Page 1

AT-200 Air-Powered Crimping Tool

AT-200 AIR-POWERED CRIMPING TOOL

Operating and Maintenance Instructions with

With Optional Bench Adapter and Foot Switch shown

Description

Operation

Maintenance

Order No. 19279-0001

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 1 of 20

Revision: G Revision Date: 01-17-14

Page 2

AT-200 Air-Powered Crimping Tool

Read and understand all of the instructions and safety information in this manual before

operating or servicing this tool.

Keep this manual available when using this tool.

Replacement manuals are available for download at no charge at www.molex.com.

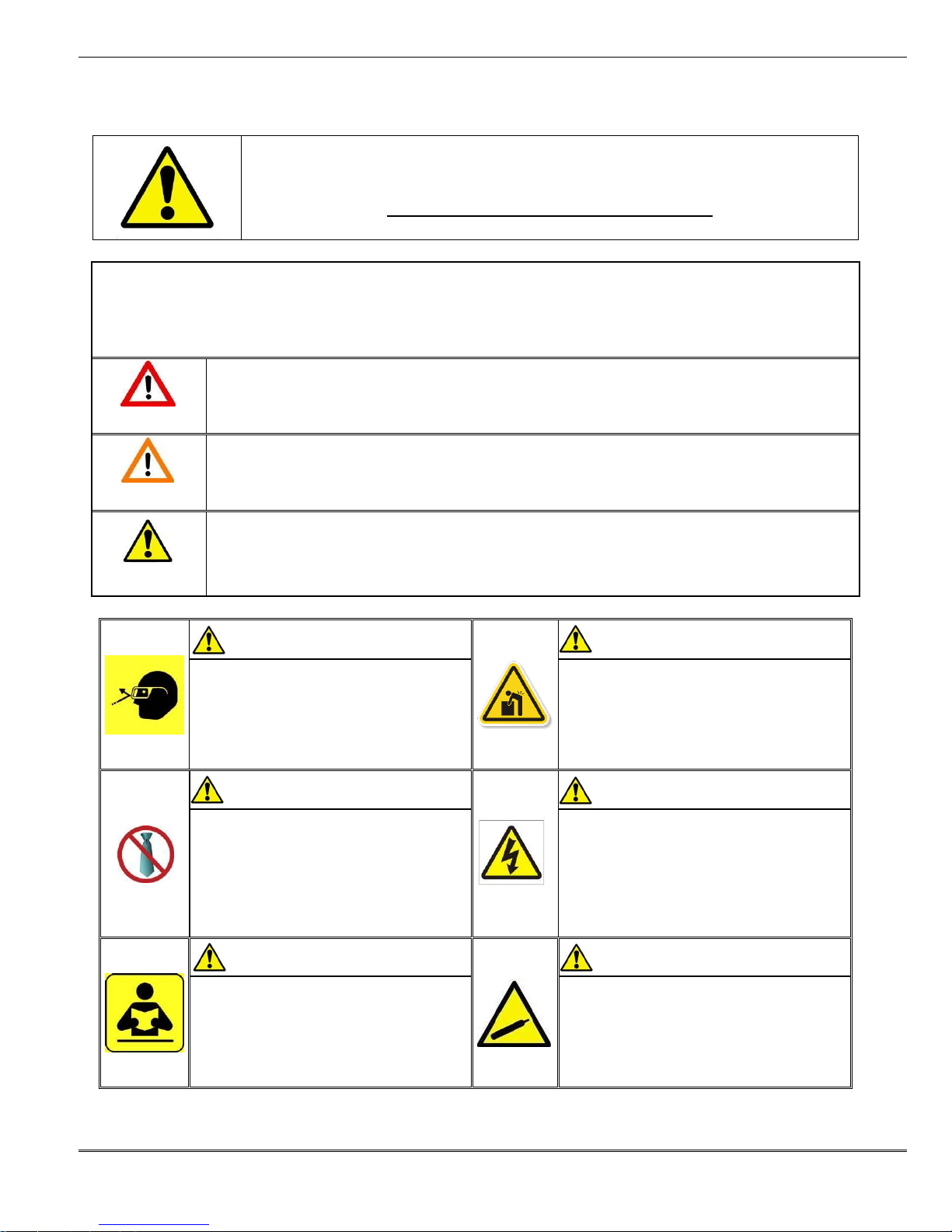

SAFETY ALERT SYMBOL

This symbol is used to call your attention to hazards or unsafe practices which could result in an injury

or property damage. The signal word, defined below, indicates the severity of the hazard. The message

after the signal word provides information for preventing or avoiding the hazard.

DANGER

DANGER:

Indicates an imminently hazardous situation which, if not avoided, could result in death or serious injury.

WARNING

WARNING:

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION:

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION may also be used to alert against unsafe practices associated with events that could lead

to personal injury.

WARNING

WARNING

Always wear proper eye protection when

Operating or servicing this equipment.

Failure to wear eye protection could result

in serious eye injury from flying debris.

Heavy Object

To avoid muscle strain or back injury, use lifting

aids and proper lifting techniques when removing

or replacing.

Failure to observe these precautions may result in

injury or property damage.

WARNING

WARNING

Never wear clothing or jewelery that is loose or

That could potentially hang into the equipement

and get caught.

Failure to observe this warning could result in

Severe Injury or death.

Never install or service this machine while

connected to any electrical power source.

Disconnect power by unplugging the press

from its power source.

Failure to observe this warning could result

In severe injury or death.

WARNING

WARNING

Never operate, service, install, or adjust this

machine without proper instruction and without

first reading and understanding the instructions

in this manual and all applicable press and/or

wire processing machine.

manuals.

Never Install or service this machine while

connected to the compressed air source.

Failure to observe this warning could result

In severe injury or death.

Safety Warnings and Information

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 2 of 20

Revision: G Revision Date: 01-17-14

Page 3

AT-200 Air-Powered Crimping Tool

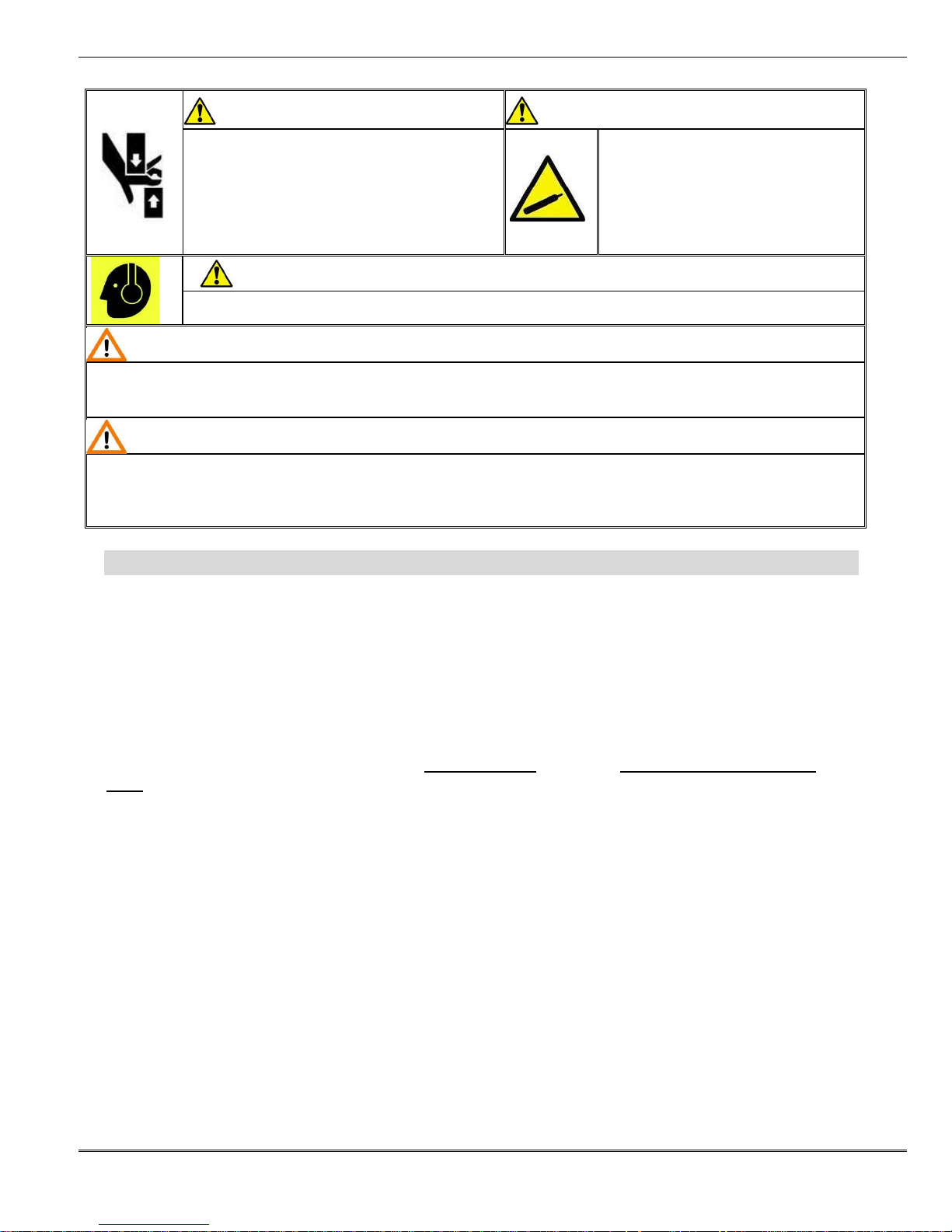

WARNING

WARNING

Never use this machine without guards or safety

devices that are intended

to prevent hands from remaining in the die space.

Failure to observe this warning could result in

Severe injury or death.

Do not use compressed air to clean

this equipment.

The forces created by compressed

air can force debris into the tool.

Failure to observe these precautions may

result in injury or property damage.

WARNING

Always wear proper ear protection when Operating or servicing this equipment.

CAUTION

The Molex at-200 air powered crimping tool is designed to be used with air powered crimp tools heads and tooling supplied by Molex.

Use of tool heads or tooling from any other source may result in damage or injury.

Molex will not be liable for any damage or injury from use of non-Molex components in this tool.

CAUTION

Never perform any service or maintenance other than as described in this manual.

Never modify, alter or misuse this tool

Molex crimp specifications are valid only when used with Molex terminals, applicators and tooling.

Failure to observe this precaution may result in injury and property damage.

Tooling Technical Assistance

Molex offers tooling technical assistance for customers who may need some guidance for tooling adjustments. This

support can be obtained by calling either of the two numbers listed below and asking for the Molex Tooling Group.

Call Toll Free 1-800-786-6539 (US) 1-630-969-4550 (Global).

This assistance is limited to the operation and set-up of a customer’s tool. Questions with regard to Molex connector

products or how to identify the proper tooling and/ or tooling documentation should be directed to your local Molex

personnel or Customer Service Representative.

When calling for service on the press a copy of the Operation Manual and Specific Applicator Tooling Specification

Sheet should be present and a person that is familiar with the applicator should be present. Be sure the following

information is supplied:

1. Customer name

2. Customer address

3. Person to contact such as (name, title, e-mail, and telephone number

4. Applicator order number (Lease number also if applicable)

5. Serial number (Lease number also if applicable)

6. Molex Connector product order number

7. Urgency of request

8. Nature of problem

Molex Application Tooling Group

2200 Wellington Court

Lisle, IL 60532, USA

Tel: +1 (630) 969-4550

Fax:+1 (630) 505-0049

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 3 of 20

Revision: G Revision Date: 01-17-14

Visit our Web site at http://www.molex.com

Page 4

AT-200 Air-Powered Crimping Tool

Table of Contents

Contents

AT-200 AIR-POWERED CRIMPING TOOL .................................................................................................................. 1

Order No. 19279-0001 ................................................................................................................................................... 1

Safety Warnings and Information .................................................................................................................................. 2

Table of Contents .......................................................................................................................................................... 4

Section 1 ....................................................................................................................................................................... 5

General Description ................................................................................................................................................... 5

1.1 Description .................................................................................................................................................... 6

1.2 Features ........................................................................................................................................................ 6

1.3 Technical Specification .................................................................................................................................. 6

1.4 Delivery Check .............................................................................................................................................. 6

1.5 Tools .............................................................................................................................................................. 6

1.6 Specification Sheets ...................................................................................................................................... 6

Section 2 ....................................................................................................................................................................... 7

2.1 Set-Up ........................................................................................................................................................... 8

2.2 Operation ....................................................................................................................................................... 9

Section 3 ..................................................................................................................................................................... 10

Adjustments ............................................................................................................................................................. 10

3.1 Changing Crimp Tool Heads ....................................................................................................................... 11

3.2 Insulation Support Crimp Adjustment .......................................................................................................... 12

3.3 Insulation Support Crimp Adjustment .......................................................................................................... 12

3.4 Terminal Crimping ....................................................................................................................................... 12

3.5 Maintenance ................................................................................................................................................ 12

3.6 Warranty ...................................................................................................................................................... 13

Section 4 ..................................................................................................................................................................... 14

Parts List and Assemblies ....................................................................................................................................... 14

4.1 19279-0001 Parts List and Assembly Drawings .......................................................................................... 15

4.2 19279-0135 Parts List ................................................................................................................................. 16

4.2 19279-0135 Assembly Drawings ................................................................................................................. 17

4.3 19078-0307 (Optional) Parts List and Assembly Drawings.......................................................................... 18

4.4 64001-4000 (Optional) Parts List and Assembly Drawing ........................................................................... 19

4.5 19279-0099 Parts List and Assembly Drawings .......................................................................................... 20

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 4 of 20

Revision: G Revision Date: 01-17-14

Page 5

AT-200 Air-Powered Crimping Tool

General Description

1.1 Description

1.2 Features

1.3 Technical Specifications

1.4 Delivery Check

1.5 Tools

1.6 Specification Sheets

Section 1

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 5 of 20

Revision: G Revision Date: 01-17-14

Page 6

AT-200 Air-Powered Crimping Tool

General Description

1.1 Description

The AT-200 Air-Powered Crimping Tool is a hand

held pneumatic tool weighting less than two pounds.

It is designed to crimp high quality and consistent

crimped terminals. This tool operates on standard

shop air (85 to 95 PSI) and crimps wire ranges from

26 to 8AWG.

1.2 Features

Crimping dies are easily and quickly

interchanged to reduce production down time.

Complete portable system that allows tool to be

moved and stored easily.

Tool may be used as a Potable tool, suspended

over head or bench mounted.

Higher volume output with less operator fatigue.

1.3 Technical Specification

Pneumatic:

Supply Pressure: 100 PSI (6.9 Bars) max

Cycle Time:

15 seconds

Weight

0.9kg (2lbs)

1.4 Delivery Check

Carefully remove the AT-200 Air-Powered

Crimping Tool from its shipping container and

determine that the following items are included in

the package.

19279-0001 Air-Powered Crimping Tool

19279-0140 Air Hose 1/8 NPT Male

TM-192790001 Instruction Manual

1.5 Tools

The following tools are recommended for setup

and adjustments to this tool.

1. Metric standard hex wrench set

2. Inch standard hex wrench set

3. Adjustable wrench

4. Wire stripper / cutter

5. Screw driver

Can Also Be Used With:

19078-0307 Bench Adapter Assembly with Foot

Switch

64001-4000 Electrical Control Box

1.6 Specification Sheets

Molex ships specification sheets with every Air

Crimp Tool Head. These Tool Heads are not

included with the AT-200 Air-Powered Crimp Tool.

They are ordered separately. The specification

sheet contains the following:

Terminal numbers

Wire AWG ranges

Insulation diameter ranges

Strip lengths

Pull Force

Crimp heights

Bell mouth

Bend, twist and roll limits

Tooling parts list and assembly

These are available on the Molex website

(www.molex.com).

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 6 of 20

Revision: G Revision Date: 01-17-14

Page 7

AT-200 Air-Powered Crimp Tool

2.1 Setup

2.2 Operation

Section 2

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 7 of 20

Revision: G Revision Date: 01-17-14

Page 8

AT-200 Air-Powered Crimp Tool

FILTER REGULATOR

(NOT SUPPLIED)

FOOT SWITCH

BENCH ADAPTER

TO AIR

SUPPLY

SECURE AIR CRIMPING

TOOL IN POSTION

CONNECT TUBING

FROM FOOT SWITCH

WITHOUT FITTING

Figure 2-2

CONNECT TUBING

FROM FOOT SWITCH

WITH FITTING

(NOT SUPPLIED)

TRIGGER

3/8-16 CAP

SCREW

TRIGGER SAFETY

AIR HOSE

(19279-0140)

FILTER REGULATOR

(NOT SUPPLIED)

TO AIR

SUPPLY

TRIGGER

Figure 2-1

Read the following instructions before attempting to operate this tool.

2.1 Set-Up

1. Connect the air hose to the tool and to the air supply 85 to 95 PSI. Do not exceed 100 PSI. May cause injury

or damage to the tool. Air supply must be equipped with a 1/4NPT air filter /regulator which is not supplied by

Molex. See Figure 2-1. (Available from any Industrial supply co.)

If changing to the Optional bench adapter (Order No. 19078-0307) remove the air hose (Order No. 19279-0140) from

the Air-Powered Crimp Tool and connect the tubing from the footswitch. See Figure 2-2. If using the Optional

Electrical Controls (Order No. 64001-4000), see Appendix A.

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 8 of 20

Revision: G Revision Date: 01-17-14

Page 9

AT-200 Air-Powered Crimp Tool

SAFETY

(LOCKED)

SAFETY ON TRIGGER

(UNLOCKED)

BASE

CRIMP TOOL

PUSH IN

CRIMP TOOL

Figure 2-3

SAFETY

(LOCKED)

SAFETY ON TRIGGER

(UNLOCKED)

CRIMP TOOL

SQUEEZE HERE

Figure 2-4

SQUEEZE HERE

Note: Always use the safety or disconnect air supply when changing crimping heads.

2.2 Operation

1. For the proper crimping head, use the tool order number specified on the label of connector container.

2. Strip the proper wire to the length specified on the label of connector container or on the air powered crimp

tool head specification sheet.

3. Load the desired terminal into the crimp nest. Insert the properly stripped wire into the terminal barrel.

For the Bench Mount Application

1. Slide the Air Powered Crimp Tool into the base. The safety will bump against the base top and the trigger on

the crimp tool will unlock. See Figure 2-3.

CAUTION: Air-Powered Crimp Tool will not operate if the safety in trigger is locked.

1. Push on the wire to assure it is fully seated in the terminal. Cycle the tool by activating the foot pedal.

2. Remove the crimped terminal. Inspect for proper crimp location.

For Hand Held Application

3. Push on the wire to assure it is fully seated in the terminal.

4. Activate the AT-200 Crimp Tool by sliding the safety on the trigger forward using your thumb and then

squeezing the trigger until the crimp jaws are fully closed. See Figure 2-4.

5. Release the trigger and remove the crimped terminal. Inspect for proper crimp location.

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 9 of 20

Revision: G Revision Date: 01-17-14

Page 10

AT-200 Air-Powered Crimp Tool

Adjustments

3.1. Changing Crimp Tool Heads

3.2. Insulation Support Crimp Adjustment

(Older style fixed jaw air powered crimp tools heads)

3.3. Insulation Support Crimp Adjustment

(Newer style insertion air powered crimp tools heads)

3.4. Terminal Crimping

3.5. Maintenance

Section 3

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 10 of 20

Revision: G Revision Date: 01-17-14

Page 11

AT-200 Air-Powered Crimp Tool

TURN

CLOCKWISE

(CW)

CAM

INCORRECT CAM

ALIGNMENT

#1/4-20

HOLE

CORRECT CAM

ALIGNMENT

Figure 3-2

CAM

#1/4-20

HOLE

CRIMPIMG HEAD

JAW ASSY

#1/4-20 SLOTTED

SCREWS (2)

Figure 3-1

CRIMPING HEAD

BUTTS UP

AGAINST STEPS

#1/ 4-20

SCREWS (2)

TERMINAL

LOCATOR

SLIDE IN

POWER UNIT

Figure 3-3

CAUTION: Always disconnect air supply before all maintenance.

3.1 Changing Crimp Tool Heads

1. Disconnect the air supply.

2. Remove the (2) #1 /4-20 slotted screws on both sides of

the power unit. Pull the crimp tool head jaw assembly

out of the tool. See Figure 3-1.

3. Before attempting to replace the dies, make sure the

wedge points of the cam line up with the (2) #1/4-20

holes in the front of power unit. See Figure 3-2.

If the cam is not lined up, use the following procedure.

a) Disconnect the air supply with the cam in the retracted

position trigger is up.

b) Grasp the center section of the cam with a long nose plier

and rotate the cam clockwise (CW) until the center line of the

wedge line up with (2) #1/4-20 holes in power unit. See

Figure 3-2 for the correct alignment.

c) Replace the head before cycling the tool. Be sure both

screws are in place and tightened.

4. To replace the crimp tool head, hold power unit in left hand as

shown in Figure 3-3.

5. Grasp the crimp tool head with the right hand and with the

terminal locator facing you. Slide the crimp tool head assembly

into the body of the power unit until the side plates of the crimp

tool head butt against the steps in the power unit. Be sure the

jaw return springs clear the cam in the power unit. See Figure 3-3.

6. Line up the holes in the crimp tool head with the holes in the housing of the power unit.

7. Replace the (2) #1/4-20 screws and tighten securely. The tool is now ready for use.

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 11 of 20

Revision: G Revision Date: 01-17-14

Page 12

AT-200 Air-Powered Crimp Tool

LOOSEN THE

M4 SCREW

LUBRICATION POINTS

(BOTH SIDES)

LIGHT OIL (EVERY MONTH

OR 5,000 CRIMPS)

Figure 3-5

3/32” HEX

WRENCH

LUBRICATION POINTS

LIGHT OIL (EVERY MONTH

OR 5,000 CRIMPS)

INSULATION CRIMPING

ADJUSTMENT SCREWS

Figure 3-4

3.2 Insulation Support Crimp Adjustment

(Older style fixed jaw air powered crimp tools heads)

1. The crimp tool heads for the insulated terminals and the

connectors feature an adjustable insulation support crimp to

accommodate varying wire insulation diameters (See Figure

3-4) for old style crimp tool head.

2. The adjustment screw on each crimp head tool is set at the

factory at the M position. This setting will give the best

crimp on most wires. Two other adjustment settings are

available: S, the smallest configuration and L, the largest

configuration.

3. Crimp a terminal or connector and inspect the insulation

support sleeve crimp or configuration. A properly crimped sleeve snugly grasps the wire insulation.

4. If the crimp configuration is too loose, change the adjustment setting by removing the air powered crimp tool

head from the AT-200 and setting adjustment screw to the S position. Re-insert the air powered crimp tool

head into the AT-200 and crimp, and inspect the insulation support sleeve.

5. If crimp configuration is too tight, change adjustment setting by removing the air powered crimp tool head from

the AT-200 and setting adjustment screw to the L position. Re-insert the air powered crimp tool head into the

AT-200 and crimp, and inspect insulation support sleeve.

3.3 Insulation Support Crimp Adjustment

(Newer style jaw air powered crimp tools)

For the new style crimp head tools, if the insulation part of the crimp needs to be adjusted, first loosen the M4 screw

on the bottom tool jaw, then insert a 3/32” Hex wrench (supplied) into the bottom of the lower die. See Figure 3.1. A

clockwise (CW) rotation decreases the insulation crimp while a counter-clockwise (CCW) rotation increases the

insulation crimp. After adjusting retighten the M4 screw.

3.4 Terminal Crimping

Specifications and Instructions for crimping are included with the individual air powered crimp tool heads.

3.5 Maintenance

CAUTION: Always disconnect air supply

before all maintenance.

It is recommended that each operator of the tool

be made aware of, and responsible for, the

following maintenance steps:

1. Remove dust, moisture and other

contaminants with a clean brush, or soft,

lint-free cloth.

2. Do not use any abrasive materials that could damage the tool.

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 12 of 20

Revision: G Revision Date: 01-17-14

Page 13

AT-200 Air-Powered Crimp Tool

3. Make certain all pins; pivot points and bearing surfaces are protected with a thin coat of high quality machine

oil. Do not oil excessively. This tool needs cleaning and lubrication for a maximum service life of trouble-free

crimping. Using a light oil, such as 30 weight automotive oil on the oil points shown in Figure 3-5, every 5,000

crimps or monthly will significantly enhance the tool life and ensure a stable calibration.

4. When tool is not in use store the tool in a clean, dry area.

3.6 Warranty

This tool is for electrical terminal crimping purposes only. This tool is made of the best quality materials. All vital

components are long-life tested. All tools are warranted to be free of manufacturing defects for a period of 30 days.

Should such a defect occur, we would repair or exchange the tool free of charge. This repair or exchange will not

be applicable to altered, misused or damaged tools.

If seals are damaged the warranty is invalid.

CAUTION: Molex crimp specifications are valid only when used with Molex terminals and tooling.

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 13 of 20

Revision: G Revision Date: 01-17-14

Page 14

AT-200 Air-Powered Crimp Tool

Section 4

Parts List and Assemblies

4.1 19279-0001 Parts List and Assembly Drawings

4.2 19279-0135 Parts List and Assembly Drawings

4.3 19078-0307 Parts List and Assembly Drawings (Optional)

4.4 64001-4000 Parts List and Assembly Drawings (Optional)

4.5 19279-0099 Parts List and Assembly Drawings

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 14 of 20

Revision: G Revision Date: 01-17-14

Page 15

AT-200 Air-Powered Crimp Tool

2

6 3 1

4

5

(2)

Figure 4-1

19279-0001-Air Power Crimp Tool Assembly Figure 4-1

Item

Order No.

Engineering No.

Description

Qty

Notes

1

19279-0080

19279-0080

Cam For AT-200 Air Tool

1 2

19279-0135

19279-0135

AT-200 Air Powered Crimping Tool

1

Figure 4-2

3

19279-0140

19279-0140

Air Hose 1/8 NPT Male FTG

1 4

19279-0161

19279-0161

Screw Silver Slotted

2 5

N/A

N/A

#1/4-1/8 Hex Bushing

1** 6

N/A

N/A

#1/4-28 by 3/4 Cup Point SSS

1**

** Available from an industrial supply company such as MSC (1-800-645-7270).

4.1 19279-0001 Parts List and Assembly Drawings

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 15 of 20

Revision: G Revision Date: 01-17-14

Page 16

AT-200 Air-Powered Crimp Tool

19279-0135-AT-200 Air Powered Crimping Tool Figure 4-2

Item

Order No.

Eng. No.

Description

Qty

1

N/A

N/A

1/4 ID by 3/8 OD by 1/16” Cross Section Buna O-Ring

4**

2

N/A

N/A

5/32 ID by 9/32 OD by 1/16” Cross Section Buna O-Ring

2**

3

N/A

N/A

3/8 ID by 1/2 OD by 1/16” Cross Section Buna O-Ring

2**

4

N/A

N/A

1/2 ID by 11/16 OD by 3/32” Cross Section Buna O-Ring

1**

5

N/A

N/A

1.0 ID by 1-13/16 OD by 3/32” Cross Section Buna O-Ring

4**

6

N/A

N/A

1-5/8 ID by 1-3/4OD by 1/16” Cross Section Buna O-Ring

3**

7

N/A

N/A

.180 OD by .017 WD Torsion Spring

1**

8

N/A

N/A

.455 OD by .038 WD by .625” FL Compression Spring

1**

9

N/A

N/A

Retaining Ring 2.012 OD by .062” Thick

5**

10

N/A

N/A

#4-40 by .50 Long SHCS

1**

11

N/A

N/A

#6-32 by .25” Long Flat Head Phillips

1**

12

N/A

N/A

#6-32 by .88“ Long Flat Head Phillips

2**

13

N/A

N/A

#8-32 by .375” Long Round Head Phillips

2**

14

N/A

N/A

1/16 Diameter by .187” Long Dowel Pin

1**

15

N/A

N/A

1/16 Diameter by .25” Long Dowel Pin

1**

16

N/A

N/A

1/8 Diameter by .75” Long Spring Pin

1**

17

N/A

N/A

3/32 Diameter by .75” Long Dowel Pin

1**

** Available from an industrial supply company such as MSC (1-800-645-7270).

4.2 19279-0135 Parts List

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 16 of 20

Revision: G Revision Date: 01-17-14

Page 17

AT-200 Air-Powered Crimp Tool

11

12

(2)

Figure 4-2

8

(4)

4 5 5 6 9

9

3

5 6 3

2 2 13

10

7

15

14

16

5

9

(2)

9

9 1 6

17

4.2 19279-0135 Assembly Drawings

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 17 of 20

Revision: G Revision Date: 01-17-14

Page 18

AT-200 Air-Powered Crimp Tool

3

6 7 4

2

3

5

1

(2)

(2)

Figure 4-3

19078-0307-Optional Bench Adapter Figure 4-3

Item

Order No.

Engineering No.

Description

Qty 1 N/A

N/A

Dual Air Hose (1/8 ID by 8’)

1** 2 N/A

N/A

Air Foot Switch (3B – 30A2 – S)

1**

3

N/A

N/A

1/8” NPT – M Fitting, by 1/8 Barb

3** 4 N/A

N/A

1/8” Close Nipple (M/M)

1** 5 N/A

N/A

Clippard Thread on Hose Clamp

2** 6 N/A

N/A

1/8” Fitting Brass Pipe Tee M/F/F

1** 7 N/A

N/A

1/8” Brass Coupling - 1/8 (F/F)

1**

** Available from an industrial supply company such as MSC (1-800-645-7270).

4.3 19078-0307 (Optional) Parts List and Assembly Drawings

(See ATS-19078-0307 specification sheet for installation)

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 18 of 20

Revision: G Revision Date: 01-17-14

Page 19

AT-200 Air-Powered Crimp Tool

3

6

4

7

1 2 9 1 5

5

Figure 3

REF

EMERGENCY

STOP

TO AIR

SUPPLY

TO

120 VAC

Figure 4-4

1/4 NPT by 1/4 TUBE

FITTING (REF)

8

64001-4000 Optional Full Cycle/ Pressure Electrical Control Box Figure 4-4

Item

Order No.

Description

Qty

1

64001-4000

Electrical Controls

Ref

2

62500-1265

Power Supply

1

3

63800-8394

Footswitch Assembly

1

4

69018-6237

Power Cord

1

5

N/A

1/4“ OD Tubing

**

6

N/A

1/8 NPT by 1/4 Tube Fitting

**

7

19078-0307

Bench Adapter

Ref

8

19279-0001

Air Power Crimp Tool

Ref

9

N/A

Filter Regulator

Ref

** Available from an industrial supply company such as MSC (1-800-645-7270).

4.4 64001-4000 (Optional) Parts List and Assembly Drawing

(See ATS-640014000 specification sheet for installation)

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 19 of 20

Revision: G Revision Date: 01-17-14

Page 20

AT-200 Air-Powered Crimp Tool

3

4

2 5 1

Figure 4-5

19279-0099-Trigger Safety Kit Figure 4-5

Item

Order No.

Engineering No.

Description

Qty 1 19279-0203

19279-0203

Pivot Block

1 2 19279-0204

19279-0204

Safety Latch

1

3

63600-0052

63600-0052

Torsion Spring

1 4 N/A

N/A

#4-40 by .50” Long SHCS

1** 5 N/A

N/A

3/32 Diameter by 3/4 Long Dowel Pin

1**

** Available from an industrial supply company such as MSC (1-800-645-7270).

4.5 19279-0099 Parts List and Assembly Drawings

(See ATS-19279-00099 specification sheet for installation)

This assembly is included in the AT-200 Air-Powered Crimp Tool 19279-0001 however for older

models of this tool it is recommended to purchase the Trigger Safety Kit 19279-0099.

Visit our Web site at www.molex.com

Doc No: TM-192790001 Release Date: 07-01-02 UNCONTROLLED COPY Page 20 of 20

Revision: G Revision Date: 01-17-14

Loading...

Loading...