Page 1

CS 150 Battery Crim pi ng Tool

BATTERY POWERED CRIMPING TOOL

Description

Operation

Maintenance

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

Instruct ion Manual

Order No. 63816- 0200

UNCONTRO L L ED CO P Y Page 1 of 21

Page 2

CS 150 Battery Crim pi ng Tool

1 Safety Warnings and Information

2 General Description

3 Setup and Adjustments

4 Crimping Dies Go-No go

5 Preventive Maintenance

6 Troubleshooting

Table of Content s

SECTION

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 2 of 21

Page 3

CS 150 Battery Crim pi ng Tool

Read and understand all of the instructions and safety information in this

Manual before operating or servicing this tool.

Keep this manual available when using t hi s t ool

Replacement manuals are available upon request at no charge at

www.molex.com.

SAFETY

ALERT

SYMBOL

This symbol is used to call your attenti on t o hazards or unsafe pract ices which could result i n an i njury

or property damage. The signal word, def i ned below, indicates the severity of the hazard. The message

after the signal word provides inf orm ation for preventing or avoiding t he hazard.

DANGER

WARNING

CAUTION

WARNING WARNING

Electric shock hazard:

This tool is not i nsul ated. When using this

unit near energized electrical lines, use

proper personal protective equipment.

Failure to observe this warning coul d

Result in severe injury or death.

WARNING WARNING

Skin injection hazard:

Do not use hands to check for oil l eaks.

High pressure oil easily punct ures ski n

causing serious injury, gangrene, or death.

If injured, seek m edi cal help immediately

to remove oil.

DANGER:

Indicates an imminently hazardous situation which, if not avoided, will result in

Death or serious injury.

WARNING:

Indicates a potentially hazardous situation which, if not avoided, will result in

Death or serious injury.

CAUTION:

Indicates a potential ly hazardous situat i on whi ch, if not avoided, may result in

Minor or moderate injury. CA UTION may also be used to alert against unsaf e

practices associated with events that could l ead t o personal injury.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection coul d

result in serious eye injury from flying

debris or hydraulic oil.

Pinch points:

Keep hands away from the crimpi ng

head when crimping.

Failure to observe this warning coul d

Result In severe inj ury or death.

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 3 of 21

Page 4

CS 150 Battery Crim pi ng Tool

Do not use solvents or flammable liquids to cl ean

the crimping tool .

Solvents or flammable liquids could ignit e and

cause serious injury or property damage.

WARNING WARNING

WARNING WARNING

Do not dispose of the battery in a fire. It will vent fumes and may explode.

Failure to observe this warning coul d resul t i n severe i nj ury f rom harm f ul

fumes or burns from flyi ng debris

CAUTION CAUTION

Do not operate the tool wi thout the dies. Damage t o the ram or crimping

head can result.

Do not operate with t he cri m pi ng head open. D am age to the ram or

seals can result.

This tool is not desi gned for continuous use. After 100 crimpi ng cycl es,

allow the crimpi ng tool to cool down for 15 minutes.

Do not place the tool in a vise. The crimping tool is designed for hand-held

Operation only.

This tool may be used in dam p or wet environments; however, we

recommend air-drying the tool bef ore use if it becomes soaked.

Use this tool f or t he m anuf acturer’s intended purpose only.

Failure to observe these precautions m ay result in injury or property damage.

An incomplete crim p can cause a f i re.

Use proper die, connector, and cable combi nations.

Improper combinations can resul t i n an

incomplete crimp.

The relief valve will sound to indicate a completed

crimp. If you do not hear t he sound of t he rel i ef valve,

the crimp is not com pl et e.

Failure to observe these warnings could resul t in severe

injury or death.

Inspect tool and di es bef ore use. Replace any worn or

damaged parts. A damaged or improperly assembl ed

tool can break and strike someone nearby.

Failure to observe this warning coul d resul t in severe

injury or death.

Do not allow anything to contact the battery’s terminals.

Do not immerse the bat tery in liquid. Liqui d m ay

create a short circuit and damage t he bat t e ry.

If the batt ery is i m mersed, contact your service

center for proper handling.

Do not place the batt ery i nt o a pocket, tool pouch, or

tool box with conduct ive objects.

Conductive objects m ay creat e a short circuit and

damage the battery.

Do not place a battery on moist ground or grass.

Moisture may create a short ci rcuit and damage the

battery.

Failure to observe these precautions m ay resul t i n injury

or property damage.

CAUTION CAUTION

Do not store the batt ery at m ore t han 60 °C (140 °F). Dam age t o the

battery can result.

Do not use another manufact urer’s charger. Other manufacturers’

chargers may overcharge and damage the battery.

Do not attempt to open the battery. It contains no user-serviceable parts.

Failure to observe these precautions m ay result in injury or property damage.

For Service, Contact Your Local Molex Sales Office

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

Do not perform any service or maintenance other than as

described in this manual .

Failure to observe this precauti on m ay resul t i n i njury

and property damage.

Molex Application Tooling Group

2200 Wellington Court

Lisle, Illinois 60532

Tel: 630-969-4550

Fax: 630-505-0049

UNCONTRO L L ED CO P Y Page 4 of 21

Page 5

CS 150 Battery Crim pi ng Tool

2.1 Description

2.2 Features

2.3 Technical Specifications

2.4 Delivery Check

2.5 Tools

Section 2

General Description

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 5 of 21

Page 6

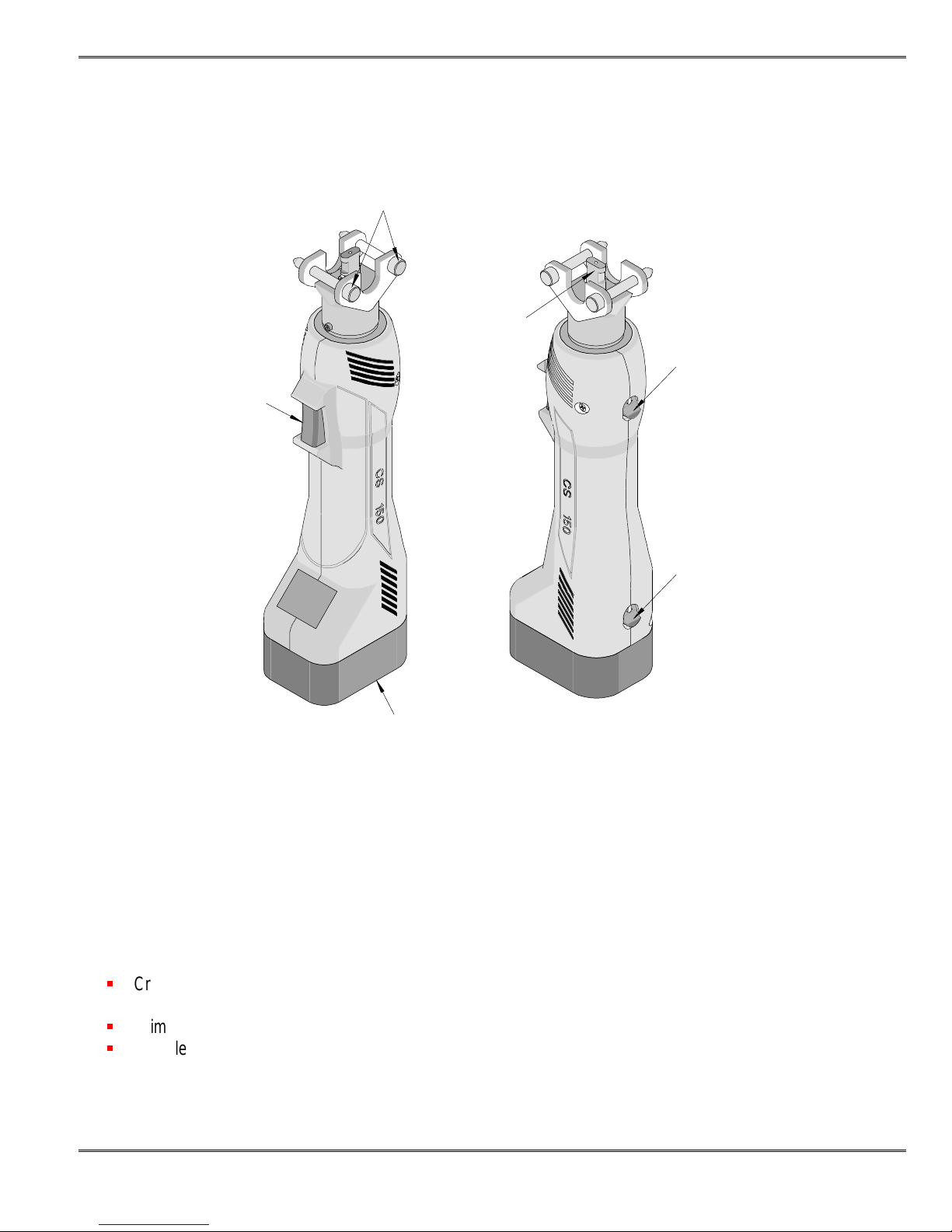

CS 150 Battery Crim pi ng Tool

Figure 2

General Description

2

Principal M echani cal Parts of the 63816-0200 (Battery charger not shown)

TRIGGER

2.1 Description

The Molex Battery Crimpi ng Tool i s designed t o crimp 8 to 4/0 AWG insulated and uninsulat ed terminals and

splices. This tool has an automatic retractabl e system which returns the crimpi ng adapter along with the

crimping dies to the start i ng posit i on when the maximum force is reached. It i s equipped wi th a special brake

that will stop the forward motion of t he crimping dies when the trigger is released. The crimping head can be

rotated 360o for better access in diff i cul t worki ng sit uations.

2.2 Features

Crimps a wide range of products with i nt erchangeable tool heads and tool kits, which reduce the overall cost

and provide production flexibility.

Crimping heads and dies are easily and quickly interchanged to reduce production down t i m e.

Complete portable system that allo ws t ool to be moved and stored easily.

LOCKING

PINS (2 )

CRIMPING

HEAD

ADAPTER

RECHARGEABLE

(NiCad 9.6V) BATTERY

RETRACT

SLIDE

UNLOCKING

SWITCH

-1

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 6 of 21

Page 7

CS 150 Battery Crim pi ng Tool

2.3 Technical Specification

Dimensions

(with battery)

Length 292.1mm (11.50”)

Width 76.2mm (3.00“)

Depth 50.8mm (2.00“)

Unpacked Weight 1.5kg (3.31lbs)

Production Rate

250 cycles per hour maximum, dependi ng on operat or sk ill and t ool kit inst alled.

Battery

Voltage 9.6V

Capacity 1.3 Ah

Charging Time: Approximately 40 Minut es, about 15 m i nutes with fast-charger

Crimps/battery-charge 150 at 10mm

2

Operating Parameters

Maximum Force 15kN (1.7 tons)

Cycle Time 2.0 seconds

Stroke Length 9.0mm (.354”)

Ambient Temperat ure -20oC to +40oC

Sound Level 75dB (A) in a distance of 1. 0m

Vibrations <2.5m/s

2

2.4 Delivery Check

Carefully remove the CS 150 B attery Crimping Tool from i t s shippi ng cont ainer and determine that the

following item s are included i n the package.

á

CS 150 Battery Cri m ping Tool wi th battery

á

Battery Charger

á

Carrying Case

á

63816-0200 Instruction Manual

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 7 of 21

Page 8

CS 150 Battery Crim pi ng Tool

3.1. Setup

3.2. Operation

3.3. Installation of Tool Kits

Section 3

Set-Up and Adjustments

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 8 of 21

Page 9

CS 150 Battery Crim pi ng Tool

3.1 Set-Up

Before starting any work on electri cal appl i cat ions m ake sure there are no

live cables or parts in the immediate area of the user.

CRIMPING

HEAD WITH

TOOLING

WARNING

Remove the battery from the crimping tool bef ore

installing and removing dies in t he crimp head.

1. Select the appropriat e crim ping head wi th the proper tooling kit

inserted for the applicat i on needed.

2. Remove the locking pins (2) from the adapt er pl at e on the crimping

tool.

3. Place the crimping head into the adapter and push down until it

engages into the slot of t he adapter.

4. Replace the locking pins (2) making sure the crimping head is secure.

The locking pins can be inserted from either side of the adapter plate.

See Figure 3-1.

WARNING

Electric shock hazard:

This tool is not insulated. When using this

unit near energized electrical lines, use

proper personal protective equipment.

Failure to observe this warning coul d

Result in severe injury or death.

LOCKING

LATCH

ADAPTER

PLATES

LOCKING

PINS (2 )

WITH LOCATOR

CRIMPING

HEAD

ADAPTER

CRIMPING

TOOL

RETRACT

SLIDE

Figure 3-1

WARNING

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection coul d

result in serious eye injury f rom flying

debris or hydraulic oil.

3.2 Operation

1. Insert the proper termi nal or connector i nto the tooling nest and push on the

trigger in the handle just enough so t he di es contact the terminal or connector

securely. Release the trigger. This all ows t he operator to make adjustments

to the connector before the final terminati on.

2. Insert the wire or cable into the terminal. Push on the wire or cable to assure it is fu ll y seat ed in t he

terminal.

3. Hold the trigger down again unti l t he crim pi ng tool achieves pressure relief, which is accompanied by an

audible “pop”.

TERMINAL

AND WIRE

IN PLACE

HOLD

TRIGGER

DOWN

Figure 3-2

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 9 of 21

Page 10

CS 150 Battery Crim pi ng Tool

The crimping operation can be i nt errupted at any time during the cycle by releasing the trigger.

4. The crimping cycle is compl ete when the dies are complet el y closed and the maximum crim pi ng f orce i s

reached. The dies will automatically release and will go back to their original position.

Note: In case of a n e rro r or emergency, th e ram can be retract e d be fore the crim p i n g cycl e is complete . To do

this push the retractor slide t owards t he bat tery. See Figure 3-1.

Warning: DO NOT crimp copper and AI conducting material together or special connecting material. If

a different conducting m at eri al has t o be crim ped, pl ease contact t he m anufacturer.

WARNING

An incomplete crimp can cause a f i re.

Use proper die, connector, and cable combinat i ons. I m proper combinat i ons can result i n an i ncom pl et e crim p.

The relief valve will sound to indicate a completed crimp. If you do not hear the sound of the relief valve,

the crimp is not compl et e.

Failure to observe these warnings could result i n severe inj ury or death.

3.3 Preventive Instructions

WARNING

Do not dispose of the battery in a fire. It will vent f umes and may explode.

Failure to observe this warning could result i n severe inj ury f rom harm ful fumes or burns from flying debris.

WARNING

Inspect tool and dies before use. Repl ace any worn or damaged part s. A dam aged or i m properl y

assembled tool can break and strike someone nearby.

Failure to observe this warning could result i n severe inj ury or deat h.

CAUTION

Do not operate the tool without the dies. Damage t o the ram or crimping head can result.

Do not operate with t he crimpi ng head open. Damage to the ram or seals can result.

This tool is not designed for continuous use. After 100 crimping cycles, al l ow the crimping tool t o

cool down for 15 minutes.

Do not place the tool in a vise. The crimpi ng tool is designed for hand-held operation only.

This tool may be used in damp or wet environment s; however, we recomm end ai r-drying the tool

before use if it becomes soaked.

Use this tool for t he m anuf act urer’s intended purpose only.

Failure to observe these precautions may result in i nj ury or propert y damage.

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 10 of 21

Page 11

CS 150 Battery Crim pi ng Tool

CAUTION

Do not allow anything to cont act the battery’s term i n a l s.

Do not immerse the battery in liquid. Liquid m ay create a short ci rcuit and dam age the battery.

If the battery is immersed, contact your service center for proper handl i ng.

Do not place the battery into a pocket, tool pouch, or tool box with conductive objects.

Conductive objects may create a short circuit and damage t he battery.

Do not place a battery on moist ground or grass. M oist ure m ay create a short circuit and damage

the battery.

Failure to observe these precautions may result in i nj ury or propert y damage.

Avoid dropping this tool. Extreme shock may damage the internal mechanism and result i n m al f unct i on of the

tool.

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 11 of 21

Page 12

CS 150 Battery Crim pi ng Tool

Terminal Specifications and Crimping Operation

4.1 Scope

4.2 Terminal Specifications Chart

Section 4

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 12 of 21

Page 13

CS 150 Battery Crim pi ng Tool

4.1 SCOPE

This tool is designed to crimp various Molex term i nal s and splices using our offering of crimping heads.

Testing

Mechanical

The tensile test, or pull test, is a means of evaluating t he m echanical properties of the crimped connections.

The following charts show the UL specifi cat i ons f or various wire sizes. The t ensil e st rength is shown in

pounds, which indicates the mini m um acceptabl e f orce t o break or separate the terminal from the conductor.

Wire Size (AWG) Tooling Color Code *UL – 486A **UL – 486C ***MIL-T-7928

22 8 8

20 13 10

18 20 10

16 30 15

14 50 25

12 70 35

10 80 40

8 Red 90 45 225

6 Blue 100 50 300

4 Yellow 140 - 400

2 Red 180 - 550

1 Blue 200 - 650

1/0 Blue 250 - 700

2/0 Yellow 300 - 750

3/0 Red 350 - 825

4/0 Blue 450 - 875

*UL – 486A – Terminals (Copper Conductors Only)

**UL – 486C – Butt Sli ces and Paral le l Slices (Over 6 AWG use 486A values)

***MIL-T-7928 - Military Approved Terminals only as listed

4.2 Crimping Terminals

Specifications and Inst ruct i ons f or crim ping are i ncl uded with the individual Bat tery Powered Crimp Tool

Heads.

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 13 of 21

Page 14

CS 150 Battery Crim pi ng Tool

5.1 Periodic Cleaning

5.2 Storage

5.3 Battery and Charging Unit

5.4 Disposal

5.5 Warranty

Section 5

Preventive Maintenance

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 14 of 21

Page 15

CS 150 Battery Crim pi ng Tool

5.1 Periodic Cleaning

Always clean tool after use and keep moving part s clear of di rt and debris.

This tool is basically maintenance free, onl y the bol t joints at the crimping head have t o be oil ed regul arl y.

Before use:

1. Inspect dies fo r wear or dam age such as cracks, gouges, or chips.

2. Inspect the tool f or dam age or l eaks. I f damage is detected, return the tool to a Molex representat i ve f or

inspection.

After use:

1. Wipe all tool surfaces clean with a dam p cl ot h and m i l d det ergent. Excessive dirt and grit can contribute

to the premature wear of t he tool’s internal mechanical parts. If this tool becomes dirty with excessive

debris it may jam and become damaged during operat i on.

3. Fully retract the ram. Place the tool in the carrying case. S tore in a cool, dry place.

4. Charge the battery.

WARNING WARNING

Skin injection hazard:

Do not use hands to check for oil l eaks.

High pressure oil easily punct ures ski n

causing serious injury, gangrene, or death.

Monthly:

1. Thoroughly clean all surfaces.

A routine should be established to keep t he tool as free from dirt as possible.

If injured, seek m edi cal help immediately

to remove oil.

Do not use solvents or flammable liquids to

clean the crimping t ool .

Solvents or flammable liquids could ignite and

cause serious injury or property damage.

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 15 of 21

Page 16

CS 150 Battery Crim pi ng Tool

An example of a maint enance chart i s shown below. Copy and use thi s chart t o track the maintenance of

this crimping tool or use thi s as a tem pl at e to create you own schedule or use your company’s standard

chart, if applicable.

Preventive Maintenance Chart

CHECK SHEET MONTH

Week

1

2

3

4

Cleaning Daily After use

Lubrication (2) bolts in crimping head Use SAE 10W

Hydraulic oil

Daily

Use

YEAR _________

Days of the Week

MON TUE WED THU FRI SAT

SUN

Solution

Schedule should be adjusted up or down depending on usage. Molex recommends t hat a log of preventive

maintenance be kept with t he tool.

5.2 Storage

In order to protect t he t ool agai nst damages, this tool should be cleaned carefully aft er every use. I t should

then be placed into the carrying case along with the charging unit, crimp heads and the inst ruct ion m anual

and stored in a dry location.

5.3 Battery and Charging Unit

CAUTION WARNING

Do not store the batt ery at m ore t han 60 °C (140 °F). Damage t o t he

battery can result.

Do not use another manufact urer’s charger. Ot her m anuf act urers’

chargers may overcharge and damage the battery.

Do not attempt to open the battery. It contains no user-serviceable parts.

Failure to observe these precautions may result in injury or property damage.

CAUTION

Do not allow anyt hi ng t o contact the battery’s termi nals.

Do not immerse the bat tery in liquid. Liqui d m ay creat e a short ci rcui t and dam age the battery.

If the batt ery is i m mersed, contact your service center for proper handling.

Do not place the batt ery i nt o a pocket, tool pouch, or tool box w i t h conductive objects.

Conductive objects m ay creat e a short ci rcui t and dam age the battery.

Do not place a battery on moist ground or grass. Moisture may create a short circuit and damage the battery.

Failure to observe these precautions m ay result in injury or property damage.

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

Do not dis p o s e o f th e b atte ry in a fir e . It will v e n t fumes

and may explode.

Failure to observe this warning coul d resul t in severe

injury from harmful fumes or burns from flying debris

UNCONTRO L L ED CO P Y Page 16 of 21

Page 17

CS 150 Battery Crim pi ng Tool

The charging unit is run with a nominal voltage of 110V and a frequency of 50-60Hz . New bat t eri es must be

charged before use. To remove the battery f rom t he crim pi ng t ool push down on t he bat tery lock and pull out.

See Figure 4-1. To charge the batt ery plug i n the charging unit into a power source and slide the bat t e ry

upside down into the charging unit. The norm al charging t i m e i s about 40 mi nutes. The charging level of the

battery cartridge can be checked by the right LED (m ul ticolor) of the charging unit .

Color Left LED (red) Right LED (multicolor)

Red Charging Unit is ready to operate. Battery def ect

Red

Flashing

Charging Unit is out of order.

New or unused battery’s

voltage capacity is insufficient.

Battery too hot or too cold. Remove the battery.

Safety components possibly defected.

Green --- Charging cycle stared.

Battery full y charged. Chargi ng uni t swit ches aut om at i call y

Green

Flashing

---

into a maintaining level.

Battery can stay in charge for an indefinite tim e wi t h out

being damaged.

Yellow --- Battery is at l east 90% charged. Charging can be t erm i nated.

--- ---

If the Right LE D does not l i ght up, the circuit of t he bat tery

is disconnected or the battery is incorrectly pol arized.

Notes:

1. If the standard capacity of t he battery is not achieved, it does not m ean t hat the battery is fault y. The full

capacity of the bat tery can be achieved after 3 charging/ di schargi ng cycl es.

2. If there is a noticeable decrease in speed of t he crim pi ng t ool t he battery should

be recharged.

Charge the battery at room temperature between 10oC-40oC (500F-104oF).

3. The battery should be charged before storing.

Cautions:

1. Charging a battery which has been used recently or in the sun or a long period

of time the ri ght LED might flash red, (Tem peratures greater than 65

In this case let the bat tery cool down and try again.

2. Charging the battery at l ow temperatures under 5oC (41oF) is not possible. The

battery temperature must be warmed up before st arting the battery cycl e again.

3. Do not expose the charging unit to rain or snow.

4. Do not charge the battery in or around explosive materials or gases.

5. Do not use any other (dry or car) battery with t he charging uni t or the crimping

tool.

6. Do not use the cord as a handle to carry the batt ery unit .

7. Do not pull the cord out of a wal l socket wi t h force.

8. Do not pull the plug of t he charging uni t until after t he battery has been charged.

9. Do not insert foreign object s into the ducts of the charging unit .

10. Do not disassemble the charging unit.

11. Do not place the battery in your pocket or a tool box, if there are conduct ive m at eri al s such as coins,

keys, tools or other metallic parts may cause injury or property damage.

o

C (149oF).

Figure 4-1

PUCH DOWN

ON SWITH

BATTERY

UNIT

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 17 of 21

Page 18

CS 150 Battery Crim pi ng Tool

5.4 Disposal

When this tool is no longer operating properly the different components of this tool will need to be disposed of

separately.

1. The hydraulic oil must be disposed of at a local drop-off recycling center.

ATTENTION

Disposal of Hydraulic fluid represents a danger t o ground-water. Uncontrolled draining of

or improper disposal is under penalty (environmental liabilit y law) t hru the Environmental

Protection Agency (EPA) guidelines.

2. The battery must be di sposed of accordi ng to the Rechargeable Battery Recycling Corporation

(RBRC) guidelines.

3. The remaining parts of thi s tool m ust be disposed of according to the domestic environmental

standards or the Environmental Protection Agency (EPA) guidelines.

4. Because of possible environmental damage, we recomm end di sposal of t he tool by a professional

company.

ATTENTION

Do not dispose of this tool in your residential or commercial waste,

as it would be hazardous to the environment.

5.5 Warranty

All tools are warranted t o be free of manufacturing def ect s f or a period of 30 days. Should such a defect

occur, we will repair or exchange the tool free of charge. This repair or exchange will not be applicable to

altered, misused, or damaged tools. This tool is designed for hand use only. A ny clam ping, fixturing, or use

of handle extensions voids this warranty. A fter one year Molex recommends the crimping t ool be returned to

a Molex representative for inspection. Only the heads of the crimping tool are perm i t ted to be changed by the

operator.

ATTENTION

Do not damage the seals of thi s tool .

If seals are damaged the warranty is inval id .

CAUTION: Mol ex crimp specif i cat ions are vali d onl y when used wit h M ole x term i nal s and t ool i ng.

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 18 of 21

Page 19

CS 150 Battery Crim pi ng Tool

6.1. Parts List and Assembly Drawing

6.2. Troubleshooting

Section 6

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 19 of 21

Page 20

CS 150 Battery Crim pi ng Tool

6.1 Parts List and Assembly Drawings

Item Order No Description Quantity

1 63816-0200 Battery Crimp Tool CS 150 1

2 63816-0201 Battery Powered Tool Head (without tool i ng) CSE30 1

3 63816-0202 Battery Unit CS 150 1

2

1

3

Figure 6-1

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 20 of 21

Page 21

CS 150 Battery Crim pi ng Tool

6.2 Troubleshooting

Make sure the battery is charged before toubl eshooti ng this tool.

Symptom

Tool is

inoperative.

Dies stop

during operation.

Cause Solution

Dirt, contaminants, etc.,

in ram area of tool.

Battery unit cont act s corroded.

Battery unit cont act s damaged. Reform the contacts.

Tool parts worn or damaged. Contact a Molex representative.

Oil level is low. Contact a Molex representati ve.

Air in Hydrau l ic system.

Clean the crimping tool.

Clean contacts with pencil eraser or

contact cleaner

Pull the trigger and hol d t he retract slide

simultaneously for about 10 seconds.

LED glows for

20 seconds.

Crimping Tool

loses oil.

Americas Headquar ters

Lisle, Illinois 60532 U.S.A.

1-800-78MOLEX

amerinfo@molex.com

Battery charge is low. Charge or replace battery unit.

Damage to the internal seal. Contact a Mol ex representative

Far East North Hea dquarters

Yamato, K anagawa, J apan

81-462-65-2324

feninfo@molex.com

Visit our Web site at http://www.molex.com

Far East South He adqua rters

Jurong, Singapore

65-6-268-6868

fesinfo@molex.com

European Headquarters

Munich, Germany

49-89-413092-0

eurinfo@molex.com

Corporate Headqua rters

2222 Wellington Ct.

Lisle, I L 60532 U.S.A.

630-969-4550

Fax: 630-969-1352

Doc No: ATS-638160200 Release Date: 12-06-07

Revision: A Revision Date: 12-06-07

UNCONTRO L L ED CO P Y Page 21 of 21

Loading...

Loading...