Page 1

BradCommunications

from Molex Inc.

IP67 Industrial Ethernet Switches

™

Hardware Reference Guide

Document Edition: 1.1

Document #: 715-5000

Document Edition: 1.1

Page 2

Hardware Reference Guide IP67 Industrial Ethernet Switches

Date: February 8th, 2016

This document applies to the following Ethernet switch products: DRL-750, DRL-780,

DRL-781 and DRL-782.

Copyright ©2016 Woodhead Software & Electronics, a division of Molex

This document and its contents are the proprietary and confidential property of Molex and/or

its subsidiaries and may not be used or disclosed to others without the express prior written

consent of Molex and/or its subsidiaries.

All other trade names are trademarks or registered trademarks of their respective companies.

At Molex, we strive to ensure accuracy in our documentation. However, due to rapidly

evolving products, software or hardware changes occasionally may not be reflected in our

documents. If you notice any inaccuracies, please contact us (see Appendix C of this

document).

Written and designed at Molex, Zone d’Activité du Thuit Anger, 185 H Voie Romaine,

27370 Le Thuit Anger, France.

Hardcopies are not controlled.

ii

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

Document Edition: 1.1, Document # 715-5000

© Molex Inc.

Page 3

IP67 Industrial Ethernet Switches Hardware Reference Guide

Preface

Preface Sections:

• Purpose of this Guide

• Conventions

Preface iii

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 4

Hardware Reference Guide IP67 Industrial Ethernet Switches

Purpose of this Guide

This manual explains how to install and maintain the IP-67 Industrial Ethernet Switches.

Conventions

This guide uses special notation to help enhance your understanding.

Special Notation

The following special notations are used throughout this guide:

Warning

Warning messages alert the reader to situations where personal injury

may result. Warnings are accompanied by the symbol shown, and

precede the topic to which they refer.

Caution

Caution messages alert the reader to situations where equipment damage

may result. Cautions are accompanied by the symbol shown, and

precede the topic to which they refer.

Note

A note provides additional information, emphasizes a point, or gives a

tip for easier operation. Notes are accompanied by the symbol shown,

and follow the text to which they refer.

iv

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Preface

Page 5

Contents

Preface .......................................................................................................................... iii

Purpose of this Guide .............................................................................................................. iv

Conventions ............................................................................................................................ iv

1.General Information ................................................................................................... 7

Overview ................................................................................................................................. 8

Part Numbering........................................................................................................................ 8

Operation ................................................................................................................................. 9

Performance Specifications ...................................................................................................... 9

2.LED Indicators .......................................................................................................... 10

Overview ............................................................................................................................... 11

Power LEDs .......................................................................................................................... 12

ACT/LNK LEDs .................................................................................................................... 13

10/100 LEDs .......................................................................................................................... 13

3.Installation ................................................................................................................ 14

Overview ............................................................................................................................... 15

Procedure ............................................................................................................................... 15

Typical Cabling ..................................................................................................................... 16

4.Power Wiring ............................................................................................................ 17

Overview ............................................................................................................................... 18

Power-supply Redundancy ..................................................................................................... 20

Daisy-Chaining Module’s Power-supply ................................................................................ 20

5.Communication Ports Wiring .................................................................................. 21

Overview ............................................................................................................................... 22

M12 Ethernet Wiring ............................................................................................................. 22

Ethernet Connector Pinout ..................................................................................................... 23

Ethernet Cable Length ........................................................................................................... 23

Duplex Operation ................................................................................................................... 23

Verifying Connectivity .......................................................................................................... 23

6.Switch Features ........................................................................................................ 24

Switch Features...................................................................................................................... 25

7.Technical Specifications ......................................................................................... 28

Technical Specifications ........................................................................................................ 29

Preface v

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 6

Hardware Reference Guide IP67 Industrial Ethernet Switches

Dimensions ............................................................................................................................ 31

Cable Flow...………………………………………………………………………………… 34

8.Cabling Guidelines ................................................................................................... 35

Overview ............................................................................................................................... 36

Cable Categories .................................................................................................................... 36

Cable Routing ........................................................................................................................ 37

Bonding and Grounding ......................................................................................................... 37

Data Cable Shielding ............................................................................................................. 38

Conforming to IP67 ............................................................................................................... 38

Planning your installation ...................................................................................................... 38

A.Standards and Safety .............................................................................................. 39

CE Statement ......................................................................................................................... 40

General Warnings .................................................................................................................. 40

B.Warranty and Support ............................................................................................. 41

Statement of Limited Warranty .............................................................................................. 42

Technical Support .................................................................................................................. 43

Getting Help .......................................................................................................................... 45

vi

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Preface

Page 7

IP67 Industrial Ethernet Switches Hardware Reference Guide

1

General Information

Chapter Sections:

• Overview

• Part Numbering

• Operation

• Performance Specifications

General Information 7

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 8

Hardware Reference Guide IP67 Industrial Ethernet Switches

Overview

This manual will help you install and maintain the IP-67 Industrial Ethernet Switches. These

switches are designed to interconnect Ethernet nodes in a harsh environment and increase

network performance.

Part Numbering

Part Number Device

DRL-750 IP67 Fast Ethernet Unmanaged Switch

DRL-780 IP67 Fast Ethernet Unmanaged Switch

DRL-781 IP67 Fast Ethernet Unmanaged Switch

DRL-782 IP67 Fast Ethernet Unmanaged Switch

Network : 5 ports M12

Power : 5 pins M12 (redundant 9 to 36 VDC)

Network : 8 ports M12

Power : 5 pins Mini-Change Power in / Power out connectors (redundant 9 to 36 VDC)

Network : 8 ports M12

Power : 4 pins Mini-Change Power in / Power out connectors (redundant 9 to 36 VDC)

Network : 8 ports M12

Power : 5 pins M12 Power in / Power out connectors (redundant 9 to 36 VDC)

8 General Information

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 9

IP67 Industrial Ethernet Switches Hardware Reference Guide

Operation

Unlike an Ethernet hub, which broadcasts all messages received out all ports, the DRL-7xx

series route Ethernet messages to the appropriate port. In other words, it prepares the network

for optimal bandwidth conditions, reduces the number of collisions.

The DRL-7xx series supports 10BaseT (10 Mbps) or 100BaseT (100 Mbps) on the M-12

ports. Each port, independent of the others, will auto-negotiate the speed and duplex mode.

This allows both 10 Mbps (full or half duplex) and 100Mbps (full or half duplex) devices to

be connected to the same DRL-7xx series Switch.

Performance Specifications

The performance specifications are as follows. For complete technical specifications,

including switch dimensions, refer to Appendix A.

Table 1: Performance Specifications

Ethernet Switch Type Unmanaged

Ports 10BaseT/100BaseTx M12

Required Voltage 9-36VDC (See Appendix A for power consumption for each model)

Ethernet Standards IEEE 802.3 (10BaseT), 802.3u (100BaseTX), 802.3x (Full Duplex)

Ethernet Protocols All standard IEEE 802.3 protocols supported

Speed Per Port 10 Mbps/100Mbps

Ethernet Isolation 1500 Volts RMS (for 1 minute)

Operating Temperature -40 to 80°C

Humidity 5 to 95% (non-condensing)

General Information 9

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 10

Hardware Reference Guide IP67 Industrial Ethernet Switches

2

LED Indicators

Chapter Sections:

• Overview

• Power LEDs

• ACT / LNK LEDs

• 10 / 100 LEDs

10

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

LED Indicators

Page 11

IP67 Industrial Ethernet Switches Hardware Reference Guide

Overview

The DRL-7xx series have communication LEDs for each port and power LEDs. Refer to the

sample pictures below for LED locations.

Power LEDs

PWR1/PWR2

Power LEDs

PWR1/PWR2

Each Port has its own

Activity and Speed LEDs

Each Port has its own

Activity and Speed LEDs

Figure 1 - LEDs on DRL-78x Figure 2 - LEDs on DRL-750

LEDs Indicators 11

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 12

Hardware Reference Guide IP67 Industrial Ethernet Switches

Power LEDs

The Power LEDs indicate the switch is correctly powered.

LED State Meaning

Off Device is powered Off

Green Power is connected correctly

DRL-780 / DRL-781 / DRL-782

There are two Power LEDs on the DRL-78x Switches. PWR1 is used for primary power, and

PWR2 is used for secondary power. Both indicate if power is being applied to the respective

terminal.

Note

The DRL-780/DRL-781/DRL-782 operates while either (or both)

DRL-750

The DRL-750 has only one Power LED. The LED will be lit if power is applied to one or

both of the +24VDC terminals.

PWR1/PWR2 LED lit.

In power redundancy mode, both PWR1 and PWR2 will be lit.

12

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

LED Indicators

Page 13

IP67 Industrial Ethernet Switches Hardware Reference Guide

ACT/LNK LEDs

The Ethernet activity (ACT) is reported through one LED. There is one of these LEDs per

M12 port.

LED State Meaning

Off There is no activity on this port

Flashing Green Communication activity detected.

10/100 LEDs

These LEDs indicate the communication speed detected on the port. There is one of these

LEDs per M12 port.

LED State Meaning

Off There is no proper Ethernet connection (link)

Yellow A 10 Mbps (10BaseT) connection is detected.

Green A 100 Mbps (100BaseTx) connection is detected.

between the port and another Ethernet device.

Make sure the cabling is correct and that all cables

are plugged securely into the ports, at both ends.

For Ethernet wiring directions, refer to Section 5.

LEDs Indicators 13

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 14

Hardware Reference Guide IP67 Industrial Ethernet Switches

3

Installation

Chapter Contents:

• Overview

• Procedure

• Dimensions

• Cables flow

14 Installation

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 15

IP67 Industrial Ethernet Switches Hardware Reference Guide

Overview

The IP67 Switches should be screwed directly to a flat panel or on a machine frame. Refer to

the pictures below.

Note

Mounting the Switch to a surface that is not flat can cause the circuit

board inside the device to be flexed, possibly damaging it.

Procedure

Connect Protective Earth to the Ground Nut.

Connect Ethernet ports.

Note

Allow for enough room to route the Ethernet cables.

Warning

Install the IP67 Industrial Ethernet Switch in accordance with local and

national electrical codes.

Connect the Power Supply to the power terminals. This will start the switch operation.

Installation 15

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 16

Hardware Reference Guide IP67 Industrial Ethernet Switches

Typical Cabling

From Power Supply

To other Ethernet

Equipments

Protection Earth

To downstream powered equipments

DRL-780/781 IP67

Ethernet Switch

(*)

See P/N references in IP67 HarshIO product catalog

16 Installation

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

Ethernet connection

Figure 3 - Typical Switch Cabling

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

TCDxx-yyy(*) IP67

Ethernet I/O Block

Device

Page 17

IP67 Industrial Ethernet Switches Hardware Reference Guide

4

Power Wiring

Chapter Contents:

• Overview

• Power Supply Redundancy

• Daisy-Chaining Module’s Power-supply

Power Wiring 17

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 18

Hardware Reference Guide IP67 Industrial Ethernet Switches

Overview

IP67 Switches can be powered from the same DC source that is used to power your I/O

devices. 9 to 36 VDC needs to be applied across the +24VDC1 and Common (0v) terminals.

The third terminal (PE) should be tied to panel or chassis ground, first making sure the

possible grounding point is free of electrical noise.

To reduce downtime resulting from power loss, the switch can be powered redundantly by

connecting a second power supply to the +24VDC2 terminal and the Common terminal (0v).

Pin Signal

1 0V 1

2 0V 1

Mini-change 5-pins power input, male

connector

Figure 4 - 5 Pins Mini-Change Power Connector Pinout

3 PE2

4 +24VDC1

5 +24VDC2

Shell PE2

Mini-change 5-pins power output, female

connector

1

Both 0V terminals are connected internally

2

Both PE terminals are connected internally

18

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Power Wiring

Page 19

IP67 Industrial Ethernet Switches Hardware Reference Guide

Pin Signal

1 0V 1

2 0V 1

3 +24VDC1

4 +24VDC2

Shell PE

Mini-change 4-pins power input, male

connector

Figure 5 - 4 Pins Mini-Change Power connector Pinout

M12 A-Coded 5-pins power male

Figure 6 - 5 Pins M12 Power connector Pinout

connector

Mini-change 4-pins power output, female

Pin Signal

1 +24VDC1

2 +24VDC2

3 0V 1

4 0V 1

5 PE 2

Shell PE 2

connector

Note

Connecting the power supply will start device operation.

1

Both 0V terminals are connected internally

2

Both PE terminals are connected internally

Power Wiring 19

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 20

Hardware Reference Guide IP67 Industrial Ethernet Switches

Warning

Equipment should be installed in accordance with local and national

country wiring codes.

Power-supply Redundancy

IP67 switches can operate from either +24VDC1 or +24VDC2. When using power supply

redundancy, two different power supplies shall be used. If one of these power supplies would

fail, the DRL-7xx Industrial Switch will continue to operate transparently.

Daisy-Chaining Module’s Power-supply

The DRL-78x has 2 power ports to allow daisy chaining power from one device to another.

This feature could be used to power additional I/O blocks or switches without power tees or

taps.

Warning

While daisy-chaining power between modules, the total current (amps)

needs to be calculated for the whole chain and that value must not exceed

8 A (DRL-780, DRL-781) or 4 A (DRL-782) per power-supply pin, either

+24VDC or 0V terminal. The power requirements of the DRL-78x also need

to be considered in power budgeting (refers to Fig. 10).

20

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Power Wiring

Page 21

IP67 Industrial Ethernet Switches Hardware Reference Guide

5

Communication Ports Wiring

Chapter Contents:

• Overview

• M12 Ethernet Wiring

• Ethernet Connector Pinout

• Ethernet Cable Length

• Duplex Operation

• Verifying Connectivity

Communication Ports Wiring 21

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 22

Hardware Reference Guide IP67 Industrial Ethernet Switches

Overview

Switches provide connections to standard Ethernet devices, such as PLCs, Ethernet I/O and

industrial computers. These devices are connected to the switch using standard M12

communication ports.

Figure 7 - Switch Connections

M12 Ethernet Wiring

Use data-quality (not voice-quality) twisted pair cable, rated category 5 (or better), with M12

D-Coded connectors. For best performance, use shielded cable. Straight through or crossover

M12 cable can be used, regardless of the device the switch is to be connected to, as all the

DRL-700 Series Switches are capable of auto-mdi/mdix-crossover detection.

The M12 Ethernet port connector bodies are metallic and are connected to the PE connection

point (either terminal or screw). Therefore, shielded cables may be used to provide further

protection.

To prevent ground loops, the cable shield should be tied to the metal connector body at one

end of the cable only. For increased reliability, electrical isolation is also provided on the

Ethernet ports.

22

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Communication Ports Wiring

Page 23

IP67 Industrial Ethernet Switches Hardware Reference Guide

Ethernet Connector Pinout

Table 6: Ethernet Connector Pinouts

Pin Signal

1 TX+

2 RX+

3 TX-

4 RX-

Figure 8 - M12 Ethernet D-Coded Connector

Ethernet Cable Length

The maximum cable length for 10BaseT / 100BaseTx is typically 100 meters (328 ft.).

Duplex Operation

All Ethernet ports will auto-sense for Full or Half duplex operation.

Verifying Connectivity

When all Ethernet connections have been made, check the LEDs corresponding to the ports

with devices connected. Each port that is in use, the LED should be ON or blinking. If a port

LED is off, check for connectivity problems between that port and the network device

connected to it. In addition, the LED color should indicate the speed your device is connected

at (for more details, refer to Chapter 2, LED Indicators).

Communication Ports Wiring 23

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 24

Hardware Reference Guide IP67 Industrial Ethernet Switches

6

Switch Features

Chapter Contents:

• Switch Features

24

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Switch Features

Page 25

IP67 Industrial Ethernet Switches Hardware Reference Guide

Switch Features

Below is a brief description of the features of the IP67 Industrial Ethernet Switches DRL-7xx

series.

10BaseT and 100BaseTx Auto-Negotiation

Standard Ethernet (10BaseT) has a maximum speed of 10 Mbps. Fast Ethernet (100BaseTx)

has a maximum speed of 100 Mbps. The M12 ports on the switches automatically select the

appropriate speed.

1K / 8K MAC Addresses with Automatic Learning, Aging and Migration

Each Ethernet device inserts its unique “MAC” address into each message it sends out. The

port on the switch used for a given MAC address is automatically learned when a frame is

received from that address. Once an address is learned, the switch will route messages to the

appropriate port only, instead of broadcasting messages out all ports, like a hub. A timestamp

is also placed in memory when a new address is learned. This timestamp is used with the

aging feature, which will remove unused MAC addresses from the table after 300 seconds. If

a device moves, the associated port on the switch will be changed (migrated) as needed. Up

to 1,024 MAC addresses can be stored and monitored at any time on the DRL-750 and 8,192

on the DRL-78x.

Auto-Crossover (Auto-MDI/MDI-X)

The switch ports will automatically detect the cable type (straight-thru vs. cross-over) and reconfigure accordingly.

Auto-Sensing or Auto-Negotiating Speed

The switch ports will auto-negotiate with the connected device to determine the optimal

speed (10 Mbps vs. 100 Mbps).

Backoff Operation

The switches will drop a packet after 16 consecutive retransmit attempts.

Switch Features 25

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 26

Hardware Reference Guide IP67 Industrial Ethernet Switches

Back Pressure for Half-Duplex

The switches will apply “back pressure” when necessary with half-duplex operation. This

will reduce congestion on busy networks.

Buffering

SRAM is used for buffering the messages. The DRL-750 has an internal 512 Kbit SRAM for

buffering, and the DRL-78x have 1 Mbit.

Unmanaged Operation

The switches require no supervisory processor to operate properly.

Flow Control

The switches automatically support flow control frames on both transmit and receive sides.

Forwarding

The switches support store and forward mode. They forward messages with known addresses

out the appropriate port only. Messages with unknown addresses, broadcast messages, and

multicast messages get forwarded out all ports, except the source port. The switches will not

forward error packets, 802.3x pause frames, or “local” packets.

Full/half-Duplex Operation

The switches’ ports support both full and half duplex flow control.

Illegal Frames

Illegal frames, as defined by IEEE 802.3, will be dropped. This includes short frames, long

frames and FCS error frames.

26

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Switch Features

Page 27

IP67 Industrial Ethernet Switches Hardware Reference Guide

IEEE 802.3 Compliant

The switches abide to the IEEE 802.3 standard for 10BaseT and 100BaseTX Ethernet

communications.

Late Collision

If a packet experiences collisions after 512 bit times of transmission, it will be dropped.

Latency

The typical latency of a message is 5 microseconds or faster. The latency is the time it takes a

message to be routed internally to a switch from one port to another.

Plug and Play

This means that most of the switches’ functions or features are automatic and that no optional

parameters need to be set. Just plug in your Ethernet cables, apply power, and the unit will

immediately begin to operate.

Protocol Independent

The switches simultaneously support all popular Ethernet protocols and networks, such as

TCP/IP and NetBEUI that run over standard Ethernet (IEEE 802.3).

Switch Features 27

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 28

Hardware Reference Guide IP67 Industrial Ethernet Switches

7

Technical Specifications

Appendix Contents:

• Technical Specifications

• Dimensions

• Cable flow

28

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Technical Specifications

Page 29

IP67 Industrial Ethernet Switches Hardware Reference Guide

Technical Specifications

The hardware technical specifications for the Unmanaged Switches are as follows.

10/100BaseT Ports Shielded M12

Protocols supported All standard IEEE 802.3

Ethernet compliancy IEEE 802.3, 802.3u, 802.3x

Auto-crossover Yes, allows you to use straight or cross wired cables

Auto-sensing operation Full and half duplex

Auto-negotiating 10BaseT and 100BaseTx

Auto-polarity Yes, on the TD and RD pair

Flow control Automatic

Ethernet isolation 1500 VRMS 1 minute

Plug and play Yes

Cable requirements Twisted pair (Cat. 5 or better) (shielded recommended)

Max. cable distance 100 meters

Figure 9 - Copper Ports: (10BaseT or 100BaseTx)

Technical Specifications 29

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 30

Hardware Reference Guide IP67 Industrial Ethernet Switches

DRL-75x DRL-78x

Ethernet switch type

Ethernet ports

Switching technology

Latency for 10Mbps ports

Latency for 100Mbps ports

Duplex operation

Mounting

Power in connector

Power out connector (daisy-chain)

Power input

Input power (max)

(all ports active at 100Mbps)

Input voltage (all models)

Ethernet isolation

Unmanaged

5 x M12 Fast Ethernet 8 x M12 Fast Ethernet

Store and forward

16us + frame time (typical)

5us + frame time (typical)

Full or half

Direct panel mounting

Mini Change Male 5 pins (DRL-780)

M12 Male A-Coded 5 pins

Mini Change Male 4 pins (DRL-781)

M12 Male A-Coded 5 pins (DRL-782)

Mini Change Female 5 pins (DRL-780)

N/A

Mini Change Female 4 pins (DRL-781)

M12 Female A-Coded 5 pins (DRL-782)

Redundant Input Terminals

2.0 W 2.4 W

9-36VDC (continuous)

1500 VRMS 1 minute

Operating temperature range

Storage temperature range

Humidity (non-condensing)

Vibration

Shock

Electrical safety

EMI emissions

EMC immunity

Packaging

Dimensions

Weight

30

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

-40 to +80°C

-40 to +90°C

5 to 95% RH

7g (IEC68-2-6)

50g (IEC68-2-29)

EN61010-1

EN55022 class B EN55022 class A

EN61000-4-3 10V/m radiated

EN61000-4-6 10V conducted

EN61000-4-4

EN61000-4-5

EN61000-4-2 8Kv contact / 16Kv air

IP67 protection

220 x 60 x 37 mm

See figure 11 for details.

230 g 580g

Figure 10 - General Specifications

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

EN61000-4-3 10V/m radiated

EN61000-4-6 10V conducted

EN61000-4-4

EN61000-4-5

EN61000-4-2 4Kv contact / 8Kv air

176 x 30 x 34 mm

See figure 12 & 13 for details.

Technical Specifications

Page 31

IP67 Industrial Ethernet Switches Hardware Reference Guide

Dimensions

Technical Specifications 31

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

Figure 11 - DRL-750 Dimensions

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 32

Hardware Reference Guide IP67 Industrial Ethernet Switches

Figure 12 - DRL-780, DRL-781 Dimensions

32

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Technical Specifications

Page 33

IP67 Industrial Ethernet Switches Hardware Reference Guide

Technical Specifications 33

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

Figure 13 - DRL-782 Dimensions

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 34

Hardware Reference Guide IP67 Industrial Ethernet Switches

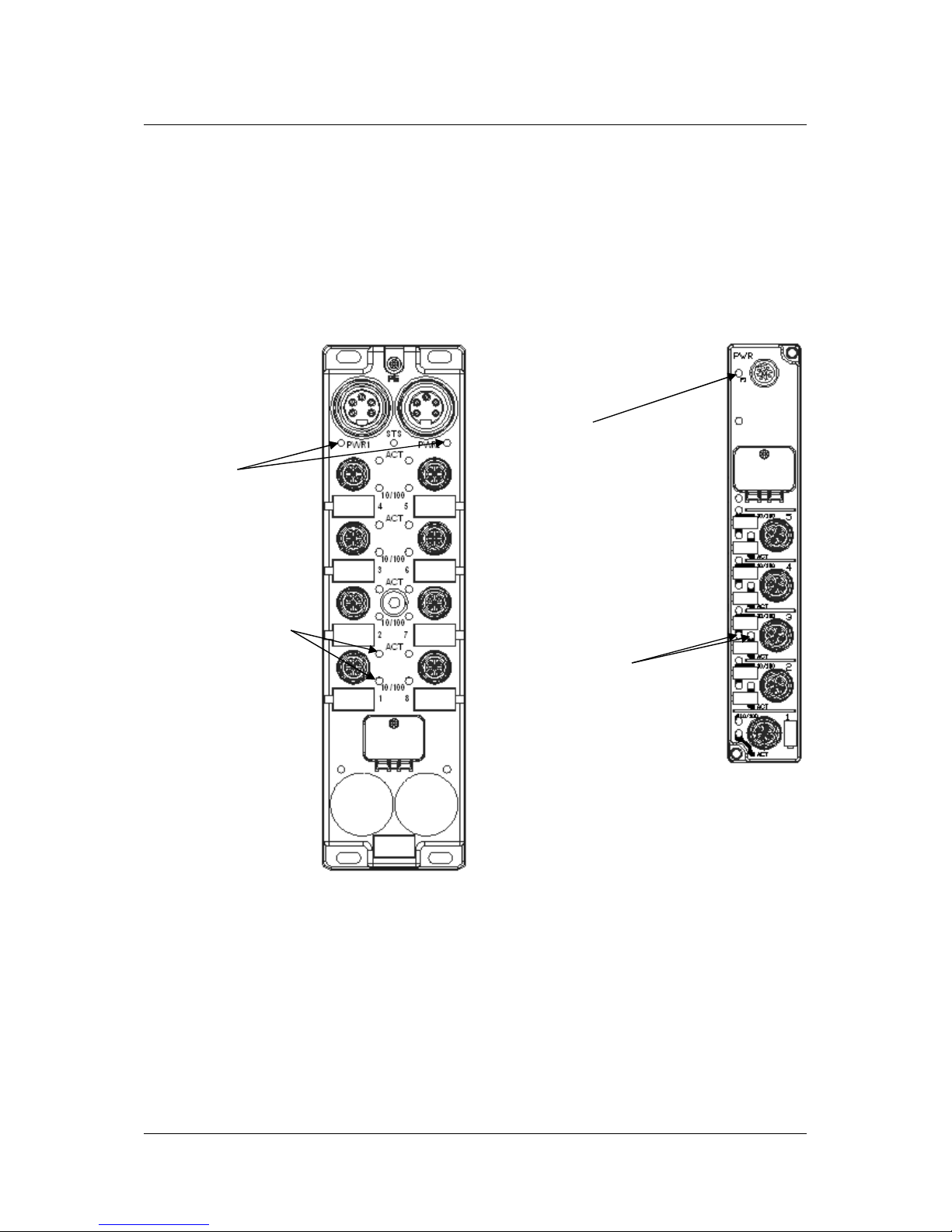

Cable Flow

Figure 14 - Cable flow on DRL-78x Figure 13 - Cable flow on DRL-750

34

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Technical Specifications

Page 35

IP67 Industrial Ethernet Switches Hardware Reference Guide

8

Cabling Guidelines

Appendix Sections

• Overview

• Cable Categories

• Cable Routing

• Bonding and Grounding

• Data Cable Shielding

• Conforming to IP67

• Planning your Installation

Cabling Guidelines 35

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 36

Hardware Reference Guide IP67 Industrial Ethernet Switches

Overview

The following chapter highlights some basic cabling rules that must be implemented to

achieve reliable operation of your network. Industrial networks must be robust enough to

avoid costly process downtime. Every part of the design should be carefully selected to

perform in a harsh environment over its lifetime. Specifically Devices, Connectors and

Cables should be chosen based on their behavior regarding:

- Vibrations

- Climatic stresses

- Electric noise

- Chemical aggression

Cable Categories

IEEE Guide for the Installation of Electrical Equipment to Minimize Electrical Noise Inputs to

Controllers from External Sources (IEEE Std 518-1982)

planning the network, every cable shall be assigned a category to help routing.

Cable Category Cable Type

Aggressors High-power AC lines

DC I/O lines connecting solenoids, relays or switches

These conductors correspond to IEEE levels 3 (low susceptibility) & 4 (power)

Victims Low-power analog or digital lines

Communication lines

These conductors correspond to IEEE levels 1 (high susceptibility) & 2 (medium

susceptibility)

defines 4 cables categories. When

36

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Cabling Guidelines

Page 37

IP67 Industrial Ethernet Switches Hardware Reference Guide

Cable Routing

As a general guide:

- Cables of the same category shall be routed together and never cross each other.

- If crossing cables is necessary it should be done at right angles to reduce any negative

impact. This is especially important when crossing communication and power wires.

- When running disturbing cables (class 1 and 2) parallel they should be kept apart from

Data cables with a minimum separation of 0.30m to limit capacitive and radiated

coupling.

- All cables should be routed in metal cableways.

Bonding and Grounding

Proper bonding and grounding of your equipments is a key point to meet safety regulations. It

will also help in reducing EMI and ground noise effects.

The PE on power connector needs to be connected only when no earth connection is

available. In order to avoid ground loops, it is recommended that the one of the Protected

Earth connection points (PE in Power connector OR FE screw to the chassis) be grounded.

Connecting the DRL-78x to earth

requires a bonding lead with an M3 ring

terminals. See picture below for details.

The DRL_750 can be grounded through its top

right or bottom left holes using either a bonding

lead with an M3 ring terminal or directly to an

earthed chassis with M3 screws.

Cabling Guidelines 37

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 38

Hardware Reference Guide IP67 Industrial Ethernet Switches

Data Cable Shielding

The IP67 Industrial Ethernet Switches are designed for mounting directly on machine frames.

This kind of environment, subject to high electrical noise, requires usage of suitable cable

type. Shielded Cables (STP) shall be selected for this type of application, as they provide

good noise immunity to the whole system.

Conforming to IP67

To ensure the device is IP67 rated, all connectors (Power supply, Ethernet ports) need to be

connected to an IP67 cable, or terminated with the appropriate caps.

Planning your installation

Always use cables/connectors suitable for your application. It’s important to go with

cables/connectors designed for an industrial environment.

Caution

A DC power source that complies with the Safety Extra Low Voltage

(SELV) requirements of UL 1950, CSA C22.2 No. 950-95, EN 60950,

and IEC 60950 must be used when powering the DRL-700 Series of IP67

Industrial Ethernet Switches.

38

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Cabling Guidelines

Page 39

IP67 Industrial Ethernet Switches Hardware Reference Guide

A

Standards and Safety

Appendix Sections

• CE Statement

• General Warnings

Standards and Safety 39

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 40

Hardware Reference Guide IP67 Industrial Ethernet Switches

The applicable standards and certifications are:

CE Mark

Electrical safety - EN61010-1 (IEC61010)

EMI emissions - EN55011

EMC immunity – EN61326

General Warnings

Caution

This equipment is neither designed for, nor intended for operation in

installations where it is subject to hazardous voltages and hazardous

currents.

Note

To maintain compliance with the limits and requirements of the EMC

Directive, it is required to use quality interfacing cables and connectors

when connecting to this device.

Note

The supply voltage for this equipment must be delivered as Separated

Extra Low Voltage (SELV).

40

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Standards and Safety

Page 41

IP67 Industrial Ethernet Switches Hardware Reference Guide

B

Warranty and Support

Appendix Sections:

• Statement of Limited Warranty

• Technical Support

Warranty and Support 41

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 42

Hardware Reference Guide IP67 Industrial Ethernet Switches

Statement of Limited Warranty

Brad™ from Molex, manufacturer of DRL-7xx products, warrants to Buyer that products,

except software, manufactured by Brad ™ will be free from defects in material and

workmanship. Brad ™ obligation under this warranty will be limited to repairing or replacing

the defective parts within one year of the date of installation. Products may be returned by

Buyer only after permission has been obtained from Brad ™. Buyer will prepay all freight

charges to return any products to the repair facility designated by Brad ™.

Brad ™ further warrants that any software supplied as part of a product sale, except obsolete

products, will be free from non-conformances with Brad ™ published specifications for a

period of 90 days from the time of delivery. While Brad ™ endeavors to improve the features

and performance of its products, no effort on the part of Brad ™ to investigate, improve or

modify DRL-7xx modules at the request of a customer will obligate Brad ™ in any way.

For the convenience of existing customers, Brad ™ continues to supply certain products that

are classified as obsolete. No warranty on the software features of these products is stated or

implied and Brad ™ specifically is not obligated to improve the design of these products in

any way. Information about the status of any product is available upon request and customers

are advised to inquire about the status of older products prior to making a purchase.

This limited warranty does not cover losses or damages which occur in shipment to or from

Buyer or due to improper installation, maintenance, misuse, neglect or any cause other than

ordinary commercial or industrial applications. In particular, Brad ™ makes no warranties

whatsoever with respect to implied warranties of merchantability or fitness for any particular

purpose. All such warranties are hereby expressly disclaimed. No oral or written information

or advice given by Brad ™ or Brad representative shall create a warranty or in any way

increase the scope of this warranty. This limited warranty is in lieu of all other warranties

whether oral or written, expressed or implied. Brad liability shall not exceed the price of the

individual units, which are the basis of the claim. In no event shall Brad ™ be liable for any

loss of profits, loss of use of facilities or device, or other indirect, incidental or consequential

damages.

Although every effort has been made to ensure the accuracy of this document, all information

is subject to change without any notice. Brad ™ takes no liability for any errors in this

document or for direct, indirect, or consequential damage resulting from the use of this

manual.

42

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Warranty and Support

Page 43

IP67 Industrial Ethernet Switches Hardware Reference Guide

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular installation,

Brad ™ cannot assume responsibility or liability for actual use based on the examples and

diagrams.

COPYRIGHTS and TRADEMARKS

Reproduction of the contents of this manual, in whole or in part, without written permission

of Brad ™ is prohibited.

Mini-Change®, Ultra-Lock™, Brad™ are all registered trademarks of Molex, Inc.

All other products or trademarks are the property of their respective owners.

Warranty and Support 43

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Page 44

Hardware Reference Guide IP67 Industrial Ethernet Switches

Technical Support

Please ensure that you have the following information readily available before calling for

technical support:

Switch type and serial number

Details of the problem you are experiencing: switch type and version, target network,

and circumstances that may have caused the problem

Note

Your switch identification is located on the backside of the device.

Serial number

Switch type

Locate required support information on back label

(DRL-78x)

Serial number

Switch type

Locate required support information on back label

(DRL-75x)

44

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Warranty and Support

Page 45

IP67 Industrial Ethernet Switches Hardware Reference Guide

Getting Help

Technical support is available during regular business hours by email or telephone.

To get more information, please go to our Brad® Automation products Support Center where

you can find:

• Support Request - For technical inquiries and product support, you can initiate a

support ticket and a member of our team will respond.

• Download Center - Download software, demo software, user manuals, quick-start

guides, and technical notes. The Download Center can be searched by part number,

protocol or keyword.

•

Knowledge Base - Connects you to technical documentation, what’s new!, and the

latest patches.

Worldwide Technical Support Contacts - Our Worldwide Technical Support covers

Europe, Middle East, Africa, North America, South America, and Asia. Our Support Teams

have extensive knowledge in the commissioning, diagnostics, and configuration of our

automation products portfolio. They will be glad to assist you with any further questions you

might have.

Warranty and Support 45

Use, duplication or disclosure of this document or any of the information contained herein is subject to the restrictions on page ii of this document.

© Woodhead Software & Electronics, a division of Molex

Document Edition: 1.1, Document # 715-5000

Loading...

Loading...