Page 1

EN

This Datasheet is presented by

the manufacturer

DE

Dieses Datenblatt wird vom

Hersteller bereitgestellt

FR

Cette fiche technique est

présentée par le fabricant

EN - For pricing and availability in your local country please visit one of the below links:

DE - Informationen zu Preisen und Verfügbarkeit in Ihrem Land erhalten Sie über die unten aufgeführten Links:

FR - Pour connaître les tarifs et la disponibilité dans votre pays, cliquez sur l'un des liens suivants:

19228-0030

Page 2

ATP-301 Air Tape Press

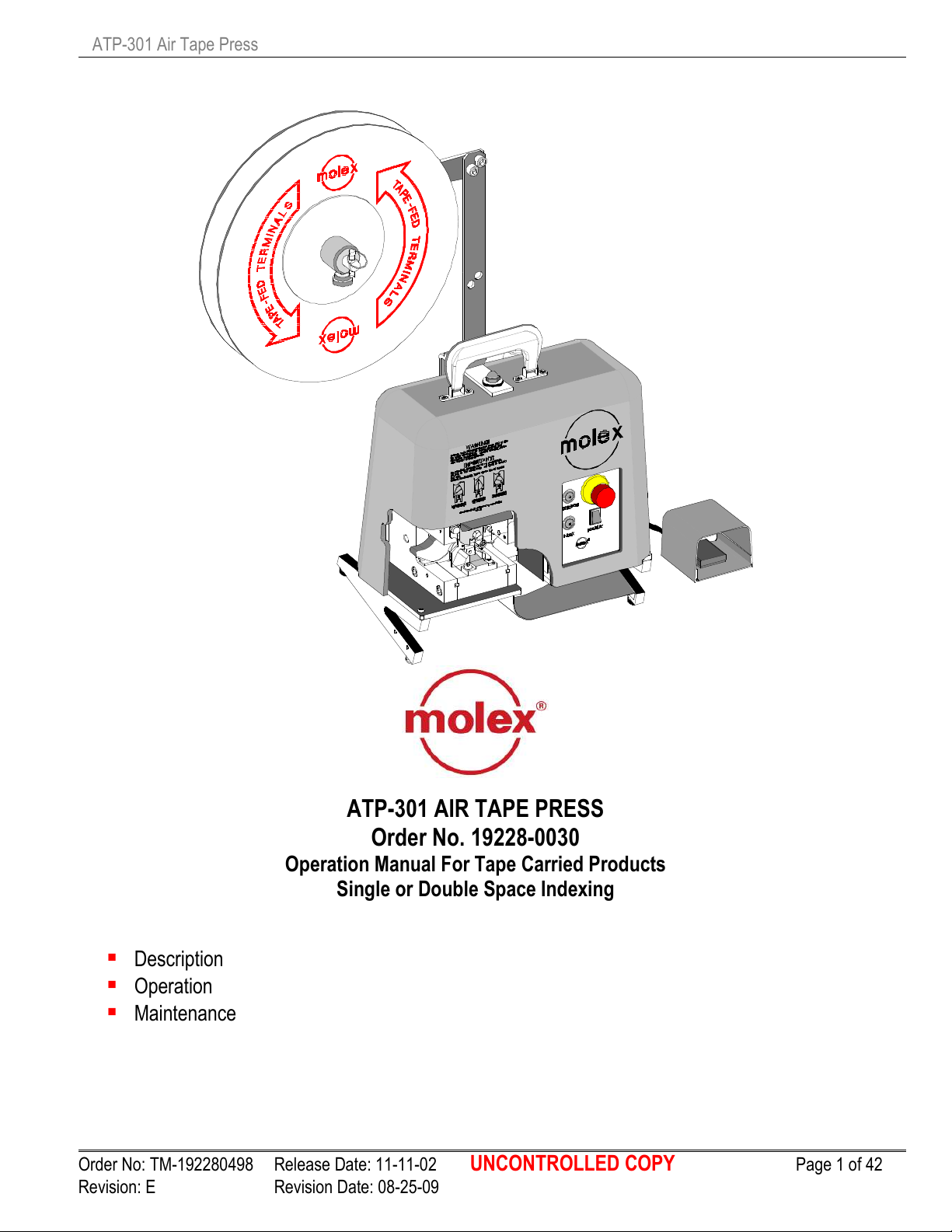

ATP-301 AIR TAPE PRESS

Order No. 19228-0030

Operation Manual For Tape Carried Products

Single or Double Space Indexing

Description

Operation

Maintenance

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 1 of 42

Revision: E Revision Date: 08-25-09

Page 3

ATP-301 Air Tape Press

WARNING

NEVER USE THIS TOOL WITHOUT GUARDS OR SAFETY DEVICES THAT ARE INTENDED TO

PREVENT HANDS FROM REMAINING IN THE CRIMP TOOLING AREA.

NEVER OPERATE, SERVICE, INSTALL OR ADJUST THIS TOOL WITHOUT PROPER INSTRUCTION

AND WITHOUT FIRST READING AND UNDERSTANDING THE INSTRUCTIONS IN THIS

MANUAL AND ALL APPLICABLE AIR POWERED CRIMPING TOOL MANUALS.

NEVER SERVICE THIS MACHINE WHILE IT IS CONNECTED TO ANY ELECTRICAL POWER

SOURCE. DISCONNECT POWER BY UNPLUGGING THE PRESS FROM ITS POWER

SOURCE.

NEVER INSTALL OR REMOVE CRIMP TOOLING WITH THE AIR LINE CONNECTED.

NEVER OPERATE THE PRESS WITH AIR PRESSURE GREATER THAN 110 PSI (AT PRESS

REGULATOR).

CAUTION MOLEX CRIMP SPECIFICATIONS ARE VALID ONLY WHEN USING MOLEX TERMINALS AND

MOLEX APPLICATORS AND TOOLING.

WORK SAFELY AT ALL TIMES

For Service, Contact Your

Local Molex Sales Office

Molex Application Tooling Group

2200 Wellington Court

Lisle, IL 60532

Tel: (630) 969-4550

Fax: (630) 505-0049

Visit our Web site at http://www.molex.com

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 2 of 42

Revision: E Revision Date: 08-25-09

Page 4

ATP-301 Air Tape Press

Table of Contents

SECTION

1 General Description

2 Installation

3 Setup - Operation

4 Maintenance

5 Parts List, Assembly Drawings, Electrical, Pneumatic and Troubleshooting

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 3 of 42

Revision: E Revision Date: 08-25-09

Page 5

ATP-301 Air Tape Press

1.1. Description

1.2. Features

1.3. Technical Specifications

1.4. Delivery Check

1.5. Tools

Section 1

General Description

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 4 of 42

Revision: E Revision Date: 08-25-09

Page 6

ATP-301 Air Tape Press

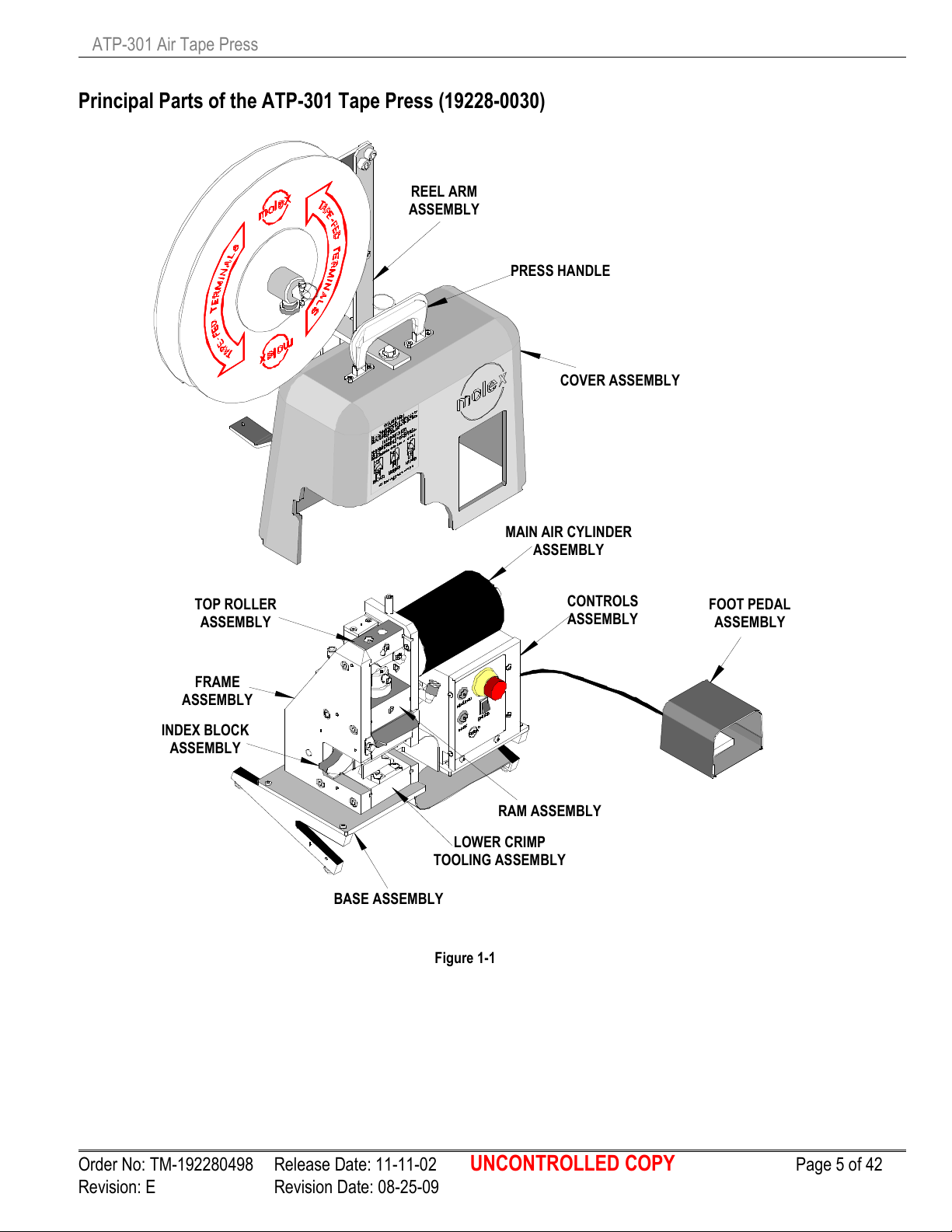

Figure 1

-1

REEL ARM

COVER ASSEMBLY

FOOT PEDAL

MAIN AIR CYLINDER

TOP ROLLER

CONTROLS

INDEX BLOCK

RAM ASSEMBLY

LOWER CRIMP

BASE ASSEMBLY

FRAM

E

PRESS HANDLE

Principal Parts of the ATP-301 Tape Press (19228-0030)

ASSEMBLY

ASSEMBLY

ASSEMBLY

ASSEMBLY

ASSEMBLY

TOOLING ASSEMBLY

ASSEMBLY

ASSEMBLY

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 5 of 42

Revision: E Revision Date: 08-25-09

Page 7

ATP-301 Air Tape Press

General Descrition

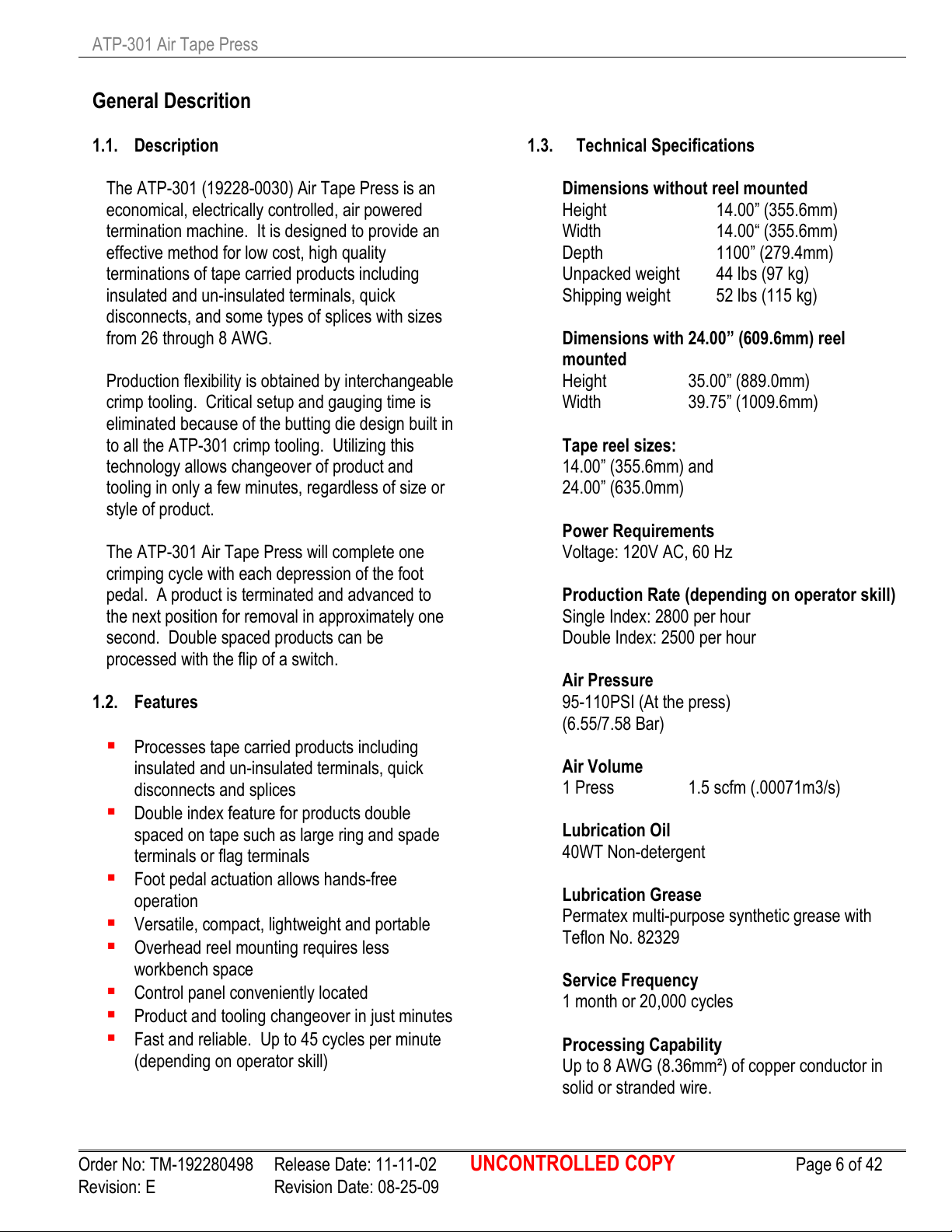

1.1. Description

The ATP-301 (19228-0030) Air Tape Press is an

economical, electrically controlled, air powered

termination machine. It is designed to provide an

effective method for low cost, high quality

terminations of tape carried products including

insulated and un-insulated terminals, quick

disconnects, and some types of splices with sizes

from 26 through 8 AWG.

Production flexibility is obtained by interchangeable

crimp tooling. Critical setup and gauging time is

eliminated because of the butting die design built in

to all the ATP-301 crimp tooling. Utilizing this

technology allows changeover of product and

tooling in only a few minutes, regardless of size or

style of product.

The ATP-301 Air Tape Press will complete one

crimping cycle with each depression of the foot

pedal. A product is terminated and advanced to

the next position for removal in approximately one

second. Double spaced products can be

processed with the flip of a switch.

1.2. Features

Processes tape carried products including

insulated and un-insulated terminals, quick

disconnects and splices

Double index feature for products double

spaced on tape such as large ring and spade

terminals or flag terminals

Foot pedal actuation allows hands-free

operation

Versatile, compact, lightweight and portable

Overhead reel mounting requires less

workbench space

Control panel conveniently located

Product and tooling changeover in just minutes

Fast and reliable. Up to 45 cycles per minute

(depending on operator skill)

1.3. Technical Specifications

Dimensions without reel mounted

Height 14.00” (355.6mm)

Width 14.00“ (355.6mm)

Depth 1100” (279.4mm)

Unpacked weight 44 lbs (97 kg)

Shipping weight 52 lbs (115 kg)

Dimensions with 24.00” (609.6mm) reel

mounted

Height 35.00” (889.0mm)

Width 39.75” (1009.6mm)

Tape reel sizes:

14.00” (355.6mm) and

24.00” (635.0mm)

Power Requirements

Voltage: 120V AC, 60 Hz

Production Rate (depending on operator skill)

Single Index: 2800 per hour

Double Index: 2500 per hour

Air Pressure

95-110PSI (At the press)

(6.55/7.58 Bar)

Air Volume

1 Press 1.5 scfm (.00071m3/s)

Lubrication Oil

40WT Non-detergent

Lubrication Grease

Permatex multi-purpose synthetic grease with

Teflon No. 82329

Service Frequency

1 month or 20,000 cycles

Processing Capability

Up to 8 AWG (8.36mm²) of copper conductor in

solid or stranded wire.

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 6 of 42

Revision: E Revision Date: 08-25-09

Page 8

ATP-301 Air Tape Press

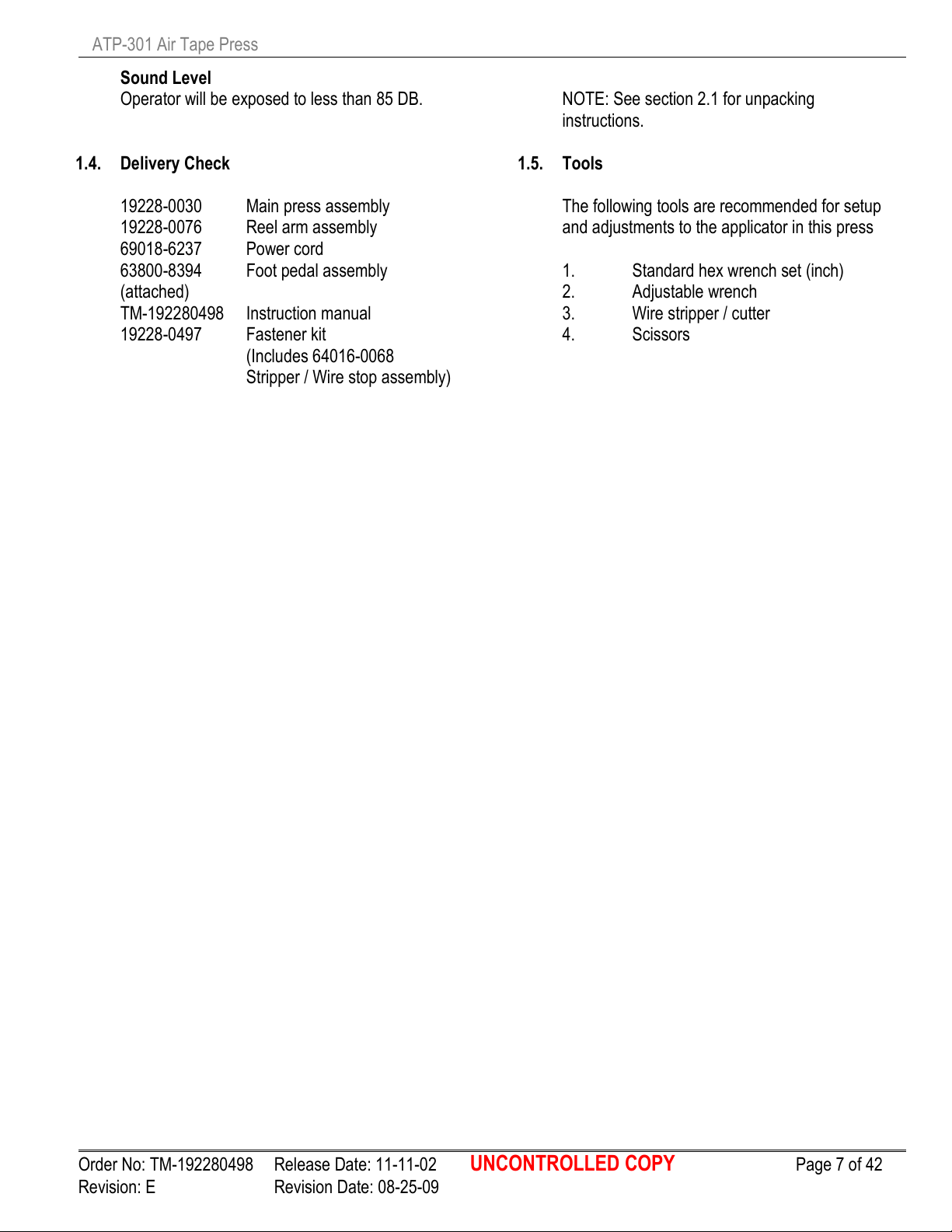

Sound Level

Operator will be exposed to less than 85 DB.

1.4. Delivery Check

19228-0030 Main press assembly

19228-0076 Reel arm assembly

69018-6237 Power cord

63800-8394 Foot pedal assembly

(attached)

TM-192280498 Instruction manual

19228-0497 Fastener kit

(Includes 64016-0068

Stripper / Wire stop assembly)

NOTE: See section 2.1 for unpacking

instructions.

1.5. Tools

The following tools are recommended for setup

and adjustments to the applicator in this press

1. Standard hex wrench set (inch)

2. Adjustable wrench

3. Wire stripper / cutter

4. Scissors

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 7 of 42

Revision: E Revision Date: 08-25-09

Page 9

ATP-301 Air Tape Press

Section 2

Installation

2.1. Unpacking and Positioning the Press

2.2. Reel Arm Assembly Installation

2.3. Air Supply and Electrical Power Connection

2.4. Tape Reel Installation

2.5. Crimp Tooling Installation and Removal

2.6. Insulation Punch Adjustment

2.7. Die Spacer Installation

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 8 of 42

Revision: E Revision Date: 08-25-09

Page 10

ATP-301 Air Tape Press

CROSS MEMBER

3/8”-16 ACORN NUT

3/8”-16 THR

EADED STUD

3/8”-16 SHCS (2)

REEL SHAFT

PRESS HANDLE

AIR COUPLING

AIR LINE W/COUPLING

POWER SUPPLY

POWER CORD

FOOT PEDAL CORD

Figure 2

-2

Read the following instructions before attempting to operate tool.

2.1. Unpacking and Positioning the Press

Open the top of the shipping carton. Locate and

remove the reel arm assembly and set aside.

Remove the packaging film and foam as required to

gain access to the air press. Use the press handle

to lift the unit out of the shipping carton. As the

press is lifted with one hand, support the foot pedal

assembly with the other and place the unit on a

clean, flat surface. Remove the plastic covering

from around the air press and verify that all items

are present (See delivery check: Section 1.4).

Position the air press on top of a flat, sturdy

workbench approximately 4.00” (100mm) back from

the front edge. Check that the crimping position is

ergonomic for the operator’s size. A bench height

of 30.00 to 32.00” (762 to 813mm) should provide operator comfort and allow both feet to rest on the floor.

The foot pedal should be placed in a comfortable position. A chair or stool with an adjustable height and

backrest should be provided for maximum comfort and back support for the operator.

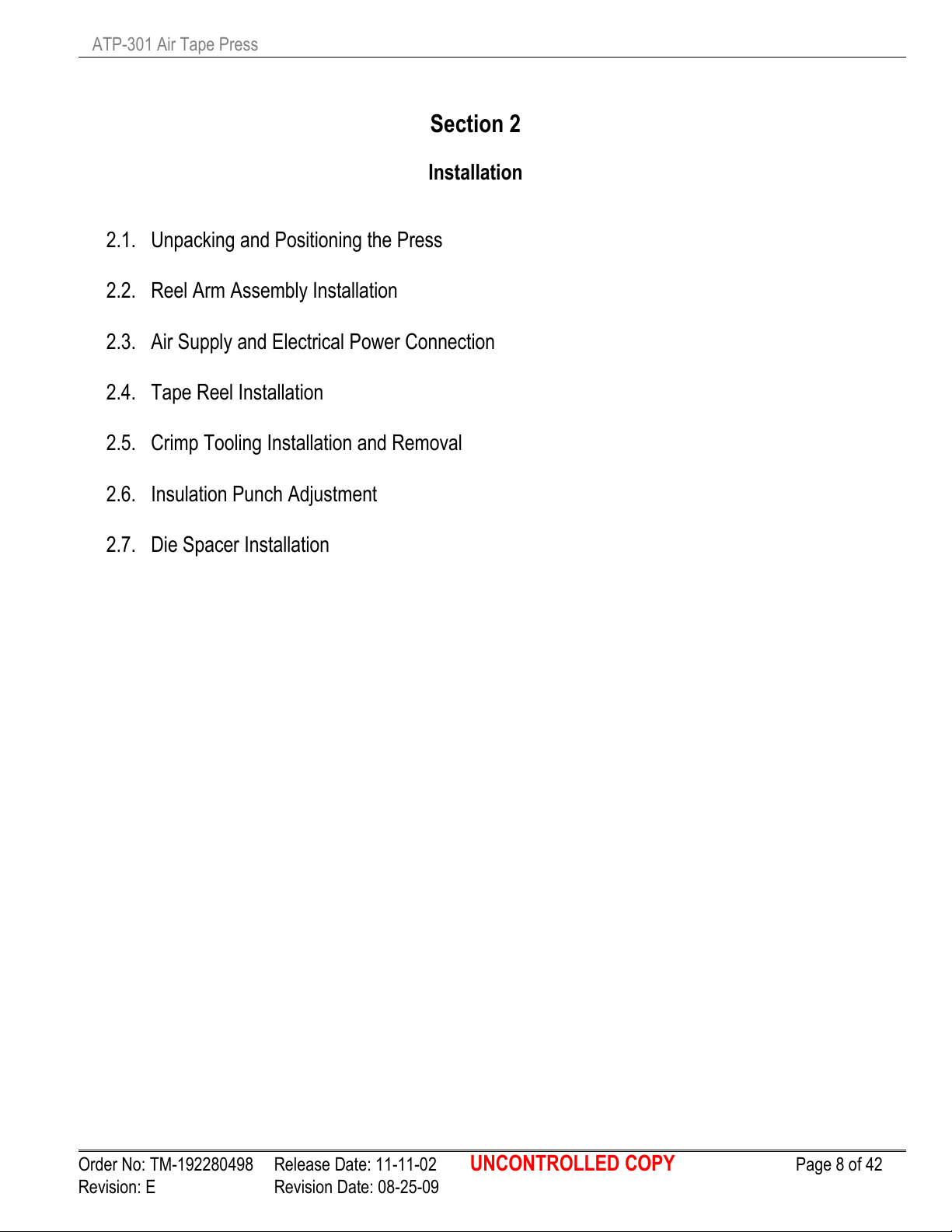

2.2. Reel Arm Assembly Installation (See Figure 2-1)

1. Remove the 3/8-16” acorn nut and (2) 3/8” washers from the top cover.

2. Locate the reel arm assembly and disassemble the cross member by removing (2) 3/8” SHCS. Reposition

the cross member in a horizontal position extending to the left side with the reel shaft oriented to the front

and replace the (2) 3/8” SHCS and tighten securely.

3. Place the reel arm assembly over the 3/8-16” stud on the top of the cover, and replace the 3/8-16” acorn

nut and tighten securely. The (2) 3/8”

washers are not required for mounting the

reel arm to the press but may be required

for future use if the reel arm assembly is

removed and the press is to be transported.

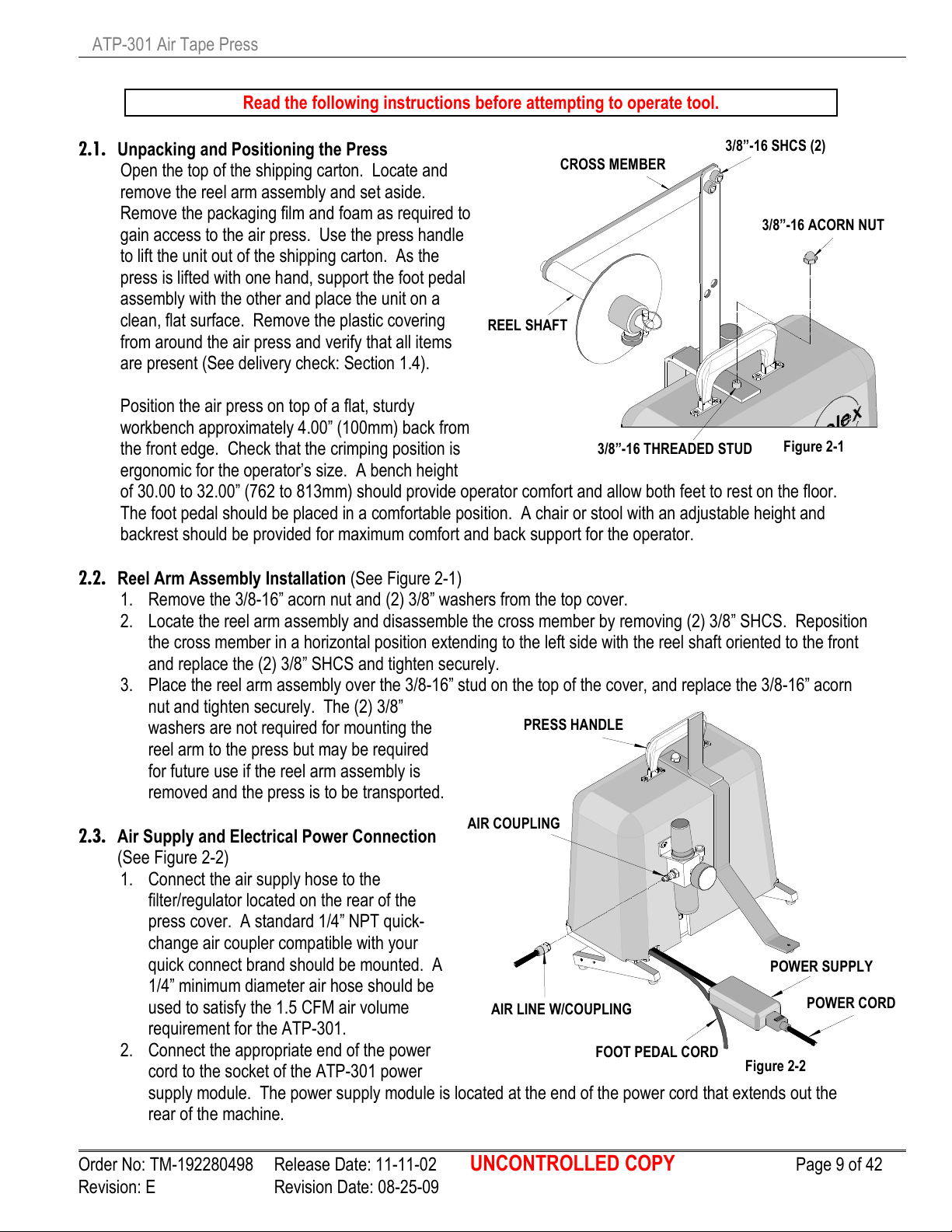

2.3. Air Supply and Electrical Power Connection

(See Figure 2-2)

1. Connect the air supply hose to the

filter/regulator located on the rear of the

press cover. A standard 1/4” NPT quick-

change air coupler compatible with your

quick connect brand should be mounted. A

1/4” minimum diameter air hose should be

used to satisfy the 1.5 CFM air volume

requirement for the ATP-301.

2. Connect the appropriate end of the power

cord to the socket of the ATP-301 power

supply module. The power supply module is located at the end of the power cord that extends out the

rear of the machine.

Figure 2-1

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 9 of 42

Revision: E Revision Date: 08-25-09

Page 11

ATP-301 Air Tape Press

REEL SHAFT

THUMB SCREW

DISC

QUICK RELEASE PIN

LOGO FACING

TAPE REEL

Figure 2

-3

CRIMP TOOLING MTG

INSULATION ADJ. CAM

UPPER PUNCH HOLDER

LOWER ANVIL

SAFETY SHEILD

THUMB SCREW

Figure 2

-4

INSULATION ANVIL (I1)

INSULATION PUNCH (I2)

CONDUCTOR PUNCH (E2)

DIE SPACERS (IF REQUIRED)

3. Connect the appropriate end of the power cord to a grounded electrical outlet (120V AC).

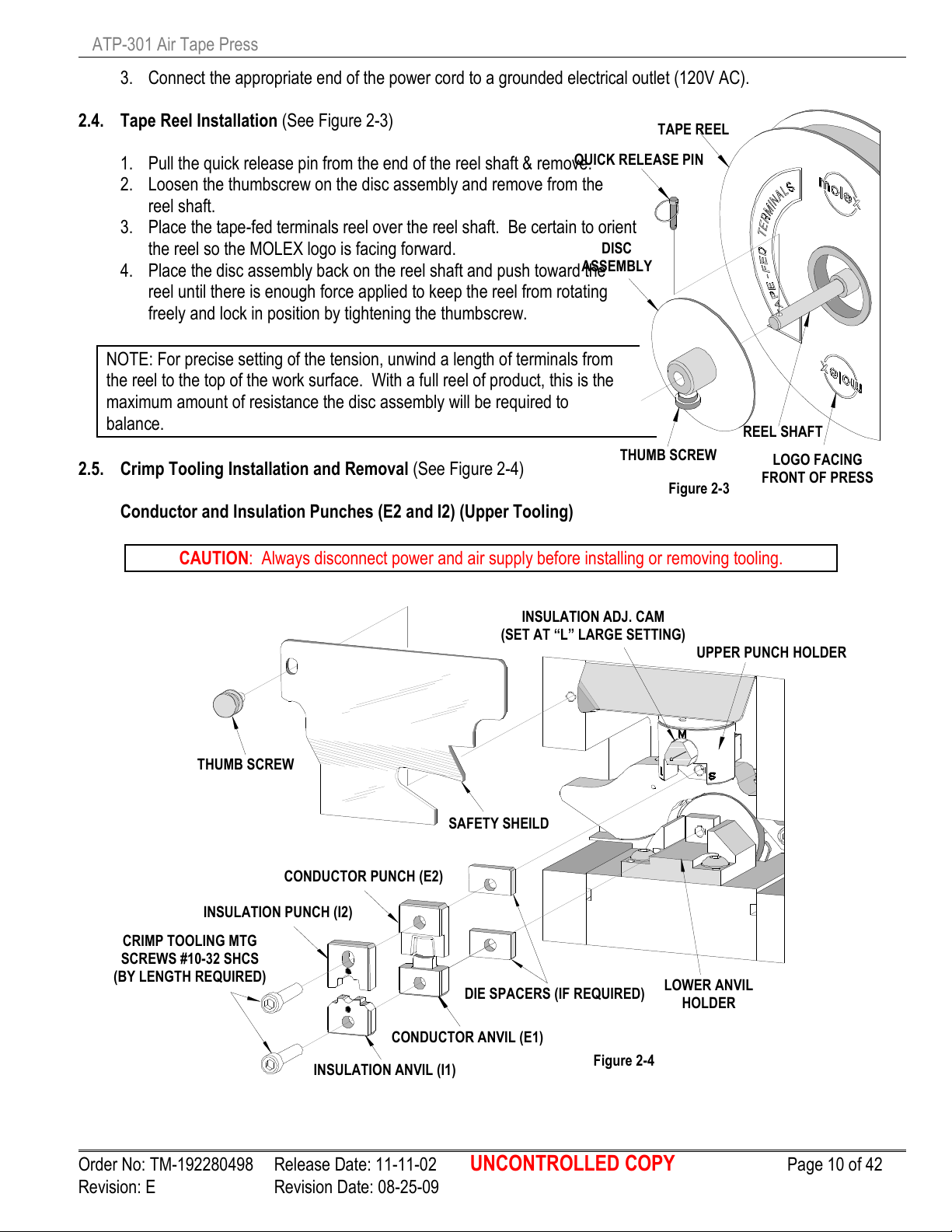

2.4. Tape Reel Installation (See Figure 2-3)

1. Pull the quick release pin from the end of the reel shaft & remove.

2. Loosen the thumbscrew on the disc assembly and remove from the

reel shaft.

3. Place the tape-fed terminals reel over the reel shaft. Be certain to orient

the reel so the MOLEX logo is facing forward.

4. Place the disc assembly back on the reel shaft and push toward the

ASSEMBLY

reel until there is enough force applied to keep the reel from rotating

freely and lock in position by tightening the thumbscrew.

NOTE: For precise setting of the tension, unwind a length of terminals from

the reel to the top of the work surface. With a full reel of product, this is the

maximum amount of resistance the disc assembly will be required to

balance.

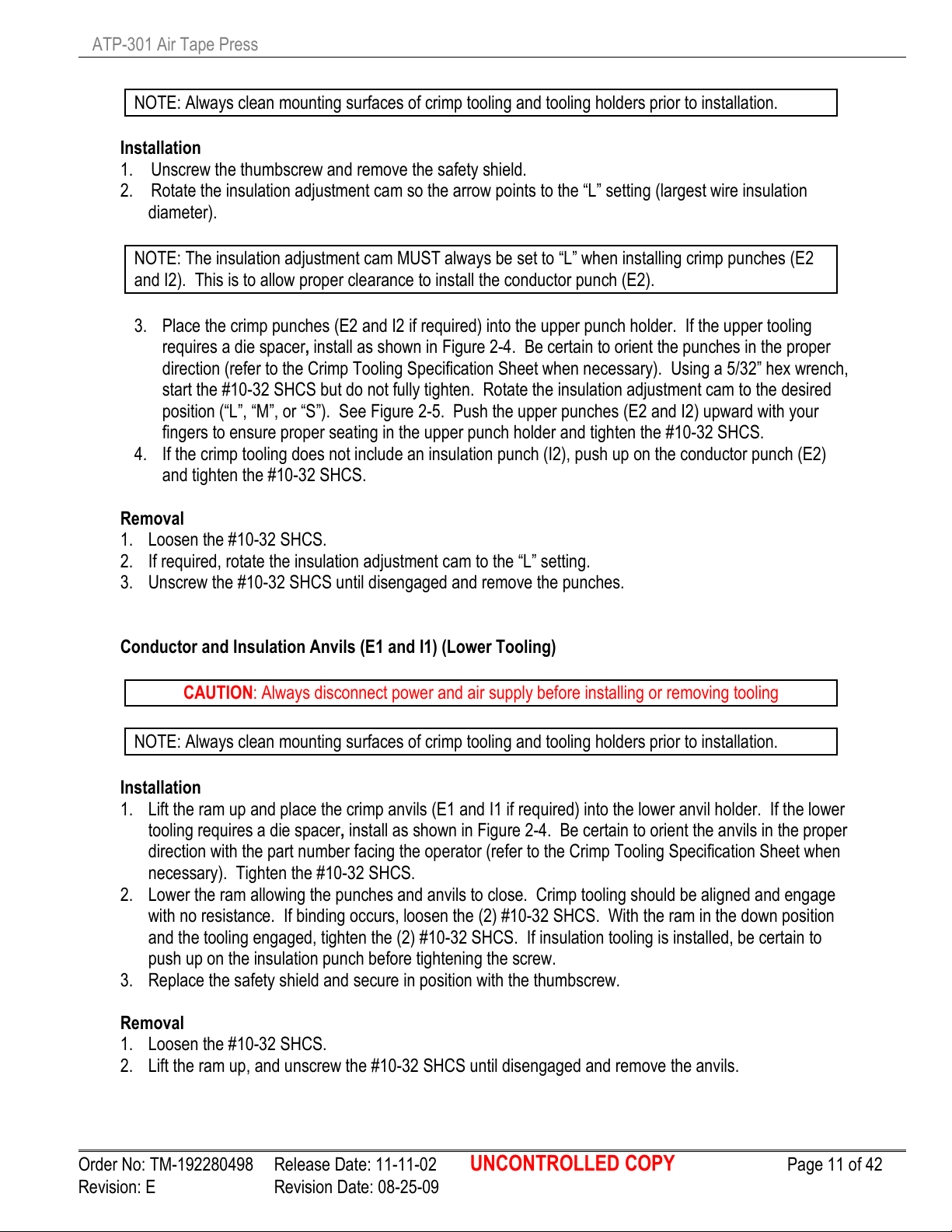

2.5. Crimp Tooling Installation and Removal (See Figure 2-4)

Conductor and Insulation Punches (E2 and I2) (Upper Tooling)

CAUTION: Always disconnect power and air supply before installing or removing tooling.

(SET AT “L” LARGE SETTING)

SCREWS #10-32 SHCS

(BY LENGTH REQUIRED)

CONDUCTOR ANVIL (E1)

FRONT OF PRESS

HOLDER

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 10 of 42

Revision: E Revision Date: 08-25-09

Page 12

ATP-301 Air Tape Press

NOTE: Always clean mounting surfaces of crimp tooling and tooling holders prior to installation.

Installation

1. Unscrew the thumbscrew and remove the safety shield.

2. Rotate the insulation adjustment cam so the arrow points to the “L” setting (largest wire insulation

diameter).

NOTE: The insulation adjustment cam MUST always be set to “L” when installing crimp punches (E2

and I2). This is to allow proper clearance to install the conductor punch (E2).

3. Place the crimp punches (E2 and I2 if required) into the upper punch holder. If the upper tooling

requires a die spacer, install as shown in Figure 2-4. Be certain to orient the punches in the proper

direction (refer to the Crimp Tooling Specification Sheet when necessary). Using a 5/32” hex wrench,

start the #10-32 SHCS but do not fully tighten. Rotate the insulation adjustment cam to the desired

position (“L”, “M”, or “S”). See Figure 2-5. Push the upper punches (E2 and I2) upward with your

fingers to ensure proper seating in the upper punch holder and tighten the #10-32 SHCS.

4. If the crimp tooling does not include an insulation punch (I2), push up on the conductor punch (E2)

and tighten the #10-32 SHCS.

Removal

1. Loosen the #10-32 SHCS.

2. If required, rotate the insulation adjustment cam to the “L” setting.

3. Unscrew the #10-32 SHCS until disengaged and remove the punches.

Conductor and Insulation Anvils (E1 and I1) (Lower Tooling)

CAUTION: Always disconnect power and air supply before installing or removing tooling

NOTE: Always clean mounting surfaces of crimp tooling and tooling holders prior to installation.

Installation

1. Lift the ram up and place the crimp anvils (E1 and I1 if required) into the lower anvil holder. If the lower

tooling requires a die spacer, install as shown in Figure 2-4. Be certain to orient the anvils in the proper

direction with the part number facing the operator (refer to the Crimp Tooling Specification Sheet when

necessary). Tighten the #10-32 SHCS.

2. Lower the ram allowing the punches and anvils to close. Crimp tooling should be aligned and engage

with no resistance. If binding occurs, loosen the (2) #10-32 SHCS. With the ram in the down position

and the tooling engaged, tighten the (2) #10-32 SHCS. If insulation tooling is installed, be certain to

push up on the insulation punch before tightening the screw.

3. Replace the safety shield and secure in position with the thumbscrew.

Removal

1. Loosen the #10-32 SHCS.

2. Lift the ram up, and unscrew the #10-32 SHCS until disengaged and remove the anvils.

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 11 of 42

Revision: E Revision Date: 08-25-09

Page 13

ATP-301 Air Tape Press

RAM

“S” SETTING FOR

INSULATION CRIMP PUNCH IS IN

CRIMP PUNCH

UPPER PUNCH

“L” SETTING FOR

“M” SETTING FOR MEDIUM

INSULATION CRIMP PUNCH IS IN

INSULATION

Figure

2-5

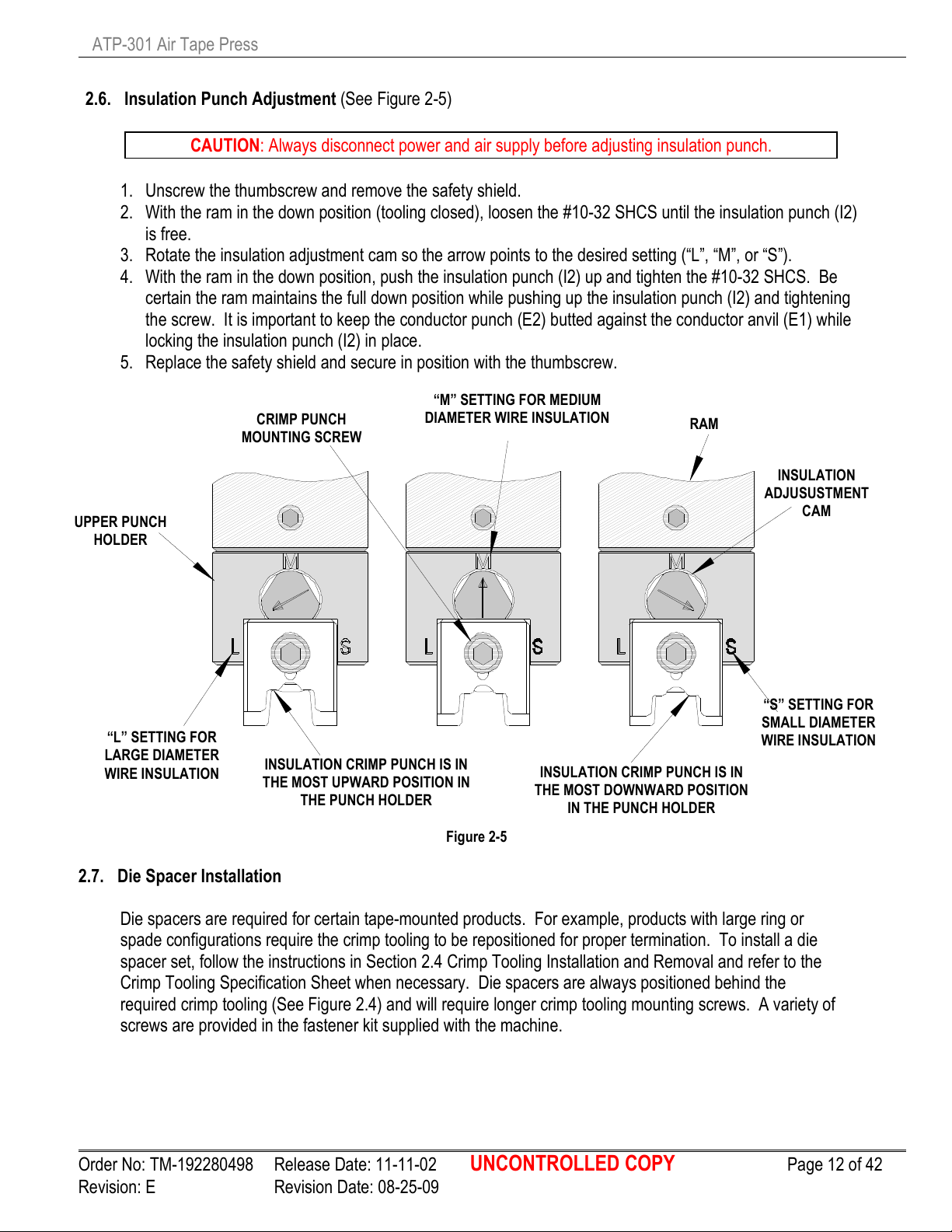

2.6. Insulation Punch Adjustment (See Figure 2-5)

CAUTION: Always disconnect power and air supply before adjusting insulation punch.

1. Unscrew the thumbscrew and remove the safety shield.

2. With the ram in the down position (tooling closed), loosen the #10-32 SHCS until the insulation punch (I2)

is free.

3. Rotate the insulation adjustment cam so the arrow points to the desired setting (“L”, “M”, or “S”).

4. With the ram in the down position, push the insulation punch (I2) up and tighten the #10-32 SHCS. Be

certain the ram maintains the full down position while pushing up the insulation punch (I2) and tightening

the screw. It is important to keep the conductor punch (E2) butted against the conductor anvil (E1) while

locking the insulation punch (I2) in place.

5. Replace the safety shield and secure in position with the thumbscrew.

MOUNTING SCREW

DIAMETER WIRE INSULATION

ADJUSUSTMENT

HOLDER

LARGE DIAMETER

WIRE INSULATION

THE MOST UPWARD POSITION IN

THE PUNCH HOLDER

THE MOST DOWNWARD POSITION

IN THE PUNCH HOLDER

SMALL DIAMETER

WIRE INSULATION

2.7. Die Spacer Installation

Die spacers are required for certain tape-mounted products. For example, products with large ring or

spade configurations require the crimp tooling to be repositioned for proper termination. To install a die

spacer set, follow the instructions in Section 2.4 Crimp Tooling Installation and Removal and refer to the

Crimp Tooling Specification Sheet when necessary. Die spacers are always positioned behind the

required crimp tooling (See Figure 2.4) and will require longer crimp tooling mounting screws. A variety of

screws are provided in the fastener kit supplied with the machine.

CAM

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 12 of 42

Revision: E Revision Date: 08-25-09

Page 14

ATP-301 Air Tape Press

3.1. Control Panel Operation

3.2. Loading Taped Product

3.3. Removing Taped Product

3.4. Wire Stop Installation

3.5. Stripper Installation

Section 3

Setup-Operation

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 13 of 42

Revision: E Revision Date: 08-25-09

Page 15

ATP-301 Air Tape Press

POWER

MANUAL

E-STOP BUTTON

Figure 3

-1

DOUBLE

3.1. Control Panel Operation (See Figure 3-1)

1. Pressing POWER ON (momentary) push button

permits power to the machine unless one or both of

the following conditions exist.

a) The power cord is not properly plugged in a power

ON

BUTTON

source.

b) The E-STOP push button is depressed (in the off

position).

This green push button will illuminate when power is

INDEX

BUTTON

on.

2. Pressing the E-STOP push button will power down the

machine. This is a locking push button. To reset the

(INDEX

SWITCH)

E-STOP, rotate the push button clockwise until it

resets. The switch will pop out when reset. The

POWER ON push button will not supply power to the

machine until the E-STOP is reset.

3. The INDEX (momentary) push button is used to index the tape product without terminating the terminals.

This push button operates in two stages described below.

a) Pressing this push button the first time will cause the ram to rise to the full up position and index the

tape. This red push button will flash on and off when the machine is in this condition.

b) Pressing this push button a second time will allow the ram to lower down but will not actuate the main

ram cylinder for termination. The ram will fall down and capture the terminal (if present in the

termination position). The push button will stop flashing at this time to indicate that it is no longer

active.

NOTE: When the red INDEX push button is depressed and no motion is performed, the red light will flash

on and off. One or both of the following conditions may exist.

a) The E-STOP push button is depressed (in the off position). Push INDEX one time to stop the flashing

condition. Rotate the E-STOP clockwise to reset and press the POWER ON push button to restore

power to the machine.

b) The air supply is disconnected. Press INDEX one time to stop the flashing condition. Reconnect the

airline. Push INDEX to initiate the index cycle.

CAUTION: It is recommended to always deactivate the index cycle by pressing INDEX one time to stop

the flashing condition before POWER ON or RECONNECTING the air supply. If the light is flashing, the

machine will perform the index immediately upon restoration of power or air supply.

4. The DOUBLE INDEX (rocker) switch changes the machine from single index mode to double index

mode. When this switch is in the off position (the “o” symbol on the lower half of switch depressed), the

machine will single index. When this switch is on (the “l” symbol on the upper half of switch depressed),

the machine will perform double indexing.

NOTE: The following two items are not on the control panel.

5. The WORKLAMPS will remain illuminated at all times as long as there is power to the machine. There

is no on/off switch for the work lamps.

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 14 of 42

Revision: E Revision Date: 08-25-09

Page 16

ATP-301 Air Tape Press

CUT TAPE ON A

Figure3

-2

Figure 3

-3

TAPE INDEX WHEEL

UPPER TAPE GUIDE

LOWER TAPE GUIDE

CARRIER TAPE

LOWER ANVIL HOLDER

SAFETY SHIELD

UPPER PU

NCH HOLDER

TERMINAL

6. The FOOT PEDAL (SWITCH) should be placed on the floor and positioned for operator comfort.

Pressing the foot pedal and releasing will initiate one press cycle.

3.2. Loading Taped Product (See Figure 3-3)

DIAGONAL

1. Prepare the tape for loading. Use scissors to cut the tape

on a diagonal. The diagonal cut must pass between the

slots in the tape. See Figure 3-2.

2. Slide the tape between the upper and lower tape guides

with the rear edge of the tape against the rail on the lower

guide. Push the tape to the right into the mechanism until

the slot in the tape engages to first tooth on the index

wheel. Listen for a click sound when the slot snaps over

the tooth in the wheel.

NOTE: If the wire stop assembly is installed, check position of tape after each index to ensure the tape has

passed under the wire stop. It may be necessary to lift the wire stop over the tape.

Depending on the condition of the tape, the above step may have to be repeated until successful.

3. Press the Index push button on the control panel twice to index the tape (See Section 3.1, Item 3 for

more details on the Index push button). Repeat this step as necessary until a terminal is in the

termination position centered over the lower anvil or anvils.

NOTE: It is recommended the operator always observe the tape as it passes through the exit guides

to the right of the crimp tooling. Adjustment of the tape may be required to maintain a smooth flow of

the used tape through the upper and lower exit guides.

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 15 of 42

Revision: E Revision Date: 08-25-09

Page 17

ATP-301 Air Tape Press

Figure 3

-4

THUMBSCREW

LOCATE AND PUSH LIP

#10-32 X 3/4” SHCS

SIDE PLATE

WIRE STOP BLADE

STRIPPER /WIRE

STOP

64016

-

0068 STRIPPER/ WIRE STOP CONFIGURATIONS

WIRE STOP ASSEMBLY

STRIPPER ASSEMBLY

3.3 Removing Taped Product

1. When 5 wires remain to be terminated, cut the tape off with 4 terminals to the left of the crimp tooling.

2. When terminations are complete, cycle or index the machine as required to allow the tape to exit the

feed mechanism. The foot switch or the index push button can be used to run the tape out of the

machine.

ASSEMBLY (AS SHIPPED)

(STRIPPER REMOVED)

(WIRE STOP REMOVED)

3.4 Wire Stop Installation

Note: The Wire Stop Assembly is not installed at the factory. It is supplied with the machine and can be

installed at anytime. It is recommended for use with terminals that do not have a wire stop feature such as

un-insulated rings and spades.

Prior to installing the wire stop into the press, remove the stripper from the sub-assembly. See stripper/wire

stop configurations. This is done by removing the #10-32 Low Head SHCS from the end of the support that

mounts the stripper.

CAUTION: Always disconnect power and air supply before installing or removing wire stop.

FOR SAFETY SHIELD

OF MOUNTING BLOCK

UNDER THE SIDE PLATE

(SHOWN WITH TOOLING REMOVED)

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 16 of 42

Revision: E Revision Date: 08-25-09

Page 18

ATP-301 Air Tape Press

GAP

TERMINAL

TAPE

WIRE STOP

SUPPORT

TOP VIEW (Termi

nation area with wire stop)

#10-32 X 3/4”LG. SHCS

C

ONDUCTOR

.250 DIA. X .125 LG.

1. Unscrew the thumbscrew and remove the safety shield.

NOTE: Although not necessary, it is recommended that all crimp tooling and taped products be removed

before mounting the wire stop assembly.

2. Position the wire stop assembly on the inside wall of the right side plate. Be certain the lip of the support

block locates under the edge of the side plate and secure with the #10-32 x 3/4” SHCS into the far #10-32

tapped hole. See Figure 3-4.

NOTE: Crimp tooling must be installed for the following step.

3. To properly position the wire stop, loosen the

#10-32 SHCS. While pushing up on the

mounting block, slide the assembly in or out

BLADE

SOC SHOULDER SCREW

to achieve the required gap between the rear

of the terminal conductor barrel and the front

face of the wire stop blade (See Figure 3-5)

(ADJUST AS

REQUIRED)

and lock in place by tightening the #10-32

SHCS.

4. Replace the safety shield and secure in

position with the thumbscrew.

NOTE: Taped product must be loaded for the

following step.

ANVIL (E1)

5. Make a test sample to evaluate the position

of the wire stop. If the wire brush on the far

side of the terminal is too long or too short,

CONDUCTOR

BARREL

adjust the gap between the conductor barrel

and wire stop blade per step 3 above.

Figure 3-5

3.5 Stripper Installation

Note: The Stripper Assembly is not installed at the factory. It is supplied with the machine and can be

installed at anytime. It is recommended for use with terminals that stick in the conductor punch after

termination.

Prior to installing the wire stripper into the press, remove the wire stop from the sub-assembly. See

stripper / wire stop configurations. This is done by removing the 1/4” diameter x 1/8” long Shoulder Screw

from the end of the support bar that mounts the wire stop blade.

CAUTION: Always disconnect power and air supply before installing or removing wire stripper.

1. Unscrew the thumbscrew and remove the safety shield.

NOTE: Although not necessary, it is recommended that all crimp tooling and taped products be removed

before mounting the stripper assembly.

WIRE STOP

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 17 of 42

Revision: E Revision Date: 08-25-09

Page 19

ATP-301 Air Tape Press

STRIPPER GAP

ANVIL (E1/I1)

STRIPPER BAR

#10-32 SHCS FOR

Figure 3

-6

LO

CATE AND PUSH LIP

TERMINAL TO BE CRIMPED

#10-32 X 1/2” LG.

#10-32 X 3/4” LG.

2. Position the stripper assembly on the inside wall of the right side plate. Be certain the lip of the support

block locates under the edge of the side plate and install the #10-32 x 3/4” SHCS into the far #10-32

tapped hole. Slide the block all the way forward (toward you) and tighten the #10 SHCS. See Figure 3-

6.

PUNCH (E2/I2)

LOW HEAD SHCS

(STRIPPER HEIGHT ADJUST)

SEE NOTE 5

OF MOUNTING BLOCK

UNDER THE SIDE PLATE

(STRIPPER IN/OUT ADJUST)

3. Adjust the height of stripper bar by loosening the #10-32 x 1/2“ Low Head SHCS and position the

stripper bar up and down in the center of the mounting slot and tighten the screw.

NOTE: Crimp tooling must be installed for the following step.

4. To properly position the support block depth, loosen the #10-32 x 3/ 4” SHCS and slide the entire

assembly in until the stripper pad clears to #10-32 SHCS that mounts the conductor (E2) or insulation

(I2) punch and tighten the #10-32 SHCS. See Figure 3-6.

NOTE: Taped product must be loaded for the following step.

5. Adjust the stripper gap by positioning the stripper bar height. Loosen the #10-32 x 1/2” Low Head SHCS

on the end of the support block and slide the stripper bar down so it is positioned just above the terminal

that is to be crimped, and tighten the #10 Low Head SHCS. See Figure 3-6. To verify the stripper gap,

push the index button twice to advance the terminal. Repeat this several times. If the terminal does not

position properly between the punch and anvil, increase the stripper gap as required until the terminal

positions properly.

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 18 of 42

Revision: E Revision Date: 08-25-09

Page 20

ATP-301 Air Tape Press

Section 4

Maintenance

4.1 Cleaning

4.2 Compressed Air System Maintenance

4.3 Lubrication

4.4 Spare Parts

4.5 Perishable Parts

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 19 of 42

Revision: E Revision Date: 08-25-09

Page 21

ATP-301 Air Tape Press

4.1. Cleaning

WARNING: Disconnect electrical power and

air supply before all maintenance.

For efficient operation, the ATP-301 Tape Press

should be cleaned daily. Use a soft bristle brush to

remove debris from critical areas such as the crimp

tooling and tape feed wheel assembly. For best

results, remove the safety shield, taped product,

and crimp tooling from the press. Using your

thumb, lift open the upper tape guide and brush out

all debris between the upper and lower tape feed

guides, around the tape feed wheel, and to the right

where the tape exits the machine. Brush and then

use a clean cloth to wipe off the upper and lower

tooling mounting areas. Before reinstalling tooling,

wipe all sides of the punches and anvils with a

clean cloth.

Use window cleaner and cloth to clean the safety

shield. Never use solvents. If the shield is

severely scuffed or scratched, replacement may be

necessary. See Section 5 for part numbers.

CAUTION: Never use compressed air to clean the

machine.

4.2. Compressed Air System Maintenance

WARNING: Disconnect electrical power and air

supply before all maintenance.

Due to the nature of the system, air compressors

commonly create condensation and moisture in the

system. This will cause problems in any pneumatic

piece of equipment. The moisture will cause

premature corrosion inside the valves and device.

As the tool operates, commonly there is an exhaust

port that will spray the moisture out and cause the

mechanical aspect of the tool to corrode. This tool

is designed for a clean, dry air system. To

maximize the life span of your tool you should

maintain a low moisture system. This may include

a weekly spot check of the moisture in your lines.

This can be checked easily. Connect an air nozzle

to a low point in the hard piping or near the press.

Blowing air onto a piece of paper for a period of

time, you will see if any moisture is being

circulated.

All air compressors have a dump valve or plug on

the underside of the tank. With the compressor

off and no pressure in the system . . . you can

open this and drain any built up moisture. There

can also be moisture collected in the drop down

pipes from overhead. There should be an extra

length of pipe with a valve to drain. Water can

collect at these points, and not be blown through.

4.3. Lubrication

For trouble free operation, regular maintenance is

mandatory. The following maintenance procedures

will help ensure top quality machine performance.

Depending on machine usage, the time between

maintenance can vary. For machines with high

daily cycle counts, over 1,000 cycles per day,

maintenance is required more often than machines

used for lower volumes, under 1,000 cycles per

day. It is recommended to perform the following

maintenance at least every 20,000 cycles. This

could be once a month for low volume users or

every two to three days for high volume production.

The following formula and examples can be used to

determine maintenance frequency:

C x H = D then 20,000 ÷ D = #

Where: C = cycles per hour

H = hours per day

D = cycles per day

20,000 = maintenance frequency

# = Number of days between

maintenance

Example for a low volume user: 220 cycles

per hour for 4 hours per day

220 x 4 = 880 and then 20,000 ÷ 880 = 22.72

or maintenance every 23 days.

Example for a high volume user: 360 cycles

per hour for 8 hours per day

360 x 8 = 2,880 and then 20,000 ÷ 2,880 =

6.94 or maintenance every 7 days.

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 20 of 42

Revision: E Revision Date: 08-25-09

Page 22

ATP-301 Air Tape Press

Figure 4

-1

GREASE

OIL

GREASE

FRONT

GREASE

BACK

GREASE

WARNING: Disconnect electrical power and air supply before all maintenance.

1. Remove the 3/8-16” acorn nut from the top of the press.

2. Remove and set aside the reel arm assembly.

3. Remove and set aside the cover assembly. Use caution when lifting the cover. The lower edge of the

opening for the control panel can interfere with push buttons and damage the controls.

4. Lubricate all points shown in Figures 4-1 with the specified oil and grease (or equivalent).

Lubricate with 40WT non-detergent oil and grease with Permatex multi-purpose synthetic grease with

Teflon No. 82329.

WARNING: Never use solvents or penetrants for any lubrication on the machine.

5. Replace the cover and reel arm assemblies, and secure with the 3/8-16” acorn nut.

An example of a maintenance chart is shown below. Copy and use this chart to track the maintenance of

your ATP-301 or use this as a template to create you own schedule or use your company’s standard chart if

applicable.

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 21 of 42

Revision: E Revision Date: 08-25-09

Page 23

ATP-301 Air Tape Press

Preventive Maintenance Chart

Daily: Clean (See Section 4.1).

As Required: Lubrication (See Section 4.3).

CHECK SHEET MONTH YEAR _________

Week Daily Clean

1

2

3

4

(As Required)

Lubricate

Schedule should be adjusted up or down depending on usage. Molex recommends that a log of preventive

maintenance be kept with the press.

4.4 Spare Parts

Customers are responsible for maintaining the ATP-301 Air Tape Press. Spare parts are available.

Moving and functioning parts can be damaged or wear out over time and will require replacement.

Molex recommends that the customer keep some or all of them in stock to reduce production down time.

These parts are identified in the Parts List. See Section 5.

4.5 Perishable Parts

Customers are responsible for maintaining the ATP-301 Air Tape Press. Perishable parts are those

parts that come in contact with the product and may wear out over time. Molex recommends that all

customers keep at least one set of the perishable tool kit in stock at all times. This will reduce the

amount of production down time. For the proper perishable tool kit information, refer to the Crimp

Tooling Specification Sheet supplied with the tool kit.

MON TUE WED THU FRI SAT SUN

Days of the Week

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 22 of 42

Revision: E Revision Date: 08-25-09

Page 24

ATP-301 Air Tape Press

5.1. Parts Lists and Assembly Drawings

5.2. Electrical Schematic

5.3. Pneumatic Diagram

5.4. Troubleshooting

Section 5

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 23 of 42

Revision: E Revision Date: 08-25-09

Page 25

ATP-301 Air Tape Press

5.1. Parts List and Assembly Drawings

19228-0030 Air Tape Press Figure 1-1

Figure Description Qty

Figure 5-1 Ram/Index Cylinder Assembly 1

Figure 5-2 Main Air/Top Roller Assembly 1

Figure 5-3 Index Block Assembly 1

Figure 5-4 Lower Tooling Assembly 1

Figure 5-5 Base Assembly 1

Figure 5-6 Cover Assembly 1

Figure 5-7 Reel Arm Assembly 1

Figure 5-8 Frame Assembly 1

Figure 5-9 Controls Assembly 1

Ram / Index Cylinder Parts List (See Figure 5-1)

Ram/Index Cylinder Assembly Figure 5-1

Item Order No. Engineering No. Description Qty

1 11-31-6809 AM60018-46 Male Connector #10-32 THD-5/32” Tube 1**

2 11-32-1111 AM60001-150 Male Connector #10-32 THD-1/4” Tube 1**

3 19228-0068 23195-01 Index Cylinder Assembly 1

4 19228-0108 23155-02 Ram Roller - Lower 1

5 19228-0109 23155-03 Ram Lift Pin 1

6 19228-0116 23155-27 Light Deflector 1

7 19228-0138 23156-31 Index Lever 1

8 19228-0147 23157-07 Cam - Insulation Crimp 1

9 19228-0199 23155-01 Ram 1

10 19228-0201 23157-05 Upper Punch Holder 1

11 19228-0204 23154-07 Block - Ram Guide 1

12 19228-0240 23157-06 Back Plate-Upper Punch Holder 1

13 19228-0406 23155-11 Ram Lock Screw 1

14 62500-1172 62500-1172 Miniature Lamp 2

15 63700-3795 63700-3795 Precision Pivot Pin 1

16 63700-3796 63700-3796 Bushing-Ram Guide 1

17 64000-0008 64000-0008 Key 2

18 64000-0097 64000-0097 Work Light Assembly 1

19 N/A N/A E-Ring. (5/32” External) 1**

20 N/A N/A 3/8-16 Jam Nut 1**

21 N/A N/A #6-32 by 1/4” Long BHCS 4**

22 N/A N/A #8-32 by 1/2” Long SHCS 2**

23 N/A N/A #10-32 by 1-1/4” Long SHCS 2**

24 N/A N/A #8-32 by 3/16” Long SSS (Cup Pt.) 1**

25 N/A N/A 1/4-20 by 3/8” Long SSS (Cup Pt. with Nylok) 1**

26 N/A N/A Retaining Ring (1/8” External) 1**

27 N/A N/A Retaining Ring (3/8” External) 1**

The components indicated with **are available from an Industrial supply company such as MSC (1-800-645-7270).

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 24 of 42

Revision: E Revision Date: 08-25-09

Page 26

ATP-301 Air Tape Press

RAM/INDEX CYLINDER ASSEMBLY

(2)

6

23

13

4

14

7

12

17

20

10

25

(2)

16

8

1

24

2

18

(2)

15

3

26

(2)

(2)

21

27

9

22

19

(2)

21

5

11

(2)

Ram / Index Cylinder Assembly

Figure 5-1

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 25 of 42

Revision: E Revision Date: 08-25-09

Page 27

ATP-301 Air Tape Press

(2)

MAIN AIR CYLINDER/ TOP

ROLLER ASSEMBLY

1

7

11

15

9

16

18

19

8

12

5

17

4

13

14

20

18

10

3

6

(3)

(2)

(2)

2

(2)

Main Air Cylinder / Top Roller Parts List (See Figure 5-2)

Main Air Cylinder / Top Roller Assembly Figure 5-2

Item Order No. Engineering No. Description Qty

1 11-31-1897 R8432-23 Male Elbow Fitting (1/8” NPT- 1/4” Tube) 1**

2 11-31-6809 AM60018-46 Male Connector (#10-32 THD-5/32” Tube) 1**

3 11-32-1061 AM60001-124 Male Elbow Fitting (1/4” NPT- 3/8” Tube) 1**

4 19228-0106 23154-10 Top Roller Pin 1

5 19228-0110 23155-05 Top Roller 1

6 19228-0112 23155-15 Power Cam Pin 1

7 19228-0113 23155-16 Power Cam 1

8 19228-0172 23194-01 Ram Lift Cylinder 1

9 19228-0186 23154-04 Top Roller Block 1

10 19228-0194 23192-02 Main Air Cylinder 1

11 19228-0207 23561-26D Right Side Plate REF

12 64000-0007 64000-0007 Key 2

13 N/A N/A #4-40 by 1/4” Long SHCS 1**

14 N/A N/A #6 Washer (Common) 1**

15 N/A N/A 1/4-20 by 3/4” Long SHCS 3**

16 N/A N/A #10-32 by 1-1/4” Long SHCS 2**

17 N/A N/A #8-32 by 3/16” Long SSS (Cup Pt.) 1**

18 N/A N/A #10-32 by 1/4” Long SSS (Cup Pt.) 2**

19 N/A N/A #10 Lock Washer 2**

20 N/A N/A Retaining Ring (1/4” External) 2**

The components indicated with **are available from an Industrial supply company such as MSC (1-800-645-7270).

Main Air Cylinder / Top Roller Assembly

Figure 5-2

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 26 of 42

Revision: E Revision Date: 08-25-09

Page 28

ATP-301 Air Tape Press

Index Block Parts List (See Figure 5-3)

Item Order No. Engineering No. Description Qty

1

19228-0124 23156-04 Tape Index Wheel 1

2

19228-0125 23156-07 Tape Driver Disk 1

3

19228-0127 23156-03 Thrust Bearing 1

4

19228-0128 23156-10 Ratchet Wheel 1

5

19228-0132 23156-18 Index Arm Guide 1

6

19228-0135 23156-25 Plain Bearing 1

7

19228-0136 23156-26 Housing-Ball Detent 1

8

19228-0137 23156-27 Ball Detent 1

9

19228-0141 23156-46 Spring Hold Down 1

10 19228-0142 23156-47 Spring Hold Down Post 1

11 19228-0187 23154-09 Ratchet Index Block 1

12 19228-0188 23156-44 Tape Hold Down 1

13 19228-0209 23156-30 Index Cam Deflector 1

14 19228-0400 23156-06 Tape Driver Shaft 1

15 19411-0146 26220-704 Thrust Washer 2

16

17

18

19

20

21

22

23

24

25

26

The components indicated with **are available from an Industrial supply company such as MSC (1-800-645-7270).

N/A N/A #8 Lock Washer 1**

N/A N/A #8-32 by 1/2” Long SHCS 1**

N/A N/A #8-32 by 3/4” Long BHCS 1**

N/A N/A #8-32 by 3/4” Long SHCS 2**

N/A N/A #10-32 by 1.0” Long SHCS 1**

N/A N/A 3/32” by 3/8”Long Dowel Pin 2**

N/A N/A 3/32” by 1/2”Long Dowel Pin 2**

N/A N/A 5/32” Diameter Steel Ball 1**

N/A N/A Compression Spring (.18” O.D. by .032” W. by .88” Lg.) 1**

N/A N/A Compression Spring (.24” O.D. by .032” W. by 1.0” Lg.)) 1**

N/A N/A Shim Washer (.50” I.D. by 1.13” O.D. by .010” Lg.) 1**

Index Block Assembly Figure 5-3

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 27 of 42

Revision: E Revision Date: 08-25-09

Page 29

ATP-301 Air Tape Press

(2)

(2)

16

4

21

3

15

26

24

17

8

(2) 19

5

13

12

11

6

10

9

25

INDEX BLOCK ASSEMBLY

(2)

23

7

14

1

2

22

18

20

Index Block Assembly

Figure 5-3

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 28 of 42

Revision: E Revision Date: 08-25-09

Page 30

ATP-301 Air Tape Press

(2) 8

L

OWER TOOLING ASSEMBLY

1

4

3

6

2

7

5

(2)

Lower Tooling Parts List (See Figure 5-4)

Lower Tooling Assembly Figure 5-4

Item Order No. Engineering No. Description Qty

1 19228-0145 23157-02 Lower Anvil Holder 1

2 19228-0146 23157-03 Back Plate- Lower Anvil Holder 1

3 19228-0189 23156-45 Auto Tape Start 1

4 19228-0218 23154-08 Front Base Block 1

5 64000-0008 64000-0008 Key 2

6 N/A N/A #8-32 by 3/8” Long FHCS 1**

7 N/A N/A #10-32 by 1/2” Long SHCS 1**

8 N/A N/A 1/4-20 by 3/4” Long BHCS 2**

The components indicated with **are available from an Industrial supply company such as MSC (1-800-645-7270).

Lower Tooling Assembly

Figure 5-4

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 29 of 42

Revision: E Revision Date: 08-25-09

Page 31

ATP-301 Air Tape Press

(4)

BASE ASSEMBLY

1

7

2

5

9

8

4

6

7

7

(2)

(2)

(4)

(2)

3

Base Parts List (See Figure 5-5)

Item Order No. Engineering No. Description Qty

1 19228-0102 23151-07 Rubber Bumper with Stud 4

2 19228-0103 23151-10 Upper Tape Guide 1

3 19228-0104 23151-11 Lower Tape Guide 1

4 19228-0107 23154-28 Mounting Bracket 1

5 19228-0206 23154-23 Base Plate 1

6 19228-0215 23151-09 Tilt Leg 2

7 N/A N/A #10-32 by 1/4” Long BHCS 4**

8 N/A N/A #10-32 by 1/2” Long BHCS 2**

9 N/A N/A #10-32 by 3/4” Long BHCS 4**

The components indicated with **are available from an Industrial supply company such as MSC (1-800-645-7270).

Base Assembly

Base Assembly Figure 5-5

Figure 5-5

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 30 of 42

Revision: E Revision Date: 08-25-09

Page 32

ATP-301 Air Tape Press

(2)

COVER ASSEMBLY

3

1

8

5

7

4

6

(4)

2

9

10

(2)

11

Cover Parts List (See Figure 5-6)

Item Order No. Engineering No. Description Qty

1 11-31-8944 AM60506P109 Male Elbow (1/4”NPT-1/4” Tube) 1**

2 19228-0117 23155-30 Handle Bracket 1

3 19228-5001 19228-5001 Nut Plate – Air Regulator 1

4 19818-5010 19818-5010 Cover 1

5 62500-0189 62500-0189 Filter Regulator 1

6 63700-3274 63700-3274 Handle 1

7 N/A N/A #6-32 by 1/2” Long FHCS 4**

8 N/A N/A #10-32 by 3/4” Long BHCS 2**

9 N/A N/A 3/8-16 Acorn Nut 1**

10 N/A N/A 3/8” Washer (common) 2**

11 N/A N/A Air Coupler 1/4 NPT (to Suit by Customer) REF ONLY**

The components indicated with **are available from an Industrial supply company such as MSC (1-800-645-7270).

Cover Assembly

Figure 5-6

Cover Assembly Figure 5-6

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 31 of 42

Revision: E Revision Date: 08-25-09

Page 33

ATP-301 Air Tape Press

REEL ARM ASSEMBLY

(3)

4

5

3

2

1

9

8

7

6

Reel Arm Parts List (See Figure 5-7)

Item Order No. Engineering No. Description Qty

1 19228-0102 23151-07 Rubber Bumper With Stud 1

2 19228-0179 23291-02 Reel Shaft 1

3 19228-0210 23291-22 Weldment- Reel Arm 1

4 19228-0211 23291-23 Reel Arm 1

5 19818-5010 19818-5010 Cover REF

6 64016-0053 64016-0053 Disc Assembly 1

7 69018-8135 69018-8135 Knurled knob 1

8 69018-8136 69018-8136 Quick release pin 1

9 N/A N/A 3/8-16 by 5/8” Long SHCS 3**

The components indicated with **are available from an Industrial supply company such as MSC (1-800-645-7270).

Reel Arm Assembly

Reel Arm Assembly Figure 5-7

Figure 5-7

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 32 of 42

Revision: E Revision Date: 08-25-09

Page 34

ATP-301 Air Tape Press

Frame Parts List (See Figure 5-8)

Item Order No. Engineering No. Description Qty

1 11-31-1904 R8432-30 Union Y Fitting (5/32” Tube) 1**

2 11-31-8944 AM60506P109 Male Elbow (1/4 NPT by 1/4” Tube) 1**

3 11-32-1059 AM60001-122 Male Elbow (1/4 NPT by 3/8” Tube) 1**

4 19228-0047 26110-90 Thumb Srew (#8-32 Thd) 1**

5 19228-0107 23154-28 Mounting Bracket REF

6 19228-0206 23154-23 Base Plate REF

7 19228-0207 23561-26D Right Side Plate 1

8 19228-0213 23151-05 Safety Shield 1

9 19228-0221 23154-14 Left Side Plate 1

10 62500-1089 62500-1089 Power Cord 1

11 62500-1091 62500-1091 Power Supply (24 VDC) 1

12 62500-1240 62500-1240 Exhaust Muffler (1/4 “NPT – sintered bronze) 1**

13 63700-2899 63700-2899 Quick Exhaust Valve 1

14 63800-8394 63800-8394 Foot Petal Assembly 1

15 64000-0009 64000-0009 Control Assembly 1

16 64016-0068 64016-0068 Stripper / Wire Stop Assembly 1

17 N/A N/A #4-40 by 5/8” Long SHCS 1**

18 N/A N/A #10-32 by 1/4” Long BHCS 2**

19 N/A N/A #10-32 by 1/2” Long BHCS 2**

20 N/A N/A #10-32 by 3/4” Long SHCS 1**

21 N/A N/A 1/4-20 by 3/4” Long FHCS 2**

22 N/A N/A 5/16-18 by 3/4” Long SHCS 5**

23 N/A N/A 5/16-18 by 1.0” Long SHCS 5**

24 N/A N/A 3/8-16 by 1-1/4” Long SSS (Cup Pt.) 1**

The components indicated with **are available from an Industrial supply company such as MSC (1-800-645-7270).

Frame Assembly Figure 5-8

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 33 of 42

Revision: E Revision Date: 08-25-09

Page 35

ATP-301 Air Tape Press

FRAME ASSEMBLY

1

11

9

18

2

8

5

4

14

10

3

6

(2)

(2)

17

15

19

16

20

(2)

24

12

13

7

22

(2)

23

21

Frame Assembly

Figure 5-8

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 34 of 42

Revision: E Revision Date: 08-25-09

Page 36

ATP-301 Air Tape Press

Controls Assembly and Parts List (Figure 5-9)

64000-0009 Controls Assembly Figure 5-9

Item Order No. Description Qty

1 REF Software Revision Label - ISO 1

2 62500-1055 Receptacle, 4 Pin Female 1

3 62500-1065 Omron DPDT Relay Assembly 1

4 62500-1066 Miniature Rocker Switch 1

5 62500-1082 Plastic Snap Bushing 0.562 in OD 1

6 62500-1084 Air Press Controls Enclosure Label 1

7 62500-1089 US 120V AC Power Cord, 18/3 (not shown) 1

8 62500-1091 24V DC Desktop Power Supply (not shown) 1

9 62500-1224 ZEN PLC, No Display, 10I/O 24V DC PWR 1

10 64000-0100 Power-On Pushbutton Assembly 1

11 64000-0101 Index Pushbutton Assembly 1

12 64000-0023 Air Press Controls Enclosure 1

13 64000-0024 Valve Assembly - Air Press 1

14 64000-0025 Air Dump Assembly-Air Press 1

15 64000-0065 E-Stop PB Assembly for ATP controls 1

16 64000-0097 Work Light Assembly (not shown) 1

17 N/A #4-40 by 1.0” Long BHCS 2**

18 N/A #6-32 by 1/4” Long BHCS 4**

19 N/A #8-32 by 1/4” Long BHCS 2**

20 N/A #8-32 by 1/2” Long BHCS 2**

21 N/A #8-32 by 1.25” Long SHCS 2**

22 N/A #4 Lock Washer 2**

The components indicated with **are available from an Industrial supply company such as MSC (1-800-645-7270).

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 35 of 42

Revision: E Revision Date: 08-25-09

Page 37

ATP-301 Air Tape Press

3

12

12

5

14

6

17

13

2

1

20

9

18

19

4

12

11

10

15

21

22

(PANEL)

(4)

(2)

(2)

(2)

(2)

(2)

See Next Page

See Next Page

CONTROL ASSEMBLY

SEE NOTE

(BOX)

Controls Assembly and Parts List (Figure 5-9)

BELOW

(COVER)

Figure 5-9

Note: See Item No. 1 for Control revision level.

Items No. 7, 8, and 16 not shown.

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 36 of 42

Revision: E Revision Date: 08-25-09

Page 38

ATP-301 Air Tape Press

(2)

1

3

2

9

7

6

64000

-

0025

(2)

4

5

8

10

64000

-

0024

(3)

(2)

Controls Assembly and Parts List Continued

VALVE ASSEMBLY

AIR DUMP ASSEMBLY

64000-0024 Valve Assembly

Item Order No. Eng No. Description Qty

1 11-31-1917 R8432-40 Exhaust Muffler (1/8” NPT Sintered bronze) 2**

2 11-31-8310 AM60506P106 Male Connector (1/8” NPT - 1/4” Tube) 1**

3 11-32-1084 AM60001-147 Reducer Air Fitting (1/4” Tube to 5/32” Tube) 2**

4 62500-1071 62500-1071 SMC Valve VQZ1000 Series 2

5 62500-1073 62500-1073 3 STA. Manifold VQZ1000 1/4” OT Ports 1

6 62500-1080 62500-1080 VQZ1000 Series Blanking Plate 1

7 62500-1081 62500-1081 Pipe Plug 1/8 NPT 3**

64000-0025 Air Dump Assembly

Item Order No. Eng No. Description Qty

8 11-31-1917 R8432-40 Exhaust Muffler (1/8” NPT Sintered bronze) 1**

9 11-31-8944 AM60506P109 Male Elbow (1/8” NPT - 1/4” Tube) 1**

10 62500-1079 62500-1079 3 POS. N.C. VQZ300 Valve, 1/4” OT Port 3

The components indicated with **are available from an Industrial supply company such as MSC

(1-800-645-7270).

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 37 of 42

Revision: E Revision Date: 08-25-09

Page 39

ATP-301 Air Tape Press

ATP-301 ELECTRICAL SCHEMATICS

5.2 Electrical Schematic

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 38 of 42

Revision: E Revision Date: 08-25-09

Page 40

ATP-301 Air Tape Press

ATP-301 PNEUMATIC DIAGRAM

5.3 Pneumatic Diagram

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 39 of 42

Revision: E Revision Date: 08-25-09

Page 41

ATP-301 Air Tape Press

5.4 Troubleshooting

Symptom Cause Solution

Electrically inoperative

Pneumatically inoperative

Terminals do not index

Terminals index improperly

Crimp at wrong position

Conductor crimp is

too loose

Conductor crimp is

too tight

Insulation crimp is

too loose

Insulation crimp is

too tight

Terminal slips during crimp

Power switch is off Turn power switch on

E-Stop button depressed Rotate/reset E-Stop button

Faulty power source Check voltage at power outlet

Faulty power supply Replace

Faulty air supply Check air supply pressure

Air pressure too low Adjust air regular

Restricted air flow Clean air filter

Contaminated air valves Drain/clean air system

Product reel jammed Adjust tension on reel hub

Tape not engaged Reload tape on index wheel

Tooling spacers required Locate and install spacers

Faulty index mechanism Contact Molex

Wrong tooling Replace with proper tooling

Tooling is backwards Properly mount tooling

Wrong tooling Replace with proper tooling

Tooling is backwards Properly mount tooling

Tooling spacers required Locate and install spacers

Terminal position Verify position on tape

Air pressure too low Adjust air regulator

Wrong tooling Replace with proper tooling

Tooling worn or damaged Replace tooling

Check for fractured frame Contact Molex

Lower ram roller worn Replace roller

Ram lift yoke worn Replace yoke

Wrong tooling Replace with proper tooling

Tooling worn or damaged Replace tooling

Terminal position Verify position on tape

Air pressure too low Adjust air regulator

Cam out of adjustment Readjust insulation cam

Wrong tooling Replace with proper tooling

Tooling worn or damaged Replace tooling

Check for fractured frame Contact Molex

Tooling backwards Reverse mounting of tooling

Terminal position Verify position on tape

Lower ram roller worn Replace roller

Ram lift yoke worn Replace yoke

Cam out of adjustment Readjust insulation cam

Wrong tooling Replace with proper tooling

Tooling worn or damaged Replace tooling

Terminal position Verify position on tape

Wrong tooling Replace with proper tooling

Tooling worn or damaged Replace tooling

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 40 of 42

Revision: E Revision Date: 08-25-09

Page 42

ATP-301 Air Tape Press

Symptom Cause Solution

Ram stays in up position

Foot pedal inoperative

Work light not illuminated Faulty lamp Replace lamp

Ram dirty or not lubricated

Lubricate ram (oil)

Contaminated air valves Drain/clean air system

Loose connection Tighten connection

Faulty foot pedal Replace foot pedal

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 41 of 42

Revision: E Revision Date: 08-25-09

Page 43

ATP-301 Air Tape Press

For more information review the Industrial Crimping Quality Handbook

(Order No. 64016-0065)

There is no charge for this book, which can be found on the Molex Web or contact you local Molex sales

engineer

Americas Headquarters

Lisle, Illinois 60532 U.S.A.

1-800-78MOLEX

amerinfo@molex.com

Far East North Headquarters

Yamato, Kanagawa, Japan

81-462-65-2324

feninfo@molex.com

Visit our Web site at http://www.molex.com

Far East South Headquarters

Jurong, Singapore

65-6-268-6868

fesinfo@molex.com

European Headquarters

Munich, Germany

49-89-413092-0

eurinfo@molex.com

Corporate Headquarters

2222 Wellington Ct.

Lisle, IL 60532 U.S.A.

630-969-4550

Fax: 630-969-1352

Order No: TM-192280498 Release Date: 11-11-02 UNCONTROLLED COPY Page 42 of 42

Revision: E Revision Date: 08-25-09

Page 44

EN

This Datasheet is presented by

the manufacturer

DE

Dieses Datenblatt wird vom

Hersteller bereitgestellt

FR

Cette fiche technique est

présentée par le fabricant

EN - For pricing and availability in your local country please visit one of the below links:

DE - Informationen zu Preisen und Verfügbarkeit in Ihrem Land erhalten Sie über die unten aufgeführten Links:

FR - Pour connaître les tarifs et la disponibilité dans votre pays, cliquez sur l'un des liens suivants:

19228-0030

Powered by TCPDF (www.tcpdf.org)

Loading...

Loading...