Page 1

HarshIO 600 eIP

i IP67 Digital I/O Modules for EtherNet/IP

User’s Manual

HarshIO 600 eIP

IP67 Digital I/O Modules for EtherNet/IP

Isolated Grounding and QuickConnect Versions

BradControl™ from Molex

Version 2.6

March 25th, 2013

Page 2

HarshIO 600 eIP

ii IP67 Digital I/O Modules for EtherNet/IP

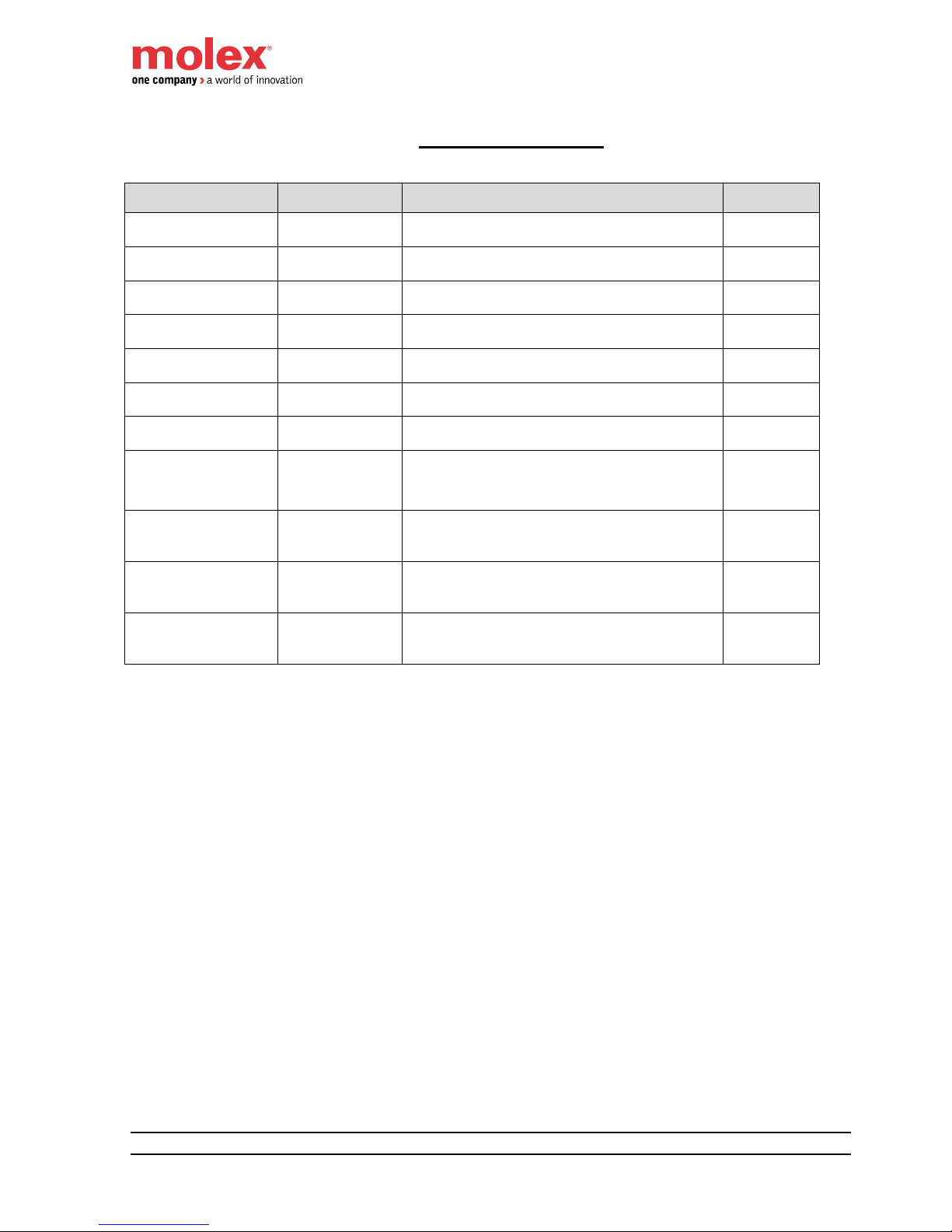

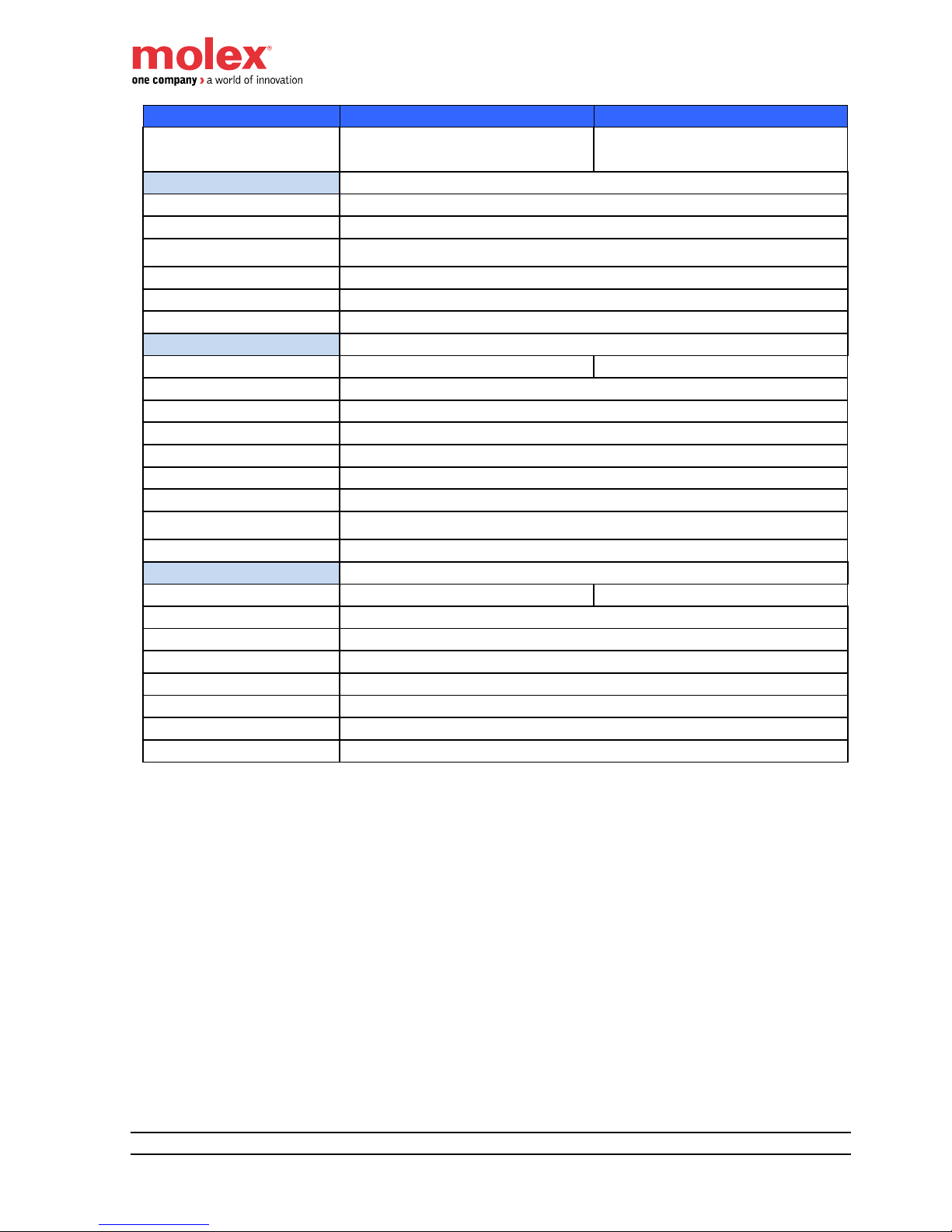

Revision History

Date

Author

Changes

Revision

January 24, 2012

E. GORY

Release version

1.0

February 06, 2012

E. GORY

Various typo corrections

Hyperlink to Molex Support and Download page

1.1

February 13, 2012

E. GORY

Various typo corrections

1.2

March 20, 2012

E. GORY

DHCP lease

1.3

September 06, 2012

E. GORY

Add 5-pin power supply module versions

Add 4-pin power 12IN/4OUT module version

2.0

September 14, 2012

E. GORY

Typo corrections

2.1

September 27, 2012

E. GORY

Typo corrections

2.2

December 11, 2012

E. GORY

Update mapping with power diagnostic bits

Add ground stub

Add EIP-Tool information and link

2.3

December 17, 2012

E. GORY

Correction 4-pin power supply wiring

Set Attribute 12 of CIP TCP/IP object (0xF5)

2.4

January 10, 2013

E. GORY

Update Listen Only (LO) connection information

2.5

March 25, 2013

E. GORY

Update default module settings

Add Chapter 9 - Web server interface

Update Chapter 8 for RXLogix 5000 v20

2.6

Although every effort has been made to ensure the accuracy of this document, all information is subject

to change without notice. Molex takes no liability for any errors in this document or for direct, indirect, or

consequential damage resulting from the use of this manual.

Page 3

HarshIO 600 eIP

iii IP67 Digital I/O Modules for EtherNet/IP

STATEMENT OF LIMITED WARRANTY

BradControl™ from Molex, manufacturer of HarshIO products, warrants to Buyer that products, except

software, manufactured by BradControl™ will be free from defects in material and workmanship.

BradControl™ obligation under this warranty will be limited to repairing or replacing the defective parts within

one year of the date of installation. Products may be returned by Buyer only after permission has been

obtained from BradControl™. Buyer will prepay all freight charges to return any products to the repair facility

designated by BradControl™.

BradControl™ further warrants that any software supplied as part of a product sale, except obsolete products,

will be free from non-conformances with BradControl™ published specifications for a period of 90 days from

the time of delivery. While BradControl™ endeavors to improve the features and performance of software

associated with its products, no effort on the part of BradControl™ to investigate, improve or modify HarshIO

modules firmware at the request of a customer will obligate BradControl™ in any way.

For the convenience of existing customers, BradControl™ continues to supply certain products that are

classified as obsolete. No warranty on the software features of these products is stated or implied and

BradControl™ specifically is not obligated to improve the design of these products in any way. Information

about the status of any product is available upon request and customers are advised to inquire about the

status of older products prior to making a purchase.

This limited warranty does not cover losses or damages which occur in shipment to or from Buyer or due to

improper installation, maintenance, misuse, neglect or any cause other than ordinary commercial or industrial

applications. In particular, BradControl™ makes no warranties whatsoever with respect to implied warranties

of merchantability or fitness for any particular purpose. All such warranties are hereby expressly disclaimed.

No oral or written information or advice given by BradControl™ or BradControl™'s representative shall create

a warranty or in any way increase the scope of this warranty. This limited warranty is in lieu of all other

warranties whether oral or written, expressed or implied. BradControl™’s liability shall not exceed the price of

the individual units, which are the basis of the claim. In no event shall BradControl™ be liable for any loss of

profits, loss of use of facilities or equipment, or other indirect, incidental or consequential damages.

Although every effort has been made to ensure the accuracy of this document, all information is subject to

change without any notice. BradControl™ takes no liability for any errors in this document or for direct, indirect,

or consequential damage resulting from the use of this manual.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, BradControl™ cannot assume

responsibility or liability for actual use based on the examples and diagrams.

COPYRIGHTS and TRADEMARKS

Reproduction of the contents of this manual, in whole or in part, without written permission of BradControl™ is

prohibited.

Mini-Change®, Ultra-Lock™, BradControl™ are all registered trademarks of Molex, Inc.

All other products or trademarks are the property of their respective owners.

Page 4

HarshIO 600 eIP

iv IP67 Digital I/O Modules for EtherNet/IP

Table of contents

1. General Safety Instructions ................................................................ 6

General information ................................................................................................. 6

Personnel qualifications .......................................................................................... 6

Preventive messages .............................................................................................. 6

Usage compliance ................................................................................................... 6

Device installation and set-up ................................................................................. 7

Device operation ..................................................................................................... 8

Electrical, mechanical and thermal specifications ................................................... 8

Preventive and corrective maintenance .................................................................. 8

2. General Description ............................................................................. 9

Introduction .............................................................................................................. 9

3. System Description ........................................................................... 11

Overview ............................................................................................................... 11

Typical application ................................................................................................. 14

Quick Connect applications ................................................................................... 15

4. Module Characteristics ..................................................................... 18

Hardware characteristics ....................................................................................... 18

Mechanical characteristics .................................................................................... 22

Physical I/O mapping ............................................................................................ 23

I/O messaging ....................................................................................................... 27

I/O data mapping ................................................................................................... 28

Pin assignment ...................................................................................................... 36

Separate grounding wiring for application using safety relays .............................. 38

Port wiring type ...................................................................................................... 40

LED assignment .................................................................................................... 41

Network IP address setting ................................................................................... 42

Display information ................................................................................................ 45

Hardware address (MAC Address) ....................................................................... 46

EDS files ................................................................................................................ 46

5. Specific Behavior ............................................................................... 47

I/O behavior ........................................................................................................... 47

IDLE behavior ........................................................................................................ 47

Duplicate IP address ............................................................................................. 47

6. EtherNet/IP Object Classes ............................................................... 48

Identity (0x01) ........................................................................................................ 48

Message Router (0x02) ......................................................................................... 49

Assembly (0x04) .................................................................................................... 50

Connection Manager (0x06) .................................................................................. 51

TCP/IP Interface (0xF5) ........................................................................................ 52

Ethernet Link (0xF6) .............................................................................................. 53

7. Getting Started ................................................................................... 54

Packaging content ................................................................................................. 54

Accessories ........................................................................................................... 54

Getting Started ...................................................................................................... 55

Page 5

HarshIO 600 eIP

v IP67 Digital I/O Modules for EtherNet/IP

8. Configuration using RSLogix 5000 .................................................. 57

ESD File ................................................................................................................ 57

Commissionning HarshIO eIP in Rockwell Logix 5000 version 20 ....................... 58

Commissionning HarshIO eIP in Rockwell Logix 5000 version 17 ....................... 74

9. Web Server Interface ......................................................................... 76

IP and Physical information ................................................................................... 77

Network Interface information ............................................................................... 78

EtherNet/IP information ......................................................................................... 79

10. Earth Connection ............................................................................... 80

11. Cables and Cordsets ......................................................................... 82

Industrial Ethernet cables ...................................................................................... 82

I/O cables .............................................................................................................. 88

Power supply cables ............................................................................................. 94

12. Product Support ................................................................................ 96

Product Information ............................................................................................... 96

Technical Support ................................................................................................. 96

Page 6

HarshIO 600 eIP

6 IP67 Digital I/O Modules for EtherNet/IP

1. General Safety Instructions

General information

The current documentation is intended for persons technically qualified to install, use and service the

products described herein. It contains the necessary information for proper use of the products. However,

for advanced use of our products, please contact your nearest dealer for additional information.

The content of this documentation is not binding and cannot extend or limit warranties.

Personnel qualifications

Only qualified persons are authorized to install, use and service the products. Use by unqualified persons or

failure to follow the safety instructions of this document, the manuals and/or those affixed to the devices, can

result in irremediable harm or damage to persons and equipment. The following personnel are deemed to be

qualified persons for:

• Equipment operation: Personnel who operates the machines and/or processes connected to the

Brad™ products. Brad™ HarshIO must be used by persons who have received training and have

been informed of the major risks involved in working in an industrial environment.

• Preventive and corrective maintenance: Persons who modify Brad™ products hardware and software

configuration and install the product updates supplied by the manufacturer. These persons must:

o be trained in Brad™ products and operation and

o have the experience and technical knowledge required to be aware of the risks (electrical

hazards in particular) involved in their job and the ways of reducing these risks for themselves,

third parties and the equipment being used.

Preventive messages

Preventive messages are designed to identify the particular risks likely to affect personnel and/or hardware.

Different message types, both in the documentation and on the products, indicate different degrees of risk:

Danger messages indicate immediate hazards that could result in death or serious injury if not averted.

Warning messages indicate situations that could result in death, serious injury or material damage.

Caution messages indicate potentially dangerous situations that could cause bodily harm or material damage.

Usage compliance

The products described in the current documentation comply with currently applicable European

Directives (EC labeling). However, they can only operate correctly with the applications for which they were

Page 7

HarshIO 600 eIP

7 IP67 Digital I/O Modules for EtherNet/IP

intended as described in the documentation, and with approved products.

As a general rule, if all the handling, transportation, and storage recommendations and installation, operation

and maintenance instructions are followed, the products will operate correctly without risk for personnel or

hardware.

Device installation and set-up

It is important to follow the rules below when installing and setting up the Brad™ HarshIO. If system installation

includes products more than thirty meters away from each other, the basic cabling rules must be closely

followed.

• Strict compliance with the safety instructions provided in this documentation or on the equipment to be

installed and implemented, is absolutely essential.

• Make sure that the installation is carried out in compliance with regulations of the user country,

• Install the equipment in a suitable environment. As a closed equipment, the Brad™ HarshIO may be

installed in two ways:

o In a casing (cabinet, chest) or,

o Directly without any additional protection, if the associated systems (power supply, cables,

sensors, etc.) already carry a protection index equivalent to IP67 or higher.

Always connect the Brad™ HarshIO to the protective earth (PE) in compliance with existing standards

(for example: use the green/yellow wires in accordance with the NFC 15 100 standard).

• LV (Low Voltage) circuits must have a protective earth connection to ensure dangerous voltage

detection.

• Before powering up the device, check that the nominal voltage is the same as the mains voltage.

• Only use FELV (Functional Extra Low Voltage) power supplies which comply with existing standards.

• Check that the power voltages are within the tolerance ranges defined in the technical specifications

for the devices.

• Always ensure that power restoration (immediate, hot or cold) will not create a hazard for personnel or

equipment.

• Ensure that emergency stop devices remain effective in any equipment operation mode, even when

abnormal (for example, in the event of a cut wire). Resetting these devices should not result in

uncontrolled or undefined restarts.

• Position the signal cables so that the automation functions will not be disrupted by any capacitive,

inductive or electromagnetic influences, etc.

• Install the automation devices and their controlling devices so that they are protected against any

adverse incident.

• Adequate safety precautions must be applied to inputs and outputs to prevent the lack of signals from

causing undefined states in the automation devices.

Page 8

HarshIO 600 eIP

8 IP67 Digital I/O Modules for EtherNet/IP

Device operation

Because Brad™ HarshIO devices are components of a control system, the safety of the entire automated

system, including that of the installation and the application, cannot be dealt with in this document. For further

information, see IEC 1131-4, describing risk reduction measures for PLC users.

See the documentation of the specific products involved for more information on operation safety.

Electrical, mechanical and thermal specifications

Detailed information about the electrical, mechanical and thermal specifications of the device is available in the

associated technical documentation (installation manuals, service instructions).

Preventive and corrective maintenance

Servicing

• When replacing parts or components, only use factory approved parts.

• In all cases, before servicing a Brad™ HarshIO, disconnect the power supply from the device

(unplug the power cord or open the power cut-out device).

• Before servicing an onsite mechanical Brad™ HarshIO, disconnect its power supply and

mechanically lock the moving parts.

• On positive logic outputs or negative logic inputs, take all the necessary precautions to prevent

any disconnected wires from coming into contact with the mechanical ground (risk of unwanted

commands).

Product end-of-life

Contact your local dealer for information on how to dispose of used products in compliance with

current regulations.

Page 9

HarshIO 600 eIP

9 IP67 Digital I/O Modules for EtherNet/IP

2. General Description

Introduction

BradControl™ HarshIO eIP (EtherNet/IP) modules provide a reliable solution for connecting industrial

controllers to I/O devices in harsh duty environments. Contained in an IP67 rated housing, BradControl I/O

modules can be machine mounted and are able to withstand areas where liquids, dust or vibration may be

present. This makes them ideally suited for many applications including material handling equipment and

automated assembly machinery.

All BradControl™ HarshIO modules with Micro-Change® (M12)

ports accept both threaded cordsets and Molex Ultra-Lock™ system.

Ultra-Lock™ connection System! The fastest, easiest and most

secure connection ever designed. Ultra-Lock™ technology is designed

for higher performance and reliability. Discover how the push-to-lock

technology of the Ultra-Lock connection system can eliminate your

downtime, increase your productivity and lower your costs. More

information visit: www.molex.com .

BradControl™ HarshIO 600 includes advanced diagnostic features. Each module embeds visible LEDs

to provide for maintenance personnel the ability to easily determine I/O, module and network status. These

statuses are also available through the process data image or via extended slave diagnostics telegram.

BradControl™ HarshIO 600 main features include:

Module is housed in an IP67 rated enclosure that when properly installed—according to IEC

60529—provides protection against the ingress of dust, water

16x digital channels with up to 1ms I/O cycle time

Integrated 2-port unmanaged Ethernet switch with cross-over capability

Isolated grounding to able to use 2 separate power supplies to power the module logic/input

ground and the module output ground for safety application

Digital input and output short circuit protection

Quick Connect feature to power up and run the HarshIO module in less than 500ms for robotic

application where I/O are control on a tool changer

BradControl™ HarshIO 600 is available in various combinations:

16x Inputs

16x Outputs

8x Inputs + 8x Outputs

12x Inputs + 4x Outputs

Whatever the combination, the digital inputs and outputs are always PNP.

Page 10

HarshIO 600 eIP

10 IP67 Digital I/O Modules for EtherNet/IP

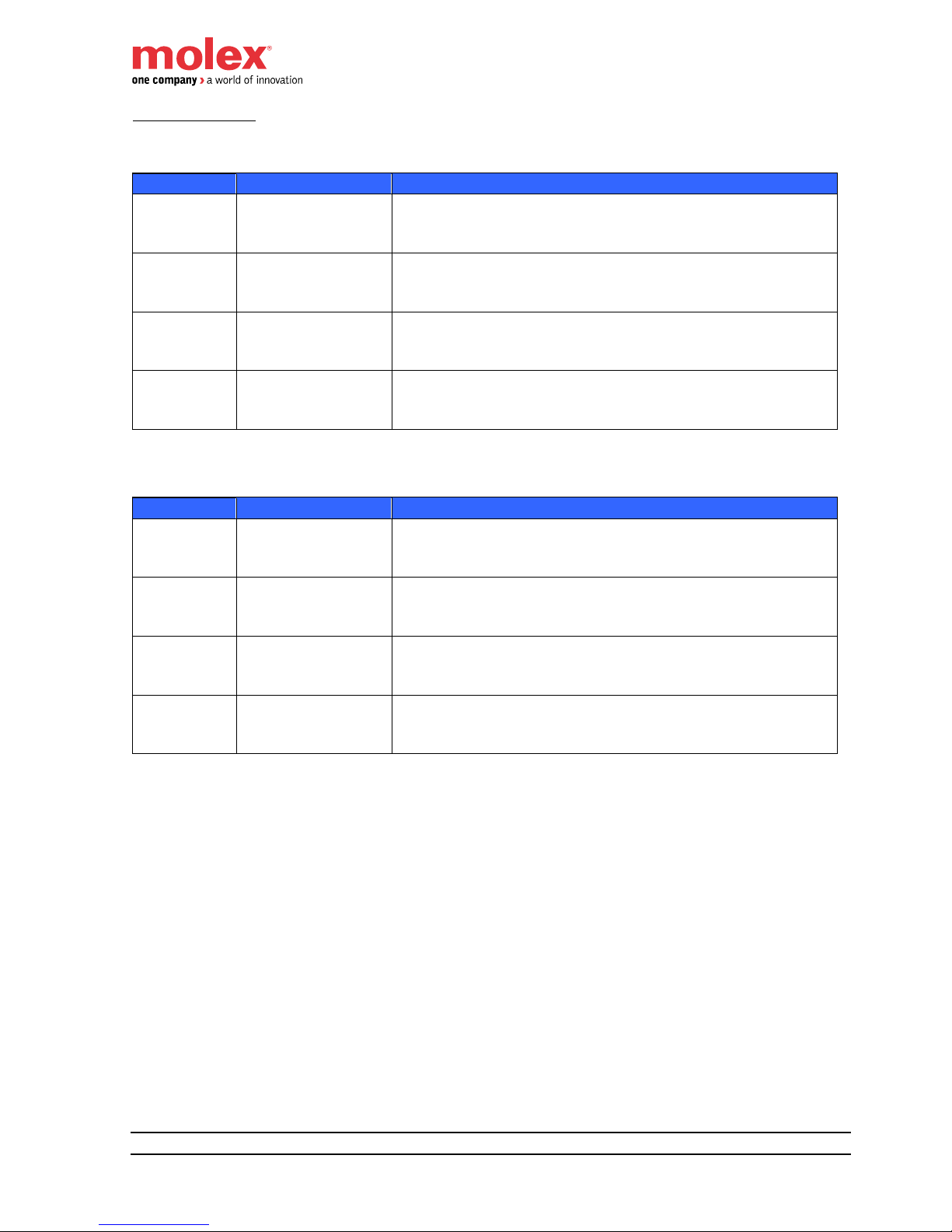

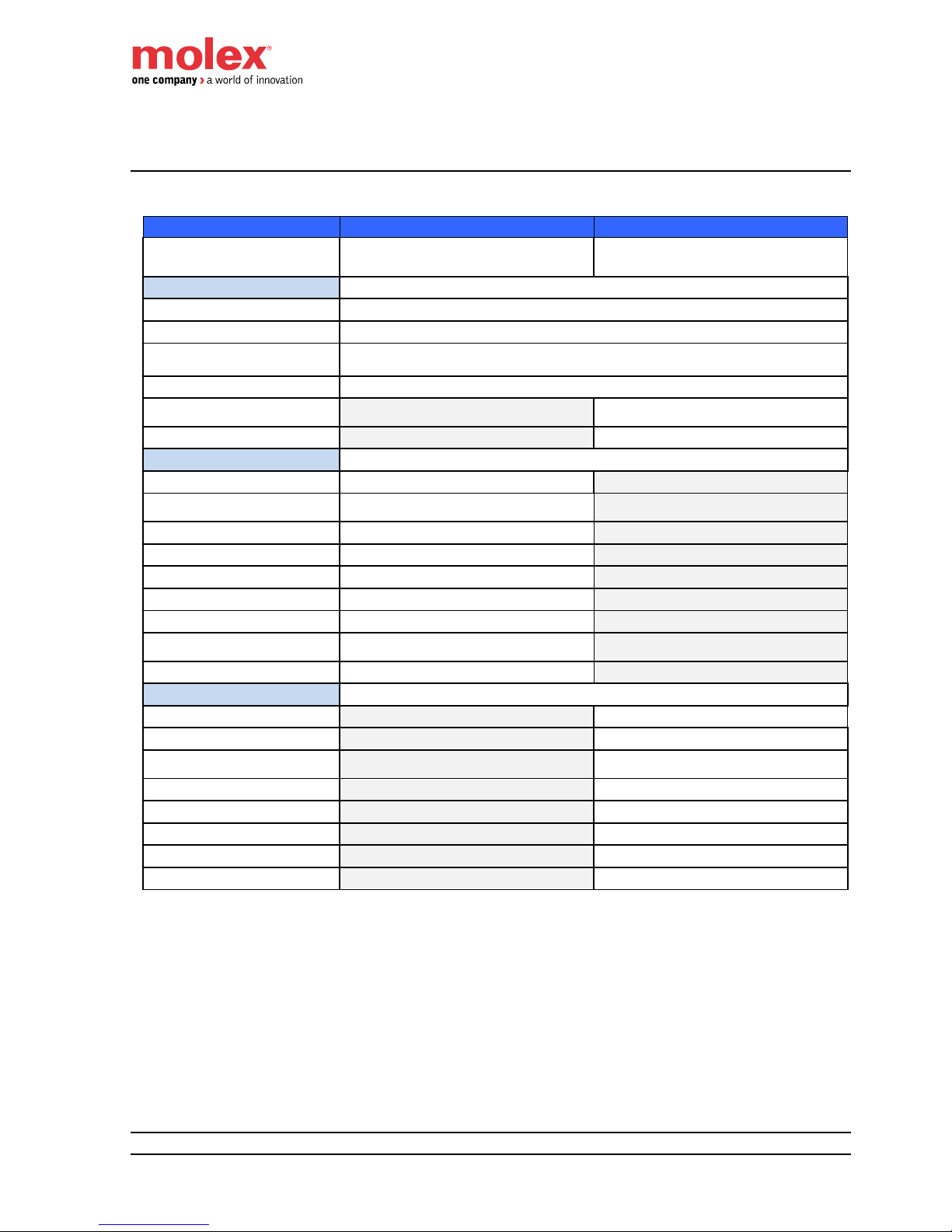

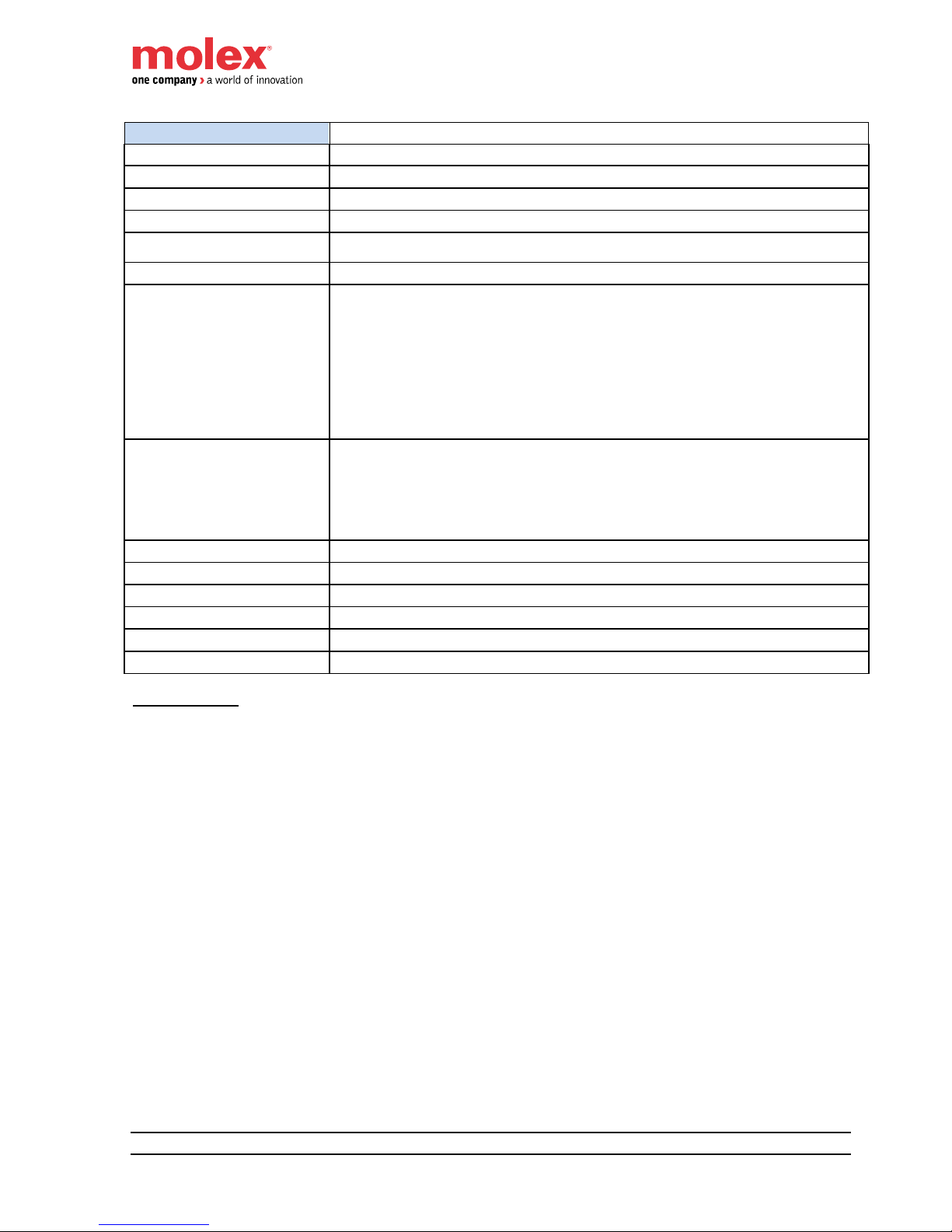

Part Number Table

4-pin power connector versions

SAP No

Material No

Description

112095-5040

TCDEI-8D0P-DYU-G

IP67 module for EtherNet/IP, 4-pin power supply connector,

16 PNP Inputs, Isolated grounding and QuickConnect

112095-5041

TCDEI-888P-DYU-G

IP67 module for EtherNet/IP, 4-pin power supply connector,

8 PNP Inputs + 8 Outputs, Isolated grounding and QuickConnect

112095-5043

TCDEI-8B4P-DYU-G

IP67 module for EtherNet/IP, 4-pin power supply connector,

12 PNP Inputs + 4 Outputs, Isolated grounding and QuickConnect

112095-5042

TCDEI-80DP-DYU-G

IP67 module for EtherNet/IP, 4-pin power supply connector,

16 Outputs, Isolated grounding and QuickConnect

5-pin power connector versions

SAP No

Material No

Description

112095-5060

TCDEI-8D0P-D1U-G

IP67 module for EtherNet/IP, 5-pin power supply connector,

16 PNP Inputs, Isolated grounding and QuickConnect

112095-5061

TCDEI-888P-D1U-G

IP67 module for EtherNet/IP, 5-pin power supply connector,

8 PNP Inputs + 8 Outputs, Isolated grounding and QuickConnect

112095-5063

TCDEI-8B4P-D1U-G

IP67 module for EtherNet/IP, 5-pin power supply connector,

12 PNP Inputs + 4 Outputs, Isolated grounding and QuickConnect

112095-5062

TCDEI-80DP-D1U-G

IP67 module for EtherNet/IP, 5-pin power supply connector,

16 Outputs, Isolated grounding and QuickConnect

Page 11

HarshIO 600 eIP

11 IP67 Digital I/O Modules for EtherNet/IP

3. System Description

Overview

HarshIO eIP modules can be used with a protocol compliant scanner as part of control system

architecture. The modules’ built-in unmanaged 2-port Ethernet switch allows you to use the network topology

that meets your application needs. These topologies include the following:

star

daisy-chain

combination of star and daisy-chain

Star topology

Star topology allows you to connect mixed I/O modules or additional equipments. Performing

maintenance on one module – for example, by removing the network cable, or by cycling power to the

module – does not affect other modules.

Page 12

HarshIO 600 eIP

12 IP67 Digital I/O Modules for EtherNet/IP

Daisy-chain topology

You can create a daisy-chain topology by using the module’s embedded switch ports to connect a series

of up to 8 HarshIO eIP modules.

NOTE: When considering the daisy chain topology, note that:

Performing maintenance on any module not physically located at the end of the daisy chain –

for example, by removing the network cable, or by cycling power to the module – affects any

modules located down the chain from the maintained module.

The embedded dual port Ethernet switch located in each module eliminates the need for

additional Ethernet switches.

Page 13

HarshIO 600 eIP

13 IP67 Digital I/O Modules for EtherNet/IP

Combination of star and daisy-chain topology

Combining star and daisy-chain topology allows you to connect HarshIO eIP modules with mixed

HarshIO modules or additional equipments.

Page 14

HarshIO 600 eIP

14 IP67 Digital I/O Modules for EtherNet/IP

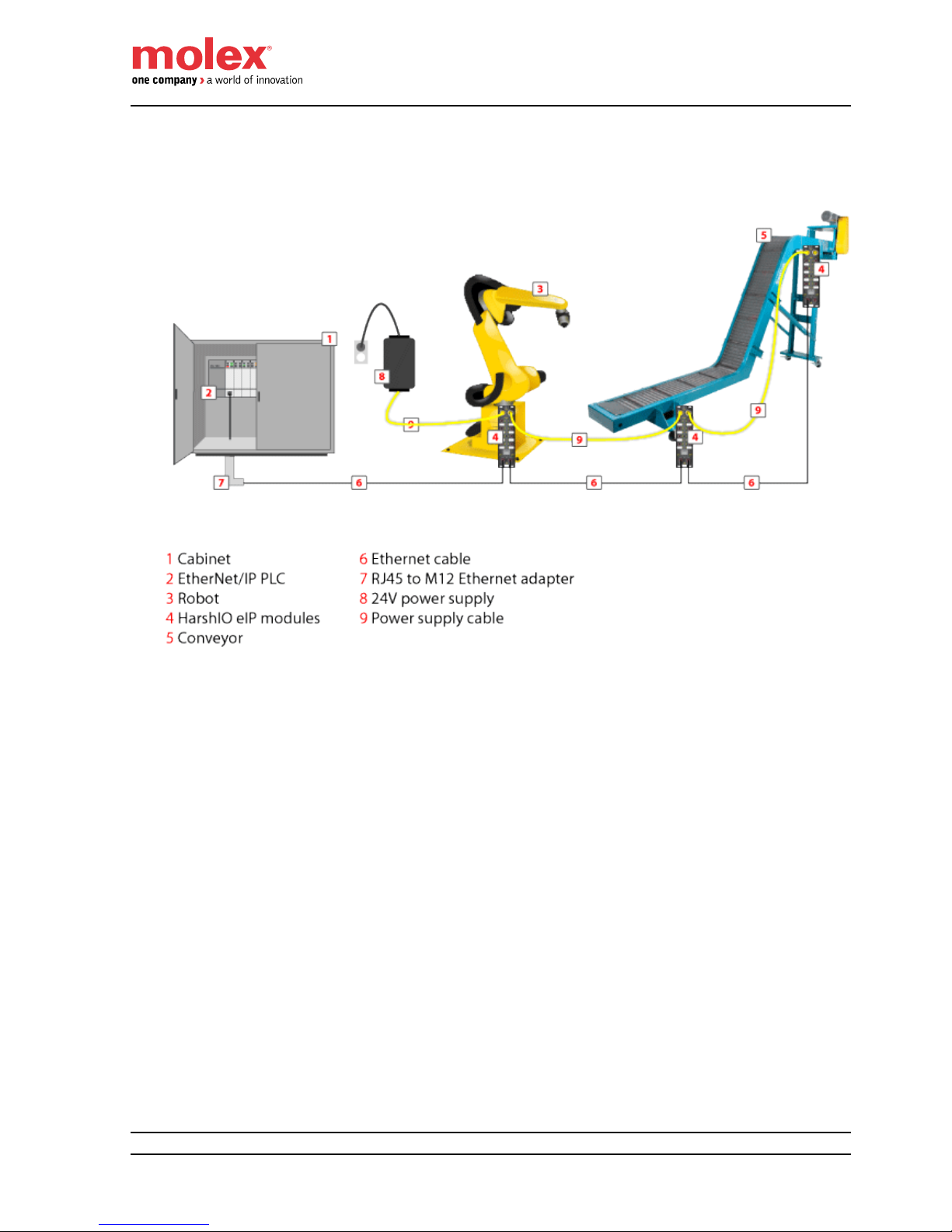

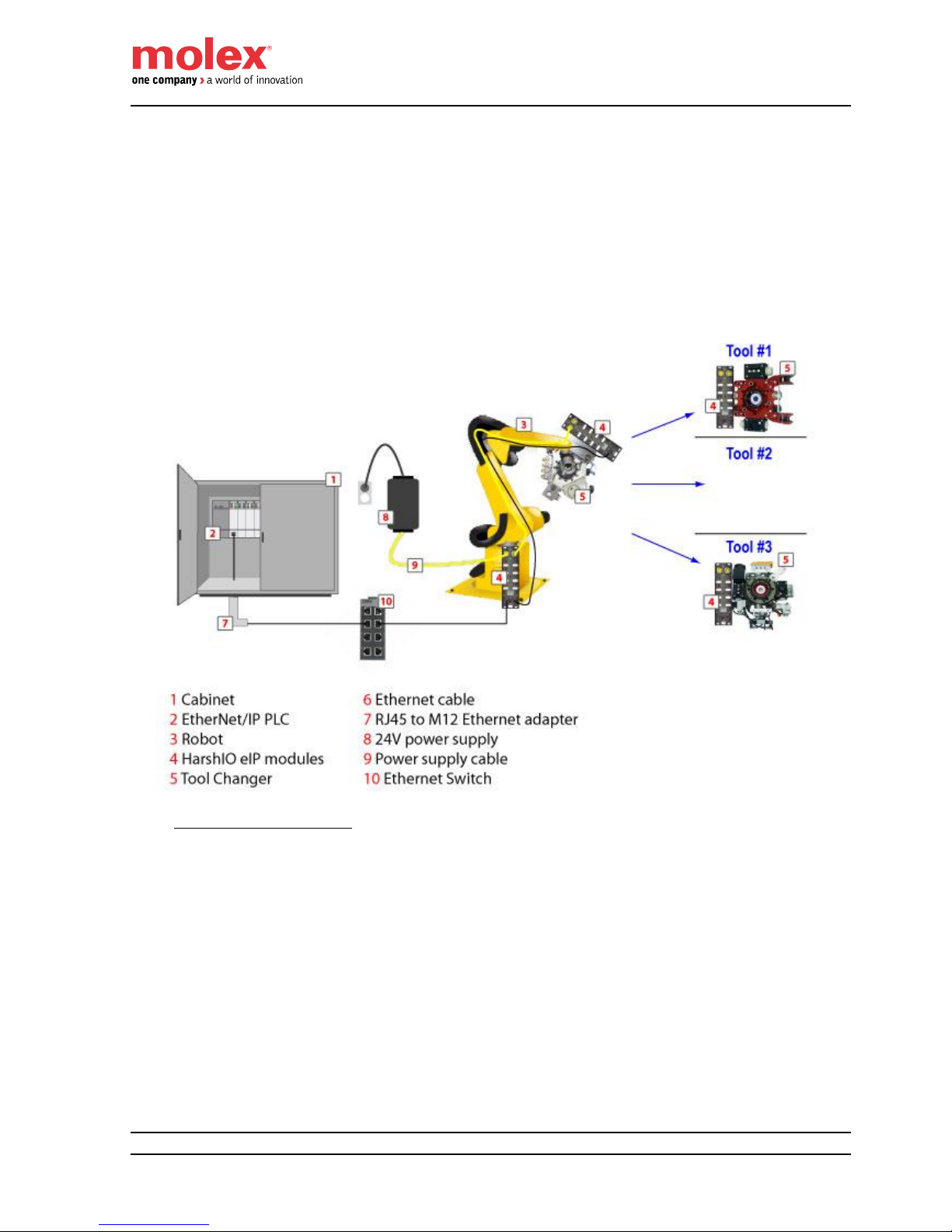

Typical application

This diagram shows you an example of a typical application using in-cabinet PLC controlling HarshIO

eIP modules mount on various industrial systems.

Page 15

HarshIO 600 eIP

15 IP67 Digital I/O Modules for EtherNet/IP

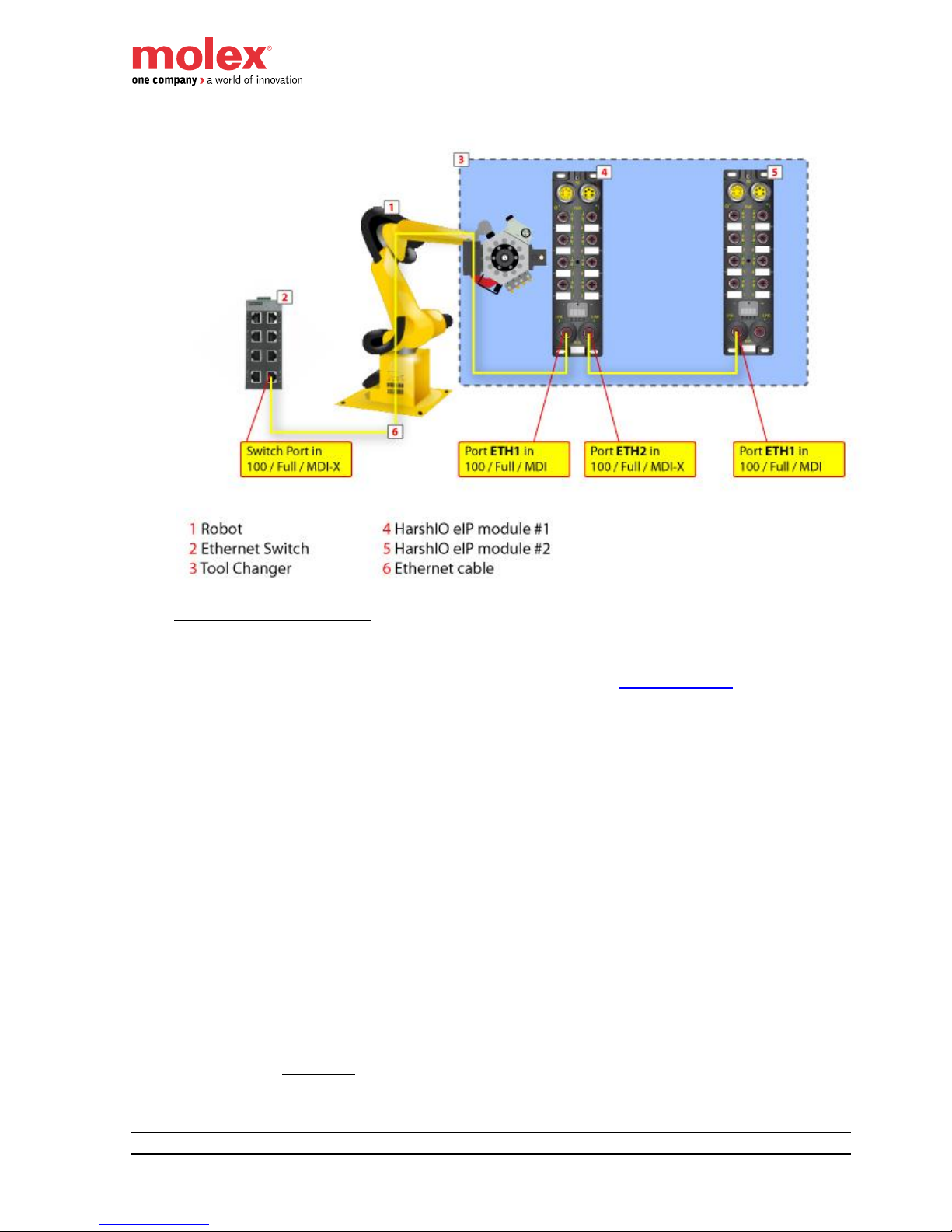

Quick Connect applications

The HarshIO eIP modules are designed to support the new Quick Connect feature according the

ODVA specifications which allow to power up, connect an EtherNet/IP scanner and start I/O cyclic data

exchange in less than 500 msec.

The Quick Connect feature is typically used in robotic application where some I/O devices are mounted

on a tool changer. The robot can disconnect and reconnect on the fly a new tool without stopping the

manufacturing process.

The diagram shows you an example of a robotic application using Quick Connect feature.

Quick Connect Architecture

When Quick Connect feature is used, the following recommendations should apply:

The Quick Connect device Ethernet switch ports must be configured with fixed speed to

100Mbps and full duplex enabled (auto negotiation is prohibited).

The Ethernet cable mounted on the robot must be connected to the ETH1 port (MDI port) of the

HarshIO eIP module. Quick Connect devices shall not use Auto-MDIX (detection of the required

cable connection type). This detection may take more time than the allowed Quick Connect

system connection time (see diagram below).

The maximum number of Quick Connect HarshIO eIP modules connected using daisy-chain

topology on the robot tool changer is recommended to be less or equal to 8. This limit can be

reduced depending of the Quick Connect performance supported by the EtherNet/IP controller.

Page 16

HarshIO 600 eIP

16 IP67 Digital I/O Modules for EtherNet/IP

Enabling Quick Connect mode

The HarshIO eIP modules can be configured for Quick Connect mode according the 2 methods:

1. Set Byte 9, Bit 0 of the configuration assembly (see chapter I/O Data Mapping).

- a value of “0” automatically

o disables Quick Connect

o sets ETH1 and ETH2 Ethernet ports to autonegociation and Auto-MDIX

- a value of “1” automatically

o enables Quick Connect

o sets ETH1 port to 100 Full Duplex MDI

o sets ETH2 port to 100 Full Duplex MDIX

2. Set Attribute 12 of CIP TCP/IP object (0xF5) using Explicit Messaging

- a value of “0” automatically

o disables Quick Connect

o sets ETH1 and ETH2 Ethernet ports to Auto-MDIX

- a value of “1” automatically

o enables Quick Connect

o sets ETH1 port to MDI

o sets ETH2 port to MDIX

Remember: Don’t forget also to force the ETH1/ETH2 ports speed to 100 Full Duplex

by setting to 1 the Attribute 6 of CIP Ethernet Link object (0xF6).

Page 17

HarshIO 600 eIP

17 IP67 Digital I/O Modules for EtherNet/IP

Caution: If method 2 is used, don’t forget to set to “0” the Configuration Assembly data

size (see chapter I/O Data Mapping) to avoid overwriting the Quick Connect Attribute

during the I/O connection with the EtherNet/IP scanner (Forward Open request).

Note: After each change of Quick Connect mode (means enable disable), the HarshIO module stores

the new requested mode in its non-volatile memory. The module behaves in this mode until the next

modification.

Note: The modification of a Quick Connect mode is applied after the next power supply cycling of the

module or by sending a Reset command (CIP object 0x01, Instance 1 Service 5).

Page 18

HarshIO 600 eIP

18 IP67 Digital I/O Modules for EtherNet/IP

4. Module Characteristics

Hardware characteristics

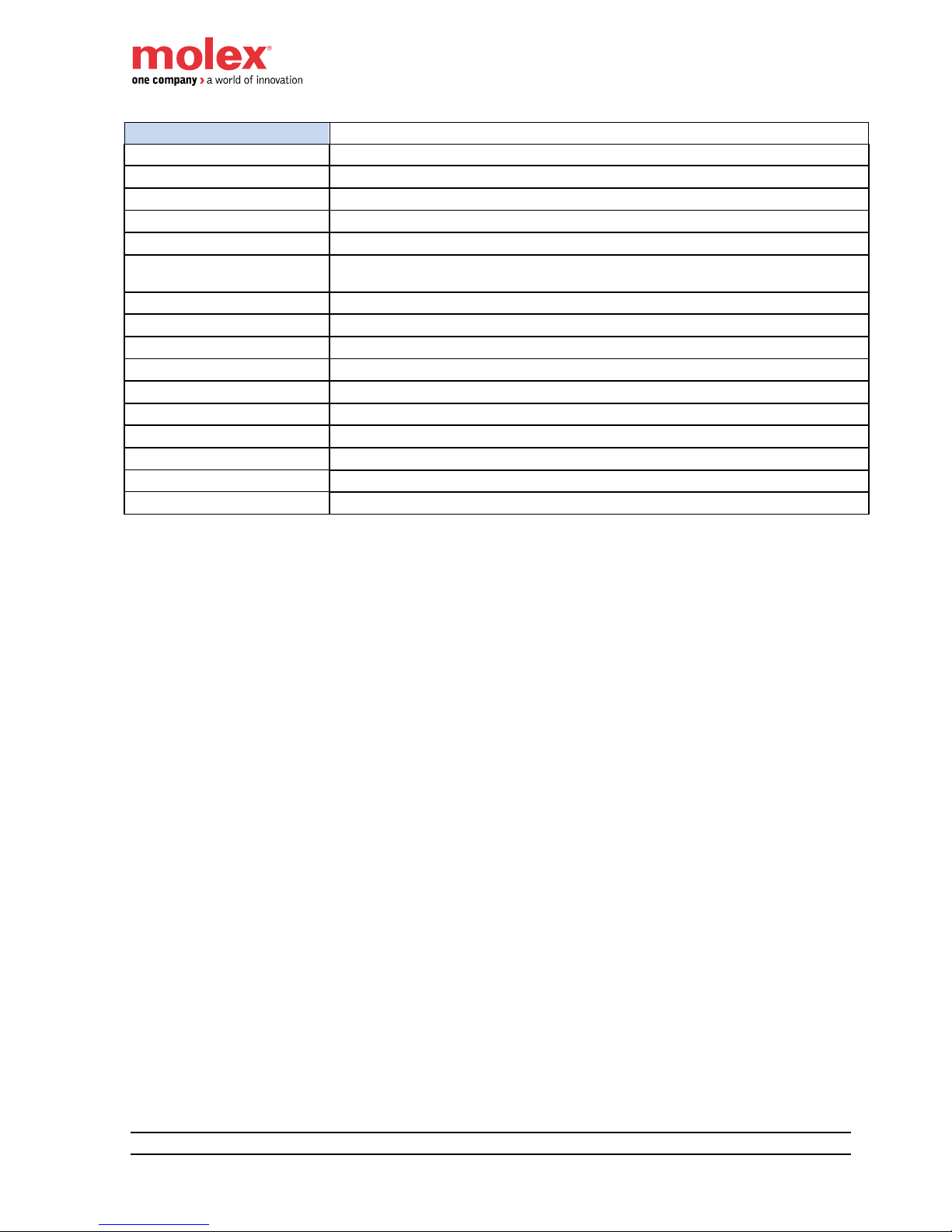

Type

16x INPUTS

16x OUTPUTS

Product Reference

TCDEI-8D0P-DYU-G (4-pin power version)

TCDEI-8D0P-D1U-G (5-pin power version)

TCDEI-80DP-DYU-G (4-pin power version)

TCDEI-80DP-D1U-G (5-pin power version)

Power Power IN connector

Mini Change (7/8”), 4-pin or 5-pin, male, stainless steel, Maximum 8 A

Power OUT connector

Mini Change (7/8”), 4-pin or 5-pin, female, stainless steel, Maximum 8 A

Module & Input power (UB)

24 VDC, -15/+20% (protected against power crossing).

Warning, a voltage over 30 VDC will destroy the module

Operating current (UB)

68 mA

Output power (UL)

Not Applicable

24 VDC, -15/+20%

(protected against power crossing)

Operating current (UL)

Not Applicable

10 mA (without load)

Inputs

Channels

16 channels, 2 or 3-wire

Not Applicable

Connector

M12 Ultra-Lock, 5-pin, female, A-Coded,

stainless steel

Not Applicable

Input type

PNP, Sinking

Not Applicable

Input voltage

UB

Not Applicable

Sensor power supply

140 mA at 25°C

Not Applicable

Input channel voltage (“1”)

10V … 30V

Not Applicable

Input channel voltage (“0”)

-0.2V … 5V

Not Applicable

Input short circuit

protection (per port)

600mA

Not Applicable

Input filter

1 … 5 ms (5 ms by default)

Not Applicable

Outputs

Channels

Not Applicable

16 channels, 2-wire

Output voltage

Not Applicable

UL -1 VDC

Connector

Not Applicable

M12 Ultra-Lock, 5-pin, female, A-Coded,

stainless steel

Output type

Not Applicable

PNP, Sourcing

Output current

Not Applicable

2 A per channel

Maximum output current

Not Applicable

8.0 A at 25°C ; total for all outputs combined

Short circuit current (typical)

Not Applicable

up to 6.5 A

Switching frequency

Not Applicable

200 Hz

Page 19

HarshIO 600 eIP

19 IP67 Digital I/O Modules for EtherNet/IP

Type

12x INPUTS + 4x OUTPUTS

8x INPUTS + 8x OUTPUTS

Product Reference

TCDEI-8B4P-DYU-G (4-pin power version)

TCDEI-8B4P-D1U-G (5-pin power version)

TCDEI-888P-DYU-G (4-pin power version)

TCDEI-888P-D1U-G (5-pin power version)

Power

Power IN connector

Mini Change (7/8”), 4-pin or 5-pin, male, stainless steel, Maximum 8 A

Power OUT connector

Mini Change (7/8”), 4-pin or 5-pin, female, stainless steel, Maximum 8 A

Module & Input power (UB)

24 VDC, -15/+20% (protected against power crossing)

Warning, a voltage over 30 VDC will destroy the module

Operating current (UB)

68 mA

Output power (UL)

24 VDC, -15/+20% (protected against power crossing)

Operating current (UL)

10 mA (without load)

Inputs

Channels

12 channels, 2 or 3-wire

8 channels, 2 or 3-wire

Connector

M12 Ultra-Lock, 5-pin, female, A-Coded, stainless steel

Input type

PNP, Sinking

Input voltage

UB

Sensor power supply

140 mA at 25°C

Input channel voltage (“1”)

10V … 30V

Input channel voltage (“0”)

-0.2V … 5V

Input short circuit

protection (per port)

600mA

Input filter

1 … 5 ms (5 ms by default)

Outputs

Channels

4 channels, 2-wire

8 channels, 2-wire

Output voltage

UL -1 VDC

Connector

M12 Ultra-Lock, 5-pin, female, A-Coded, stainless steel

Output type

PNP, Sourcing

Output current

2 A per channel

Maximum output current

8.0 A at 25°C ; total for all outputs combined

Short circuit current (typical)

up to 6.5 A

Switching frequency

200 Hz

Page 20

HarshIO 600 eIP

20 IP67 Digital I/O Modules for EtherNet/IP

Fieldbus Ethernet connectors

M12, 4-pin, female, D-Coded, stainless steel, shielded

IP setting

DHCP based on MAC (infinite lease), Static IP

Protocol

EtherNet/IP Adapter according specification Vol 1-3.9 (CIP) and Vol 2 – 1.10 (EtherNet/IP)

Data access

Implicit messages for I/O data transfer

Implicit (I/O) connection

1x Exclusive Owner (EO) connection (with or without configuration data)

Up to 7 Listen Only (LO) or Input Only (IO) connections (with or without configuration data)

Explicit (EM) connection

Up to 8

Supported CIP Objects

0x01 – Identity object

0x02 – Message Router object

0x04 – Assembly object

o 103: TO (Input process data)

o 104: OT (Output process data)

o 106: Configuration

o 198: OT Heartbeat (Input Only)

o 199: OT Heartbeat (Listen Only)

0x06 – Connection Manager object

0xF5 – TCP/IP Interface object

0xF6 – Ethernet Link object

Integrated Switch

2x ports integrated switch

Speed: 10/100Mbps

Auto negotiation

Auto crossing

Auto polarity

1x status Led / port

Storm Protection against network loop (Broadcast, Multicast and Unicast packets)

Daisy Chain (Ethernet)

Up to 8 HarshIO

Ethernet Packet

Manage up to 9000 packet/sec

Request Packet Interval (RPI)

from 1 ms up to 65535 ms (default 30 ms)

IP Address Conflict Detection

Yes (ACD supported)

Quick Connect

Yes (Class A)

ODVA conformance

Yes

Default IP setting:

IP address: DHCP

Subnet mask: DHCP

Gateway: DHCP

ETH1 port: Auto negotiation + Auto-MDI

ETH2 port: Auto negotiation + Auto-MDI

Quick Connect: Disabled

ACD Enabled

Page 21

HarshIO 600 eIP

21 IP67 Digital I/O Modules for EtherNet/IP

Mechanical

Housing dimension

600 x 220 x 20 mm (2.36"x8.66"x.780")

Housing material

PBT VALOX 420 SEO Black 7701

Flammability Standard

UL 94 V-0

Corner mounting hole

4 mounting holes, 5 x10 mm

Central mounting hole

1 mounting hole, 4.45 mm

Ground stud

Yes, stainless steel (allows the continuity of the ground when the module is mounted on the chassis

machine)

Operating temperature

-25°c … +70°c

Storage temperature

-40°c … +90°c

Vibration resistance

7G (15,7Hz to 500Hz), 3 axis

Shock resistance

15g, 11ms, 3 axis

Electro-magnetic compatibility

EN 61000-6-2 / EN 61000-6-4

Relative humidity

10 % to 95 %, non-condensing

Protection Class

IP67

Approval

CE (according IEC 61131-2), UL / cUL

Environmental

RoHS and REACH

MTBF

100 000 hours / 11 years at 70°C

Page 22

HarshIO 600 eIP

22 IP67 Digital I/O Modules for EtherNet/IP

Mechanical characteristics

Size and dimensions (in mm)

60,

0

220,0

20

,0

3

7,1

31

,5

38,

0

210,0

107

4,45

5x10

+

-

PE

Ui Uo

I 0

I 1

I 2

I 3

I 4

I 5

I 6

I 7

I 8

I 9

I 10

I 11

I 12

I 13

I 14

I 15

ETH1

LINK

ETH2

LINK

BUS

I

X

UL UB

Page 23

HarshIO 600 eIP

23 IP67 Digital I/O Modules for EtherNet/IP

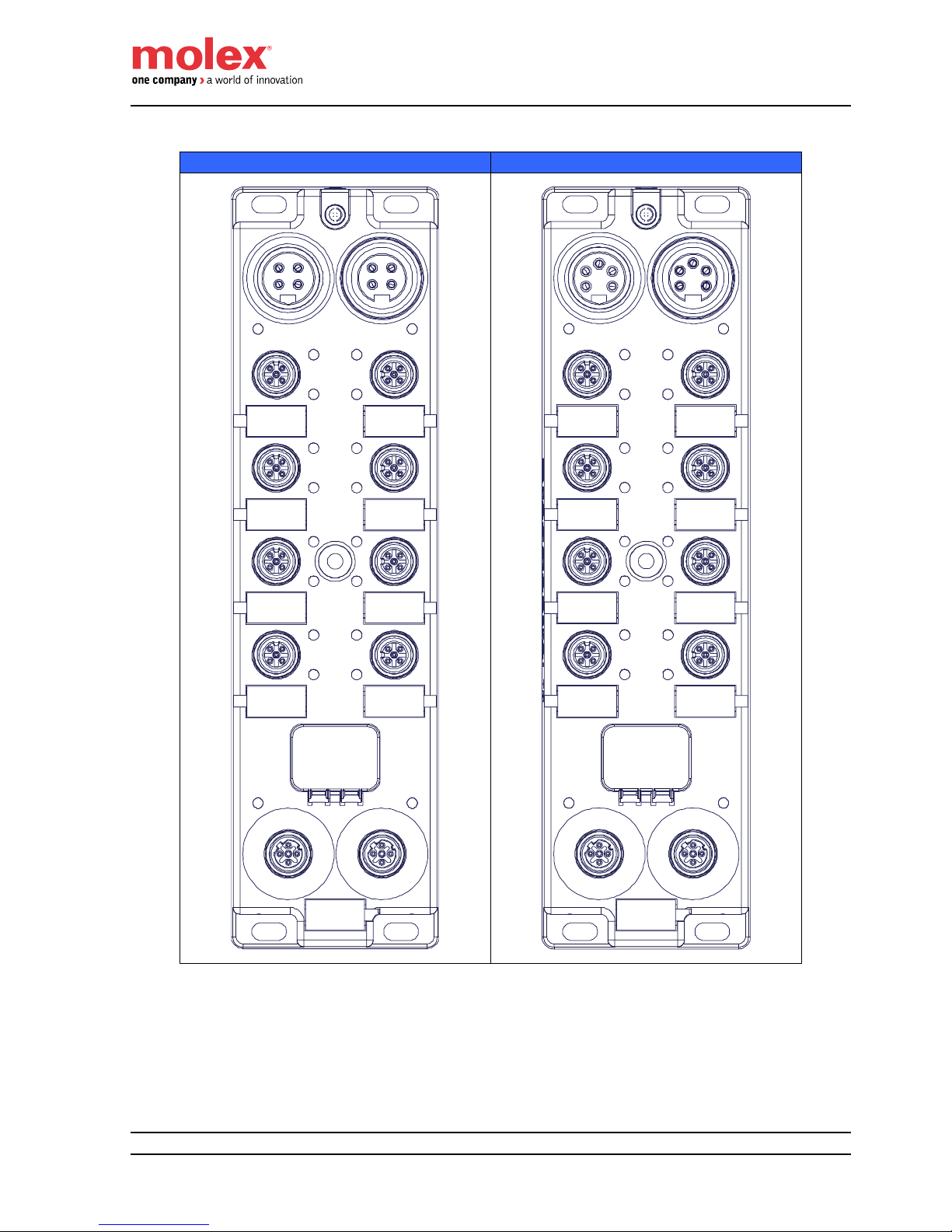

Physical I/O mapping

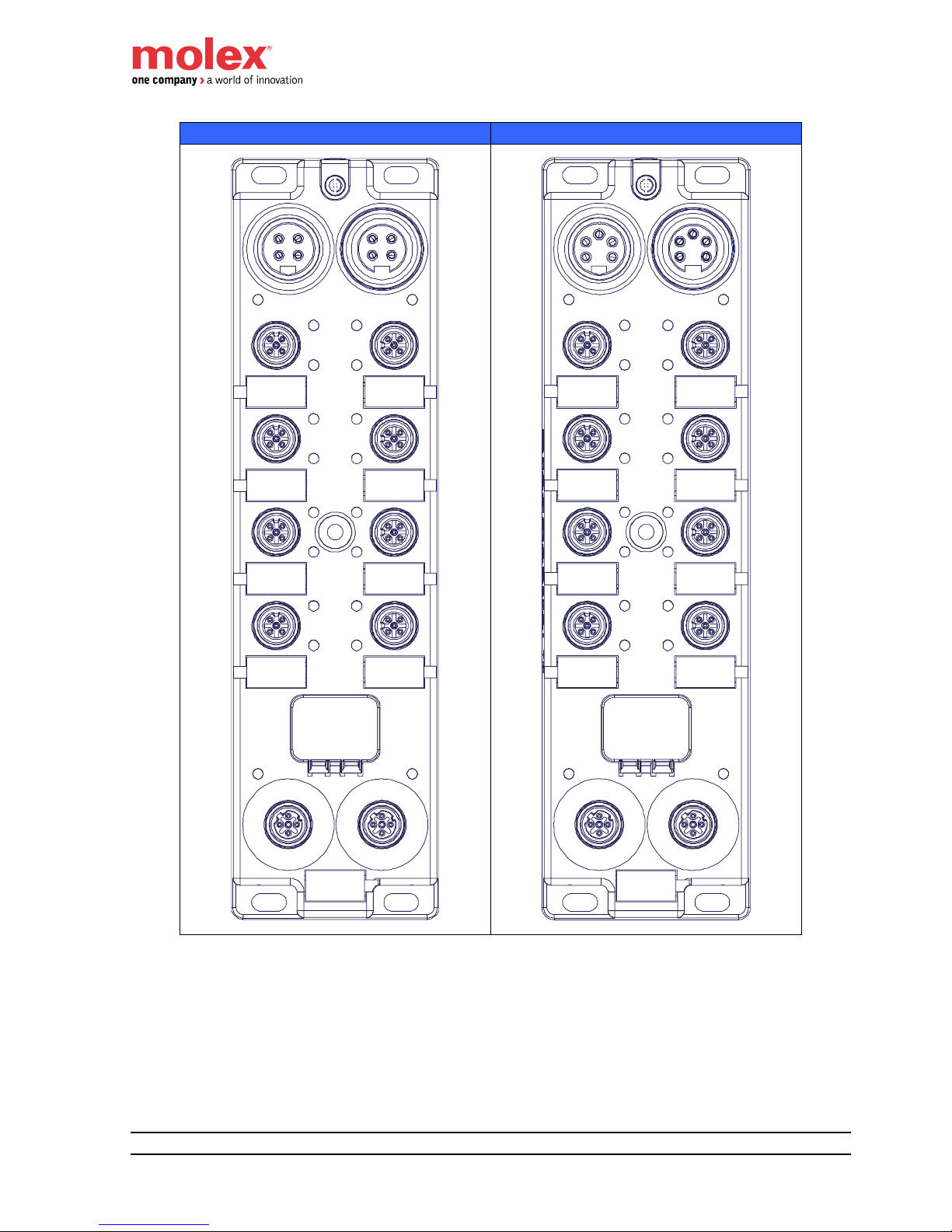

16x Inputs (4-pin power connector)

16x Inputs (5-pin power connector)

+

-

PE

Ui Uo

ETH1

LINK

ETH2

LINK

BUS

I

X

UL UB

I0

I1

I2

I3

I4

I5

I6

I7

I8

I9

I10

I11

I12

I13

I14

I15

+-

PE

Ui Uo

ETH1

LINK

ETH2

LINK

BUS

I X

UL UB

I0

I1

I2

I3

I4

I5

I6

I7

I8

I9

I10

I11

I12

I13

I14

I15

Page 24

HarshIO 600 eIP

24 IP67 Digital I/O Modules for EtherNet/IP

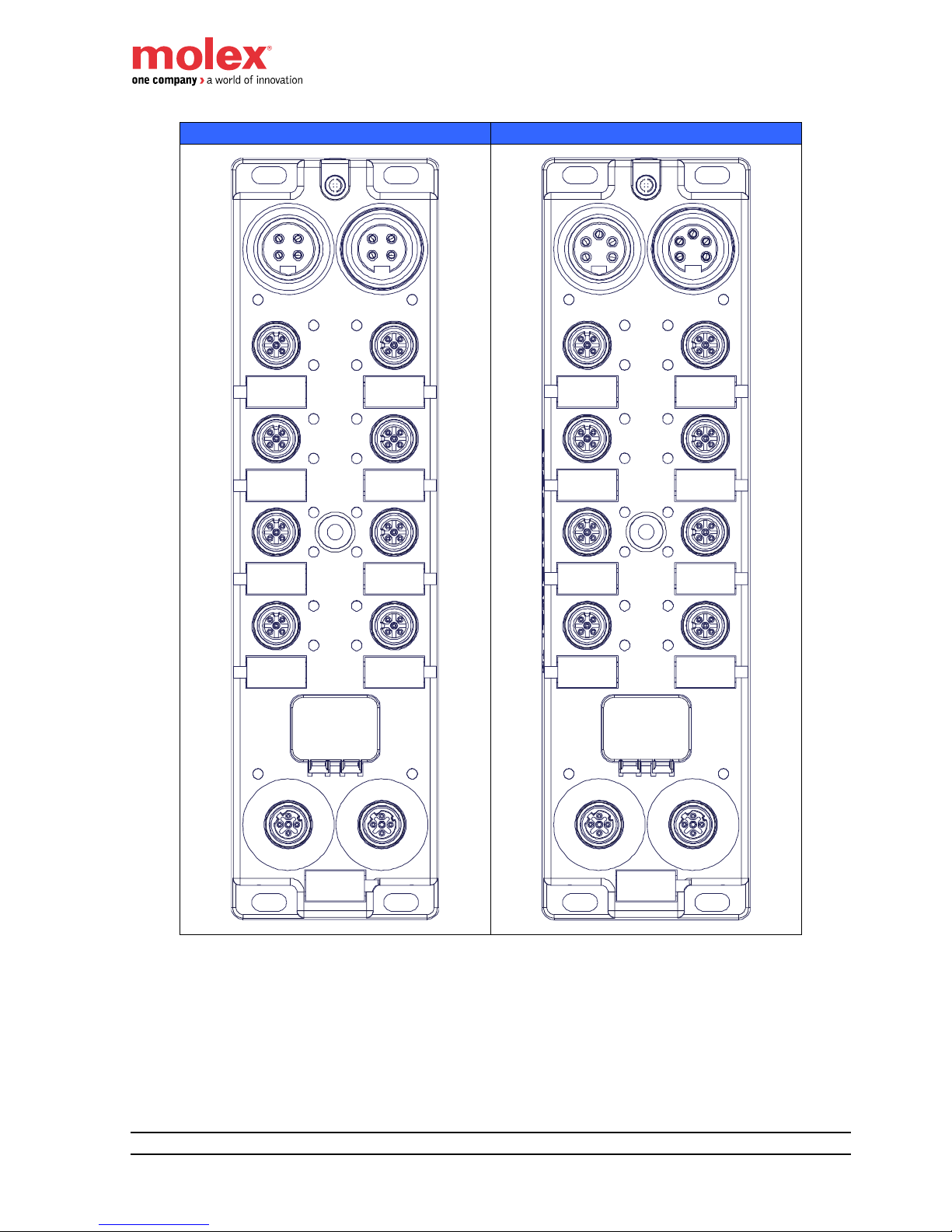

12x Inputs + 4x Outputs (4-pin power connector)

12x Inputs + 4x Outputs (5-pin power connector)

+

-

PE

Ui Uo

ETH1

LINK

ETH2

LINK

BUS

I

X

UL UB

I0

I1

I2

I

3

I4

I5

I6

I7

I8

I9

I10

I

11

O0

O1

O2

O3

+-

PE

Ui Uo

ETH1

LINK

ETH2

LINK

BUS

I X

UL UB

I0

I1

I2

I3

I4

I5

I6

I7

I8

I9

I10

I11

O0

O1

O2

O3

Page 25

HarshIO 600 eIP

25 IP67 Digital I/O Modules for EtherNet/IP

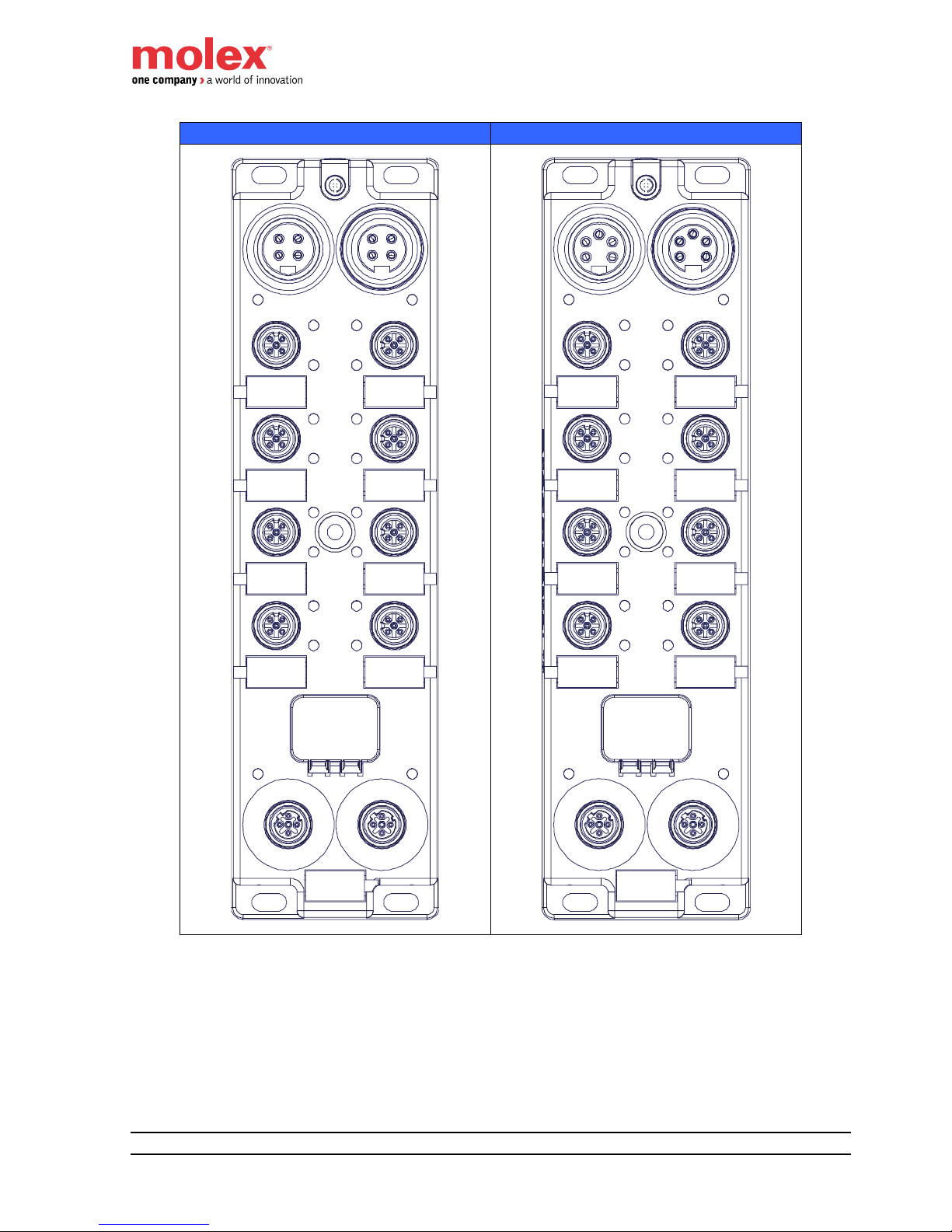

8x Inputs + 8x Outputs (4-pin power connector)

8x Inputs + 8x Outputs (5-pin power connector)

+

-

PE

Ui Uo

ETH1

LINK

ETH2

LINK

BUS

I

X

UL UB

I0

I1

I2

I3

I4

I5

I6

I7

O0

O1

O2

O3

O4

O5

O6

O7

+-

PE

Ui Uo

ETH1

LINK

ETH2

LINK

BUS

I X

UL UB

I0

I1

I2

I3

I4

I5

I6

I7

O0

O1

O2

O3

O4

O5

O6

O7

Page 26

HarshIO 600 eIP

26 IP67 Digital I/O Modules for EtherNet/IP

16x Outputs (4-pin power connector)

16x Outputs (5-pin power connector)

+

-

PE

Ui Uo

ETH1

LINK

ETH2

LINK

BUS

I

X

UL UB

O0

O1

O2

O3

O4

O5

O6

O7

O8

O9

O10

O11

O12

O13

O14

O15

+-

PE

Ui Uo

ETH1

LINK

ETH2

LINK

BUS

I X

UL UB

O0

O1

O2

O3

O4

O5

O6

O7

O8

O9

O10

O11

O12

O13

O14

O15

Page 27

HarshIO 600 eIP

27 IP67 Digital I/O Modules for EtherNet/IP

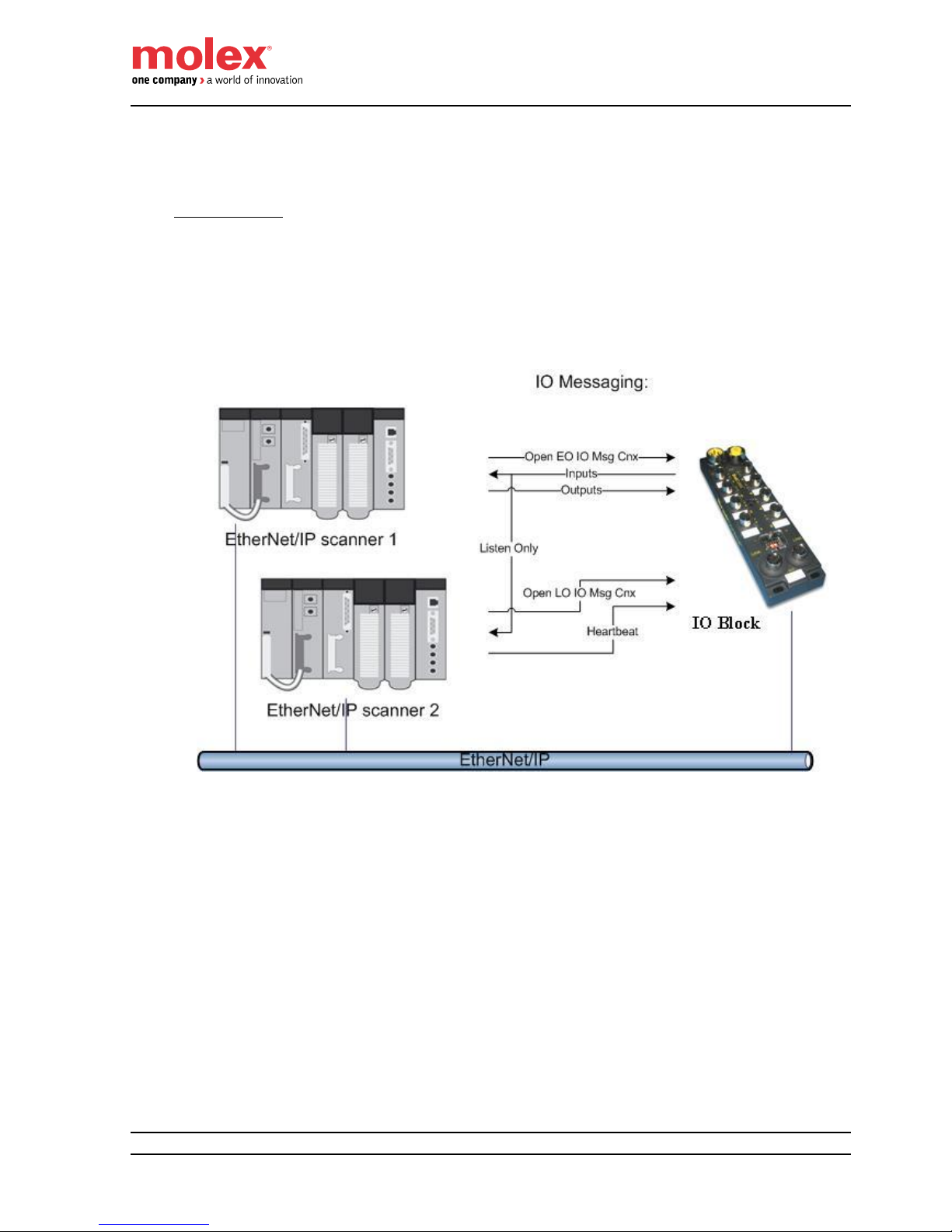

I/O messaging

The firmware embedded in the HarshIO 600 eIP supports up to a maximum of 8 I/O connections. Fewer

connections allow faster data I/O update rates (RPI value).

I/O Connections:

- Module supports 2 Transport Class 1 I/O connections (Cyclic and Change-Of-State triggers):

o 1x Exclusive Owner

Unicast and Multicast (TO) connection

Unicast (OT) connection

o 7x Listen Only or Input Only

Multicast (TO) connection

Page 28

HarshIO 600 eIP

28 IP67 Digital I/O Modules for EtherNet/IP

I/O data mapping

The I/O process data are available through the EtherNet/IP assemblies:

Assembly #103 for Input process data

Assembly #104 for Output process data

Assembly #106 for Configuration data

o Note: The data size can be set to “0” if the scanner doesn’t need to send Configuration data

at the establishment of the connection (Forward Open request).

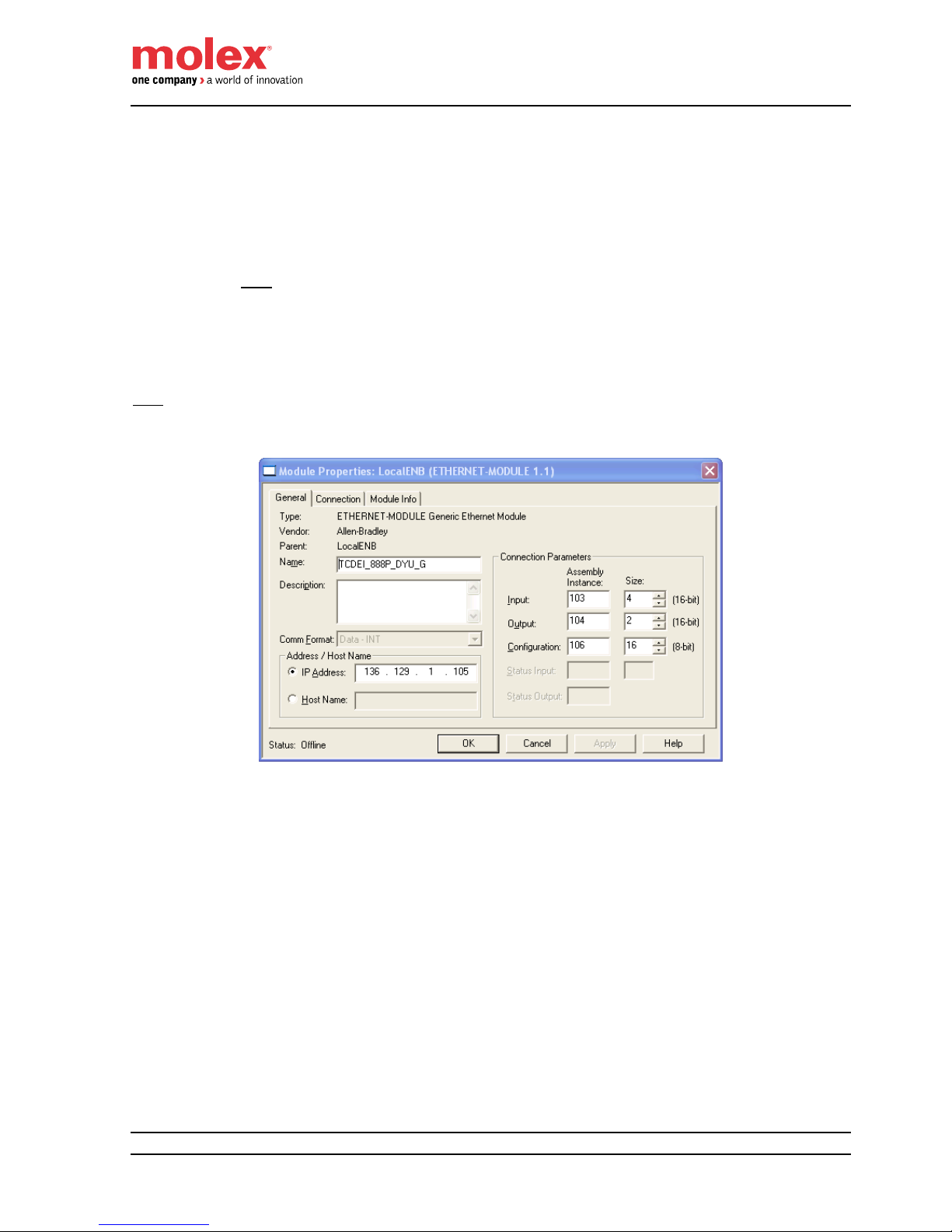

Note: If your controller configuration software doesn’t support the management of EDS files, you may have to

configure manually the assembly numbers to access the process data.

– Example of HarshIO 8in/8Out assembly configuration

in Rockwell Automation RSLogix 5000 –

Page 29

HarshIO 600 eIP

29 IP67 Digital I/O Modules for EtherNet/IP

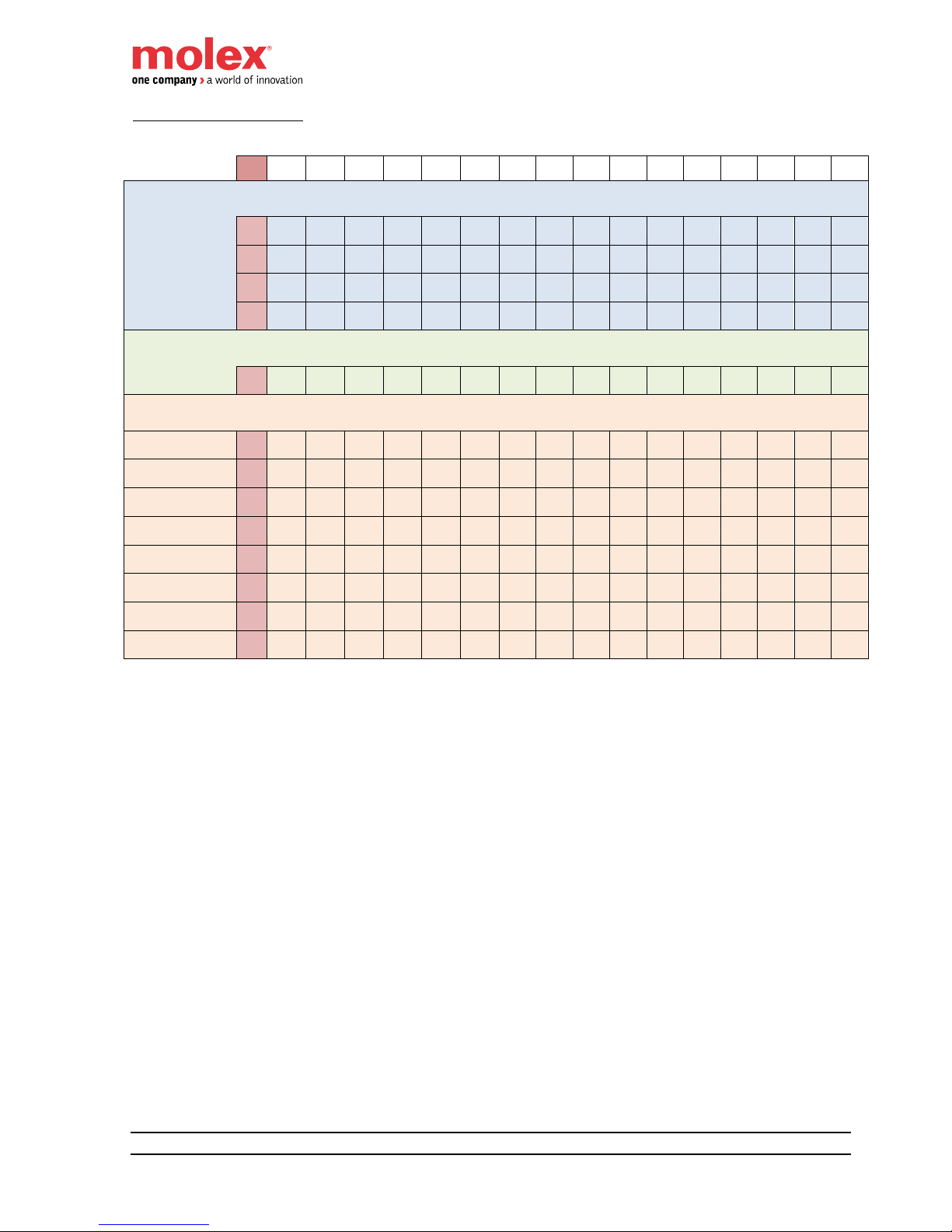

16 Inputs module versions

Byte

Offset

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Input Data (Assembly #103), Size: 8 bytes

Data

00

n/u

n/u

n/u

n/u

n/u

n/u

Diag

UB

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Input Data

02

I15

I14

I13

I12

I11

I10

I9

I8

I7

I6

I5

I4

I3

I2

I1

I0

Port Status

04

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Port Status

06

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

PS P7

PS P6

PS P5

PS P4

PS P3

PS P2

PS P1

PS P0

Output data (Assembly #104), Size: 2 bytes

Output Data

00

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Configuration (Assembly #106), Size: 16 bytes

Data

00

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

02

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

04

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

06

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

08

n/u

n/u

n/u

n/u

n/u

n/u

n/u

QC

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

10

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

12

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

14

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u: Not used

Ix: Input channel x

PS: Port Status (short circuit detected on a port driving Input channels)

QC: Quick Connect, 1 = Enable; 0 = Disable

Diag UB: Diagnostic Logic/Input power supply (UB)

Set to 1, if UB is < 14.1 VDC

o All Outputs activated are de-energized

o All Outputs activated have diagnostic leds to RED

o All Outputs activated have Port Status (CS Ox) bit set to 1

Set to 0, if UB is > 14.6 VDC

o All Outputs activated are energized

o All Outputs activated have diagnostic leds to GREEN

o All Outputs activated have Port Status (CS Ox) bit set to 0

Page 30

HarshIO 600 eIP

30 IP67 Digital I/O Modules for EtherNet/IP

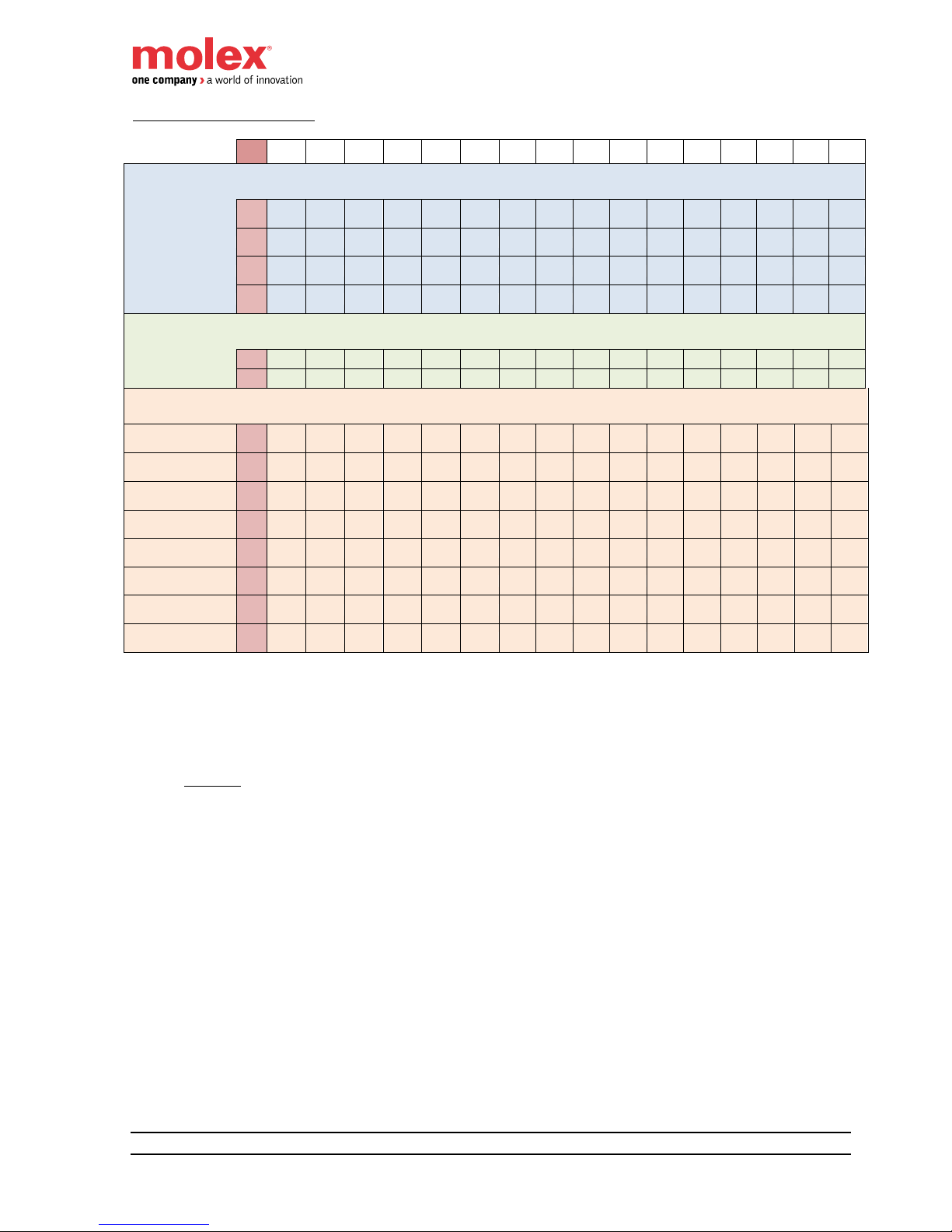

16 Outputs module versions

Byte

Offset

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Input Data (Assembly #103), Size: 8 bytes

Data

00

n/u

n/u

n/u

n/u

n/u

n/u

Diag

UB

n/u

Diag

UL

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Input Data

02

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Port Status

04

CS O7

CS O6

CS O5

CS O4

CS O3

CS O2

CS O1

CS O0

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Port Status

06

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

CS

O15

CS

O14

CS

O13

CS

O12

CS

O11

CS

O10

CS

O9

CS

O8

Output data (Assembly #104), Size: 4 bytes

00

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Output Data

02

O15

O14

O13

O12

O11

O10

O9

O8

O7

O6

O5

O4

O3

O2

O1

O0

Configuration (Assembly #106), Size: 16 bytes

Data

00

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

02

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

04

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

06

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

08

n/u

n/u

n/u

n/u

n/u

n/u

n/u

QC

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

10

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

12

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

14

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u: Not used

CS: Channel status (short circuit on Output channel or impossible to drive the Output)

If output power supply (UL) is down, output channel status (CS) is set for the corresponding activated

output channels. The module display shows the message:”IO: ERR”.

Example: if the output “O3” is active and UL goes down, the “CS O3” status bit is set to 1.

Ox: Output channel x

QC: Quick Connect, 1 = Enable; 0 = Disable

Diag UB: Diagnostic Logic/Input power supply (UB)

Set to 1, if UB is < 14.1 VDC

o All Outputs activated are de-energized

o All Outputs activated have diagnostic leds to RED

o All Outputs activated have Port Status (CS Ox) bit set to 1

Set to 0, if UB is > 14.6 VDC

o All Outputs activated are energized

o All Outputs activated have diagnostic leds to GREEN

o All Outputs activated have Port Status (CS Ox) bit set to 0

Diag UL: Diagnostic Output power supply (UL)

Set to 1, if UL is < 17.6 VDC

o All Outputs activated are de-energized

o All Outputs activated have diagnostic leds to RED

Page 31

HarshIO 600 eIP

31 IP67 Digital I/O Modules for EtherNet/IP

o All Outputs activated have Port Status (CS Ox) bit set to 1

Set to 0, if UL is > 18.1 VDC

o All Outputs activated are energized

o All Outputs activated have diagnostic leds to GREEN

o All Outputs activated have Port Status (CS Ox) bit set to 0

Page 32

HarshIO 600 eIP

32 IP67 Digital I/O Modules for EtherNet/IP

12 Inputs + 4 Outputs module versions

Byte

Offset

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Input Data (Assembly #103), Size: 8 bytes

Data

00

n/u

n/u

n/u

n/u

n/u

n/u

Diag

UB

n/u

Diag

UL

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Input Data

02

n/u

n/u

n/u

n/u

I11

I10

I9

I8

I7

I6

I5

I4

I3

I2

I1

I0

Port Status

04

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Port Status

06

n/u

n/u

n/u

n/u

CS O3

CS O2

CS O1

CS O0

n/u

n/u

PS P5

PS P4

PS P3

PS P2

PS P1

PS P0

Output data (Assembly #104), Size: 4 bytes

00

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Output Data

02

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

O3

O2

O1

O0

Configuration (Assembly #106), Size: 16 bytes

Data

00

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

02

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

04

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

06

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

08

n/u

n/u

n/u

n/u

n/u

n/u

n/u

QC

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

10

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

12

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

14

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u: Not used

Ix: Input channel x

Ox: Output channel x

PS: Input Port Status (short circuit on Input channel)

CS: Channel status (short circuit on Output channel or impossible to drive the Output)

If output power supply (UL) is down, output channel status (CS) is set for the corresponding activated

output channels. The module display shows the message:”IO: ERR”.

Example: if the output “O3” is active and UL goes down, the “CS O3” status bit is set to 1.

QC: Quick Connect, 1 = Enable; 0 = Disable

Diag UB: Diagnostic Logic/Input power supply (UB)

Set to 1, if UB is < 14.1 VDC

o All Outputs activated are de-energized

o All Outputs activated have diagnostic leds to RED

o All Outputs activated have Port Status (CS Ox) bit set to 1

Set to 0, if UB is > 14.6 VDC

o All Outputs activated are energized

o All Outputs activated have diagnostic leds to GREEN

o All Outputs activated have Port Status (CS Ox) bit set to 0

Page 33

HarshIO 600 eIP

33 IP67 Digital I/O Modules for EtherNet/IP

Diag UL: Diagnostic Output power supply (UL)

Set to 1, if UL is < 17.6 VDC

o All Outputs activated are de-energized

o All Outputs activated have diagnostic leds to RED

o All Outputs activated have Port Status (CS Ox) bit set to 1

Set to 0, if UL is > 18.1 VDC

o All Outputs activated are energized

o All Outputs activated have diagnostic leds to GREEN

o All Outputs activated have Port Status (CS Ox) bit set to 0

Page 34

HarshIO 600 eIP

34 IP67 Digital I/O Modules for EtherNet/IP

8 Inputs + 8 Outputs module versions

Byte

Offset

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Input Data (Assembly #103), Size: 8 bytes

Data

00

n/u

n/u

n/u

n/u

n/u

n/u

Diag

UB

n/u

Diag

UL

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Input Data

02

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

I7

I6

I5

I4

I3

I2

I1

I0

Port Status

04

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Port Status

06

CS O7

CS O6

CS O5

CS O4

CS O3

CS O2

CS O1

CS O0

n/u

n/u

n/u

n/u

PS P3

PS P2

PS P1

PS P0

Output data (Assembly #104), Size: 4 bytes

00

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Output Data

02

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

O7

O6

O5

O4

O3

O2

O1

O0

Configuration (Assembly #106), Size: 16 bytes

Data

00

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

02

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

04

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

06

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

08

n/u

n/u

n/u

n/u

n/u

n/u

n/u

QC

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

10

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

12

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

Data

14

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u

n/u: Not used

Ix: Input channel x

Ox: Output channel x

PS: Input Port Status (short circuit on Input channel)

CS: Channel status (short circuit on Output channel or impossible to drive the Output)

If output power supply (UL) is down, output channel status (CS) is set for the corresponding activated

output channels. The module display shows the message:”IO: ERR”.

Example: if the output “O3” is active and UL goes down, the “CS O3” status bit is set to 1.

QC: Quick Connect, 1 = Enable; 0 = Disable

Diag UB: Diagnostic Logic/Input power supply (UB)

Set to 1, if UB is < 14.1 VDC

o All Outputs activated are de-energized

o All Outputs activated have diagnostic leds to RED

o All Outputs activated have Port Status (CS Ox) bit set to 1

Set to 0, if UB is > 14.6 VDC

o All Outputs activated are energized

o All Outputs activated have diagnostic leds to GREEN

o All Outputs activated have Port Status (CS Ox) bit set to 0

Page 35

HarshIO 600 eIP

35 IP67 Digital I/O Modules for EtherNet/IP

Diag UL: Diagnostic Output power supply (UL)

Set to 1, if UL is < 17.6 VDC

o All Outputs activated are de-energized

o All Outputs activated have diagnostic leds to RED

o All Outputs activated have Port Status (CS Ox) bit set to 1

Set to 0, if UL is > 18.1 VDC

o All Outputs activated are energized

o All Outputs activated have diagnostic leds to GREEN

o All Outputs activated have Port Status (CS Ox) bit set to 0

Page 36

HarshIO 600 eIP

36 IP67 Digital I/O Modules for EtherNet/IP

Pin assignment

4-pin power supply versions

1

4

2

3

5

4

31

2

Power IN

4-pole, 7/8 (Mini-Change), Male

I/O Ports

5-pole, M12 (Micro-Change),

Female, A-Code

Power OUT

4-pole, 7/8 (Mini-Change), Female

Wiring Information:

1 - 24 VDC (Outputs Power)

2 - 24 VDC (Module & Inputs Power)

3 - 0 V (Ground Module & Inputs Power)

4 - 0 V (Outputs Power)

Wiring Information:

1 - +24 VDC

2 - B Input / Output

3 - 0 V (Ground)

4 - A Input / Output

5 - PE (Protected Earth)

2

3

4

1

PE

Wiring Information:

1 -TX+

2 - RX+

3 -TX4 - RX-

Ethernet Port 1 (ETH1)

4-pole, M12(Micro-Change),

Female, D-Code

Ethernet Port 2 (ETH2)

4-pole, M12(Micro-Change),

Female, D-Code

3

2

1

4

PE

PE

2

13

4

+

-

PE

Ui Uo

I 0

I 1

I 2

I 3

I 4

I 5

I 6

I 7

I 8

I 9

I 10

I 11

I 12

I 13

I 14

I 15

ETH1

LINK

ETH2

LINK

BUS

I

X

UL UB

Page 37

HarshIO 600 eIP

37 IP67 Digital I/O Modules for EtherNet/IP

5-pin power supply versions

Wiring Information:

1 - 0 V (Outputs Power)

2 - 0 V (Module & Inputs Power)

3 - PE (Protected Earth)

4 - 24 VDC (Module & Inputs Power)

5 - 24 VDC (Outputs Power)

1

4

2

3

5

Input Ports

5-pole, M12 (Micro-Change),

Female, A-Code

Wiring Information:

1 - +24 VDC

2 - Input (even)

3 - 0 V (Ground)

4 - Input (odd)

5 - PE (Protected Earth)

2

3

4

1

PE

Wiring Information:

1 -TX+

2 - RX+

3 -TX4 - RX-

Ethernet Port 1 (ETH1)

4-pole, M12(Micro-Change),

Female, D-Code

Ethernet Port 2 (ETH2)

4-pole, M12(Micro-Change),

Female, D-Code

3

2

1

4

PE

PE

1

4

2

3

5

Output Ports

5-pole, M12 (Micro-Change),

Female, A-Code

Wiring Information:

1 - n/c

2 - Output (even)

3 - 0 V (Ground)

4 - Output (odd)

5 - PE (Protected Earth)

1

2

3

4

5

Power IN

5-pole, 7/8 (Mini-Change), Male

1

2

3

4

5

Power OUT

5-pole, 7/8 (Mini-Change), Female

+

-

PE

Ui Uo

I0

I1

I2

I3

I4

I5

I6

I7

O0

O1

O2

O3

O4

O5

O6

O7

ETH1

LINK

ETH2

LINK

BUS

I

X

UL UB

Page 38

HarshIO 600 eIP

38 IP67 Digital I/O Modules for EtherNet/IP

Separate grounding wiring for application using safety relays

The HarshIO 600 power connector includes a separate grounding isolation between the input/logic

ground and the output ground. This feature allows powering the module with 2 distinct power supplies that is

commonly used in safety application.

Typically in automation application, a system designer is using safety relays (like Rockwell Automation

Guard I/O EtherNet/IP Safety Modules [1791ES-IB8XOBV4, 1791ES-IB16], Siemens PM-E F pp DC24V

[6ES7 138-4CF42-0AB0], Siemens PM-E F pm DC24V [6ES7 138-4CF03-0AB0]) that regularly perform the

pulse test to be able to detect a short-circuit, ground fault or an earth fault. If an error is detected the safety

function is triggered and unwanted and dangerous plant conditions are therefore avoided.

Architecture using 2 distinct grounds with safety relay

Page 39

HarshIO 600 eIP

39 IP67 Digital I/O Modules for EtherNet/IP

However if the separate grounding for safety is not required by the system designer, the HarshIO

modules can operate using a single ground for both logic/input and output.

Architecture using a single ground

Note, the connection of the common ground (Logic/Input + Output) is made outside the HarshIO

module.

Page 40

HarshIO 600 eIP

40 IP67 Digital I/O Modules for EtherNet/IP

Port wiring type

2 Input channels per port – Twin wired

2 Output channels per port – Twin wired

Note:

PNP wiring with a 2 wires input sensor

Connect pin 1 (24 V) and pin 4 or 2 (signal in)

Page 41

HarshIO 600 eIP

41 IP67 Digital I/O Modules for EtherNet/IP

+

-

PE

Ui Uo

ETH1

LINK

ETH2

LINK

BUS

I

X

UL UB

I0

I1

I2

I3

I4

I5

I6

I7

I8

I9

I10

I11

O0

O1

O2

O3

LED assignment

Quick Connect feature

In case of using Quick Connect mode, it

is mandatory

to connect the Ethernet cable

coming from the arm of the robot to

port ETH1

to connect a second module using

daisy chain topoology to port ETH2

Outputs Power LED (UL)

Green: Auxiliary Power supplied

Off: Auxiliary Power not supplied

Note: The outputs of the module operate

only if the LED is ON

16x Channel LED

Green: I/O Signal active

Off: I/O Signal not active

Red: Fault. Need Diagnostics

2x Ethernet Link Diagnostic LED

Green: 100 Mbps

Solid On: link without activity

Blink: link with activity

Yellow: 10 Mbps

Solid On: link without activity

Blink: link with activity

Module & Inputs power LED (UB)

Green: Auxiliary Power supplied

Off: Auxiliary Power not supplied

Scrolling digit display

IP address

I/O Fault

EtherNet/IP Status

IP Setting Push Buttons

Push button for IP Address mode and

setting

Quick Connect feature

In case of using Quick Connect, it is

mandatory to connect the port ETH2 to

the Ethernet cable going to an additional

HarshIO module mounted on the tool

changer.

In-coming Bus Power Connector (Ui)

Use this connector to power the module.

Out-coming Bus Power Connector (Uo)

Use this connector to daisy-chain the

power to an additional HarshIO eIP

module

9 Plastic labels

Available to write user information

Page 42

HarshIO 600 eIP

42 IP67 Digital I/O Modules for EtherNet/IP

Network IP address setting

The HarshIO 600 eIP is configured in DHCP mode by default. When connecting to a network with a DHCP

server, an IP address is automatically assigned to the module.

You can stop the DHCP procedure (in case of no DHCP server on the network) by touching the push-buttons

located in the Window area of the module .

The Factory default IP Address is 192.168.1.1

To change or set the default IP address, the operator has the possibility to use one of the following methods:

1. Use of the display

Use the push-buttons and the scrolling display; This method only allows an operator to change the

last byte of the IP address (192.168.1.x). To change the network IP address, push on the right or left

button of the clear window of the HarshIO module.

o Right button behavior (clockwise) :

o Left button behavior (counterclockwise) :

Note: When IP address is selected, it will be stored in non-volatile memory after 5 seconds of inactivity

on the push-button. The IP address will be taken in account after a module reset or a power cycle.

During this phase, a message “NEED RESET” is showed on the display of the module.

Note: When changing DHCP mode into Static IP mode, the mask of the Static IP address

(xxx.xxx.xxx.) will be the same as it was in DHCP mode (given by the DHCP server).

xxx.xxx.xxx.001

xxx.xxx.xxx.254

xxx.xxx.xxx.001

xxx.xxx.xxx.254

Static IP

Static IP

DHCP

DHCP

Page 43

HarshIO 600 eIP

43 IP67 Digital I/O Modules for EtherNet/IP

2. Use Molex EtherNet/IP Tools

To change the IP settings of the module, you have to use a software tool like Molex EtherNet/IP Tools

that manages Explicit Messaging requests to access module CIP objects (0xF5 TCP/IP and 0xF6

Ethernet Link) to set parameters like:

o Static or dynamic IP addressing

o IP address

o Network mask

o Etc.

The software can be download free-of-charge here.

There is no installation setup. Just copy the files in a new folder and launch EIP_Tools.exe.

Select your computer Ethernet interface by clicking Options.

Select Send List Identity Request on UDP to discover all the EtherNet/IP devices connected to the

network. Select a device in the list

Page 44

HarshIO 600 eIP

44 IP67 Digital I/O Modules for EtherNet/IP

Click on F5 TCP/IP tab and then on Get_Attribute_All. The device parameters are displayed.

For example to modify the IP Address parameter, write the new IP and select Set_Attribute button to

send the command.

Page 45

HarshIO 600 eIP

45 IP67 Digital I/O Modules for EtherNet/IP

Display information

The 4-digit LED display shows the Ethernet configuration and the global state of the module.

Information present into the display:

Module information

o NEED RESET: Means that the module requires a reset via software (using CIP Identity object) or

a power cycle

Ethernet IP addressing mode

o STORED_IP: xxx.xxx.xxx.xxx: Stored IP Address

o DHCP: xxx.xxx.xxx.xxx: DHCP mode (assignment based on MAC address)

I/O status

o IO:ERR: I/O error detection (short circuit on output or input power supply)

Ethernet information

o STARTING...: Waiting IP address from DHCP server.

Note: The HarshIO module send a DHCP request with an infinite lease (The IP address assignes

never expired). According the configuration of the DHCP server, it can accept or modify the

lease to a different period.

o IPCONFLICT: The module has detected an IP address conflict

o WAIT LINK: No link has been detected on the both Ethernet ports. If the IP address is

configured as static then the IP address will be displayed

EtherNet/IP Information

o EIP:NO_CNX: No connection is established with a scanner

o EIP:OPERATE: Connection in progress: An I/O connection was opened, but I/O data are not yet

exchanged with the scanner

o EIPRUN: The module exchange data with a scanner.

o EIP:IDLE: The connection is established, but I/O are not exchanged

o EIP:TIMEOUT: The connection has been lost with a scanner

o EIP:CLOSE: The close connection has been received from a scanner

o RST: The module has received a "reset" command on the Identity Object and will reboot shortly

Page 46

HarshIO 600 eIP

46 IP67 Digital I/O Modules for EtherNet/IP

Hardware address (MAC Address)

Each HarshIO 600 eIP has a unique Ethernet MAC address figured on the attached label on the back of the

module. This address has a fixed length of 6 bytes (48 bits) including the manufacturer’s ID and the serial

number of the HarshIO module.

The MAC address will be defined as the following:

Manufacturer ID

Family

Serial Number

00.A0.91

3

X.XX.XX

EDS files

The EDS files can be downloaded from the Molex website:

http://www.molex.com/molex/mysst/DownloadCenter.action

Configure the HarshIO 600 eIP via the EDS file. In this EDS file, the HarshIO 600 eIP is implemented as

standard device in your system.

EDS file list for HarshIO 600 eIP devices:

4-pin power supply versions

Name

EDS File

Product

Code

TCDEI-8D0P-DYU-G

0008000C03200601.eds

0x320

TCDEI-888P-DYU-G

0008000C03230601.eds

0x323

TCDEI-8B4P-DYU-G

0008000C03220601.eds

0x322

TCDEI-80DP-DYU-G

0008000C03290601.eds

0x329

5-pin power supply versions

Name

EDS File

Product

Code

TCDEI-8D0P-D1U-G

0008000C03400601.eds

0x0340

TCDEI-8B4P-D1U-G

0008000C03420601.eds

0x0342

TCDEI-888P-D1U-G

0008000C03430601.eds

0x0343

TCDEI-80DP-D1U-G

0008000C03490601.eds

0x0349

Page 47

HarshIO 600 eIP

47 IP67 Digital I/O Modules for EtherNet/IP

5. Specific Behavior

I/O behavior

When the HarshIO 600 eIP is running (Scanner connection in progress) if the module detects a connection

lost with the Scanner, the module sets automatically the output process data to 0.

The detection of the connection lost with the Scanner is calculated based on the time-out (multiplier x RPI)

defined in the I/O connection (Forward_Open request) sent by the scanner.

IDLE behavior

An EtherNet/IP scanner can produce the output process data in IDLE mode (typically when it is in

programming mode). In this case the controller maintains its I/O connections open but informs the devices the

output process data must not be processed.

When the HarshIO 600 eIP received output data in IDLE mode,

the scrolling display shows EIP:IDLE

the module sets all its outputs to 0

the module produces its inputs to the scanner

Duplicate IP address

The HarshIO 600 eIP performs a duplicate IP address checking according to ACD method (IPv4 Address

Conflict Detection) defined by ODVA and RFC 5227.

The goal of this feature is to ensure that the IP address is not used by another device on the network. This

mechanism is done during boot up of the module, during module operation (if a new device inserted to the

network is trying to use the same IP) or after software reset (CIP object 0x01, Instance 1 Service 5).

If the module detects another device with the same IP address, it will:

- Defend its IP address

- If conflict is confirmed

o The module will release its IP address

o The display will show the message : IP CONFLICT

Page 48

HarshIO 600 eIP

48 IP67 Digital I/O Modules for EtherNet/IP

6. EtherNet/IP Object Classes

The following services are accessible through the use of EtherNet/IP Explicit Messaging.

Identity (0x01)

This object allows reading the identity of the module.

Class Attributes

Id

Description

Get

Set

Limits

01h

Revision

1

02h

Max Instance

1

03h

Number of instances

1

Supported Not supported

Class Services

Id

Service

Param. Options

01h

Get_Attributes_All

0Eh

Get_Attribute_Single

Instance Attributes

Id

Description

Get

Set

Limits

01h

Vendor Id

8

02h

Device Type

12

03h

Product Code

Depends on the product

04h

Revision

Depends on the revision

05h

Status

06h

Serial Number

07h

Product Name

Depends on the product

Supported Not supported

Instance Services

Id

Service

Param. Options

01h

Get_Attributes_All

05h

Reset 0Eh

Get_Attribute_Single

Page 49

HarshIO 600 eIP

49 IP67 Digital I/O Modules for EtherNet/IP

Message Router (0x02)

Class Attributes

Id

Description

Get

Set

Limits

1

Revision

4 Optional Attribute List

5 Optional Service List

6 Max ID of class attributes

7 Max ID of instance attributes

Supported Not Supported

Class Services

Service

Param. Options

Get_Attributes_All

Get_Attribute_Single

Supported Not Supported

Instance Attributes

Id

Description

Get

Set

Limits

1

Object List

2 Maximum connections supported

3 Number of active connections

4 Active connections list

Supported Not Supported

Instance Services

Service

Param. Options

Get_Attributes_All

Get_Attribute_Single

Supported Not Supported

Page 50

HarshIO 600 eIP

50 IP67 Digital I/O Modules for EtherNet/IP

Assembly (0x04)

This object allows to access I/O process data.

Class Attributes

Id

Description

Get

Set

Limits

01h

Revision

2

02h

Max Instance

199

03h

Number of instances

4

Supported Not supported

Class Services

Service

Param. Options

Get_Attribute_Single

Supported Not Supported

Instance Attributes

Id

Description

Get

Set

Limits

03h

Data

Set command is

not allowed if an

exclusive owner

connection is

open

Supported Not supported

Instance Services

Id

Service

Param. Options

0Eh

Get_Attribute_Single

10h

Set_Attribute_Single

Page 51

HarshIO 600 eIP

51 IP67 Digital I/O Modules for EtherNet/IP

Connection Manager (0x06)

Class Attributes

Id

Description

Get

Set

Limits

01h

Revision

1

02h

Max Instance

1

03h

Number of instances

1

Supported Not supported

Class Services

Id

Service

Param. Options

01h

Get_Attributes_All

0Eh

Get_Attribute_Single

Instance Attributes

Id

Description

Get

Set

Limits

01h

Open Requests

02h

Open Format Rejects

03h

Open Resource Rejects

04h

Open Other Rejects

05h

Close Requests

06h

Close Format Requests

07h

Close Other Requests

08h

Connection Timeouts

Supported Not supported

Instance Services

Id

Service

Param. Options

01h

Get_Attributes_All

0Eh

Get_Attribute_Single

4Eh

Forward_Close

54h

Forward_Open

5Bh

Large_Forward_Open

Class 3 only

Page 52

HarshIO 600 eIP

52 IP67 Digital I/O Modules for EtherNet/IP

TCP/IP Interface (0xF5)

Class Attributes

Id

Description

Get

Set

Limits

01h

Revision

2

02h

Max Instance

1

03h

Number of instances

1

Supported Not supported

Class Services

Id

Service

Param. Options

01h

Get_Attributes_All

0Eh

Get_Attribute_Single

Instance Attributes

Id

Description