Page 1

Hand Crimp Tool For C-Grid III™ Female Crimp Terminals

CRIMP HEIGHT

HAND CRIMP TOOL

Specificat ion Sheet

Order No. 63819- 0200

FEATURES

A full cycle ratcheting hand tool ensures compl ete crimps

Ergonomic soft grip handles f or comfortable crimping

A precision user-friendly termi nal l ocat or wi re st op hol ds t erm inal s in t he proper crim pi ng position

Right and Left handed appli cati ons

This tool is IPC/ WHM A A-620 Class 2 compliant as indicated.

This tool is RoHS compliant, however RoHS compliant i s not requi red

SCOPE

Products: C-Grid III™ Female Crimp Terminals, 22-28 AWG

Í

Terminal Series No.

90119

Terminal Order No. Wire Si ze

Æ

Loose Piece

90119-2109

90119-2110

90119-2111

90119-2120

90119-2121

90119-2122

Æ

Customer to cut of f t erm i nal from reel: 0.15mm (.006”) maximum Cut-off Tab.

Reel

90119-0109

90119-0110

90119-0111

90119-0120

90119-0121

90119-0122

Í

AWG mm² mm In. mm In.

22-24 0.35-0.20 1.02-1.47 .040-.058 2.80-3.30 .110-.130

26-28 0.12-0.08 0.76-1.22 .030-.048 2.80-3.30 .110-.130

See Conditions on page 2.

Insulation Diameter

DEFINITION OF TERMS

BRUSH

BELL MOUTH

INSULATION

CRIMP

CONDUCTOR

CRIMP

STRIP

LENGTH

The above terminal drawing is a generic term inal represent ation. It is not an i m age of a terminal listed i n the

scope.

BEND UP

BEND

DOWN

Strip Length

ROLLING

TWISTING

TYPE 4D

Doc No: ATS-63819-0200 Release Date: 11-02-07

Revision: A Revision Date: 11-02-07

UNCONTRO L L ED CO P Y Page 1 of 7

Page 2

Hand Crimp Tool For C-Grid III™ Female Crimp Terminals

TERM

CONDITIONS:

After crimping, the conductor profiles should measure the fol l owi ng.

Series No

90119

Í

Wire Size

AWG mm2 mm In. mm In. mm In. mm In. N Lb. 22-24 26-28

22 0.35 0.71-0.81 .028-.032 1.18 .046 1.60 .063 1.60 .063 39.2 8.82 X

24 0.20 0.71-0.81 .028-.032 1.18 .046 1.60 .063 1.60 .063 29.4 6.61 X

26 0.12 0.59-0.69 .023-.027 1.16 .045 1.40 .055 1.40 .055 19.6 4.41 X

28 0.08 0.59-0.69 .023-.027 1.16 .045 1.40 .055 1.40 .055 9.8 2.20 X

To Achieve IPC-A-620 Class 2 Crimps, the following over-all wire insulat i on di am et er ranges are recommended:

Profile 22 - 24: 1.02 – 1.47mm (. 040-. 058 i nch) Profi l e 26 - 28: 0. 89 - 1. 22m m (.035-. 048 i nch)

Conductor Crimp Insulation Crimp Terminal

Height (Ref.) Width (Ref.) Height (Ref.) Width (Ref.)

Pull Force

Minimum

Í

Profile

OPERATION

CAUTION: I nst al l onl y Mol ex t erm i nal s li sted above wi t h this tool. Do not crimp hardened obj ect s as damage can

occur to the tool or die.

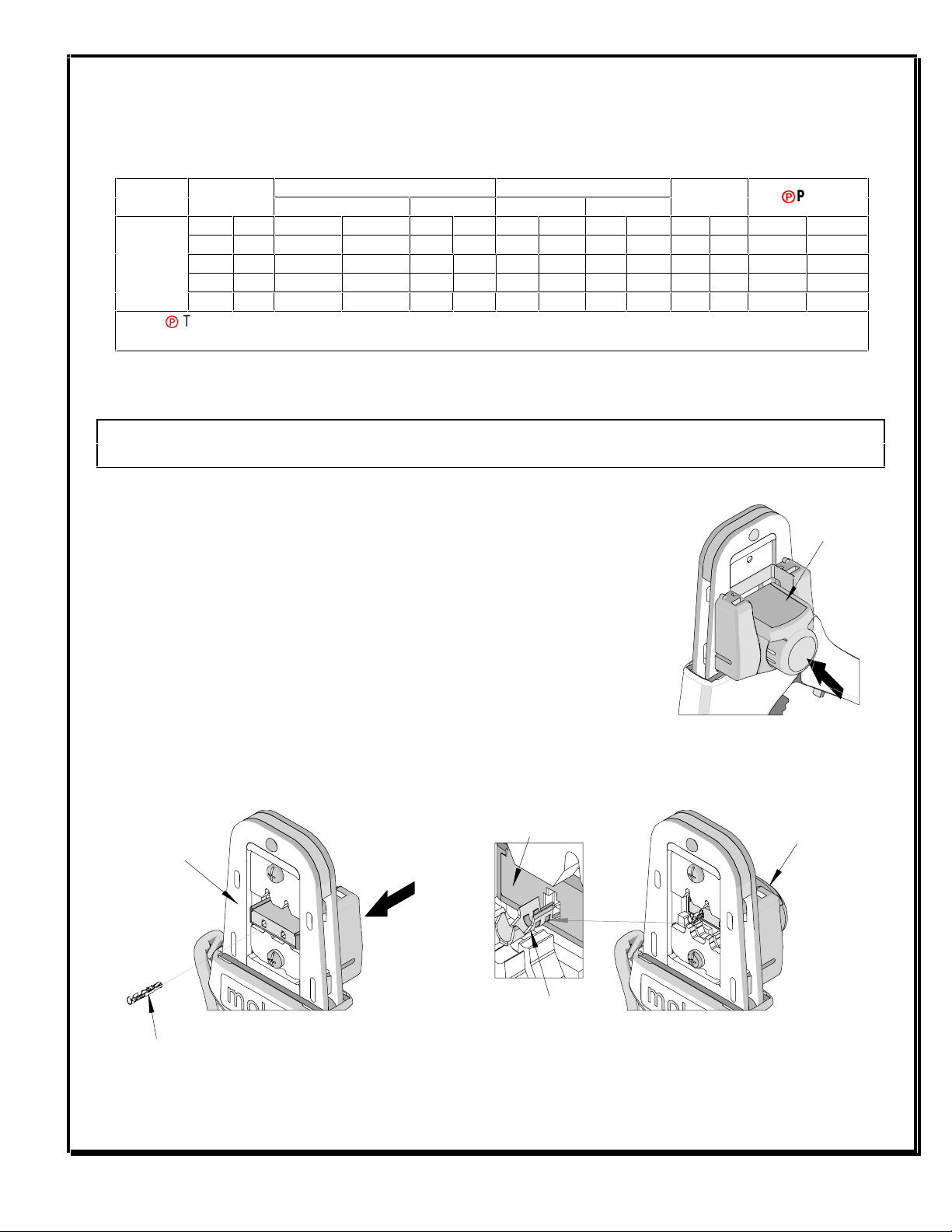

Open the tool by squeezing the handles together. At the end of t he closing

stroke, the ratchet mechanism will release the handles and the hand tool will

LOCATOR

IN DOWN

POSTION

spring open. See Figure 1.

Crimping Terminals

1. Select the desired terminal listed in t he preceding chart s.

2. Make sure the center of the locator is in the down positi on. With the locator

attached, push the locator but ton on the back of the hand tool t o bri ng t he

locator forward through the tooling. See Figure 2.

3. While holding the locator button in, l oad the terminal into t he proper nest

opening in the locator based on the wi re gauge or t erm i nal t ype m arkings on

the hand tooling. S ee Figure 3.

LOCATOR

PUSHED THRU

TOOLING

LOCATOR

LOCATOR

BUTTON

PUSHED IN

INAL

TERMINAL

Figure 3

Figure 2

PUSH ON THE

LOCATOR BUTTON

RELEASE

LOCATOR BUTTON

Doc No: ATS-63819-0200 Release Date: 11-02-07

Revision: A Revision Date: 11-02-07

UNCONTRO L L ED CO P Y Page 2 of 7

Page 3

Hand Crimp Tool For C-Grid III™ Female Crimp Terminals

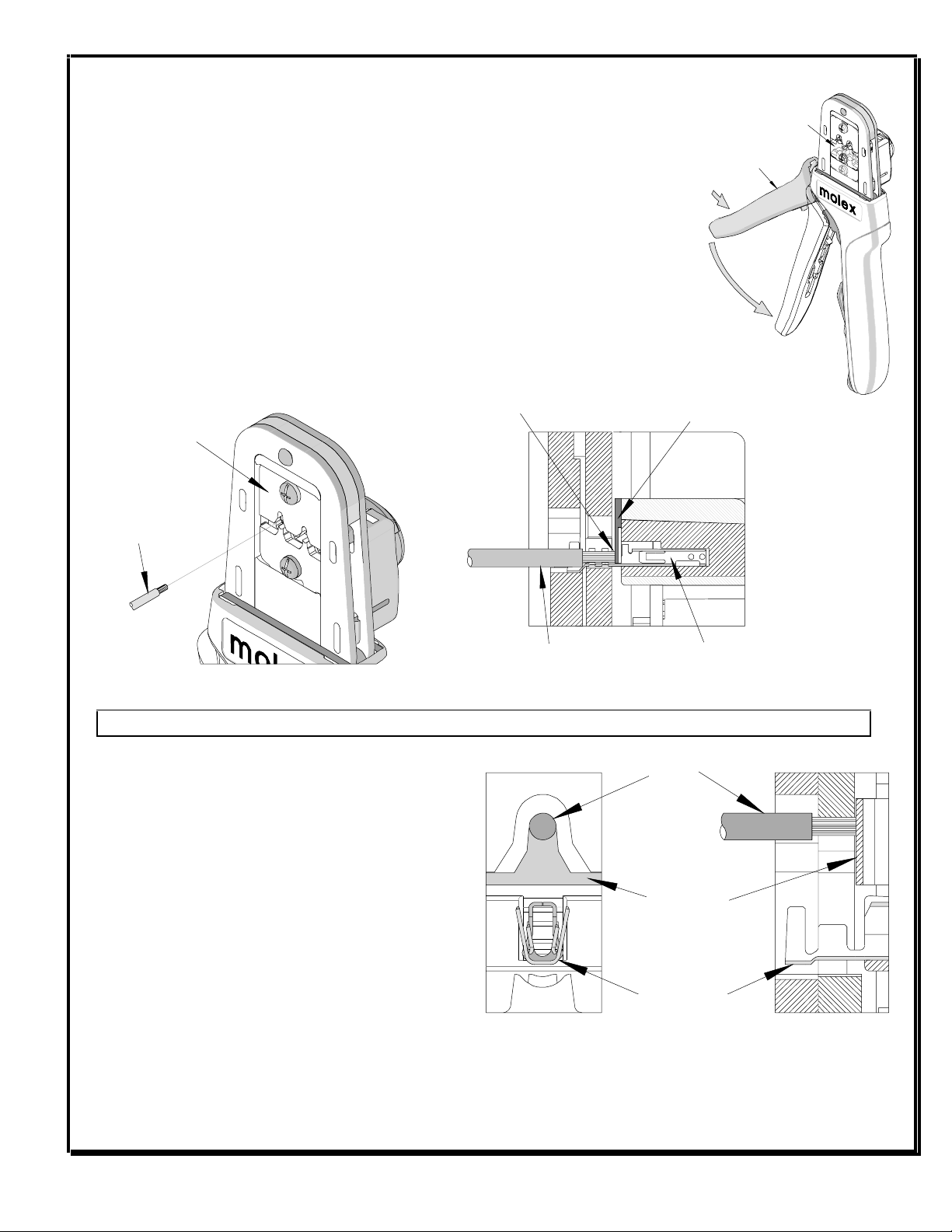

WIRE STOP IS PART

FIRST RATCHET

4. Release the locator button, allowing t he l ocat or t o ret urn to the crimping

position.

5. Close the tool handle until the first rat chet position engages. See

Figure 4.

6. Insert the properly stripped wire through the term i nal and agai nst the

wire stop. See Figure 5.

7. Crimp the terminal by squeezing the tool handles until the ratchet

mechanism cycle has been completed. Release the handles t o open

the jaws.

OPEN

POSITION

TERMINAL

WIRE AGAINST THE

WIRE STOP

OF THE LOCATOR

PRE-STRIPPED

WIRE

Figure 5

WIRE

TERMINAL

Note: The tamper proof ratchet action will not release the tool unt il it has been f ully closed.

WIRE

8. Remove the crimped terminal from the t erm inal

locator by pulling on the wire.

9. Visually inspect the crimped terminal for proper

crimp location.

10. On some large O.D. wi res, it may not be possible

to insert the wire wi th the tool partial l y closed.

WIRE STOP

Those wires should be inserted with the hand tool

in the open position. Insert the wire above the

terminal in the punch and against the wire stop

Figure 6

then close the tool. S ee Figure 6.

TERMINAL

TOOLING

PARTIALLY

CLOSED

PARTIALLY

CLOSE HANDLE

POSITION

Figure 4

Doc No: ATS-63819-0200 Release Date: 11-02-07

Revision: A Revision Date: 11-02-07

UNCONTRO L L ED CO P Y Page 3 of 7

Page 4

Hand Crimp Tool For C-Grid III™ Female Crimp Terminals

TOOLING

LOWER TABS

Note:

A crimp height chart is provided with this manual as Reference Only.

Due to the wide range of wires, st rands,

insulation diameters, and durom et ers avail able, actual crimp height measurement s may very slightl y. A n

occasional, destructive, pull f orce t est should be performed to check hand tool crimp. Pul l Force value Must

exceed the Minimum pull f orce specifi cat ions l ist ed.

LOCATOR

Locator Replacement

See the parts list on t he l ast page of this

document for the proper locat or order num ber.

Follow the steps below to replace t he l ocat or.

1. Open the crimp hand tool.

SQUEEZE

HERE

Figure 7A

2. Squeeze gently on the lower area shown in

Figure 7A with your thumb and i ndex fi nger.

The lower tabs of the locator should

disengage from the hand tool.

3. Lift and pull away from the hand tool. The

top locator hooks should slip out of t he t op

slots easily. See Figure 7A.

4. To reinstall the new locator, make sure the

hand tool is in the open position.

5. Press the red insert down as far as it will go

as shown in Figure 7B.

6. Holding onto the lower part of the locat or wi th your thumb and index finger, i nsert the locators top hooks (2)

into the hand tool t op slots.

7. Rotate the locator down and press the lower tabs into the two bottom slots of the hand tool. To secure the

locator into place, the lower tabs must snap into

place on the hand tool frame.

Right or Left Hand Operation

This hand tool has an added feature that can be

converted from a right handed applicat ion to a left

handed application. It is necessary to reverse the

M3 BHCS

tooling if using t he left handed application along wit h

the locator. Follo w t he st eps below:

1. The locator must be removed before reversing

the tooling.

2. Remove the M3 BHCS which is holding the upper

tooling.

3. Flip the upper tooling to the opposite side and

replace the M3 BHCS. M ake sure t he smal l

markings on the front and back of the hand t ool f ram e, m atch up and are on the outside of the hand tool frame.

See Figure 8 and 9.

SQUEEZE

HERE

TOP SLOTS OF

HANDTOOL

TOP HOOKS

JAWS OPEN

PULL OPEN

Figure 8

PUSH ON

HANDLE

MAKE SURE

CENTER OF LOCATOR

IS IN THE

DOWN POSITION

Figure 7B

TOOLING

Doc No: ATS-63819-0200 Release Date: 11-02-07

Revision: A Revision Date: 11-02-07

UNCONTRO L L ED CO P Y Page 4 of 7

Page 5

Hand Crimp Tool For C-Grid III™ Female Crimp Terminals

LUBRICATION POINTS

4. Do the same thing with the lower tooli ng and t i ghten

the M3 screws. Be sure the small m arkings li ne up.

MATCH

UP MARKS

5. Reinstall the locator by following t he I nst ruct i ons in

the locator replacement secti on.

Figure 9

Maintenance

It is recommended that each operat or of the tool be

made aware of, and responsible for, the following

FRONT BACK

maintenance steps:

1. Remove dust, moisture, and other contaminant s with a clean brush, or soft, lint free cloth.

2. Do not use any abrasive materials that could damage the tool.

3. Make certain all pins; pivot points and bearing surfaces are protected

with a thin coat of hi gh quali ty machine oil. Do not oil excessively.

The tool was engineered for durability but like any other equipment it

needs cleaning and lubrication for a maxim um service lif e of trouble

free crimping. Light oi l (such as 30 weight aut om otive oil) used at the

oil points, every 5,000 crimps or 3 months, will significantly enhance

the tool life.

4. Wipe excess oil from hand tool, particularly from crimping area. Oi l

transferred from the crimpi ng area onto certain terminati ons may

affect the elect rical characteri st i cs of an appl icat i on.

5. When tool is not in use, keep the handles closed to prevent objects

from becoming lodged in the crimpi ng di es, and st ore the tool in a

(BOTH SIDES) LIGHT OIL

(EVERY 3 MONTHS OR

5,000 CRIM PS)

clean, dry area.

Figure 10

Miscrimps or Jams

Should this tool ever become stuck or jamm ed i n a part i al l y closed positi on, Do No t force the handles open or

closed. The tool will open easily by pressing up on the ratchet release lever in the movable handle. See Figure

11.

How to Adjust Tool Preload (See Figure 12)

This hand tool is factory preset to 25-45 LBS. preload. It may be necessary

over the life of t he t ool t o adj ust tool handle preload force. Listed bel ow are

the steps required to adjust t he crimpi ng f orce of the hand tool to obtain

proper crimp conditions:

1. Hold the hand tool in the palm of your hand as shown in Figure 10.

Using the index finger squeeze the link towards t he top of the hand tool

frame. This will release the preload adjustment wheel.

RATCHET RELEASE

LEVER

Figure 11

Doc No: ATS-63819-0200 Release Date: 11-02-07

Revision: A Revision Date: 11-02-07

UNCONTRO L L ED CO P Y Page 5 of 7

Page 6

Hand Crimp Tool For C-Grid III™ Female Crimp Terminals

RATCHET

2. Rotate the setting wheel counter-clockwise (CCW) to increase handle force. The numbers will display higher.

To decrease handle force rotate the sett i ng wheel clockwise (CW).

3. Release the link to lock the setting wheel in place.

4. Check the crimp specifications or

conduct a pull test aft er t ool handl e

preload force is adjusted.

RELEASE LEVER

SQUEEZE

THE LINK IN

THE HANDLE

HOLD THE HAND

TOOL IN POSITION

Warranty

This tool is for electrical t erm i nal crimpi ng

purposes only. This tool is made of the

best quality materi als. All vital

components are long life test ed. A l l tools

are warranted to be free of m anuf act uri ng

defects for a period of 30 days. S hould

such a defect occur, we will repair or

Figure 12

exchange the tool free of charge. This

repair or exchange will not be applicable

to altered, mi sused, or dam aged t ool s.

SETTING

WHEEL

This tool is designed for hand use only.

Any clamping, fixt uri ng, or use of handl e ext ensions voids thi s warrant y.

CAUTION: Mol ex crimp specif i cat ions are vali d onl y when used wit h M ole x term i nal s and t ool i ng.

CAUTIONS:

1. Manually powered hand tools are intended for low volume or fiel d repai r. This tool is NOT int ended for

production use. Repetiti ve use of t hi s t ool should be avoided.

2. Insulated rubber handles are not protection against electrical shock.

3. Wear eye protection at all times.

4. Use only the Molex terminals specified for crimping wi t h this tool.

Certification

Molex does not certify or re-certi f y hand t ool s but rather supplies the following gui del i nes f or custom ers t o re-cert i fy

hand tools.

%

This tool is qualified to pull force only. To re-certif y, crim p a terminal to a wire, whi ch has been stri pped

12.7mm (1/2”) long, so t here i s no crimpi ng of the insulation. Pu ll the terminal and wire at a rate no faster than

25mm (1.00”) per minute. See t he M ol ex web sit e for the Quality Crimp Handbook f or m ore i nf o rm at i on on pul l

testing.

%

If the tool does not m eet minimum pull f orce values, handle prel oad should be i ncreased and the pull test

rerun, (See How to Adj ust Preload).

%

When the hand tool is no longer capable of achieving m i nim um pul l f orce, i t should be taken out of service and

replaced.

Doc No: ATS-63819-0200 Release Date: 11-02-07

Revision: A Revision Date: 11-02-07

UNCONTRO L L ED CO P Y Page 6 of 7

Page 7

Hand Crimp Tool For C-Grid III™ Female Crimp Terminals

PARTS LIST

Item Number Order Number Description Quantity

REF 63819-0200 Hand Crimp Tool Figure 13

1 63819-0275 Locator Assembly 1

2 63810-0104 Spring, Return 1

3 63810-0105 Spring, Ratchet 1

Americas Headquar ters

Lisle, Illinois 60532 U.S.A.

1-800-78MOLEX

amerinfo@molex.com

1

Far East North Hea dquarters

Yamato, K anagawa, J apan

81-462-65-2324

feninfo@molex.com

Visit our Web site at http://www. molex.com

Figure 13

Far East South He adqua rters

Jurong, Singapore

65-6-268-6868

fesinfo@molex.com

2

RATCHET

RELEASE LEVER

3

European Headquarters

Munich, Germany

49-89-413092-0

eurinfo@molex.com

Corporate Headqua rters

2222 Wellington Ct.

Lisle, I L 60532 U.S.A.

630-969-4550

Fax: 630-969-1352

Doc No: ATS-63819-0200 Release Date: 11-02-07

Revision: A Revision Date: 11-02-07

UNCONTRO L L ED CO P Y Page 7 of 7

Loading...

Loading...