Page 1

Impact™ Backplane and Daughtercard Tooling

IMPACT™ Backplane and DaughterCard

Installation and Repair Tooling

Operation Manual

Order No. 62201-8799

Description

Operation

Maintenance

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 1 of 35

Revision: G Revision Date: 06-16-14

Page 2

Impact™ Backplane and Daughtercard Tooling

Read and understand all of the instructions and safety information in this

manual before operating or servicing this tool.

Keep this manual available when using this tool.

Replacement manuals are available for download at no charge at

www.molex.com.

SAFETY ALERT SYMBOL

This symbol is used to call your attention to hazards or unsafe practices which could result in an injury or property

damage. The signal word, defined below, indicates the severity of the hazard. The message after the signal word

provides information for preventing or avoiding the hazard.

DANGER

DANGER:

Indicates an imminently hazardous situation which, if not avoided, could result in death or serious injury.

WARNING

WARNING:

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION:

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION may also be used to alert against unsafe practices associated with events that could lead

to personal injury.

WARNING

WARNING

Always wear proper eye protection when

Operating or servicing these tools.

Failure to wear eye protection could result

in serious eye injury from flying debris.

Never use a press without guards or

safety devices that are intended to prevent

hands from remaining in the die space.

Failure to observe this warning could result

in severe injury or death.

WARNING

WARNING

Never wear clothing or jewelery that is loose or

That Could potentially hang into the equipement

And get caught.

Failure to observe this warning could result in

Severe Injury or death.

Never install or service these tool while

connected to any electrical power source.

Disconnect power by unplugging the press

from its power source.

Failure to observe this warning could result

In severe injury or death.

WARNING

WARNING

Never operate, service, install, or adjust this

Machine without proper instruction and without

first reading and understanding the instructions

in this manual and all applicable press and/or

wire processing machine

manuals.

Use extreme caution when using compressed

air to clean the equipment.

The forces created by compressed air can force

debris into the tool.

Failure to observe these precautions may

result in injury or property damage.

Safety Warnings and Information

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 2 of 35

Revision: G Revision Date: 06-16-14

Page 3

Impact™ Backplane and Daughtercard Tooling

CAUTION

Never perform any service or maintenance other than as described in this manual.

Never modify, alter or misuse the equipment

Failure to observe this precaution may result in injury and property damage.

Tooling Technical Assistance

Molex offers tooling technical assistance for customers who may need some guidance for tooling adjustments. This support

can be obtained by calling either of the two numbers listed below and asking for the Molex Tooling Group.

Call Toll Free 1-800-786-6539 (US) 1-630-969-4550 (Global).

This assistance is limited to the operation and set-up of a customer’s Molex Tools tool. Questions with regard to Molex

connector products or how to identify the proper tooling and/ or tooling documentation should be directed to your local Molex

personnel or Customer Service Representative.

When calling for service on these tools it is recommended to have the following: a copy of the Operation Manual, the

Specific Application Specification Sheet and a person familiar with the tools should be present. The following information is

also recommended to supply:

1. Customer name

2. Customer address

3. Person to contact such as (name, title, e-mail, and telephone number)

4. Tools order number (Lease number also if applicable)

5. Serial number (Lease number also if applicable)

6. Molex Connector product order number

7. Urgency of request

8. Nature of problem

Molex Application Tooling Group

2200 Wellington Court

Lisle, IL 60532, USA

Tel: +1 (630) 969-4550

Fax:+1 (630) 505-0049

Visit our Web site at http://www.molex.com

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 3 of 35

Revision: G Revision Date: 06-16-14

Page 4

Impact™ Backplane and Daughtercard Tooling

Table of Contents

IMPACT™ Backplane and DaughterCard ............................................................................................................................................... 1

Order No. 62201-8799 ............................................................................................................................................................................. 1

Safety Warnings and Information ............................................................................................................................................................ 2

Table of Contents .................................................................................................................................................................................... 4

Section 1 .................................................................................................................................................................................................. 5

General Description ............................................................................................................................................................................. 6

1.1 Description ............................................................................................................................................................................. 6

1.2 Features ................................................................................................................................................................................. 6

1.3 Technical Specifications ......................................................................................................................................................... 6

1.4 Delivery Check ....................................................................................................................................................................... 6

1.5 Tools ...................................................................................................................................................................................... 6

1.6 Press Requirements ............................................................................................................................................................... 6

Section 2 .................................................................................................................................................................................................. 7

Installation and Operation ................................................................................................................................................................... 7

2.1 Printed Circuit Board Support ................................................................................................................................................ 8

2.2 Press Stroke Adjustment ........................................................................................................................................................ 8

2.3 Installation .............................................................................................................................................................................. 8

2.4 Operation ............................................................................................................................................................................... 9

Section 3 ................................................................................................................................................................................................ 13

Maintenance ...................................................................................................................................................................................... 13

3.1. Cleaning ............................................................................................................................................................................... 14

3.2 Lubrication............................................................................................................................................................................ 14

3.3 Troubleshooting ................................................................................................................................................................... 14

Section 4 ................................................................................................................................................................................................ 15

Available Tools .................................................................................................................................................................................. 15

4.1 Standard Press-In-Tools ...................................................................................................................................................... 16

Table 4-1....................................................................................................................................................................................... 16

Table 4-2....................................................................................................................................................................................... 25

Table 4-3....................................................................................................................................................................................... 25

4.2 Standard Tool Ordering Procedure ...................................................................................................................................... 29

Section 5 ................................................................................................................................................................................................ 30

5.1 Impact™ Backplane Repair Procedure: ............................................................................................................................... 31

5.2 Glossary of Terms: ............................................................................................................................................................... 35

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 4 of 35

Revision: G Revision Date: 06-16-14

Page 5

Impact™ Backplane and Daughtercard Tooling

Section 1

Press Requirements for Impact™ Connectors

1.1 Description

1.2 Features

1.3 Technical Specifications

1.4 Delivery Check

1.5 Tools

1.6 Press Requirements

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 5 of 35

Revision: G Revision Date: 06-16-14

Page 6

Impact™ Backplane and Daughtercard Tooling

General Description

1.1 Description

This manual covers the tooling available to press Molex

Impact™ Backplane Power Modules, Backplane

Connectors, Daughtercard and Coplanar Modules into

printed circuit boards. Repair tools and custom tools are

also covered. All insertion tooling is designed to go into

a flat platen press.

1.2 Features

The press-in tooling is designed so that one module will

press in one connector, or several modules can be

mounted in a tool holder and be used to press in any

combination of connectors in one operation. See Section

4-2 (Ordering Instructions) for details.

1.3 Technical Specifications

Dimensions and Weight

The dimensions and weight depend on the size of the

tooling used.

1.4 Delivery Check

Carefully remove the tooling from its shipping container

and check to be sure what was received matches the

purchase order and no damage has occurred.

1.5 Tools

A metric hex wrench set will be required to assemble or

disassemble tooling mounted in the optional tooling

holder.

Molex Presses

Molex does not offer a press that is suitable for this

application. The customer is encouraged to use one

of the many industry-standard presses to install the

Impact™ connectors.

1.6 Press Requirements

All Impact™ insertion tools are designed to fit in a flat platen

(or flat rock) press.

The press must have sufficient working area to accept the

size of the printed circuit board.

The press frame and base must withstand the insertion force

requirements for the Impact™ products.

Insertion Force Requirements

Backplane assemblies: 2.7kgf (6 lb.) per pin

Daughtercard assemblies: 1.8kgf (4 lb.) per pin

Power module assemblies: 6kgf (13.2 lb.) per pin

Press Operation Characteristics

The capability to detect force variations as low as 4.5kg

(10 lb.) during the press-in cycle; excessive force

measurement should stop the press-in cycle.

The rate of pressing can be regulated as low as

0.13mm (0.005 in) per second.

Press stroke control to within ±0.25mm (0.010 in.).

Total press stroke must be at least 19mm (0.75 in.).

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 6 of 35

Revision: G Revision Date: 06-16-14

Page 7

Impact™ Backplane and Daughtercard Tooling

Installation and Operation

2.1 Printed Circuit Board Support

2.2 Press Stroke Adjustment

2.3 Installation

2.4 Operation

Section 2

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 7 of 35

Revision: G Revision Date: 06-16-14

Page 8

Impact™ Backplane and Daughtercard Tooling

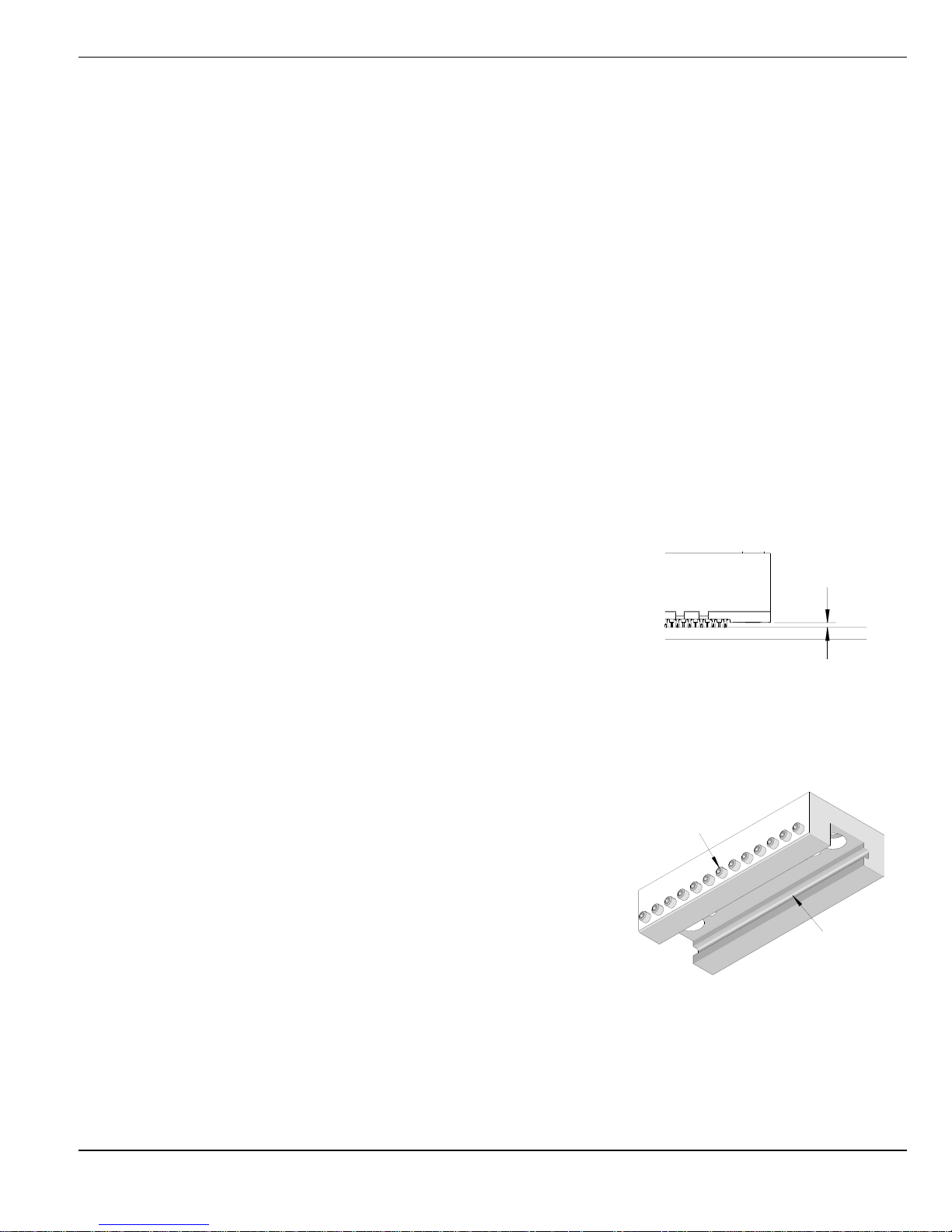

Figure 2-2

TOOLING HOLDER

M3 SET

SCREWS

KEYWAY

Figure 2-1

MAXIMUM CLEARANCE WHEN

CONNECTOR FULLY SEATED

0.10mm

(.004 in.)

Maximum

Installation and Operation

2.1 Printed Circuit Board Support

Due to the high forces required to press in compliant-pin connectors, a backup or support plate is suggested to prevent

damage to the printed circuit board. The support fixture should have clearance for the connector terminals if they

protrude through the underside of the printed circuit board. The support fixture should have some method of locating the

PCB consistently. Due to the custom nature of each application, Molex does not supply support and locating fixtures.

The customer normally fabricates the fixture to fit their application.

The following is one way of making a printed circuit board support and locating fixture:

1. Locate a suitable piece of material for the backup. It should be approximately 20mm thick and the same size or slightly

larger than the printed circuit board to be used. While aluminum could be used, a rigid nonconductive material such as a

phenolic is preferred. (A stack of scrap printed circuit boards of suitable size can also be fastened together.)

2. Obtain a scrap printed circuit board like the ones to be assembled. Attach this board to the material from step 1.

3. Using an oversize drill bit, drill through each hole where a pin from the connector will go. Drill deep enough into the

lower material to be certain the pins do not bottom out when inserted (at least 5.0mm (0.20”) deep).

4. Locate two (2) holes on the printed circuit board to use as locating points. Mount suitably sized dowel pins in these two

locations on the support fixture.

5. Clear out the support for any components mounted on the underside of the printed circuit board.

6 Place a printed circuit board on top of the support, located by the two pins, and check that the holes for the connector

pins are aligned.

7. By hand, pre-insert a connector in the printed circuit board.

8. Load the insertion tool into the connector.

9. Place the support with the printed circuit board under the press ram.

10. Press the connector into the printed circuit board and observe for any

deflection of the board when the ram is at the bottom of its stroke.

2.2 Press Stroke Adjustment

Most presses have some means of adjusting the stroke; please refer to the press

manual for press stroke adjustments. The stroke should be adjusted so that when the press ram stops in the down position,

the bottom of the connector is flush to 0.10mm (.004”) above the surface of the printed circuit board. See Figure 2-1.

2.3 Installation

To install insertion modules into a tooling holder (see Table 4-2), use the

following procedure:

1. Along the lower edge of the tooling holder is a row of M3 set screws. (See

Figure 2-2) Loosen these a few turns so that they do not protrude into the

inside of the holder.

2. Slide the insertion modules into the tooling holder in the proper order. See

Figure 2-3. The modules are keyed so that they cannot be installed

backwards.

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 8 of 35

Revision: G Revision Date: 06-16-14

Page 9

Impact™ Backplane and Daughtercard Tooling

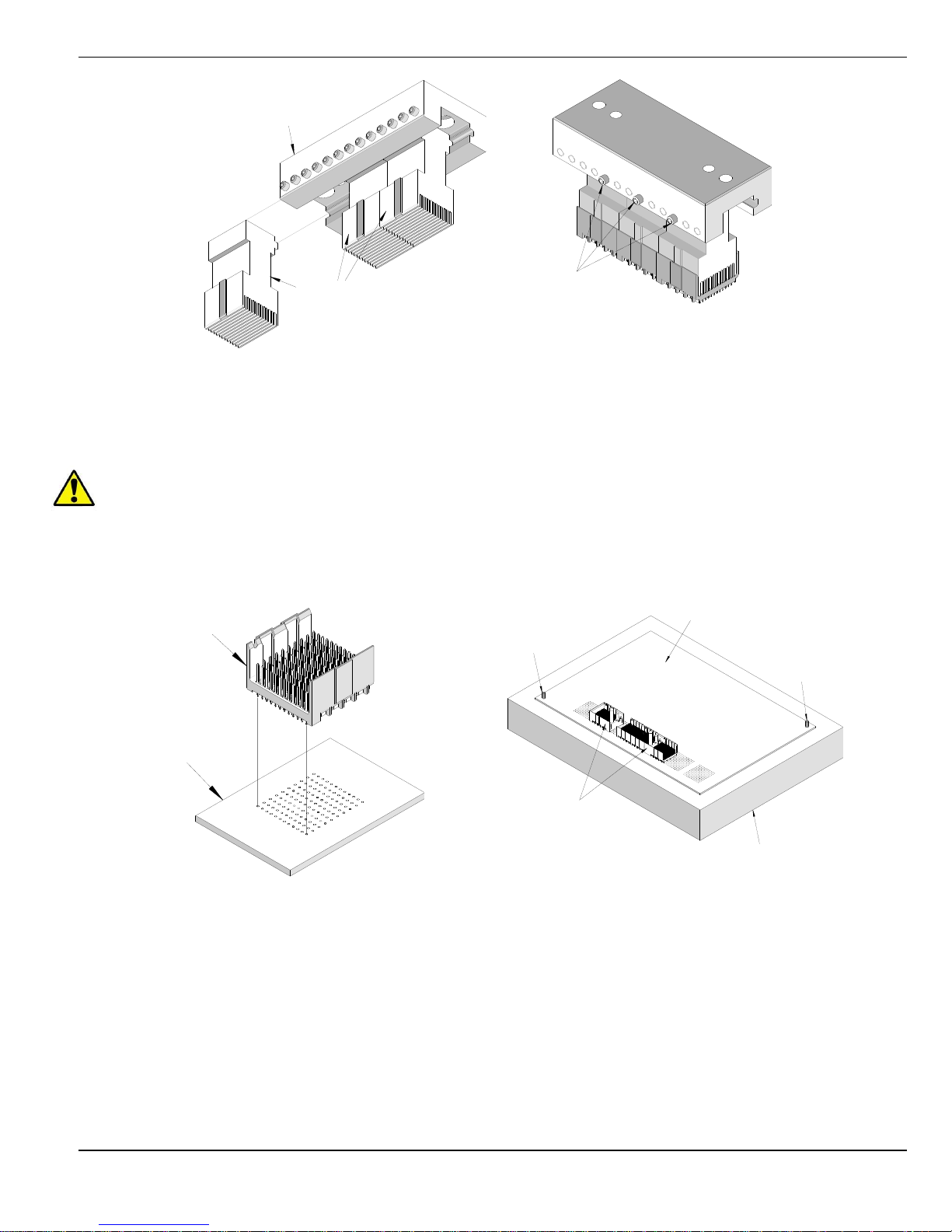

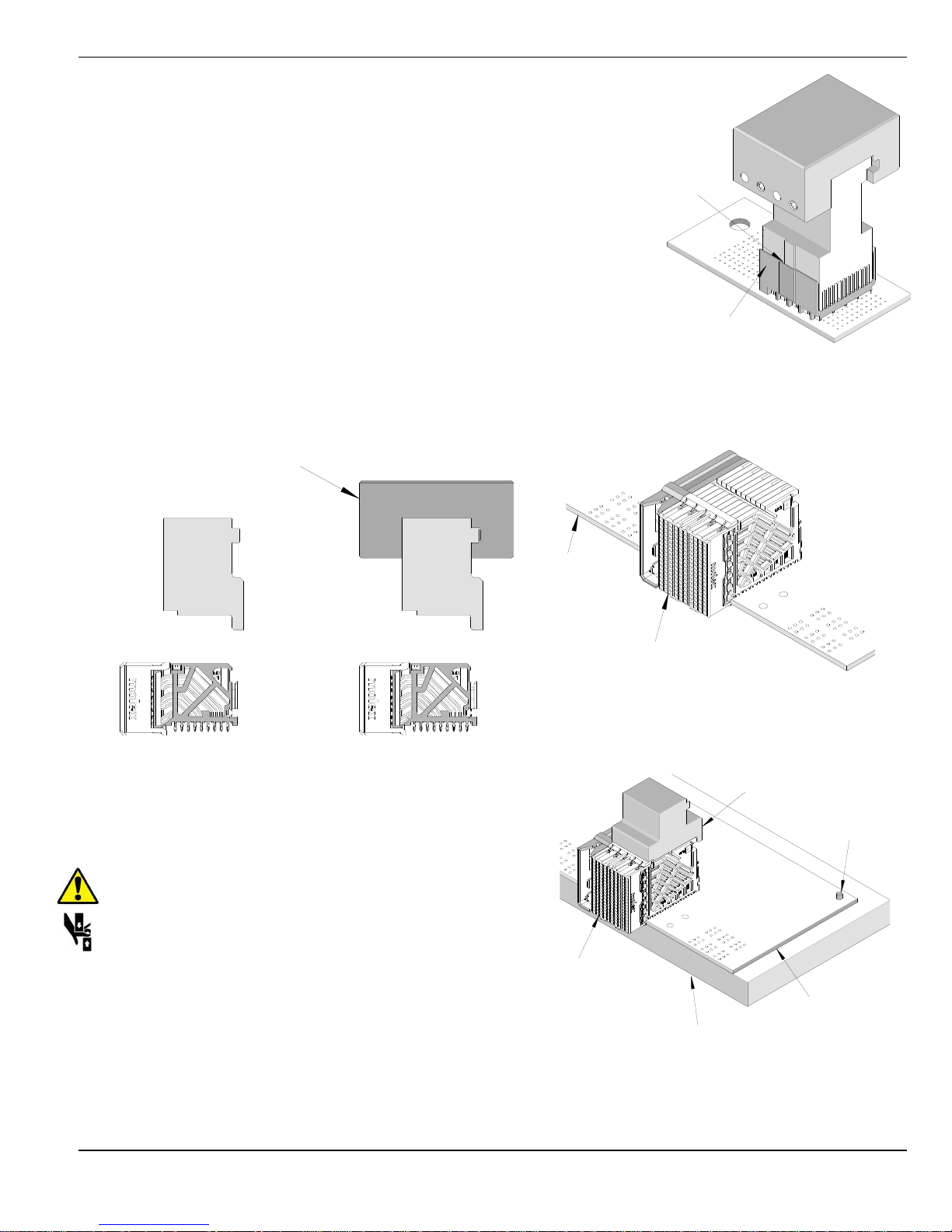

Figure 2-3

MOUNTING INSERT MODULE IN

A MOUNTING BLOCK

TYPICAL INSERTION

MODULES

TOOLING HOLDER

Figure 2-4

TYPICAL INSERTION

TOOL ASSEMBLY

M3 x 8mm LONG

SET SCREWS (3)

EVENLY SPACED

Figure 2-6

CONNECTOR ASSEMBLY

ON PC BOARD SUPPORT PALLET

SUPPORT PALLET

LOCATING PIN

LOCATING PIN

PC BOARD

CONNECTOR

ASSEMBLY

Figure 2-5

ALIGNING TERMINAL PINS TO HOLES

PC BOARD

SIGNAL MODULE

3. Tighten the M3 set screws against the modules with two (2) set screws evenly spaced on a 10mm wide insertion tool and

at least three (3) set screws evenly spaced on a 25mm wide insertion tool. Figure 2-4 shows a typical completed

assembly.

CAUTION: Do not over tighten the setscrews; this could damage the insertion tool.

NOTE: See Section 4 for details on selecting modules and Press-In tools combinations.

2.4 Operation

Backplane Insertion Tooling

1. Carefully pre-insert, by hand, the backplane signal module(s) into the printed circuit board hole pattern. Make sure the

connector(s) are oriented properly by confirming the location of the #1 circuit notch with respect to the printed circuit

board layout. See Figure 2-5.

2. Place the pre-loaded board into the support pallet (Optional). See Figure 2-6.

3. Locate the tooling assembly in the connector assembly, carefully checking alignment. The orientation keys on the tool must

engage with the groove on the connector housing. See Figure 2-7.

4. Position the pre-loaded support pallet under the press ram.

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 9 of 35

Revision: G Revision Date: 06-16-14

Page 10

Impact™ Backplane and Daughtercard Tooling

Figure 2-10

LOCATING PIN

SUPPORT PALLET

CONNECTOR

ASSEMBLY

PC BOARD

PRESS-IN

TOOL

WITH 62201-95XX

RAIL

Figure 2-8

ALONE

Figure 2-9

TYPICAL DAUGHTERCARD

ASSEMBLY ON THE PC BOARD

SIGNAL MODULE

PCB

ORIENTATION

KEY

Figure 2-7

TOOLING LOCATED IN THE

CONNECTOR ASSEMBLY

CONNECTOR

HOUSING

5. Cycle the insertion press.

6. Press the header assembly until there is less than 0.10mm (.004 in)

clearance between the bottom of the plastic housing and the surface of the

printed circuit board.

7. Remove the loaded support pallet.

8. Carefully remove the insertion tool assembly. Remove the printed circuit

board from the pallet.

Daughtercard Insertion Tooling

Operation for inserting daughtercard assemblies is similar to backplanes and

can be used alone or stacked in a tool holder for larger connector assemblies.

See Figure 2-8.

1. Locate the daughtercard connector assembly on the printed circuit board.

2. Pre-insert the assembly into the board by hand. Check for proper seating,

without contact pins bending under the assembly after pre loading on to the

Printed circuit board. See Figure 2-9.

3. Locate the printed circuit board with the connector assembly

on the support pallet.

4. Position the insertion tooling on the connector assembly.

See Figure 2-10.Position the printed circuit board under the

press platen (Optional).

CAUTION: To prevent injury, never operate any press

without the guards in place. Refer to the press

manufacturer’s instruction manual.

5. Press the daughtercard module until there is less than

0.10mm (.004 in) clearance between the bottom of the

plastic housing and the surface of the printed circuit board.

6. Remove the loaded support pallet from the press.

7. Remove the insertion tool.

8. Carefully remove the assembled printed circuit board from the support pallet.

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 10 of 35

Revision: G Revision Date: 06-16-14

Page 11

Impact™ Backplane and Daughtercard Tooling

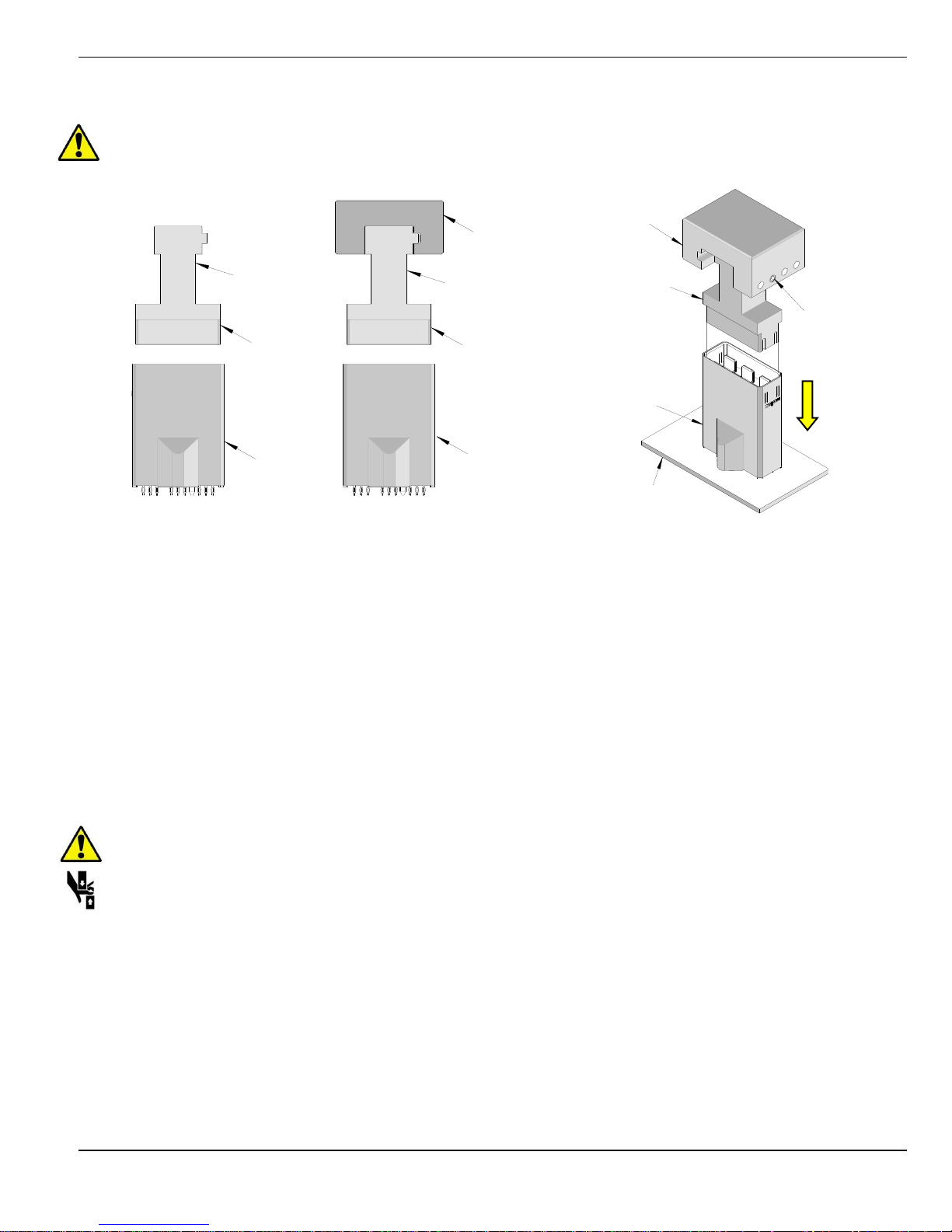

WITH

62201-95XX

RAIL

Figure 2-11

ALONE

PRESS-IN

TOOL

POWER

HEADER

PRESS-IN

TOOL

POWER

HEADER

GUIDE

SURFACE

GUIDE

SURFACE

Figure 2-12

TOOLING

HOLDER

M3 SET

SCREW

VERTICAL

POWER

MODULE

PC BOARD

VERTICAL

PRESS-IN

TOOL

Vertical Power Module Press-In Tooling

CAUTION: Vertical Power Module must be installed separately without any backplane or daughtercard

assemblies in the combinations.

Depending on the number of modules to be installed and/or the press used, this tool can be used as a stand-alone or with a

group of press-in tools, mounted in a 62201-95XX holder (ordered separately). See Figure 2-11.

1. If the tooling holder is being used, slide the insertion modules into the tooling holder in the proper order. The modules are

keyed so that they cannot be installed backwards.

2. Now tighten the M3 set screws against the modules using the following setups:

One (1) set screw against modules under 10mm wide

Two (2) set screws evenly spaced on a 10mm wide power module.

At least three (3) set screws evenly spaced on a 25mm wide power module.

3. Carefully pre-insert, by hand, the vertical power module(s) into the printed circuit board hole pattern. See Figure 2-12.

Make sure the module(s) are oriented properly to the printed circuit board layout.

4. Line-up the Press-In tool so that the guide surfaces on the tool are in line with the sides of the vertical power module.

See Figure 2-11.

5. Using the application tool and an appropriate press, seat the vertical power module until there is less than 0.10mm

(.004 in) clearance between the bottom of the plastic housing and the surface of the printed circuit board.

CAUTION: To prevent injury, never operate any press without the guards in place. Refer to the press

manufacturer’s instruction manual.

Right Angle Power Module Press-In Tooling

Depending on the number of connectors to be installed and/or the press used, this tool can be used alone or with a group of

press-in tools, mounted in a 62201-95XX holder (ordered separately). See Figure 2-13 and 2-14.

1. If the tooling holder is being used, slide the Press-In Tools into the tooling holder in the proper order. The Press-In Tools

are keyed so that they cannot be installed backwards.

2. Tighten the M3 set screws against the Press-In Tool using the following setups:

One (1) set screw is used against the Press-In Tool under 10mm guide module.

Two (2) set screws evenly spaced on a 10mm wide Press-In Tool.

At least three (3) set screws evenly spaced on a 25mm wide Press-In Tool.

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 11 of 35

Revision: G Revision Date: 06-16-14

Page 12

Impact™ Backplane and Daughtercard Tooling

Figure 2-15

0.10mm (0.004”)

Maximum

Figure 2-14

Right angle power module is seated along side the

Daughtercard signal module.

For ganged power modules, additional power

module press-in-tools may be needed;

see sales drawings for ganged product dimensions.

PCB REF

RIGHT ANGLE POWER MODULE and

DAUGHTERCARD PRESS-IN TOOL REF

TOOLING HOLDER

62201-95XX

RIGHT ANGLE

POWER MODULE

DAUGHTERCARD

Figure 2-13

STAND-ALONE

DAUGHTERCARD

PRESS-IN TOOL REF

PCB REF

RIGHT ANGLE

POWER MODULE REF

RIGHT ANGLE POWER

MODULE PRESS-IN TOOL

DAUGHTERCARD

3. Carefully insert, by hand, the power module(s) into the printed circuit board hole pattern.

4. Place the application tool on top of the power module with the back guide surface of the tool against the back of the

power module. See Figure 2-14.

5. Using the application tool and an appropriate press, seat the power module until there is less than 0.10mm (.004 in)

clearance between the bottom of the plastic housing and the surface of the printed circuit board. See Figure 2-15.

CAUTION: To prevent injury, never operate any press without the guards in place. Refer to the press

manufacturer’s instruction manual.

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 12 of 35

Revision: G Revision Date: 06-16-14

Page 13

Impact™ Backplane and Daughtercard Tooling

3.1 Cleaning

3.2 Lubrication

3.3 Troubleshooting

Section 3

Maintenance

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 13 of 35

Revision: G Revision Date: 06-16-14

Page 14

Impact™ Backplane and Daughtercard Tooling

Symptom

Cause

Solution

Connector

damage

Press stroke set too low.

Refer to the appropriate press manual

and adjust the stroke. See Section 2.2

Connector and/or tooling not properly aligned

Check Fixture and Repair as required.

Check alignment of fixture in press

Check to be sure the press platen is

pressing squarely on the tooling block.

Tooling bent or damaged

Replace tool

3.1. Cleaning

Once a day, the support fixture should be cleaned of dust and plating particles and other debris. Compressed air may be

necessary to remove debris from the pin clearance holes.

CAUTION: Use extreme caution when using compressed air for cleaning, it can cause debris to get lodged in

the tooling or come flying out at the operator. USE of proper safety glasses by the operator and onlookers is

required.

3.2 Lubrication

There is no lubrication required on any of the Impact™ tooling. However, presses may have their own requirements for

lubrication and maintenance. The instruction manual for the specific press being used should be referred to.

3.3 Troubleshooting

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 14 of 35

Revision: G Revision Date: 06-16-14

Page 15

Impact™ Backplane and Daughtercard Tooling

4.1 Standard Press-In-Tools

Table 4-1 Assembly Tooling for Impact™ Signal and Power Assemblies

Table 4-2 Standard Tool Holders for Molex Press Fit Insertion Tools

Table 4-3 Field Repair Tooling for Impact™ Backplane and Daughtercard Assemblies

4.2 Standard Tool Ordering Procedure

Section 4

Available Tools

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 15 of 35

Revision: G Revision Date: 06-16-14

Page 16

Impact™ Backplane and Daughtercard Tooling

Impact™ 100 Ohm Products – Insertion Tools

Pair

Column

Product

Module Type

Series

Tool

Width

Illustration

2

8

100 Ohm Coplanar

RAM

170026

62201-8851

15.1mm

(0.59 In.)

10

100 Ohm Conventional

BP

76453

76455

171290

62201-8692

18.8mm

(0.74 In.)

100 Ohm Coplanar

RAM

76450

62201-8778

18.8mm

(0.74 In.)

100 Ohm Conventional

DC

76460

100 Ohm Coplanar

RAM

170026

12

100 Ohm

RAM

76450

62201-8979

22.7mm

(0.89 In.)

16

100 Ohm Conventional

BP

76453

76455

171290

62201-8694

30.22mm

(1.19 In.)

100 Ohm Conventional

DC

76460

62201-8779

30.22m

(1.19 In.)

100 Ohm Coplanar

RAM

76450

62201-8779

30.22m

(1.19 In.)

100 Ohm Conventional

DC

76460

100 Ohm Custom

RAM

170026

18

100 Ohm Custom

RAM

170026

62201-8852

34.0mm

(1.34 In.)

3

6

100 Ohm Conventional

BP

76162

76165

171292

62201-8781

11.2mm

(0.44 In.)

100 Ohm Orthogonal

BP

76855

76856

171344

171345

62203-0460

12.0mm

(0.47 In.)

100 Ohm Conventional

DC

76170

62201-8780

11.2mm

(0.44 In.)

100 Ohm Mezzanine

Mezzanine

170415

62201-8859

11.4mm

(0.45 In.)

4.1 Standard Press-In-Tools

Standard Insertion Tools

All the applicable Impact™ connectors and the standard tooling required for each connector are located in these tables.

TABLE 4-1

Assembly Tooling (For use in standard tool holder)

Refer to the individual instruction sheets for more information on Individual tools.

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 16 of 35

Revision: G Revision Date: 06-16-14

Page 17

Impact™ Backplane and Daughtercard Tooling

Impact™ 100 Ohm Products – Insertion Tools

Pair

Column

Product

Module Type

Series

Tool

Width

Illustration

100 Ohm Orthogonal

DC

76860

62201-8744

11.80mm

(0.46 In.)

3 6 100 Ohm Ortho Direct

RAM

171573

62203-0026

15.0mm

(0.59 In.)

3

8

100 Ohm Orthogonal

BP

76855

76856

171344

62203-0465

12.0mm

(0.47 In.)

100 Ohm Conventional

BP

76162

76165

171292

62201-8674

15.0mm

(0.59 In.)

100 Ohm Conventional

DC

76170

62201-8675

15.0mm

(0.59 In.)

100 Ohm Coplanar

RAM

76410

100 Ohm Mezzanine

Mezzanine

170415

62201-8858

15.2mm

(0.60 In.)

100 Ohm Orthogonal

DC

76860

62201-8746

15.85mm

(0.62 In.)

3

10

100 Ohm Conventional

BP

76162

76165

171292

62201-8647

18.8mm

(0.74 In.)

100 Ohm Conventional

DC

76170

62201-8646

18.9mm

(0.74 In.)

100 Ohm Coplanar

RAM

76410

100 Ohm Mezzanine

Mezzanine

170415

62201-8857

19.0mm

(0.75 In.)

3

14

Impact XTR

DC

171180

62201-8868

13.8mm

(0.54 In.)

100 Ohm Conventional

BP

76162

62201-8853

26.45mm

(1.04 In.)

3

16

100 Ohm Conventional

BP

76162

171292

62201-8651

30.25mm

(1.19 In.)

100 Ohm Mezzanine

Mezzanine

170415

62201-8856

30.4mm

(1.20 In.)

100 Ohm Conventional

DC

76170

62201-8650

30.3mm

(1.19 In.)

100 Ohm Coplanar

RAM

76410

100 Ohm Coplanar

RAM

170027

4 6 100 Ohm Orthogonal

BP

76845

171348

62203-0470

12.0mm

(0.47 In.)

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 17 of 35

Revision: G Revision Date: 06-16-14

Page 18

Impact™ Backplane and Daughtercard Tooling

Impact™ 100 Ohm Products – Insertion Tools

Pair

Column

Product

Module Type

Series

Tool

Width

Illustration

4 6 100 Ohm Conventional

BP

76152

76155

171294

62201-8679

11.2mm

(0.44 In.)

4 6 100 Ohm Conventional

DC

76160

62201-8748

11.75mm

(0.46 In.)

4 6 100 Ohm Orthogonal

DC

76850

4

8

100 Ohm Orthogonal

BP

76845

76846

171348

62203-0575

16.9mm

(0.67 In.)

100 Ohm Conventional

BP

76152

76155

171294

171295

62201-8676

15.0mm

(0.59 In.)

100 Ohm Conventional

BP

76152

62201-8793

15.0mm

(0.59 In.)

100 Ohm Orthogonal

Routable

BP

76849

62201-8678

15.0mm

(0.59 In.)

100 Ohm Conventional

DC

76160

62201-8677

15.0mm

(0.59 In.)

100 Ohm Coplanar

RAM

76500

100 Ohm Orthogonal

DC

76850

100 Ohm Ortho Direct

RAM

76730

171574

62203-0027

20.0mm

(0.79 In.)

4

10

100 Ohm Orthogonal

BP

76845

171348

62203-0475

16.05mm

(0.63 In.)

100 Ohm Conventional

BP

76152

76155

171294

62201-8640

18.4mm

(0.72 In.)

100 Ohm Conventional

DC

76160

62201-8641

18.9mm

(0.74 In.)

100 Ohm Coplanar

RAM

76500

100 Ohm Orthogonal

DC

76850

4

16

100 Ohm Conventional

BP

76152

76155

171294

62201-8644

30.25mm

(1.19 In.)

100 Ohm Conventional

DC

76160

62201-8645

30.25mm

(1.19 In.)

100 Ohm Coplanar

RAM

76500

5

8

100 Ohm Orthogonal

BP

76985

171352

62203-0480

16.05mm

(0.63 In.)

100 Ohm Orthogonal

DC

76990

62201-8754

18.8mm

(0.74 In.)

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 18 of 35

Revision: G Revision Date: 06-16-14

Page 19

Impact™ Backplane and Daughtercard Tooling

Impact™ 100 Ohm Products – Insertion Tools

Pair

Column

Product

Module Type

Series

Tool

Width

Illustration

100 Ohm Conventional

BP

76055

171296

62201-8854

15.1mm

(0.59 In.)

5

10

100 Ohm Orthogonal

BP

76985

171352

62203-0580

20.95mm

(0.82 In.)

5

10

100 Ohm Conventional

BP

76055

76163

171296

62201-8658

18.8mm

(0.74 In.)

100 Ohm Mezzanine

Mezzanine

76530

62201-8695

19.0mm

(0.75 In.)

100 Ohm Conventional

DC

76060

62201-8657

18.9mm

(0.74 In.)

100 Ohm Orthogonal

76990

100 Ohm Ortho Direct

RAM

76725

171575

62203-0028

22.0mm

(0.87 In.)

5

12

100 Ohm Orthogonal

BP

76985

76986

171352

62203-0585

25.0mm

(0.98 In.)

100 Ohm Conventional

BP

76163

76055

171296

62201-8708

22.6mm

(0.89 In.)

100 Ohm Mezzanine

Mezzanine

76530

62201-8860

22.8mm

(0.90 In.)

100 Ohm Conventional

DC

76060

62201-8735

18.8mm

(0.74 In.)

100 Ohm Orthogonal

76990

5

14

100 Ohm Conventional

BP

76055

76163

171296

62201-8783

26.45mm

(1.04 In.)

100 Ohm Conventional

DC

76060

62201-8782

26.45mm

(1.04 In.)

100 Ohm Mezzanine

Mezzanine

76530

62201-8861

26.6mm

(1.05 In.)

5

16

100 Ohm Conventional

BP

76055

76163

171293

171296

171297

62201-8665

30.25mm

(1.19 In.)

5

16

100 Ohm Mezzanine

Mezzanine

76530

62201-8696

30.4mm

(1.20 In.)

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 19 of 35

Revision: G Revision Date: 06-16-14

Page 20

Impact™ Backplane and Daughtercard Tooling

Impact™ 100 Ohm Products – Insertion Tools

Pair

Column

Product

Module Type

Series

Tool

Width

Illustration

5

16

100 Ohm Conventional

DC

76060

62201-8659

30.25mm

(1.19 In.)

6

10

100 Ohm Orthogonal

BP

76285

171356

62203-0495

20.95mm

(0.82 In.)

6

10

100 Ohm Conventional

BP

76142

76145

171298

62201-8662

18.8mm

(0.74 In.)

6

10

100 Ohm Conventional

DC

76150

62201-8661

18.8mm

(0.74 In.)

100 Ohm Orthogonal

DC

76290

100 Ohm Coplanar

RAM

76560

6

12

100 Ohm Orthogonal

BP

76285

76286

171356

62203-0485

25.00mm

(0.98 In.)

100 Ohm Orthogonal

DC

76290

62201-8762

23.9mm

(0.94 In.)

100 Ohm Ortho Direct

RAM

76735

171576

62203-0029

26.0mm

(1.02 in.)

6

14

100 Ohm Conventional

BP

76142

76145

171298

62201-8639

26.5mm

(1.04 In.)

100 Ohm Conventional

DC

76150

62201-8698

18.8mm

(0.74 In.)

100 Ohm Coplanar

RAM

76560

6

16

100 Ohm Conventional

BP

76142

62201-8855

30.25mm

(1.19 In.)

100 Ohm Conventional

BP

76145

171298

62201-8664

30.25mm

(1.19 In.)

100 Ohm Conventional

DC

76150

62201-8663

30.25mm

(1.19 In.)

100 Ohm Coplanar

RAM

76560

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 20 of 35

Revision: G Revision Date: 06-16-14

Page 21

Impact™ Backplane and Daughtercard Tooling

Impact™ 85 Ohm Plus Products – Insertion Tools

Pair

Column

Product

Module Type

Series

Tool

Width

Illustration

2 8 85 Ohm Plus Conventional

BP

171065

62201-8841

15.05mm

(0.59 In.)

2

10

85 Ohm Plus Conventional

BP

171065

62201-8844

18.8mm

(0.74 In.)

85 Ohm Plus Conventional

DC

76460

62201-8778

18.9mm

(0.74 In.)

2

16

85 Ohm Plus Conventional

DC

76460

62201-8779

30.3mm

(1.19 In.)

2

16

85 Ohm Plus Conventional

BP

171065

62201-8847

30.3mm

(1.19 in.)

3

8

85 Ohm Plus Conventional

BP

170513

170522

170525

62201-8801

15.0mm

(0.59 In.)

85 Ohm Plus Conventional

DC

170530

62201-8675

15.0mm

(0.59 In.)

3

10

85 Ohm Plus Conventional

BP

170513

170522

170525

62201-8813

18.9mm

(0.74 In.)

85 Ohm Plus Conventional

DC

170530

62201-8646

18.9mm

(0.74 In.)

3

16

85 Ohm Plus Conventional

BP

170513

170522

170525

62201-8816

30.25m

(1.19 In.)

85 Ohm Plus Conventional

DC

170530

62201-8650

30.3mm

(1.19 In.)

4 6 85 Ohm Plus Conventional

BP

170335

62201-8869

15.0mm

(0.59 In.)

4

8

85 Ohm Plus Conventional

BP

170335

170515

62201-8787

15.0mm

(0.59 In.)

85 Ohm Plus Conventional

DC

170340

62201-8677

15.0mm

(0.59 In.)

85 Ohm Plus Mezzanine

Mezzanine

170390

62201-8863

15.2mm

(0.60 In.)

4

10

85 Ohm Plus Mezzanine

Mezzanine

170390

62201-8717

19.0mm

(0.75 In.)

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 21 of 35

Revision: G Revision Date: 06-16-14

Page 22

Impact™ Backplane and Daughtercard Tooling

Impact™ 85 Ohm Plus Products – Insertion Tools

Pair

Column

Product

Module Type

Series

Tool

Width

Illustration

4

10

85 Ohm Plus Conventional

BP

170332

170335

170515

62201-8790

18.8mm

(0.74 In.)

4

10

85 Ohm Plus Conventional

DC

170340

62201-8641

18.9mm

(0.74 In.)

4

12

85 Ohm Plus Mezzanine

Mezzanine

170390

62201-8864

22.8mm

(0.9 In.)

4

12

85 Ohm Plus Conventional

BP

170335

170515

62201-8833

22.7mm

(0.89 In.)

4

12

85 Ohm Plus Conventional

DC

170340

62201-8839

22.7mm

(0.89 In.)

4

14

85 Ohm Plus Mezzanine

Mezzanine

170390

62201-8865

26.6mm

(1.05 In.)

85 Ohm Plus Conventional

BP

170335

170515

62201-8836

26.5mm

(1.04 In.)

85 Ohm Plus Conventional

DC

170340

62201-8840

26.46mm

(1.04 In.)

4

16

85 Ohm Plus Mezzanine

Mezzanine

170390

62201-8866

30.4mm

(1.20 In.)

85 Ohm Plus Conventional

BP

170332

170335

170515

62201-8826

30.25mm

(1.19 In.)

85 Ohm Plus Conventional

DC

170340

62201-8645

30.25mm

(1.19 In.)

4

18

85 Ohm Plus Conventional

BP

170332

62201-8784

34.1mm

(1.34 In.)

85 Ohm Plus Mezzanine

Mezzanine

170390

62201-8718

34.0mm

(1.34 In.)

5

10

OLD 85 Ohm Conventional

BP

76772

76775

62201-8731

18.8mm

(0.74 In.)

85 Ohm Plus Conventional

BP

170475

170517

62201-8821

18.8mm

(0.74 In.)

OLD 85 Ohm Conventional

DC

76780

62201-8657

18.9mm

(0.74 In.)

85 Ohm Plus Conventional

170480

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 22 of 35

Revision: G Revision Date: 06-16-14

Page 23

Impact™ Backplane and Daughtercard Tooling

Impact™ 85 Ohm Plus Products – Insertion Tools

Pair

Column

Product

Module Type

Series

Tool

Width

Illustration

5

12

85 Ohm Plus Conventional

BP

170472

170475

170517

170518

62201-8804

22.7mm

(0.89 In.)

85 Ohm Plus Conventional

DC

170480

62201-8735

18.8mm

(0.74 In.)

5

16

OLD 85 Ohm Conventional

BP

76772

76775

62201-8701

30.25mm

(1.19 In.)

5

16

85 Ohm Plus Conventional

BP

170475

170517

62201-8824

30.25mm

(1.19 In.)

5

16

OLD 85 Ohm Conventional

DC

76780

62201-8659

30.25mm

(1.19 In.)

5

16

85 Ohm Plus Conventional

170480

6 8 85 Ohm Plus Conventional

BP

170535

62201-8882

15.05mm

(0.593 In.)

6

10

85 Ohm Plus Conventional

BP

170519

170535

62201-8807

18.8mm

(0.74 In.)

85 Ohm Plus Orthogonal

BP

171415

62203-0900

TBD

85 Ohm Plus Conventional

DC

170540

62201-8862

18.9mm

(0.74 In.)

85 Ohm Plus Orthogonal

DC

171420

62201-8867

19.8mm

(0.78 In.)

6

12

85 Ohm Plus Orthogonal

DC

171420

62201-8762

23.9mm

(0.94 In.)

85 Ohm Plus Orthogonal

BP

171415

62201-8850

25mm

(0.98 In.)

6

14

85 Ohm Plus Conventional

BP

170535

62201-8876

26.5mm

(1.04 In.)

6

16

85 Ohm Plus Conventional

BP

170519

170520

170532

170535

62201-8810

30.25mm

(1.19 In.)

85 Ohm Plus Conventional

DC

170540

62201-8663

30.25mm

(1.19 In.)

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 23 of 35

Revision: G Revision Date: 06-16-14

Page 24

Impact™ Backplane and Daughtercard Tooling

Impact™ Power Modules – Insertion Tools

Pair

Product

Module Type

Series

Tool

Width

Illustration

3

Power

Right Angle Header

78211

62201-8649

11.0mm

(0.43 In.)

Right Angle Header

78347

Right Angle Receptacle

78348

Vertical Receptacle

78212

62201-8648

18.2mm

(0.72 In.)

Vertical Plug

78399

62201-8687

11.0mm

(0.43 In.)

4

Power

Right Angle Header

78213

78659

62201-8642

11.0mm

(0.43 In.)

Right Angle Receptacle

78248

78666

Right Angle Header

78349

78671

Right Angle Receptacle

78350

Right Angle Header

78451

78672

Vertical Receptacle

78214

62201-8643

15.0mm

(0.59 In.)

5

Power

Right Angle Header

78215

78351

78352

62201-8668

11.0mm

(0.43 In.)

Vertical Receptacle

78216

62201-8667

15.0mm

(0.59 In.)

Vertical Header

78446

78679

78692

62201-8697

11.0mm

(0.43 In.)

6

Power

Right Angle Header

78217

78353

78217

62201-8669

11.0mm

(0.43 In.)

Vertical Receptacle

78218

62201-8666

15.0mm

(0.59 In.)

Vertical Header

78442

62201-8689

11.0mm

(0.43 In.)

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 24 of 35

Revision: G Revision Date: 06-16-14

Page 25

Impact™ Backplane and Daughtercard Tooling

Tool Description

Holder Length

Illustration

Tool Holder 62201-9501

24.0mm (0.94 In.)

Tool Holder 62201-9502

72.0mm (2.83 In.)

Tool Holder 62201-9503

156.0mm (6.14 In.)

Tool Holder 62201-9504

216.0mm (8.50 In.)

Tool Holder 62201-9509

254.0mm (10.0 In.)

Tool Holder 62201-9511

304.8mm (12.0 In.)

Tool Holder 62201-9512

406.4mm (16.0 In.)

Impact™ 85 Ohm, 100 Ohm, and Power Products – Repair Tools

Pair

Product

Module Type

Series

Tool

Illustration

2

100 Ohm Conventional

DC

76460

62202-4300 Extractor

100 Ohm Coplanar

RAM

76450

62202-4350 Extractor

100 Ohm Conventional

BP

76455

62100-9610 Extractor

62100-5800

Signal Pin Inserter

Pliers for Pin Removal:

Newark 96F8903

MSC 00321885

3

100 Ohm Conventional

DC

76170

62202-4600 Extractor

100 Ohm Orthogonal

76860

85 Ohm plus Conventional

170530

100 Ohm Coplanar

RAM

76410

62202-4350 Extractor

3

100 Ohm Conventional

BP

76165

62100-9610 Extractor

85 Ohm Plus Conventional

170513

170522

170525

85 Ohm Plus Conventional

BP

170513

170522

170525

62100-5850

Signal Pin Inserter

3

100 Ohm Conventional

BP

76162

76165

171292

62100-5800

Signal Pin Inserter

TABLE 4-2

Standard Tool Holders for Molex Press Fit Insertion Tools

TABLE 4-3

Field Repair Tooling for Impact™ Signal and Power Assemblies

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 25 of 35

Revision: G Revision Date: 06-16-14

Page 26

Impact™ Backplane and Daughtercard Tooling

Impact™ 85 Ohm, 100 Ohm, and Power Products – Repair Tools

Pair

Product

Module Type

Series

Tool

Illustration

Pliers for Pin Removal:

Newark 96F8903

or MSC 00321885

100 Ohm Orthogonal

BP

76855

76856

171344

171345

62100-9620 Extractor

3

Power

Vertical

Header

78399

62100-8000 Extractor

Vertical

Receptacle

78212

62100-8300 Extractor

Right Angle

Header

78211

78347

62202-4500 Extractor

4

100 Ohm Conventional

DC

76160

62202-4300 Extractor

100 Ohm Orthogonal

76850

85 Ohm plus Conventional

170340

171574

100 Ohm Coplanar

RAM

76500

62202-4350 Extractor

100 Ohm Conventional

BP

76152, 76155

171294

62100-9610 Extractor

85 Ohm Plus Conventional

170332, 170335

170515

85 Ohm Plus Conventional

BP

170332

170335

170515

62100-5850

Signal Pin Inserter

4

100 Ohm Conventional

BP

76152, 76155,

171294, 76152,

76155, 171294

62100-5800

Signal Pin Inserter

Pliers for Pin Removal:

Newark 96F8903

or MSC 00321885

100 Ohm Orthogonal

BP

76845

62100-9620 Extractor

85 Ohm PLUS Conventional

Mezzanine

(18mm height)

170390

62100-2150 Extractor

62100-2180 Extractor

Mezzanine

(37mm height)

62100-2100 Extractor

4

Power

Right Angle

Header

78213

78349

62202-4500 Extractor

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 26 of 35

Revision: G Revision Date: 06-16-14

Page 27

Impact™ Backplane and Daughtercard Tooling

Impact™ 85 Ohm, 100 Ohm, and Power Products – Repair Tools

Pair

Product

Module Type

Series

Tool

Illustration

5

100 Ohm Conventional

DC

76060

62202-4300 Extractor

100 Ohm Orthogonal

76990

85 Ohm plus Conventional

170480

5

100 Ohm Conventional

BP

76055, 76163

171293, 171296,

171297

62100-9610 Extractor

85 Ohm Plus Conventional

170472, 170475,

170517, 170518

85 Ohm Plus Conventional

BP

170472, 170475,

170517, 170518

62100-5850

Signal Pin Inserter

5

100 Ohm Conventional

BP

76055, 76163,

171293, 171296,

171297

62100-5800

Signal Pin Inserter

Pliers for Pin Removal:

Newark 96F8903

or MSC 00321885

5

100 Ohm Orthogonal

BP

76985

76986

171352

62100-9620 Extractor

100 Ohm Conventional

Mezzanine

(37mm height)

76530

62100-2170 Extractor

5

Power

Vertical

Header

78446, 78692

62100-8200 Extractor

Vertical

Receptacle

78216

Right Angle

Header

78215

78351

62202-4500 Extractor

6

100 Ohm Conventional

DC

76150

62202-4300 Extractor

100 Ohm Orthogonal

76290

85 Ohm plus Conventional

170540

100 Ohm Coplanar

RAM

76560

62202-4350 Extractor

100 Ohm Conventional

BP

76142, 76145,

171298

62100-9610 Extractor

85 Ohm Plus Conventional

170519, 170520,

170532, 170535

85 Ohm Plus Conventional

BP

170519, 170520,

170532, 170535

62100-5850

Signal Pin Inserter

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 27 of 35

Revision: G Revision Date: 06-16-14

Page 28

Impact™ Backplane and Daughtercard Tooling

Impact™ 85 Ohm, 100 Ohm, and Power Products – Repair Tools

Pair

Product

Module Type

Series

Tool

Illustration

6

100 Ohm Conventional

BP

76142

76145

171298

62100-5800

Signal Pin Inserter

Pliers for Pin Removal:

Newark 96F8903

or MSC 00321885

100 Ohm Orthogonal

BP

76285

76286

171356

62100-9620 Extractor

6

Power

Vertical

Header

78442

62100-8200 Extractor

Vertical

Receptacle

78218

Right Angle

Header

78353

62202-4500 Extractor

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 28 of 35

Revision: G Revision Date: 06-16-14

Page 29

Impact™ Backplane and Daughtercard Tooling

Figure 4-1

TYPICAL INSERTION

TOOL ASSEMBLY

4.2 Standard Tool Ordering Procedure

Stacking Tooling

All the insertion tooling listed in Table 4-1 can be stacked in any combination to be

able to simultaneously press in any arrangement of stacked connectors. Tooling

holders are available in various lengths. Figure 4-1 shows a typical setup for a 4

pair by 8 column backplane signal module in a standard tool holder.

Ordering Insertion Tooling for Backplane Connectors

In order to insert a typical row of backplane connectors, it is necessary to select the

individual insertion tools and then pick the appropriate tooling holder (See

example).

Basic Procedure

CAUTION: The vertical power module must be installed separately without any backplane or daughtercard

assemblies in the combinations.

1. Determine the combination of signal modules to be inserted.

2. Select the proper press-in tools from Table 4-1 and Table 4-2.

3. Table 4-1 and Table 4-2 shows the tool widths. Record the width of each tool selected.

NOTE: Make sure that if you require four of a particular tool, write down its length 4 times.

4. Total up the tool widths.

5. Using the width just calculated, select the next largest tooling holder from Table 4-3. The tooling holder can be shorter

than the total tooling but not by more than 0.5 mm per side.

6. The insertion tools and tooling holder selected above must be ordered separately.

Ordering Daughtercard Tooling

Daughtercard connectors only come in standard module sizes. The Daughtercard insertion modules lengths are based on the

module size. Therefore, insertion tools can be used individually for a connector assembly or stacked in a tool holder for

multiple connector assemblies. Select the specific tool for your connector from Table 4-3.

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 29 of 35

Revision: G Revision Date: 06-16-14

Page 30

Impact™ Backplane and Daughtercard Tooling

Section 5

Repair and Replacement

5.1 Backplane Repair Procedure

5.2 Daughtercard Repair Procedure

5.3 Glossary of Terms

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 30 of 35

Revision: G Revision Date: 06-16-14

Page 31

Impact™ Backplane and Daughtercard Tooling

Figure 5-2

INSERTION TOOL

CONTACTS SHOULDER IS

FLUSH AGAINST TOOL TIP

TERMINAL

CLAMP

SIGNAL

CONTACT

INSERTION

TOOL

HOUSING

CONTACT

ADJACENT

ROW

REPLACED

CONTACT

SIGNAL

PCB

Figure 5-3

NEEDLE

NOSE

PLIERS

CONNECTOR

SIGNAL PINS

FIGURE 5-1

5.1 Impact™ Backplane Repair Procedure:

Removal and Replacement of Signal Pair Pins

The following tools are required:

Signal Pin Replacement Tool 62100-5800 (100 Ohm)

Signal Pin Replacement Tool 62100-5850 (85 Ohm)

Needle nose pliers (miniature) *

Tweezers *

* Not supplied by Molex

Removal

To remove damaged signal pins, grasp them with the needle nose

pliers and pull straight up from the board. See Figure 5-1. In some

cases it may be necessary to straighten a bent pin with the tweezers to allow access with the pliers.

NOTE: Never reuse a backplane signal pin once it has been removed. In addition, no more than three pins should be

pressed into any plated through hole. Replacement pins should be removed from a spare virgin connector.

Replacement

1. Place the replacement signal contact at the tip of the insertion tool and slide the contact so it rests underneath the

terminal clamp. See Figure 5-2.

2. The signal contact will be guided using the groove located on the insertion tool and should be pushed all the way

underneath the terminal clamp.

3. The signal contact is completely seated in the insertion tool when, the contacts shoulder is resting against the insertion

tool tip and can no longer be moved up.

4. Make sure the signal contact is in the correct orientation. Check the column where the repair signal contact is being

replaced and compare the column to the contact signal on the insertion tool. The two should be the same. The adjacent

column is oriented in the opposite direction. See Figure 5-3.

5. Line-up the pins tip on the signal contact, with the hole in the signal module and push the pin tip with the insertion tool

through the housing and the printed circuit board.

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 31 of 35

Revision: G Revision Date: 06-16-14

Page 32

Impact™ Backplane and Daughtercard Tooling

HOUSING

CONTACT POSITIONED

IN THE GROOVE OF THE

INSERTION TOOL

INSERTION TOOL

FLUSH WITH HOUSING

INSERTION TOOL

Figure 5-4

Figure 5-6

21mm

(.83”)

17mm

(.67”)

PCB

REMOVAL

TOOL

D’CARD SIGNAL

MODULE

FIGURE 5-5

6. There is a clearance groove on the opposite side of the tool. When inserting the signal contact, make sure the

adjacent row is positioned in this groove.

7. Continue pushing the signal contact until the insertion tool and

terminal shoulder are seated securely to the inside housing surface.

See Figure 5-4.

8. Pull the insertion tool straight up and remove. Check the final

seating of the signal contact, the terminal shoulder should be

seated flush with inside surface on housing.

Impact™ Daughtercard Repair Procedure

The following tools are required:

Module Removal Tool 62202-4300

Pallet to support Printed circuit board *

Small arbor press (optional)*

*Not supplied by Molex

Connector Removal

Before removing the DaughterCard Signal Module from the printed

circuit board, the rows of the module have to be determined. This is required so the Removal tool jaws can be set-up

correctly to match the proper DaughterCard Row Series. Count the number of

rows on the Front Wafer Housing. See ATS-62202-4300 for tool set up.

OPERATING SPACE (Keep Out Zone)

A certain amount of space is required on the printed circuit board for the Removal

Tool to fit over the daughtercard signal module. Make sure there are no other

components in this space. See Figure 5-6.

1. Before removing individual modules be certain the tool is adjusted to the

correct row size. See Figure 5-7.

Revision: G Revision Date: 06-16-14

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 32 of 35

Page 33

Impact™ Backplane and Daughtercard Tooling

REMOVAL TOOL

CLOSED

BACK

JAW

TOOL

5 PAIR

POSITION

MODULE

PCB

JAW TEETH INSERTED

INTO SLOT OF MODULE

PCB

BACK

JAW

TOOL

FRONT

JAW TOOL

3 PAIR

POSITION

Figure 5-7

Correct Position of Jaw Tools

MODULE

GRIPPING

FINGERS ENGAGED

4 PAIR

POSITION

FRONT

JAW TOOL

2 PAIR

POSITION

REMOVAL

TOOL

CLOSED

FRONT

JAW

TOOL

2-PAIR

MODULE

BACK

JAW

TOOL

JAW TEETH

INSERTED

INTO SLOT

OF MODULE

FRONT AND BACK

JAWS RESTING ON

SIGNAL MODULE

FRONTJAW

TOOL

6 PAIR

POSITION

MODULE

JAW TEETH INSERTED

INTO SLOT OF MODULE

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 33 of 35

Revision: G Revision Date: 06-16-14

Page 34

Impact™ Backplane and Daughtercard Tooling

2. Position the 62202-4300 Removal Tool over the defective module with the toothed jaw located over the mating end of the

connector and the slotted jaw over the stiffener on the opposite end of the module.

3. While holding the tool in position over the module, squeeze the handles until the jaws clamp firmly. While applying

pressure to the handles, pull straight up until the connector comes off the board.

Backplane Module Replacement

Follow operation instruction from section 2.4.

Power Module Removal

Daughtercard power modules should be removed using the 62200-4500 pliers. Clamp the pliers over the mating and

stiffener side of the module and pull up. Be careful of any adjacent signal modules while removing the powers.

See Table 4-3 for vertical power module removal tools.

Power Module Replacement

Follow operation instructions from section 2.4.

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 34 of 35

Revision: G Revision Date: 06-16-14

Page 35

Impact™ Backplane and Daughtercard Tooling

Backup

(or Support)

Pallet

A simple fixture used to locate and support a printed circuit while a compliant

pin connector is being pressed into the pc board. Considerable force is required

to press one of these connectors into a pc board, thus the pc board must be

adequately supported to avoid being damaged. It must have adequate clearance

for the terminals when they protrude through the pc board.

Compliant Pin

Connector

A connector which has terminals that are designed to give slightly when pressed

into a hole in a pc board so that the terminal (pin) makes solid electrical contact

with the printed circuit board, alleviating the need for soldering.

Flat Platen Press

A press in which the upper tooling or die set is not attached to the press ram.

The ram has a simple flat plate (or platen) attached to it. For this application, the

upper tooling is positioned in the connector(s). The press ram comes down on

top this tooling and presses on it. When the press ram goes back up, the upper

tooling stays with the connector.

PCB

Abbreviation for printed circuit board

Upper Tooling

The tooling that goes on top of the connector. It contains the mounting block

and dies (or tools) necessary to properly apply pressure where required to push

the connector’s compliant terminals and locking posts into the holes in the printed

circuit board.

5.2 Glossary of Terms:

Visit our Web site at http://www.molex.com

Doc. No: TM-622018799 Release Date: 08-31-09 UNCONTROLLED COPY Page 35 of 35

Revision: G Revision Date: 06-16-14

Loading...

Loading...