Page 1

RHT2251-CC Hand Crimp Tool

Hand Crimp Tool

Operating Instruction Sheet

And Specifications

Part No. 64001-4900

Eng. No. RHT 2251-CC

(Replaces 19285-0023)

FEATURES

A full cycle ratcheting hand tool ensures complete crimps

Long handles for comfortable crimping with reduced crimping force

A precision user-friendly terminal locator wire stop holds terminals in the proper crimping position

Single color-coded crimp pocket eliminates the possibility of using the wrong pocket

SCOPE

AviKrimp Fully Insulated Quick Disconnect Female Couplers and, Perma-Seal Fully Insulated Snap Plug Receptacles 10 - 16 AWG.

Testing

Mechanical

The tensile test, or pull test, is a means of evaluating the mechanical properties of the crimped connections. The following charts

show the UL specifications for various wire sizes. The tensile strength is shown in pounds and indicates the minimum acceptable

force to break or separate the terminal from the conductor.

Wire Size (AWG) *UL - 486 A *UL - 310

16 30 30

14 50 50

12 70 70

10 80 80

UL - 310 - Quick Disconnects Couplers

*UL - 486 A - Terminals (Copper conductors only)

The following is a partial list of the product part numbers and their specifications that this tool is designed to run. We will be adding to

this list and an up to date copy is available on www.molex.com.

Terminal No. Terminal Eng No. (REF)

19164-0054 SBRB-8156N .300 7.60 N/A N/A

19164-0055 SBRB-8180N .300 7.60 N/A N/A

Terminal No. Terminal Eng No. (REF)

19005-0010 C-2265 .313 7.94 .275 6.99

Doc No. 64001-4900 Release Date: 10-15-04 UNCONTROLLED COPY Page 1 of 6

Revision: A Revision Date: 10-15-04

Wire Size: 14 – 16 AWG 2.00 – 1.30 mm²

Wire Strip Length Insul. Dia. Max.

In mm In mm

Wire Size: 10 – 12 AWG 5.00 – 3.30 mm²

Wire Strip Length Insul. Dia. Max.

In mm In mm

Page 2

RHT2251-CC Hand Crimp Tool

CONDUCTOR

OPERATION

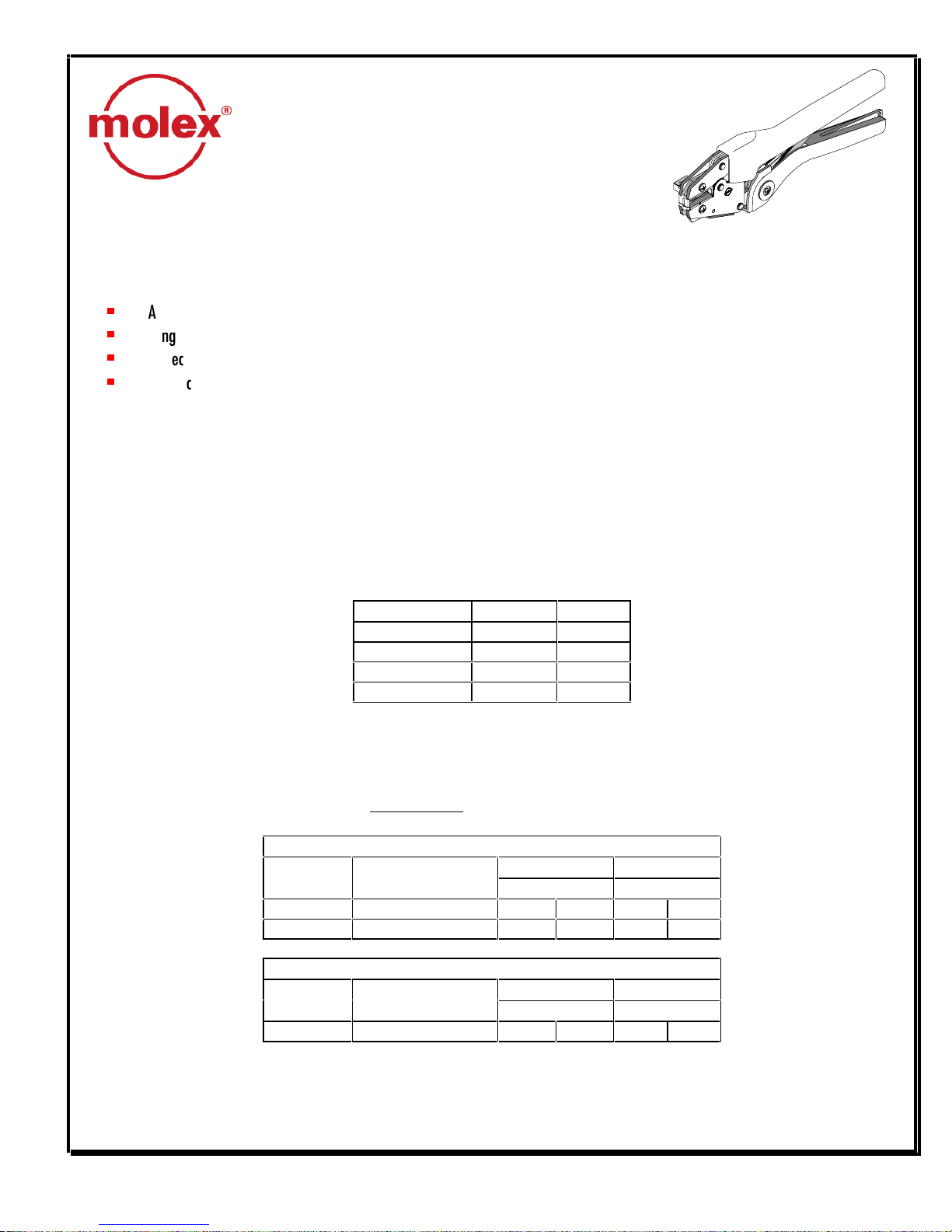

Open the tool by first closing the jaws sufficiently for the ratchet

mechanism to release.

TERMINAL

JAWS OPEN

POCKET OF

LOCATOR

LOCATOR

Figure 1

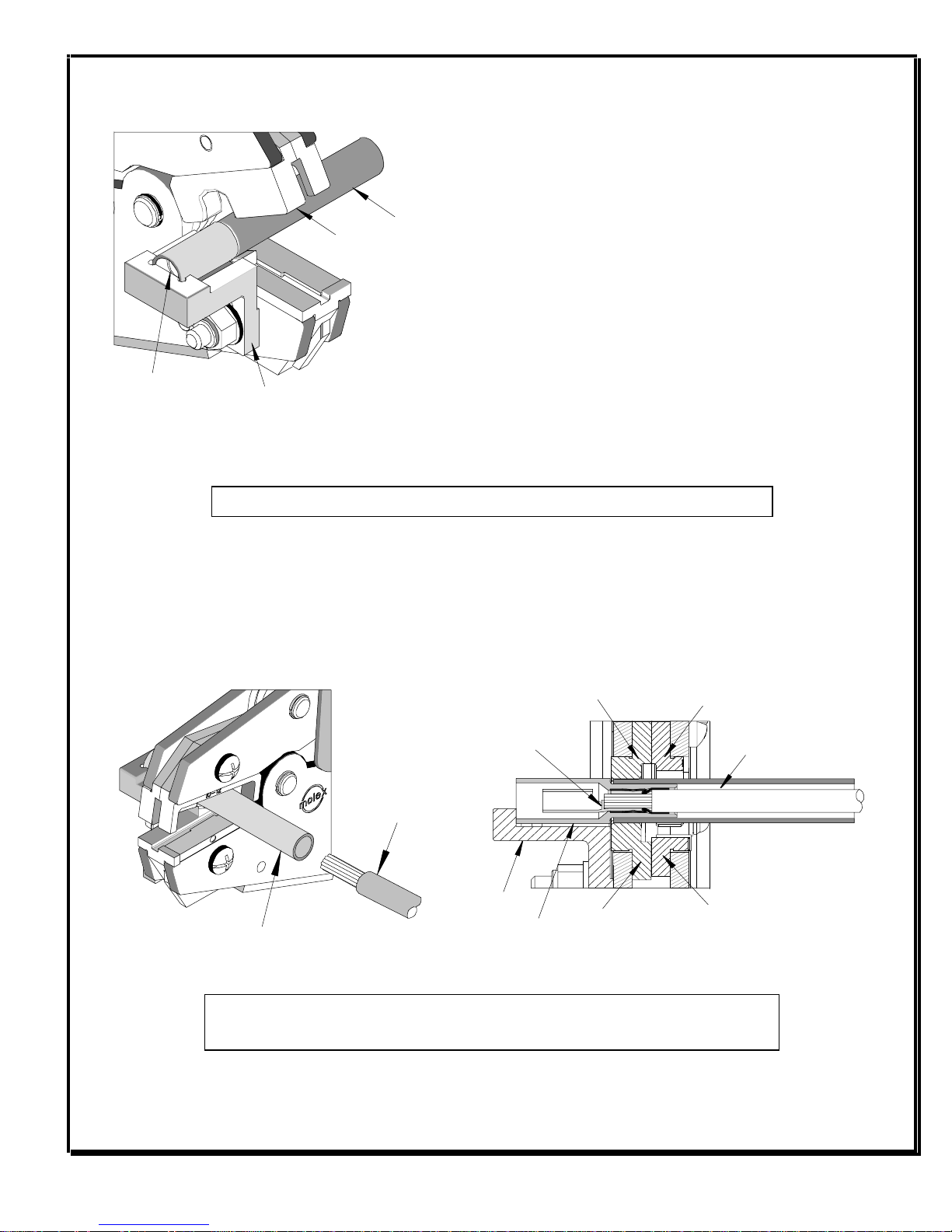

4. Insert the properly stripped wire into the terminal barrel (See Figure 2 and 3). The wire insulation will stop against the taper of the

terminal. Cycle the tool.

Note: The tamper proof ratchet action will not release the tool until it has been fully closed.

5. Remove the crimp and inspect for proper crimp location, and check for insulation closure. Molex offers a Crimp Inspection

Handbook for closed barrel industrial product. See our website or contact your sales engineer.

6. If the insulation part of the crimp needs to be adjusted, first loosen the M4 screw on the bottom tool jaw, then insert a 3/32 hex

wrench (supplied) into the bottom of the lower die (See Figure 4). A clockwise (CW) rotation decreases insulation crimp while a

counter-clockwise (CCW) rotation increases insulation crimp. After adjusting retighten the M4 screw.

WIRE

TERMINAL

Figure 2

Note: Whenever crimping without the locator, make sure the seam of the terminal is oriented

up or down in the tool if using unbrazed product, as this will provide higher pull force values.

Crimping Terminals

1. Adjust the locator up or down until the terminal being run sits flat

and straight in the tool.

2. Position the terminal with the barrel facing up into the color-coded

nest. Make sure the end of the terminal fits into the locator

pocket securely and the front edge of the barrel is flush against

the front edge of the locator, (See Figure 1).

3. Partially close the tool to hold the terminal in place (See Figure

2).

WIRE STOP

BUILT INTO

TERMINAL

LOCATOR

TERMINAL

PUNCH

CONDUCTOR

ANVIL

PUNCH

INSERT

ANVIL

INSERT

WIRE

Figure 3

Doc No. 64001-4900 Release Date: 10-15-04 UNCONTROLLED COPY Page 2 of 6

Revision: A Revision Date: 10-15-04

Page 3

RHT2251-CC Hand Crimp Tool

3/32” HEX

WRENCH

Maintenance

It is recommended that each operator of the tool be made

aware of, and responsible for, the following maintenance

steps:

1. Remove dust, moisture and other contaminants with a

LOOSEN M4

SCREW

clean brush, or soft, lint-free cloth.

2. Do not use any abrasive materials that could damage the

tool.

3. Make certain all pin, pivot points and bearing surfaces

are protected with a thin coat of high quality machine oil.

Figure 4

Do not oil excessively. The 64001-4900 (RHT-2251-CC)

was engineered for durability, but like any fine piece of

equipment it needs cleaning and lubrication for a maximum service life of trouble-free crimping. A light oil, such as 30 weight

automotive oil used at the oil points shown in Figure 4, every 5,000 crimps or 3 months will significantly enhance the tool life and

ensure a stable calibration.

4. When tool is not in use, keep the handles closed to prevent objects from becoming lodged in the crimping dies, and store the tool

in a clean, dry area.

LUBRICATION POINTS

(BOTH SIDES) LIGHT OIL

(EVERY 3 MONTHS

OR 5,000 CRIMPS)

Miscrimps or Jams

Should this tool ever become stuck or jammed in a partially closed position, Do Not force the handles open or closed. The tool will

open easily by pressing the ratchet release lever (See Figure 5).

How To Adjust Tool Preload (See Figure 5)

Over the life of the tool, it may be necessary to

adjust tool handle preload force. Listed below

are the steps required to adjust the crimping

force of the hand tool to obtain proper crimp

conditions:

1. Remove the screw and plastic cover washer.

Note the setting wheel position.

2. Lift the setting wheel off the axle. Turn the

eccentric axle with a screwdriver.

3. Turning the eccentric axle counter-clockwise

will increase handle force.

4. Replace the setting wheel to the axle,

aligning the nearest notch in the setting

wheel to the dowel pin.

5. Replace the plastic cover washer and screw.

6. Check the crimp specifications after tool crimp force is adjusted.

RATCHET

RELEASE LEVER

PUSH UP

PRELOAD

TEST POINT

PRELOAD

TEST POINT

PRELOAD

ADJUSTMENT

LOCKING SCREW

1.00

1.00

Figure 5

Doc No. 64001-4900 Release Date: 10-15-04 UNCONTROLLED COPY Page 3 of 6

Revision: A Revision Date: 10-15-04

Page 4

RHT2251-CC Hand Crimp Tool

Tool Calibration

PIN GAUGE IN

CONDUCTOR CRIMP

A Certificate of Calibration (see last page) was supplied with the tool. To

recalibrate this tool, pin gauge measurements should be taken in each

conductor nest and compared to this chart. The tool should be lubricated

prior to recalibration to ensure consistent measurements. Handle preload is

factory set to 25-45 LBS. See How to Adjust Tool Preload (See Figure 5) to

recalibrate.

“ Confining ” Crimp

Nest Color Code

Yellow

Wire Range

“X” Dimension

Conductor Crimp

AWG mm² Mean Go No Go

10 - 12 5.00 – 3.30 .127 .124 .132 o

Crimp

Inspection

Marking

14 - 16 1.30 - 2.00 .127 .124 .132 o

Warranty

This tool is for electrical terminal crimping purposes only. This tool is made of the best quality materials. All vital components are

long-life tested. All tools are warranted to be free of manufacturing defects for a period of 30 days. Should such a defect occur, we

will repair or exchange the tool free of charge. This repair or exchange will not be applicable to altered, misused or damaged tools.

This tool is designed for hand use only. Any clamping, fixturing, or use of handle extensions voids this warranty.

Hand held crimping tools are intended for low volume, prototyping, or repair requirements only.

Caution: Repetitive use of this tool should be avoided.

X

Doc No. 64001-4900 Release Date: 10-15-04 UNCONTROLLED COPY Page 4 of 6

Revision: A Revision Date: 10-15-04

Page 5

RHT2251-CC Hand Crimp Tool

Figure 6

PARTS LIST

** The following purchased parts are available from an Industrial supply company such as MSC (1-800-645-7270).

5

M4 LOCKNUT W/

3

6

10

Item Order No Description Quantity

64001-4900 Hand Crimp Tool (Fig. 6)

1 64000-0076 Repair Kit (Springs, Pins and E-Rings) 1

2 63810-0000 Handle 1

3 64001-4975 Locator Assembly 1

4 64001-4970 Tooling Kit 1

Tooling Kit Only

5 64001-4802 Conductor Punch 1

6 64001-4801 Conductor Anvil 1

7 64001-4904 Insert Punch 1

8 64001-4911 Insert Anvil 1

9 N/A 4 mm Dia. by 5.0 mm Lg.Roll Pins 2**

10 N/A #10-32 by 5/16” Lg. Cup Pt. Set Screw 1**

2

HEX NYLON

M4 FLAT WASHER

(2)

9

7

8

1

4

FOR SPRING

ACCESS SWING

OPEN COVER

REPAIR KIT. ALL PARTS REQUIRED FOR

REPAIR. (ONLY MAIN SPRING SHOWN)

PAN HEAD SCREW

RATCHET

RELEASE LEVER

SCREW AND PLASTIC

COVER FOR HANDTOOL

PRELOAD ADJUSTMENT

M4 X 12LG

PAN HEADSCREW

M4 X 25LG

Doc No. 64001-4900 Release Date: 10-15-04 UNCONTROLLED COPY Page 5 of 6

Revision: A Revision Date: 10-15-04

Page 6

RHT2251-CC Hand Crimp Tool

Tool Order Number __________________

Tool Eng. Number ___________________

Tool Revision ___________________

Serial Number ___________________

Date of Manufacture__________________

Pin Gauge of Conductor Nest/Nests or Slug height if the nest is the “F” Crimp style.

Range Conductor Nest # 1 = ____________-- Actual = ______________

Range Conductor Nest # 2 = ___N/A

Range Conductor Nest # 3 = ___N/A

Technician ______________

Date of Calibration ______________

Calibration should be done every 5,000 cycles or 3 months.

Tools should be lubricated during this operation.

Certificate of Calibration

Handle Load Range at 1 inch from the Tips =______________

Actual =_____________

______-- Actual = ______________

______-- Actual = ______________

Molex Application Tooling Group

1150 E. Diehl Road

Naperville, IL 60563

Tel: (630) 969-4550

Fax (630) 505-0049

Doc No. 64001-4900 Release Date: 10-15-04 UNCONTROLLED COPY Page 6 of 6

Revision: A Revision Date: 10-15-04

Loading...

Loading...