Page 1

FineAdjust Applicator

Description

Operation

Maintenance

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 1 of 50

Revision: G Revision Date: 01-15-13

FineAdjust™ APPLICATOR

Operation Manual

Order No 63800-4900

Page 2

FineAdjust Applicator

Read

and

understand

all of the instructions and safety information in this manual

before

CAUTION:

WARNING

WARNING

Heavy Object

WARNING

WARNING

Never

install or service this machine while

WARNING

WARNING

Never

operate, service, install, or adjust this

This symbol is used to call your attention to hazards or unsafe practices which could result in an injury

or property damage. The signal word, defined below, indicates the severity of the hazard. The message

after the signal word provides information for preventing or avoiding the hazard.

DANGER

WARNING

Safety Warnings and Information

operating or servicing this tool.

Keep this manual available when using this tool.

Replacement manuals are available for download at no charge at www.molex.com.

SAFETY ALERT SYMBOL

DANGER:

Indicates an imminently hazardous situation which, if not avoided, could result in death or serious injury.

WARNING:

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION may also be used to alert against unsafe practices associated with events that could lead

to personal injury.

Always wear proper eye protection when

Operating or servicing this equipment.

Failure to wear eye protection could result

in serious eye injury from flying debris.

Never wear clothing or jewelery that is loose or

That could potentially hang into the equipement

and get caught.

Failure to observe this warning could result in

Severe Injury or death.

machine without proper instruction and without

first reading and understanding the instructions

in this manual and all applicable press and/or

wire processing machine.

manuals.

To avoid muscle strain or back injury, use lifting

aids and proper lifting techniques when removing

or replacing.

Failure to observe these precautions may result in

injury or property damage.

connected to any electrical power source.

Disconnect power by unplugging the press

from its power source.

Failure to observe this warning could result

In severe injury or death.

Always hand cycle the applicator in the equipment

to ensure the tooling is properly aligned.

Failure to observe these precautions may result in

Injury or property damage.

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 2 of 50

Revision: G Revision Date: 01-15-13

Page 3

FineAdjust Applicator

WARNING

WARNING

Do not use

compressed air to clean

WARNING

CAUTION

The Molex applicators a

re designed to operate in presses with standard shut heights of 135.80mm (5.346”).

CAUTION

Never

perform any se

rvice or maintenance other than as described in this manual.

Never use this press or wire processing machine

without guards or safety devices that are intended

to prevent hands from remaining in the die space.

Failure to observe this warning could result in

Severe injury or death.

Always wear proper ear protection when Operating or servicing this applicator.

Installation in crimp presses with other than standard shut heights can cause severe tool breakage. It is advisable that before

installation, a check of the shut height be performed. Molex will not be liable for any damages as a result of installation in a

crimp press with nonstandard or improperly set shut height.

Failure to observe these precautions may result in injury or property damage.

Never modify, alter or misuse the equipment

Molex crimp specifications are valid only when used with Molex terminals, applicators and tooling.

Failure to observe this precaution may result in injury and property damage.

this equipment.

The forces created by compressed

air can force debris into the tool.

Failure to observe these precautions may

result in injury or property damage.

Tooling Technical Assistance

Molex offers tooling technical assistance for customers who may need some guidance for tooling adjustments. This support can

be obtained by calling either of the two numbers listed below and asking for the Molex Tooling Group.

Call Toll Free 1-800-786-6539 (US) 1-630-969-4550 (Global).

This assistance is limited to the operation and set-up of a customer’s Molex Press. Questions with regard to Molex connector

products or how to identify the proper tooling and/ or tooling documentation should be directed to your local Molex personnel or

Customer Service Representative.

When calling for service on the press a copy of the Tooling Manual and Specific Applicator Tooling Specification Sheet should be

present and a person that is familiar with the applicator should be present. Be sure the following information is supplied:

1. Customer name

2. Customer address

3. Person to contact such as (name, title, e-mail, and telephone number

4. Applicator order number (Lease number also if applicable)

5. Serial number (Lease number also if applicable)

6. Molex Connector product order number

7. Urgency of request

8. Nature of problem

Molex Application Tooling Group

2200 Wellington Court

Lisle, IL 60532, USA

Tel: +1 (630) 969-4550

Fax:+1 (630) 505-0049

Visit our Web site at http://www.molex.com

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 3 of 50

Revision: G Revision Date: 01-15-13

Page 4

FineAdjust Applicator

Table of Contents

Contents

FineAdjust™ APPLICATOR .......................................................................................................................................... 1

Order No 63800-4900 .................................................................................................................................................... 1

Safety Warnings and Information .................................................................................................................................. 2

Table of Contents ........................................................................................................................................................ 4

Section 1 ................................................................................................................................................................... 6

General Description .............................................................................................................................................. 6

Principal Mechanical Parts of the FineAdjust Applicator ....................................................................................... 7

1.1 Description................................................................................................................................................. 8

1.2 Features .................................................................................................................................................... 8

1.3 Technical Specification .............................................................................................................................. 8

1.4 Delivery Check .......................................................................................................................................... 8

1.5 Tools .......................................................................................................................................................... 9

1.6 Specification Sheets .................................................................................................................................. 9

Section 2 ................................................................................................................................................................. 10

Set-Up and Operation ......................................................................................................................................... 10

2.1 Shut Height .............................................................................................................................................. 11

2.2 Set-Up ..................................................................................................................................................... 11

2.3. Adjustments ............................................................................................................................................. 13

2.4 Crimp Tooling Installation and Removal .................................................................................................. 16

Section 3 ................................................................................................................................................................. 18

Maintenance ....................................................................................................................................................... 18

3.1 Cleaning .................................................................................................................................................. 19

3.2 Lubrication ............................................................................................................................................... 19

3.3 Spare Parts.............................................................................................................................................. 20

3.4 Perishable Parts ...................................................................................................................................... 20

3.5 Storage .................................................................................................................................................... 21

Section 4 ................................................................................................................................................................. 22

Styles of FineAdjust ............................................................................................................................................ 23

4.1 STYLE A-FineAdjust Applicator ............................................................................................................... 24

4.1 STYLE A FineAdjust Applicator Assembly............................................................................................... 26

4.1 STYLE A FineAdjust Applicator Assembly (Cont.) ................................................................................... 27

4.2 STYLE B-FineAdjust Applicator ............................................................................................................... 28

4.2 STYLE B FineAdjust Applicator Assembly............................................................................................... 30

4.2 STYLE B FineAdjust Applicator Assembly (Cont.) .................................................................................. 31

4.3 STYLE C-FineAdjust Applicator ............................................................................................................... 32

4.3 STYLE C FineAdjust Applicator Assembly .............................................................................................. 34

4.3 STYLE C FineAdjust Applicator Assembly (Cont.) ................................................................................. 35

4.4 Troubleshooting ....................................................................................................................................... 36

Appendix A .............................................................................................................................................................. 38

Crimp Terminations ............................................................................................................................................ 38

A.1 Conductor Brush and Terminal Position ................................................................................................. 39

A.2 Conductor Bell Mouth and Terminal Cutoff Tab ....................................................................................... 40

A.3 Conductor Height Measurement .............................................................................................................. 41

A.4 Insulation Crimp ....................................................................................................................................... 41

A.5 Pull Force Testing .................................................................................................................................... 43

Appendix B .............................................................................................................................................................. 45

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 4 of 50

Revision: G Revision Date: 01-15-13

Page 5

FineAdjust Applicator

Statistical Process Control (Summary) ............................................................................................................... 45

B.1 Crimp Process Control ............................................................................................................................ 46

B.2 Process Capability ................................................................................................................................... 46

B.3 Production ............................................................................................................................................... 47

Appendix C ............................................................................................................................................................. 49

Options .................................................................................................................................................................... 49

Terminal Oiler ................................................................................................... Error! Bookmark not defined.50

Order No. 63890-0719 ...................................................................................... Error! Bookmark not defined.50

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 5 of 50

Revision: G Revision Date: 01-15-13

Page 6

FineAdjust Applicator

General Description

1.1 Description

1.2 Features

1.3 Technical Specifications

1.4 Delivery Check

1.5 Crimp Tooling Accessories

1.6 Tools

1.7 Specification Sheets

Section 1

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 6 of 50

Revision: G Revision Date: 01-15-13

Page 7

FineAdjust Applicator

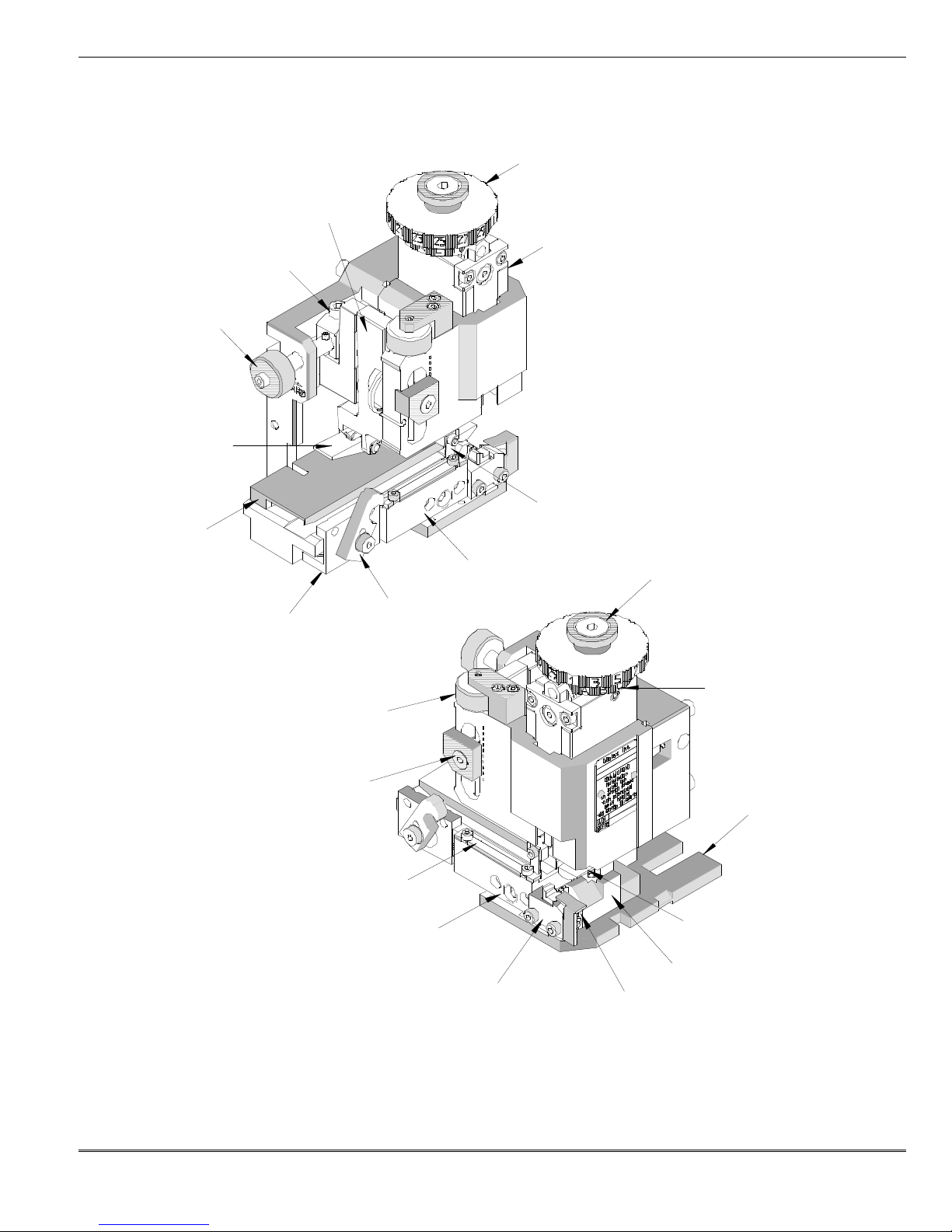

Figure 1

-1

PIVOT ARM

FORWARD FEED

FORWARD FEED

INSULATION

RAM

DRAG FRAME

DRAG RELEASE

TRACK

FEED FINGER

CONDUCTOR

BACK STROKE

LUG BOLT

WIRE STOP

ANVIL MOUNTING BLOCK

ANVILS

FRONT COVER

TRACK

CUT-OFF PLUNGER

FEED

FINGER

BACK STROKE

Principal Mechanical Parts of the FineAdjust Applicator

ADJUSTING KNOB

REAR COVER

LOCKING SCREW

LEVER

ADJUSTING KNOB

LOCKING SCREW

ADJUSTING SCREW

ADJUSTING CAM

ADJUSTING CAM

BASE PLATE

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 7 of 50

Revision: G Revision Date: 01-15-13

AND RETAINER

Page 8

FineAdjust Applicator

General Descrition

1.1 Description

The Molex FineAdjust™ Applicator is designed to provide

an effective method of applying a wide range of side feed

terminals to a pre-stripped discrete wire. It is the most

advanced version of a "universal" crimping tool available. It

is designed to allow for quick adjustments of crimp height,

track position, and terminal feed without taking the

applicator out of the press and without shimming. This

allows easy adjustment of crimp height to the target value

with improved process capability, even after a wire changeover.

This applicator works in the Molex TM-2000 and TM-3000

Universal Press and in most industry standard presses.

The FineAdjust™ applicator offers minimal setup time

without the need for shimming, is versatile, reliable, easy to

install, and is designed for mid-volume to high-volume,

semi or fully automatic operations.

Molex offers the following crimp presses for operating the

Fine Adjust Applicator™:

TM-2000 Press 120 V 60 Hz. 63800-8300

TM-2000 Press 240 V 50 Hz. 63800-8400

TM-3000 Press 120 V 60 Hz. 63801-7200

TM-3000 Press 240 V 50 Hz. 63801-7300

TM-4000 Press 240 V 60 Hz. 63801-7600

The FineAdjust Applicator is also compatible with most

OEM presses (Artos, Mecal, Komax, Megomat, Toyojamco,

etc). It also adapts to most wire processing machines.

1.2 Features

Fine adjustment allows users to achieve target with

little effort by adjusting in increments (14 settings) of

.015mm (.0006") for conductor crimp height and (29

settings) in increments of .063mm (.0025") for

insulation height.

Independent adjustment rings allow users to quickly

adjust the conductor or insulation crimp height without

affecting each other.

Quick tooling removal with the push of a button for fast

and easy punch change.

Track adjustment for bell mouth and cut-off tab is

adjusted while the applicator is in the press for fast and

easy setup.

Compatible with the Molex TM-2000, TM-3000, TM-

4000 Universal Press, and most industry standard

presses. However, it does NOT fit into Molex TM40/42 press.

Directly adapts to most automatic wire processing

machines.

Quick set-up time; plus the crimp height, track and feed

adjustments can be preset in applicator.

Applicator designed to industry standard mounting and

shut height 135.80mm (5.346").

Automatic terminal feed with applicator in press.

Adjustable terminal feed with applicator in press.

Terminals are separated from carrier strip automatically

during crimping operation.

Quiet operation with low maintenance and easy to

keep clean.

The FineAdjust™ available for most Molex brand

terminals.

1.3 Technical Specification

Dimensions

Width: 132mm (5.2")

Depth: 101mm (4.0")

Height: 152mm (6.0")

Weight

4.1kg (9lbs)

Press Stroke Compatibility

41.28mm (1 5/8")

28.58mm (1 1/8")

Guarding

The FineAdjust™ Applicator is supplied with no

guards and is intended to be used with the guards

supplied by the press manufacturer.

Caution: DO NOT use the applicator

without guards

1.4 Delivery Check

Carefully remove the FineAdjust Applicator from its

shipping container and determine that the following

items are included in the package.

FineAdjust Applicator 1

(Tooled for desired terminal)

11-18-4238 Short Feed Cam 1

Specification Sheets 1

TM-638004900

Operation Manual 1

Sample Crimped Terminals 5

Crimp Tooling Accessories

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 8 of 50

Revision: G Revision Date: 01-15-13

Page 9

FineAdjust Applicator

63890-0719 Terminal Oiler (Appendix C)

63800-2800 Digital Crimp Micrometer

1.5 Tools

The following tools are recommended for setup and

adjustments to the applicator:

1. Metric standard hex wrench set

2. Adjustable wrench

3. Wire stripper / cutter

4. Scissors

1.6 Specification Sheets

Molex ships specification sheets with every

applicator. The specification sheet contains the

following:

ΕΕΕΕ Terminal numbers

ΕΕΕΕ Wire AWG ranges

ΕΕΕΕ Insulation diameter ranges

ΕΕΕΕ Strip lengths

ΕΕΕΕ Pull force

ΕΕΕΕ Crimp heights

ΕΕΕΕ Bell mouth

ΕΕΕΕ Bend, twist, and roll limits

ΕΕΕΕ Tooling parts list and assembly

The specification sheet should be filed. These are

available on the Molex website (www.molex.com).

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 9 of 50

Revision: G Revision Date: 01-15-13

Page 10

FineAdjust Applicator

Section 2

Set-Up and Operation

2.1. Shut Height

2.2. Set-Up

2.3. Adjustments

2.4. Crimp Tooling Installation and Removal

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 10 of 50

Revision: G Revision Date: 01-15-13

Page 11

FineAdjust Applicator

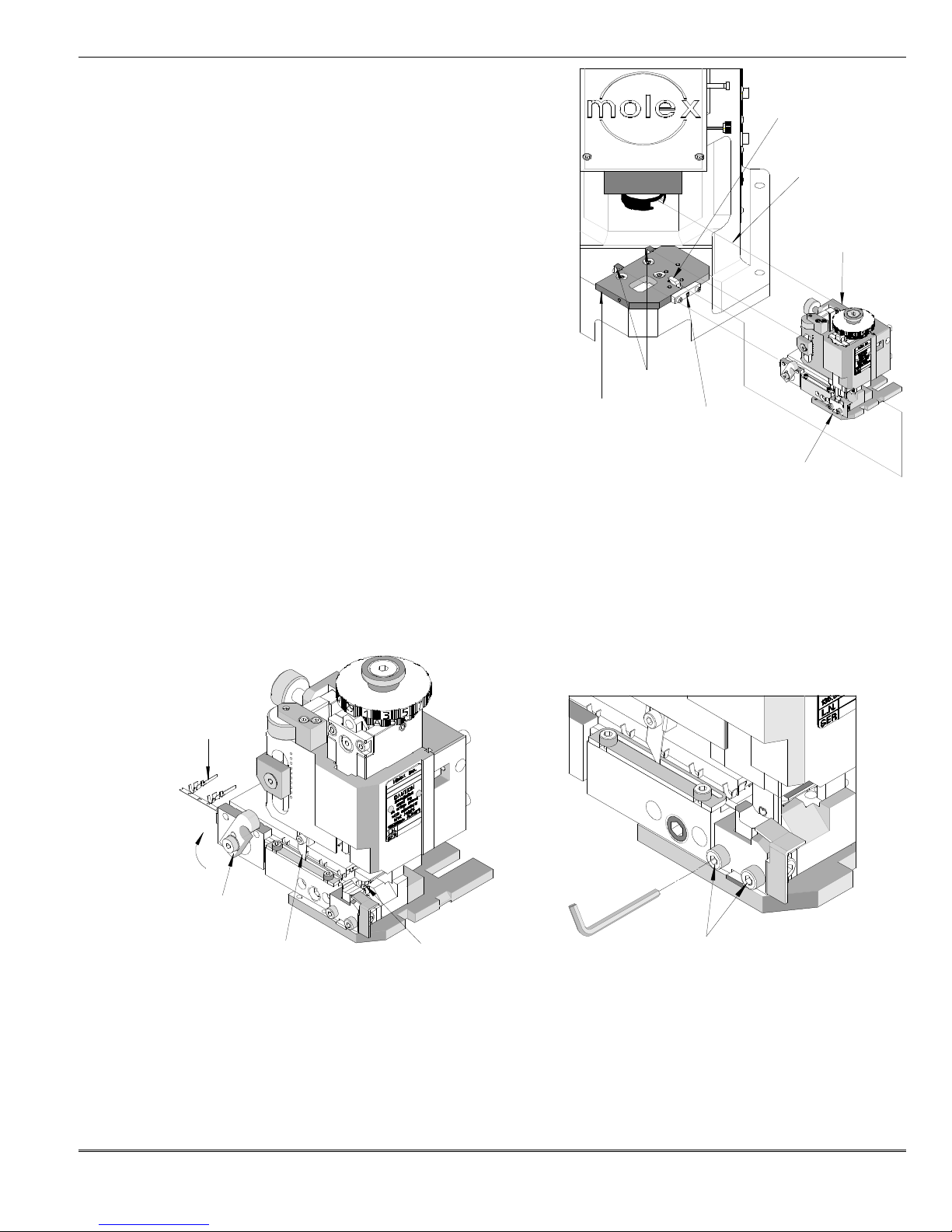

PRESS

PRESS QUICK

SHUT HEIGHT

Read the following instructions before attempting to operate the applicators.

2.1 Shut Height

The Molex FineAdjust Applicators are designed to operate in crimp

presses with standard shut height of 135.80mm (5.346").

Installation in crimp presses with other than standard shut heights

can cause severe tool breakage. It is recommended that before

installation, a check of the shut height be performed. The correct

shut height is required to prevent the punches from hitting the anvils

and the cut-off tooling from bottoming out on the base plate. It also

allows the movement of applicators from press to similar press

without adjusting the applicator or press shut height.

The shut height of the press can be checked with a shut height

gauge, which is calibrated under load to achieve the 135.80mm

(5.346") measurement. It is recommended that the shut height be

checked monthly. A shut height gauge is available from most press

manufacturers.

Measuring Press Shut Height

GAUGE

CHANGE

MOUNTING PLATE

Figure 2-1

1. Always disconnect the power supply from the press. Remove the machine guards if necessary.

2. Remove the applicator from the press. See “Applicator Installation and Removal” (below) for additional information. Make

sure that the bottom of the press ram and quick change mounting plate are free from foreign material.

3. Place the shut height gauge into the press on the press quick change mounting plate. See Figure 2-1.

4. Manually cycle the press to the down stroke position. (Follow press manufacturer’s instructions on manually cycling the

press.)

5. Read the shut height measurement from the front of the gauge. Follow gauge manufacturers’ instruction, usually the gauge

reads “0” when set correctly.

6. If adjustments are necessary, refer to the press manufacturer for adjustment of the press shut height.

7. Repeat the above steps until the correct shut height is obtained.

8. Shut height gauges must be calibrated on a regular basis.

2.2 Set-Up

IMPORTANT

Power must be shut off and electrical cord disconnected. Manual press cycling is an absolutely required procedure

for safety and preventing equipment damage. Always cycle by hand when trouble shooting or changing adjustments,

tooling, applicator, or accessories.

The principal mechanical parts of the FineAdjust are illustrated in Section 4.1 Assembly Drawings.

Applicator Installation and Removal

1 All presses must be equipped with a common universal type quick-change mounting plate and adapter on the press.

Contact the press manufacturer for specific information.

2 Always turn off and disconnect the power supply to the press. Remove the press guards.

3 Clean the quick change mounting plate of scrap or chips that may interfere with the FineAdjust applicator installation.

4 For the TM-2000 and TM-3000 Presses follow the procedure below:

a. Using a 4mm hex wrench, turn the M5 SHCS clockwise until the locking clamp is fully opened.

b. Visually align the applicator base plate slots with the location clamps on the press quick-change mounting plate.

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 11 of 50

Revision: G Revision Date: 01-15-13

Page 12

FineAdjust Applicator

ENGAGE PRESS

BASE PLATE

LOCKING CLAMP

QUICK

LOCATOR

TERMINAL

FEED FINGER

1ST

TERMINAL

c. Slide the applicator onto the quick-change mounting plate

until the two notches on the left side engage against the

stops, and at the same time, guide the lug bolt into the

adapter on the press. See Figure 2-2.

d. To lock applicator, turn the M5 SHCS counter clockwise until

tight.

YOKE

5 Some presses have locking latches on the quick change

mounting plate, which have to be flipped up to secure the

applicator. Others have knurled finger screws or "T" type latches.

APPLICATOR

Most of these are located on the right side of the quick change

mounting plate to secure the position of the applicator. These

must be in place and secured before operating the press.

6 Replace the press guards.

Remove the applicator by reversing the previous steps. When storing

an applicator, always leave a strip of terminals in the applicator to

prevent damage to the tooling. See Section 3.5 Storage.

Fitting Terminal Strip

1. The specified terminals are printed on the setup sheet for the

applicator. Only use the Molex terminals on the setup sheet

CHANGE

MOUNTING

PLATE

CLAMPS

M5 SHCS

Figure 2-2

which is supplied with the applicator.

2. Always disconnect the power supply from the press. Remove the machine guards if necessary.

3. Rotate the drag release until the drag frame is in the upright position. This will allow the terminal to slide with ease through

the applicator track. See Figure 2-3.

4. Push the terminal strip until the first terminal comes to rest centered above the anvil.

5. Rotate the drag release to engage the terminal drag frame.

6. Cycle the press by hand so that the feed finger transfers the next terminal to a centered position over the anvil. Check that

all other parts slide and engage without any interference. It is recommended to go through this procedure several times.

STRIP

Figure 2-4

DRAG RELEASE

Figure 2-3

CENTERED

ABOVE ANVILS

RELEASE M4 SHCS

7. When unloading the terminal strip, make sure the power is turned off and disconnected from the press. Remove the

machine guards if necessary.

8. Rotate the drag release until the drag frame is in the upright position.

9. Raise feed finger and pull terminal strip back until disengaged from applicator track. See Figure 2-3. If preferred, cut the

terminal carrier strip and pull it through the applicator with needle nose pliers.

10. Replace the machine guards before operating the press.

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 12 of 50

Revision: G Revision Date: 01-15-13

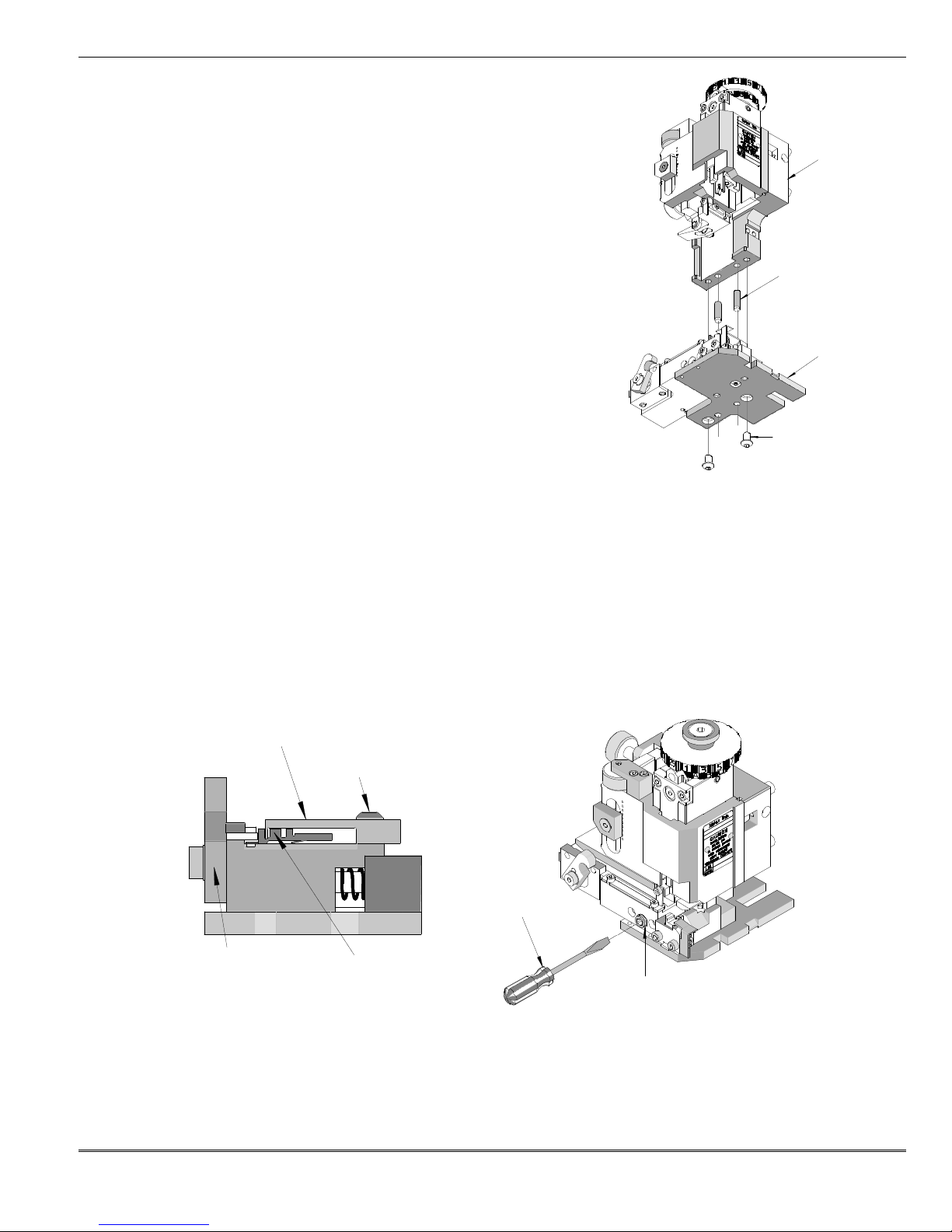

Page 13

FineAdjust Applicator

APPLICATOR

6mm X 20mm

M6 X 10mm

M10

TERMINAL

M4 X 12mm

DRAG RELEASE

Punch and Anvil Alignments

Note: Always clean mounting surfaces of crimp tooling and tooling holders before

alignment.

1. Always disconnect the power supply from the press. Remove the machine

guards if necessary.

2. With a terminal in position over the anvils, slightly release anvil mounting

screw. See Figure 2-4.

3. Gently hand-cycle the ram of the press to bottom of its stroke. Tighten anvil-

DOWEL PIN (2)

mounting screws in this position to ensure perfect alignment of punches and

anvils.

4. Hand cycle the press ram to the highest position.

BASE PLATE

5. Replace the machine guards before operating the press.

2.3. Adjustments

Cover Plate Adjustments

1. Always disconnect the power supply from the press. Remove the machine

Figure 2-5

BHCS (2)

guards if necessary.

2. Remove the applicator from the press. Refer to Applicator Installation and Removal.

3. Rotate the drag release until the drag frame is in the upright position. The rear cover plate should be adjusted so that the

terminal strip will slide smoothly through the track with no resistance.

4. Some applicators require the removal of the applicator frame from the base plate. This is done by removing the two M6

BHCS located on the bottom of the base plate. See Figure 2-5.

5. Loosen the two M4 BHCS to adjust the position of the rear cover. See Figure 2-6.

6. Slide terminal strip through the track to ensure accurate cover positioning.

7. After the correct position is achieved, tighten the two M4 BHCS.

8. Reattach the applicator frame to the base plate if needed. Locate the position of the frame using the dowel pins. Tighten

the two M6 BHCS to secure the frame to the base plate.

REAR COVER

BHCS (2)

SCREWDRIVER

UP POSITION

Figure 2-6

LOCK SCREW

Figure 2-7

Track Position Adjustment

1. Disconnect power from the press. Remove the machine guards if necessary.

2. To position the terminal track in or out, first use a 6mm hex wrench to loosen the M10 lock screw located on the front of the

track.

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 13 of 50

Revision: G Revision Date: 01-15-13

Page 14

FineAdjust Applicator

Press St

roke

mm In.

Figure

2-9

FEED FINGER

FEED FINGER

TERMINAL

Figure 2

-8

PUSH DOWN

3. Put a regular screwdriver through the hole in the lock screw and turn the adjusting screw to position the terminal in the

correct location. See Figure 2-7. Turning the screw clockwise will move the track towards the operator; to move the track

towards the applicator turn the screw counterclockwise. Depending on the amount of movement, the feed finger mount may

need to be loosened and readjusted. See Feed Finger adjustment.

7 To lock the track in position, tighten the M10 lock screw.

8 If the feed finger mount was loosened during the track positioning, remember to tighten its mounting screw.

9 Replace machine guards.

10 Hand cycle the press to ensure the terminal is positioned properly on the anvils and does not have an excessive cutoff tab.

Also, verify the terminal feed operation.

11 Restore power to the press, crimp a terminal under power, and observe the quality of the termination.

12 Repeat the above steps until the desired terminal position is obtained.

Feed Finger Adjustments

M3 SHCS

1. Position the feed finger to properly feed the next terminal in

position. Typically, terminals are fed by the carrier strip.

2. Depending on the feed cam installation (pre-feed or postfeed), move the press ram until the feed is forward (this makes

the feed finger mount more accessible), and then disconnect

power from the press. Remove the machine guards if

necessary.

3. Using a 2.5mm hex wrench, loosen the M3 SHCS located on

the feed finger mount. While holding the feed finger lever

down slightly, slide the feed finger to the desired position. See

Figure 2-8.

LEVER

FEED FINGER

MOUNT

4. If the feed finger mount cannot be moved far enough, remove

the M3 SHCS completely and install it in another tapped hole

in the feed finger lever. In addition, the feed finger mount can be reversed (the feed finger must be reversed as well) to gain

additional adjustment.

5. Tighten the M3 SHCS to lock the feed finger in position.

Feed Stroke Cam Adjustments

1. The terminal feed stroke is driven by a cam mounted to the applicator

ram. Two feed cams are shipped with the applicator. The standard cam

is installed in the applicator. The spare cam is for presses with short

strokes (for example, 28mm). Using the standard cam with a shortstroke press may result in insufficient feed stroke or incorrect feed

timing.

2. Determine what feed timing is desired. Typically, when the applicator is

mounted in a wire processing machine, the feed stroke cam should be

assembled in the down stroke position. While the press is idle in the up

position, a terminal will not be present over the anvil. For most bench

applications, the cam is installed in the up stroke position. This will leave

a terminal over the anvil when the press is idle in the up position. See

Figure 2-9.

3. Turn off and disconnect the power supply from the press. Remove the

machine guards if necessary.

4. Remove the applicator from the press. See Applicator Installation and

Removal.

5. Pull back on the feed pivot lever and remove the ram from the applicator.

6. Holding on to the ram, use a 3mm hex wrench to remove the M4 SHCS

holding the cam on the back of the ram.

7. Position the cam in the desired position for feeding and attach with the M4 screw. See Figure 2-9.

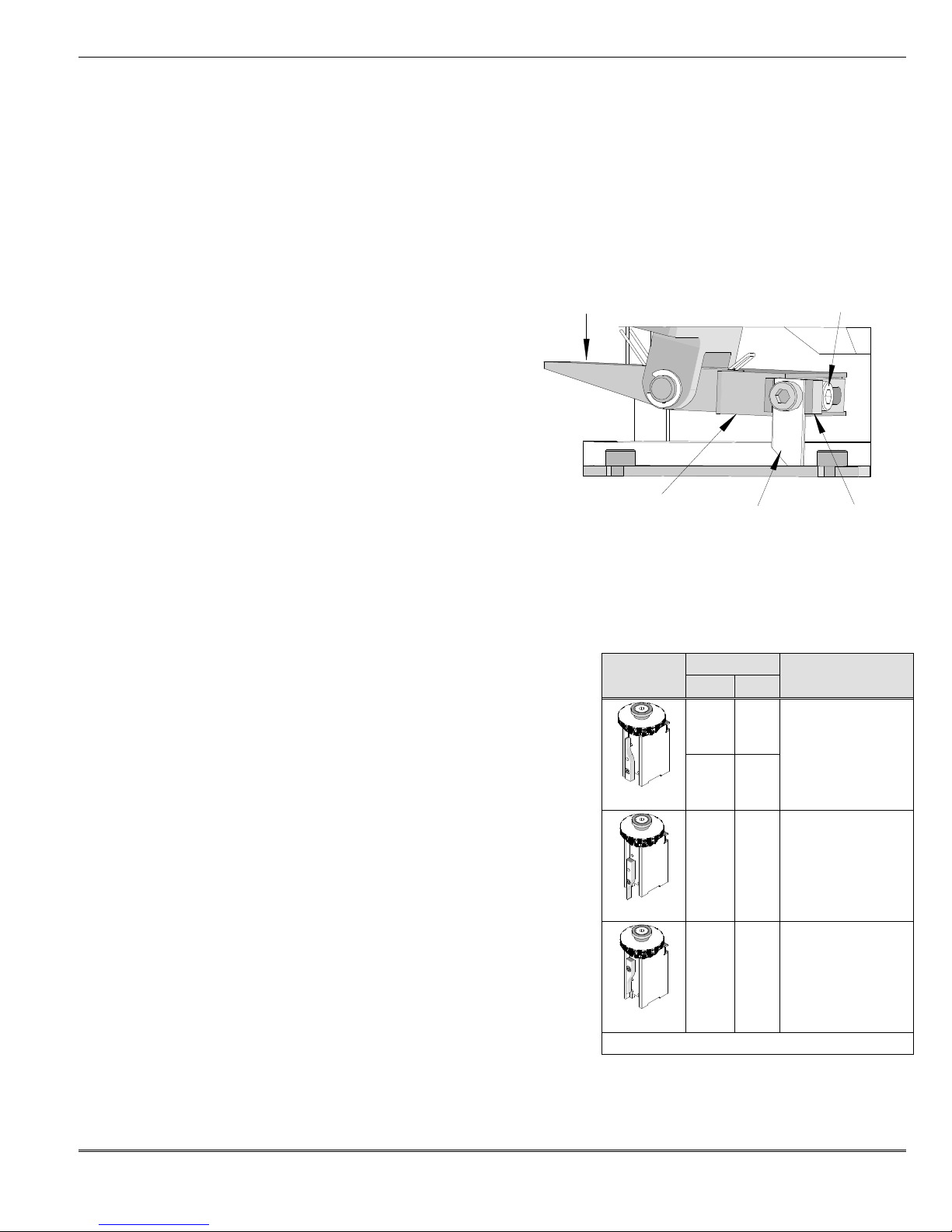

Feed Cam

Order No.

63800-0305

63800-0305

11-18-4238

41.28 1-5/8

28.58 1-1/8

41.28 1-5/8

28.58 1-1/8

Feed Timing

Up stroke

(terminal present

over anvil)

Down stroke

(terminal not present

over anvil)

Down stroke

(terminal not present

over anvil)

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 14 of 50

Revision: G Revision Date: 01-15-13

Page 15

FineAdjust Applicator

PIVOT CLAMP

FORWARD

M5 SHCS

BACK

Figure 2

-11

INSULATION

CONDUCTOR

Forward Feed Adjustments

1. The forward feed position must locate the terminal that is

FEED LOCK

being crimped exactly over the anvils.

2. Disconnect the power from the press. Remove the

machine guards if necessary.

3. Make sure there is a terminal over the anvils and the feed

finger is fully forward (closest to the anvils).

4. Loosen the M5 SHCS.

5. Turn the forward feed adjusting knob to position the

FEED

STROKE

ADJ. KNOB

STROKE

ADJ. KNOB

terminal. To decrease the feed position, turn the forward

feed adjusting knob clockwise. To increase the feed

position turn the forward feed adjusting knob

counterclockwise. See Figure 2-10.

6. When adjusting to decrease the feed position, it is

Figure 2-10

M5 FHCS

necessary to pull the terminal strip backwards until it is against the feed finger. When increasing the feed position, the feed

finger will push the terminal farther over the anvils.

7. After properly adjusting the forward feed position of the terminal, tighten the M5 SHCS with a 4mm hex wrench.

Back Stroke Feed Adjustments

CAM (TOP)

1. To properly feed the terminal strip, the back feed stroke should have

enough over-travel to pick up the next terminal. Too much over

travel may, in some cases, cause a double-feed.

2. Disconnect the power from the press. Remove the machine guards if

necessary.

3. To achieve the correct backstroke location, adjust the position of the

hinge bushing. First, use a 3mm hex wrench to loosen the M5 FHCS

holding the pivot clamp. Turning the backstroke adjustment knob

(which is located above the hinge bushing) clockwise will raise the

hinge bushing and will increase the backstroke. Turning the knob

counter clockwise (CCW) will lower the hinge bushing and will

CAM (BOTTOM)

decrease the feed backstroke. When adjustment is complete, tighten

the pivot clamp securely. See Figure 2-10.

4. Since back feed stroke adjustment may not be visibly obvious, the terminal feed should be cycled (by hand, if possible) to

observe the changes.

5. Back feed stroke adjustments may affect the entire feed linkage; re-adjustment of the forward feed stroke could be

necessary. See Forward Feed Adjustments.

Conductor Crimp Punch Adjustments

1. With the guards intact, place a stripped length of suitable wire into the terminal and terminate the wire under power.

2. Inspect the quality of conductor crimp and measure the crimp height. See Appendix A.3 Conductor Crimp Height

Measurement.

3. If adjustments are necessary, turn off and disconnect the power supply from the press. Remove the machine guards.

4. The desired crimp height can be achieved by rotating the conductor-adjusting cam. See Figure 2-11. Each increment

represents approximately 0.015mm (.0006") for a total adjustment of 1.80mm (.071"). The "A" setting is the loosest crimp

height and the "N" setting is the tightest. If you find that the crimp height is not acceptable, you can rotate the adjusting cam

until the desired crimp height is obtained. See Section 2.1, Shut Height. No shimming of the applicator is required.

5. Replace the machine guards and repeat the previous steps until the desired crimp height is obtained. See Appendix A.3,

Conductor Crimp Height Measurement.

6. Perform a pull test on conductor crimp to verify the mechanical integrity of the crimp. See Appendix A.5, Pull Force Test.

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 15 of 50

Revision: G Revision Date: 01-15-13

Page 16

FineAdjust Applicator

Figure 2

-12

WIRE STOP

M5 SHCS

RAM

PUNCH RELEASE

Insulation Crimp Punch Adjustment

1. Place a stripped length of the appropriate wire into the terminal and

crimp under power.

2. Observe quality of insulation crimp and measure the crimp height.

See Appendix A.4, Insulation Crimp.

3. If adjustments are necessary, always turn off and disconnect the

power supply from the press. Remove the machine guards.

4. Rotate the insulation-adjusting cam to achieve the desired insulation

height. Each increment represents approximately 0.06mm (.0025") for

a total adjustment of 3.00mm (.118"). The "1" setting is for the highest

(most loose) crimp height and the "29" setting the lowest (most tight)

crimp height.

5. Repeat the previous steps until the desired insulation height is

obtained.

Note: Due to the large variety of insulation wall thickness, materials, and diameter, Molex does not specify insulation crimp

height. For each different wire type, the insulation crimp height can be measured, recorded, and inspected as a quality indicator.

Wire Stop Adjustment

For automatic wire processing machines, the wire stop can be used to assist in the stripping of the terminal from the punches.

However, in certain circumstances the wire stop will need to be removed when running on an automated machine.

1. Check the setup documents to obtain the correct strip length.

2. Place the correct wire into the terminal and crimp the wire under power.

3. Observe quality of crimp and the wire position. See Appendix A.1 Conductor Brush and Terminal Position.

4. If adjustments are necessary, turn off and disconnect the power supply from the press. Remove the machine guards.

5. Use a 4mm hex wrench to loosen the M5 SHCS located on the side of the frame. See Figure 2-12.

6. Adjust the position of the wire stop by moving the wire stop, towards the operator decreases the brush length and towards

the press increases it.

7. Tighten the M5 SHCS.

8. Hand cycle the press to ensure the applicator is functioning properly. Then crimp a terminal under power and observe the

quality of the termination.

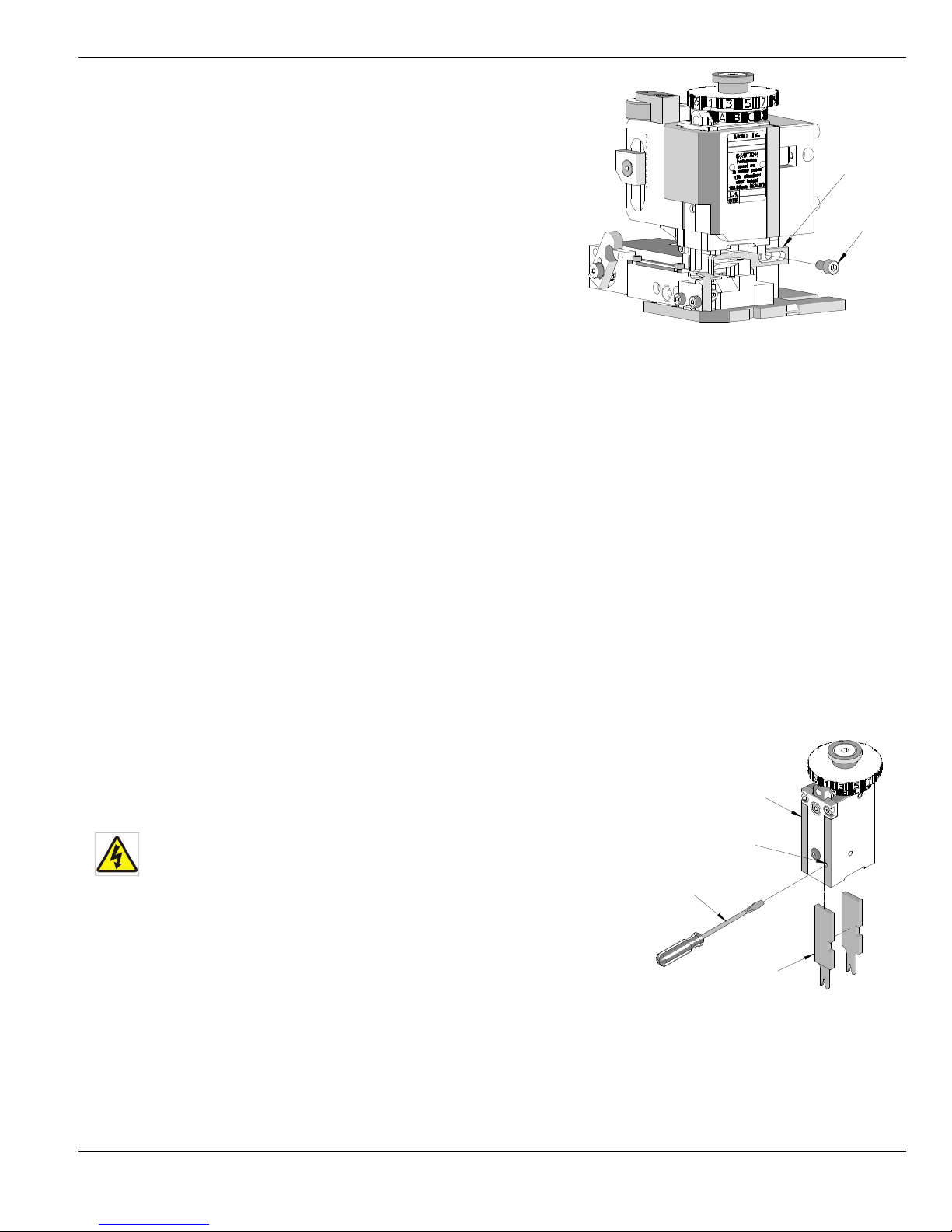

2.4 Crimp Tooling Installation and Removal

Installation and Removal of the Upper Tooling (Punches)

Caution: Always disconnect power supply before installing or

removing tooling.

SCREWDRIVER

NOTE: Always clean mounting surfaces of crimp tooling and tooling holders

before installation.

1. Always turn off and disconnect the power supply from the press. Remove

the machine guards if necessary.

2. Remove the applicator from the press. See Section 2.2, Applicator

Installation and Removal.

3. Pull back the feed arm and remove the ram from the applicator.

4. With a small screw driver, push in the punch release button located on the front of the ram. See Figure 2-13.

5. Pull the punches out the bottom of the ram.

6. Reverse the previous steps to reinstall the punches.

BUTTON

PUNCHES

Figure 2-13

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 16 of 50

Revision: G Revision Date: 01-15-13

Page 17

FineAdjust Applicator

REMOVE M4 SHCS

Installation and Removal of the Lower Tooling (Anvils)

Caution: Always disconnect power supply before installing or

removing tooling.

NOTE: Always clean mounting surfaces of crimp tooling and tooling holders

before installation.

1. Always turn off and disconnect the power supply from the press.

Remove the machine guards if necessary.

2. Make sure the ram is all the way in the up position.

3. Remove the M4 SHCS that are holding the lower tooling in place and pull

out the tooling. See Figure 2-14.

4. Put in the new anvils, leaving the mounting screws loose. For tightening,

see Section 2.2, Punch and Anvil Alignment.

Figure 2-14

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 17 of 50

Revision: G Revision Date: 01-15-13

Page 18

FineAdjust Applicator

Maintenance

3.1 Cleaning

3.2 Lubrication

3.3 Spare parts

3.4 Perishable Parts

3.5 Storage

Section 3

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 18 of 50

Revision: G Revision Date: 01-15-13

Page 19

FineAdjust Applicator

OIL FEED FINGER

GREASE RAM

OIL

3.1 Cleaning

Caution: Always disconnect power supply before installing or removing tooling.

For efficient operation, the FineAdjust Applicator should be cleaned daily. Use a soft bristle brush to remove debris from

critical areas such as the crimp tooling. For best results, remove the crimp tooling from the press. Brush and then use a

clean cloth to wipe off the upper and lower tooling mounting areas. Before reinstalling tooling, wipe all sides of the

punches and anvils with a clean cloth.

3.2 Lubrication

WARNING: Disconnect electrical power before all maintenance.

1. Grease the ram including the cam.

2. Oil the feed finger assembly and all moving parts.

3. Lubricate with multipurpose synthetic lubricant with Teflon or an equivalent. Molex ships its applicators pregreased with Permatex multi-purpose synthetic grease with Teflon No. 82329. A SAE 30WT non-detergent oil or

light spindle oil or 3-n-1 oil should be used on pivot points.

WARNING: Never use penetrants such as WD40 for any lubrication on the machine.

4. Lubricate all points shown in Figures 3-1 with the specified oil and grease (or equivalent).

ASSEMBLY

An example of a maintenance chart is shown below. Copy and use this chart to track the maintenance of your

FineAdjust Applicator or use this as a template to create you own schedule or use your company’s standard chart, if

applicable.

AND FEED CAM

Figure 3-1

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 19 of 50

Revision: G Revision Date: 01-15-13

Page 20

FineAdjust Applicator

Days of the Week

MON

TUE WED

THU

FRI SAT SUN

1

2

3

4

Cleaning

Inspect all tooling,

Items

Cycles Brass Alloys

Cycles Steel

Actual

Punches

300,000/500,000

200,000/400,000

Anvils

500,000/750,000

400,000/750,000

Cut-off Plungers

300,000/500,000

200,000/400,000

Feed Fingers

300,000/900,000

300,000/900,000

Cut-off Punches

500,000/750,000

200,000/400,000

Cut-off Blades

300,000/500,000

200,000/300,000

Preventive Maintenance Chart

Daily: Clean. See Section 3.1.

As Required: Lubricate. See Section 3.2.

CHECK SHEET MONTH YEAR _________

Week

Daily

Cycles

Daily

Clean

Solution

Reapply grease

25,000 Yes

Reapply oil

feed fingers etc.

25,000 Yes

for wear

Schedule should be adjusted up or down depending on usage. Molex recommends that a log of preventive

maintenance be kept with the press.

Soft Brush Industrial

Degreaser

Replace if signs

of wear.

3.3 Spare Parts

Customers are responsible for maintaining the FineAdjust Applicator. Spare parts are available. Moving and

functioning parts can be damaged or wear out over time and will require replacement. Molex recommends that the

customer keep some or all of them in stock to reduce production down time.

3.4 Perishable Parts

Customers are responsible for maintaining the FineAdjust Applicator. Perishable parts are those parts that come in

contact with the product and will wear out over time. Molex recommends that all customers keep at least one set of the

perishable tool kits in stock at all times. This will reduce the amount of production down time. For the proper

perishable tool kit information, refer to the Crimp Tooling Specification Sheet supplied with the Applicator.

Tooling Replacement Schedule

The following is offered as a general guideline for tooling replacement. The manufacturer should monitor the process

and collect data on actual frequency as tool wear varies on different terminal materials and tool life can be increased

with good maintenance practices or decrease with lack of maintenance.

Judgment on tool replacement should be based on the attributes of the crimp they produce.

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 20 of 50

Revision: G Revision Date: 01-15-13

Page 21

FineAdjust Applicator

Punches

On Terminal

Notes

Scoring

Uneven Curls

Replace

Tip Loss

Open seam

Replace

Anvils

Rounded Edges

Large Extrusion

Replace

Chipping

Burrs

-

On Tabs

Replace

Worn Cut Edges

Burrs

Replace

Cut-Off Plungers and Punches

Chipped or Rounded

Burr on Tab

Replace

Cut Edge

Burr on Tab

Replace

Cut-off Dies

Burrs on Cut Area

Replace

See the following chart for common signs of wear.

3.5 Storage

To prevent the bottoming of the ram, which can cause damage to the crimp punches and anvils leave a strip of

terminals in the applicator or place a piece of wood or rubber between the punches and the anvils.

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 21 of 50

Revision: G Revision Date: 01-15-13

Page 22

FineAdjust Applicator

Parts Lists, Assembly Drawings and Troubleshooting

4.1 Style A FineAdjust Applicator

4.2 Style B FineAdjust Applicator

4.3 Style C FineAdjust Applicator

4.4 Troubleshooting

Section 4

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 22 of 50

Revision: G Revision Date: 01-15-13

Page 23

FineAdjust Applicator

STYLE A

STYLE C

NUT

FLAT HEAD

STYLE B

KNOB

FLAT HEAD

FLAT SURFACE

KNOB

Styles of FineAdjust

CAP SCREW

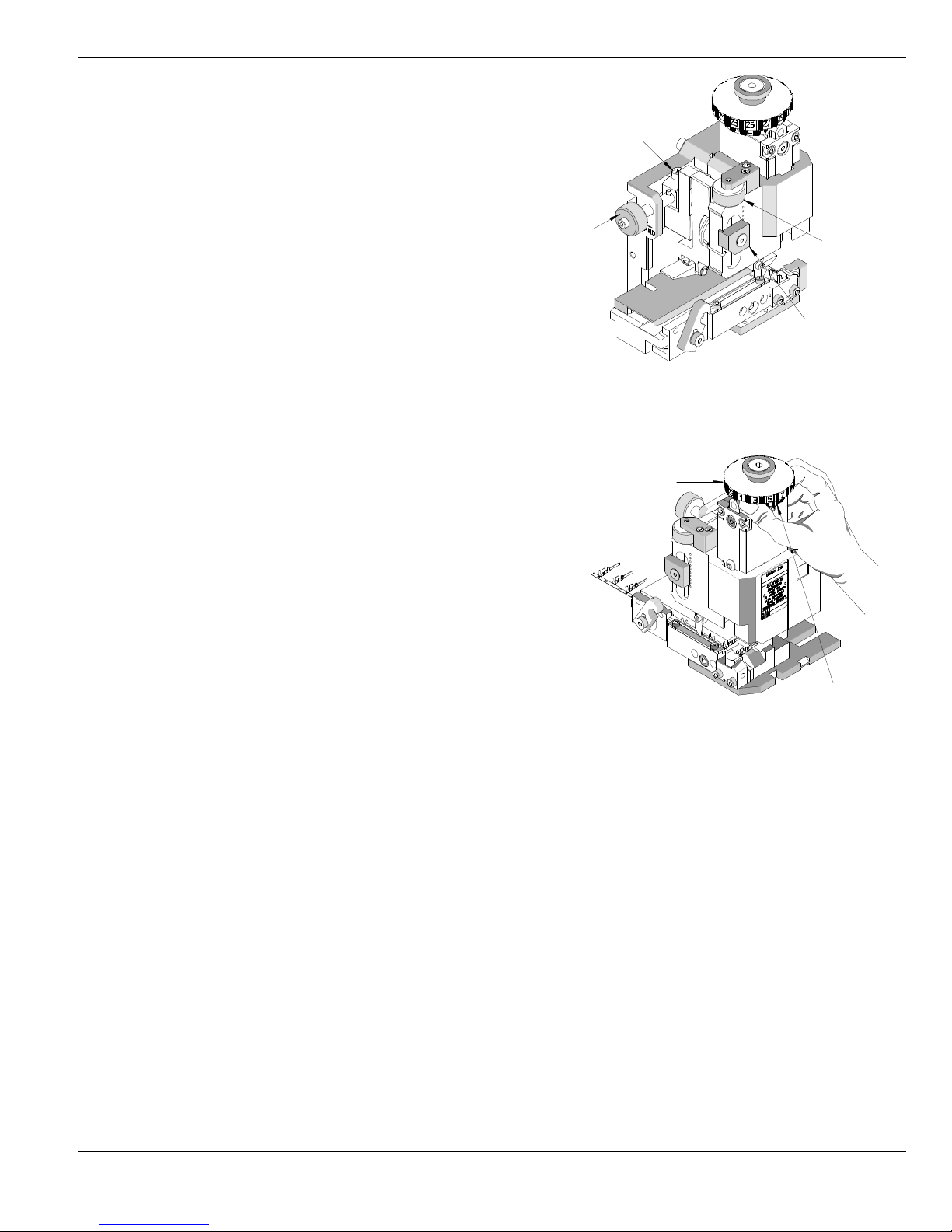

In the effort to continually improve the FineAdjust Applicator, we have multiple styles working in the field.

To determine the style of applicator you are using, look at the pictures above. Figure 4-1, 4-2, and 4-3

point out the major differences between the styles of this applicator. Identify your applicator style and

use the appropriate parts list and assembly drawing to order replacement parts.

Figure 4-2

FLAT SURFACE

KNOB

Figure 4-1

HEX HOLE

CAP SCREW

LEVER

FULL TRACK

Figure 4-3

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 23 of 50

Revision: G Revision Date: 01-15-13

Page 24

FineAdjust Applicator

STYLE A

-

FineAdjust Applicator

Item Order No.

Engineering No.

Description

Qty

1 11-18-

4238 60700

-1

Feed Cam (Short) Optional

1

2 11-32-

5346 600000Y422

M4 Ball Spring Plunger

4

3 11-41-

0127 60678

-27

Compression Spring (

Associated

# C0180

-

016-0500)

1

4

63600

-

0481 63600

-

0481 Shoulder Screw M5

by 10

mm Long 1

5

63800

-

0115 63800

-

0115 Spacer Tube

1

6

63800

-

0117 63800

-

0117 Feed Pawl Lever

1

7

63800

-

0118 63800

-

0118 Hinge Bushing

1

8

63800

-

0119 63800

-

0119 Feed Finger

1

9

63800

-

0120 63800

-

0120 Feed Arm

1

10

63800

-

0121 63800

-

0121 Lever Feed Pivot

1

11

63800-

0122 63800

-

0122 Feed Adjusting Screw

1

12

63800

-

0123 63800

-

0123 Slider

-

Feed Cam

1

14

63800

-

0125 63800

-

0125 Torsion Spring

-

Hinge

1

15

63800

-

0127 63800

-

0127 Torsion Spring

-

Feed Pawl

1

16

63800

-

0129 63800

-

0129 Washe

r –3.40mm

Thick 1

17

63800

-

0140 63800

-

0140 Cylinder Pin

1

18

63800

-

0141 63800

-

0141 Slider

1

19

63800

-

0142 63800

-

0142 Roller

-

Cam Follower

1

20

63800

-

0143 63800

-

0143 Pin-Cam Follower

1

21

63800

-

0144 63800

-

0144 Key Stock 3

mm by 3mm

by 29mm Long

2

22

63800

-

0301 63800-

0301 Back Frame

1

23

63800

-

0302 63800

-

0302 Face Plate

1

24

63800

-

0303 63800

-

0303 Base Plate

1

25

63800

-

0304 63800

-

0304 Ram-Terminator Tooling

1

26

63800

-

0305 63800

-

0305 Feed Cam

1

27

63800

-

4906 63800

-

4906 Insulation Striker

1

28

63800

-

0308 63800

-

0308 Terminal

Track

1

29

63800

-

4309 63800

-

4309 Rear Support Block

1

30

63800

-

0310 63800

-

0310 Adjusting Screw

1

31

63800

-

0311 63800

-

0311 Locking Screw

1

32

63800

-

0312 63800

-

0312 Drag Frame

1

33

63800

-

0313 63800

-

0313 Drag Cam

1

34

63800

-

0314 63800

-

0314 Retaining Bar

1

35

63800

-0316 63800

-

0316 Guide Pin

-

Drag Frame

2

36

63800

-

0330 63800

-

0330 Lug Bolt

1

37

63800

-

0331 63800

-

0331 Conductor Adjusting Cam

1

38

63800

-

0332 63800

-

0332 Insulation Adjusting Cam

1

39

63800

-

0335 63800

-

0335 Serial Tag

1

40

63800

-

0345 63800

-

0345 Retaining Plate

1

41 63800-4946 63800

-4946

Conductor Striker

1

42

63800

-

0347 63800

-

0347 Retaining Rod

1

43

63800

-

0348 63800

-

0348 Detent Spacer

1

44

N/A N/A Compression Spring (Lee Spring # LC

-

032E-0MW)

4**

45

N/A N/A Extension Spring (Lee Spring #LE

-

041C-9) 1**

46

N/A N/A Snap Ring

3.2mm

ID by 7

mm OD by .62

mm Thick 2**

47

N/A N/A Washer .512" ID by 1.125" OD by 0.15” Thick

1**

48

N/A N/A Washer .512" ID by 1.125" OD by 0.18” Thick

1**

4.1 STYLE A-FineAdjust Applicator

Parts List and Assembly Drawings (See Figure 4-4 and 4-5)

13 63800-0124 63800-0124 Pin-Feed Adjusting 1

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 24 of 50

Revision: G Revision Date: 01-15-13

Page 25

FineAdjust Applicator

STYLE A

-

FineAdjust Applicator

Item Order No.

Engineering No.

Description

Qty

49

N/A N/A M3 by 6

mm Long FHCS

2**

50

N/A N/A M4 Hex Nut

1**

51

N/A N/A M4 by 8

mm Long BHCS

1**

52

N/A N/A M4 by 8

mm Long SHCS

3**

53

N/A N/A M4 by 10

mm Long Set Screw

1**

54

N/A N/A M4 by 12

mm Long BHCS

2**

55

N/A N/A M4 by 45

mm Long SHCS

1**

56

N/A N/A M5 by 6

mm Long BHCS

1**

57

N/A N/A M5 by 10

mm Long SHCS

1**

58

N/A N/A M5 by 35

mm Long SHCS

4**

59

N/A N/A M6 by 1

0mm

Long BHCS

2**

60

N/A N/A M6 by 8

mm Long Set Screw

1**

61

N/A N/A M12 Self Locking Hex Nut

1**

62

N/A N/A 3mm by 12

mm Long Roll Pin

2**

63

N/A N/A 5mm by 20

mm Long Dowel Pin

1**

64

N/A N/A 5mm by 25

mm Long Dowel Pin

1**

65

N/A N/A 6mm by 10

mm Long Dowel Pin

1**

66

N/A N/A 6mm by 12

mm Long Dowel Pin

2**

67

N/A N/A 6mm by 20

mm Long Dowel Pin

1**

68

N/A N/A 6mm by 45

mm Long Dowel Pin

2**

69

N/A N/A #2 (.098 Dia.) by .125 in. Long Drive Screw

2**

** Available from an industrial supply company such as MSC (1

-

800-645-7270).

Check Applicator Number Tag or Part Number on part when ordering.

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 25 of 50

Revision: G Revision Date: 01-15-13

Page 26

FineAdjust Applicator

7

6

18

12

5

10

11

31

19

9

21

(2)

See Figure 4

-5

58

64

45

63

66

68

49

(2)

34

30

29

65

59

67

51

44

61

(2)

28

39

55

33

4.1 STYLE A FineAdjust Applicator Assembly

50

23

(2)

32

44

(2)

62

14

17

15

13

57

20

(2)

69

(2)

22

(2)

8

(2)

56

(4)

54

24

(2)

54

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 26 of 50

Revision: G Revision Date: 01-15-13

35

STYLE A

Figure 4-4

Page 27

FineAdjust Applicator

(4)

25

16

23

26

1

27

2

Reference

STYLE A

43

37

48

47

41

40

52

42

53

52

4.1 STYLE A FineAdjust Applicator Assembly (Cont.)

(2)

4

3

36

38

60

See Figure 4-4

Figure 4-5

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 27 of 50

Revision: G Revision Date: 01-15-13

Page 28

FineAdjust Applicator

STYLE B

-

FineAdjust Applicator

Item Order No.

Engineering No.

Description

Qty

1 11-18-

4238 60700

-1

Feed Cam (Short) Optional

1

2 11-32-

5346 600000Y422

M4 Ball Spring Plunger

4

3 11-41-

0127 60678

-27

Compression Spring (Assoc

iated # C0180

-

016-0500)

1

4

63600

-

0481 63600

-

0481 Shoulder Screw M5 by 10

mm Long 1

5

63800

-

0115 63800

-

0115 Spacer Tube

1

6

63800

-

0120 63800

-

0120 Feed Arm

1

7

63800

-

0121 63800

-

0121 Lev

er Feed Pivot

1

8

63800

-

0123 63800

-

0123 Slider

-

Feed Cam

1

10

63800

-

0127 63800

-

0127 Torsion Spring

-

Feed Pawl

1

11

63800

-

0140 63800

-

0140 Cylinder Pin

1

12

63800

-

0142 63800

-

0142 Roller

-

Cam Follower

1

13

63800

-

0143 63800-

0143 Pin-Cam Follower

1

14

63800

-

0144 63800

-

0144 Key Stock 3 by 3 by 19mm Long

2

15

63800

-

0304 63800

-

0304 Ram-Terminator Tooling

1

16

63800

-

0308 63800

-

0308 Terminal Track

1

17

63800

-

0310 63800

-

0310 Adjusting Screw

1

18

63800

-

0311 63800

-

0311 Locking Screw

1

19

63800

-

0312 63800

-

0312 Drag Frame

1

20

63800

-

0313 63800

-

0313 Drag Cam

1

21

63800

-

0314 63800

-

0314 Retaining Bar

1

22

63800

-

0316 63800

-

0316 Guide Pin

-

Drag Frame

2

23

63800

-

0330 63800

-

0330 Lug

Bolt 1

24

63800

-

0331 63800

-

0331 Conductor Adjusting Cam

1

25

63800

-

0332 6

3800-0332 Insulation Adjusting Cam

1

26

63800

-

0345 63800

-

0345 Retaining Plate

1

27

63800

-

0347 63800

-

0347 Retaining Rod

1

28

63800

-

0348 63800

-

0348 Detent Spacer

1

29

63800

-

4309 63800

-

4309 Rear Support Block

1

30

63800

-

4902 63800

-

4902 Face Plate

1

31

63800

-

4906 63

800-4906 Insulation Striker

1

32

63800

-

4946 63800

-

4946 Conductor Striker

1

33

63801

-

0129 63801

-

0129 Washer 3.40mm Thick

1

34

63801

-

3202 63801

-

3202 Feed Cam

1

35

63801

-

3211 63801

-

3211 Back Frame

1

36

63801

-

3225 63801

-

3225 Torsion Spring

1

37

63801

-

3281 63801

-

3281

Base Plate

1

38

63801

-

4462 63801

-

4462 Feed Finger Mount

1

39

63801

-

4561 63801

-

4561 Feed Finger

1

40

63890

-

0817 63890

-

0817 Feed Pawl Lever

1

41

63890

-

0881 63890

-

0881 Adjusting Screw

1

42

63890

-

0883 63890

-

0883 Adjusting Knob Retainer

1

43

63890

-

0884 63890

-

0884 A

djustable Pivot

1

44

63890

-

0885 63890

-

0885 Slider

1

45

63890

-

0886 63890

-

0886 Feed Positioning Screw

1

46

63890

-

0887 63890

-

0887 Pivot Clamp

1

47

63890

-

0899 63890

-

0899 Feed Adjusting Knob

2

48

63890

-

0999 63890

-

0999 Serial Tag

1

4.2 STYLE B-FineAdjust Applicator

Parts List and Assembly Drawings (See Figure 4-6 and 4-7)

9 63800-0124 63800-0124 Pin-Feed Adjusting 1

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 28 of 50

Revision: G Revision Date: 01-15-13

Page 29

FineAdjust Applicator

STYLE B

-

FineAdjust Applicator

Item Order No.

Engineering No.

Description

Qty

49

69028

-

0660 69028

-

0660 Compression

Spring (Lee Spring # LC

-

032E-0MW)

4**

50

N/A N/A #2 (.098

in. Diameter

) by .125 in. Long Drive Screw

2**

51

N/A N/A M3 by 5

mm Long SHCS

1**

52

N/A N/A M3 by 6

mm Long FHCS

2**

53

N/A N/A M3 by 12

mm Long SHCS

1**

54

N/A N/A M3 by 20

mm Long SHCS

2**

55

N/A N/A M4 by 8mm

Long SHCS

3**

56

N/A N/A M4 by 8

mm Long Set Screw

1**

57

N/A N/A M4 by 10

mm Long Set Screw

1**

58

N/A N/A M4 by 12

mm Long BHCS

3**

59

N/A N/A M4 by 16

mm Long SHCS

1**

60

N/A N/A M5 by 6

mm Long BHCS

1**

61

N/A N/A M5 by 8

mm Long FHCS

1**

62

N/A N/A M5 by 1

0mm

Long SHCS

1**

63

N/A N/A M5 by 35

mm Long SHCS

4**

64

N/A N/A M6 by 8

mm Long Set Screw

1**

65

N/A N/A 3mm by 12

mm Long Roll Pin

2**

66

N/A N/A 5mm by 20

mm Long Dowel Pin

1**

67

N/A N/A 5mm by 25

mm Long Dowel Pin

1**

68

N/A N/A 6mm by 10

mm Long Dowel Pin

2**

69

N/A N/A 6mm by 20

mm Long Dowel Pin

2**

70

N/A N/A 6mm by 45

mm Long Dowel Pin

2**

71

N/A N/A Extension Spring (Lee Spring #LE

-

041C-9) 1**

72

N/A N/A Snap Ring 3.2

mm

ID by 7

mm OD by .62

mm Thick

2**

73

N/A N/A Washer .512

” ID by 1.125

” OD by 0.15” Thick

1**

74 N/A N/A Washer .512

” ID by 1.125

” OD by 0.18” Thick

1**

** Available from an industrial supply company such as MSC (1

-

800-645-7270).

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 29 of 50

Revision: G Revision Date: 01-15-13

Page 30

FineAdjust Applicator

19

61

69

8

42

STYLE B

16

29

12

47

30

68

10

(2)

49

13

39

See

70

49

65

41

59

65

51

(2)

17

58

22

43

11

45

(2)

40

44

38

48

56

20

(2)

63

67

18

14

35

(2)

4.2 STYLE B FineAdjust Applicator Assembly

47

46

Figure 4-7

50

54

(2)

36

66

6

(2)

5

(2)

(2)

72

71

(2)

62

9

7

(2)

53

(2)

Figure 4-6

60

(4)

58

52

21

(2)

37

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 30 of 50

Revision: G Revision Date: 01-15-13

Page 31

FineAdjust Applicator

(4)

15

33

30

1

2

Reference

4

STYLE B

23

24

26

55

27

57

4.2 STYLE B FineAdjust Applicator Assembly (Cont.)

32

31

(2)

73

3

Figure 4-7

25

28

74

See Figure 4-6

34

55

64

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 31 of 50

Revision: G Revision Date: 01-15-13

Page 32

FineAdjust Applicator

STYLE C

-

FineAdjust Applicator

-

Item Order No.

Engineering No.

Description

Qty

1 11-18-4238 60700

-1

Feed Cam (Short) Optional

1

2 11-32-

5346 600000Y422

M4 Ball Spring Plunger

5

3 11-41-

0127 60678

-27

Compression Spring (Assoc

iated # C0180

-

016-0500)

1

4

63443

-

6202 63443

-

6202 Terminal Track

1

5

63600

-

0481 63600

-

0481 Shoulder Screw M

5 by 10

mm Long 1

6

63600

-

1561 63600

-

1561 Washer 6 I.D. by 10 O.D. by 0.3mm Thick

1

7

63600

-

2644 63600

-

2644 Stripper Bolt 6 O.D. by 10mm Long

1

8

63800

-

0120 63800

-

0120 Feed Arm

1

9

63800

-

0121 63800

-

0121 Lever Feed Pivot

1

10

63800

-

0123 63800

-

0123 Slider

-

Feed Cam

1

12

63800

-

0127 63800

-

0127 Torsion Spring

-

Feed Pawl

1

13

63800

-

0140 63800

-

0140 Cylinder Pin

1

14

63800

-

0142 63800

-

0142 Roller

-

Cam Follower

1

15

63800

-

0143 63800

-

0143 Pin-Cam Follower

1

16

63800

-

0144 63800

-

0144 Key Stock 3 by

3 by 19mm Long

2

17

63800

-

0304 63800

-

0304 Ram-Terminator Tooling

1

18

63800

-

0310 63800

-

0310 Adjusting Screw

1

19

63800

-

0311 63800

-

0311 Locking Screw

1

20

63800

-

0312 63800

-

0312 Drag Frame

1

21

63800

-

0314 63800

-

0314 Retaining Bar

1

22

63800

-

0316 63800

-

0316 Guide

Pin-Drag Frame

2

23

63800

-

0345 63800

-

0345 Retaining Plate

1

24

63800

-

0347 63800

-

0347 Retaining Rod

1

25

63800

-

4309 63800

-

4309 Rear Support Block

1

26

63800

-

4903 63800

-

4903 Face Plate

1

27

63800

-

4906 63800

-

4906 Insulation Striker

1

28

63800

-

4946 63800

-

4946 Condu

ctor Striker

1

29

63801

-

3202 63801

-

3202 Feed Cam

1

30

63801

-

3211 63801

-

3211 Back Frame

1

31

63801

-

3225 63801

-

3225 Torsion Spring

1

32

63801

-

3281 63801

-

3281 Base Plate

1

33

63801

-

4462 63801

-

4462 Feed Finger Mount

1

34

63801

-

4561 63801

-

4561 Feed Finger

1

35

63801

-5862 63801

-

5862 Drag Cam Lever

1

36

63801

-

6444 63801

-

6444 Conductor Adjusting Cam

1

37

63801

-

6445 63801

-

6445 Insulation Adjusting Cam

1

38

63801

-

6446 63801

-

6446 Detent Spacer

1

39

63801

-

6447 63801

-

6447 Ram Adapter

1

40

63890

-

0817 63890

-

0817 Feed Pawl Lever

1

41 63890-0885 63890

-

0885 Slider

1

42

63890

-

0881 63890

-

0881 Adjusting Screw

1

43

63890

-

0883 63890

-

0883 Adjusting Knob Retainer

1

44

63890

-

0884 63890

-

0884 Adjustable Pivot

1

45

63890

-

0886 63890

-

0886 Feed Positioning Screw

1

46

63890

-

0887 63890

-

0887 Pivot Clamp

1

47 63890-0899 63890

-

0899 Feed Adjusting Knob

2

48

63890

-

0999 63890

-

0999 Serial Tag

1

4.3 STYLE C-FineAdjust Applicator

Parts List and Assembly Drawings (See Figure 4-8 and 4-9)

11 63800-0124 63800-0124 Pin-Feed Adjusting 1

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 32 of 50

Revision: G Revision Date: 01-15-13

Page 33

FineAdjust Applicator

STYLE C

-

FineAdjust Applicator

-

Item Order No.

Engineering No.

Description

Qty

49

69028

-

0660 69028

-

0660 Compression Spring (Lee Spring # LC

-

032E-0MW)

4**

50

N/A N/A #2 (.098

in. Diameter) by .125 in. Long Drive Screw

2**

51

N/A N/A M3 by 5

mm Long SHCS

1**

52

N/A N/A M3 by 6

mm Long FHCS

2**

53

N/A N/A M3 by 12

mm Long SHCS

1**

54

N/A N/A M3 by 20

mm Long SHCS

2**

55

N/A N/A M4 by 8

mm Long SHCS

3**

56

N/A N/A M4 by 8

mm Long Set Screw

1**

57

N/A N/A M4 by 10

mm Long Set Screw

1**

58

N/A N/A M4 by 12

mm Long BHCS

1**

59

N/A N/A M4 by 16

mm Long SHCS

1**

60

N/A N/A M5 by 6

mm Long BHCS

1**

61

N/A N/A M5 by 8

mm Long FHCS

1**

62

N/A N/A M5 by 10

mm Long SHCS

1**

63

N/A N/A M5 by 35

mm Long SHCS

4**

64

N/A N/A M6 by 8

mm Long Set Screw

1**

65

N/A N/A M6 by 10

mm Long BHCS

2**

66

N/A N/A M8 by

20mm Long FHCS

1**

67

N/A N/A 3mm by 12

mm Long Roll Pin

2**

68

N/A N/A 5mm by 20

mm Long Dowel Pin

1**

69

N/A N/A 5mm by 25

mm Long Dowel Pin

1**

70

N/A N/A 6mm by 10

mm Long Dowel Pin

2**

71

N/A N/A 6mm by 20

mm Long Dowel Pin

2**

72

N/A N/A 6mm by 45

mm Long Dowel

Pin 2**

73

N/A N/A Extension Spring (Lee Spring #LE

-

041C-9) 1**

74

N/A N/A Snap Ring 3.2

mm ID by 7

mm OD by .62

mm Thick 2**

** Available from an industrial supply company such as MSC (1

-

800-645-7270).

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 33 of 50

Revision: G Revision Date: 01-15-13

Page 34

FineAdjust Applicator

STYLE C

19

60

72

52

9

See

(2)

(4)

14

15

65

32

71

21

51

25

8

4

46

48

44

56

41

31

22

43

47

35

53

42

47

59

62

58

63

16

4.3 STYLE C FineAdjust Applicator Assembly

61

Figure 4-9

26

50

(2)

54

(2)

13

20

7

(2)

67

68

12

49

(2)

6

45

(2)

74

40

34

11

33

Figure 4-8

73

69

(2)

49

30

10

(2)

(2)

(2)

70

(2)

18

(2)

(2)

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 34 of 50

Revision: G Revision Date: 01-15-13

Page 35

FineAdjust Applicator

17

26

29

1

27

2

Reference

5

(2)

STYLE C

39

38

2

55

24

64

4.3 STYLE C FineAdjust Applicator Assembly (Cont.)

23

(3)

36

28

3

Figure 4-9

66

37

(2)

55

57

See Figure 4-8

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 35 of 50

Revision: G Revision Date: 01-15-13

Page 36

FineAdjust Applicator

T

erminals bent or damaged

Replace terminals

Feed finger worn or not properly adjusted

Check proper finger setting

Drag plate

not

holding terminal strip back

Check compression springs

Terminal jammed under cover plate

Clear and reinsert terminals

Conductor

punch worn

Replace

Adjust base and track for proper

Cut-off plunger adjusted to

o tight against anvil

Readjust

Cut-off plunger spring damag

ed or broken

Replace spring

Cut edges worn, plunger sides or

Remove scoring marks. If problem not

Wrong tooling

Replace with proper tooling

Tooling worn or

damaged

Replace tooling

Wrong cam setting

Back off one setting

Press shut height

too high

Calibrate press

shut height

Wrong tooling

Replace with proper tooling

Cam out of adjustment

Readjust conductor cam

Press shut h

eight

is too low

Calibrate press

shut height

Cam out of adjustment

Readjust insulation cam

Wrong tooling

Replace with proper tooling

Press shut height

is too low

Calibrate press

shut height

Wrong tooling

Replace with proper tooling

Tooling worn or damaged

Replace tooling

Install a terminal oiler.

4.4 Troubleshooting

Symptom Cause Solution

Terminals

not feeding

Excessive Bellmouth

Cut-off plunger does

not return to

original position

Conductor crimp is

too loose

Conductor crimp is

too tight

Insulation crimp is

too tight

Terminal sticks

during crimping

Track out of position

plunger retainer scored

Gold plating and/or some high tensile materials

alignment with the punches and anvil

solved, replace with new cut-off parts

See Appendix C

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 36 of 50

Revision: G Revision Date: 01-15-13

Page 37

FineAdjust Applicator

For more information use the Quality Crimping Handbook

There is no charge for this book, which can be found on the Molex Website (www.molex.com) or contact your

local Molex sales engineer

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 37 of 50

Revision: G Revision Date: 01-15-13

Page 38

FineAdjust Applicator

Appendix A

Crimp Terminations

A.1 Conductor Brush and Terminal Position

A.2 Conductor Bell mouth and Terminal Cut-off Tab

A.3 Conductor Crimp Height Measurement

A.4 Insulation Crimp

A.5 Pull Force Testing

Doc. No: TM-638004900 Release Date: 09-04-03 UNCONTROLLED COPY Page 38 of 50

Revision: G Revision Date: 01-15-13

Page 39

FineAdjust Applicator

INSULATION

BRUSH

STRIP

BELL

CRIMP H

EIGHT

BEND

BEND UP

ROLLING

CONDUCTOR

TWISTING

CUT-OFF

SEAM

Figure A

-6

A-5 Insulation

e

dge centered in the

t

ransition

a

rea,

A-6

Insulation

e

dge

under insulation

grip,