safety instructions of

the prevailing standards and other relevant national and local instructions concerning conductor dimensioning

and protection, earthing, overcurrent protection and so on.

The individual, who has carried out the mounting or the installation, is liable for damages which result from the

mounting or from the connection.

We have checked the contents of this manual for agreement with the hardware and software described. Since

deviations cannot be precluded entirely, we cannot guarantee full agreement. However, the data in this manual

are reviewed regularly. Necessary corrections are included in subsequent editions.

Suggestions for improvement are welcome.

The manufacturer is no liable for damage resulting from missing or insufficient knowledge of the manual.

Therefore, it is recommended to the operator to obtain written instructions from qualified people.

Modifications or functional alterations on the product are not allowed due to safety reasons. Any modification

on the product not explicitly authorized by the manufacturer will result in loss of any liability claims to the

vendor. The same applies if non authorized parts or equipment are used.

Copyright

This manual is to be treated confidentially. It has been provided only for the personnel, which uses the

product. The transfer of this document to third parties without the authorization in writing of the vendor is

prohibited.

Note!

The contents, texts, drawings, pictures and any other illustrations are copyrighted and

subject to other protection rights. Any person unlawfully using this publication is liable to

criminal prosecution.

Use of this manual

This safety manual contains information for the intended use of the HarshIO safety modules.

Knowledge of regulations and the proper technical implementation of the safety instructions detailed in this

manual performed by qualified personnel are prerequisites for safely planning, engineering, programming,

installing and starting up the HarshIO safety modules as well as for ensuring safety during their operation and

maintenance.

Molex will not be held liable for severe personal injuries, damage to property or the surroundings caused by

any of the following: unqualified personnel working on or with the devices, de-activation or bypassing of safety

functions or failure to comply with the instructions detailed in this manual.

The manual contains safety instructions, description of the modules and information about life cycle.

Page 11

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

11 IP67 Safety Digital I/O Modules

2. General Safety Instructions

This chapter gives an overview of all important safety aspects for optimum protection of the personnel, as well

as for the safe and fault-free operation.

Intended use

The modules have been engineered and designed exclusively for the proper use described in this

documentation. The modules are intended to be used if considering all references and information of this

manual.

Warning!

Danger by not intended use!

Each use of the product, which differs from the intended use, can lead to dangerous

situations.

Therefore:

Use the product only as intended.

Use the product only together with the recommended components.

Consider all the data in this manual.

Ensure that only qualified personnel works with the product.

Ensure during configuration that the product is operated within its specifications.

Ensure that the power supply corresponds to the given specifications.

Only use the product in a technically adequate condition.

Only use the product in combination with approved components.

Changes and modifications at the product

To avoid endangerments and to ensure the optimal operating, neither changes nor modifications should be

made to the product, which are not specially approved by the manufacturer.

Responsibility of the user

The product is used in the factory automation environment. The user of the product is subject of the statutory

duties to work safely.

In addition to the safety instructions in this manual, for the usage environment of the product, adhere to the

relevant accident prevention and environmental protection regulations.

The user must be informed about the valid industrial safety regulations in order to evaluate additionally

dangers, which arise as a result of the special conditions for the product in the place of operation. This is

to be transcribed with working instructions for the operation of the product.

These working instructions must be kept in the direct environment of the product and accessible at any

time for people who work with the product.

Page 12

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

12 IP67 Safety Digital I/O Modules

Fully adhere to the working instructions.

The product is only to be operated in a technically flawless and reliable condition.

Documentation

Every person working with the product must have read and understood the operating instructions before

carrying out any work. The manual must be available to all personnel involved in:

project design

installation

commissioning

operation

decommissioning

The following conditions must be met before using or commissioning the components

described in this manual

Warning!

Modification to the process control system should only be carried out when the

system has been disconnected from power!

Installation and modifications shall only be performed by properly trained personnel

The national rules and regulations of the respective country must be satisfied

(installation, safety, EMC ...)

Danger!

To prevent hazards and ensure optimum performance, no changes, modifications or

conversions may be made to the product that have not been expressly approved by the

manufacturer.

Maintenance

The corresponding safety module is maintenance-free.

Spare parts

Please use only original spare parts of Molex.

Warning!

Incorrect or faulty spare parts can cause damage, malfunction or failure as well as

affect security and safety function.

Shipping

For shipping always use the original packaging.

Page 13

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

13 IP67 Safety Digital I/O Modules

Disposal

National rules and regulations apply to the disposal of the unit. Please check with the local authorities for the

correct local disposal procedures.

Education of the personnel

Warning!

Risk of injury resulting from insufficient qualification!

Improper use can cause considerable personal injury and material damage.

Qualification

The automation system may only be operated by persons, which are trained, instructed and authorized.

Troubleshooting, maintenance, cleaning, and replacement must be performed only by skilled or trained

personnel.

Qualified

personnel

These persons have to know the instruction manual and have to act accordingly.

Commissioning and training should only be performed by qualified personnel.

Operating

personnel

These are electrical engineers and electricians of the customer or third party, which are

authorized by the manufacturer and which have learned installation and commissioning

by the manufacturer and are allowed to ground, mark and install electrical circuits and

devices in accordance to the standard safety technology.

Qualified personnel is trained and instructed according to the corresponding valid

standards in safety technology in the care and use of appropriate safety equipment.

Personal protective equipment

During work, the wearing of personal protective equipment is needed to minimize health hazards.

Always wear the necessary protective equipment for the corresponding job.

For your own safety regard the signs, which are in your work space.

Work clothing

is close-fitting clothing with low tensile strength, with tight sleeves and without a

protruding part. Depending on the application it should be prevented, that the carrier

gets serious injured or is exposed to health risk during work.

For reasons of injury no jewelry like rings and chains should be worn.

Protective helmet

for protection against falling and flying objects.

Safety shoes

for protection against falling heavy objects.

Page 14

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

14 IP67 Safety Digital I/O Modules

Protective gloves

To protect hands from friction abrasions, punctures or injuries, as well as from contact

with hot objects

Eye protector

To protect eyes from flying parts and liquid splashes

Special hazards

In the following section the residual risks are identified, which result from the hazard analysis.

Regard the listed safety warnings here and the notes in the whole manual to reduce health hazards and to

avoid dangerous situations.

Electric current

Danger!

Risk of death by electric current!

Contact with live parts is immediate danger to life. Damage of the insulation or of

components can be danger to life.

Therefore:

Immediately turn off the power supply when the insulation is damaged. Work on the

electrical system only by qualified personnel.

Always power-off and secure the electrical system during work.

Risk by residual energy

Danger!

Risk of death by electric current!

After disconnecting the device from main voltage, parts such as power connections

should only be touched when the capacitors are discharged in the device.

Therefore:

Regard discharge time of the capacitors; do not touch live parts before having observed

a period of 1 minute.

If there are additional connected capacitors on the link, the discharge of the link can last

considerably longer. In this case you have to determine the required waiting period or

even to measure whether the device is safe.

Moving objects

Warning!

Risk of injury from moving parts!

Rotary and linear moving parts can cause serious injuries.

Therefore:

Do not touch moving parts during operation. Do not open the cover during operation.

The mechanical residual energy depends on the application.

Page 15

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

15 IP67 Safety Digital I/O Modules

Driven components rotate respectively move for a certain time even after switching off

the power supply.

Fire fighting

Danger!

Risk of death by electric current!

Risk of an electrical shock when using a conducting firefighting medium.

Therefore use the following firefighting medium:

ABC powder / CO2

Behavior with dangers and accidents

Preventive measures

Always be prepared for accidents or fire!

Keep first-aid equipment (first aid kit, blankets etc.) and fire extinguishers handy.

Make personnel familiar with accident message, first aid and rescue mechanisms.

In case of emergency: act correctly

Set immediately the device with emergency stop out of operation.

Initiate first-aid measures.

Rescue persons from the danger zone.

Inform responsible on-site.

Call medical and / or fire department.

Clear the access routes for emergency vehicles.

Sign-posting

Warning!

Danger of injury by illegible symbols

In course of time stickers and symbols on the equipment can get dirty or otherwise

become unrecognizable.

Therefore:

Please always maintain all safety warnings and operation instructions on the device in

easily readable condition.

Page 16

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

16 IP67 Safety Digital I/O Modules

3. Product Overview

This chapter gives an overview of the product usage and main features.

Introduction

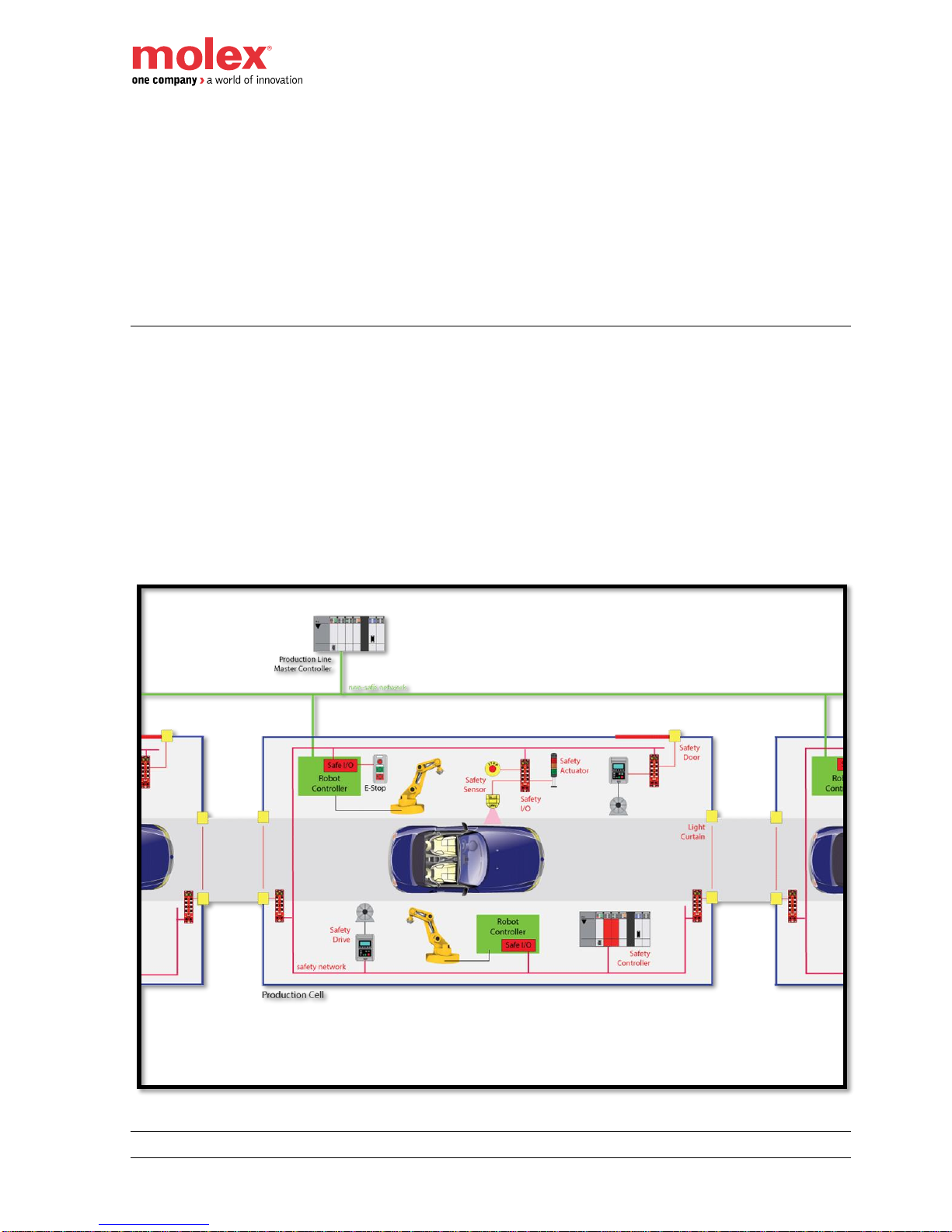

EtherNet/IP™ CIP Safety™ Brad™ HarshIO modules provide a reliable solution for the monitoring of safety

input devices (interlock switches, emergency stops, light curtains, laser scanners …) as well as the control of

safety output devices (relays, muting lamps, fail-safe motor starters…) with industrial safety controllers in

harsh duty environments. Contained in an IP67 rated housing, Brad HarshIO can be machine mounted and

are able to withstand areas where liquids, dust or vibration may be present.

EtherNet/IP™ CIP Safety™ HarshIO module serves mainly applications for automotive manufacturers and

machine builders looking for on-machine safety I/O connection to reduce cabinet space. The IP67 60mm

housing with M12 connectors make HarshIO modules ideally suited for many safety applications including

material handling equipment, automated assembly machinery and automotive applications running robots into

cells.

- Example of safety application used for automotive assembly line -

Page 17

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

17 IP67 Safety Digital I/O Modules

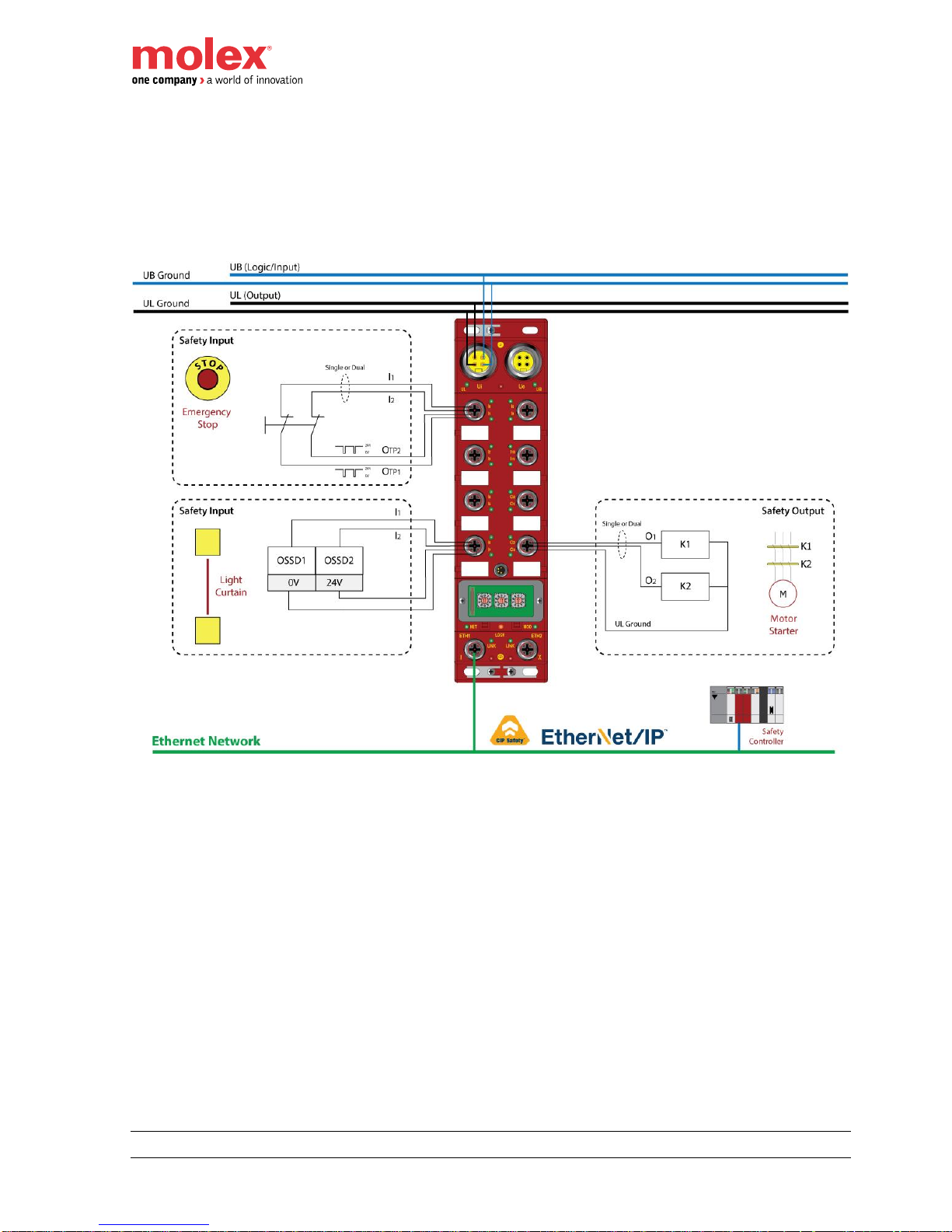

The combination of EtherNet/IP and CIP Safety protocols allow exchanging safety process I/O and diagnostics

information over a single Ethernet network. The modules need to be configured in order to suit with the safety

function definitions, up to SIL 3 as defined by IEC 61508 or CAT 4/ PLe as defined by ISO 13849-1 (in

particular, inputs and outputs could be set for use as dual-channel).

The diagram below shows some examples of safety I/O wirings.

Page 18

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

18 IP67 Safety Digital I/O Modules

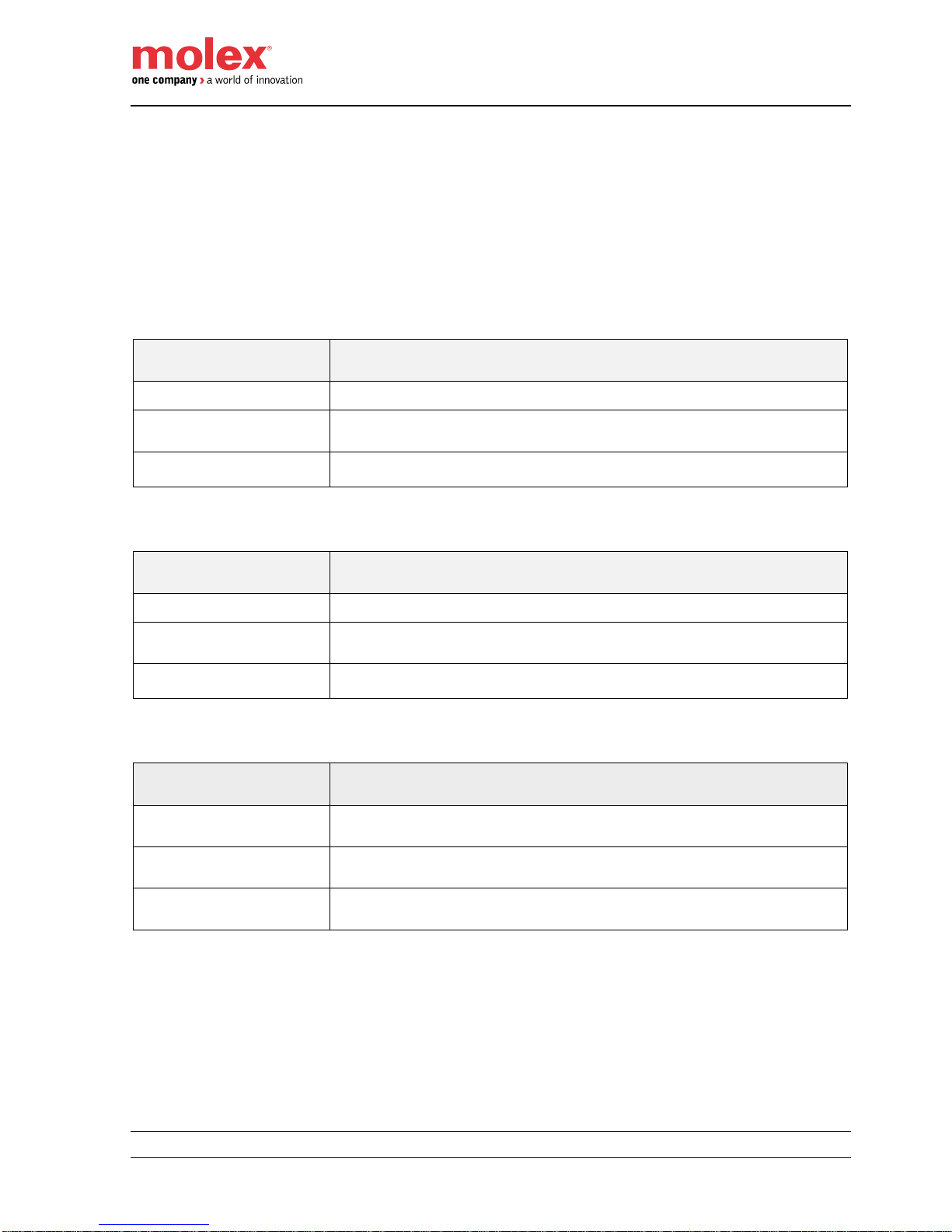

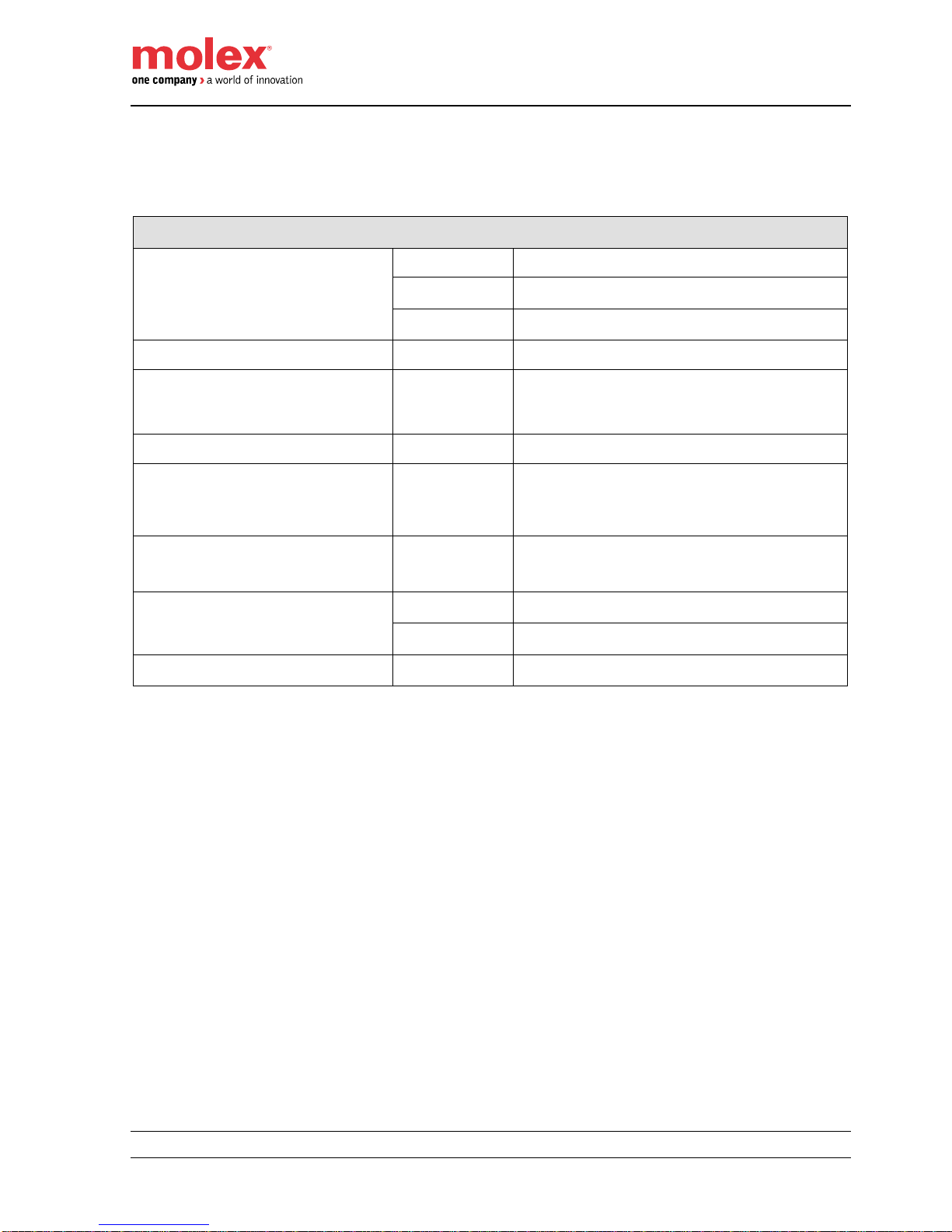

Functional safety - safety relevant parameters

This chapter describes parameters associated to functional safety. In according to IEC 61508, Safety means

first that a system is free from unwarrantable risks. Functional safety is a part of the total safety, which

guarantees the fail-safe response of a safety system according to the input conditions. Here internal safetyrelevant device errors must be detected and lead to a safe condition.

Safety relevant parameters may always be found in the according manuals of the modules.

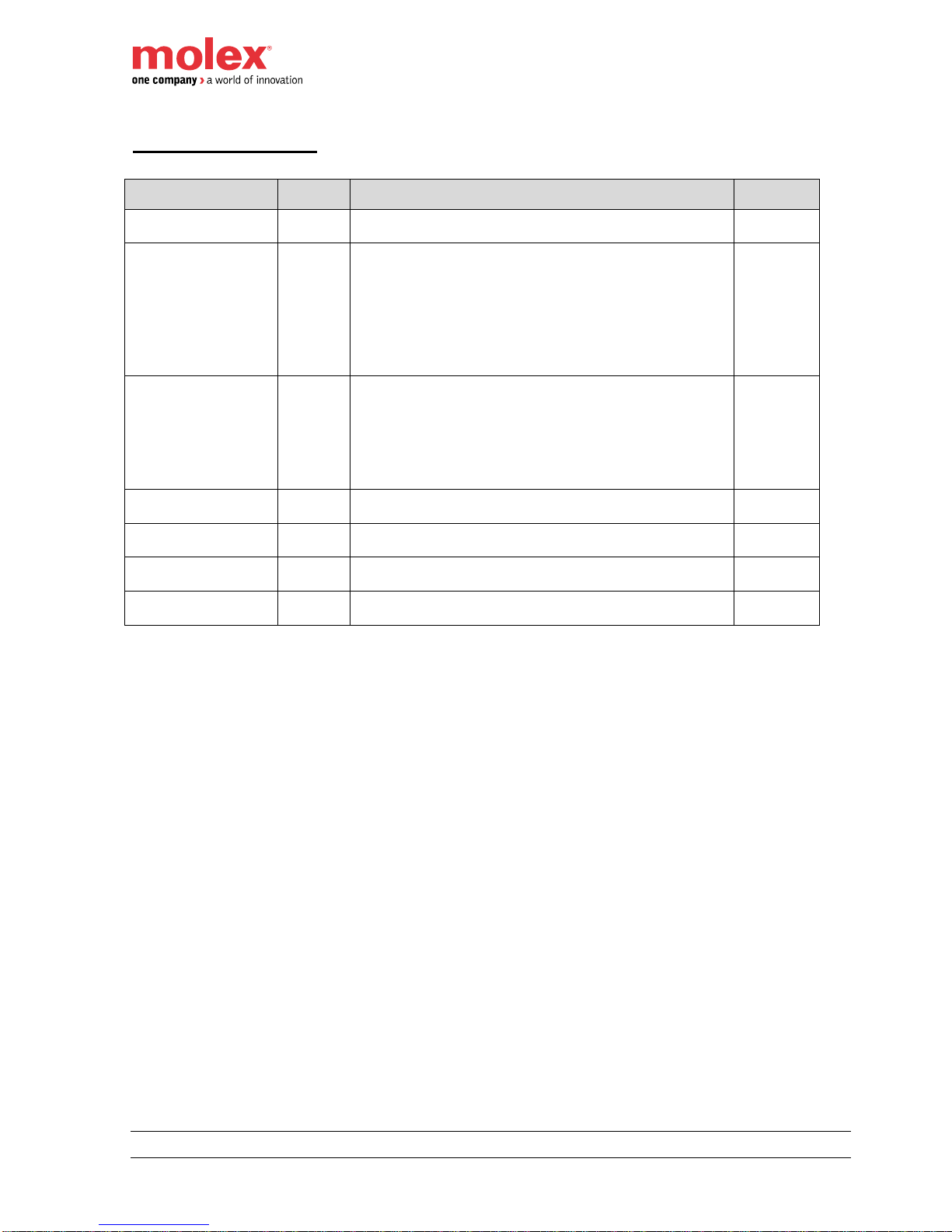

TCDEC-8B4P-D1U-Gx and TCDEC-8B4P-DYU-Gx products:

Parameters according to

IEC 61508

Meaning

PFH = 1 *10

-10

/h

Probability of failure per Hour: Probability of danger failure per hour

PFDavg = 8.74 * 10

-06

Probability of Failure on Demand average: Average of probability of failure on

demand

SFF according SIL 3

Safe Failure Fraction: Fraction of failure, which lead to a safe state.

TCDEC-8B4P-D1U-Gx and TCDEC-8B4P-DYU-Gx products:

Parameters according to

IEC 61508

Meaning

PFH = 8.67 *10

-11

/h

Probability of failure per Hour: Probability of danger failure per hour

PFDavg = 7.65 * 10

-06

Probability of Failure on Demand average: Average of probability of failure on

demand

SFF according SIL 3

Safe Failure Fraction: Fraction of failure, which lead to a safe state.

All products:

Parameters according to

DIN EN ISO 13849-1

Meaning

MTTFd: High

Mean Time To dangerous Failure

DCavg: High

Diagnostic Coverage average

Service Life: 20 years

During the expected life of the device of up to 20 years, no proof test is

required

Page 19

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

19 IP67 Safety Digital I/O Modules

Product environmental and safety instructions

Approvals, directives, standards

The HarshIO safety module has been designed to comply with the following directives and standards:

Conformity and approval

CE*

2006/42/EC

Machinery directive

2011/65/UE

RoHS 2 directive

2014/30/EU

EMC directive for industrial use (Class-B)

UL Listed

UL 508

Approval for USA and Canada

IEC 61508

Ed 2010

Functional Safety of

Electrical/Electronic/Programmable Electronic

Safety-related Systems (E/E/PE, or E/E/PES)

ISO 13849-1

Ed 2015

Safety of machinery

IEC 62061

Ed 2012

Safety of machinery: Functional safety of

electrical, electronic and programmable

electronic control systems

IEC 61131-2

Ed 2007

Programmable logic controllers - Equipment

Requirements and Tests

ODVA conformance

Vol 2 – 1.18

EtherNet/IP™

Vol 5 – 2.6

CIP Safety™

IEC 60529

Ed 2010

IP67 degree of protection

*CE Declaration of conformity can be found in section ‘Certifications’ of this manual

The HarshIO has been designed and produced specifically for:

communication and process control

general control and automation applications

industrial applications

operation within the environmental conditions specified in the technical data

This product was EMC tested for use in industrial areas. If it is to be used in personal or business and trade

environments, the resulting system must go through EMC qualification.

Page 20

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

20 IP67 Safety Digital I/O Modules

Explosive environments

Danger!

This device is not certified for applications in

explosive environments (EX-zone)

Power supply and Electrical safety

The device is developed for operation on 24 VDC power supplies, which correspond to the PELV-/SELV

regulations in accordance to EN 50178.

Risk of injury by electric current!

There may only devices be connected to the module, which have a safe separation

from the mains (such as 120V/230V/600V) power.

The power supply to generate 24 V power must correspond to the requirements for

PELV/SELV according to EN 50178.

IP67 rating

The product complies with IP67 when installed. All caps of non-used connectors shall be mounting on the

product to maintain the IP67 rating during operation.

Danger!

Risk of electric power!

Contact with live parts is immediate danger to life.

Mission time

The expected life time of the HarshIO module is up to 20 years with no proof test necessary.

Warning!

If the user calculates their safety application with the specified data for >20 years, the

HarshIO has to be decommissioned and replaced. A proof test cannot be established

by the user.

Earthing

Warning!

Connections to earth shall be wired accordingly to the relevant chapter of this manual in

order to warrant EMC characteristics of the product.

Page 21

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

21 IP67 Safety Digital I/O Modules

Product features

EtherNet/IP CIP Safety HarshIO main features include:

Safety Inputs

o To connect safety devices, such as emergency stop push buttons, gate switches, and safety light

curtains.

o Single or dual channel modes supported.

o Dual-channel mode evaluates consistency between two input signals (channels), which allows

use of the module for Safety Category 3 and 4. The time of a logical discrepancy between two

channels can be monitored using a discrepancy time setting.

o Each safety input has its own associated test output to check external wiring short-circuit.

o Independently adjustable ON and OFF delay are available per channel.

Test Outputs

o Separate test outputs are provided for external short circuit detection of a safety input.

o Power (24 V) can be supplied to devices, such as safety sensors.

o Test outputs can be configured as standard non-safe outputs.

o 2 test outputs can be used for broken wire detection of a muting lamp.

Safety Outputs or Bipolar Safety Outputs

o Up to 1A for safety outputs and up to 2A for bipolar per output point.

o Dual-channel mode evaluates consistency between two output signals (channels).

o Safety outputs can be pulse tested to detect field wiring shorts to 24 VDC.

o Bipolar safety outputs use pulse testing to detect a short to 24 VDC on the safety sourcing output,

and a short to 0VDC on the safety sinking output.

I/O Safety RPI with up to 10ms cycle time

IP67 rated enclosure that when properly installed provides protection against the ingress of dust, water

Integrated 2-port unmanaged Ethernet switch with cross-over and DLR capability

Isolated grounding to able to use 2 separate power supplies to energize the module logic/inputs and

outputs.

Protective earth (for power supplies)

Functional earth (for Ethernet connectors)

Diagnostic visible LEDs

Easy commissioning via Molex Safety Network Configuration Tool (SNCT)

On-board memory key (Window or M8 versions) allowing to store module configuration and perform

replacement in few minutes without any special tool or re-commissioning.

3 rotary switches to set IP address

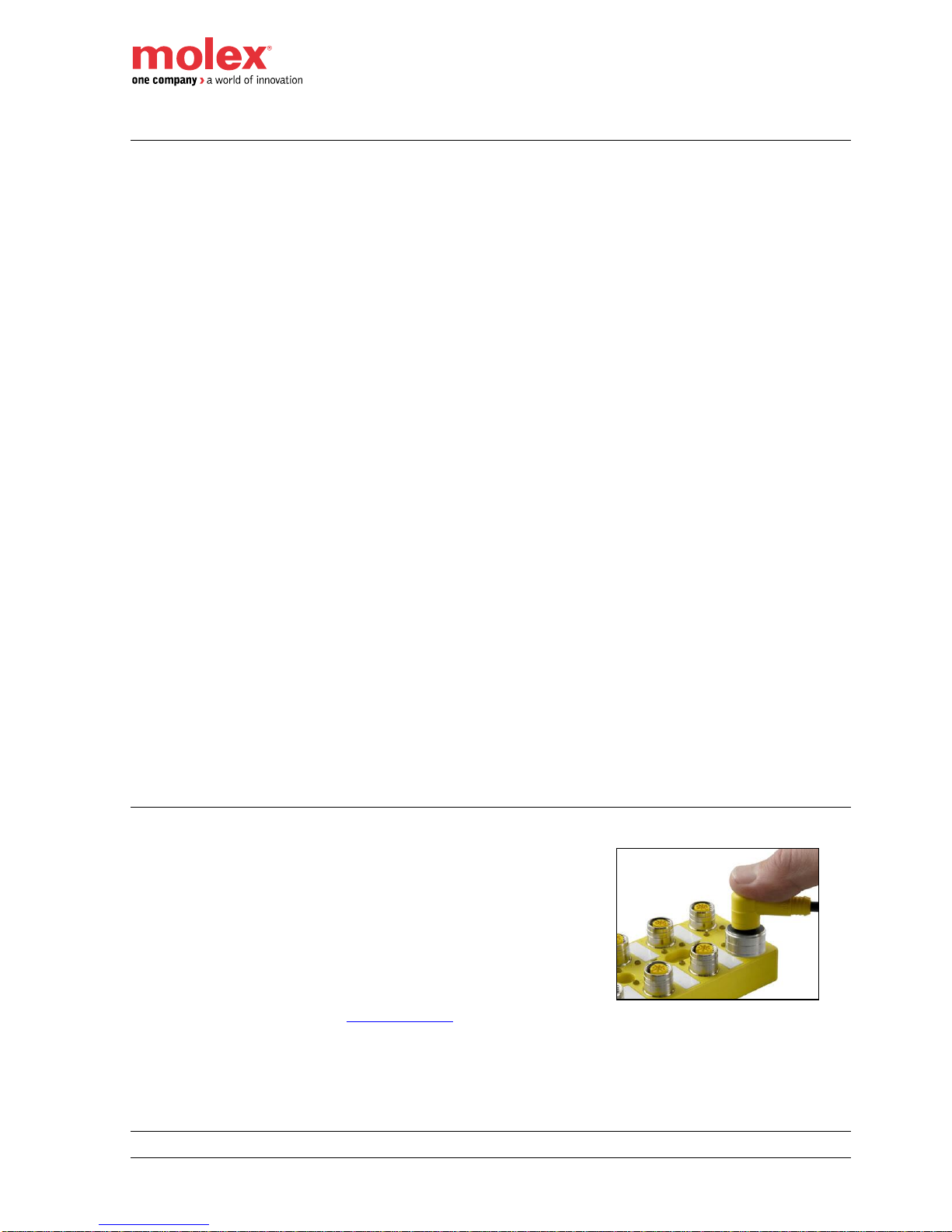

Ultra-Lock M12 connectivity

HarshIO safety modules with Micro-Change® (M12) ports accept both

threaded cordsets and Molex Ultra-Lock™ system.

Ultra-Lock™ connection System! The fastest, easiest and most secure

connection ever designed. Ultra-Lock™ technology is designed for

higher performance and reliability.

Discover how the push-to-lock technology of the Ultra-Lock connection

system can eliminate the downtime, increase the productivity and lower

the costs. More information visit: www.molex.com.

Page 22

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

22 IP67 Safety Digital I/O Modules

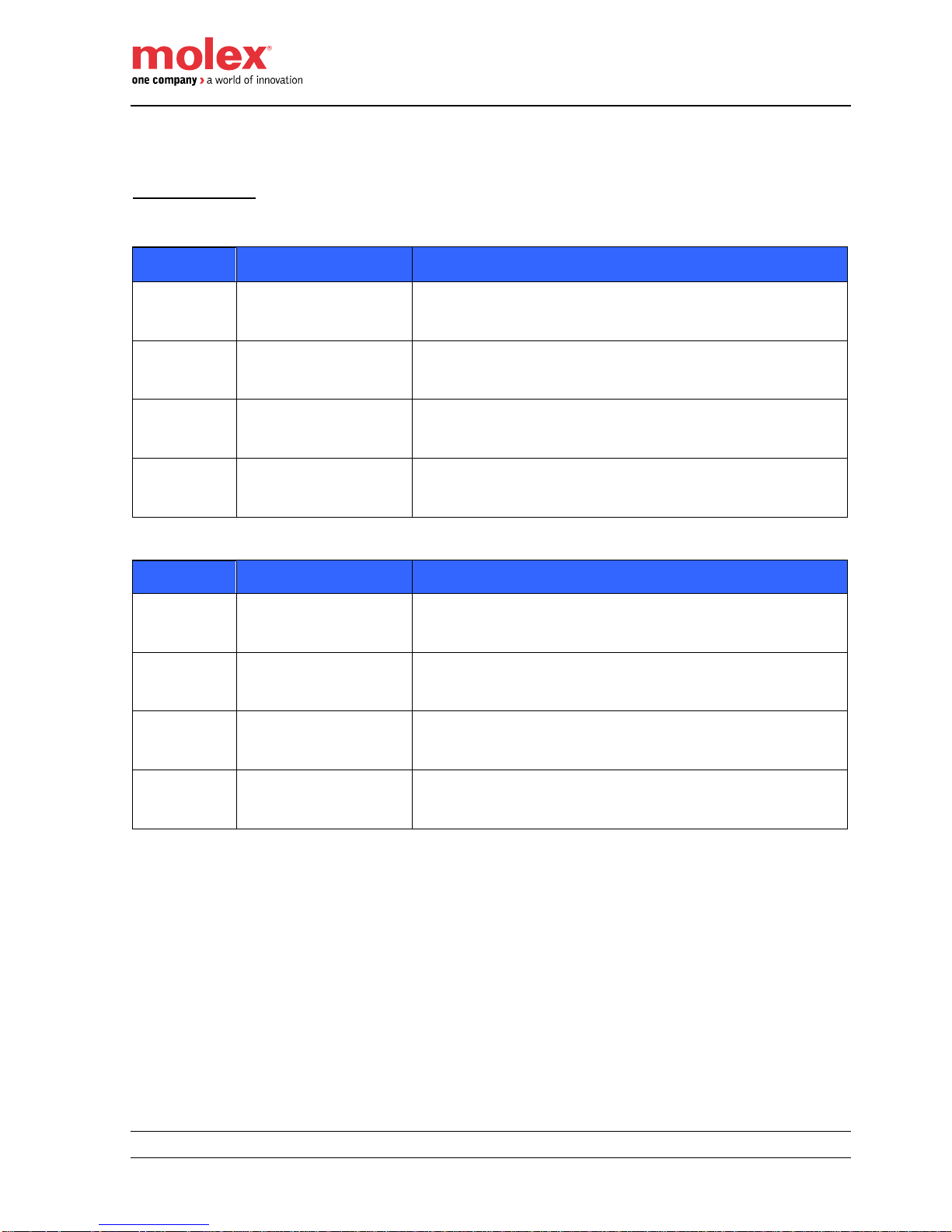

Ordering information

This user safety manual applies to the following HarshIO product references:

Part Number Table

4-pin 7/8” power connector versions

SAP No

Material No

Description

112095-5107

TCDEC-8B4P-DYU-GW

EtherNet/IP CIP Safety IP67 module, 4-pin power connector,

12 Safety Inputs + 4 Safety Outputs, Windows key

112095-5127

TCDEC-8B4P-DYU-G8

EtherNet/IP CIP Safety IP67 module, 4-pin power connector,

12 Safety Inputs + 4 Safety Outputs, M8 key

112095-5108

TCDEC-8B4B-DYU-GW

EtherNet/IP CIP Safety IP67 module, 4-pin power connector,

12 Safety Inputs + 2 Safety Bipolar Outputs, Windows key

112095-5128

TCDEC-8B4B-DYU-G8

EtherNet/IP CIP Safety IP67 module, 4-pin power connector,

12 Safety Inputs + 2 Safety Bipolar Outputs, M8 key

5-pin 7/8” power connector versions

SAP No

Material No

Description

112095-5111

TCDEC-8B4P-D1U-GW

EtherNet/IP CIP Safety IP67 module, 5-pin power connector,

12 Safety Inputs + 4 Safety Outputs, Windows key

112095-5129

TCDEC-8B4P-D1U-G8

EtherNet/IP CIP Safety IP67 module, 5-pin power connector,

12 Safety Inputs + 4 Safety Outputs, M8 key

112095-5112

TCDEC-8B4B-D1U-GW

EtherNet/IP CIP Safety IP67 module, 5-pin power connector,

12 Safety Inputs + 2 Safety Bipolar Outputs, Windows key

112095-5130

TCDEC-8B4B-D1U-G8

EtherNet/IP CIP Safety IP67 module, 5-pin power connector,

12 Safety Inputs + 2 Safety Bipolar Outputs, M8 key

Page 23

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

23 IP67 Safety Digital I/O Modules

Ethernet topologies

EtherNet/IP CIP Safety HarshIO IO module can be used with a protocol compliant scanner as part of control

system architecture. The modules built-in 2-port Ethernet DLR capable switch allowing to use the network

topology that meets the application needs. These topologies include the following:

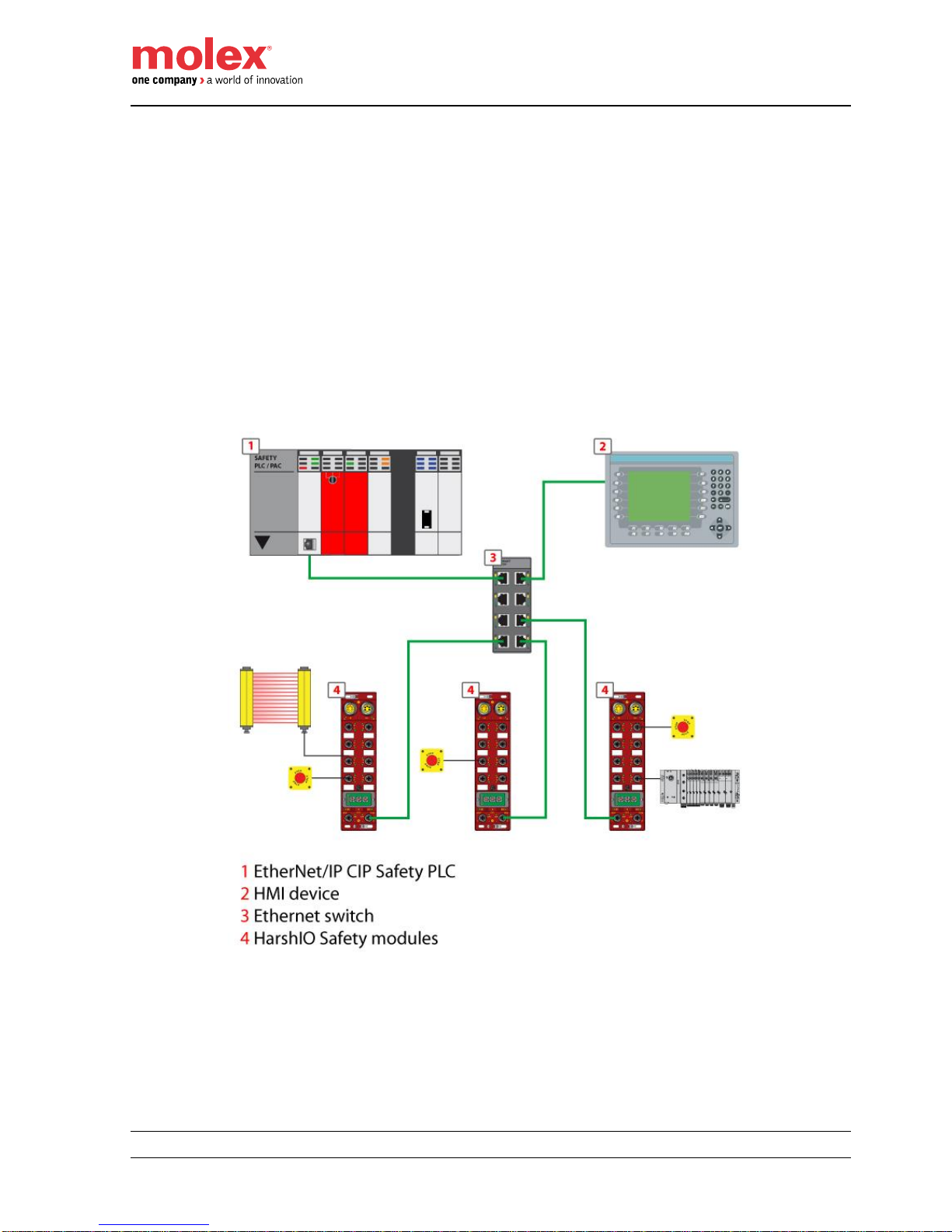

Star

Daisy-chain

Combination of star and daisy-chain

DLR for Ethernet media ring redundancy

Star topology

Star topology allows to connect mixed I/O modules or additional devices. Performing maintenance on one

module – for example, by removing the network cable, or by cycling power to the module – does not affect

other modules.

Page 24

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

24 IP67 Safety Digital I/O Modules

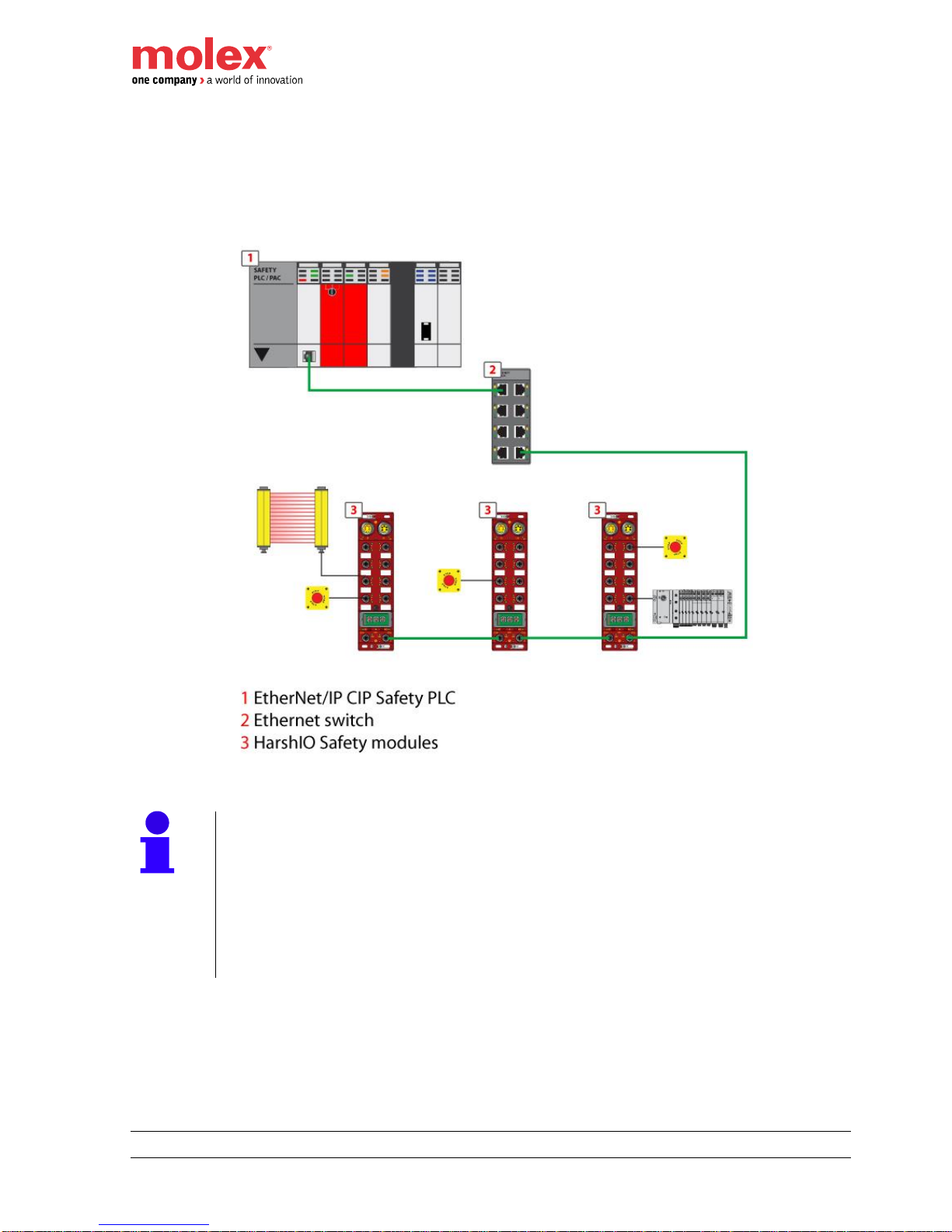

Daisy-chain topology

Daisy-chain ring topology is the easiest way to add more EtherNet/IP CIP Safety HarshIO IO module or

additional devices in the system by daisy-chaining, or connecting each industrial device in series to the next.

This topology is the simplest and cost-effective solution because it takes full advantage of the dual port

Ethernet switch integrated in HarshIO modules and reduces the overall Ethernet cable length.

Note!

When considering the daisy chain topology, note that:

Performing maintenance on any module not physically located at the end of the

daisy chain – for example, by removing the network cable, or by cycling power to

the module – affects any modules located down the chain from the maintained

module.

The embedded dual port Ethernet switch located in each module eliminates the

need for additional Ethernet switches

Page 25

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

25 IP67 Safety Digital I/O Modules

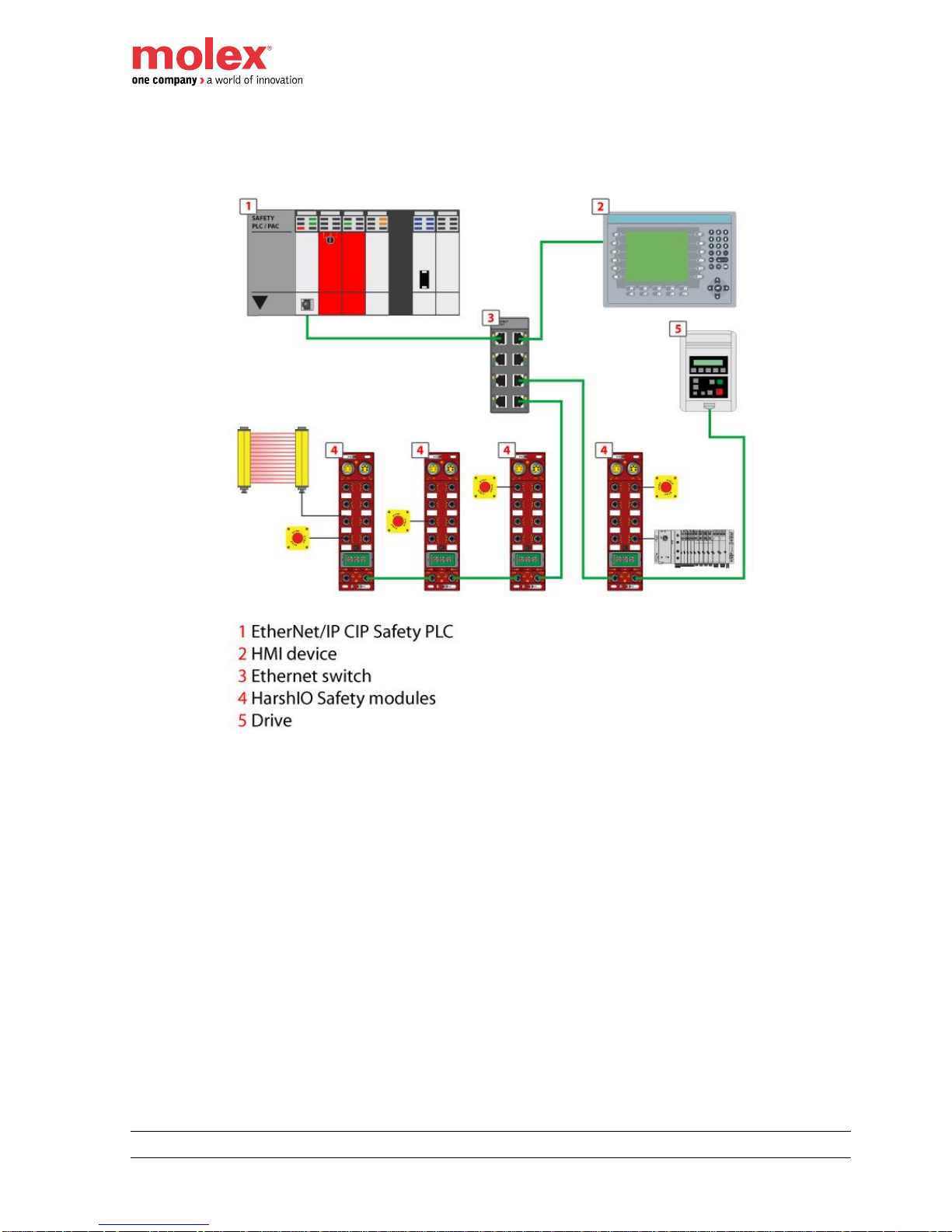

Combination of star and daisy-chain topology

Combining star and daisy-chain topology allows connecting EtherNet/IP CIP Safety HarshIO IO modules with

mixed HarshIO modules or additional devices.

Page 26

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

26 IP67 Safety Digital I/O Modules

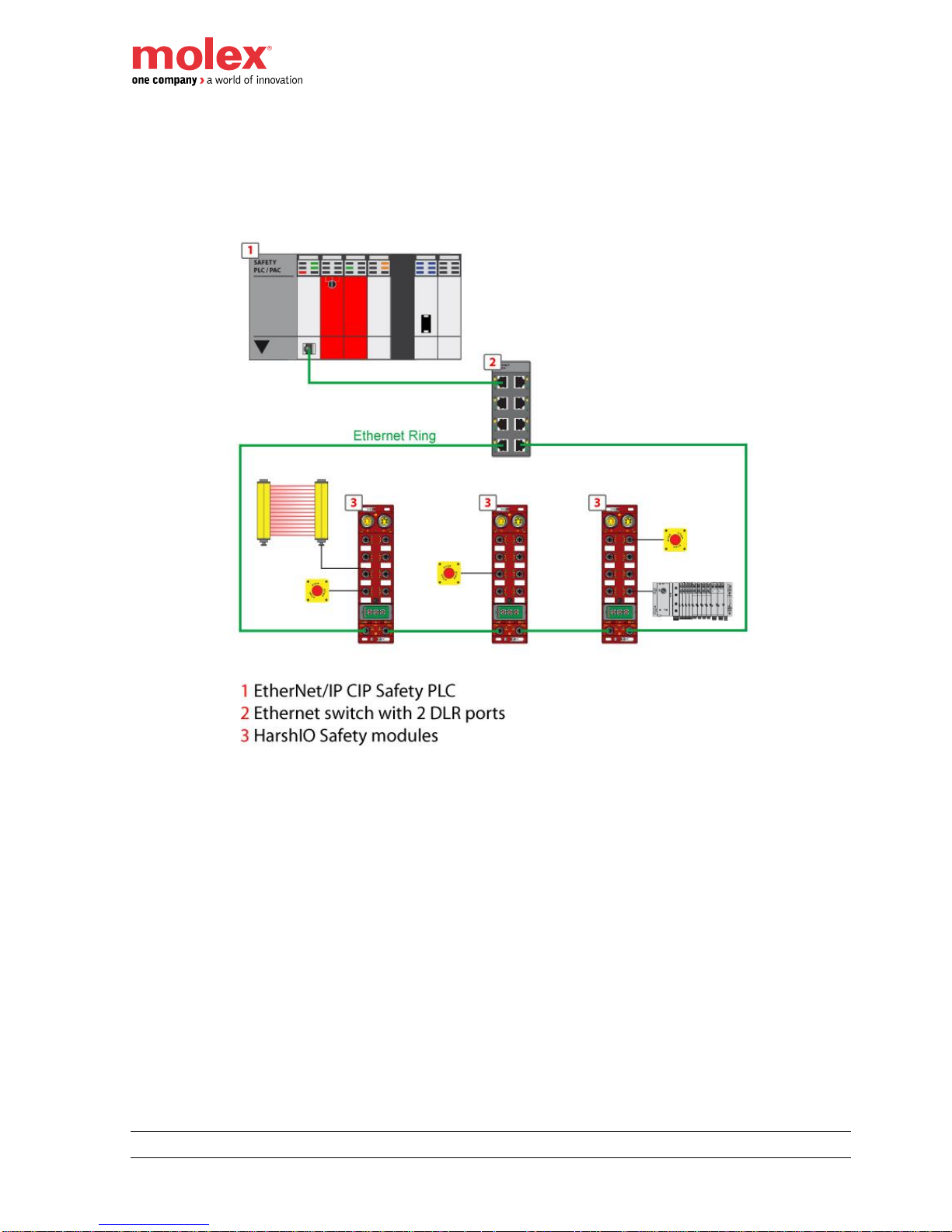

DLR Ring topology

DLR ring topology allows including mixed I/O modules and additional devices in a ring. Performing

maintenance on one module – for example, by removing the network cable, or by removing a module does not

affect other modules as the disruption can be detected and the CIP safety communication can be then routed

adequately.

Page 27

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

27 IP67 Safety Digital I/O Modules

4. Functional Safety Functions

EtherNet/IP CIP Safety HarshIO modules can achieve the following safety classes by making suitable

parameter settings and wiring.

Safety Classes

I/O Configuration

Per IEC 61508 / IEC 62061

Per ISO 13849-1

Dual I/O Channel

SIL 3

PL e / Cat. 4

Single I/O Channel

SIL 2

PL d / Cat. 2

Safety States

The safety states of the HarshIO module are defined as the following:

Safe Outputs are switched OFF

Safe Inputs are reported in the OFF state on the network

Warning!

HarshIO modules are to be used in systems where the OFF state is the safety state.

Page 28

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

28 IP67 Safety Digital I/O Modules

Safety Inputs

Safety inputs are used to report the state of safety input devices.

A safety input can be configured as:

Not Used (default) - the input is disable and doesn’t participate in any safety function

Safety - the input participates to the safety function, but does not have a dependency on a test output

Safety Pulse Test - the input participates to the safety function and has a dependency on an

associated test output configured as “Pulse Test”

Standard - The input doesn’t participate in any safety function (allows to connect non-safe input

device). Nevertheless a Standard input behaves exactly like an input configured as Safety.

Using Safety Inputs on Single-Channel

The inputs are configured as 2 distinct safety inputs on the same M12 connector.

The process Input value is set to safety device physical input value and status is “1” (good) as long as no fault

is detected. On fault detection, the process Input value is turned OFF and status is “0” (bad).

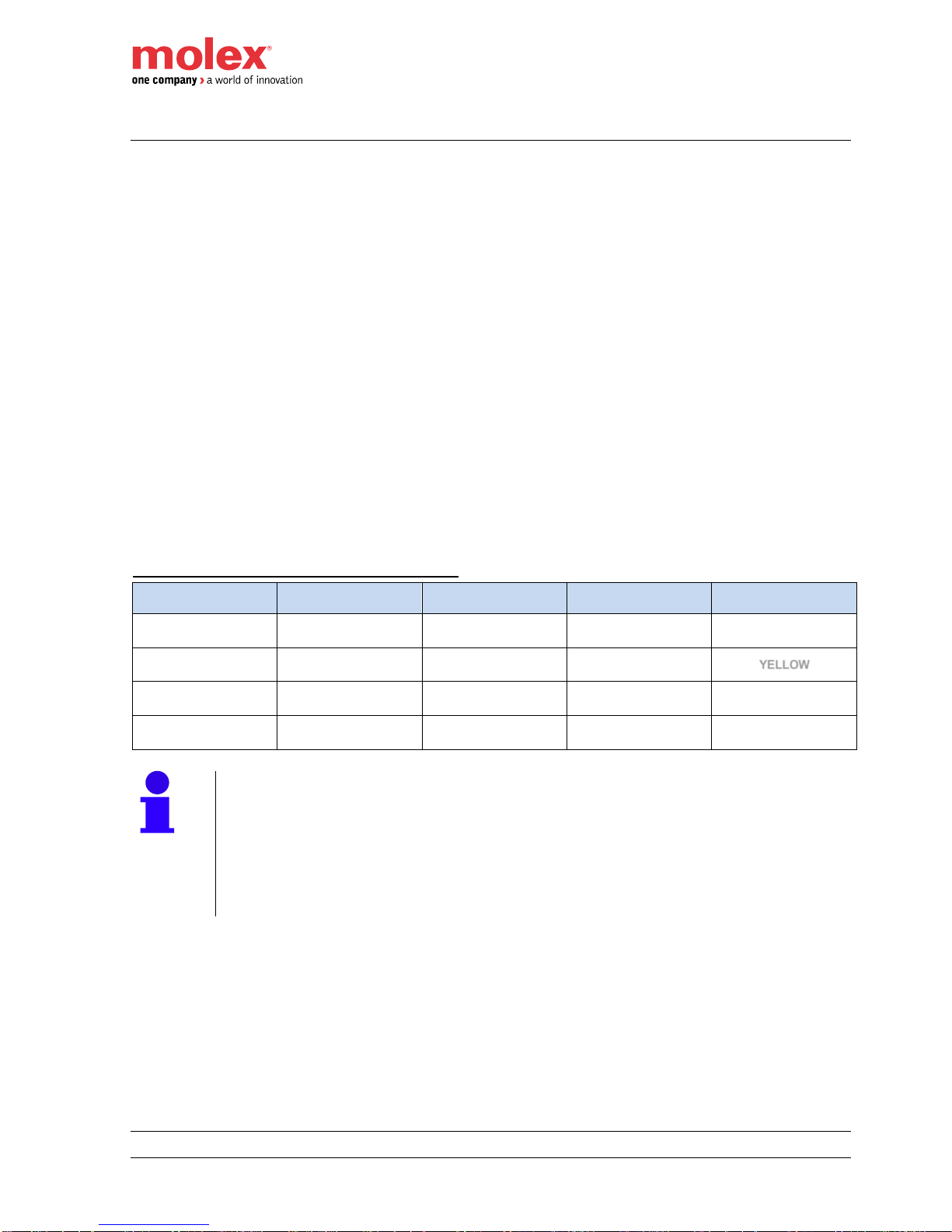

HarshIO behavior when used as single safe inputs:

Safety Device

Physical State

Fault Detected

(1)

Safe Input

Process Value

Safe Input

Process Status

Safe Input

Led Status

0 = OFF

No

0 (safe)

1

OFF

1 = ON

No

1 (active)

1

YELLOW

0 = OFF

Yes

0 (fault)

(2)

0

RED

1 = ON

Yes

0 (fault)

0

RED

Notes!

(1) When single channel input is configured as “Standard” or “Safety”, only internal

hardware faults can be detected. Input shall be configured as “Safety Pulse Test” to

allow external short to ON detection.

(2) This state is a transitory state only as it corresponds to fault reset condition

(physical value set to OFF). If physical fault still exist on the wiring, fault will be

detected again at next ON transition.

Page 29

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

29 IP67 Safety Digital I/O Modules

Using a Test Output

A test output can be configured as

Pulse Test – When the external contact of the safety device is closed, the test output pulse allows

diagnosing external wiring faults as stuck with the power supply or short with the other safety input

from the same M12 connector.

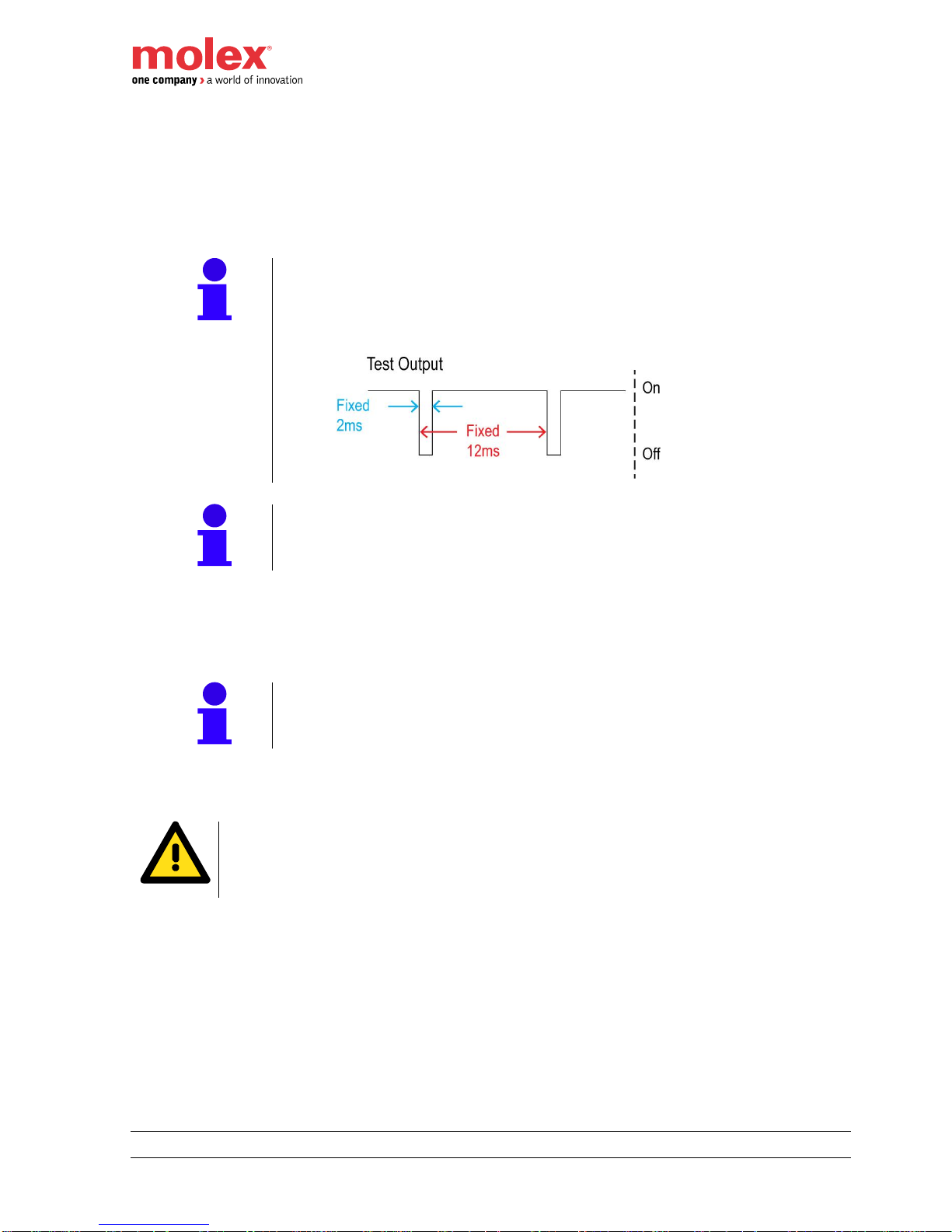

Note!

Characteristics of the pulse test

Pulse test length: 2ms

Pulse test period: 12ms

Note!

A pulse test can be configured to each safety Input of the M12 connector. It can

be also associated to the both inputs.

Power Supply – The test output is used as a power supply to supply 24 VDC for the safety input

device.

Standard – The test output is used as a non-safe digital output.

Note!

No status led is associated to test outputs. Test output values and status can

nevertheless be monitored via Inputs process image.

Muting Lamp – The test output diagnoses whether the circuit and lamp are operational.

Warning!

When test outputs are configured for Power Supply or Muting Lamp, the use of

double isolation cable could be required depending on the application and on the

expected SIL/CAT to achieve.

Page 30

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

30 IP67 Safety Digital I/O Modules

When test output is activated, Muting Lamp feature controls the output current. Below 5mA, a fault is

detected and the status is 0=OFF. Above 25mA is normal operation, the status is 1=ON.

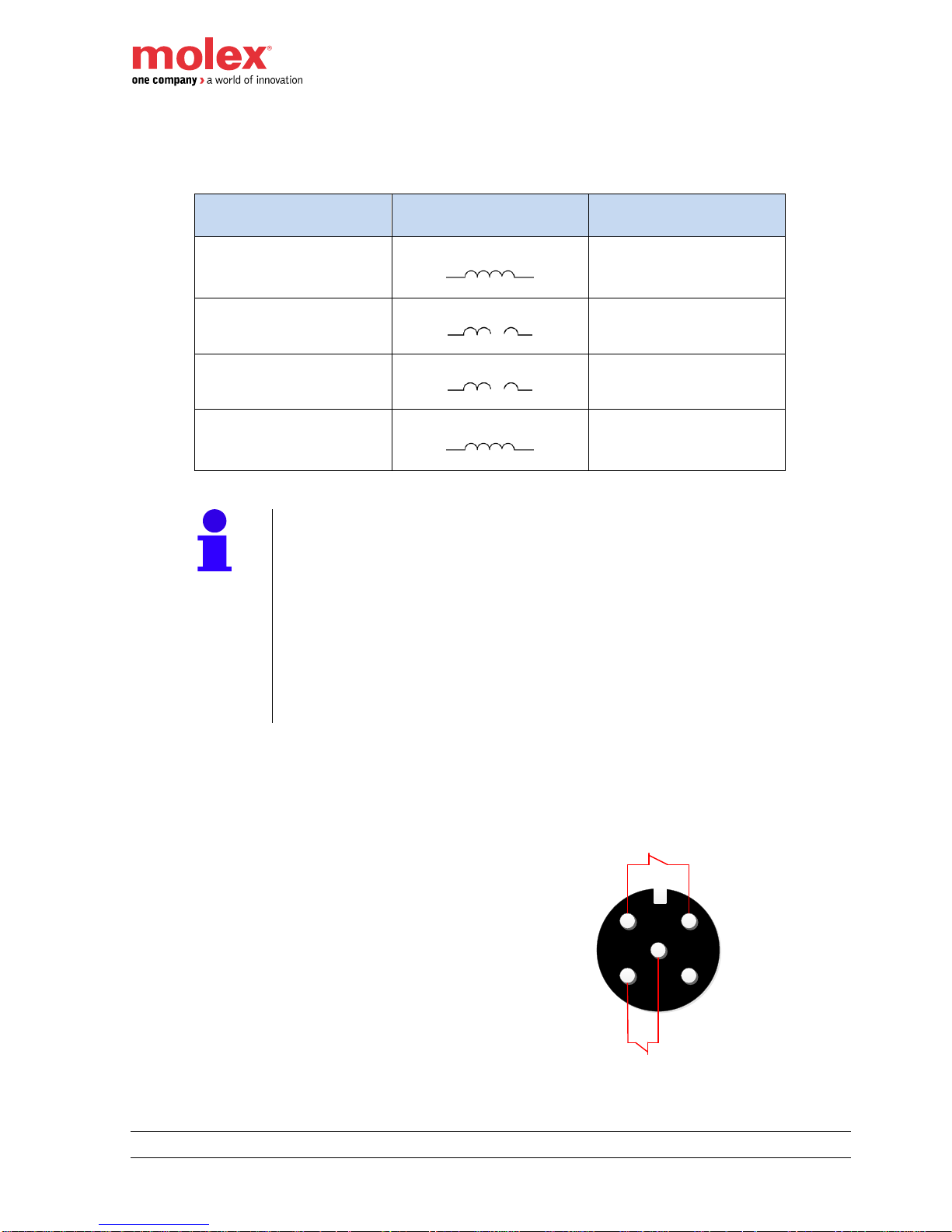

Below is a typical scenario for muting lamp broken wire detection:

Test Output Process Value

Muting Lamp Physical State

Muting Lamp Status

Step #1: 1 = ON

Lamp good

1

Step #2: 1 = ON

Lamp broken

0

Step #3: 0 = OFF

Lamp broken

0

Step #4: 0 = OFF

Lamp replaced

1

Notes!

Only Test Output 3 and Test Output 7 can be configured in Muting Lamp

mode.

When Test Output is not activated, no broken wire fault can be detected.

However, once a default has been detected (step 2), the lamp

replacement is diagnosed even if the Test Output is deactivated (step 3)

Broken wire detection is performed at a 3 second period. Two

consecutive detections are required before the status is reported as BAD,

so up to 6 seconds can be required before muting lamp status to be set to

BAD

Typical wiring of safety inputs

M12 pining and wiring of the safety inputs with the associated pulse test outputs

1: Test Output #1 (TP1, 24 VDC powered from UB)

2: Safe Input #1 (IN1)

3: Ground Logic/Input (UB GND)

4: Safe Input #0 (IN0)

5: Test Output #0 (TP0, 24 VDC powered from UB)

1

1 2

3

4

5

External Contact

TP0

IN0

IN1TP1

GND

External Contact

Page 31

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

31 IP67 Safety Digital I/O Modules

Set Dual-channel Mode and Discrepancy Time

To support redundant channel safety devices, the consistency between signals on two input channels can be

evaluated. This type of redundant wiring is called dual-channel mode.

Note!

The dual-channel feature can only work by using the 2 safety input signals of the

same M12 port of the HarshIO.

A total of six redundant channel safety devices can be connected to the HarshIO.

One redundant channel safety device per M12 port.

Either “Equivalent” or “Complementary” evaluation mode of the safety input pair has to be selected. In dualchannel mode, the HarshIO module monitors the time during which there is a discrepancy between the two

channels.

Note!

Using the HarshIO SNCT software,

The discrepancy time can be configured from 10ms to 30s, in increments of 10ms.

The discrepancy time default value is 10ms.

HarshIO behavior when used as equivalent dual safe inputs:

Safety Device

Physical State

Fault Detected

(*1)

Safe Input

Process Value

Safe Input

Process Status

Safe Input

Led Status

Input

(Pin 4)

Input+1

(Pin2)

Input

Input+1

Input

Input+1

Input

Input+1

Input

Input+1

0 = OFF

0 = OFF

No

No

0 (safe)

0 (safe) 1 1

OFF

OFF

0 = OFF

1 = ON

No

No

0 (fault)

0 (fault)

0

(a)

0

(a)

RED

(b)

RED

(b)

1 = ON

0 = OFF

No

No

0 (fault)

0 (fault)

0

(a)

0

(a)

RED

(b)

RED

(b)

1 = ON

1 = ON

No

No

1 (active)

1 (active) 1 1

YELLOW

YELLOW

- - Yes

-

0 (fault)

0 (fault) 0 0

RED

BLINKING

RED

- - -

Yes

0 (fault)

0 (fault) 0 0

BLINKING

RED

RED

(a): At “1” until discrepancy time expired.

(b): OFF until discrepancy time expired.

HarshIO behavior when used as complementary dual safe inputs:

Safety Device

Physical State

Fault Detected

(1)

Safe Input

Process Value

Safe Input

Process Status

Safe Input

Led Status

Input

(Pin 4)

Input+1

(Pin2)

Input

Input+1

Input

Input+1

Input

Input+1

Input

Input+1

0 = OFF

0 = OFF

No

No

0 (fault)

1 (fault)

0

(a)

0

(a)

RED

(b)

RED

(b)

0 = OFF

1 = ON

No

No

0 (safe)

1 (safe) 1 1

OFF

YELLOW

1 = ON

0 = OFF

No

No

1 (active)

0 (active) 1 1

YELLOW

OFF

1 = ON

1 = ON

No

No

0 (fault)

1 (fault)

0

(a)

0

(a)

RED

(b)

RED

(b)

- - Yes

-

0 (fault)

1 (fault) 0 0

RED

BLINKING

RED

- - -

Yes

0 (fault)

1 (fault) 0 0

BLINKING

RED

RED

(a): At “1” until discrepancy time expired.

(b): OFF until discrepancy time expired.

Page 32

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

32 IP67 Safety Digital I/O Modules

Notes!

(1) When dual channel inputs are configured as “Standard” or “Safety”, only internal

hardware faults and discrepancy between inputs can be detected. Inputs shall be

configured as “Safety Pulse Test” to allow external short to 1 detection

At inputs transition, during the discrepancy time, inputs are reported at the safe

state

Safety Input Fault Recovery

Note!

If a fault is detected, the safety input (or safety inputs) process value remains in the

safety state until the following procedure is applied:

1. Removed the cause of the fault.

2. Set the safety input to his safety state.

Input Delay

On-delay and Off-delay can be configured individually for each input.

On-delay

The On-delay is the minimum time necessary for a physical input switched to ON to be reported as “1” on the

network. For example, if the On-delay is set to 5ms, the Input will be reported on the network at level “1”, after

the Input has been evaluated at ON during at least 5ms.

Off-delay

The Off-delay is the minimum time necessary for a physical input switched to OFF to be reported as “0” on the

network. For example, if the Off-delay is set to 5ms, the Input will be reported on the network at level “0”, after

the Input has been evaluated at OFF during at least 5ms.

Note!

Using the HarshIO SNCT software,

On-delay and Off-delay parameters can be configured from 0 to 1000ms, in

increments of 1ms.

On-delay and Off-delay default values are 0.

Input Error Latch Time

The Input Error Latch Time is a unique parameter that applies for all the Inputs.

The purpose for latching input errors is to make sure that intermittent faults that can only exist for a few

milliseconds are latched long enough to be read by the controller. It defines the minimal duration a detected

fault on any safe inputs shall be reported on the network in order to able the controller to detect it.

Note!

Using the HarshIO SNCT software,

Input Error Latch Time default parameters can be configured from 0 to 65530ms, in

increments of 10ms.

Input Error Latch Time default value is 1000ms.

The amount of time to latch the error must be based on the RPI of the safety

connection, the application safety task watchdog, and other application specific

variables.

Page 33

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

33 IP67 Safety Digital I/O Modules

Safety Sourcing Outputs (TCDEC-8B4P-D1U-Gx and TCDEC-8B4P-DYU-Gx)

Safety sourcing outputs are used to drive the state of output devices.

Note!

HarshIO safe outputs are:

current sourcing at max. 1A

short circuit protected

pulse test configurable

A Safety Output can be configured as:

Not Used (default) - The output is disable and doesn’t participate in any safety function.

Safety Pulse Test - The output generates pulse tests (when the output is active) to monitor short-

circuit between output pin and power supply (stuck at “1”), or short with other active output from the

same M12 connector.

Notes!

Using the HarshIO SNCT software,

The Pulse tests length is configurable from 300µs to 10ms, in increments

of 100µs.

Pulse tests length default value is 500µs

Pulse tests period: 468ms

In addition to external shorts detection, all safety functions involved in

outputs switch-off are also diagnosed at each period. So a series of 4

pulse tests are applied on each safety output.

Note!

The pulse test should be configured according to the impedance of the connected

device. HarshIO safety has been design to control a wide range of device by using

an active discharge circuit. For each pulse test higher than 500µs (or equal), if a

residual voltage is present, a 50mA current is clamped during 300µs.

Nevertheless, if it is not enough and output goes into safe state due to the

capacitive load of the connected equipment, the pulse length can be increased (up

to 10ms).

Page 34

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

34 IP67 Safety Digital I/O Modules

Notes!

Safety Sourcing outputs should not be used to provide power to a device

or sub-system whom the resistive and capacitive load could vary during

operation.

Warning!

Be careful of the response time of the output device to prevent any malfunction

because of pulse test.

Safety No Pulse Test - The output is used without pulse test.

Note!

In this mode, diagnostics are done on the output. When a sourcing output is

switched off, the measured state can be different to the expected one due to the

capacitive load of the connected equipment. HarshIO have been design to control

a wide range of equipment by using an active discharge circuit. When a sourcing

output is switched off, if a residual voltage is present, a 50mA current is clamped

during 2ms.

M12 pining and wiring of the safety sourcing outputs:

1: 24 VDC (powered from UL)

2: Safe Output #1 (OUT1)

3: Ground Output (UL GND)

4: Safe Output #0 (OUT0)

5: Ground Output (UL GND)

Note!

The maximum current available on the Pins #1 (24 VDC) of the 2 Output sourcing ports

is 3.5A.

1

1 2

34

5

External Load

OUT0

OUT1

GND

External Load

GND

24V

Page 35

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

35 IP67 Safety Digital I/O Modules

Using Safety Sourcing Outputs in Single-Channel Outputs

Outputs from the same M12 connector are configured as 2 single channel outputs.

When activated by the logic controller, output is turned ON and status is “1” (good) as long as no fault is

detected. On fault detection, Output is forced to safe state OFF and status is set to “0” (bad).

HarshIO behavior when used as single safe outputs:

Safe Output

Process Value

Fault Detected

Safety Device

Physical State

Safe Output

Process Status

Safe Output

Led Status

0

No

0 = OFF (safe)

1

OFF

1

No

1 = ON (active)

1

YELLOW

-

Yes

(on output itself)

0 = OFF (fault)

0

RED

-

Yes

(on the partner)

0 = OFF (fault)

0

BLINKING RED

Note!

When a fault is detected on a single channel output, both outputs on the same M12

connector will switch to safe state.

Note!

When no pulse test is configured on a safety output, only read back value is used to

detect fault, so only short to 1 when output is driven to 0 and short to 0 when output

is driven to 1 are detected

When pulse tests are activated, internal faults as well as short to 1 can be then

detected

Using Safety Outputs as Dual-Channel outputs

Outputs from the same M12 connector can be configured as an output pair.

When both output process values are activated by the logic controller, the dual outputs are turned ON and

status is “1” (good) as long as no fault is detected. On hardware fault detection or discrepancy of output

process values, outputs are forced to safe state OFF and status is set to “0” (bad).

HarshIO behavior when used as dual safe outputs:

Safe Output

Process Value

Fault Detected

Safety Device

Physical State

Safe Output

Process Status

Safe Output

Led Status

Output

Output+1

Output

Output+1

Output

(Pin 4)

Output+1

(Pin2)

Output

Output+1

Output

Output+1

0

0

No

No

0 = OFF

(safe)

0 = OFF

(safe)

1 1 OFF

OFF

0

1

No

No

0 = OFF

(fault)

0 = OFF

(fault)

0 0 RED

RED

1

0

No

No

0 = OFF

(fault)

0 = OFF

(fault)

0 0 RED

RED 1 1

No

No

1 = ON

(active)

1 = ON

(active)

1

1

YELLOW

YELLOW

- - Yes

-

0 = OFF

(fault)

0 = OFF

(fault)

0 0 RED

BLINKING

RED

- - -

Yes

0 = OFF

(fault)

0 = OFF

(fault)

0

0

BLINKING

RED

RED

Page 36

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

36 IP67 Safety Digital I/O Modules

Safety Output Fault Recovery

Note!

If a fault is detected, the safety output (or safety outputs) physical value remains in the

safety state until the following procedure is applied:

Removed the cause of the fault.

Set the safety output to his safety state.

Output Error Latch Time

The Output Error Latch Time is a unique parameter that applies for all the Outputs.

The purpose for latching output errors is to make sure that intermittent faults that can only exist for a few

milliseconds are latched long enough to be read by the controller. It defines the minimal duration a detected

fault on any safety outputs shall be reported on the network in order to able the controller to detect it.

Note!

Using the HarshIO SNCT software,

Output Error Latch Time default parameters can be configured from 0 to 65530ms,

in increments of 10ms.

Output Error Latch Time default value is 1000ms.

The amount of time to latch the error must be based on the RPI of the safety

connection, the application safety task watchdog, and other application specific

variables.

Page 37

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

37 IP67 Safety Digital I/O Modules

Bipolar Safety Outputs (TCDEC-8B4B-D1U-Gx and TCDEC-8B4B-DYU-Gx)

Bipolar safety outputs are used to drive the state of output devices.

The bipolar outputs combines the safety sourcing output and the safety sinking output of the same M12

connector as a output pair in dual channel mode and can support current up to 2A.

Note!

HarshIO bipolar safety outputs are:

current sourcing at max. 2A.

always configured in dual-channel mode meaning that a maximum of two safety

output devices can be connected to a HarshIO module.

short circuit protected

A bipolar Safety Output can be configured as:

Not Used (default) - The bipolar outputs are disable and don’t participate in any safety function.

Safety Pulse Test - The output sourcing generates a pulse test (when the output is active) to monitor

short-circuit between output sourcing signal and power supply (stuck at “1”). The output sinking

generates a pulse test (when the output is active) to monitor short-circuit between output sinking signal

and ground (stuck at “0”).

Note!

Using the HarshIO SNCT software,

Each safety bipolar output pair can be configured individually with or

without pulse test.

The Pulse test length is configurable from 300µs to 10ms, in increments

of 100µs, with a default value of 700µs. In the case of bipolar outputs,

pulse management has been designed in order that the default value

should work in almost applications, including applications where the

resistive and capacitive load of the connected device or sub-system can

vary during operation. It is then strongly recommended to keep default

value unchanged. Changing this parameter should be done only if an

issue is observed during application testing.

Pulse test period: 468ms

In addition to external shorts detection, all safety functions involved in

outputs switch-off are also diagnosed at each period. So a series of 4

pulse tests are applied on each safety output.

Page 38

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

38 IP67 Safety Digital I/O Modules

Note!

The pulse test should be configured according to the impedance of the connected

device. HarshIO safety bipolar output has been design to control a wide range of

device by using an active discharge circuit. For each pulse test higher than 700µs

(or equal), if a residual voltage is present, a 50mA current is clamped during

500µs. Nevertheless, if it is not enough and output goes into safe state due to the

capacitive load of the connected equipment, the pulse length can be increased (up

to 10ms).

Safety No Pulse Test - The bipolar output is used without a pulse test.

M12 pining and wiring of the safety bipolar outputs:

1: 24 VDC (powered from UL)

2: Safety Output #1 (OUT1 - Sinking)

3: Ground Output (UL GND)

4: Safety Output #0 (OUT0 - Sourcing)

5: Ground Output (UL GND)

Note!

The maximum current available on the Pins #1 (24 VDC) of the 2 Output bipolar ports is

3.5A.

Danger!

Load(s) shall never be connected between Pin 4 (sourcing output) and GND as well as

between Pin 2 (sinking output) and 24 V.

24 V and GND pins shall only be used to provide power to external device but shall

never been wired in association with a safety output.

Note!

A frequent use of bipolar safety outputs is to power and Molex non-safe HarshIO

modules from the bipolar M12 connector.

A special M12 – Mini change cable can be ordered for easy wiring. In this case:

UB (logic and Input) of the non safe module are powered by the 24 V (pin 1) of

the bipolar connector.

UL (Output) of the non-safe module is directly switched on/switched off by the

bipolar pair (pin 2 and 4).

1

1 2

34

5

OUT0

OUT1

GND

External Load

24V GND

Page 39

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

39 IP67 Safety Digital I/O Modules

I/O Status

HarshIO safety module provides status information to monitor the I/O circuit. The status information can be

read by the EtherNet/IP scanner.

Note!

When a fault is detected, the status value is “0” meaning bad. On normal operation, the

status value is “1” meaning good.

Each individual point listed below has its own individual status:

Safety Input Status

Test Output Status

Safety Output Status (sourcing or bipolar)

Behavior in case of fault

Detected fault

Fail safe state

applied on

Method to recover

Fieldbus

communication

availability

Safety Input pulse test

failure

(single channel)

Faulted safe input

1. Remove the fault

2. Switch input in the safe state

Yes

Wait latch error time expired

Safety Input pulse test

failure

(dual channel)

Safety inputs pair

1. Remove the fault

2. Switch input in the safe state

Yes

Wait latch error time expired

Safety input pair

discrepancy

(dual channel)

Safety inputs pair

1. Remove the fault

2. Switch input in the safe state

Yes

Wait latch error time expired

Safety output pulse test

failure or read back value

error

(single channel)

Both single safety

outputs on same

connector

1. Remove the fault

2. Switch outputs in the safe state

Yes

Wait latch error time expired

Safety output pulse test

failure or read back value

error

(dual channel)

Safety output pair

1. Remove the fault

2. Switch outputs in the safe state

Yes

Wait latch error time expired

Safety output discrepancy

error

(dual channel)

Safety Output pair

1. Remove the fault

2. Switch outputs in the safe state

Yes

Wait latch error time expired

Page 40

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

40 IP67 Safety Digital I/O Modules

Overvoltage/under

voltage error on input

power (UB)

Whole module (all

safety inputs and

outputs)

Power cycle needed

Yes

Overvoltage error on

output power (UL)

Whole module (all

safety inputs and

outputs)

Power cycle needed

Yes

Under voltage error on

output power (UL)

All Safety outputs

1. Remove the fault

2. Switch outputs in the safe state

Yes

Overcurrent on input

power (UB)

Whole module (all

safety inputs and

outputs)

Power cycle needed

Yes

Overcurrent on output

power (UL)

Whole module (all

safety outputs)

Power cycle needed

Yes

Temperature error

Whole module (all

safety inputs and

outputs)

Power cycle needed

NO Critical Error

All I/O leds blinked

Internal hardware error

(CPU, RAM, ADC

3,3V,…)

Whole module (all

safety inputs and

outputs)

Power cycle needed

NO Critical Error

All I/O leds blinked

CIP Safety

communication error

(input connection)

All safety inputs

Originator to restart connection

Yes

CIP Safety

communication error

(output connection)

All safety outputs

Originator to restart connection

Yes

Rotary Change Value

Whole module (all

safety inputs and

outputs)

Power cycle needed

Yes

Remove External Key

Whole module (all

safety inputs and

outputs)

Power cycle needed

Yes

Page 41

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

41 IP67 Safety Digital I/O Modules

Response Time

Calculate the response time

In order to calculate the response time of a safety function, the worst-case response times of all components

involved must be added to the delays on the communication paths. Below are the response times of the

HarshIO safety modules to perform these calculations.

Warning!

The safety function is not guaranteed if the following response times are calculated

incorrectly.

1. Maximum response time of a digital safety input (single and dual-channel modes)

Calculate the maximum response time of a safety Input in error-free state. The response time is

calculated from the instant of the physical event happened to a connected sensor and the emission of

the corresponding telegram on the EtherNet/IP network by the HarshIO safety module.

Calculation Delay Times

Response time of the connected sensor/switch + _______ ms

HarshIO Input delay configured + 500μs tolerance + _______.5 ms

Internal maximum processing time of HarshIO module PTIN max + 10.5 ms

---------------------------Maximum response time of a digital safety input = _______ ms

2. Maximum response time of a digital safety output (single and dual-channel modes)

Calculate the maximum response time of a safety output in error-free state. The response time is

calculated from the moment a telegram is received by the HarshIO safety module and the actuator

physical processes the switch-off physical event.

Calculation Delay Times

Internal maximum processing time of HarshIO module PTOUT max: + 4.5 ms

HarshIO pulse test configured + _______ ms

Switch-off time of connected actuator/relay + _______ ms

Additional Switch-off delay (physical signal time commutation) + _______ ms

---------------------------Maximum response time of a digital safety output = _______ ms

Note!

The maximum response type of a detected safety error is 10ms (emission of the

corresponding telegram on the EtherNet/IP network by the HarshIO safety module).

Page 42

EtherNet/IP™ CIP Safety™ IP67 HarshIO 600

42 IP67 Safety Digital I/O Modules

5. Product Characteristics

Hardware characteristics

Type

12x Safe Inputs + 4x Safe Outputs

12x Safe Inputs +

2x Bipolar Safe Outputs

Product Reference

TCDEC-8B4P-DYU-G

TCDEC-8B4P-D1U-G

TCDEC-8B4B-DYU-G

TCDEC-8B4B-D1U-G

Safety

SIL (per IEC 61508 / IEC 62061)

Up to SIL3 (when configured in dual I/O Channel)

CAT (per ISO 13849-1)

Up to Cat. 4 (when configured in dual I/O Channel)

PL (per ISO 13849-1)

Up to PL e (when configured in dual I/O Channel)

PFH

9.70E-11

9.02E-11

PFDavg

8.47E-06

7.88E-06

DCavg

98.66%

98.58%

MTTF

679 years

851 years

Service Life

20 Years

Power

Power IN connector

Mini Change (7/8”), 4-pin or 5-pin, male, stainless steel, shielded, Maximum 8 A

Power OUT connector

Mini Change (7/8”), 4-pin or 5-pin, female, stainless steel, shielded, Maximum 8 A

Module & Input power (UB)

24 VDC, -15% / +20% (protected against power crossing).

Operating current (UB)

<100 mA

Output power (UL)

24 VDC, -15% / +20% (protected against power crossing)

Operating current (UL)

<20 mA (without load)

Safe Inputs

Channels

12 channels

Connector

M12 Ultra-Lock, 5-pin, female, A-Coded, stainless steel, unshielded

(*)

Input type

IEC61131-2 type 3

Input voltage

UB

On / Off delay

Configurable from 0 to 1000ms (0 by default)

Warning!

If UB is over 36 V for a period of 2 seconds or more. The safety module will go in fail

state (all LEDs are blinking in red) and considered as destroyed. Indeed, the internal